valve stem HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 970 of 2189

Start Clutch Control@

T

Start Clutch Calibration Procedure

NOTE: When the following parts are replaced, the TCM

must memorize the feedback signal for the start clutch

control.

. TCM

. Transmissionassembly

. Stan clutch assembly

. Lower valve bodv assembly

. Engine assembly or overhaul

'96 Model Only

CAUTION: Do not uso this procsdure on'97 - (X) mod-

els or you will damage the transmission. On '97 - 00

models, the TCM or PCM memorizes ths loodback sig'

nals when you drive the vehicle.

1. Engage the parking brake, and block the front

wheels securely.

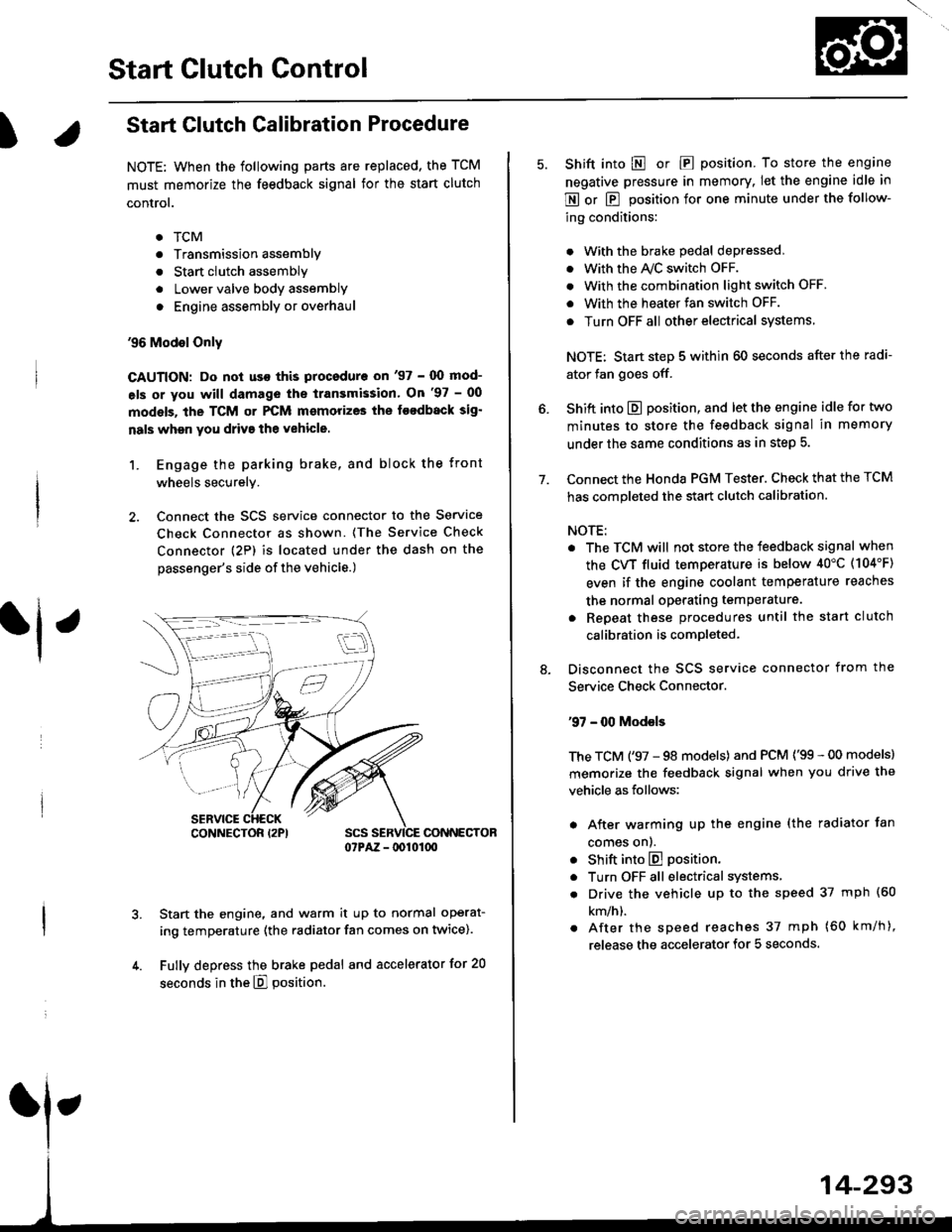

2. Connect the SCS service connector to the Service

Check Connector as shown. (The Service Check

connector (2P) is located under the dash on the

passenger's side of the vehicle.)

CONNECTOR07PAZ - lDl01(xt

Start the engine, and warm it up to normal operat-

ing temperature (the radiator fan comes on twice).

Fully depress the brake pedal and accelerator for 20

seconds in the E] position.

rl ,

CONNECTOR I2PI

14-293

7.

Shift into E o|. E position. To store the engine

negative pressure in memory. Iet the engine idle in

E or E position for one minute under the follow-

ing conditions:

. With the brake pedal depressed,

. with the y'\/c switch oFF.

. With the combination light switch OFF.

. With the heater fan switch OFF.

. Turn OFF all other electrical systems

NOTE: Start step 5 within 60 seconds after the radi-

ator fan goes off.

Shift into E position, and let the engine idle for two

minutes to store the feedback signal in memory

under the same conditions as in step 5.

Connect the Honda PGM Tester. Check that the TCM

has completed the start clutch calibration.

NOTE:

. The TCM will not store the feedback signal when

the CVT fluid temperature is below 40"C (104'F)

even if the engine coolant temperature reaches

the normal operating temperature.

. Repeat these procedures until the start clutch

calibration is completed-

Disconnect the SCS service connector from the

Service Check Connector.

'97 - 00 Models

The TCM ('97 - 98 models) and PCM ('99 - 00 models)

memorize the feedback signal when you drive the

vehicle as follows:

. After warming up the engine (the radiator fan

comes onl.

. Shift into E position.

. Turn OFF all electrical systems,

. Drive the vehicle up to the speed 37 mph (60

km/h).

. After the speed reaches 37 mph (60 km/h),

release the accelerator for 5 seconds.

Page 972 of 2189

t.

rl,

fl,

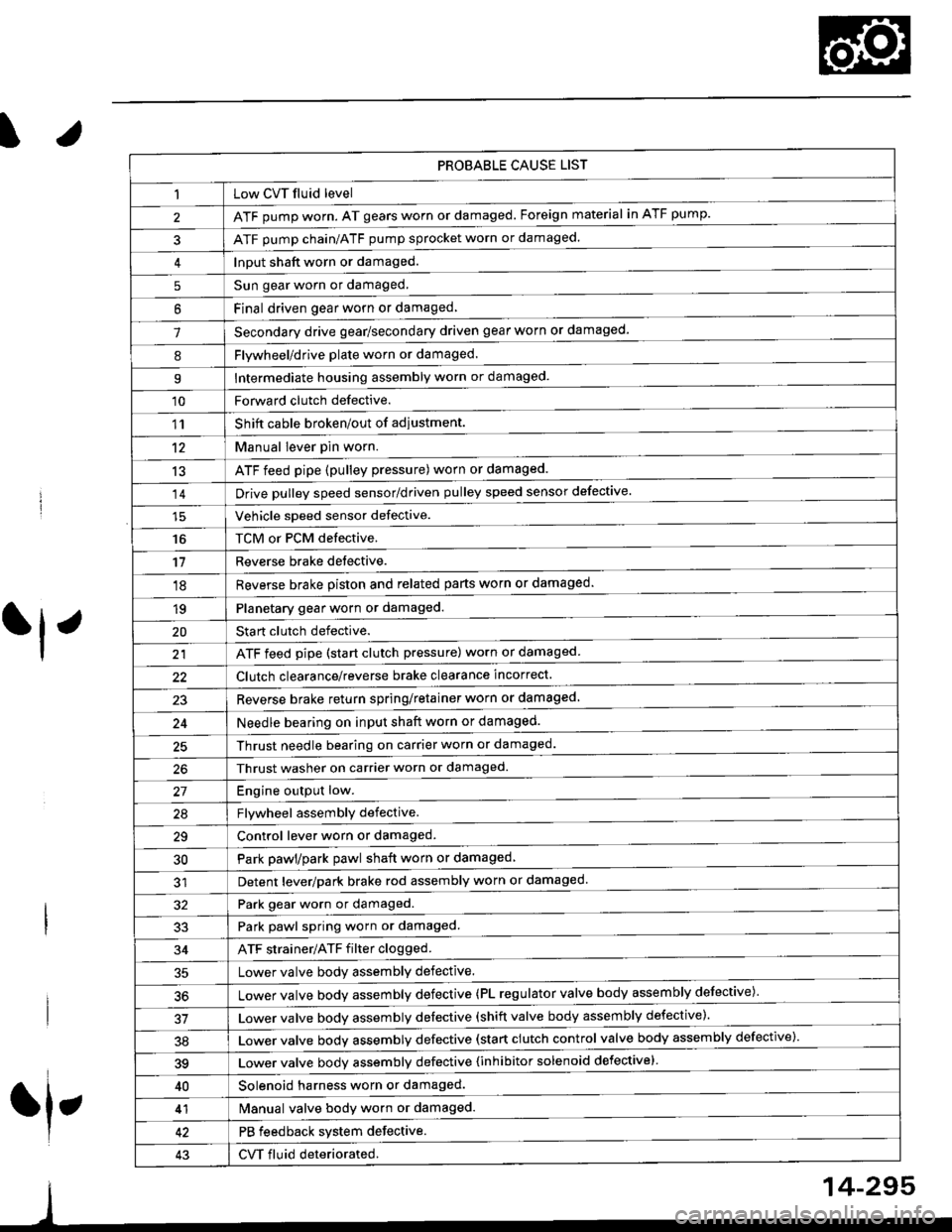

PROBABLE CAUSE LIST

Low CVT fluid level

ATF pump worn. AT gears worn or damaged. Foreign material in ATF pump.

ATF pump chain/ATF pump sprocket worn or damaged.

Input shaft worn or damaged.

Sun gear worn or damaged.

Final driven oear worn or damaqed,

Secondary drive gear/secondary driven gear worn or damaged-

5

6

1

8Flywheel/drive plate worn or damaged.

Intermediate housing assembly worn or damaged.9

'10Forward clutch defective.

Shift cable broken/out of adiustment.

M"nu"t t"uffi

ATF feed pipe (pulley pressure) worn or damaged.

Vchiclc speed sensor defective.

TCM or PCM defective.

Reverse brake detective.

1'�r

't2

13

14

16

'11

'18

1qPlanetary gear worn or damaged.

Sta rt clutch defective.

ATF feed pipe (start clutch pressure) worn or damaged

20

t't

Clutch clearance/reverse brake clearance incorrect.

23Reverse brake return spring/retainer worn or damaged

24Needle bearing on input shaft worn or damaged.

25Thrust needle bearing on carrier worn or damaged.

Thrust washer on carrier worn or damaged.

Enoine outout low.------------------------

Flvwhcel assemblv defective.

Control lever worn or damaged.

Park pawl/park pawl shaft worn or damaged

Detent lever/park brake rod assembly worn or damaged

27

29

30

32Park gear worn or damaged.

Park pawl spring worn or damaged.

ATF strainer/ATF filter clogged.

Lower valve body assembly defective.

Lower valve bodv assemblv defective (PL regulator valve body assembly defective)'

33

34

50

Lower valve bodv assembly defective (shift valve body assembly defective).

Lower valve bodv assemblv defective (start clutch control valve body assembly defective)'

39Lower valve bodv assemblv defective {inhibitor solenoid defective}

40Solenoid harness worn or damaged.

Manual valve body worn or damaged.

PB feedback system defective.

CVT fluid deteriorated.

41

43

14-295

Page 1028 of 2189

Transmission

Gooler Flushing

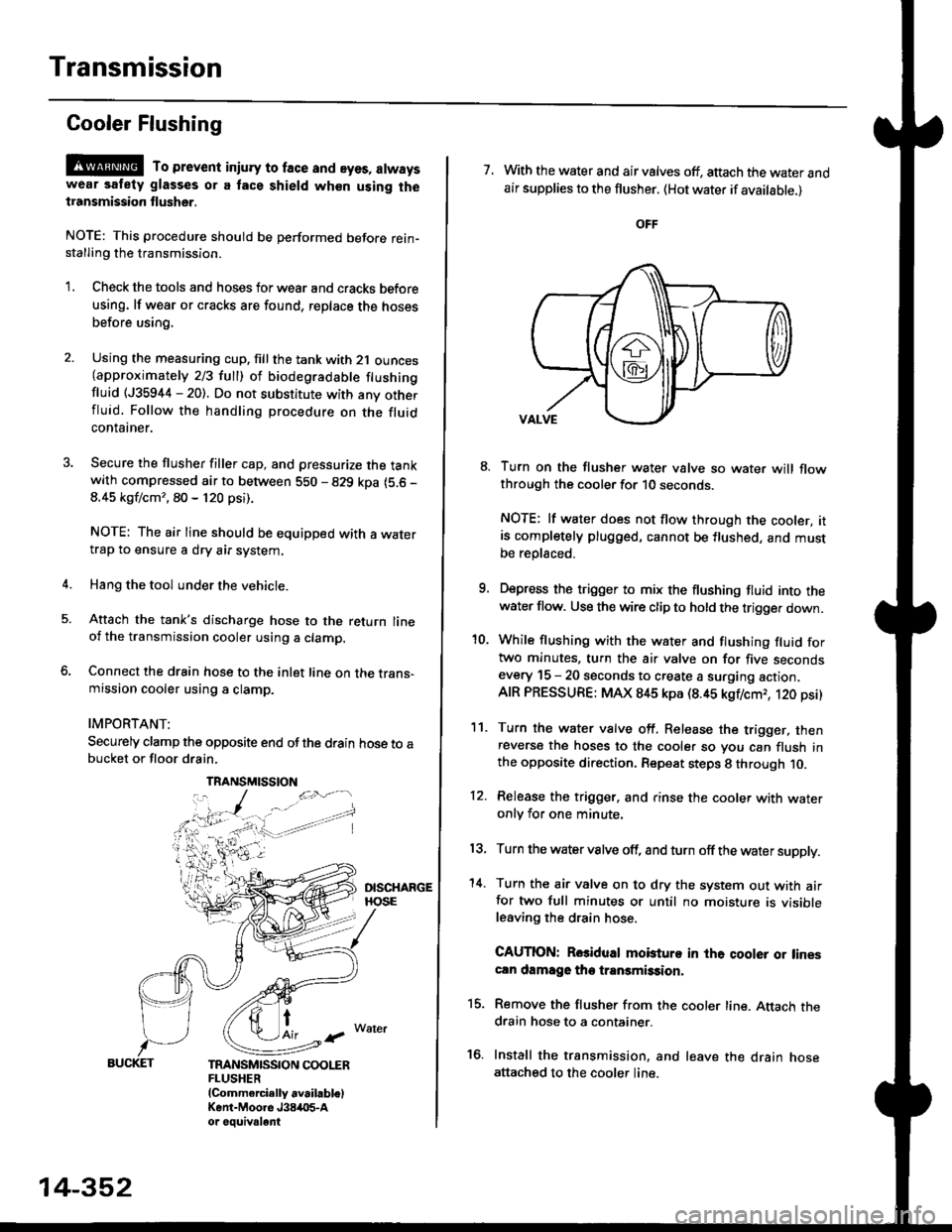

@ To prevent iniury to face and eyes, alwayswear safety glasses or a tace shield when using thetransmission flusher.

NOTE: This procedure should be performed before rein-stalling the transmission.

'1. Check the tools and hoses for wear and cracks before

using. lf wear or cracks are found, reDlace the hoses

before using.

4.

Using the measuring cup. fill the tank with 2,1 ounces(approximately 2/3 full) of biodegradable flushingfluid (J35944 - 20). Do not substitute with any otherfluid. Follow the handling procedure on the fluidcontatner.

Secure the flusher filler cap, and pressurize the tankwith compressed air to between 5S0 - 829 kpa (5.6 -

8.45 kgf/cm'�, 80 - 120 psi).

NOTE: The air line should be equipped with a watertrap to ensure a dry air system,

Hang the tool under the vehicle.

Attach the tank's discharge hose to the return lineoi the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-mission cooler using a clamp.

IMPORTANT:

Securely clamp the opposite end ofthe drain hose to abucket or floor drain,

t

TRANSMISSION COOLERFLUSHER{Commercially available)Kent-Moore J384O5-Aor oouivalent

TRANSMISSION

14-352

7. With the water and air valves off, attach the water andair supplies to the flusher. (Hot water if available.)

8. Turn on the flusher water valve so water will flowthrough the cooler for 10 seconds.

NOTE: lf water does not flow through the cooler, itis completely plugged, cannot be flushed, and mustbe replsced.

9. Depress the trigger to mix the flushing fluid into thewater flow. Use the wire clip to hold the trigger down.

'10. While flushing with the water and flushing fluid fortwo minutes. turn the air valve on for five secondsevery 15 - 20 seconds to create a surging action.AIR PRESSURE: MAX 845 kpa (8.45 kgflcmr, 120 psi)

11. Turn the water valve off. Release the trigger, thenreverse the hoses to the cooler so you can flush inthe opposite direction. Repeat steps 8 through 10.

12. Release the trigger. and rinse the cooler with wateronly for one minute.

13, Turn the water valve off, and turn off the water supply.

'14. Turn the air valve on to dry the system out with airfor two full minutes or until no moisture is visibleleaving the drain hose.

CAUTION: Rosidual mobturo in the qooler or linescln damage the transmission,

15. Remove the flusher from the cooler line. Attach thedrain hose to a container.

16. Install the transmission. and leave the drain hoseattached to the cooler line.

Page 1072 of 2189

System Description

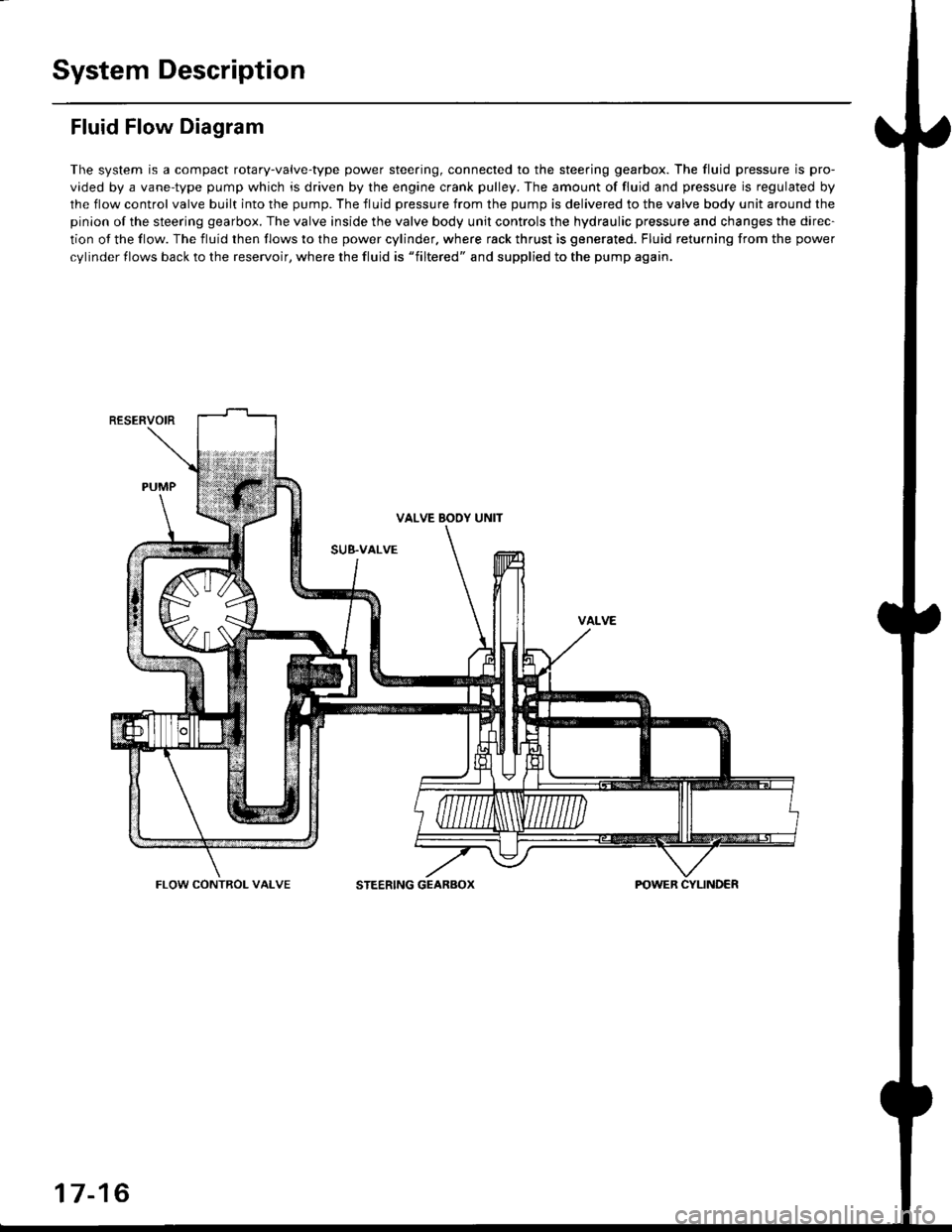

Fluid Flow Diagram

The system is a compact rotary-valve-type power steering, connected to the steering gearbox. The fluid pressure is pro-

vided by a vane-type pump which is driven by the engine crank pulley. The amount of fluid and pressure is regulated by

the flow control valve built into the pump. The fluid pressure from the pump is delivered to the valve body unit around the

pinion of the steering gearbox. The valve inside the valve body unit controls the hydraulic pressure and changes the direc-

tion of the flow. The fluid then flows to the power cylinder. where rack thrust is generated. Fluid returning from the power

cylinder flows back to the reservoir, where the fluid is "filtered" and supplied to the pump again.

RESERVOIR

VALVE BOOY UNIT

SUB.VALVE

FLOW CONTROL VALVESTEERING GEARBOX

17-16

Page 1074 of 2189

System Description

Steering Pump (cont'dl

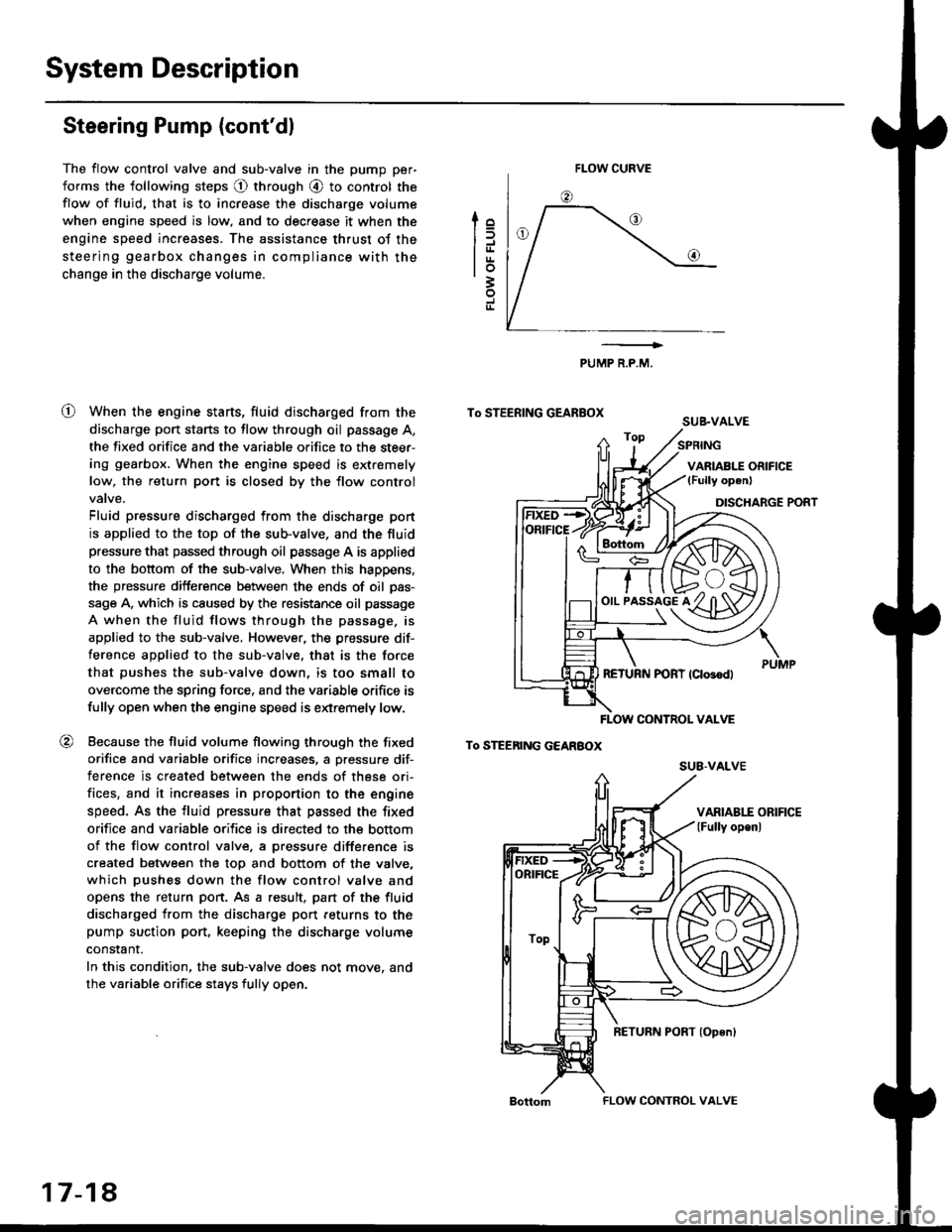

The flow control valve and sub-valve in the pump per-

forms the following steps @ through @ to control the

flow of fluid, that is to increase the discharge volume

when engine speed is low, and to decrease it when the

engine speed increases. The assistance thrust of the

steering gearbox changes in compliance with the

change in the discharge volume.

When the engine starts, fluid discharged from the

discharge port starts to flow through oil passage A,

the fixed orifice and the variable orifice to the steer-

ing gearbox. When the engine speed is extremely

low, the return port is closed by the flow control

Fluid pressure discharged from the discharge port

is applied to the top of the sub-valve, and the fluid

pressure that passed through oil passage A is applied

to the bottom of the sub-valve. When this happens,

the pressure difference between the ends of oil pas-

sage A, which is caused by the resistance oil passage

A when the fluid flows through the passage. is

applied to the sub-valve, However, the pressure dif-

ference applied to the sub-valve. that is the force

that pushes the sub-valve down, is too small to

overcome the spring force, and the variable orifice is

fully open when the engine speed is extremely low.

Because the fluid volume flowing through the fixed

orifice and variable orifice increases, a pressure dif-

terence is created between the ends of these ori-

fices, and it increases in proportion to the engine

speed. As the fluid pressure that passed the fixed

orifice and variable orifice is directed to the bottom

of the flow control valve. a pressure difference is

created between the top and bottom of the valve,

which pushes down the flow control valve and

opens the return port. As a result, pan of the fluid

discharged from the discharge port feturns to the

pump suction port, keeping the discharge volume

constant.

In this condition, the sub-valve does not move. and

the variable orifice stays fully open.

lo

trrtrrlo3

J

o

PUMP R.P.M.

To STEERING GEARBOXSUB.VALVE

To STEEnING GEARBOX

FLOW CURVE

!rs+/f/ffih\

o,,-i^"l^tKzYt)91y ul3Yl

FLOW CONTNOL VALVE

su8-vALvE

ORIFICE

ToP

17-18

FLOW CONTROL VALVE

Page 1075 of 2189

t

To STEERING GEARBOX

To STEERING GEAREOx

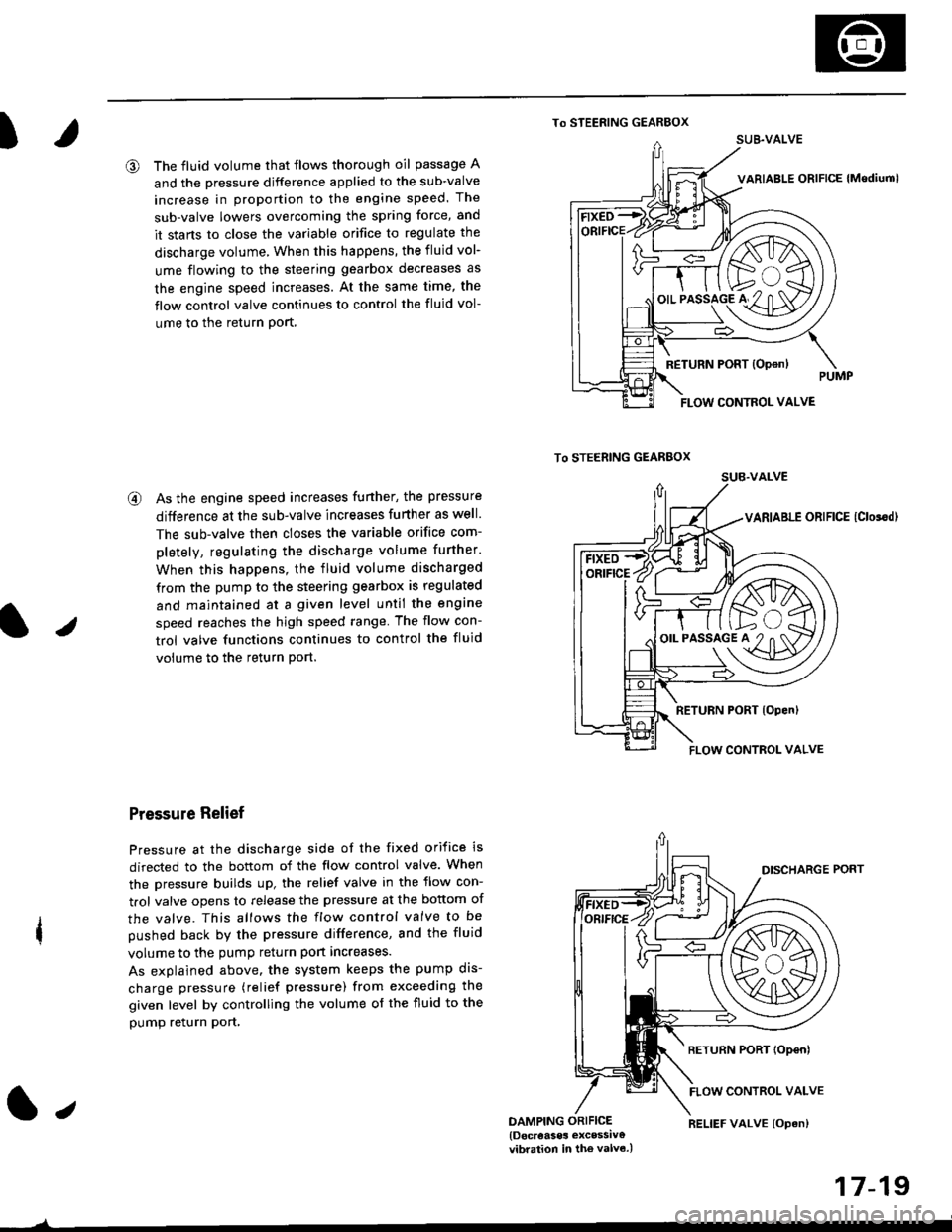

@ The fluid volume that flows thorough oil passage A

and the pressure djfference applied to the sub-valve

increase in proportion to the engine speed. The

sub-valve lowers overcoming the spring force, and

it stans to close the variable orifice to regulate the

discharge volume, When this happens, the fluid vol-

ume flowing to the steering gearbox decreases as

the engine speed increases. At the same time, the

flow control valve continues to control the fluid vol-

ume to the return Port,

@ As the engine speed increases funher, the pressure

difference at the sub-valve increases further as well.

The sub-valve then closes the variable orifice com-

pletely, regulating the discharge volume further.

When this happens, the fluid volume discharged

from the pump to the steering gearbox is regulated

and maintained at a given level until the engine

speed reaches the high speed range The flow con-

trol valve functions continues to control the fluid

volume to the return Port.

Pressure Relief

Pressure at the discharge side of the fixed orifice is

directed to the bottom of the flow control valve. When

the pressure builds up, the relief valve in the flow con-

trol valve opens to release the pressure at the bottom of

the valve. This allows the flow control valve to be

pushed back by the pressure difference, and the fluid

volume to the pump return port increases.

As explained above. the system keeps the pump dis-

charge pressure (relief pressure) from exceeding the

given level by controlling the volume of the fluid to the

pump relurn pon,

1.,DAMPING ORIFICE{Docreases excessiv€vibration in the valv6.)

17-19

)

RELIEF VALVE {Opan)

SUB.VALVE

FLOW CONTROL VALVE

/F ft>..\

'-€/K\A/A

o'.'to"5lo'#2"n af11\D7

FLOW CONTROL VALVE

Page 1076 of 2189

System Description

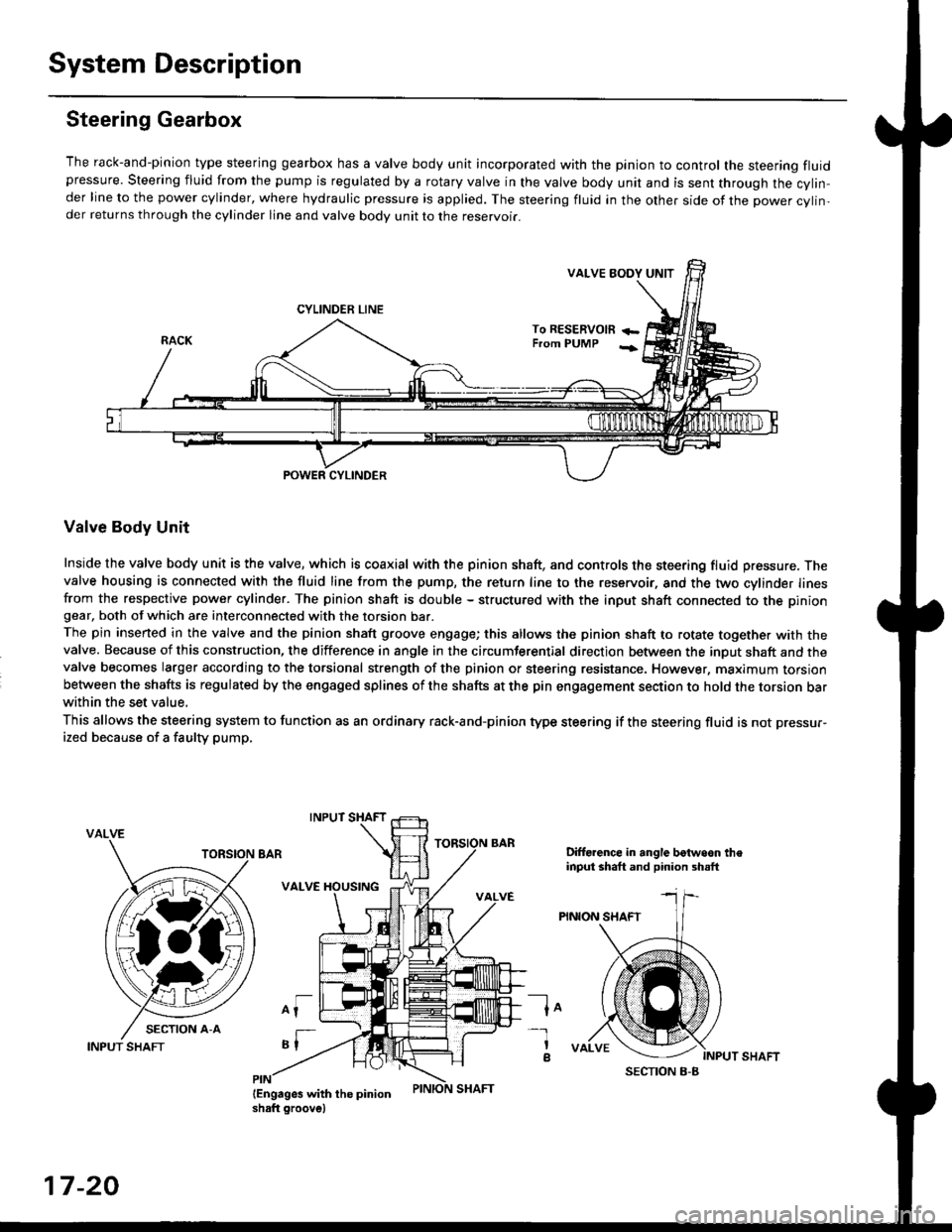

Steering Gearbox

The rack-and-pinion type steering gearbox has a valve body unit incorporated with the pinion to control the steering fluidpressure. Steering fluid from the pump is regulated by a rotary valve in the valve body unit and is sent through the cylin,der line to the power cylinder, where hydraulic pressure is applied. The steering fluid in the other side of the power cylin,der returns through the cylinder line and valve body unit to the reservoii.

VALVE EODY UNIT

CYLINDER LINE

To RESERVOm +-From PUMP -;

POWER CYLINDER

Valve Body Unit

Inside the valve body unit is the valve, which is coaxial with the pinion shaft, and controls the steering fluid pressure. Thevalve housing is connected with the fluid line from the pump, the return line to the reservoir, and the two cylinder linesfrom the respective power cylinder. The pinion shaft is double - structured with the input shaft connected to the piniongear, both of which are interconnected with the torsion bar.

The pin inserted in the valve and the pinion shaft groove engage; this allows the pinion shaft to rotate together with thevalve. Because of this construction, the difference in angle in the circumferential direction between the input shaft and thevalve becomes larger according to the torsional strength of the pinion or steering resistance. However, maximum torsionbetween the shafts is regulated by the engaged splines of the shafts at the pin engagement section to hold the torsion barwithin the set value,

This allows the steering system to function as an ordinary rack-and-pinion type steering if the steering fluid is not pressur-

ized because of a faulty pump,

VALVE

Difforence in angle botwoon theinput shaft and pinion shsft

PINION SHAFT

lo

INPUT SHAFT

-l

a

17-20

INPUT SHAFT

Page 1081 of 2189

/

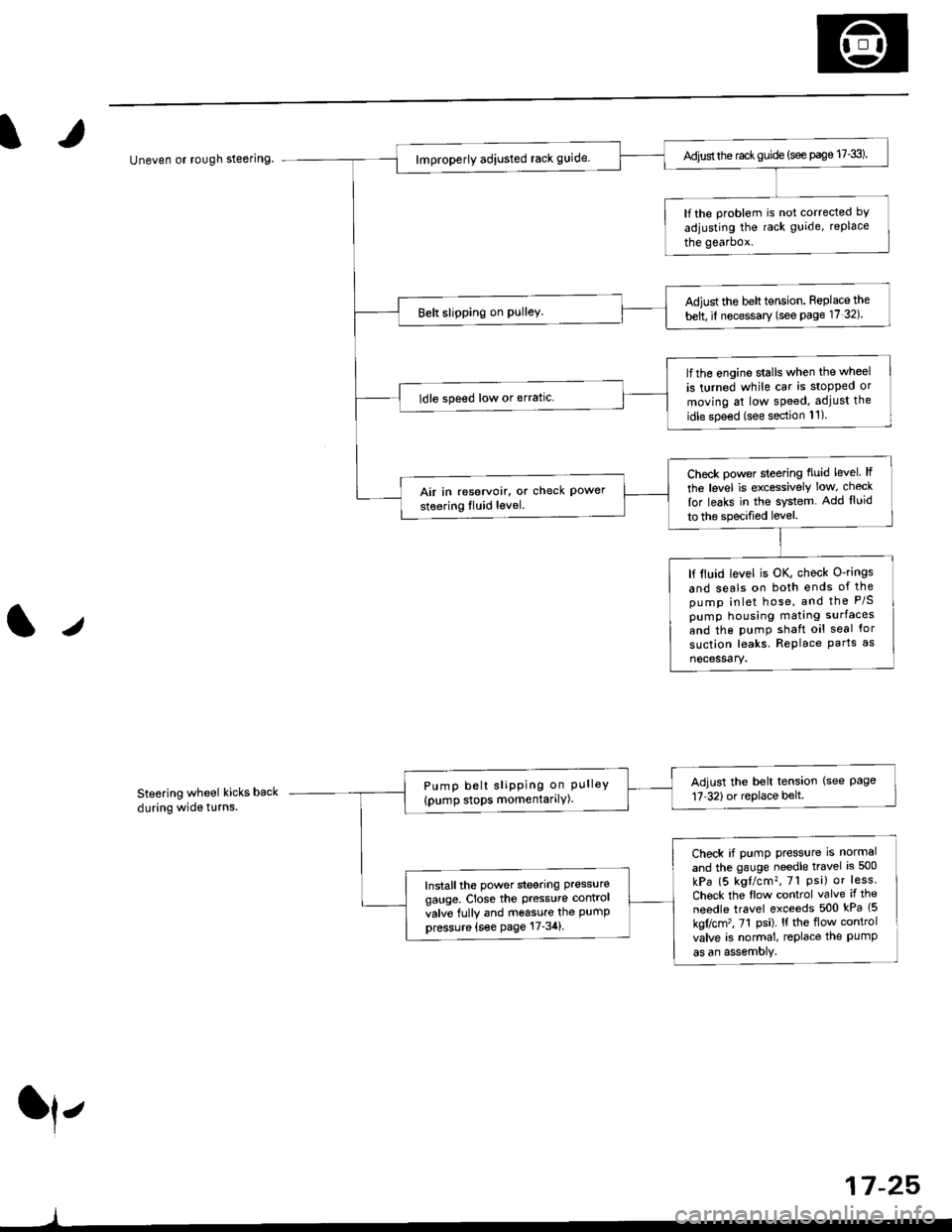

Uneven or rough steering

Steering wheel kicks back

during wide t!rns.

ll,

)

Adjust the rac* guide (see page 17-3).

lf the problem is not corrected bY

adjusting the rack guide, replace

the gearbox.

Adiust the belt tension. Feplace the

belt, il necessary (see Page 17 32).

lfthe engine stalls when the wheel

is turned while car is stopped or

moving at low speed, adjust the

idle spe€d (see section 11)

ldle speed low or erratic.

Check power sleering fluid level lf

the level is excessively low, check

lor leaks in the system. Add lluid

to the specified level.

Air in reservoir, or check Powersteering Iluid level.

lf ltuid level is OK, check O-rings

and seals on both ends of thepump inlet hose, and the P/Spump housing mating surfaces

and the pumP shaft oil seal for

suction leaks. RePlace Parts as

nocessary.

Adjust the belt tension (see Page17 32)or replace belt.Pump belt sliPPing on PLrlleY(pump stops momentarilY)

Check if pump press{rre is normal

and the gauge needle travel is 500

kPa (5 kgl/cm?, 7l Psi) or less.

Chock the flow control valve if the

needle travel exceeds 500 kPa (5

kgflcm'�, 71 Psi). l{ the flow control

valve is normal, replace the PumPas an assemoly.

Install the power steering pressure

gauge, Close the Pressure contrcl

valve fully and m6ssure the PumPpressure {s€e page 17-34}.

17 -25,

Page 1097 of 2189

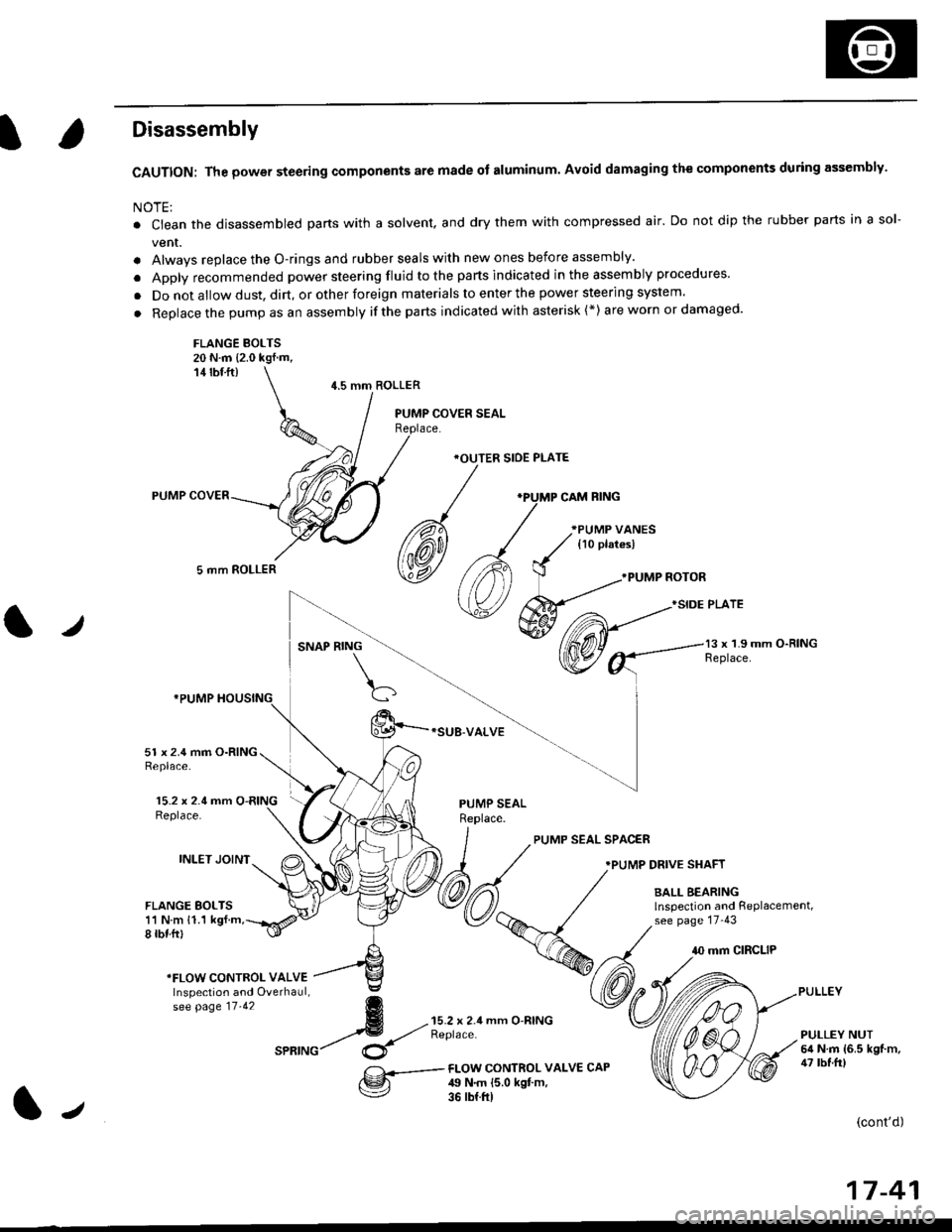

Disassembly

CAUTION: The power steering components are made of aluminum. Avoid damaging the components during assembly.

NOTE:

. Ctean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Alwavs replace the O-rings and rubber seals with new ones before assembly.

. Apply recommended power steering fluid to the parts indicated in the assembly procedures'

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.

. Replace the pump as an assembly ifthe parts indicated with asterisk (*) are worn or damaged'

FLANGE BOLTS20 N.m {2.0 kgf.m,14 rbf ft)

5 mm ROLLER

4.5 mm ROLLER

*OUTER SIOE PLATE

*SUB-VALVE

.PUMP NOTOR

}SIDE PLATE

l,/SNAP RING13 x 1.9 mm O-RINGReplace.

15.2 x 2.4 mm O-RINGReplace.

INLET JOINT

51 x 2.4 mm O-RINGReplace.

FLANGE BOLTS11 N m 11.1 kgf.m,8 rbf.ftl

PUMP SEALReplace.

PUMP SEAL SPAC€R

.PUMP DRIVE SHAFT

BALL BEARINGlnspection and RePlacement,see page 17-43

10 mm CIRCLIP

*FLOW CONTROI- VALVEInspection and Overhaul,se[ pase tt.tz g

4 --{;'rX!;'seatuc/ $

mm O-RINGPULLEY NUT6il N.m {6.5 kgf.m,47 tbf.frlFI-OW CONTROL VALV€ CAP49 N.m {5.0 kgt m,36 rb{.ft)

(cont'd)

17-41

J

Page 1111 of 2189

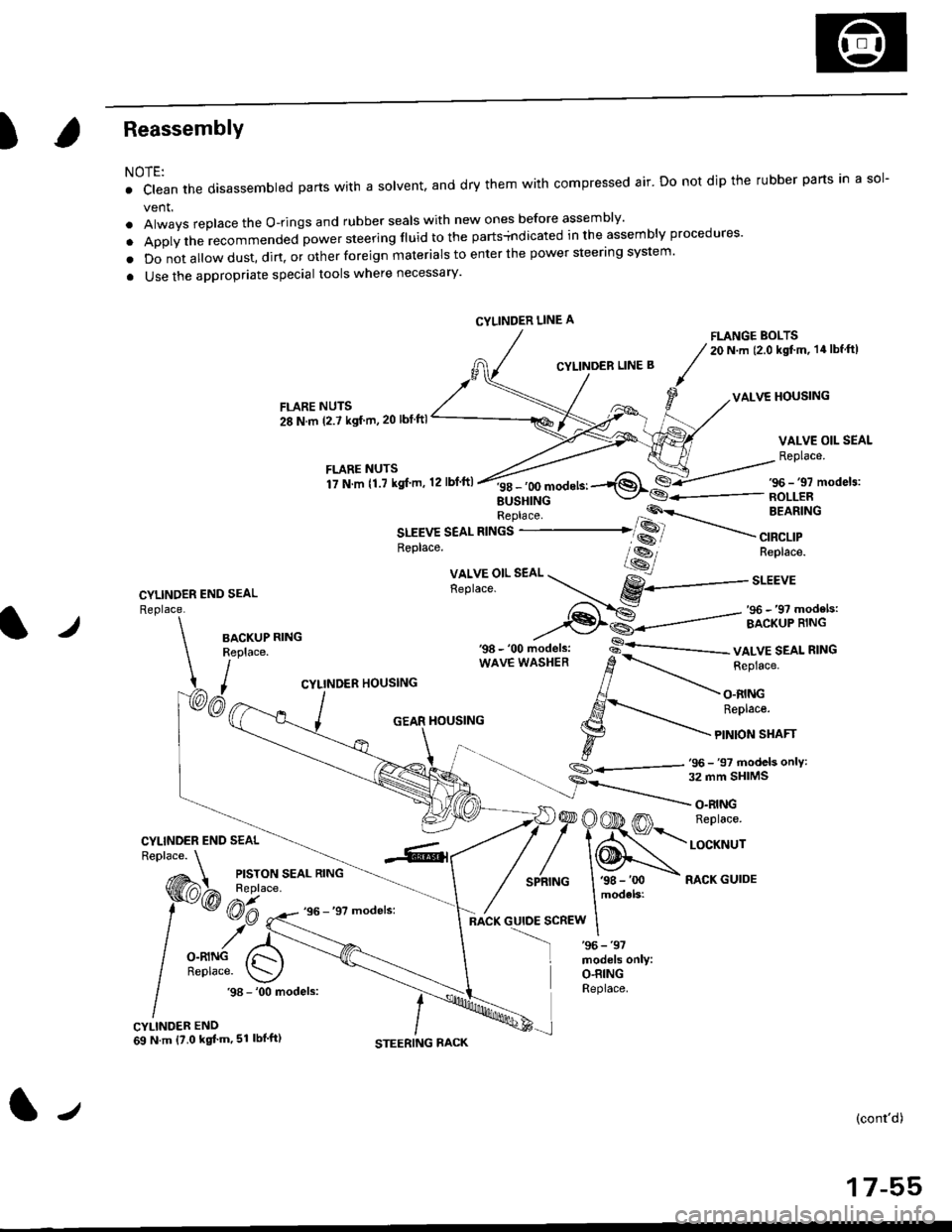

)Reassembly

NOTE:

. clean the disassembled parts wrth a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly'

. Apply the recommended power steering fluid to the parts+ndicated in the assembly procedures'

o Do not a||ow dust, dirt, or other foreign materials to enter the power steering system.

a Use the appropriate special tools where necessary'

FLANGE BOLTS20 N.m (2.0 kgt'm, 14lbf ftl

CYLINDER LINE B

VALVE HOUSINGFLARE NUTS

28 N.m (2.7 ksf m,20 lbf ftl

VALVE OIL SEAL

Replace.

CYLINDER END SEAL

Replace.

f itllTllli".",'r'o,.n,ft

''*^'*-1$*€-/s6-,,mode,3:

EUSHINGReplace 'P'\-- BEARING

SLEEVE SEAL RINGS ..-------......�� SS

.----

",a"a,,

*---

--,

Replace. lss-, Replace.

Xll,Y5"l'.

"o. --r...- gY------..r.u,

,-f-..-S: _ ,96 _,9? models:

--€l€--------=- ircriip'ii.rt'-l./BACKUPReplace.

I,

wAvE wAsHER d

-.-.-r_ i"pru"".

CYLINDER HOUSING // -\-

, AJ - O.RING

/ ,S-'..- ReDtace.

_ j GEAR HouslNG l.g --'\-

\- t F

tonsrnrr

.,_- s

- 'oo ,,iod"t., -s-'--------- vALvE SEAL R'NG

S_.<---,tj- 97 models onlY:

CYLINDER END SEAL

)@OOD m n"prac".

/'\N,."._nrNG I '98 - 'oo - RACK GUIDE

models:

:scREw I

O.RINGReplace..98 - '00 models:

CYLINDER END69 N.m {?.0 kgt'm,51 lbl'ft)

(cont'd)

17-55

CYLINDER LINE A

tJ