crank HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1490 of 2189

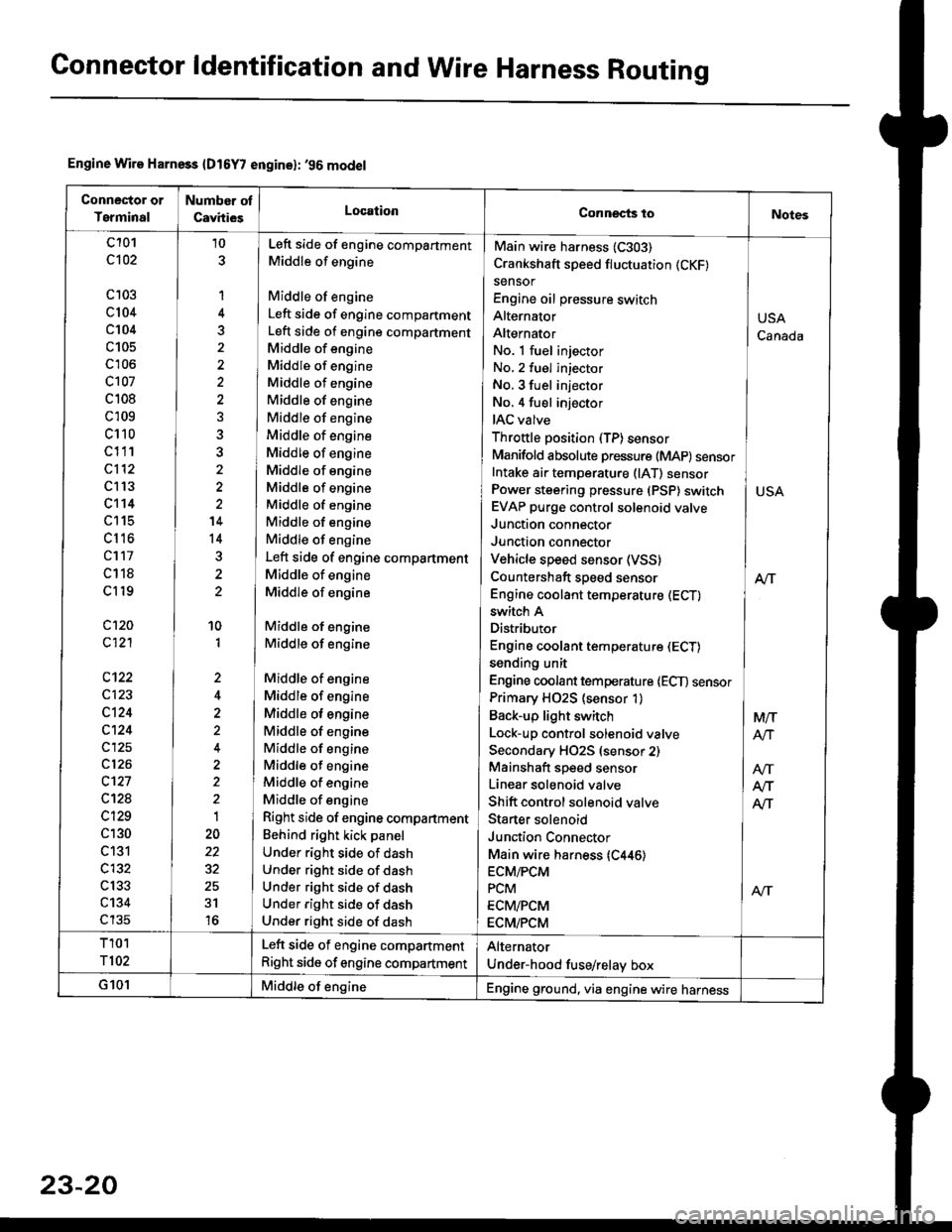

Gonnector ldentification and Wire Harness Routing

Engine Wire Harness {D16Y7 engine}: '96 model

Conneclor or

Terminal

Number ot

CavhiesLocationConnects toNotes

c101

c102

c 103

c104

c104

c105

c'r06

c107

c 108

c 109

c110

c111

c112

c l13

c't14

LttS

cl16

cl17

c118

cl19

c120

c121

c123

c124

c124

c125

c126

c't27

c12a

c129

c130

c131

c132

c133

c134

c135

10

1

4

5

'14

14

10

1

,,

2

2

1

22

31

16

No. 1 fuel injector INo. 2 fuel injector

No. 3 fuel injector INo,4 fuel injector

IAC valve l

Throttle position (TP)sensor IManifold absolute pressure (MAP) sensorIntake ai. temperature (lAT) sensor ]Power steering pressure (PSP) switch I USAEVAP purge control solenoid valve IJunction connector

Junction connector IVehicle speed sensor (VSS) |Countershaft speed sensor AlTEngine coolant temperature (ECT) I

Main wire harness (C303)

Crankshaft speed fluctuation (CKF)

sensor

Engine oil pressure switch

Alternator

Alternator

switch A

Distributor

Engine coolant temperature (ECT)

sending unit

Engine coolant temperature lECT) sensor

Primary H02S (sensor 1)

Back-up light switch

Lock-up control solenoid valve

Secondary HO2S (sensor 2)

Mainshaft speed sensor

Linear solenoid valve

Shift control solenoid valve

Staner solenoid

Junction Connector

Main wire harness {C446)ECM/PCM

PCM

ECM/PCM

ECM/PCM

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine compartment

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

USA

Canada

M/T

AtJ

Afi

T101

T102

Left side of engine compartment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-20

Page 1492 of 2189

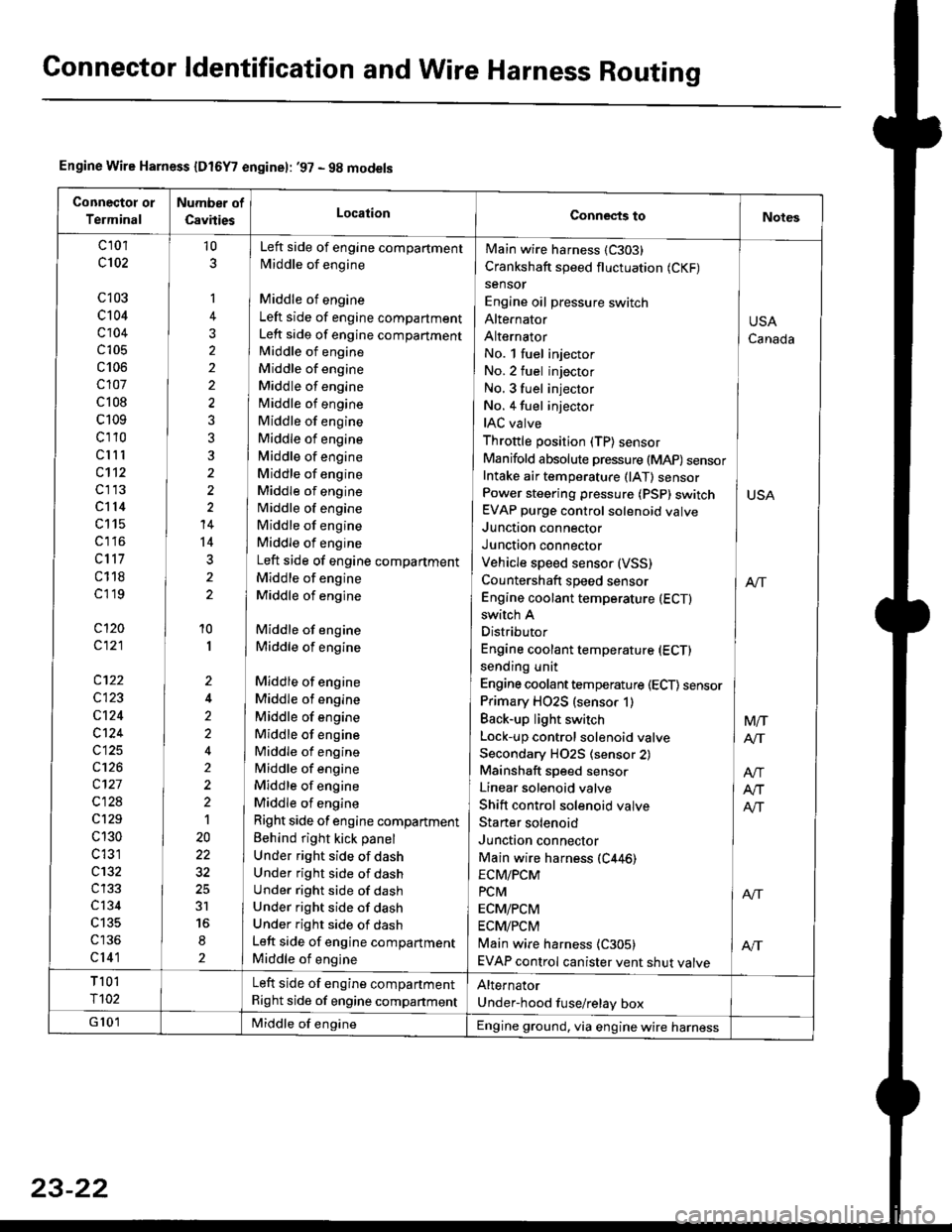

Connector ldentification and Wire Harness Routing

Engine Wire Harness {Dt6Y7 enginel: '97 - 9g models

Connectot or

Terminal

Number of

CsvitiesLocationConnects toNotes

c 101

c102

c103

c104

c104

c105

c106

c107

c 108

c109

cl10

clll

c112

cl13

cl14

c115

c1 l6

c117

c118

cl 19

cl20

c121

c122

c123

cl24

c124

c125

c126

c127

c128

c129

c 130

c 131

c132

c134

c135

cl41

10

1

2

10

I

2

2'>

4

t

20

3r

2

No. l fuel injector

No.2 fuel injector

No. 3 fuel injector INo. 4 fuel injector

IAC valve ]Throttle position (TP) sensor IManifold absolute pressure (MAP) sensorIntake air temperature (lAT) sensor ]Power steering pressure (PSp) switch I USAEVAP purge control solenoid valve

Junction connector IJunction connector IVehicle speed sensor (VSS)

Countershaft speed sensor I enEngine coolant temperature (ECTI

Main wire harness (C303)

Crankshaft speed fluctuation (CKF)

sensor

Engine oil pressure switch

Alte|'nator

Alternator

switch A

Distributor

Engine coolant temperature (ECT)

sending unit

Engine coolant temperature (ECT) sensor

Primary HO2S (sensor 1)

Back-up light switch

Lock-up control solenoid valve

Secondary H02S (sensor 2)

Mainshaft speed sensor

Linear solenoid valve

Shift control solenoid valve

Staner solenoid

Junction connector

Main wire harness (C446)

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine compartment

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Left side of engine compartment

Middle of engine

USA

Canada

Mtr

AIT

ECM/PCM

PcM I ArrECM/PCM

ECM/PCM

Main wire harness {C305) | AftEVAP control canister vent shut valve

T 101

r102

Left side of engine compartment

Right side of engine companment

Alternator

Under-hood fuse/relay box

G 101Middle of engineEngine ground, via engine wire harness

23-22

Page 1494 of 2189

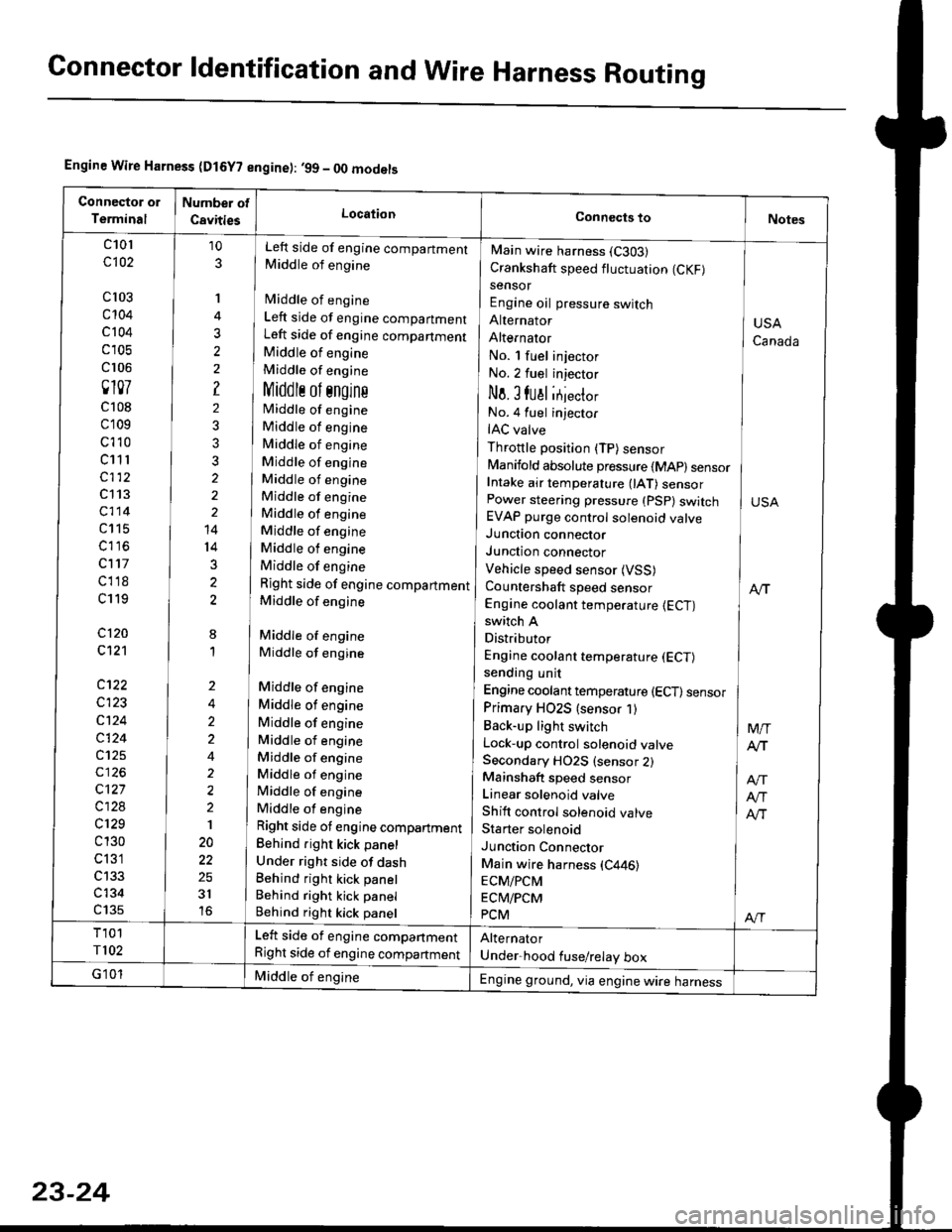

Connector ldentification and WireHarness Routing

Engine Wire Harness (D15Y? engine): ,99 - OO models

c101

c102

cl03

c't04

c 104

c 105

cr 06

0107

c108

c109

c't 10

c11 r

c112

c113

c114

c115

c116

c117

cl18

c119

c120

c121

c122

c123

c124

c124

c125

c127

c128

c129

c 130

c 131

c134

c135

10

3

'I

3

?

2

3?

2

14

14

3

2

8

1

Left side of engine compartment

Middle of engine

fvliddle of engine

Left side of engine compartment

Left side of engine companment

Middle of engine

Middle of engine

Middlr ol sngins

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side ot engine compartment

Behind right kick panel

Under right side of dashBehind right kick panel

Behind right kick panel

Behind right kick panel

Main wire harness (C303)

Crankshaft speed fluctuation (CKF)

sensor

Engine oil pressure switch

Alternator

AlternatOr

No. l fuel injector

No.2 fuel injector

No. I fual itjecto,

No.4 fuel injector

IAC valve

Throttle position (TP) sensor

Manifold absolute pressure {MAp) sensorIntake air temperature 0AT) sensorPower steering pressure (PSp) switchEVAP purge control solenoid valveJunction connector

Junction connector

Vehicle speed sensor (VSS)

Countershaft speed sensor

Engine coolant temperature {ECT)switch A

Distributor

Engine coolant temperature (ECT)

sending unit

Engine coolant temperature (ECT) sensor

Primary HO2S (sensor 1)

Back-up light switch

Lock-up control solenoid valveSecondary HO2S (sensor 2)Mainshaft speed sensor

Linear solenoid valve

Shift control solenoid valve

Starter solenoid

Junction Connector

Main wire harness (C446)

ECM/PCM

ECM/PCM

PCM

USA

Canada

M/T

Atr

Atr

Alr

Al-|.

Left side of engine compartment

Right side of engine compartment

Middle of engineEngine ground, via engine wire harness

23-24

Page 1496 of 2189

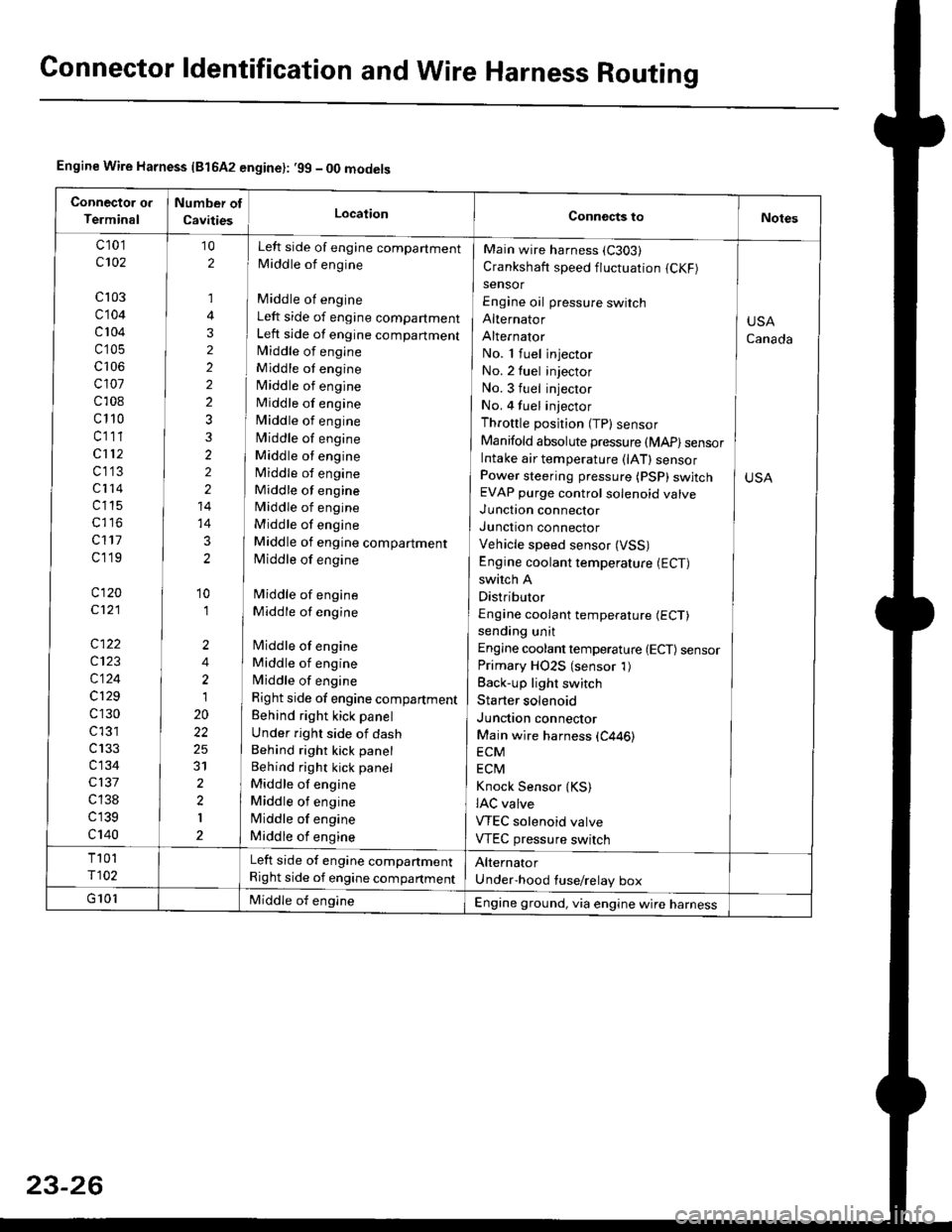

Connector ldentification and WireHarness Routing

Engine Wire Harness {81642 engine}: .99 - 00 models

c 101

c102

cl03

c104

c 104

c'105

c106

cl01

c108

c110

cl11

cl12

c1'13

c114

c115

c117

cl19

c120

c121

c122

c123

c124

c129

c130

c l31

c133

c134

c137

c 138

c139

c140

Left side of engine companment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartmentlvliddle of engine

Middle ot engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle ot engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine compartment

Middle of engine

Middle of engine

Middle of engine

lMiddle of engine

Middle of engine

Middle of engine

Right side of engine compartment

Behind right kick panel

Under right side of dash

Behind right kick panel

Behind right kick panel

Middle of engine

Middle ot engine

lMiddle of engine

Middle of engine

10

2

,]

4

3

2

2

2

2

3

3

2

2

2

14

14

3

2

'10

'I

2

4

2

1

20

22

25

31

2

2

I

Main wire harness (C303)

Crankshaft speed fluctuation (CKF)

sensor

Engine oil pressure switch

Alternator

Alternator

No. 1 fuel injector

No. 2 tuel injector

No. 3 fuel injector

No. 4 fuel injector

Throttle position (TP) sensor

Manifold absolute pressure (MAP) sensorIntake air temperature (lAT) sensorPower steering pressure (PSP) swjtchEVAP purge control solenoid valve

Junction connector

Junction connector

Vehicle speed sensor (VSS)

Engine coolant temperature (ECT)

switch A

Distributor

Engine coolant temperature (ECT)

sending unit

Engine coolant temperature {ECT) sensorPrimary HO2S (sensor 1)

Back-up light switch

Starter solenoid

Junction connector

Main wire harness (C446)

ECM

ECtvl

Knock Sensor {KS)IAC valve

VTEC solenoid valve

VTEC pressure switch

USA

Canada

Left side of engine companment

Right side of engine compartment

Engine ground, via engine wire harness

Page 1562 of 2189

Battery

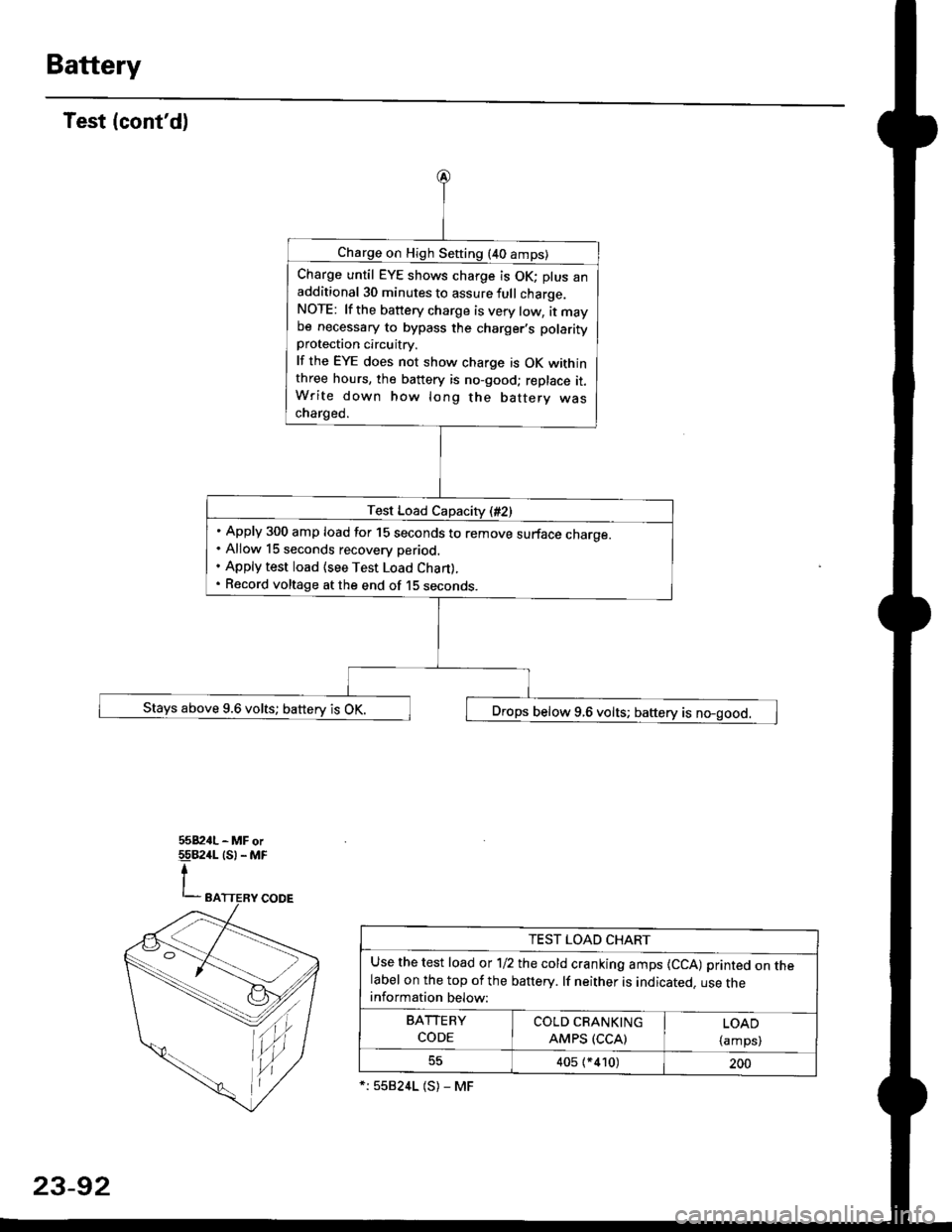

Test (cont'd)

Charge on High Sefting (40 amps)

Charge until EYE shows charge is OK; plus anadditional 30 minutes to assure full charge.NOTE: lf the battery charge is very tow, it maybe necessary to bypass the charger,s polarityprotection circuitry.

lf the EYE does not show charge is OK withinthree hours, the battery is no-good; replace it.Write down how long the battery wascharged.

Test Load Capacity (#2)

Apply 300 amp load for 15 seconds to remove surface charoe.Allow 15 seconds recovery period.

Apply test load {see Test Load Chan).

Record voltage at the end of 15 seconos.

Stays above 9.6 volts; battery is OK. ,] Drops below 9.6 volts; baftery is no-good.

tu,

TEST LOAD CHART

Use the test load or 1/2 the cold cranking amps {CCA) printed on thelabel on the top of the banery. lf neither is indicated. use theinformation below:

BArrERy coLb@

coDE I AMps (ccAl | {amps)

405 (*410)200

*:558241 (S) - MF

23-92

Page 1565 of 2189

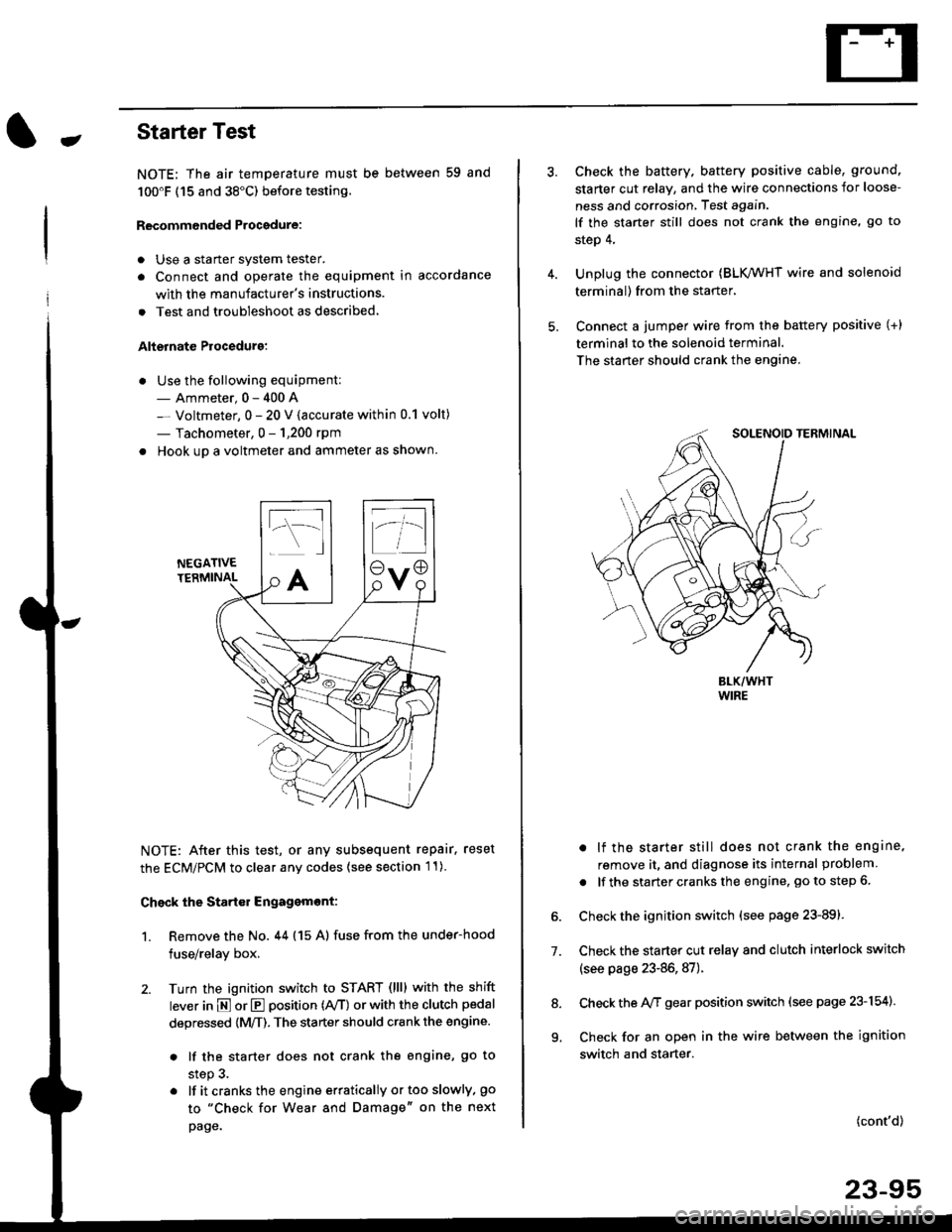

-Starter Test

NOTE; The air temoerature must be between 59 and

100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described,

Alternate Procedurg:

. Use the following equipment:- Ammeter, 0 - 400 A

- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

- Tachometer, 0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NEGATIVETERMINAL

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section l1)

Check the Start€r Engagemont:

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

2. Turn the ignition switch to START (llll with the shift

lever in E or E position (rVT) or with the clutch pedal

depressed {M/T). The starter should crank the engine.

. lf the starter does not crank the engine, go to

step 3.

. lf itcranksthe engineerraticallyortooslowly, go

to "Check for Wear and Damage" on the next

page.

Check the battery. battery positive cable, ground,

starter cut relay, and the wire connections for loose-

ness and corrosion, Test again.

lf the starter still does not crank the engine, go to

step 4,

Unplug the connector (BLK,/WHT wire and solenoid

terminal) from the starter,

Connect a jumper wire from the battery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem

. lf the startercranksthe engine, goto step 6.

Check the ignition switch (see page 23-891.

Check the starter cut relay and clutch interlock switch

(see page 23-86,87).

Check the A/f gear position switch (see page 23-154).

Check for an open in the wire between the ignition

switch and starter.

7.

(cont'd)

23-95

9.

Page 1566 of 2189

Starting System

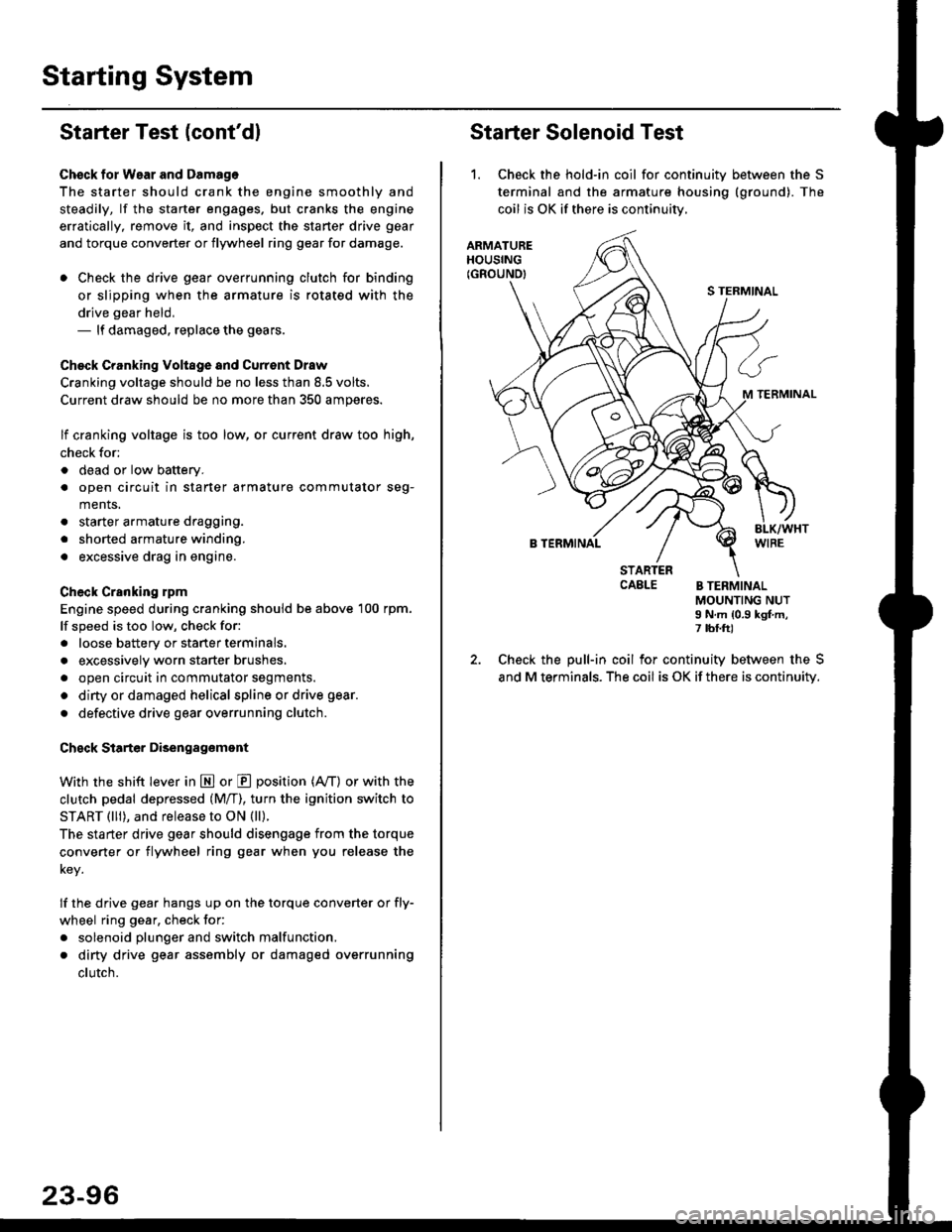

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1573 of 2189

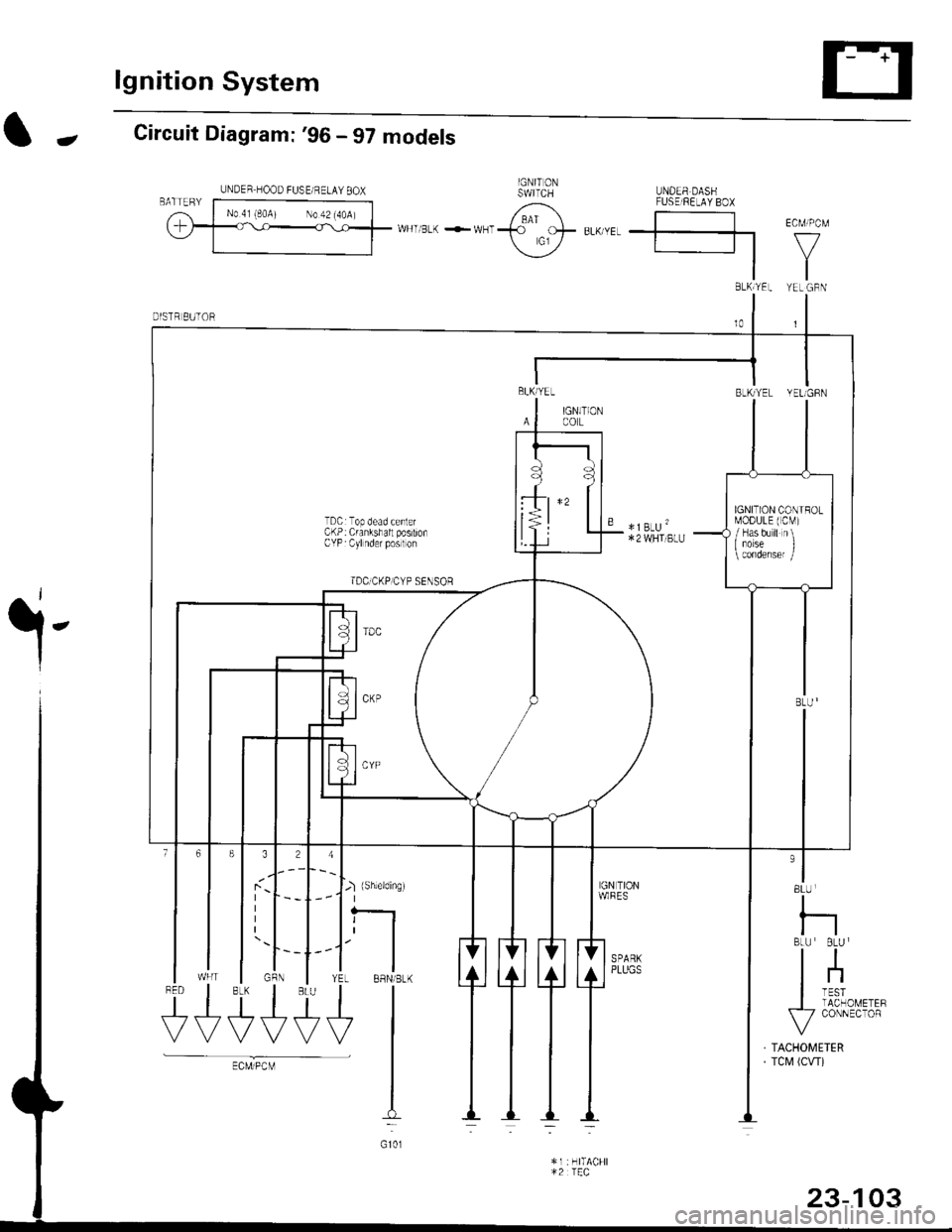

lgnition System

-Circuit Diagram: '96 - 97 models

.i-

8LU

I

nBLU BLU I

tl

lnI TESTI TACHOMETEF\-7 CONNECTOR

TACHOMETERTCM (CW)

J-) {sh,eldinsr't I

tfYEL BBN/BLK

+l

I:

G101

$t+++

UNDER HOOD FUSE/ RELAY 8OX

BLh TEL YEL GBN

BLKlYEL

IAl

BLK/YEL YELIGFN

IGN]TIONCOL

TDCrTop dead cenlerCKP: Crankshall postionCYP Cylnder poslon

TDC]CKP]CYP SENSoR

" *]BLU'*2 WHI BLU

IGNITION CONIROLMODULE (CM)

/ Has b'r ll n\I iorse I

rUSE FE-AV BO}

*u r-. .-*---{<9ot # u,,."r. | |

\j/ El v

tl

23-103

Page 1595 of 2189

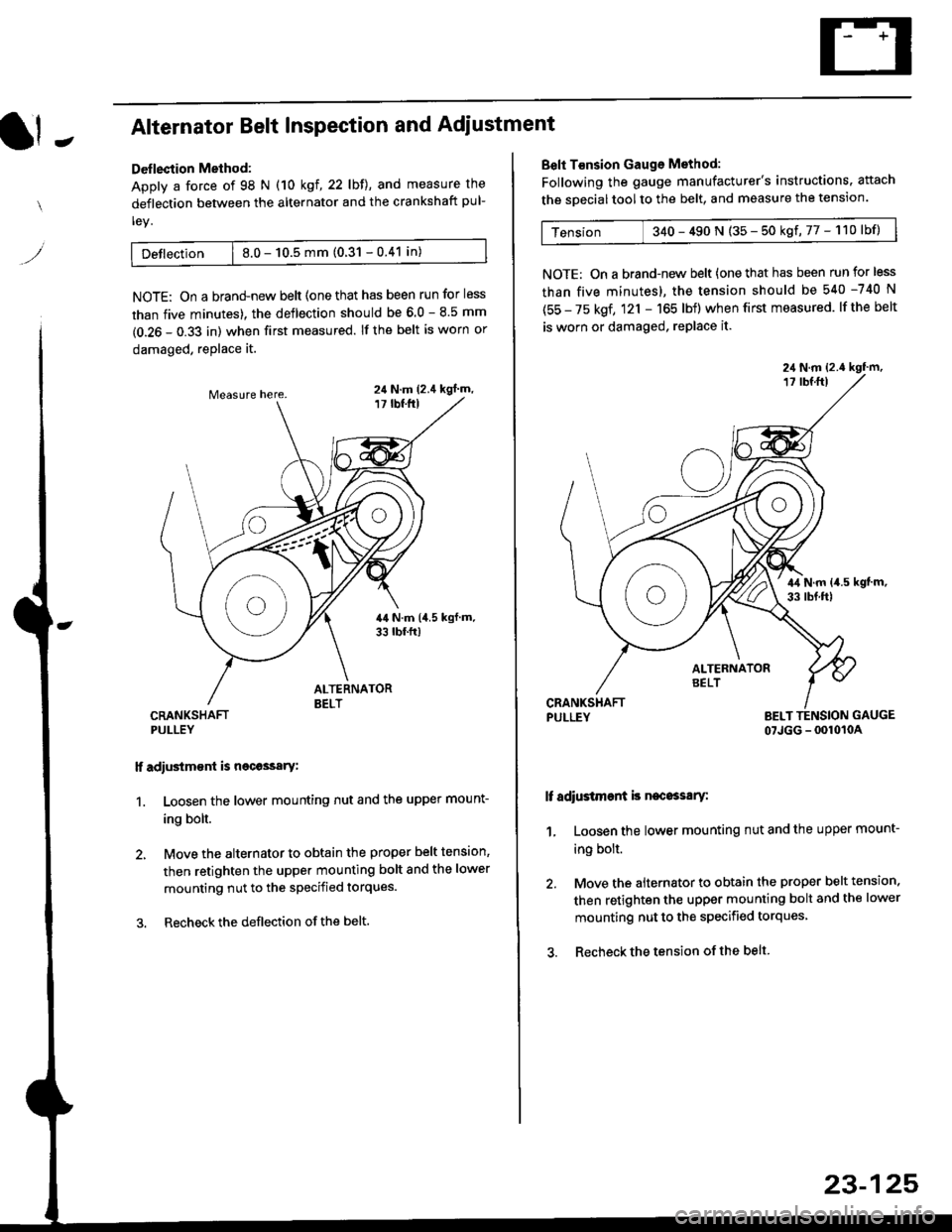

It -Alternator Belt Inspection and Adiustment

Deflection Method:

Apply a force of 98 N (10 kgl,22lbll, and measure the

deflection between the alternator and the crankshaft pul-

ley.

Detlection | 8.0 - 10.5 mm (0.31 - 0.41 in)

NOTE: On a brand-new belt {one that has been run for less

than five minutes). the deflection should be 6.0 - 8.5 mm

(0.26 - 0.33 in) when first measured. If the belt is worn or

damaged, replace it.

CRANKSHAFTPULLEY

lf adiustm€nt is necossary:

1. Loosen the lower mounting nut and the upper mount-

ing bolt.

2, Move the alternator to obtain the proper belt tension,

then retighten the upper mounting bolt and the lower

mounting nut to the specified torques.

3. Recheckthe deflection ofthe belt.

24 N.m (2.4 kgl m,

Belt T€nsion Gauge Method:

Following the gauge manufacturer's instructions. attach

the soecial tool to the belt, and measure the tension.

Tension 340 - 490 N (35 - 50 kgf,77 - 110lbf)

NOTE: On a brand-new belt {one that has been run for less

than five minutes), the tension should be 540 -740 N

(55 - 75 kgf, 121 - 165 lbf) when first measured. lf the belt

is worn or damaged, replace it.

PULLEY BELT TENSION GAUGE

07JGG - 0010104

It adiustment is necossary:

1, Loosen the lower mounting nut and the upper mount-

ing bolt.

2. Move the alternator to obtain the proper belt tension.

then retighten the upper mounting bolt and the lower

mounting nut to the specified torques

3. Recheck the tension of the belt

23-125

Page 1829 of 2189

In the "OHMS" range, the DVOM will measure

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting lhe measurement.

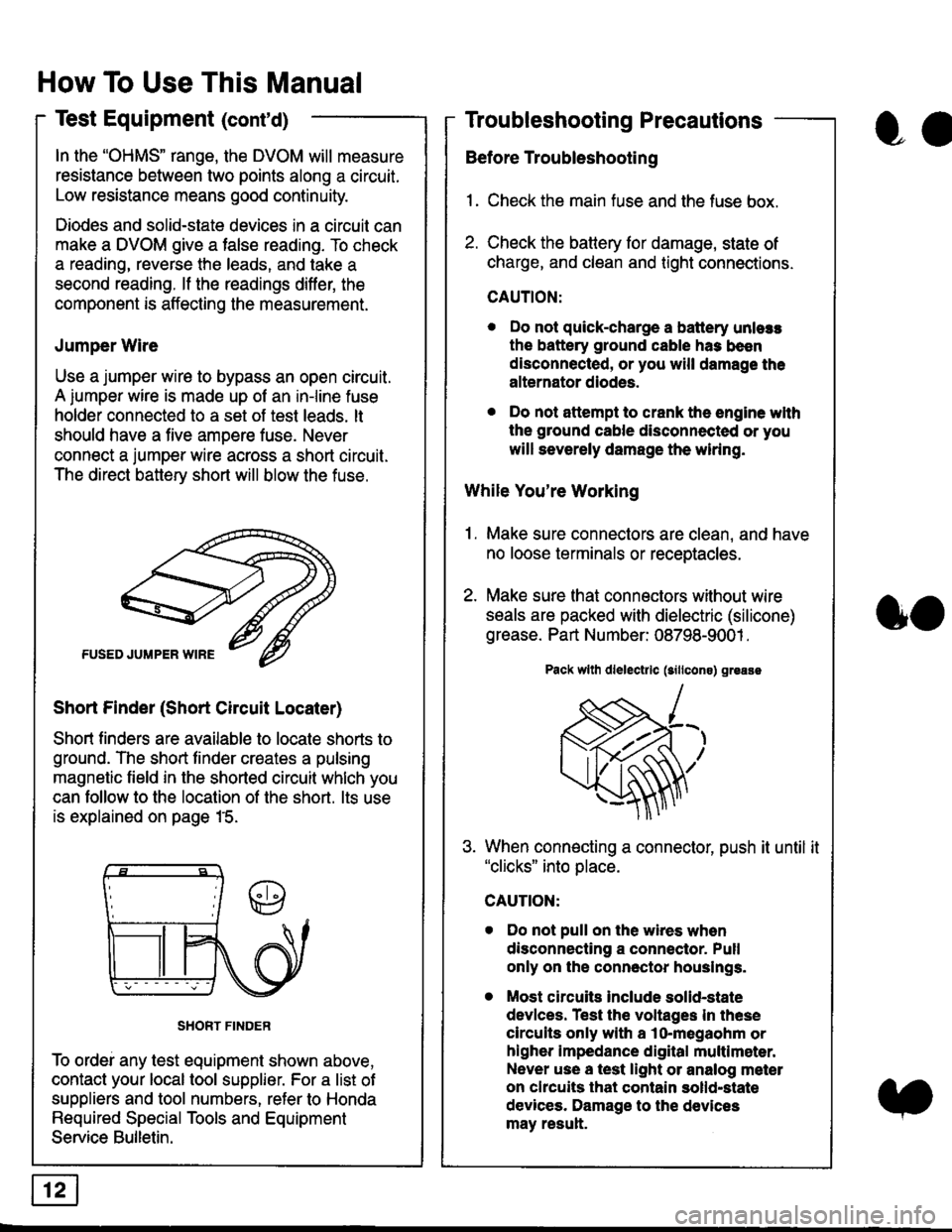

Jumper Wire

Use a jumper wire to bypass an open circuit.

A iumper wire is made up ot an in-line fuse

holder connected to a set of test leads. lt

should have a five amoere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Short finders are available to locale shorts to

ground. The short tinder creates a pulsing

magnetic field in the shorted circuit whlch you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To ordei any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Honda

Required Special Tools and Equipment

Service Bulletin.

How To Use This Manual

Test Equipment (cont'd)

oa

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage, state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unlers

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine wlth

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receptacles.

2. Make sure lhat connectors without wire

seals are packed with dielectric (silicone)

grease. Part Number: 08798-9001 .

Pack wllh dlelectrlc (sillcons) greass

When connecting a connector, push it until it"clicks" into place.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector houslngs.

Most circuits Include solid-state

devlces. Test the voltages In these

circuits only with a lo-megaohm or

higher impedance digital multlm6ter.

Never use a test light or analog meter

on chcuits that contain solld-state

devices. Damage to the devices

may result.

oo