Torque spec HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 2 of 2189

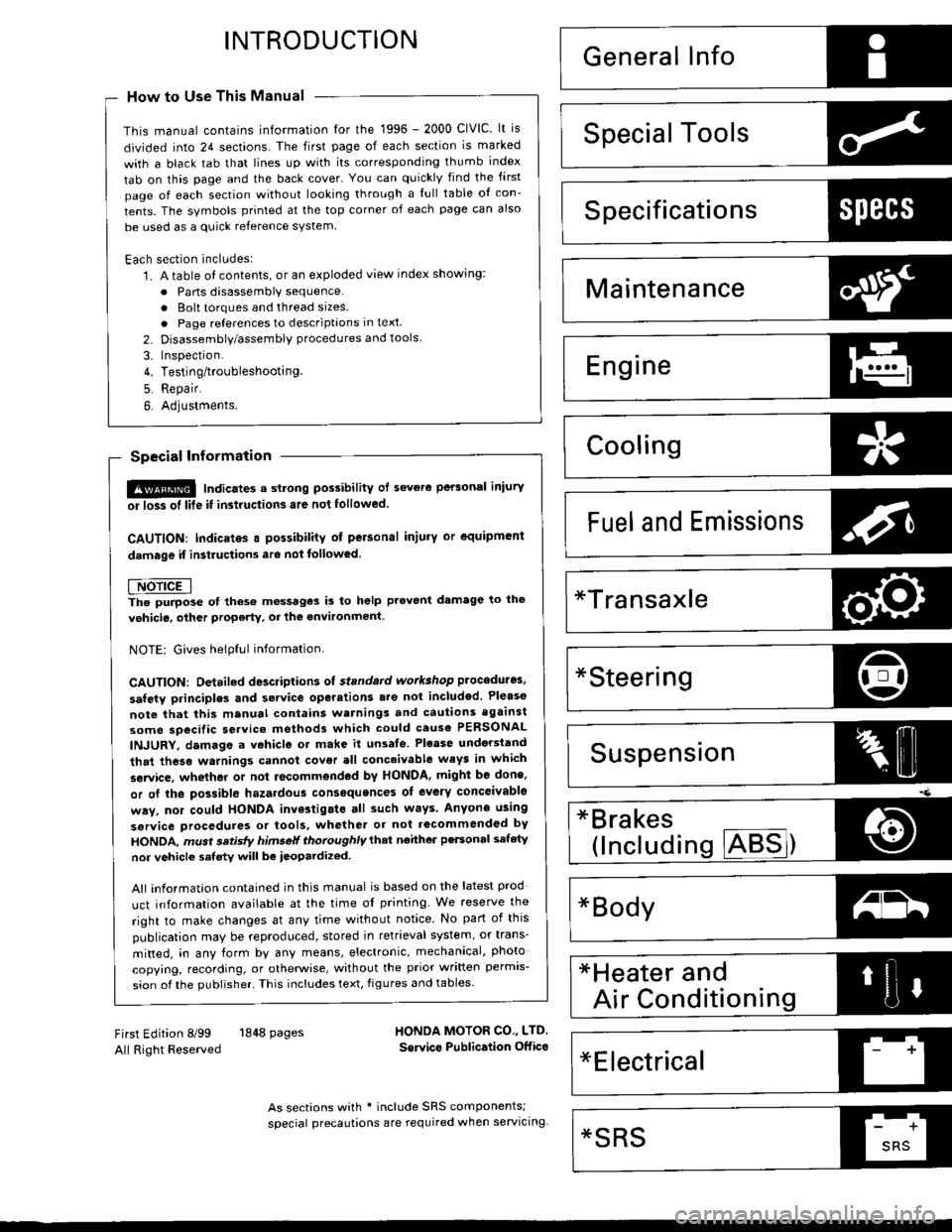

INTRODUCTION

How to Use This Manual

This manual contains information for the 1996 - 2000 ClVlC. lt is

divided into 24 sections. The first page of each section is marked

with a black tab that lines up with its corresponding thumb index

tab on this page and the back cover. You can quicklY find the first

page of each section without looking through a tull table ol con_

tents. The symbols printed at the top corner of each page can also

be used as a quick reference system.

Each section includesl

1. A table of contents, or an exploded view index showing:

. Parts disassemblY sequence.

. Bolt torques and thread sizes.

. Page references to descriptaons in text

2. Disassembly/assembly procedures and tools.

3. Inspection.

4. Testing/troubleshooting.

5. Repair.

6. Adjustments.

Special Information

!@ Indicates a sttong possibility of sover. perconal iniurY

or loss ol lite if in3tructions are not follow€d.

GAUTION: Indicaiqs a possibility ot p€lsonal injury or 6quipm.nt

damage il instiuc'tions are not followod

t Noncali-. pu.po.. ot thes6 messages is to help provent demage lo lhe

vehicle, other property, or the €nvironment.

NOTE: Gives helpful information.

CAUTfON: Detaifed descriptions ol standard workshop p.oceduro3.

safoty principles and servico operations are not included. Pleaso

note that this manual contain3 wetnings and cautions against

some sp6cific sGrvic€ methods which could cause PERSONAL

INJURY, damage a vohicle or make il unsafe. Ploase undorstand

that these warnings cannot covsr all conceivable weys in which

service. whelher or not iocommgndod bY HONDA. mighi bo done,

or ol tho possiblG hazardou3 consgquonces of ev€aY conceivablg

way, nor could HONDA invqstigato all 3uch way3. AnYono using

sgrvice procedures or lools, whethei or nol rGcommendod bY

HONDA, must srtisty hifisetf thoroughlylhat nohher pefsonal sefety

nor vehiclc satsty will be reopardi2ed.

All intormation contained in this manual is based on the latest prod

uct information available at the time oI printing We reserve the

right to make changes at any time without notice No part of this

publication may be reproduced, stored in retrieval system, or trans'

mitted, in any form by any means, electronic, mechanical, photo

copying, recording, or otherwise, without the prior written permis-

sion of the publisher. This includes text, figures and tables.

*Transaxle

ds

First Edition 8/99 1848 PagesAll Right Reserved

HONOA MOTOR CO., LTD.

Sorvico Publication Offico

As sections with * include SRS components;

sDecial precautions are lequired when servlclng

*Electrical't

*SRSSRS

Page 53 of 2189

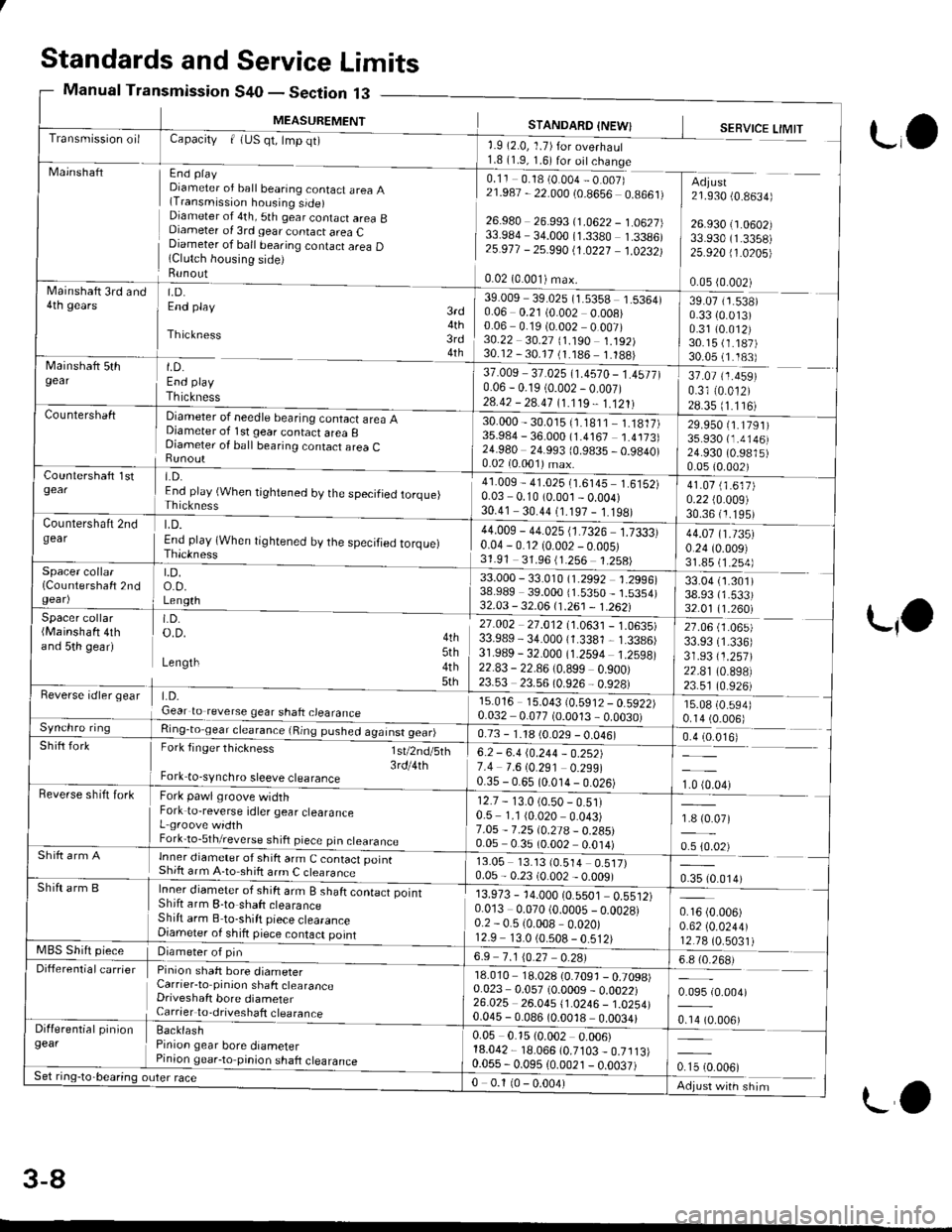

Standards and Service Limits

Manual Transmission S40 - Section 13

MEASUREMENT

Capacity | (US qt, tmp qt)

End playDiameter of ball bearing contact area A(Transmission housing side)Diameter of 4th, 5th gear contact area BDiameter of 3rd gear contact area CDiameter of ball bearing contact area D(Clutch housing side)Bunout

STANDARD INEW}'1.9 (2.0, 1.7)for overhaul1.8 (1.9, 1.6) for oitchange

0.11 0.18 (0.004 _ 0.007)21.987 - 22.000 (0.8656 0.8661)

26.980 26.993 (1.0622 _ 1.0627)33.984 34.000 (1.3380 1.3386)25.917 - 25.99011.0227 1.0232)

0.02 (0.001) max.

SEBVICE LIMIT

ro

MainshaftAdjust21.930 (0.8634)

26.930 ('1.0602i33.930 (1.3358)

25.92011.0205)

0.05 (0.002)

39.07 ('r.538)

0.33 {0.013)0.31 (0.012)

30.15 (1.187)

30.05 (1.183)

37.07 {1.459)0.31 (0.0'12)

28.35 (1.116)

LrO

39.009 39.025 (1.5358 1.5364)0.06 0.21 (0.002 0.008)0.06 0.19 (0.002 0.007)30.22 30.21 (1.190 1.192)30.12 - 30.17 (1.186 1.188)

37.009 37.025 (1.4570 _ 1.4577)0.06 - 0.19 (0.002 - 0.007)28.42 - 2a.47 11.119,1.1211Countershaft Diameter of needle bearing contact area ADjameter of lst gear contact area gDiameter of ball bearing contact area CRunout

30.000- 30.015 {1.181 1 - 1.1817)35.984 - 36.000 (1.4167 1.4173)24.980 24.993 (0.9835 - 0.9840)0.02 (0.001)max.

29.950 (1.1791)3s.930 r.4146)24.930 (0.9815)0.0s (0.002)

End play (When tightened by the specified torque)Thickness

41.009 - 41.025 ('�t.6145 1.6152)0.03 0.10 (0.001 _ 0.004)30.41 30.44 (1.197 - 1 198)

41 .01 11.617J0.22 (0.009)

30.36 (1.195)

gear End ptay (When tightened by the specified torque)44.009 - 44.025 (1.7326 1.7333)0.04 - 0.12 (0.002 - 0 005)31.91 31.96 (1.256 1.258)

44.01 11.t35)0.24 (0.009)

31.85 (1.2s4)

33.04 {1.301)38.93 (1.533)32.01 (1.260)

27.06 (1.065)

33.93 (1.336)

3r.93 {1.257)22.81 (0.898)

23.51 (0.926)

15.08 (0.594)

0.14 (0.006)

0.4 (0.016)

0.16 (0.006)

o.6210.0244112.78 (0.5031)

t.D.o. D.Length

33.000 - 33.010 (1.2992 1.2996)38.989 39.000 11.53s0_ 1.53s4)32.03 - 32.06 tl.261 - 1.2621Spacer collar(Mainshaft 4thand 5th gear)

Beverse rdler gear LD.Gear to reverse gear shaft cjearance

27.002 27.012 (1.0631 _ 1.0635)33.989 - 34.000 (1.3381 - 1.3386)3r.989 - 32.000 (1.2594 1.2598)22.83 - 22.86 (0.899 0.900)23.53 23.56 (0.926 - 0.928)

rs.016 15.043 (0.5912 _ 0.5922)0.032 0.077 (0.0013 _ 0.0030)Ring-to gear clearance {Ring pushed against gear)0.73 - 1.l8 (0 029 - 0.046)Fork finger thickness

Fork to-synchro sleeve clearance

lsv2nd/sth I 6.2 - 6.410.244 - O.ZS2)3rdl4th 7.4 i.6lO 2g1 O 2ggt0.35 - 0.65 (0.014 - 0.026)Beverse shitt fork Fork pawl groove widthFork to-reverse idler gear clearanceL groove widthFork'to-5th/reverse shift piece pin clearance

12.7 - 13.0 (0.50 _ 0.51)0.5 1. t (0.020 0.043)7 .05 - 7 .25 tO.21A - 0.28510.05 0.35 (0.002 0.014)Sh ift a rm A tnner diameter of sh ift arm C contact ffiShift arr14-go "L;L ".m C clearance13.05 13.13 (0.514 0.517)0.05 - 0.23 (0.002 _ 0.009)Inner diameter of shift arm B shaft contact pointShift arm 8-to shaft clearanceShift arm B to-shift piece clearanceDiameter of shift piece contact point

13.973 - 14.000 (0.5501 0.5512)0.013 0.070 (0.0005 _ 0.0028)0.2 - 0.5 {0.008 0.020)12.9 13.0 (0.508 - 0.512)MBS Shift prece Diameter of pin6.9 7 .1 \O.27 0 2A)

0.095 (0.004)

0.14 (0.006)

Adjust with shim

Differenlial carrier Pinion shaft bore diameterCarrier-to pinion shaft clearanceDriveshaft bore diameterCarrier to,driveshaft clearance

18.010 18.028 (0.7091 _ 0.7098)0.023 0.057 (0.0009 - 0.0022)26.025 26.04s {1.0246_ 1.0254)0.045 - 0.086 (0.0018 0.0034)BacklashPinion gear bore diameterPinion gear-to pinion shaft clearance

0.05 0.15 (0.002 0.006)18.042 - 18.066 (0.7103 _ 0.7113)0.055 - 0.095 {0.0021 _ o.oo37)

0 0.1 10 - 0.004)

3-8

LO

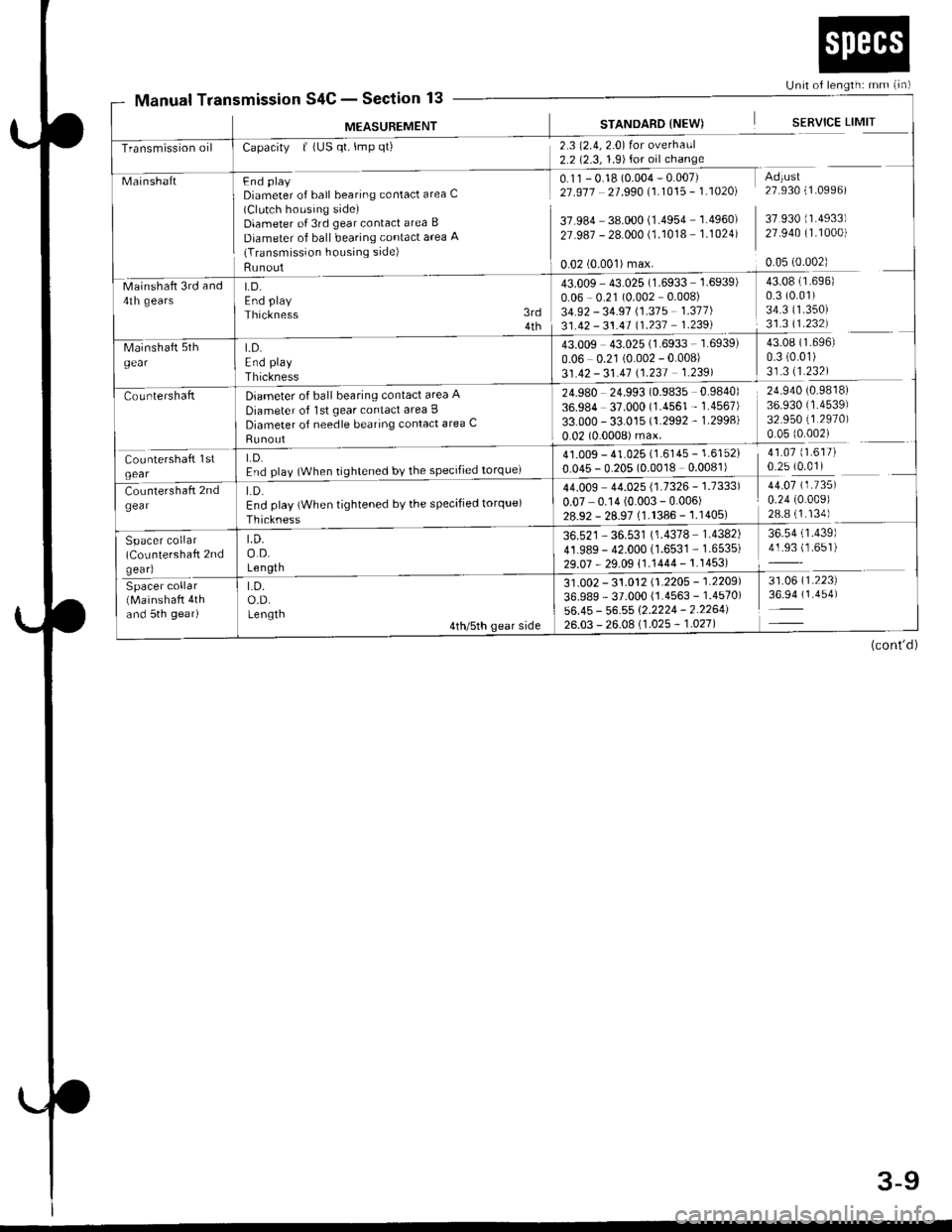

Page 54 of 2189

Unit of length: mm (in)

Transmission oil

43.009 43.025 (1.6933 - 1.6939)

0.06 0.21 (0.002 - 0.008)

31.42 - 31.41 \1.231 1.2391

t.D.End play

Thickness

Diameter of ball bearing contact area A

Diameter of lst gear contact area I

Diameter of needle bearing contact area C

Runout

LD.End play {When tightened by the specified torque)

Thickness

LD.o.D.Length

Spacer collar(CoLrntershaft 2ndgear)

Spacer collar(Mainshaft 4thand 5th gear)

LD.o.D.Lengtn

Manual TransmissionS4C - Section 13

M€ASUREMENT

MainshaftFnd plaVDiameter of ball bearing contact area C(Clutch housing side)Diameter of 3rd gear contact area B

Diameter of ball bearing contact area 'q(Transmission housing side)

Runout

Capacity | (US qt, lmp qt)

LD.End play

Thickness

2.3 (2.4,2.0) for overhaul2.2 (2.3, 1.9)for oil change

0.11 - 0.18 (0.004 - 0.007)21 .917 - 21 .990 11.1015 - 1 .10201

37.984 38.000 (1.4954 1.4960)

27.987 - 28.000 (1.1018 1.1024)

STANDARD {NEW)

0.02 (0.001)max.

SERVICE LIMIT

Adtust27.930 (1.0996)

37 930 (1.4933)

27.940 (1.1000)

0.05 (0.002)

Mainshaft 3rd and4th gears

43.009 - 43.025 (1.6933 1.6939)

0.06 - 0.21 (0.002 0.008)

34.92 - 34.91 \1.315 1.311)

31.42 - 31.41 (1.237 1.239)

24.980 24.993 (0.9835 0.9840)

36.984 37.000 (1.4561 - 1.4567)

33.000 - 33.015 (1.2992 - 1.2998)

0.02 (0.0008) max.

3rd4th

43.08 (1.696)

0.3 (0.01)

34.3 ('�t.350)

31.3 11.232)

43.08 (1.696)

0.3 (0.01)

31.311.232)

24.940 (0.9818)

36.930 (1.4539)

32.950 (1.2970)

0.05 (0.002)

41.07 (1.617)

0.25 (0.01)41.009 - 41.025 (1.6145 - 1.6152)

0.045 - 0.205 (0.0018 0.0081)

44.009 44.025 {1.7326 - 1.7333)

0.07 0.14 (0.003 - 0.006)28.92 - 28.97 (1.1386 -'�j.1405)

36.521 - 36.531 (1.4378 1.4382)

41.989- 42.000 (1.6531 - 1.6535)

29.07 - 29.09 11.1444 - 1.1453)

44.07 (1.735)

0.24 (0.009)

28.8 (1.134)

36.54 (1.439)

41.93 (1.651)

31 .0O2 - 31 .012 11 .2205 - 1 .2209'l

36.989 - 37.000 {1.4563 - 1.4570)

56.45 - 56.55 1'2.2224 - 2.2264126.03 - 26.0A 11 .025 - 1 .021 |

31.06 (1.223)

36.94 (1.454)

(cont'd)

3-9

Page 106 of 2189

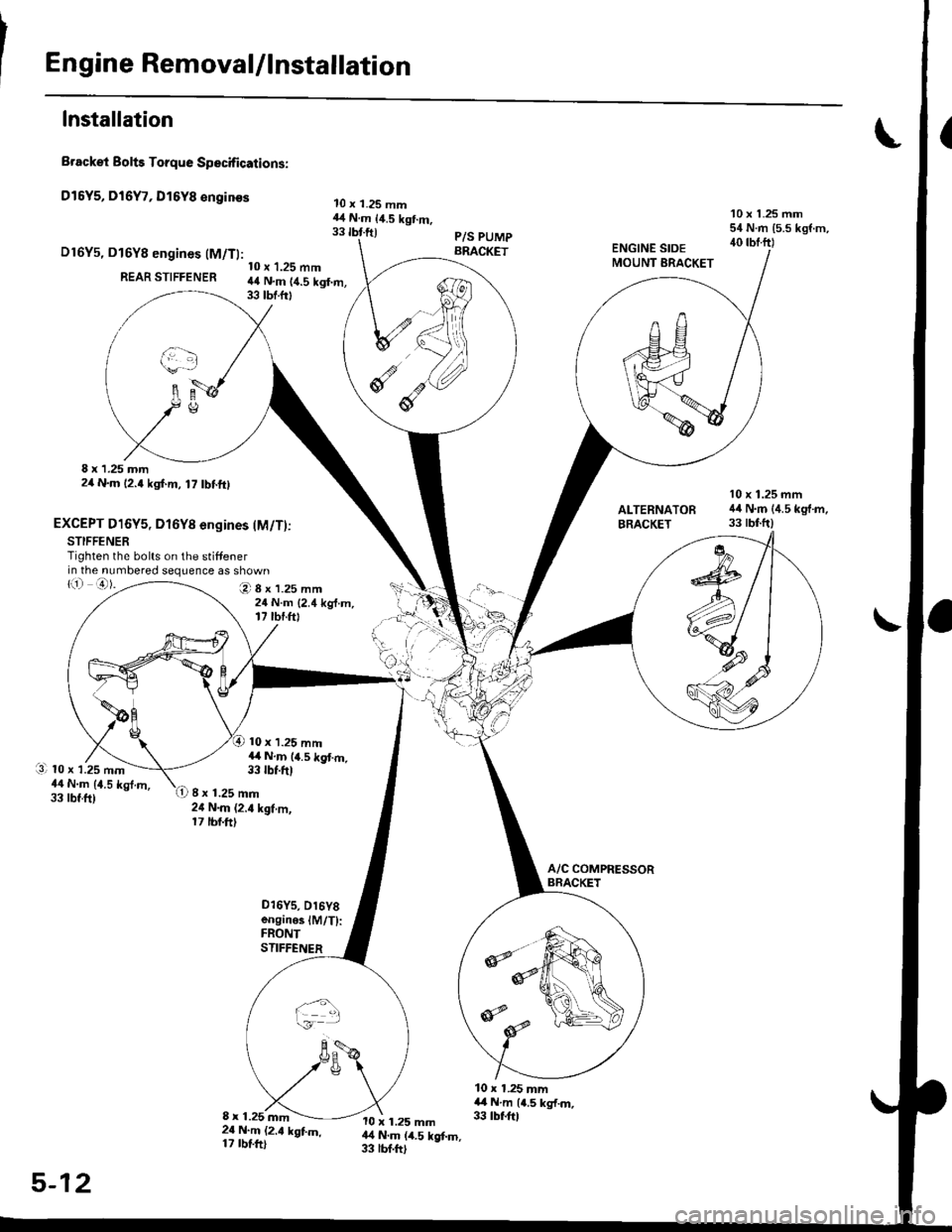

Engine RemovaUlnstallation

Installation

Brackei Bolts Torque Specifications:

Dl5Y5, Dl6Y7, Dl6Y8 €nginss

D16Y5, D16Y8 engines (M/Tl:

REAR STIFFENER

8 x 1.25 mm2/t N.m 12.4 kgf.m, 17 tbf.ftl

EXCEPT D16Y5, Dl6Yg engines lM/T)jSTIFFENERTighten the bolts on the stiffenerin the numbered sequence as shown

10 x 1.25 mm44 N.m 14.5 kgf.m,33 tbf.frt

O8x1.25mm24 N.m {2.4 kg{.m,17 tbr.ftt

10 x 1.25 mm14 N.m 14.5 kgt m,33 tbf.ft)

10 x 1.25 mm44 N.m {4.5 kgt m,33 tbr.ftl

10 x 1.25 mm54 N.m {5.5 kgf.m,40 rbf.ftl

10 x 1.25 mm44 N.m {4.5 kg'f.m,33 tbtftlALTERNATOFBRACKET

li) o).

l3l 10 x 1.25 mm44 N.m {1.5 kgt.m,33 tbt.ft)8 x 1.25 mm24 N.m (2.4 kgf.m,17 tbf.ft)

o16Ys, D16Y8enginoslM/T):FRONTSTIFFENER

10 x 1.25 mm4,4 N.m {4.5 kg{.m.33 tbf.ftl8 x 1.25 mm2{ N.m (2.t kgtm,17 rbtft)

10 x 1.25 mm14 N.m (4.5 kgf.m,33 lbf.ftl

5-12

Page 127 of 2189

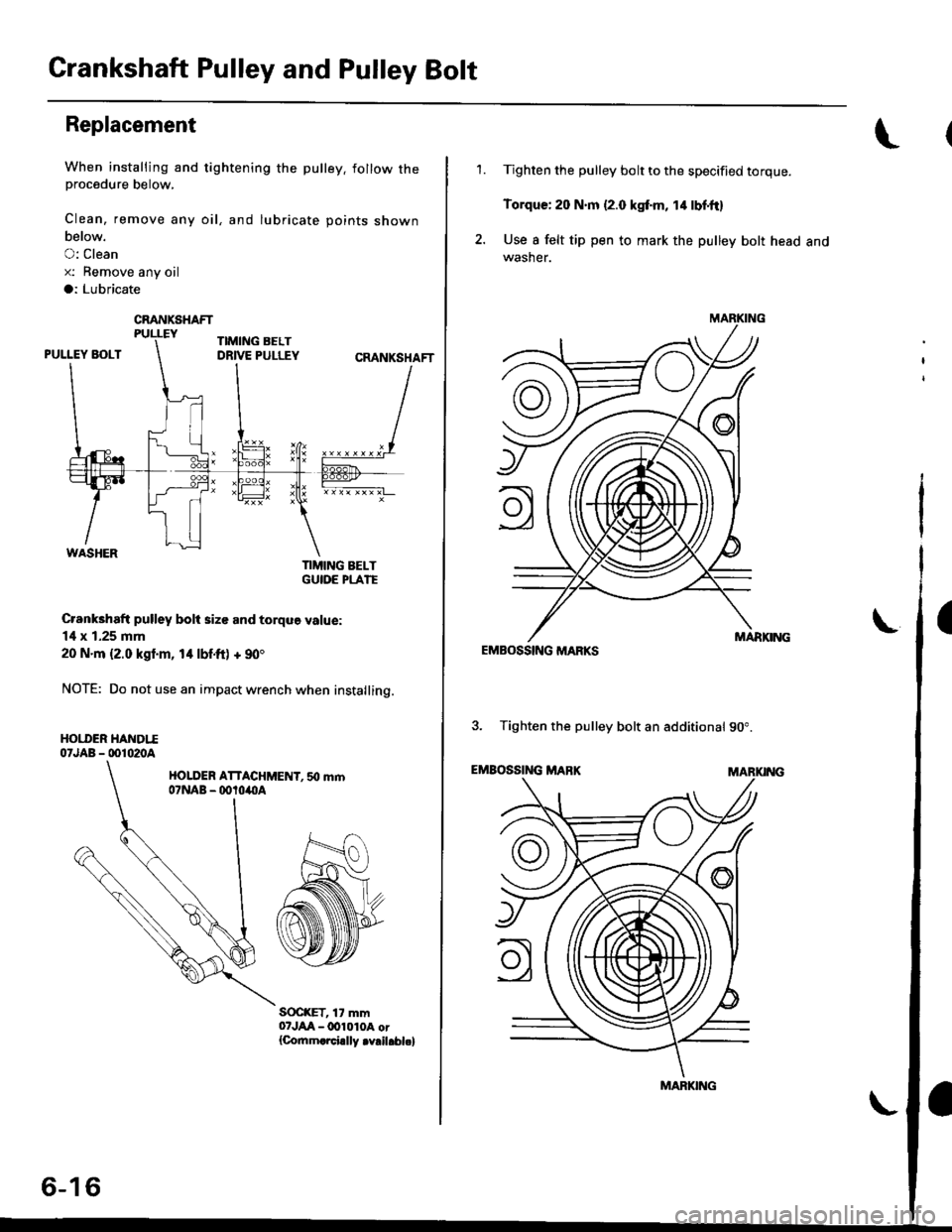

Crankshaft Pulley and Pulley Bolt

Replacement

When installing and tightening the pulley. follow theprocedure below,

Clean, remove any oil, and lubricate points shown

below.

O: Clean

x: Bemove any oil

a: Lubricate

TIMING BELTGUIOE PLATE

Crankhaft pulley bolt size and torque value:

14 x 1.25 mm

20 N.m {2.0 kgl.m, 14 lbf.ft) + 90'

NOTE: Do not use an impact wrench when installing.

HOI.I'ER HANDTI07JAB - 001020A

HOLDER ATTACHMENT. 50 mm07NAB - ootoilllA

S(rc(ET, 17 mm07JAA-lxtl010A or{Co.nm.rci.lly .v.il.bl.}

CRANKSHAFT

6-16

'1.Tighten the pulley bolt to the specified torque.

Torque: 20 N.m {2.0 kgf.m, 14 lbf'ft}

Use I felt tip pen to mark the pulley bolt head andwasher.

EMBOSSING MARKS

3. Tighten the pulley bolt an additional 90".

EMBOSSING MABKMARKING

\

MARKING

MARKING

I

Page 129 of 2189

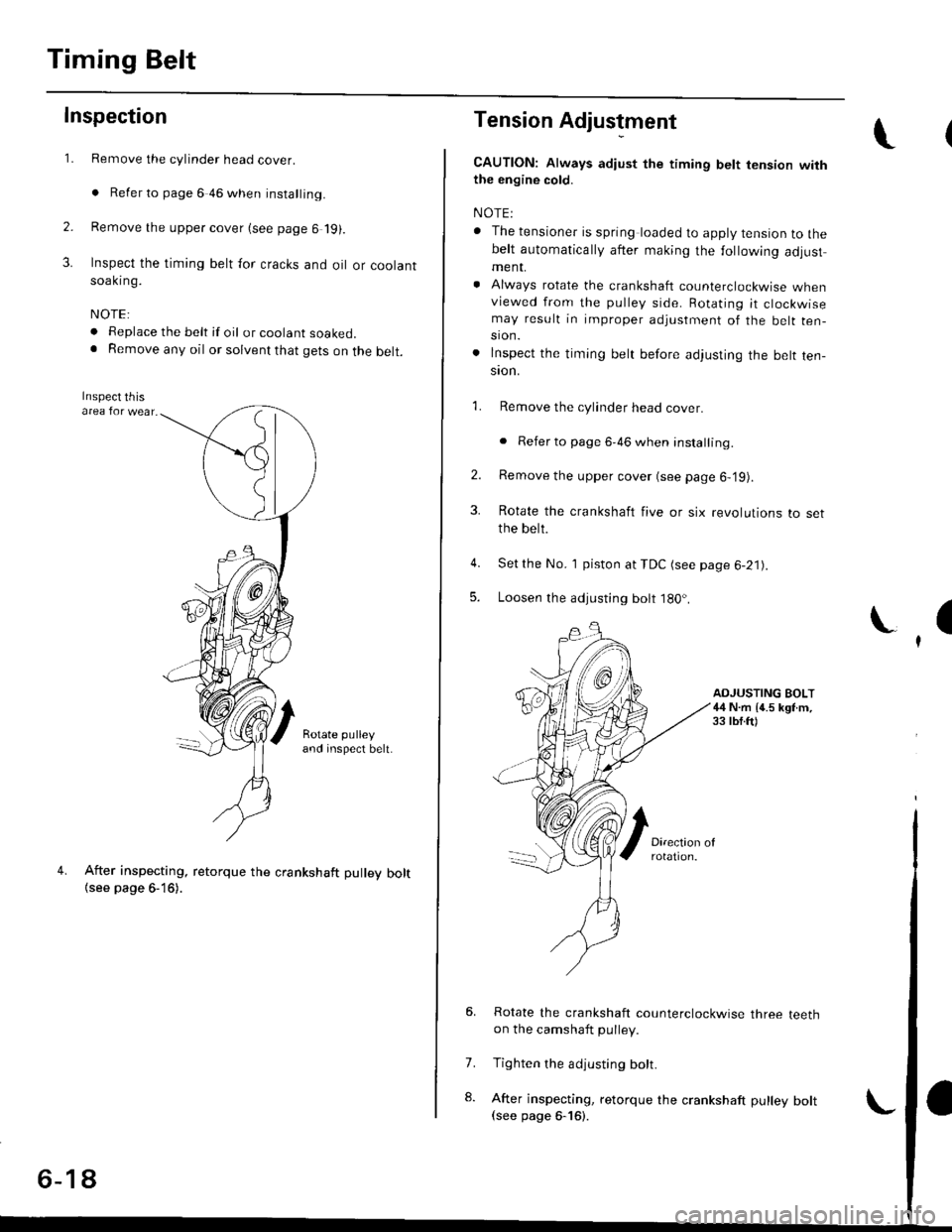

Timing Belt

Inspection

1.

2.

3.

Remove the cylinder head cover.

. Refer to page 6 46 when installing.

Remove the upper cover (see page 6 19).

Inspect the timing belt for cracks and oil or coolantsoakrng.

NOTE:

. Replace the belt if oil or coolant soaKeo.. Remove any oil or solvent that gets on the belt.

Rotate pulleyand inspect belt.

After inspecting, retorque the crankshaft pullev bolt{see page 6- 16).

o- I6

Tension Adjustment

CAUTION: lt*ays aa;j"t the timing bett rension withthe engine cold.

NOTE:

. The tensioner is spring loaded to apply tension to thebelt automatically after making the following adjustment.

. Always rotate the crankshaft counterclockwise whenviewed from the pulley side. Rotating it clockwisemay result in improper adjustment of the belt ten-sion.

. lnspect the timing belt before adjusting the belt ten-ston.

1.Remove the cylinder head cover.

. Refer to page 6,46 when installing.

Remove the upper cover (see page 6,'19).

Rotate the crankshaft five or six revolutions to setthe belt.

Set the No. 'l piston at TDC (see page 6-21).

Loosen the adjusting bolt 180'.

2.

3.

4.

5.

\I

ADJUSTING BOLT44 N.m {4.5 kgt m,33 rbf.ft)

7.

8.

Rotate the crankshaft counterclockwise three teethon the camshaft pulley.

Tighten the adjusting bolt.

After inspecting, retorque the crankshaft pulley bolt(see page 6-16).

Page 171 of 2189

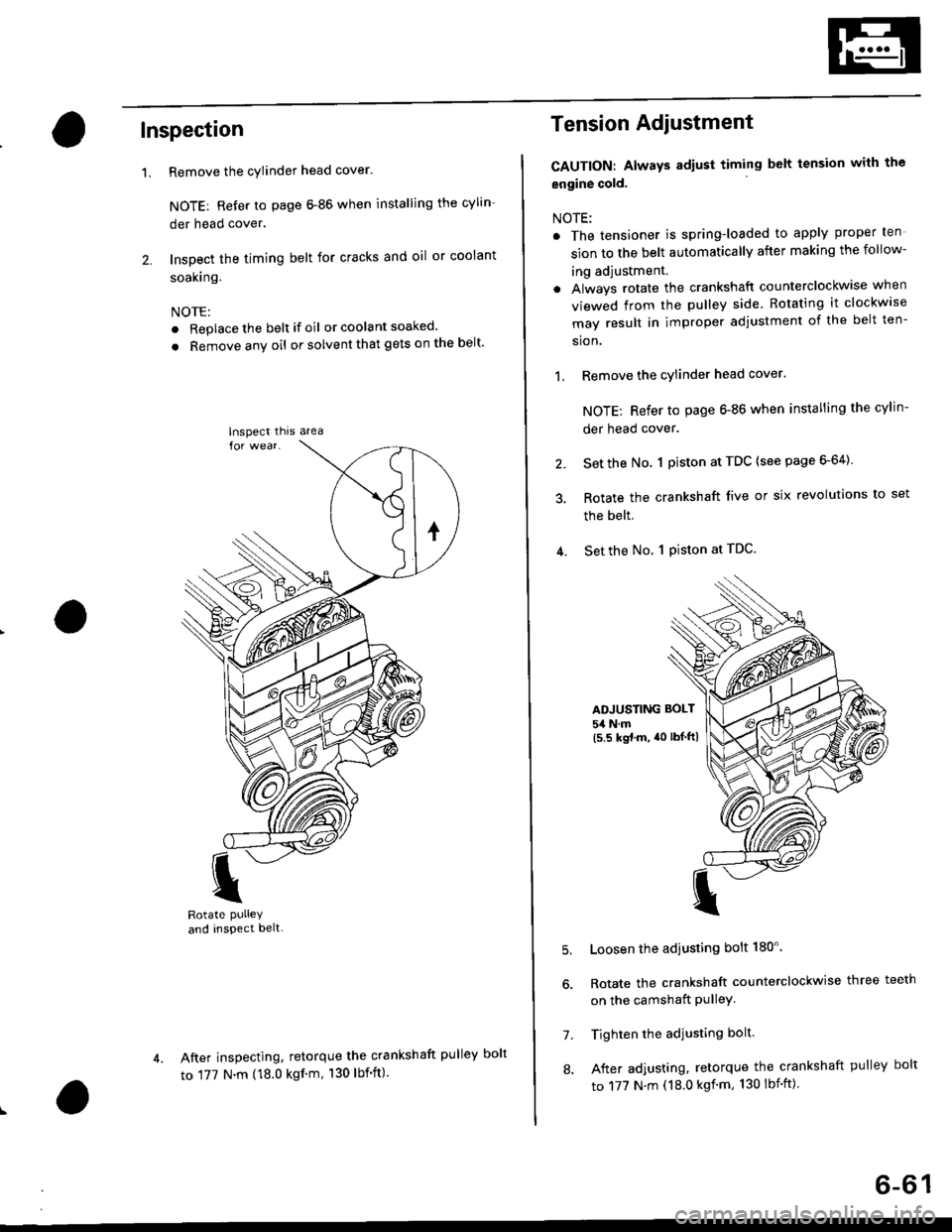

Inspection

Remove the cylinder head cover.

NOTE: Refer to page 6-86 when installing the cylin-

der head cover.

Inspect the timing belt for cracks and oil or coolant

soakrng.

NOTE:

. Replace the belt if oil or coola nt soaked.

. Remove any oil or solvent that gets on the belt'

I

Rotate PUlleYand inspect belt-

After inspecting, retorque the crankshaft pul

to 177 N.m (18.0 kgf'm, 130 lbf'ft)

'L

lnspect thrs area

Tension Adiustment

CAUTION: Always adiust timing belt tension with the

engine cold.

NOTE:

. The tensioner is spring-loaded to apply proper ten

sion to the belt automatically after making the follow-

ing adjustment.

. Always rotate the crankshaft counterclockwise when

viewed from the pulley side. Rotating it clockw'se

may result in improper adjustment of the belt ten-

sion.

1, Remove the cylinder head cover.

NOTE; Refer to page 6-86 when installing the cylin-

der head cover.

2. Set the No. 1 piston at TDC (see page 6-64)

3. Rotate the crankshaft live or six revolutions to set

the belt.

4. Set the No. 1 Piston at TDC

ADJUSTING BOLT

54 N.m(5.5 kgt.m, a0 lbtftl

5.

7.

8.

Loosen the adjusting bolt 180'.

Rotate the crankshaft counterclockwise three teeth

on the camshaft PulleY.

Tighten the adjusting bolt.

After adjusting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgf'm, 130 lbnft)

ley bolt

6-61

Page 185 of 2189

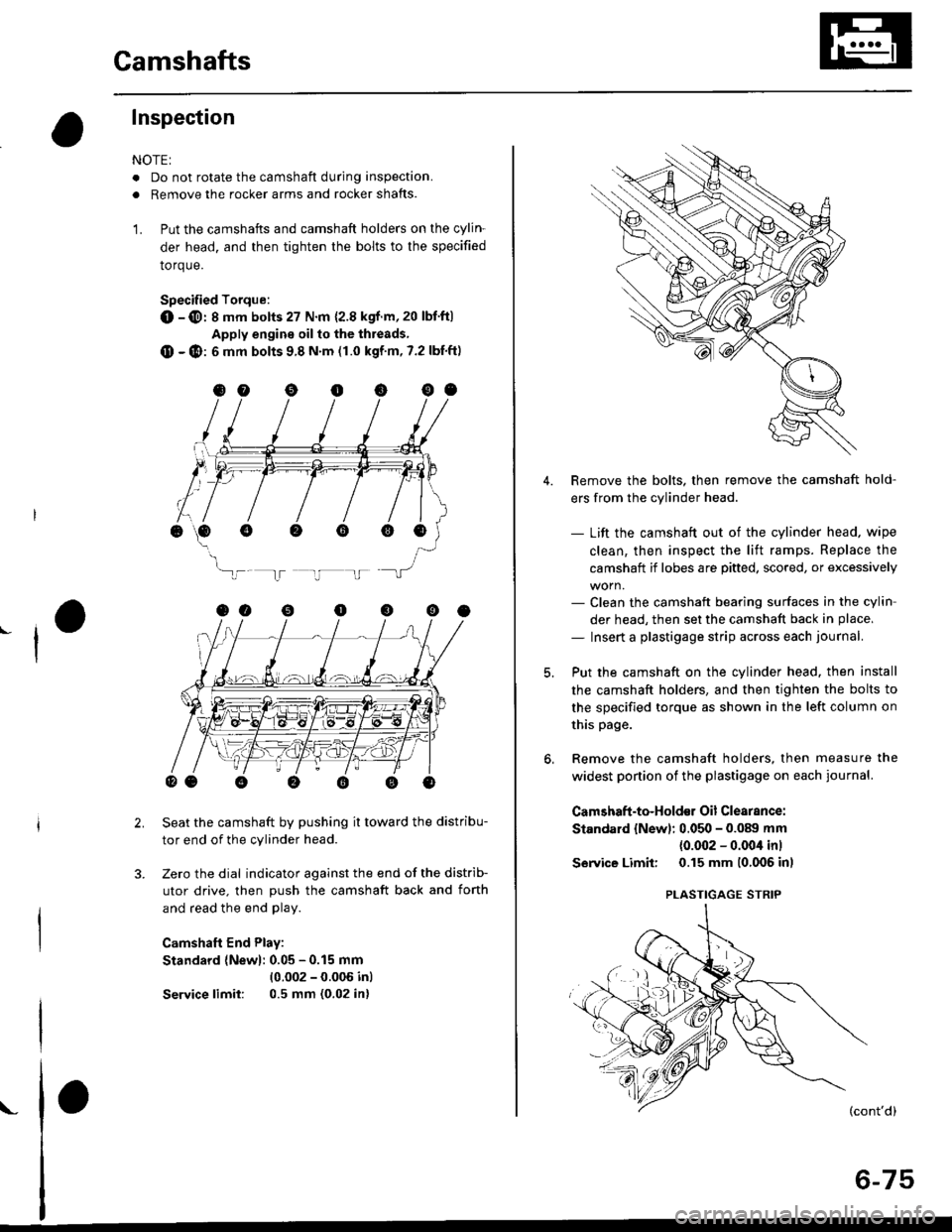

Camshafts

Inspection

NOTE:

. Do not rotate the camshaft during inspection.

. Removg the rocker arms and rocker shafts.

'L Put the camshafts and camshaft holders on the cylin-

der head. and then tighten the bolts to the specified

torque.

Specified Torque:

O -@: 8 mm botts 27 N.m {2.8 kgf.m,20 lbt'ft)

Apply engine oil to the threads,

O - @: 6 mm bolts 9.8 N.m (1.0 kgf m, 7.2 lbf'ft)

Seat the camshaft by pushing it toward the distribu-

tor end of the cylinder head.

Zero the dial indicator against the end of the distrib-

utor drive. then push the camshaft back and fonh

and read the end play.

Camshaft End Play:

Standard {New}: 0.05 - 0.15 mm

{0.002 - 0.006 inl

Service limil: 0.5 mm (0.02 in)

ooooooo

ooooo

\-

4.Remove the bolts. then remove the camshaft hold-

ers from the cylinder head.

- Lift the camshaft out of the cylinder head, wipe

clean, then inspect the lift ramps. Replace the

camshaft if lobes are pitted, scored, or excessively

- Clean the camshaft bearing surfaces in the cylin

der head, then set the camshaft back in place,

- Insert a plastigage strip across each iournal.

Put the camshaft on the cylinder head. then install

the camshaft holders, and then tighten the bolts to

the specified torque as shown in the left column on

this page.

Remove the camshaft holders, then measure the

widest portion of the plastigage on each journal.

Camshaft -to-Hold€1 Oil Clearsnce:

Standard {Newl: 0.050 - 0.089 mm

{0.002 - 0.004 inl

S6rvice Limit: 0.15 mm 10,006 inl

(cont'd)

6-75

PLASTIGAGE STRIP

Page 206 of 2189

Main Bearings

4.

Glearance

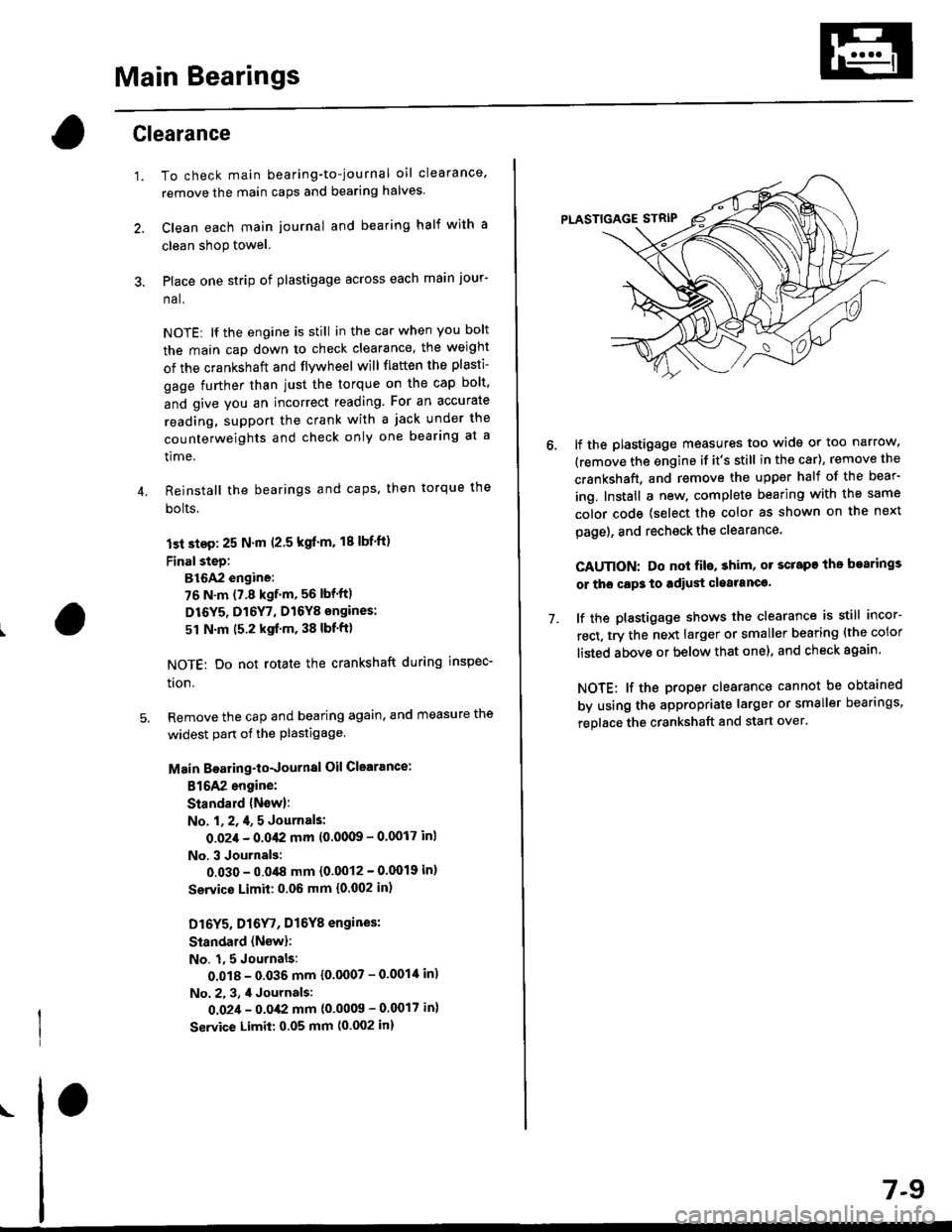

1.To check main bearing-to-journal oil clearance.

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main jour-

na l.

NOTE: lf the engine is still in the car when you bolt

the main cap down to check clearance, the weight

of the crankshaft and flvwheel will flaften the plasti-

gage further than just the torque on the cap bolt.

and give you an incorrect reading. For an accurate

reading, support the crank with a jack under the

counterweights and check only one bearing at a

time,

Reinstall the bearings and caps, then torque the

bolts.

lst step: 25 N'm (2.5 kgl'm. 18 lbf'ft)

FinalsteD:

B16A2 engine:

76 N.m (7.8 kgf.m, 56 lbf'ft)

D16Y5, Dl6Y7, D16Y8 engines:

51 N.m (5.2 kgf'm, 38 lbf'ft)

NOTE: Do not rotate the crankshaft during inspec-

tron.

Remove the cap and bearing again, and measure the

widest part ot the plastigage.

Main Boaring-toJournal Oil Clearance:

816A2 engine:

Standald {New}:

No. l, 2, 4, 5 Journals:

O.O2,l - 0.042 mm 10'00(B - 0.0017 in)

No. 3 Journals:

0.030 - 0.048 mm {0'0012 - 0'0019 in)

Servico Limit: 0.06 mm {0.002 in,

Dl6Y5, Dl6

r, Dl6Y8 engines:

Standard (Nsw):

No. 1,5 Journals:

0.018 - 0.035 mm {0.0007 - 0'001'[ in)

No. 2. 3, 4 Journals:

0.02,1 - 0.0,(2 mm {0'0009 - 0.0017 in}

Service Limit: 0.05 mm (0.002 in)

\

7-9

7.

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft, and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code {select the color as shown on the next

page), and rechsck the clearance.

CAUTION: Do nol fil€, shim, or scrape the bearings

or tho cap3 to adiust cleatanc€.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again

NOTE: lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

Page 208 of 2189

Connecting Rod Bearings

Clearance

Remove the connecting rod cap and bearing half

Clean the crankshaft rod iournal and bearing half

with a clean shop towel.

Place plastigage across the rod journal.

Reinstall the bearing half and cap, and torque the nuts.

Torque

Bl6A2 engine:

40 N.m (4.1 kgl.m, 30 lbf'ft)

Dr6Y5, D16Y7, D16Y8 enginss:

31 N'm (3.2 kgf.m, 23 lbf ftl

NOTE| Do not rotate the crankshaft during inspection.

Remove the rod cap and bearing half and measure

the widest part of the plastigage.

Connecting Rod Bearing-to.Journal Oil Glearance:

816A2 engine:

Standard lNewl: 0.032 - 0.050 mm

10.0013 - 0.0020 in)

Service Limit: 0.06 mm 10.002 inl

D16Y5, D16Y7, D16Y8 engines:

Standard lNew): 0.020 - 0.038 mm

(0.0008 - 0.0015 in)

Service Limit 0.05 mm 10.002 inl

'1.

4.

lf the plastigage measures too wide or too narrow'

remove the upper half of the bearing, install a new,

complete bearing with the same color code (select

the color as shown in the right column), and

recheck the clearance.

CAUTION: Do not lile, shim, or scrape the bearings

or the caps to adiust clgarance.

lf the plastigage shows the clearance is still incorrect.

try the next larger or smaller bearing (the color listed

above or below that one), and check clearance again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

PLASTIGAGE STRIP

\

7.

7-11

Selection

CAUTION: lf the codes are indecipherable because of

an accumulation of dirt and dust, do not sclub them

with a wile brush or scraper. Clean them only with sol-

vent or detergent,

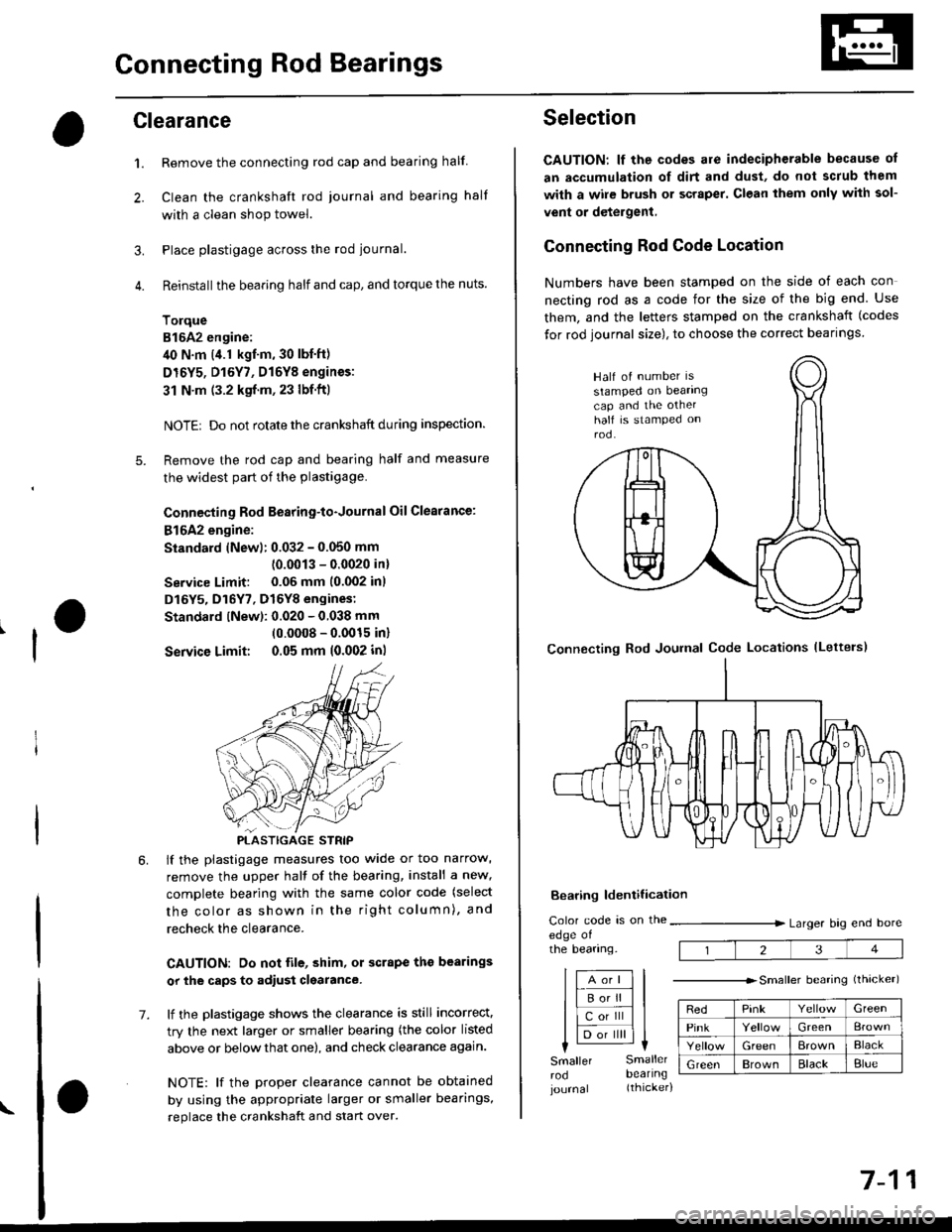

Connecting Rod Code Location

Numbers have been stamped on the side of each con

necting rod as a code for the size of the big end Use

them, and the letters stamped on the crankshaft (codes

for rod journal size), to choose the correct bearlngs

Half of number ls

stamped on bearingcap and the otherhalf is stamped onrod.

Bearing ldentilication

Color code is on theedge ofthe bearing.

lfA--;T] |

lle"'tt l;llcorlll ll

I lD;;ilril |l-l

Larger brg end bore

Smaller Smallerrod bearlngjournal (thicker)

---------------- Smallerbearing{thrcker)

RedPinkGreen

PinkGreen

GreenErownBlack

GreenBrownBlackBlue

1234

Connecting Rod Journal Code Locations (Lettels)