valve stem HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1460 of 2189

Compressor (SANDENI

Thermal Protestor Replacement

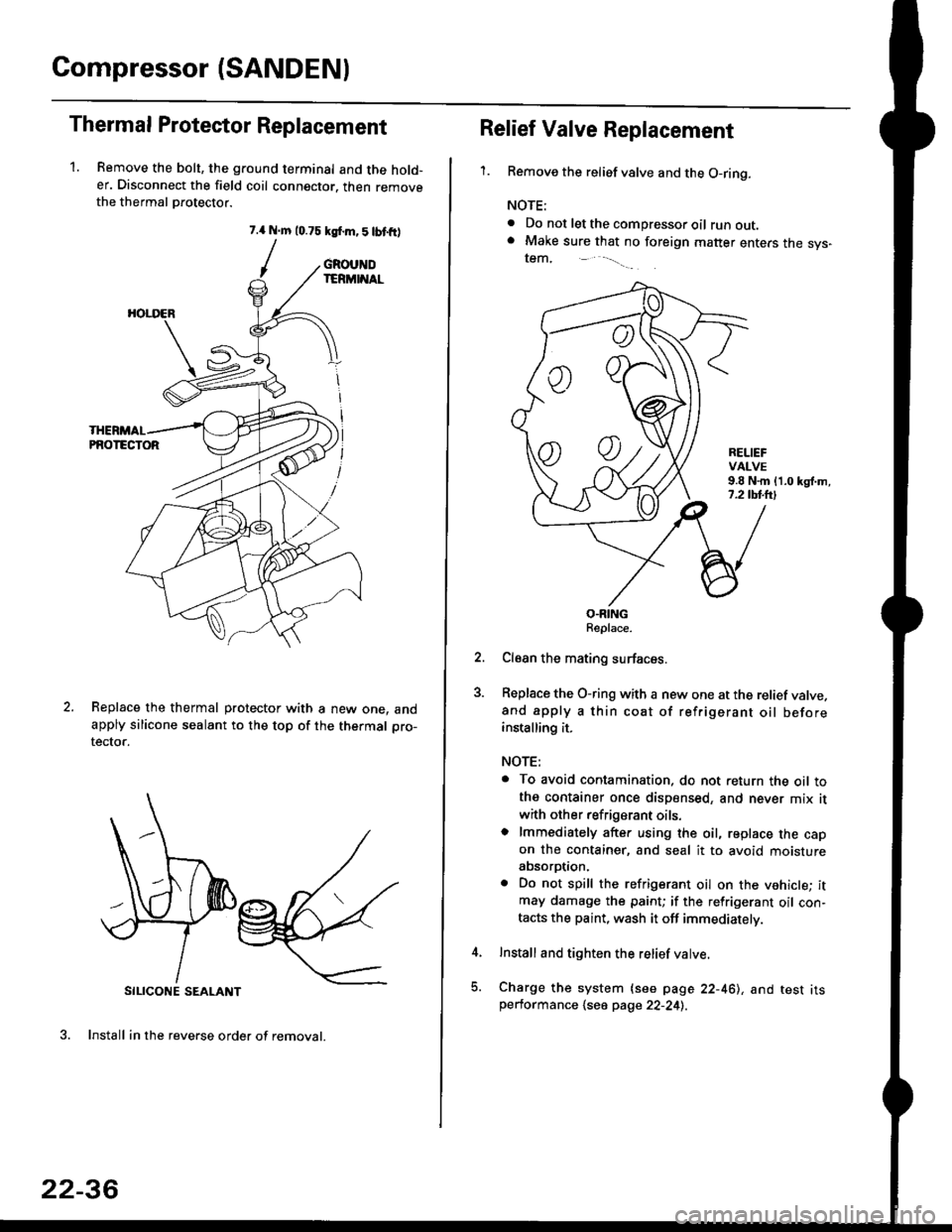

1. Remove the bolt, the ground terminal and the hold-er. Disconnect the field coil connector. then removethe thermal Drotector.

7.{ N.m 10.75 ksf.m,5lbtfr)

/

SILICONE SEALANT

3. Install in the reverse order of removal.

GROUNDIERMINAL

HOI.I'ER

PNOTECTOR

Replace the thermal protector with a new one. andapply silicone sealant to the top of the thermal pro-

tector.

22-36

oo

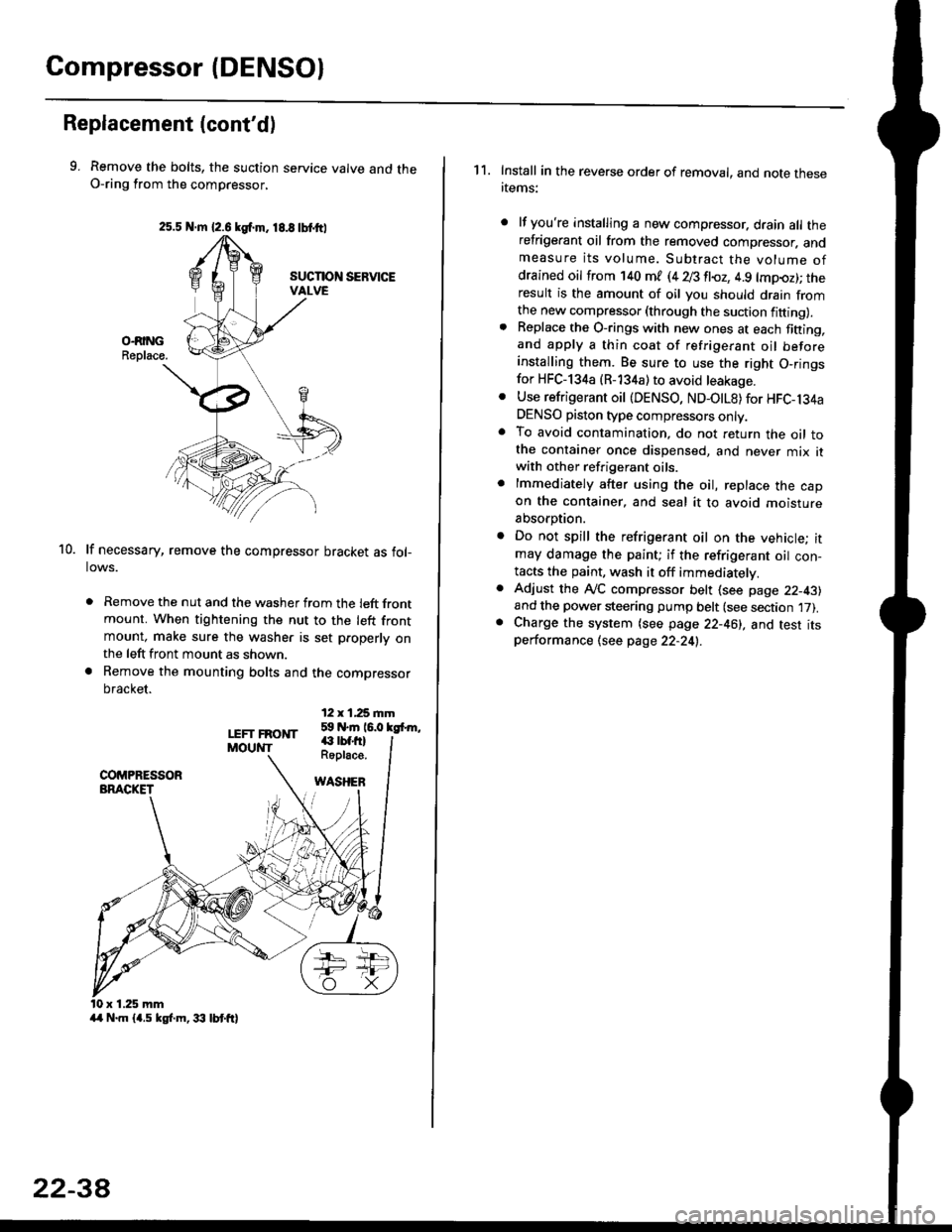

Relief Valve Replacement

'1.Remove the relief valve and the O-ring.

NOTE:

. Do not let the compressor oil runout.. Make sure that no foreign matter enters the sys-tem,

RELIEFVALVE9.8 N.m {1.0 kgl.m,7.2 tbl.lrl

O.RINGReplace.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil beforeinstalling it.

NOTE:

. To avoid contamination. do not return the oil tothe container once dispensed, and never mix it

with other refrigerant oils.o lmmediately after using the oil, replace the capon the container, and seal it to avoid moistureabsorption.

. Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediately.

Install and tighten the relief valve.

Charge the system {see page 22-461, and test itsperformance 1se6 page 22-241.

Page 1462 of 2189

Compressor (DENSOI

Replacement (cont'd)

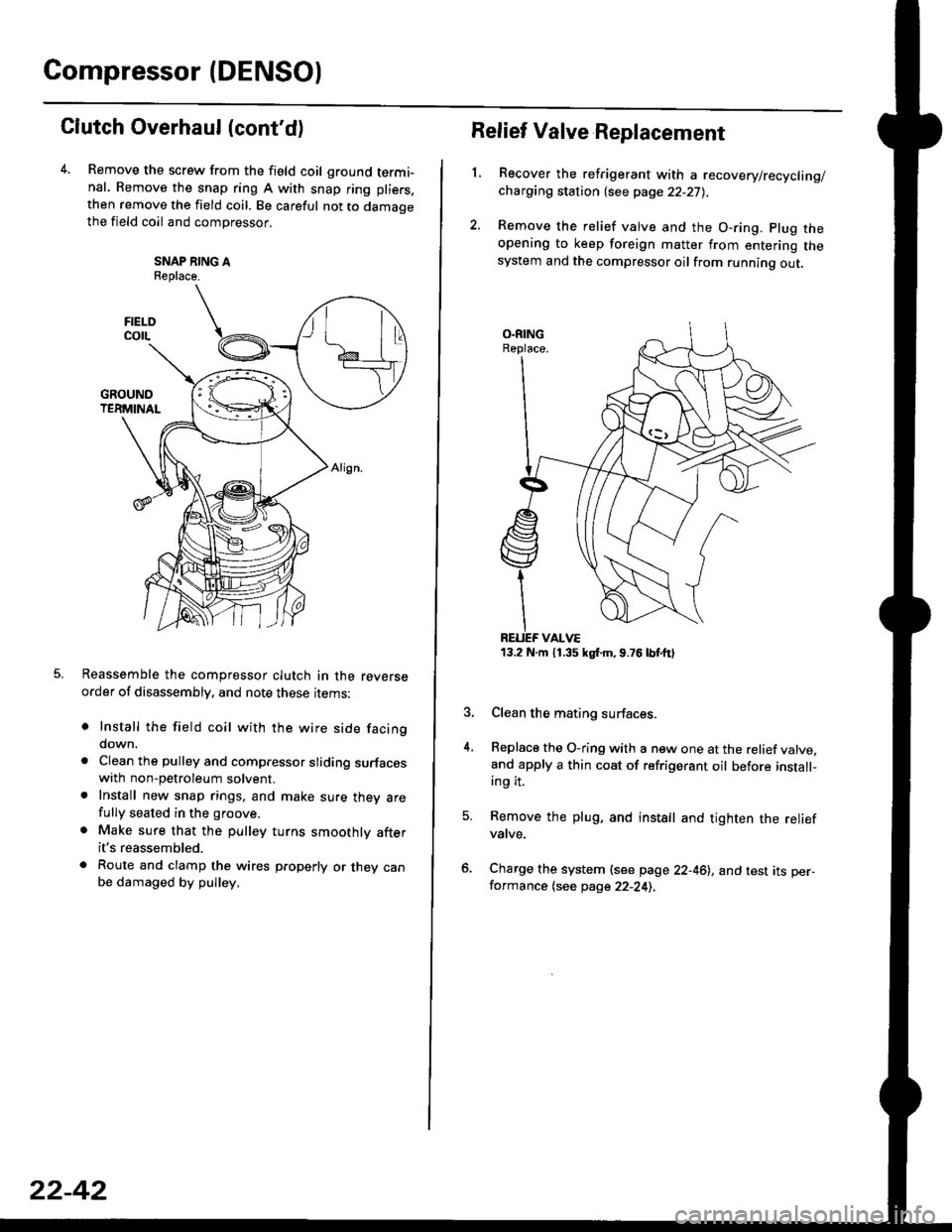

9. Remove the bolts, the suction service valve and theO-ring from the compressor,

lf necessary, remove the compressor bracket as fol-lows.

. Remove the nut and the washer from the left frontmount. When tightening the nut to the left frontmount, make sure the washer is set p.operly onthe left front mount as shown.

a Remove the mounting bolts and the compressor

bracket.

12 x 1,25 rnm59 N.m 16.0 kgfrm,

10.

LEFT FRONTMOUNT€ rbf.fi)Roplace.

WASHEB

x 1.25 mm

2s.5 N.m {2.6 kgf.m. 18.8 tbtttl

4/r N.m {4.5 kgf.m, 33 lbt ft}

22-3A

1 1. Install in the reverse order of removal, and note thesertems:

lf you're installing a new compressor. drain all therefrigerant oil from the removed compressor. andmeasure its volume. Subtract the volume ofdrained oil from '140 ml (4 28 fl{,z, 4.9 lmpoz); theresult is the amount of oil you should drain fromthe new compressor (through the suction fifting).Replace the O-rings with new ones at each fining,and apply a thin coat of refrigerant oil beforeinstalling them. Be sure to use the right O,ringsfor HFC-134a (R-134a) to avoid leakage.

Use refrigerant oil {DENSO, ND-OtL8) for HFC-134aDENSO piston type compressors only.To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refrigerant oils.

lmmediately after using the oil, replace the capon the container, and seal it to avoid moisture

absorption.

Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediatelv.

Adjust the ly'C compressor belt (see page 22-43)and the power steering pump belt (see section 17).Charge the system (see page 22-46), and test itsperformance (see page 22-24!..

Page 1466 of 2189

Compressor (DENSO)

Clutch Overhaul (cont'd)

Remove the screw from the field coil ground termi-nal. Remove the snap ring A with snap ring pliers.

then remove the field coil. Be careful not to damaoethe field coil and compressor.

SNAP NING AReplace.

Reassemble the compressor clutch in the reverseorder of disassembly, and note these rrems:

o Install the field coil with the wire side facingdown.

a Clean the pulley and compressor sliding surfaceswith non-petroleum solvent.. Install new snap rings, and make sure thev arefully seated in the groove.

. Make sure that the pulley turns smoothly afterit's reassembled.

. Route and clamp the wires p.operly or they canbe damaged by pulley.

FIELOcorL

22-42

13.2 N.m 11.35 kgt m,9.76lbtttl

Relief Valve Replacement

L

4.

Recover the refrigerant with a recovery/recycling/charging station {see page 22-27),

Remove the relief valve and the O-ring. plug theopening to keep foreign matter from entering thesystem and the compressor oilfrom running out.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil before install-ing it.

Remove the plug, and install and tighten the reliefvatve.

Charge the system (see page 22-46), and test its per-formance (see page 22-24),

Page 1470 of 2189

A/C System Service

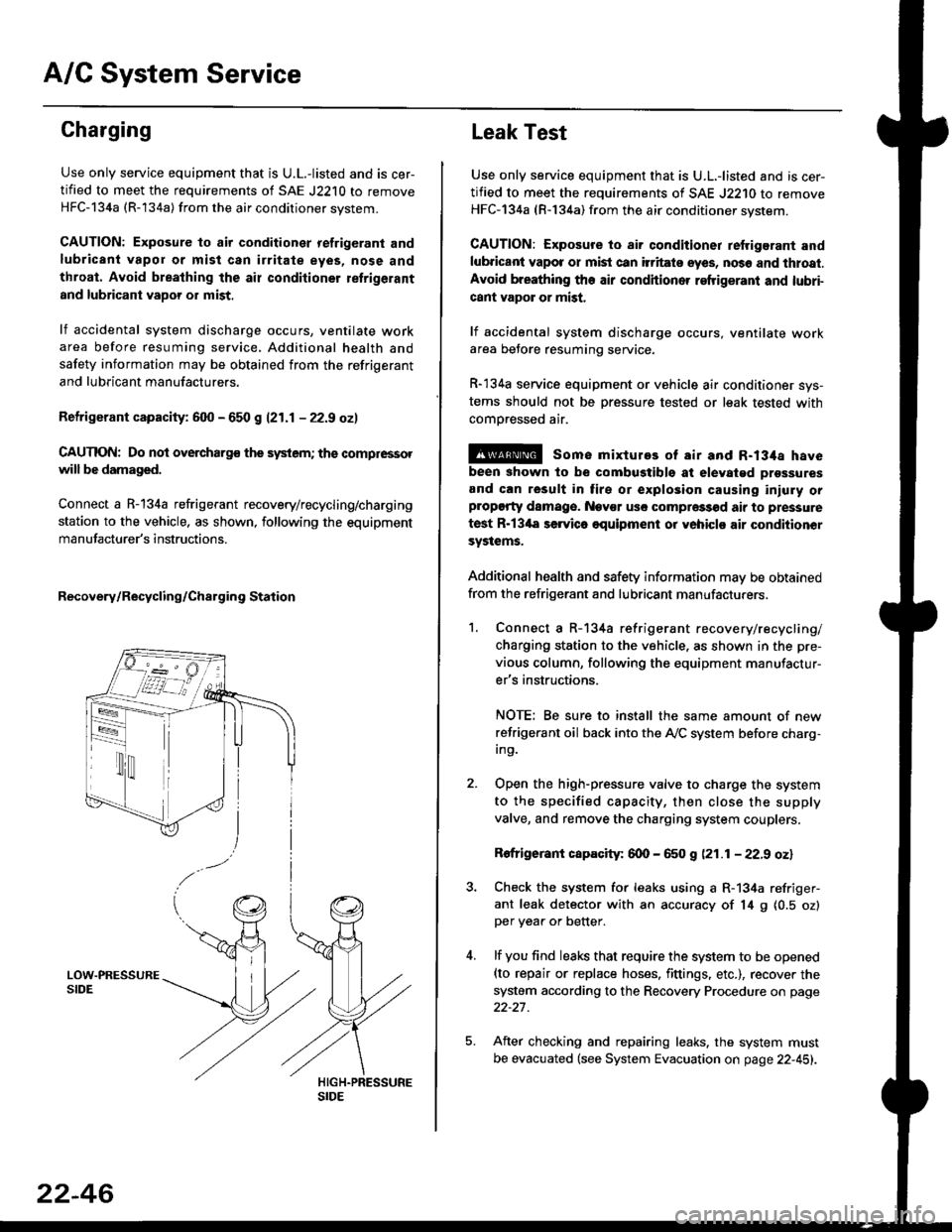

Charging

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritale eyes, nose and

throat. Avoid breathing the air conditioner retrigerant

and lubricant vaoor or mist,

lf accidental system discharge occurs, ventilate workarea before resuming service, Additional health and

safety information may be obtained from the refrigerant

and lubricant manufacturers.

Refrigerant capacityt 600 - 650 g 121.1 - 22.9 ozl

CAUnON: Do not overcharg€ the system; the comprcssor

will be damaged.

Connect a R-134a refrigerant recovery/recycling/charging

station to the vehicle, as shown, following the equipment

manufacturer's instructions.

Recovery/Recycling/Charging Station

22-46

Leak Test

Use only service equipment that is U.L,-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure io air conditioner refrigerant and

lubricant vapot or mist can itritats eyes, no36 and thtoat.

Avoid breathing the air conditioner refrigeranl and lubri-

cant vapor or mist,

lf accidental system discharge occurs, ventilate workarea betore resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

@ some mixtures of air and R-134a have

been shown to be combugtibls at elevatgd prossures

and can result in tire or explosion causing iniuly orplopgrty damage. Nev€r usc compre33od air to pressure

test R-13'la servica oquipment or yohiclo air conditionor

systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

NOTE; Be sure to install the same amount of new

refrigerant oil back into the A,/C system before charg-In9.

Open the high-pressure valve to charge the system

to the specified capacity, then close the supply

valve, and remove the charging system couplers.

Rofrigerant capacity: 600 - 650 g (21.1 - 22.9 oz)

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 9 10.5 ozlper yea. or better.

lf you find leaks that require the system to be opened(to repair or replace hoses. fittings. etc.), recover the

system according to the Recovery Procedure on page

22-27.

After checking and repairing leaks. the system must

be evacuated (see System Evacuation on page 22-451.

Page 1535 of 2189

lr-

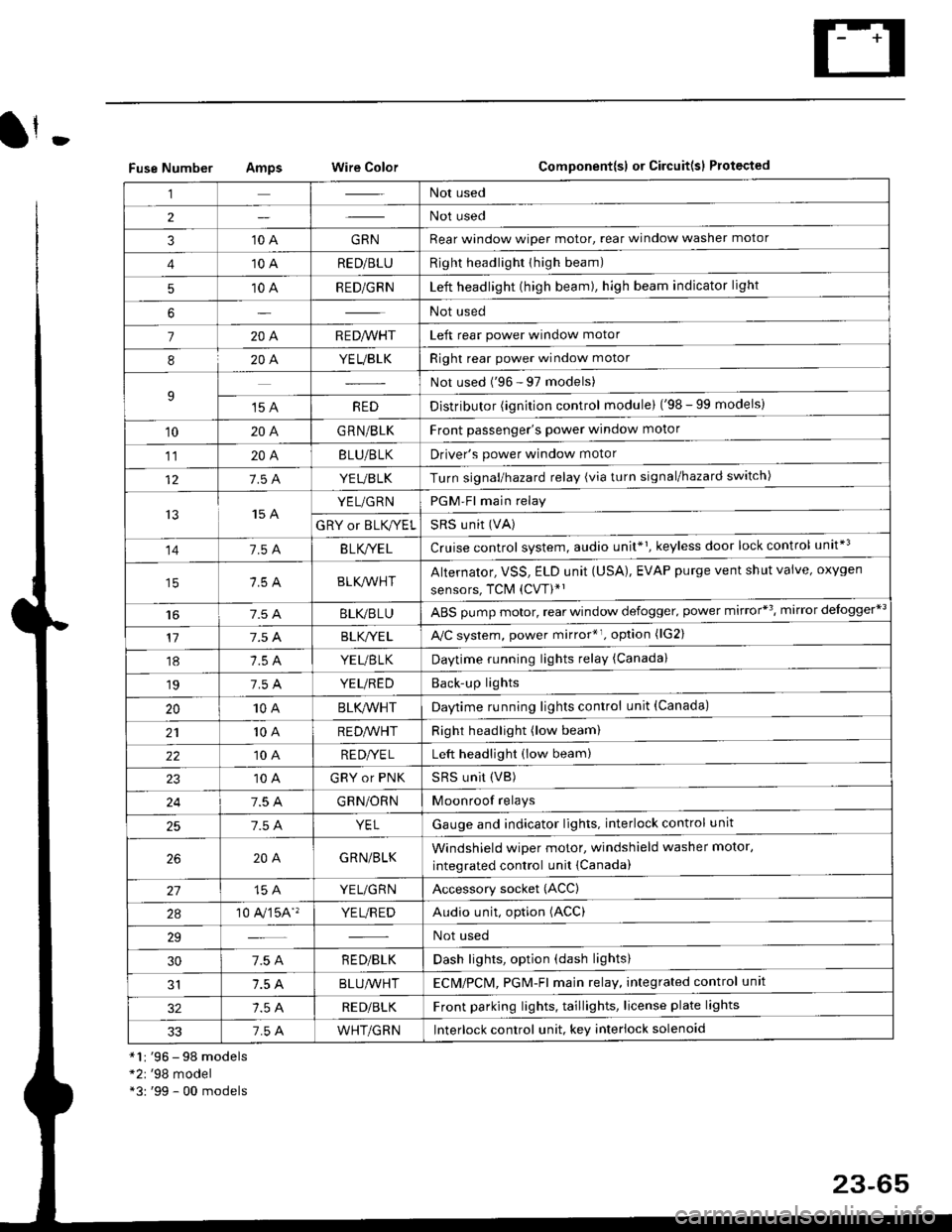

Fuse NumberAmpswire ColorComponent{sl or Circuit(sl Protected

*1r '96 - 98 models*2r '98 model*3: '99 - 00 models

,lNot used

2Not used

310 AGRNRear window wioer motor, rear window washer motor

410 ARED/BLURight headlighr thigh beam)

510 ARED/GRNLeft headlight (high beam), high beam indicator light

6Not used

7204R E D/VVHTLeft rear power window motor

820A.YEUBLKRight rear power window motor

9Not used ('96 - 97 models)

't5 AREDDistributor (ignition control module) ('98 - 99 models)

10204G RN/BLKFront passenger's power window motor

1120ABLU/BLKDriver's power window motor

127.5 AYEUBLKTurn signal/hazard relay (via turn signal/hazard switch)

t515 AYEL/GRNPGM-Fl main relay

GRY or BLK,^/ELSRS u nit (VA)

141.54B LK/YE LCruise control system, audio unit*1, keyless door lock control unit*3

BLK/lr'r'HTAlternator, VSS, ELD unit (USA), EVAP purge vent shut valve, oxygen

sensors, TCM (CVT)*'

t6BLI(,/BLUABS pump motor, rear window defogger. power mirror*3, mirror delogger*3

177.5 ABLK,/YE LA,/C system, power mirror*r. option (lG2)

18YEUBTKDaytime running lights relay (Canada)

197.5 AYEUREDBack'up lights

2010ABLK/VVHTDaytime running lights control unit (Canada)

2110 AREDA/VHTRight headlight (low beam)

2210 ARE DI/E LLeft headlight (low beam)

10 AGRY or PNKSRS UNit (VB)

247.5 AGRN/ORNMoonroof relays

257.5 AYELGauge and indicator lights. interlock control unit

204GRN/BLKWindshield wiper motor, windshield washer motor,

integrated control unit {Canada)

15 AYEL/GRNAccessory socket (ACC)

2a10 A,/'�]5A''YE L/R EDAudio unit, option (ACC)

29Not used

307.5 AR ED/BLKDash lights, option (dash lights)

1.5 ABLUA/VHTECM/PCl\4, PGM-Fl majn relay, integrated control unit

RED/BLKFront parking lights, taillights, license plate lights

337.5 AWHT/GRNlnterlock control unit. key interlock solenoid

23-65

Page 1886 of 2189

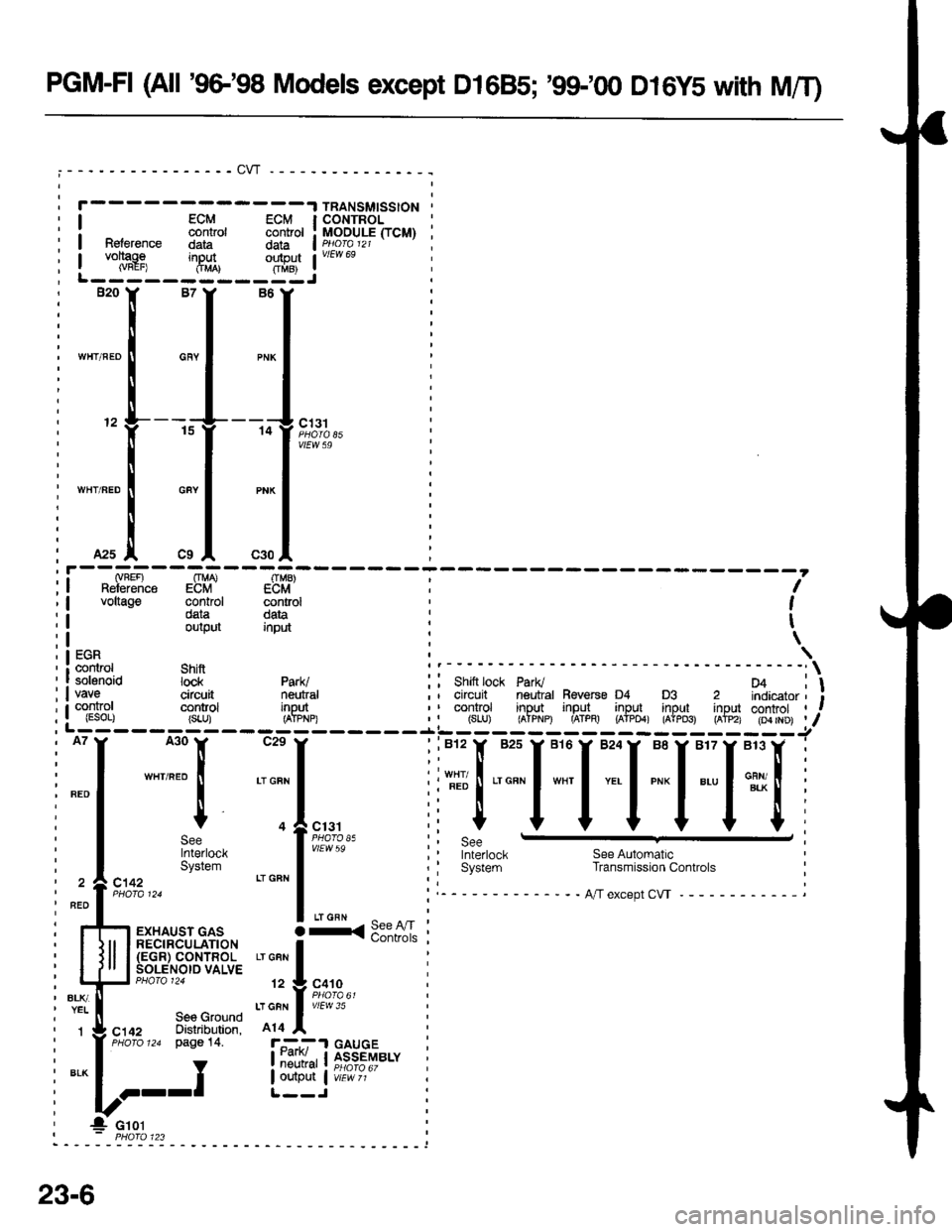

PGM-FI (All '9G'98 Models except Dl685; '99r0O D16y5 with M/T)

TRANSMISSIONCONTROLMODULE (TCM)

llEv/ 69

ECM ECMcontrol controlReference data datavollage inDutNREF) OMA}:q{.J

(VREF) OMA) OMB)Reference ECM ECMcontroldatajnput

EGRcontrol shift' I solenoid

i

-l

"""'"x :i1",'

sofenoid lock Pa(klvave Circult neutr; I vave circuit neutral| | control control inPut, ! (EsOLr {sru, (A}FNP):L------

voltag€ controldataoutput

I

{

ta

i;;;;';;

."

*

'i\,

' circuit neutral Reverse D4 D3 2 indtcator, ;' control input input input input input control | -,| (sLU) rAlPNPr TATPFI {ATpO4i dlPD3) tAfPzr rDa rNDl | /

[J=:ITTIT'{t

' Interlock See Automatrc: Svstem Transmission Controls I

i i controt

i

"'J;:;;,.,"^,

!

l1l

"lL

:1,.

i

".f:;;,.,"^, 1.,."n,

: I lt ti.."stEBkTJBi ""il*l"*

: | /" I SOLENOTD VALVE

i \J PHaro 12a I

i

t'i!",,,

Bi"ifit**1

';

i l ;;;a ',, pase 14 !'#$tl ii{"Ff*,

i

*-1.

---f !.gg1mr..

' 4 cror| - PHAfO 123

23-6

Page 1907 of 2189

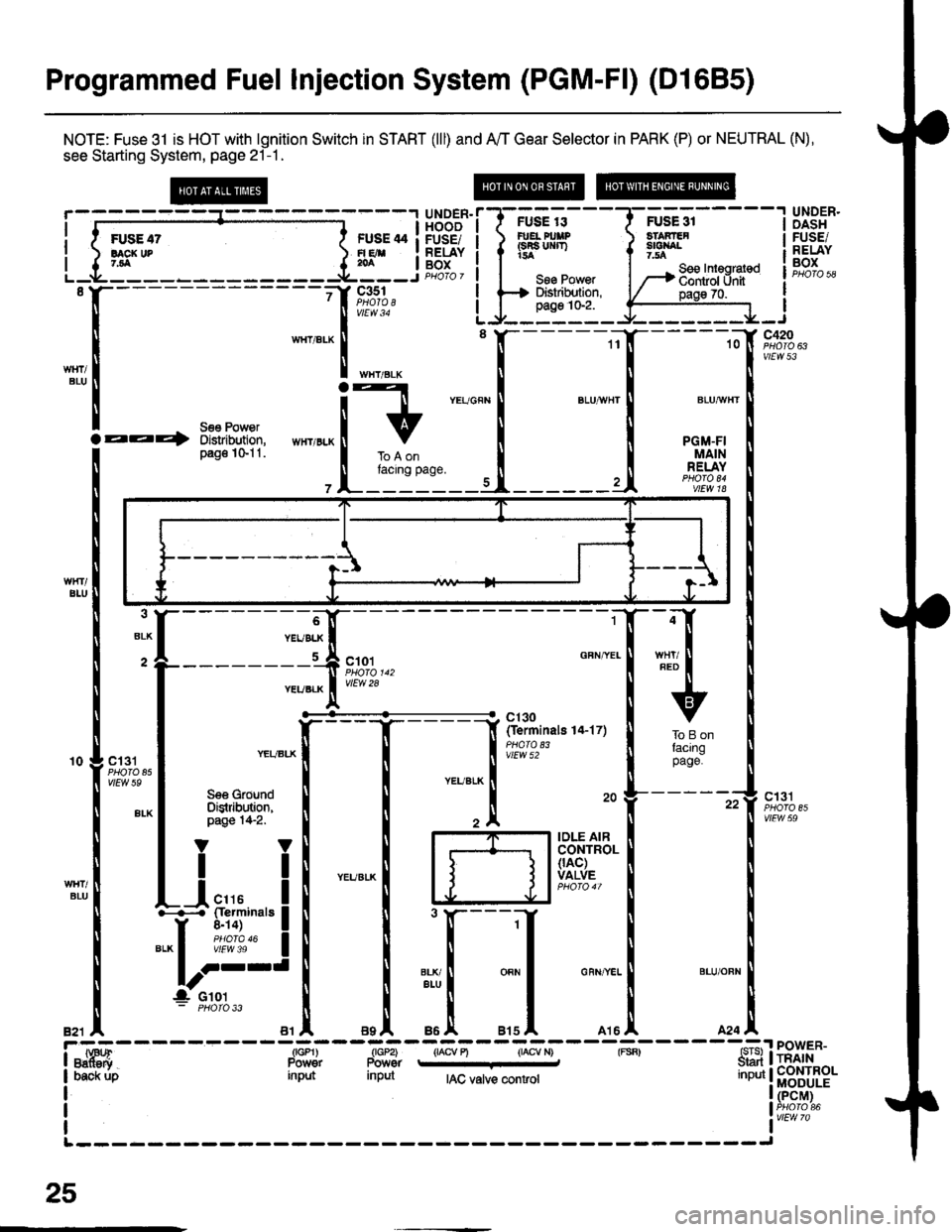

Programmed Fuel Injection System (PGM-F|) (D1685)

NOTE: Fuse 31 is HOT with lgnition Switch in START (lll) and A'/T Gear Selector in PARK (P) or NEUTRAL (N),

see Starting System, page 21-1 .

@

ii6iir-

- -TFU'E;--- - -

I gI3'5"

y#*i[HtF{,iiH.frIHHi Jiffi" !['.iF{,$SNALr5a Y 7.54| - See Inleqrat€dSse Pow€r | --+ ffii;l'i; -- | Phoro 58i ffi ffi:- |EHF? i I

p--',b"

I iffij*,**.,* iFE^l

SACI( UP7,ta

'[-------------'[&T:1,

L.[E"Jj!i_.f;ff:]_j

*L:*

ilTrr,*ii "",""[*=

{ {-

--

;[n*n-

--ftr-'lf

tlGFNYEI

T HI I

rv

J &l?3.,"","'o-,rr ! ,o"on

! #""?,* I

'rT#

*"ll

'fi-----n

h,T5$B.I

J J lvA!::, !

[--iI I

!tl

I onr I can ver- | er-u onn

Itt

A arsl rrsl a24

;t--7;,i----&;-----{IAC valve mnt.ol

;YN

IT/U

ll

v

ToBonlaclngpage

4

FED

I T------i:il;

,oln,.r I """-f-T:

-l-Lri | |d

l

wtl

Iil

i-,"ffifi

- - - - - - -- - -;s,nl - -ffi'J -.'"-

I Oac* rjp input input A

I

I

I|.-------

{F;H:{"

I

I

-"1

,,..!.'-^-*'! PowER-

f,mihHin.

I (PCM)

lif''?;"

25

BIU