shift link HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 762 of 2189

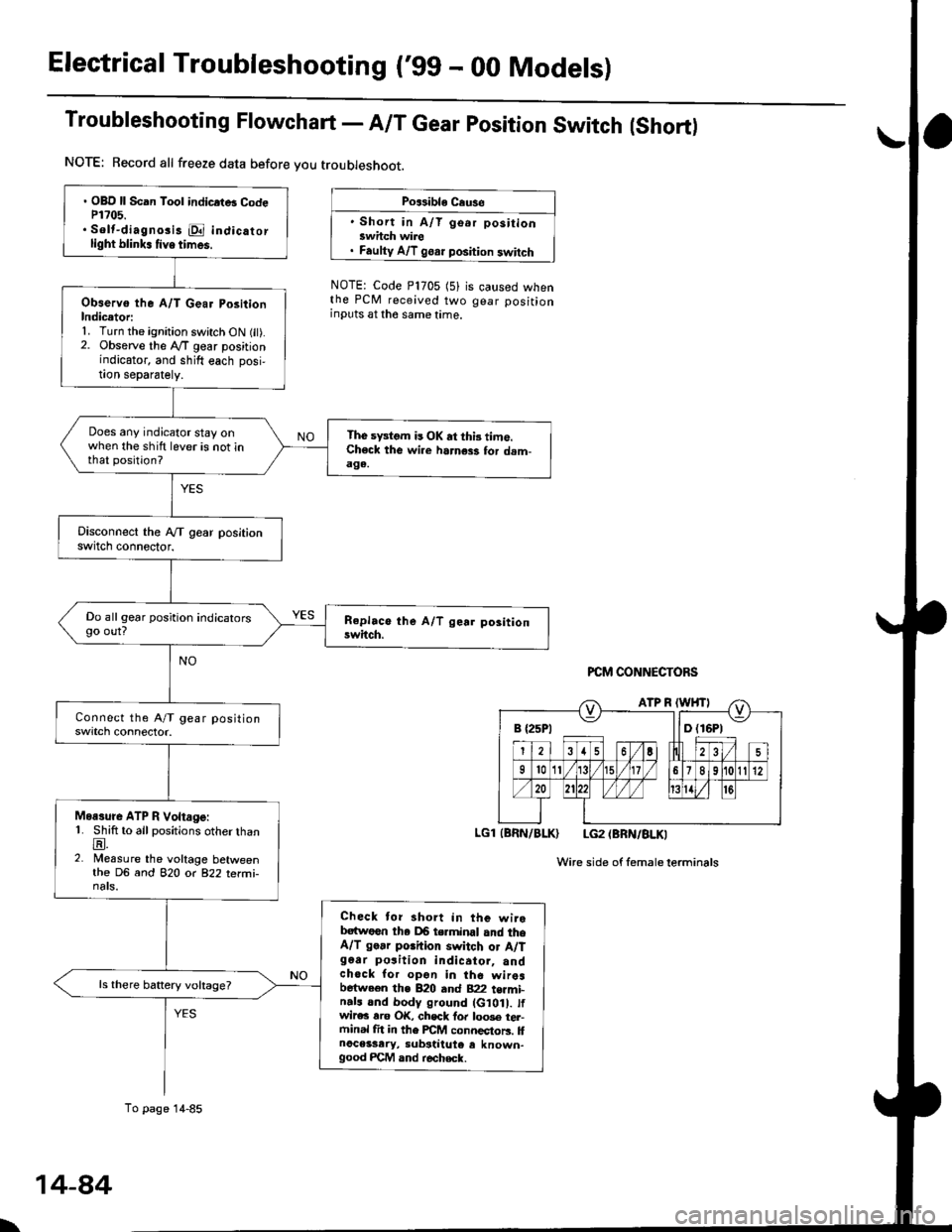

Electrical Troubleshooting ('gg - 00 Models)

Troubleshooting Flowchart - A/T Gear position Switch (Short)

NOTE: Record all freeze data before you troubleshoot.

Po$ible Cause

' Short in A/T go.r positionswhch wire. Faulty A/T goar position switch

NOTE: Code P1705 (5)the PCM received twoinputs at the same time.

is caused whengear position

PCM CONNECTORS

LGl (BRN/BLK) LG2 (BRN/BLKI

Wire side of femaleterminals

B {25P1 llD (16P1

. OBD ll Scan Tool indicrtB CodeP1?05.. Solt-diagno3i3 E indicatorlight blink. tive times.

Observo the A/T Gear PositionIndicetori1. Turn the ignition switch ON fit).2. Observe the lVT gear positionindicator, and shift each posi,!on separately.

Does any indicator stay onwhen the shift lever is not inthat position?

The sFtom is OK at thi3 time.Check the wi.e harness for dam-aga.

Do all gear position indicatorsgo out?

Moasure ATP R Voltage:1. Shift to all positions otherthanE.2. Measure the voltage betweenthe DG and 82O o( 822 terfii-nats.

Check tor short in the wirebatwoen tha DB terminal and theA/T go.r porhion switch or A/Tg6ar po3ition indicator, andchock for opon in the wiresbetween the B20 and B22 t€rmi-n.ls and body ground (G10 . tfwir€c rro OK, chsck fo. loo3e tel-ftinal fit in the FCM connectors. llnoceisary, substiiute e known-good FCM and r€check.

ls there battery voltage?

To page 14-85

\

14-84

Page 765 of 2189

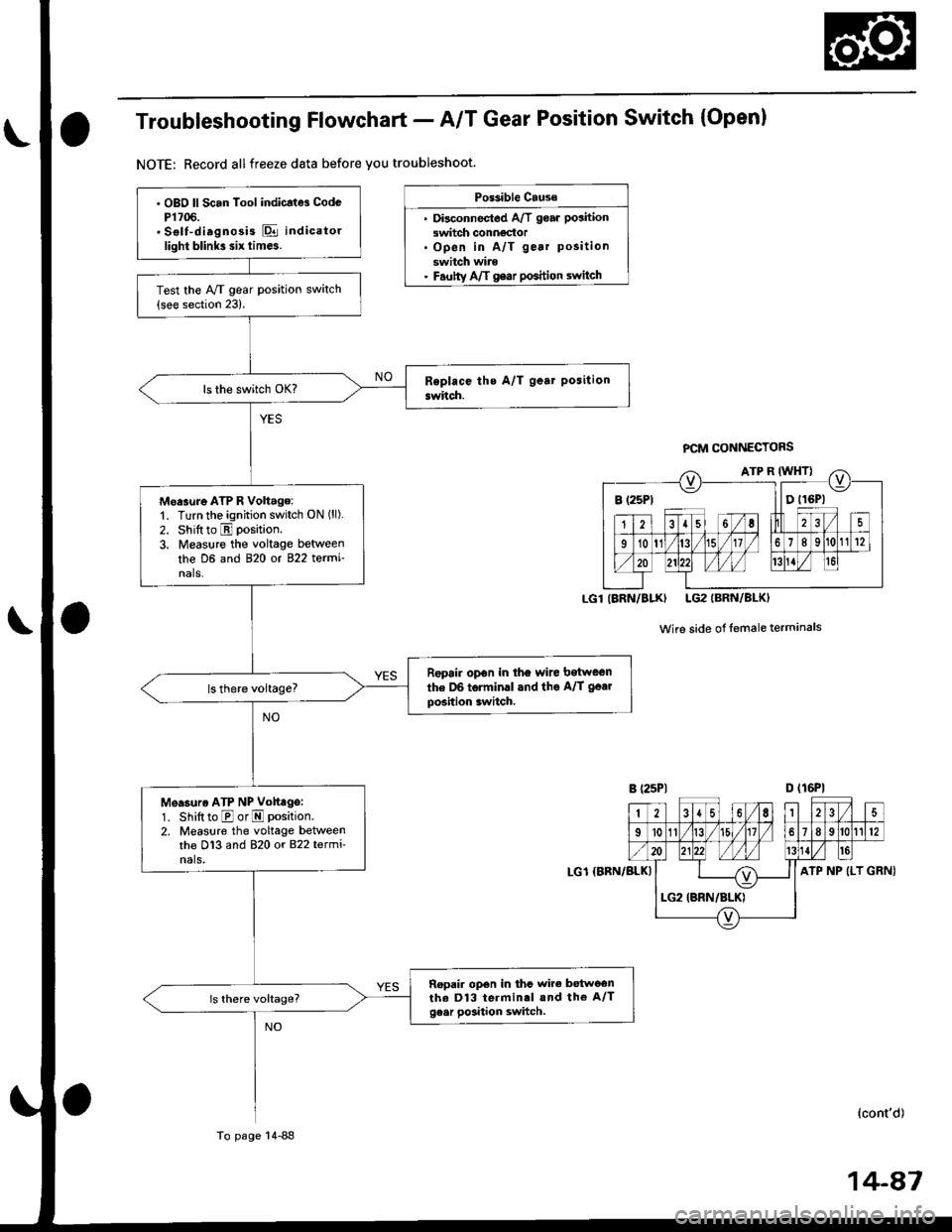

Troubleshooting Flowchart - A/T Gear Position Switch (Open)

NOTE: Record allfreeze data before you troubleshoot.

Po$ible Cause

. Disconnectod A/T goar position

switch conngdor. Open in A/T gear position

switch wire. Fautty Aft gear poshion switch

PCM CONNECTORS

Wire side of lemaleterminals

D (16P1

GRNI

B (25Pt llDtl6Pl

IARN/BLK) LG2IBRN/BLKI

2{6,|235

I't011/t5l/18912

ATP NP (LT

. OBO ll Scan Tool indicatd CodcP1706.' Sslf-diagnosis E indicatorlight blink3 six tim6.

Test the Ay'T gear position switch(see section 23).

Moasure ATP R Volt.ge:'1. Turn the ignition switch ON ('l).

2. Shift to E position.

3. Measure the voltage between

the D6 and 820 ot 822 termi'nals.

Repoir opon in the wire bitween

the D6 torminll and the A/T go.r

position switch.

Measuro ATP NP Volt ge:

1. Shift to E or E position.

2. Measlre the voltage betweenthe D13 and 820 or 822 termi-nals,

Ropair op€n in thc wire betwoonthe D13 terminrl and the A/Tge.r position switch.

LG1 {BBN/BLKI

Io page 14-88

(cont'd)

Page 767 of 2189

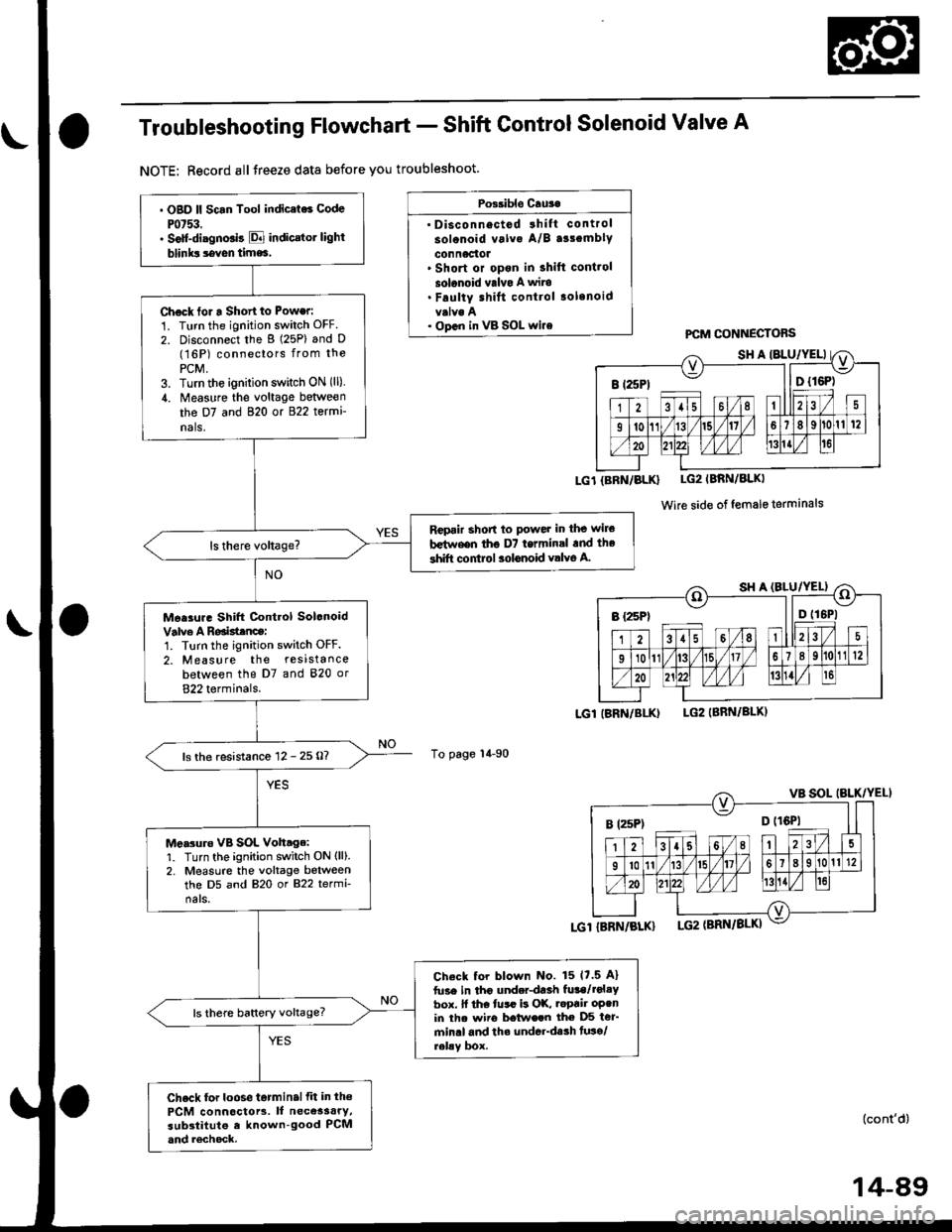

Troubleshooting Flowchart - Shift Control Solenoid Valve A

NOTE: Record allJreeze data before you troubleshoot.

Possible Cru3.

' Disconnectod 3hift control

solonoid valva A/B a33emblY

connactot. Short or opon in shift cont.ol

solonoid valvo A wits. Faulty shift control .olenoid

. op.n in vB SOL wi.e

To page 14-90

PCM CONNECTOBS

LG1{BRN/BLK} LG2IBRN/BLKI

Wire side of female terminals

LGl IBRN/BI-K)LG2IBBN/BLK)

. OBD ll Scan Tool indic.ts6 Code

Pot53.. Solt-diagno.is E indicrtot light

blinks seven time6.

Chock tor a Short to Power:

1. Turn the ignition switch OFF.

2. Disconnect the g (25P) and D(16P) conneclors from the

PCM,3. Turn the ignirion switch ON (ll)

,1. Measure the voltage between

the D7 and 820 or 822 termi

nals,

Rcpair short to powet in the wile

b€t^reen tho D7 termin.l .nd the

shift control aolonoid valve A.

Mee3ur. Shift Control Solonoid

Valve A Roaisttnce:1. Turn the ignition switch OFF.

2. Measure the resistance

between the D7 and 820 or

822 terminals.

ls the resistance 12 - 25 O?

Me.3uro vB SOL Voh.ge:1. Turn the ignition switch ON (ll).

2. Measure the voltage betweenthe D5 and 820 or 822 termi-

nals.

Check tor blown No. 15 17.5 A)

fuse in tho underdaah fula/rol.Ybox. ll the tusr is OK, .epair oPenin th. wiio betwe.n the D5 ter'min.l and th. underdssh tuso/relav box.

ls there baftery voltage?

Check for loose t6tminalfit in th€

PCM connoctors. It necessary,substitute e known-good PCMand rechock.

I t25Pt ll D {16P)

B rzsPt o trQil

(cont'd)

14-89

Page 769 of 2189

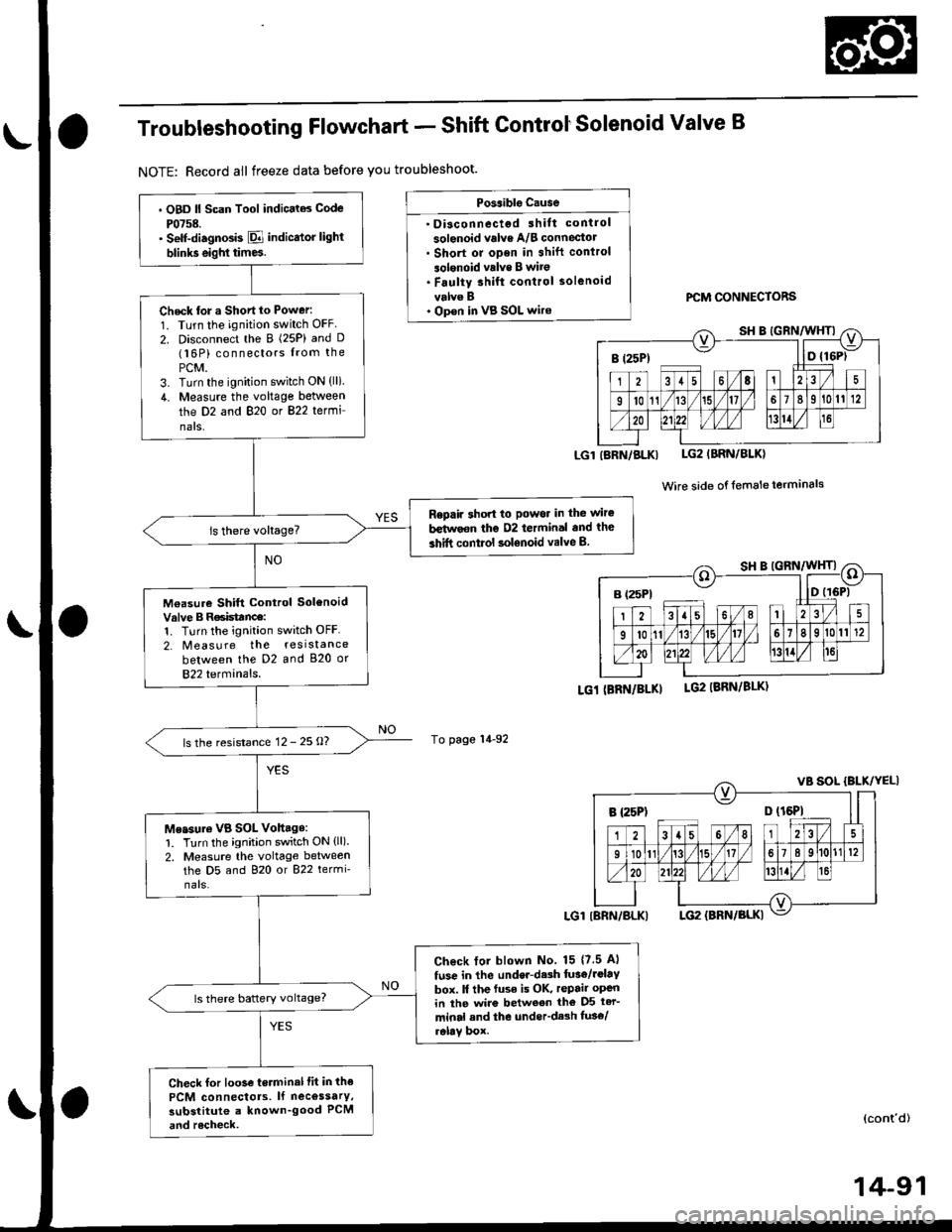

Troubleshooting Flowchart - Shift ControtSolenoid Valve B

NOTE: Record all freeze data before you troubleshoot.

Possiblg Cause

. Disconnectgd ihilt control

solenoid valve A/B conneciotr Short or oDen in shift conlrol

3olgnoid vrlve B wito. Faulty 3hift control solenoid

velve B. Op€n in VB SOL wirercM CONNECTORS

LGlIBRN/BLKI LG2IBRN/BLK)

Wire side of {emale terminals

LGi (BRi|/BLKILG2 IBRN/8LK)

To page 14-92

(cont'd)

14-91

. OBD ll Scan Tool indic.l6 Code

P0758.' Self-diagnosb El indicator light

blinks eighl tim6.

Check tor a Shortto Power:

1. Turn the ignition switch OFF

2. Disconnect the B (25P) and D(16P) connectors from the

PCM.3. Turn the ignition switch ON (lli.

4. Measure the voltage between

the D2 and 820 or 822 termi

nals,

Repaft 3hon to Powor in the wir€

b€tirvoon the D2 termin.l and the

3hift control solenoid valve B.

M€asure Shift Control SolenoidValve B R6isttnce:1. Turn the ignition switch OFF

2. Measure the resistance

between the D2 and 820 or

822 terminals.

ls the resistance 12 - 25 O?

Me.sure VB SOL Vohage:1. Turn the ignition switch ON (ll).

2. Measure the voltage betweenthe D5 and 820 or 822 termi'

nars.

Check lol blown No 15 {7.5 Al

fuse in the under-d.sh luae/rolav

box. ll the fuse is OK, repair open

in ihe wire between tho D5 ter-

minal and the under'dash fus€/relav box.

ls there battery voltage?

Check for loo3e terminal fit in the

PCM connectols. lf necossarY,

substitute a known_good PCM

and rocheck,

B (25Pt - I lD {16P)

B {25P1 D (t6Pl

Page 873 of 2189

Description

The Continuously Variable Transmission (CVT) is an electronically controlled automatic transmission with drive and driv

en Oullevs, and a steel belt. The CVT provides non stage speeds forward and one reverse. The entire unit is positioned in

line with the engine.

Transmission

Around the outside of the flywheel is a ring gear which meshes with the starter pinion when the engine is being staned.

The transmission has four parallel shafts: the input shaft, the drive pulley shaft. the driven pulley shaft, and the secondary

gear shaft. The input shaft is in line with the engine crankshaft. The drive pulley shaft and the driven pulley shaft consist of

movable and fixed face pulleys. Both pulleys are linked by the steel belt.

The input shaft includes the sun gear. The drive pulley shaft includes the forward clutch which mounts the carrier assem-

bly on the forward clutch drum. The carrier assembly includes the pinion gears which mesh with the sun gear and the ring

gear. The ring gear has a hub-mounted reverse brake disc.

The driven pulley shaft includes the start clutch and the secondary drive gear which is integral with the park gear' The sec-

ondary gear shaft is positioned between the secondary drive gear and the final driven gear. The secondary gear shaft

includes the secondary driven gear which serves to change the rotation direction. because the drive pulley shaft and the

driven oullev shaft rotate the same direction. When certain combinations of planetary gears in the transmission are

engaged by the clutches and the reverse brake, power is transmitted from the drive pulley shaft to the driven pulley shaft

to provide E, E, E, and El.

Electronic Control'96 - 98 Models:

The electronic control system consists of the Transmission Control Module (TCM), sensors, three linear solenoids, and a

inhibitor solenoid. Shifting is electronically controlled under all conditions'

The TCM is located below the dashboard, behind the kick panel on the driver's side.'99 - 00 Models:

The electronic control svstem consists of a Powertrain Control Module (PCM), sensors, three linear solenoids and an

inhibitor solenoid. Shifting is electronically controlled under all conditions. A Grade Logic Control System to control shift-

ing in E position while the vehicle is ascending or descending a slope.

The PCM is located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the Pressure Low (PL) reguiator valve body, the shift valve

body, the start clutch control valve body, and the secondary valve body. They are positioned on the lower part of the

transmission housing.

The main valve body contains the Pressure High (PH) control valve, the lubrication valve, and the pitot regulator valve.

The secondary valve body contains the PH regulator valve, the clutch reducing valve, the start clutch valve accumulator,

and the shift inhibitor valve. The PL regulator valve body contains the PL regulator valve and the PH-PL control valve

which is ioined to the PH,PL control linear solenoid. The inhibitor solenoid valve is bolted on the PL regulator valve body.

The shift valve body contains the shift valve and the shift control valve. which is joined to the shift control linear solenoid.

The start clutch control valve body contains the start clutch control valve, which is joined to the start clutch control linear

solenoid. The linear solenoids and the inhibitor solenoid are controlled by the TCM or PCM. The manual valve body which

contains the manual valve and the reverse inhibitor valve, is bolted on the intermediate housing.

The ATF pump assembly is located on the transmission housing, and is linked with the input shaft by the sprockets and

the sprocket chain. The pulleys and the clutch receive fluid from their respective feed pipes, and the reverse brake receives

fluid from internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which linear solenoid the TCM or PCM will activate.

Activating the shift control linear solenoid changes the shift control valve pressure, causing the shift valve to move. This

pressurizes the drive pulley pressure to the drive pulley and the driven pulley pressure to the driven pulley and changes

their effective pulley ratio. Activating the start clutch control linear solenoid moves the start clutch control valve. The start

clutch control valve uncovers the port, providing pressure to the start clutch to engage it(cont'd)

14-195

,!

Page 886 of 2189

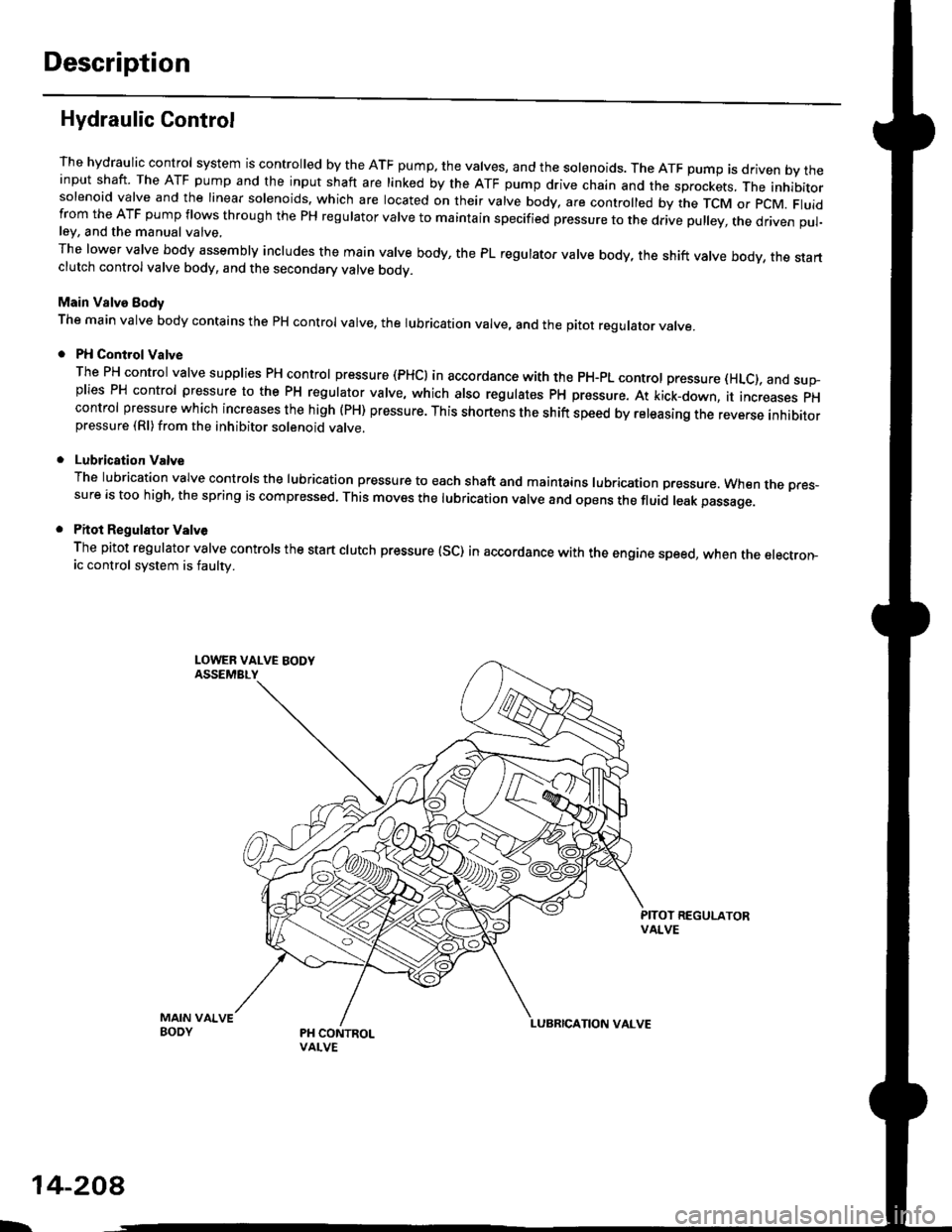

Description

Hydraulic Control

The hydraulic control system is controlled by the ATF pump. the valves, and the solenoids. The ATF pump is driven by theinput shaft. The ATF pump and the input shaft are linked by the ATF pump drive chain and the sprockets, The inhibitorsolenoid valve and the linear solenoids. which are located on their valve body, are controlled by the TCM or pcM. Fluidfrom the ATF pump flows through the PH regulator valve to maintain specified pressure to the drive pulley, the driven pul-ley, and the manual valve,

The lower valve body assembly includes the main valve body, the PL regulator valve body, the shift valve body, the startclutch control valve body, and the secondary valve bodv.

Main Valve Eody

The main valve body contains the pH control valve, the rubrication valve, and the pitot regulator valve.

PH Control Valve

The PH control valve supplies PH control pressure (PHCI in accordance with the pH-pL control pressure (HLc), and sup-plies PH control pressure to the PH regulator valve, which also regulatss PH pressure. At kick-down, it increases pHcontrol pressure which increases the high (PH) pressure. This shortens the shift speed by releasing the reverse inhibitorpressure (Rl)from the inhibitor solenoid valve.

Lubrication Valve

The lubrication valve controls the lubrication pressure to each shaft and maintains lubrication pressure. When rne pres-sure is too high, the spring is compressed. This moves the lubrication valve and opens the fluid leak passage.

Pitot Regulalor Valv6

The pitot regulator valve controls the start clutch pressure (SC) in accordance with the engine speed, when the electron-ic control system is faulw.

MAIN VAIVEBODY

L.

14-208

Page 915 of 2189

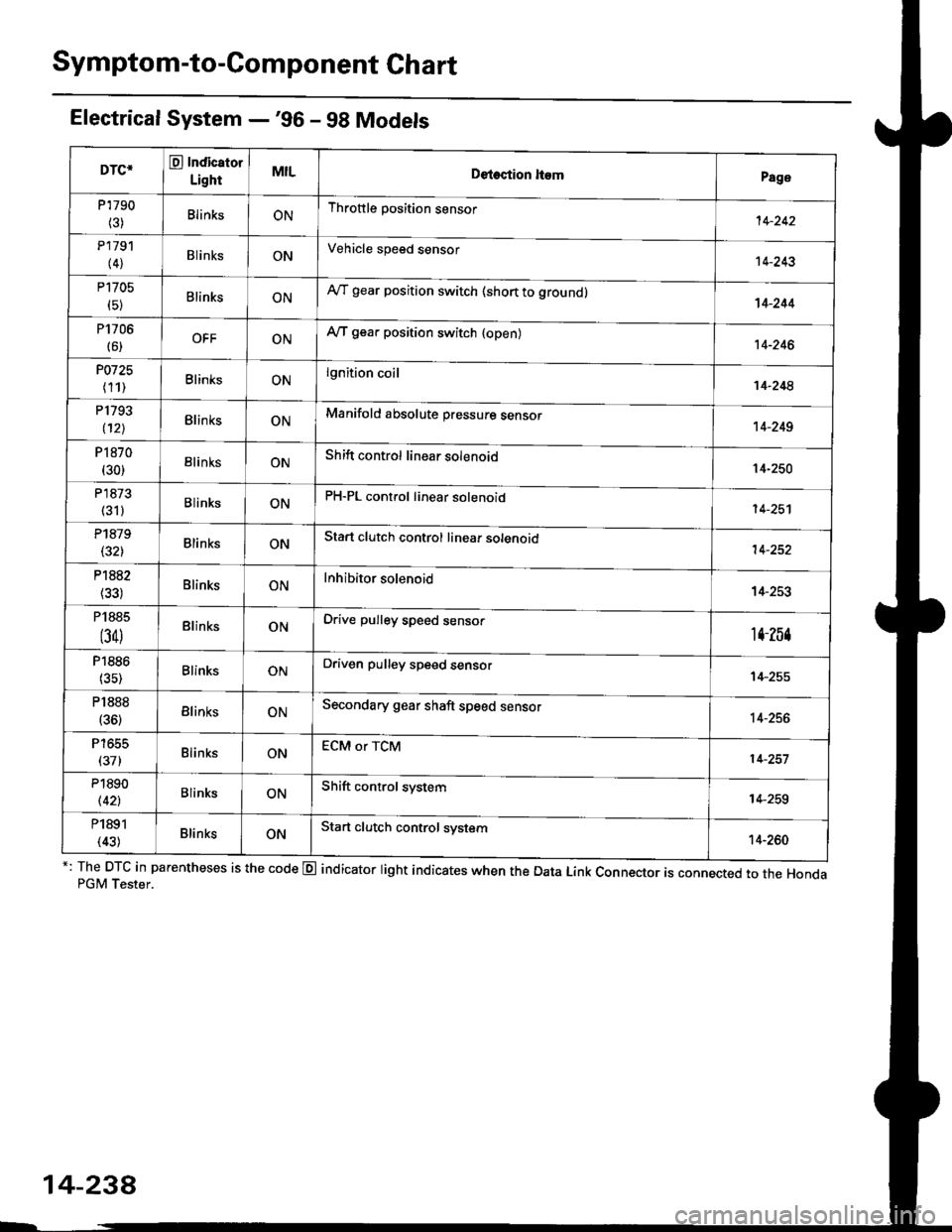

Symptom-to-Component Chart

Electrical System -'96 - 98 Models

*: The DTC in parentheses is the code @ indicator light indicates when the Data Link Connector is connected to the HondaPGM Tester.

DTC*O Indicator

LightMILDetection ltemPage

P1790

(3)BlinksONThrottle position sensor14-242

P179'l

(4)BlinksONVehicle speed sensor14-243

P1705

(5)BlinksONAy'T gear position switch (short to groundl't 4-244

P1706

(6)OFFONA/T gear position switch {open)14-246

P0725

(11)BlinksONlgnition coil14-248

P1793

112lBlinksONManifold absolute pressure sensor14-249

P 1870(30)BlinksONShift control linear solenoid14-250

P'1873

(311BlinksONPH-PL control linear solenoid14-25'l

P1879(32)BlinksONStart clutch control linear sotenoid14-252

P1882BlinksONInhibitor solenoid14-253

P1885

(34)BlinksONDrive pulley speed sensor1l-Zb4

P1886(35)BlinksONDriven pulley speed sensor14-255

P1888

(36)BlinksONSecondary gear shaft speed sensor14-256

T to55

(37)BlinksONECM or TCM14-257

P1890

l42lBlinksONShift control system14-259

P1891

(43)BlinksONStart clutch control svstem14-260

14-23a

Page 917 of 2189

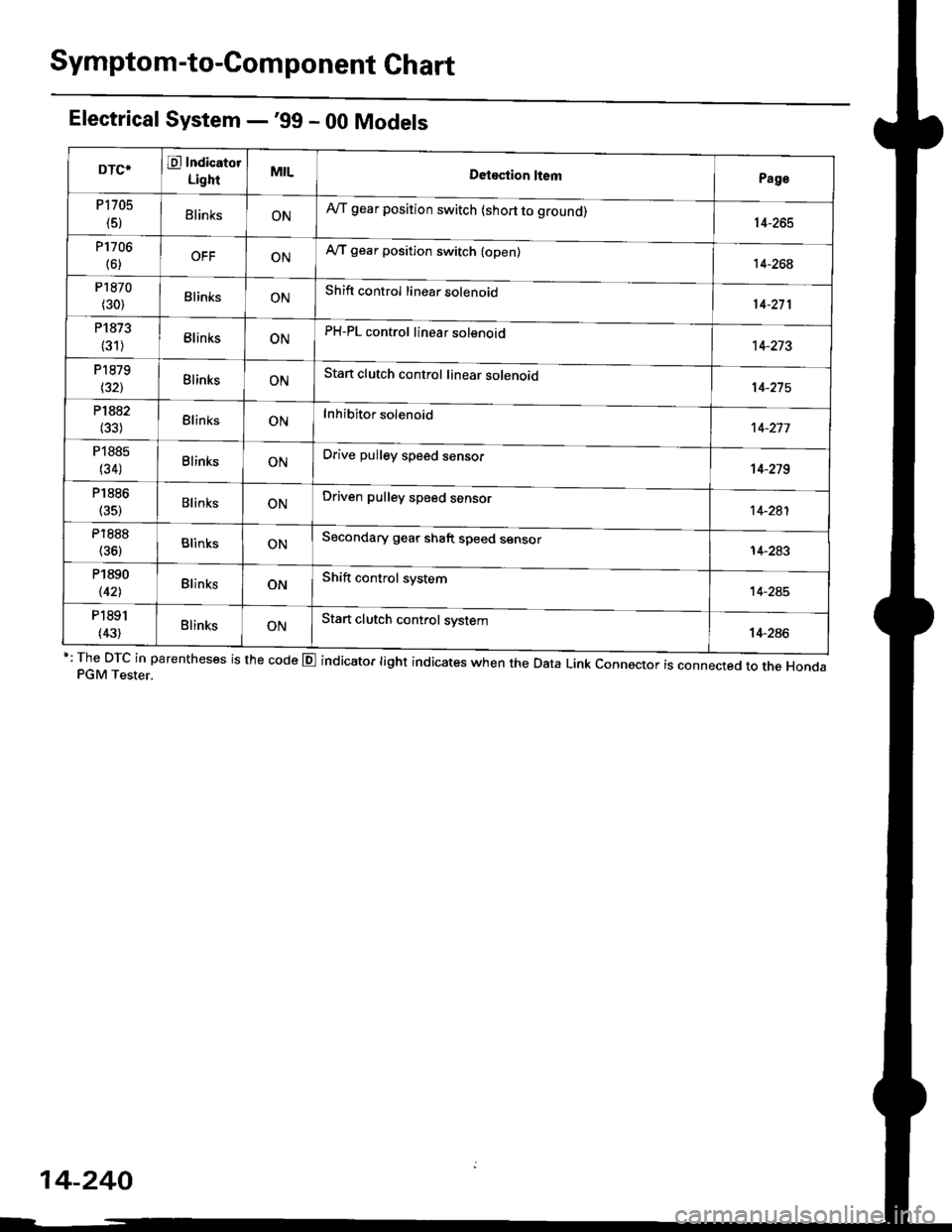

Symptom-to-Com ponent Chart

Electrical System -'99 - 00 Models

r: The DTc in parentheses is the code E indicator light indicates when the Data Link connector is connected to the HondaPGM Tester.

DTCTE Indicatot

LighrMILDetostion ltemPage

P1705

(5)ElinksONA,/T gear position switch (short to grouno,14-265

P1706

(6)OFFONA"/T gear position switch (open)14-26€

P1870

(30)BlinksONShift control linear solenoid14-271

P1873

(31)BlinksONPH-PL control linear solenoid14-213

P1879

t32lBlinksONStan clutch control linear solenoid

Inhibitor solenoid

14-215

P1882(33)BlinksON't 4-277

P1885

(34)BlinksONDrive pulley speed sensol't 4-279

P1886

(35)BlinksONDriven pulley speed sensor14-281

P1888

(36)BlinksONSecondary gear shaft speed sensor

Shift control system

14-283

P1890

\421BlinksON14-245

P1891

(43)BlinksONStart clutch control system14-286

14-240

Page 920 of 2189

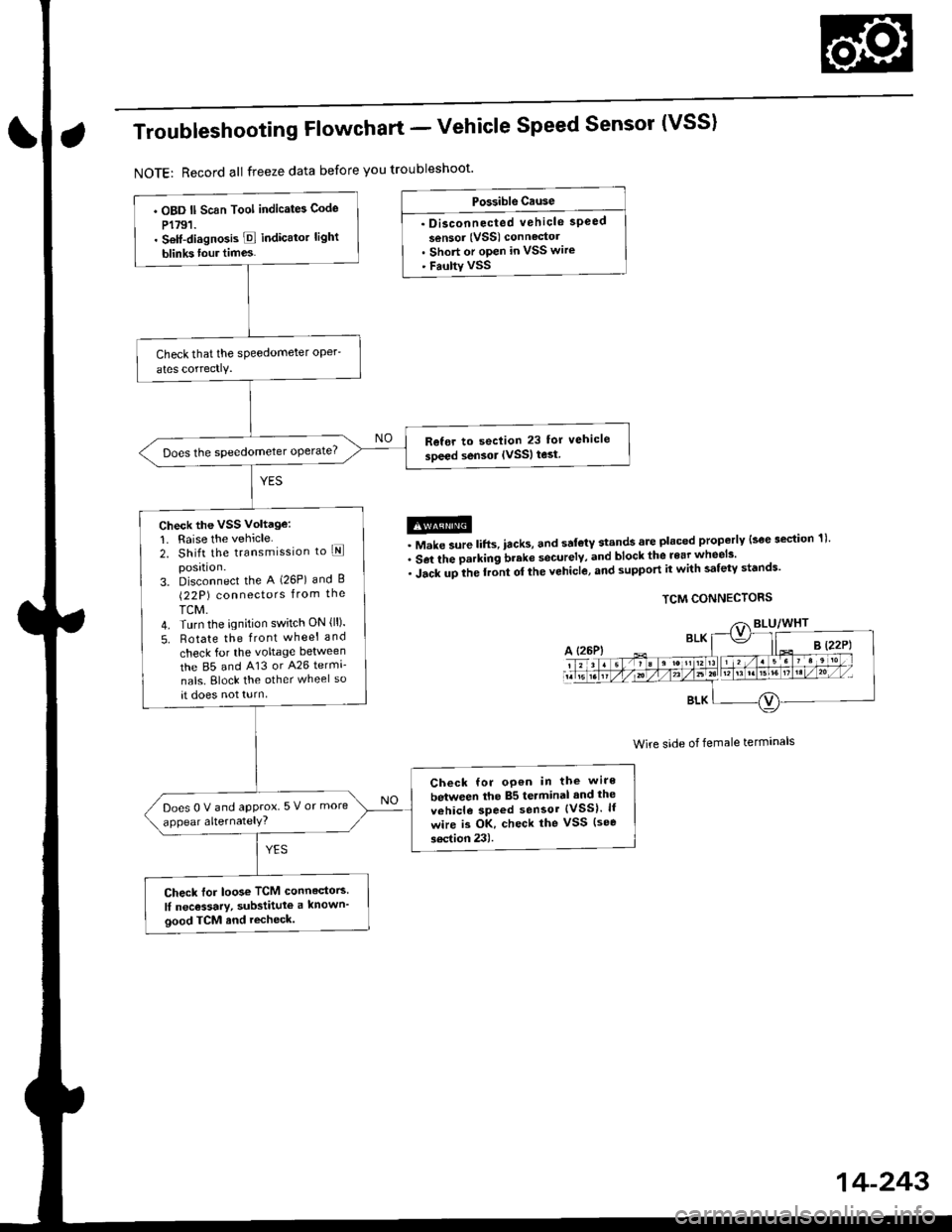

Troubleshooting Flowchart - Vehicle Speed Sensor (VSS)

NOTE: Record all freeze data before you troubleshoot'

Po$rible Ctuse

. Disconnected vehicle speed

sensor (VSS) connectol. Short or open in VSS wire' Faulty VSS

@. Make sure lifts, iacks, and sal€tY stands are placed properly lsoe section 1)'

. Set the parking brake securelv, and block the rear wheels'

. iacr upile rront or the vehicle, and support it with safety st'nds'

TCM CONNECTORS

Wire side of female terminals

. OBD ll Scan Tool indicates Code

P1791.. Setf-diagno3is E indicato. light

blinks tour times.

Refer to seclion 23 for vehicle

soeed sensor IVSSI test

Check the VSS Voltage:

1. Raise the vehicle2. Shift the transmission to lEposrtlon.3. Disconnect the A (26P) and B(22P) connectors from the

TCM.4. Turn the ignition switch ON {ll).

5. Rotate the front wheel and

check for the voltage between

the 85 and 413 or A26 termi-

nals. Block the other wheel so

at does not turn

Check for oP€n in the wire

between the 85 terminal and the

vehicle speed sensor {VSS}. lf

wire is OK, check the vSS (see

soction 23).

Does0Vandapprox 5 V or more

appear alternatelY?

Check for loos€ TCM connedors

lI nec€ssary, substitute a known'

good TCM and recheck.

14-243

Page 921 of 2189

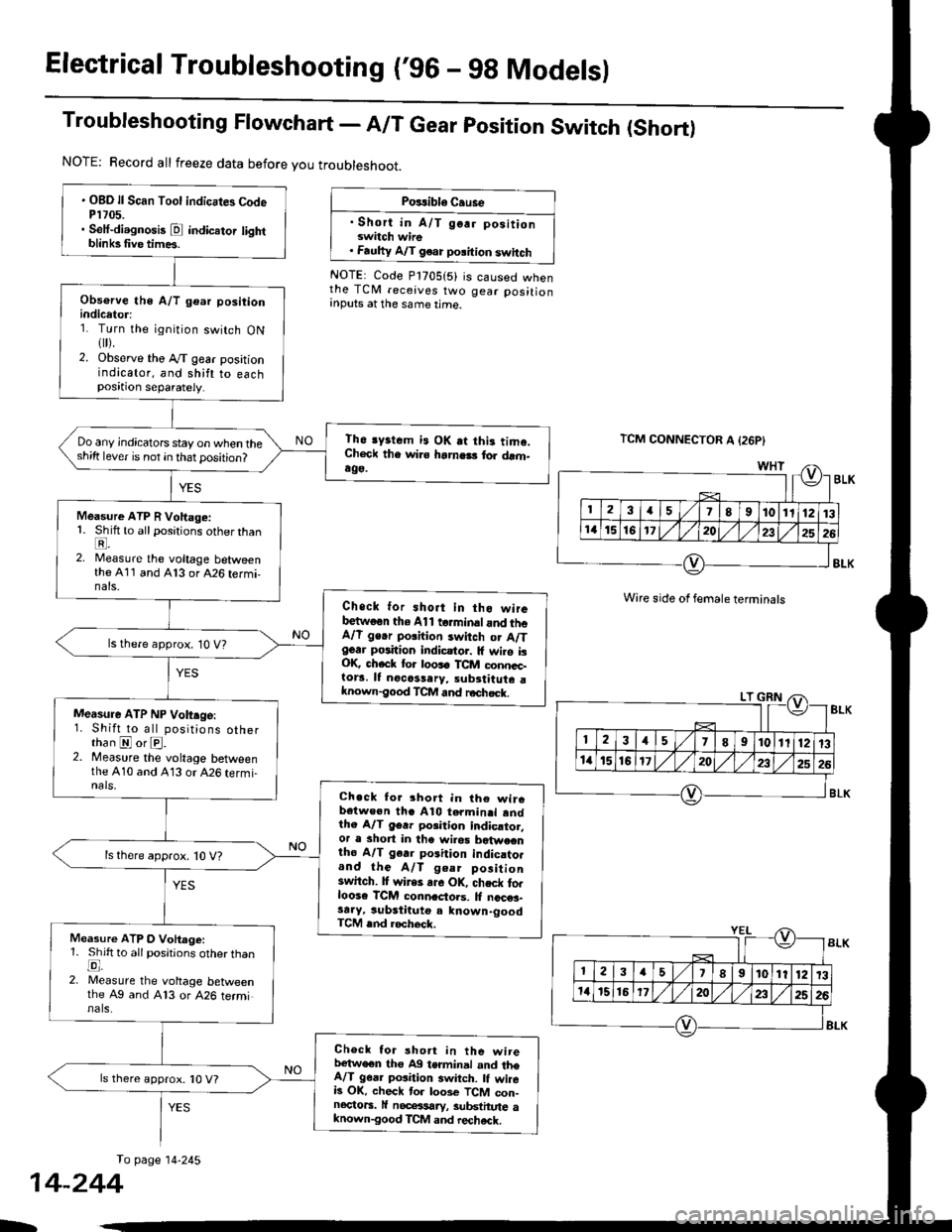

Electrical Troubleshooting ('96 - 9g Models)

Troubleshooting Flowchart - A/T Gear position Switch (Short)

NOTE: Record all freeze data before you troubleshoot.

Posrible Cause

. Short in A/T go.r positionswitch wire. Faulty A/T g€ar polition switch

NOTE: Code P1705(5) is caused whenthe TCM receives two gear positionInputs at the same time.

TCM CONNECTOR A {26P}

Wire side of female terminals

To page 14-245

. OBD ll Scan Tool indicates CodeP1705.. Seif-diagnosis @ indicator lightblinksfive times.

Obsorve the A/T gear positionindicetor:1. Turn the ignition switch ON1[).2. Observe tho Ay'T gear positionindicator, and shift to eachposition separately.

Th6 lyrtcm i3 OK at thi. tima.Check the wi.s hamels for drm.ag9.

Do any jndicators stay on when thesh;ft lever is not in that position?

Measure ATP R Vohage:1. Shift to all positions other thanE.2. Measure the voltage betweenthe 411 and A13 or A26 termi-nats.

Check for sho.t in tho wireb€twoon the Al1 t rminaland th6A/l ge.r polhion switch or A/Tgear position indicstor. lf wilo isOK check for loos6 TCM conncc-tora. It nocassery, subrtitute aknown-good TCM and r€chsck.

ls there approx. 10 V?

Measure ATP NP Volt.ge:1. Shift to all positions otherthan @ or @.2. Measure the voltage betweenthe A10 and 413 or 426 termi-nals,Ch.ck tor 3hort in th€ wircb€twe€n thc Al0 termin.l andthe A/T 96r. porition indicrtor,or a short in the wilea b?twecntho A/T gerr porition indic.to.and the A/T geer positionswitch. It wires ar6 OK, chsck forloose TCM conn.clols. ll nccNe3-sa.y, substituto a known-goodTCM rnd locheck.

ls there approx. 10 V?

Measure ATP O Vohage:1. Shift to all positions otherthanE,2. Measure the voltage betweenthe Ag and A13 or 426 terminals.

Checl tor short in the wirelr€tweon tho A9 terminal and theA/T g6a. position 3witch. lf wireb OK. check tor loos€ TCM con-nectors. lf nocelsary, substhute aknown-good TCM and rechack.

ls there approx. '10 V?

14-244

b