IGNITION SWITCH ASSEMBLY HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1566 of 2189

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

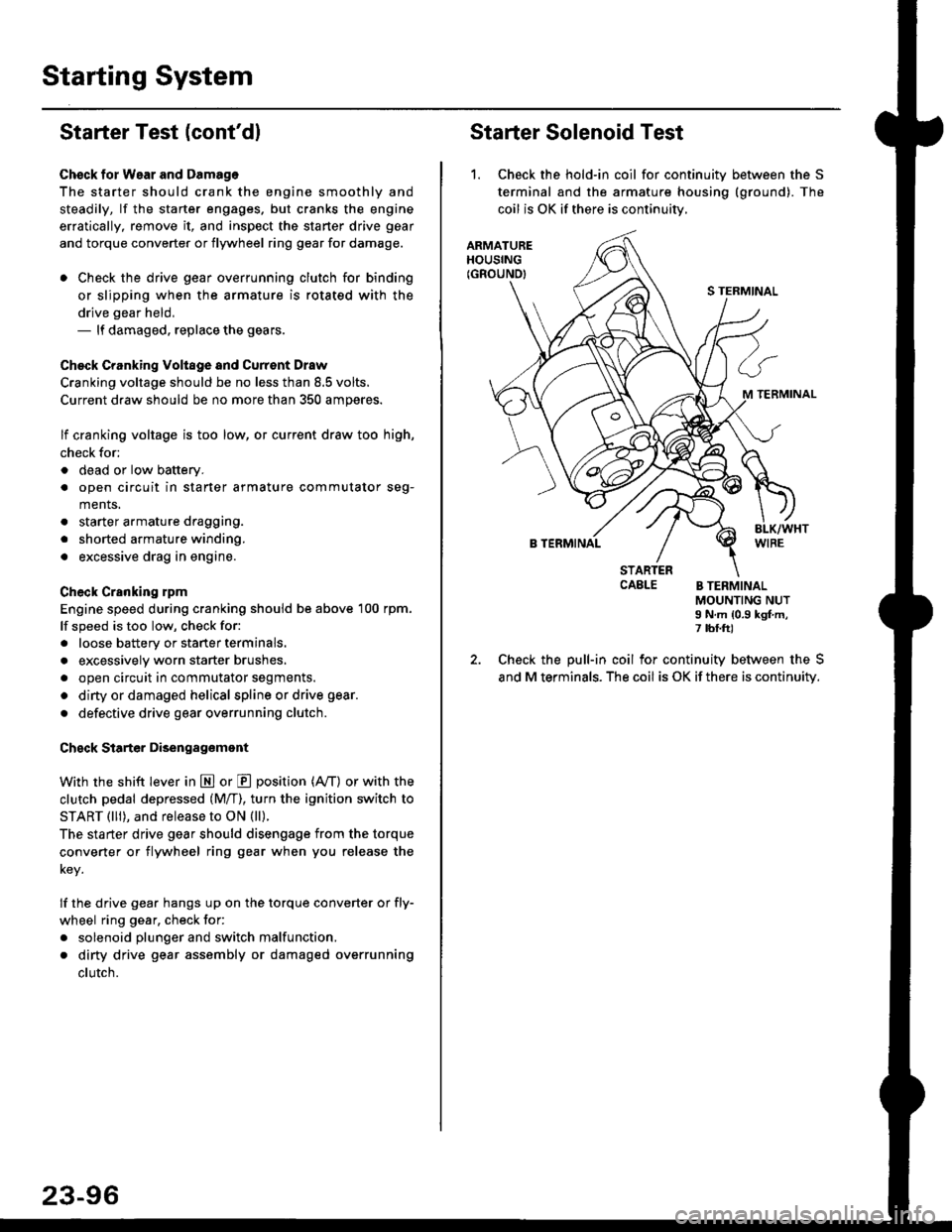

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1611 of 2189

J

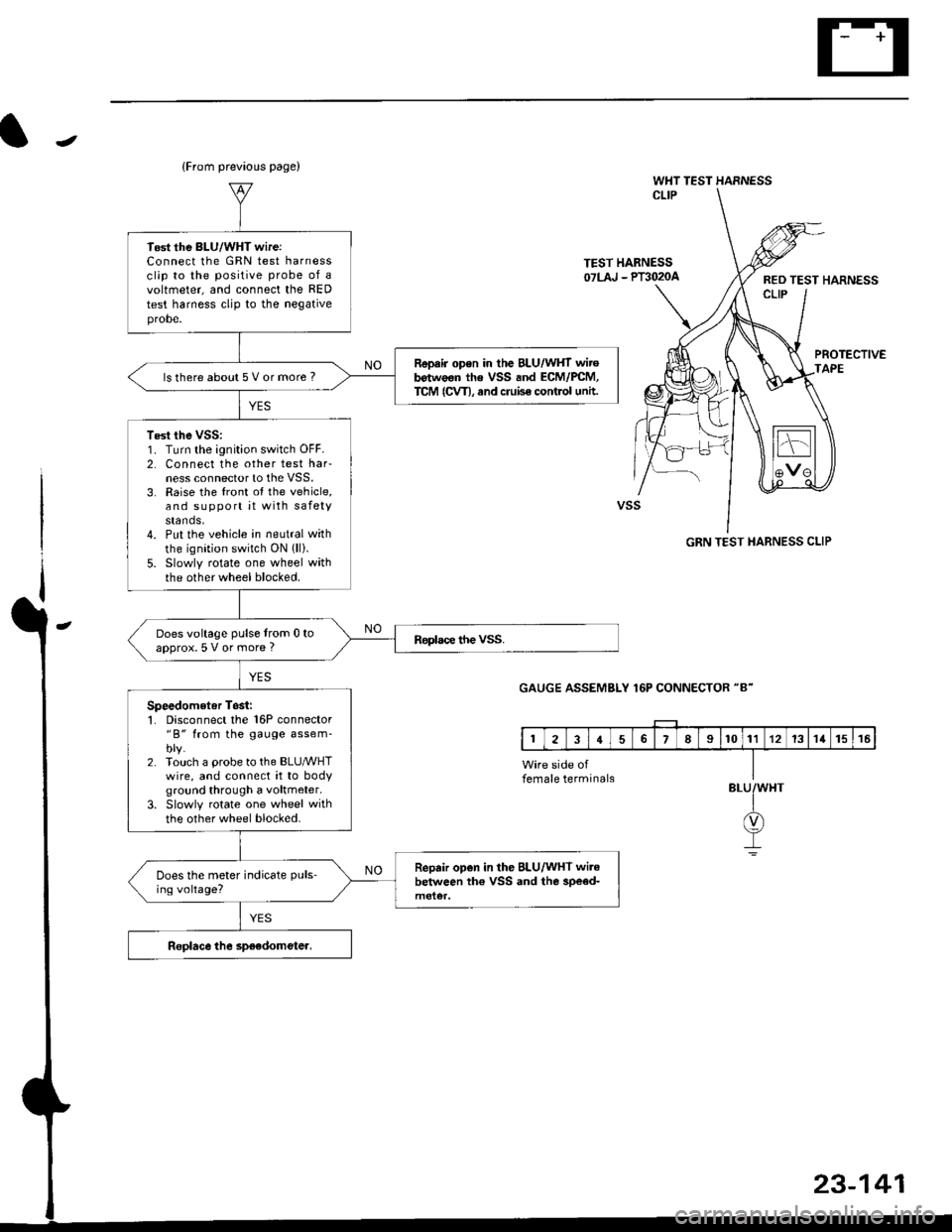

(From prevaous page)

WHT TEST HARNESSCLIP

TEST HABNESS07LAJ - Plil020aRED TEST HARNESSCLIP

PROTECTIVEAPE

GRN TEST HARNESS CLIP

GAUGE ASSEMBLY 16P CONNECTOR "8"

BLU

23-141

Tost the BLU/WHT wireiConnect lhe GRN test harnessclip to the positive probe of avoltmeter, and connect the RED

test harness clip to the negativeprobe.

Repair open in the BLU/WHT wirob€twoon the VSS and ECM/PCM,TCM (CVT), and cruise control untt.ls there about 5 V or more ?

Test the vss:1. Turn the ignition switch OFF.2. Connect the other test harness connector to the VSS.3. Raise the front ot the vehicle,and support it with safetystands,4. Put the vehicle in neutral with

the ignition switch ON (ll).

5. Slowly rotate one wheel withthe other wheel blocked.

Does voltage pulse from 0 toapprox.5 V or more ?

Speedometer Tosii'1. Disconnect the 16P connector"B" from the gauge assem-blv.2. Touch a probe to the BLUMHTwire, and connect it to bodyground through a voltmeter.

3. Slowly rotate one wheel with

the other wheel blocked.

Repair open in the BLU/WHT wi.ebelween th€ VSS and the 3pe€d-Does the meter indicate puls-

ing voltage?

female terminals

Page 1613 of 2189

J

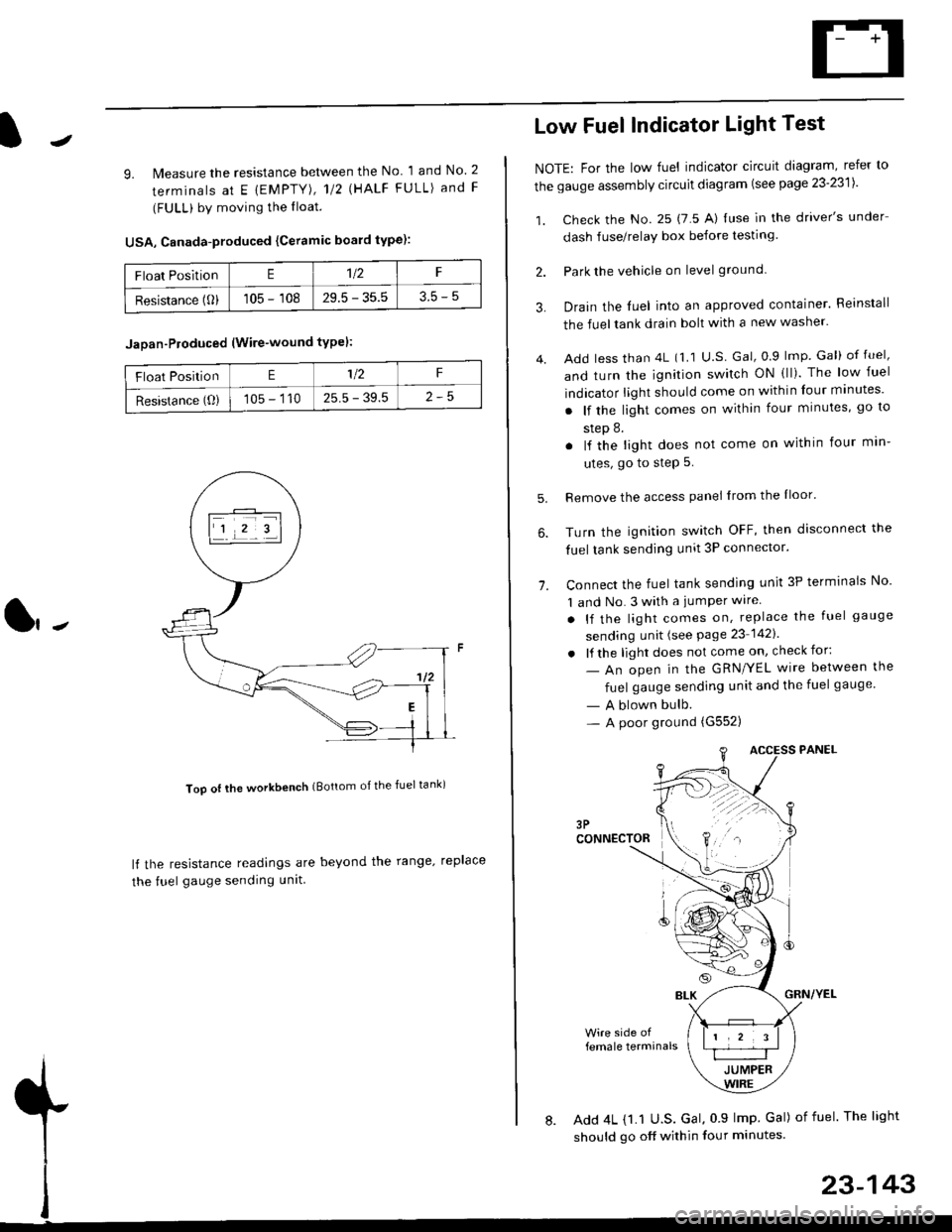

9. lMeasure the resistance between the No 1 and No. 2

terminals at E {EMPTY), 112 \HALF FULL) and F

(FULL) by moving the lloat.

USA, Canada-produced {Ceramic board type):

Too ot lhe workbench (Bottom of the fuel tank)

ll the resistance readings are beyond the range. replace

the fuel gauge sending unit

Float PositionE1t2F

Resistance (0)105 - 10829.5 - 35.53.5-5

Jaoan-Ploduced (Wire-wound typel:

Float PositionE1/2F

Resistance (O)105 - 11025.5 - 39.5

Low Fuel Indicator Light Test

NOTE: For the low fuel indicator circuit diagram, refer to

the gauge assembly circuit diagram (see page 23'2311.

1. Check the No. 25 (7 5 A) luse in the driver's under

dash fuse/relay box before testing

2. Park the vehicle on level ground.

3.

4.

Drain the luel into an approved container. Reinstall

the fueltank drain bolt with a new washer.

Add less than 4L (1 1 U.S Gal, 0.9 lmp Gal) of fuel,

and turn the ignition switch ON (ll). The low fuel

indicator light should come on within four minutes'

. lf the light comes on within four minutes, go to

step 8.

. lf the light does not come on within four min-

utes, go to step 5.

Remove the access panel lrom the Iloor'

Turn the ignition switch OFF, then disconnect the

fuel tank sending unit 3P connector.

Connect the fuel tank sending unit 3P terminals No'

1 and No. 3 with a jumPer wire

. lf the light comes on, replace the fuel gauge

sending unit (see Page 23 1421

. lf the light does not come on, check for:

- An open in the GRN/YEL wire between the

fuel gauge sending unit and the fuel gauge

- A blown bulb.- A poor ground (G552)

6.

1.

female terminals

8. Add 4L {1.1 U.S. Gal, 0 9 lmp Gal) of fuel The light

should go off within four minutes.

23-143

Page 1616 of 2189

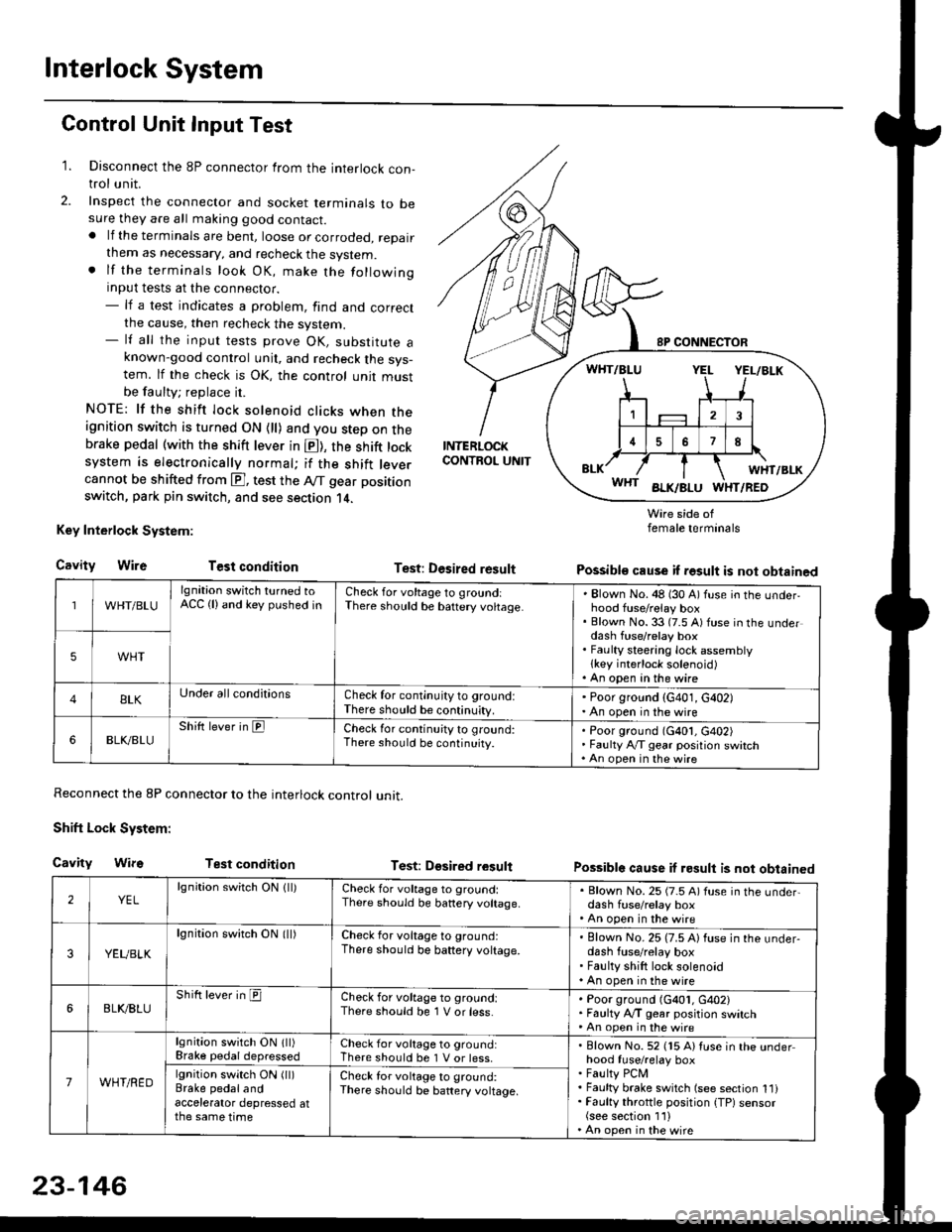

Interlock System

Control Unit Input Test

1. Disconnect the 8P connector from the interlock con-trol unit.

2. Inspect the connector and socket terminals to besure they are all making good contact.. lf the terminals are bent, loose or corroded, repairthem as necessary, and recheck the system.. lf the terminals look OK, make the followinginput tests at the connector.- lf a test indicates a problem, find and correctthe cause, then recheck the system.- lf all the input tests prove OK, substitute aknown-good control unit, and recheck the sys-tem. lf the check is OK, the control unit mustbe faulty; replace it.

NOTE: lf the shift lock solenoid clicks when theignition switch is turned ON {ll) and you step on thebrake pedal (with the shift lever in E), the shift locksystem is electronically normal; if the shift leve.cannot be shifted from E], test the Aff gear position

switch, park pin switch, and see section 14.

Key Interlock System:

CavityWireTest condition

Reconnect the 8P connector to the interlock control unit.

Shift Lock System:

Cavity WifsTest condition

INTERLOCKCONTROL UNIT

Test: Desired result

Test: Dgsired result

Wire side offemale terminals

Possible cause if result is not obtained

Possible cause if result is not obtained

WHT/BLU

lgnition switch turned toACC (lland key pushed inCheck for voltage to groundiThere should be baftery voltage.Blown No. 48 (30 A) fuse in the underhood fuse/relay boxBlown No. 33 (7.5 A) fuse in the underdash fuse/relay boxFaulty steering lock assemblylkey interlock solenoid)An open in the wire

5WHT

BLKUnder all conditionsCheck for continuity to ground:There should be continuity.

' Poor ground (G401, G402). An open in the wire

6BLK./BLUShift lever in ElCheck for continu;ty to ground:There should be continuity.Poor ground (G401, G402)Faulty Ay'T gear position switchAn open in the wire

2YELlgnition switch ON lll)Check for voltage to ground:There should be banery voltage.

. Blown No. 25 (7.5 A) fuse in the under,dash fuse/relay box. An open in the wire

3YEUBLK

lgnition swirch ON (ll)Check for voltage to ground:There should be baftery voltage.Blown No. 25 (7.5 A) fuse in the under-dash fuse/relay boxFaulty shift lock solenoidAn open in the wire

6BLI(BLUShift lever in ICheck for voltage to ground:There should be 1 V or less.Poor ground (G401, G402)Faulty A,/T gear position switchAn open in the wire

7WHT/RED

lgnition switch ON lll)Brake pedaldepressedCheck for voltage to ground:There should be 1 V or less.Blown No. 52 (15 A) Iuse in the underhood fuse/relay boxFaulty PCMFaulty brake switch (see section 1l)Faulty throttle position {TP) sensor(see section 1'l )An open in the wire

lgnition switch ON (ll)Brake pedalandaccelerator depressed atthe same time

Check for voltage to ground:There sho(Jld be battery voltage.

23-146

Page 1669 of 2189

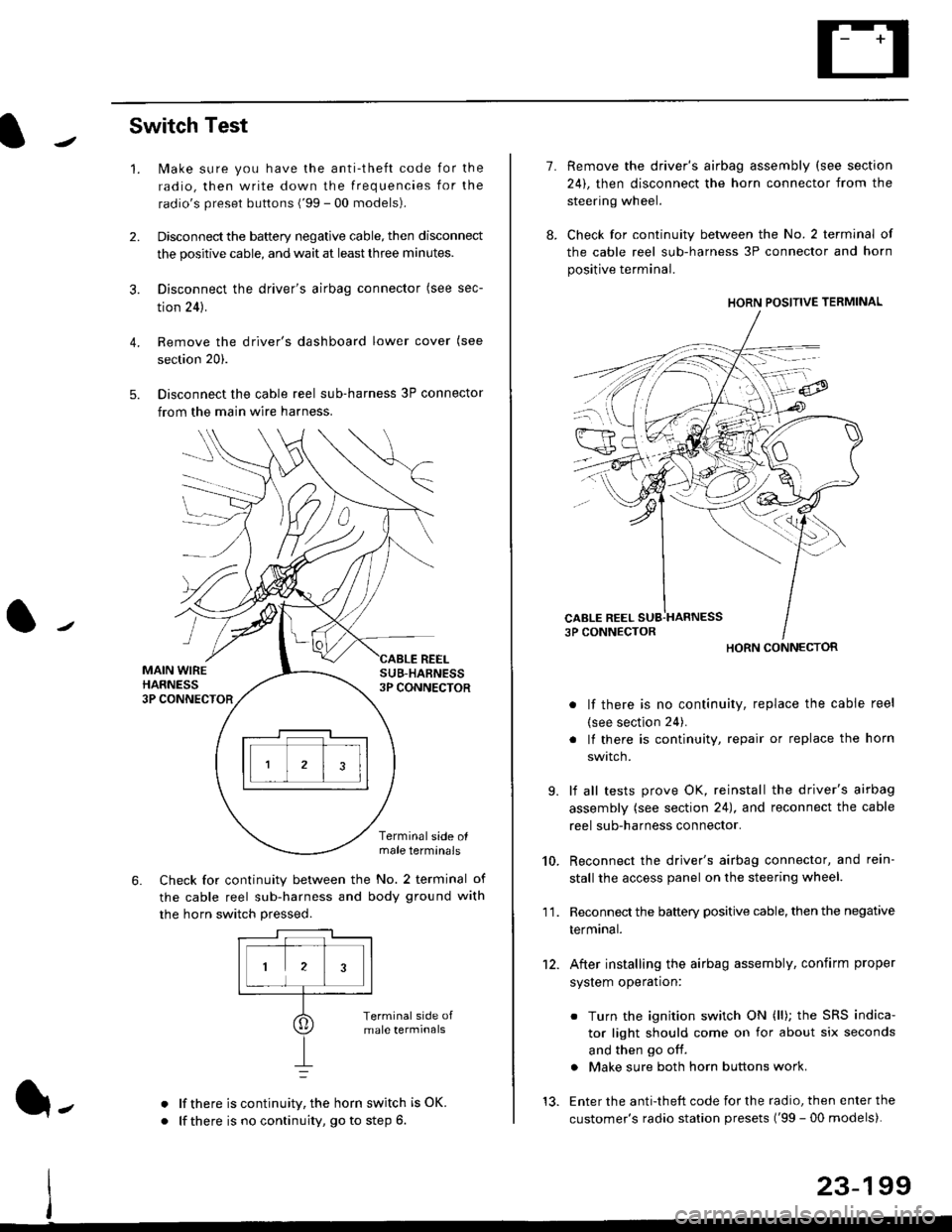

Switch Test

lMake sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable, then disconnect

the positive cable, and wait at least three minutes.

Disconnect the driver's airbag connector (see sec-

tion 24).

Remove the driver's dashboard lower cover (see

section 20).

Disconnect the cable reel sub-harness 3P connector

from the main wire harness.

2.

3.

4.

5.

1.

MAIN WIREHARNESS3P CONNECTOR

SUB-HABNESS3P CONNECTOR

REEL

6.

Terminalside olmale terminals

Check for continuity between the No. 2 terminal of

the cable reel sub-harness and body ground with

the horn switch pressed.

alf there is continuity, the horn switch is OK.

lf there is no continuity, go to step 6l-

-\

1.

8.

10.

'I 1.

9.

Remove the driver's airbag assembly (see section

24), then disconnect the horn connector from the

steering wheel.

Check for continuity between the No. 2 terminal of

the cable reel sub-harness 3P connector and horn

positive terminal.

lf there is no continuity, replace the cable reel

(see section 24).

lf there is continuity, repair or replace the horn

swtlcn,

lf all tests prove OK, reinstall the driver's airbag

assembly (see section 24), and reconnect the cable

reel sub-harness connector.

Reconnect the driver's airbag connector, and rein-

stall the access panel on the steering wheel.

Reconnect the battery positive cable, then the negative

termtnar.

After installing the airbag assembly, confirm proper

system operation:

12.

Turn the ignition switch ON (ll); the SRS indica-

tor light should come on for about six seconds

and then go off.

Make sure both horn buttons work.

13. Enter the anti-theft code for the radio, then enter the

customer's radio station presets ('99 - 00 models).

HORN CONNECTOR

23-199

Page 1744 of 2189

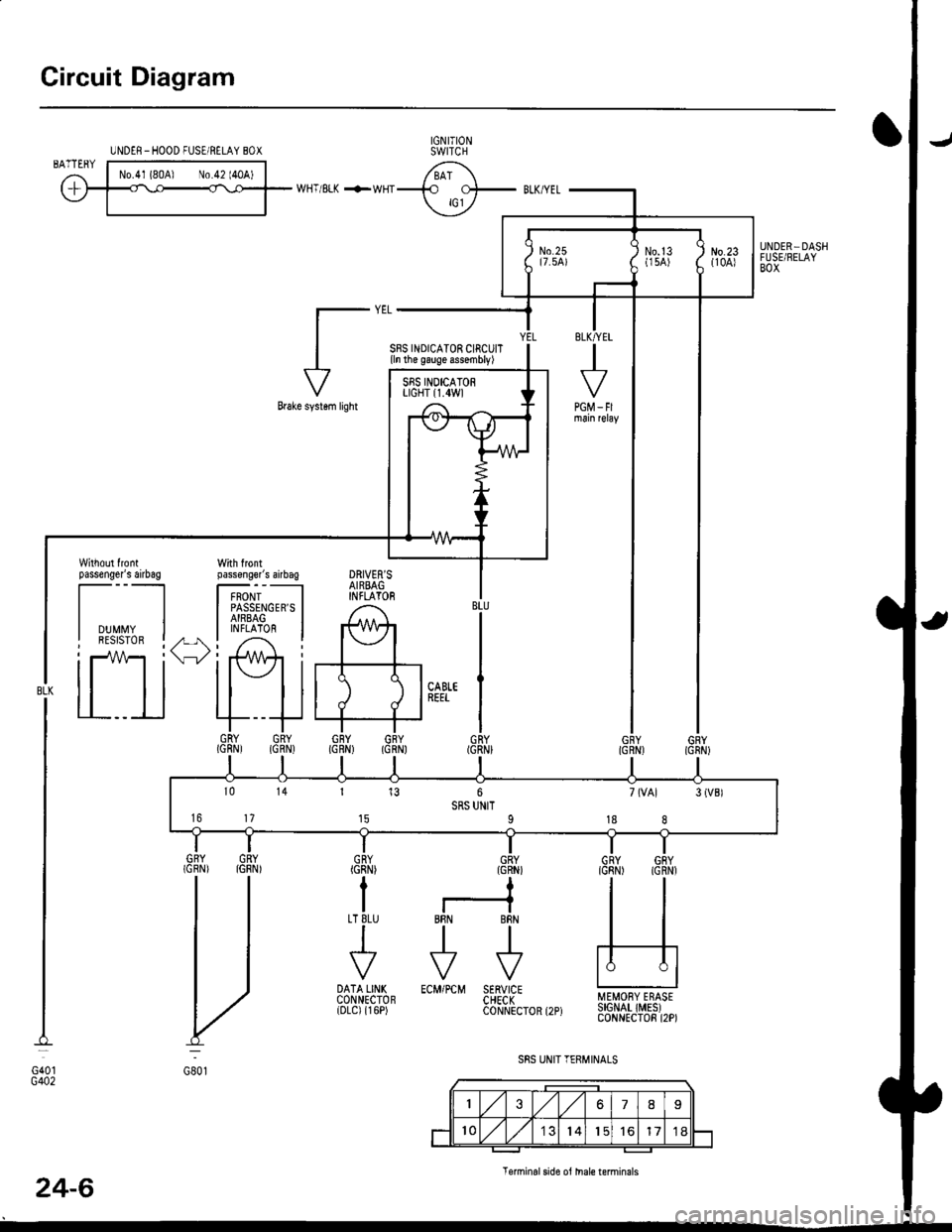

Circuit Diagram

UNDER-HOOD FUSE/RELAY 8OXIGNITIONSWITCH

WHT/8LI( +WHT

Brake systsm light

passenger's airbag

l----ltlI DUMMY II BESISTOR I

tll

tl

la rl

MEMORY ERASESIGNAT IMES)CONNECTOR I2P)

GRY{GRN)

I

BRN BRN

tl.-l- .-r-\./ \./

ECM/PCM SERVICECHECKCONNECTOR

ILT 8LU

I

t'7

DATA LINKCONNECTOR{DLC) {r6P)

GRY GRY(GRN) IGNN)

V:

G801

Teminalside oi thal€ terminals

24-6

4''

SRS UNIT TERMINALSG40tG402

SBS INDICATOR CIRCUIT{ln the gauge assembly)

PGM_FI

DRIVER'SAIRBAGINFLATOR

10 14 r 13 6 7(VAl 3{VBlSRS UNIT16 17 t5 9 18 8

Page 1745 of 2189

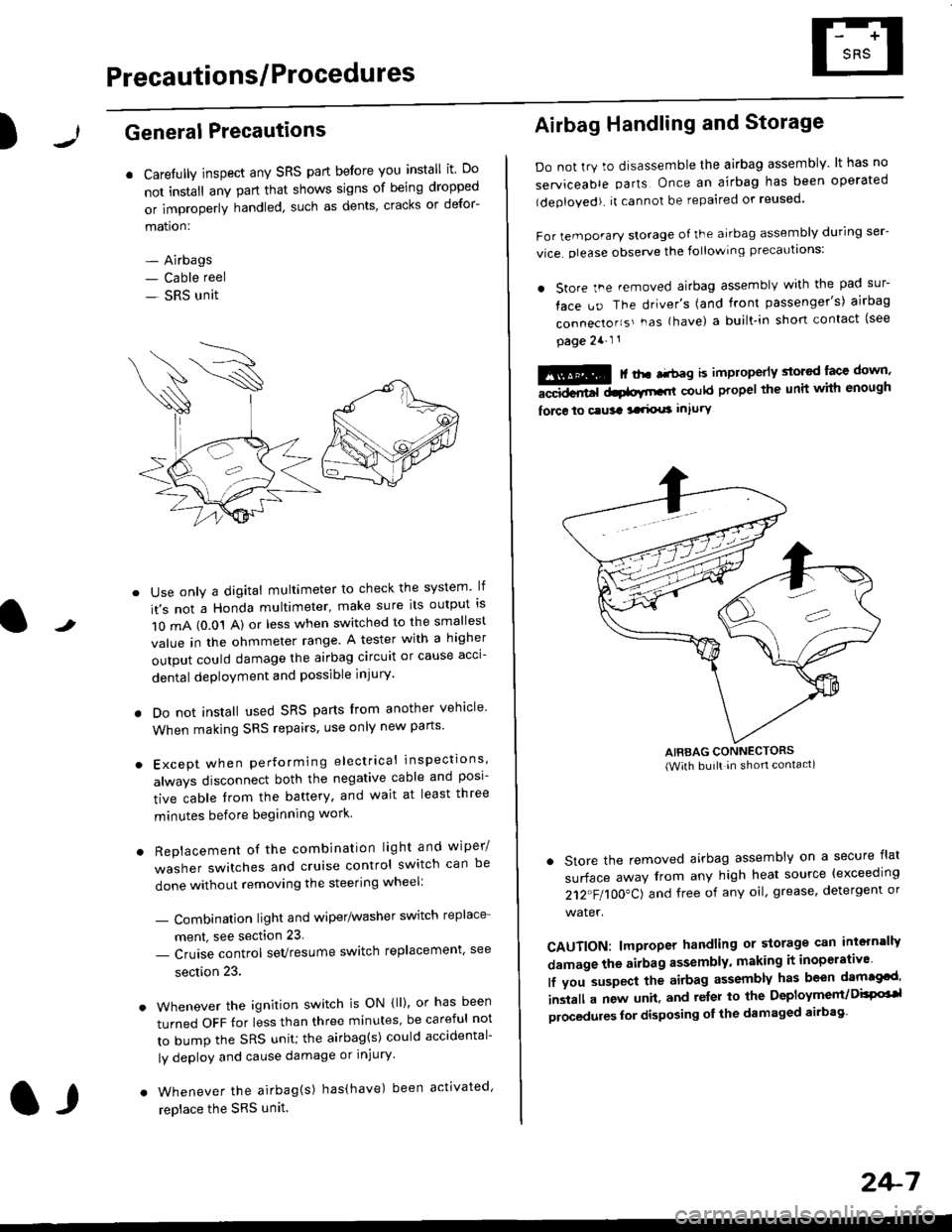

Precautions/ Procedures

)General Precautions

r Carefully inspect any SRS part before you install it Do

not install any part that shows signs of being dropped

or improperly handled' such as dents, cracks or defor-

mation:

- Airbags- Cable reel

- SRS unit

-

Use only a digital multimeter to check the system lf

it's not a Honda multimeter, make sure its output ls

1O mA (0.01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury'

I Do not install used SRS parts from another vehicle

When making SRS repairs, use only new pans'

) Except when performing electrical inspections'

always disconnect both the negative cable and posl-

tive cable from the battery, and wait at least three

minutes before beginning work

r Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combinalion light and wiper/washer switch replace

ment, see section 23

- Cruise control sevresume switch replacement' see

section 23.

. Whenever the ignition switch is ON {ll), or has been

turned OFF for less than three minutes' be careful not

to bump the SRS unit; the airbag(s) could accidental-

ly deploy and cause damage or injury'

. Whenever the airbag{s) has(have) been activated'

replace the SRS unit.l,

2+7

Airbag Handling and Storage

Do not try to disassemble the airbag assembly. lt has no

serviceable parts Once an airbag has been operated

(deployed). it cannot be repaired or reused'

For temporary storage of the airbag assembly during ser-

vice. olease observe the following precauttons:

. store the .emoved airbag assemblv with the pad sur-

face uo The driver's (and front passenger's) airbag

connecto''s'-as {have) a built.in short contact (see

page 2a-l 1

: | ..r r-+r-a k imninncrlv slorcd lace down,-""dd.r6t dtatltt-,tl could propel the unit whh enough

force lo c.usa 3a.ix! intury

AIRBAG CONNECTORS(With built in shon contact)

. Store the removed airbag assembly on a secure flat

surface away from any high heat source {exceeding

212"FI1OO"CJ and free of any oil' grease, detergent or

water.

CAUTION: lmproper handling or storage can intern'lJy

damage the airbag assembly, making it inoperativo

lf you suspect the airbag assembly has been dam€cd'

inslall a new unit. and relsr lo the Deployment/DisPG'l

olocedules for disposing ol the damaged airbag

Page 1750 of 2189

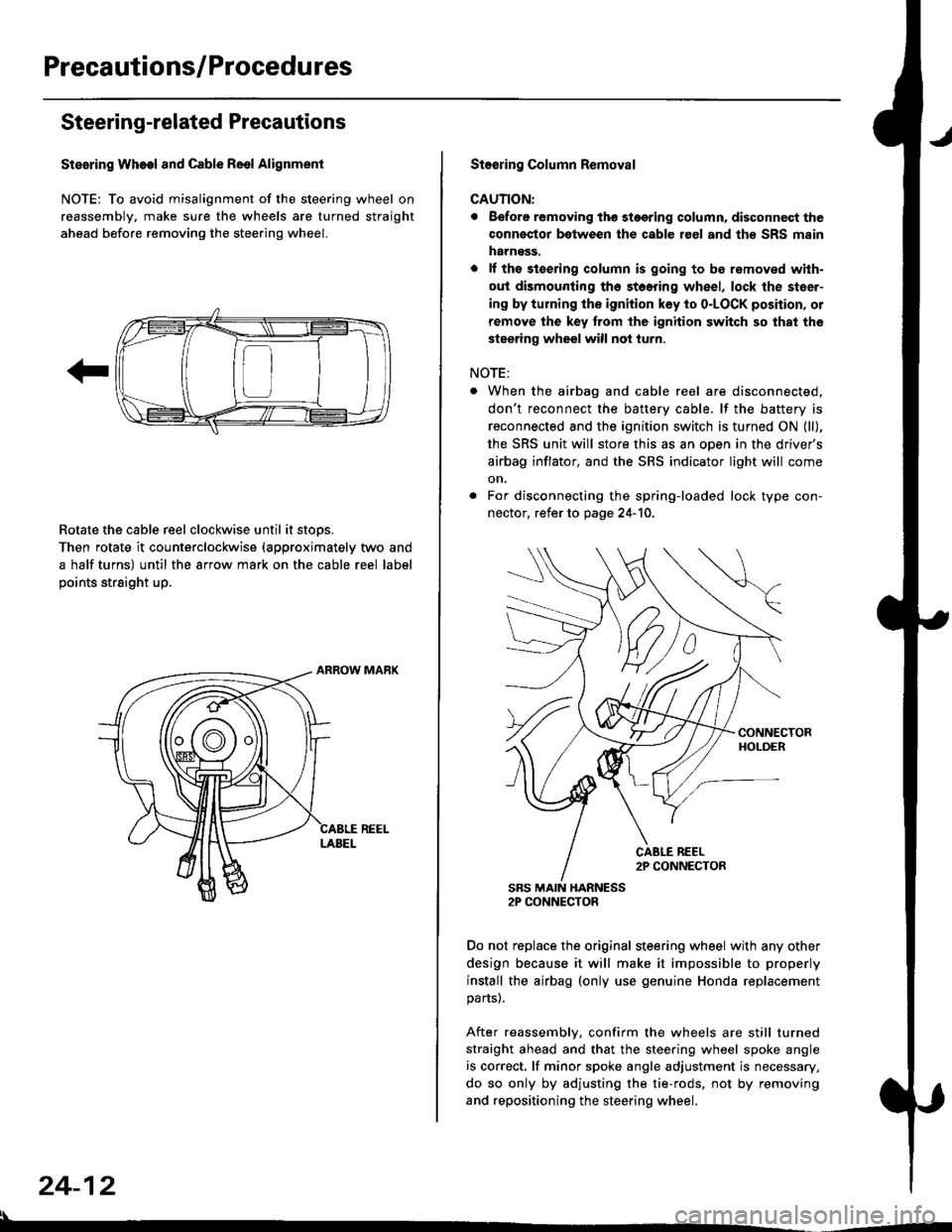

Precautions/Procedu res

Steering-related Precautions

Stesring Wheel and Cable Reol Alignment

NOTE: To avoid misalignment of the steering wheel on

reassembly, make sure the wheels are turned straight

ahead before removing the steering wheel.

Rotate the cable reel clockwise until it stops.

Then rotate it counterclockwise {approximately two and

a half turns) until the arrow mark on the cable reel label

points straight up.

24-12

:l

St€€rin9 Column Removal

CAUTION:

. Eefore removing thg stggring column. disconnect the

connsstor bqtween the cable r€el and th€ SRS msin

harness.

. lf the stoering column is going to be romoved with-

out dismounting th6 stoering wheel, lock the steer-

ing by turning the ignition key to o-LOCK position, or

remove the key trom the ignition switch so that the

steering wheel will not turn.

NOTE:

When the airbag and cable reel are disconnected,

don't reconnect the battery cable. lf the battery is

reconnected and the ignition switch is turned ON (ll),

the SRS unit will store this as an open in the driver's

airbag inflator, and the SRS indicator light will come

on.

For disconnecting the spring-loaded lock type con-

nector, refer to page 24-'10.

SRS MAIN HARNESS2P CONNECTOR

Do not replace the original steering wheel with any other

design because it will make it impossible to properly

install the airbag (only use genuine Honda replacement

parts).

After reassembly, confirm the wheels are still turned

straight ahead and that the steering wheel spoke angle

is correct. lf minor spoke angle adjustment is necessary,

do so only by adjusting the tie-rods, not by removing

and repositioning the steering wheel.

Page 1764 of 2189

Troubleshooting

The SRS Indicator Light Doesn't Come On

CAUTION: Whonever ths ignition switch is ON {ll}, or

has been turned OFF tor less than three minutes. be

careful not to bump the SRS unit; the airbagls) could

accidentally deploy .nd caus6 damage or iniuri€s.

Check tho pow€r supply (fuse):

Turn the ignition switch ON (ll), and check whether the otherindicator lights come on (brake system, etc.).

Oo the other indicator liohts como on?

YESNO

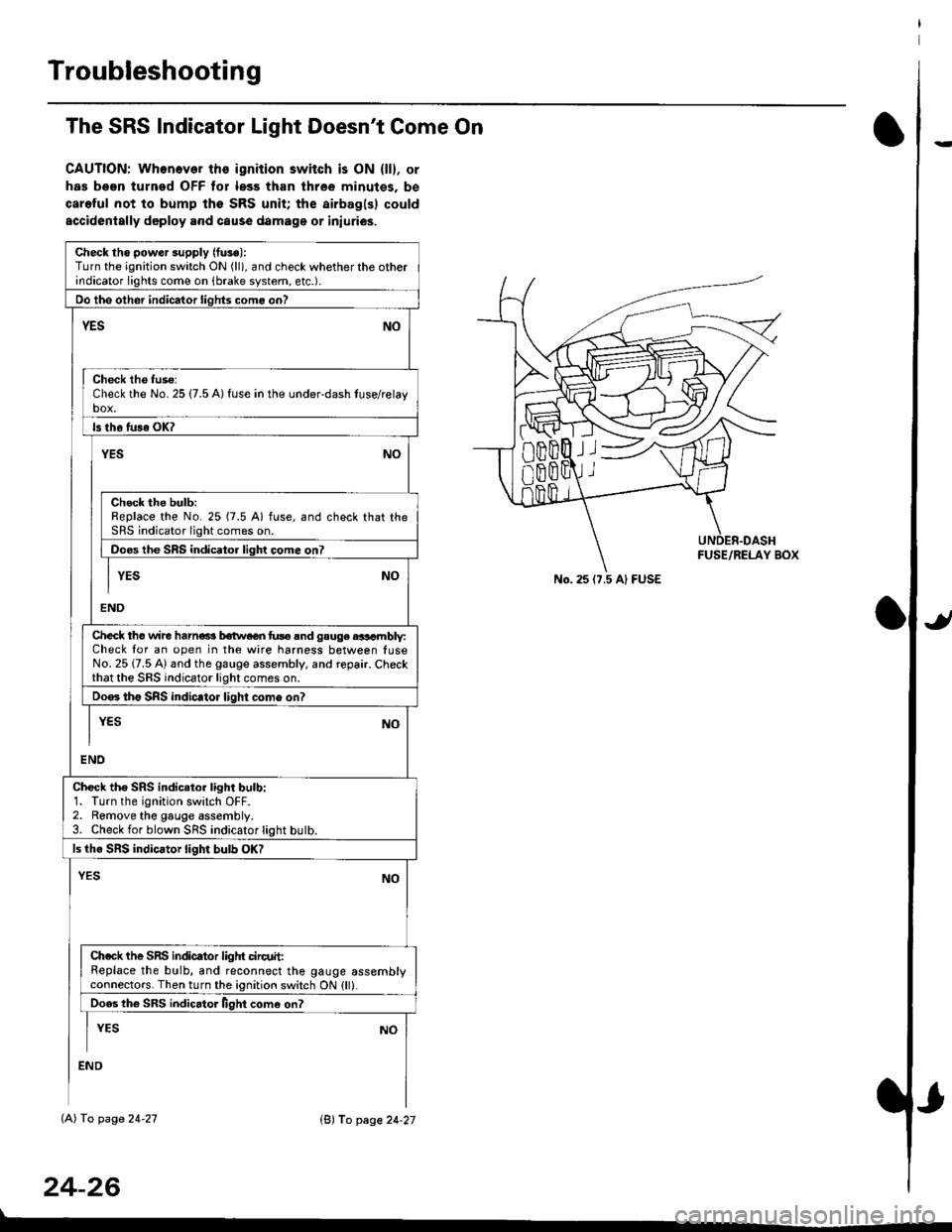

Check th6 fuso:Check the No. 25 {7.5 A) fuse in the under-dash tuse/relayb"t

ls th6 tu36 OK?

NOYES

Check the bulb:Replace the No. 25 (7.5 A) fuse, and check that theSRS indicator light comes on.

Doos the SRS indicator liqhl come on7

I YES No

END

Check tho wire harns b€twecn fus6 and gauge aasambly:Check for an open in the wire harness between luseNo. 25 {7.5 A) and the gauge assembly, and repair. Checkthat the SRS indicator light comes on.

Doo. tho SRS indic.tor light como on?

I yEs No

I

END

Check tho SRS indicator light bulb:1. Turn the ignition switch OFF.2. Remove the gauge assembly.3. Check for blown SRS indicator light butb.

ls the SRS indicator light bulb OK?

NOYES

Ch.ck the SnS indicator liglrt circuit:Replace the bulb, and reconnect the gauge assemblyconnectors. Then turn the ignition switch ON {ll}.

Ooes th6 SRS indicato. llght come on?

I YEs No

:ND

lAl To page 24-27

24-26

lB'J fo page 24-27

))

No. 25 (7.5 Al FUSE

Page 1765 of 2189

)

From page 24-26

(A)

From page 24-26

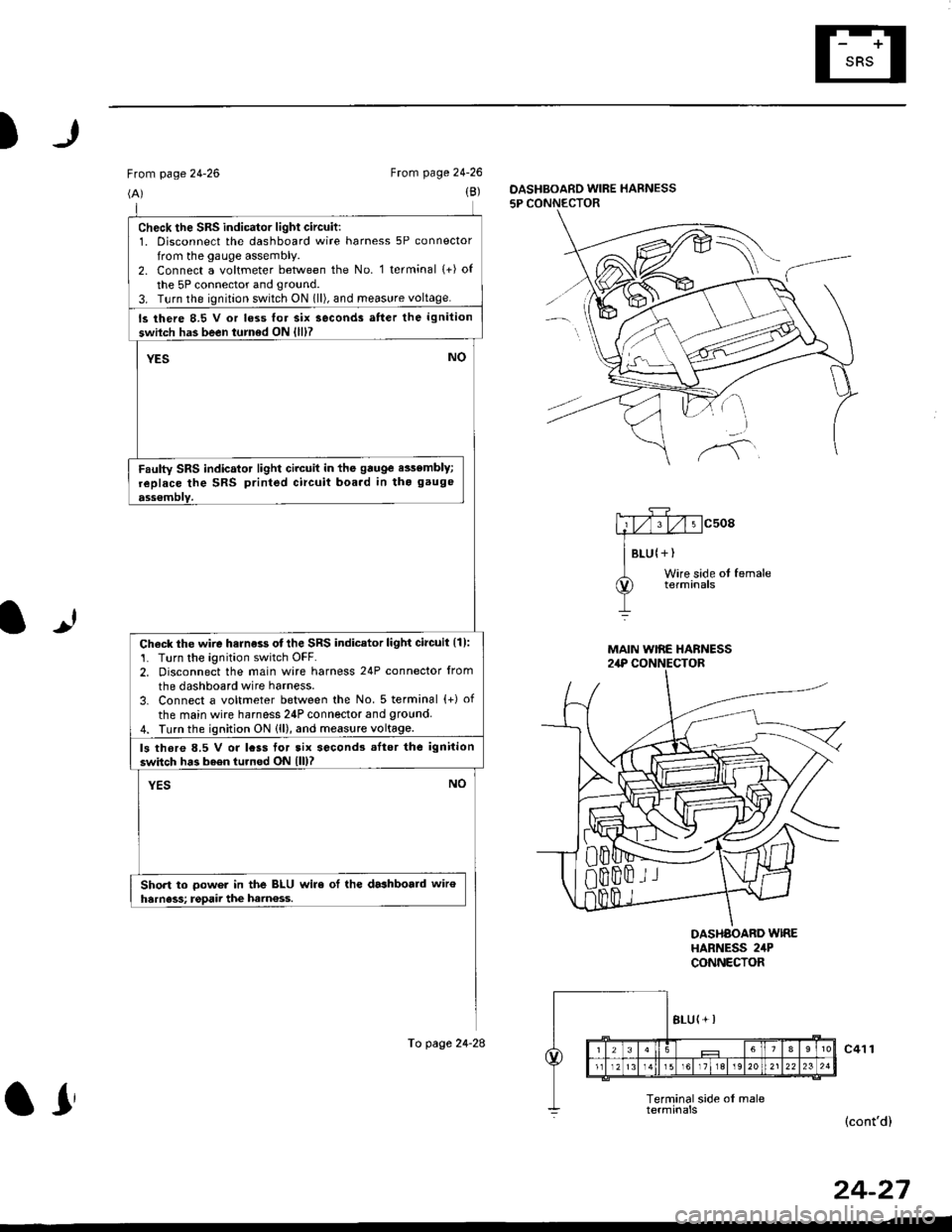

(B)DASHBOARD WIRE HARNESS

5P CONNECTOR

It

MAIN WIRE HARNESS2,rP CONNECTOR

DASHAOARD WIREHARNESS 2irPCONNECTOR

c41 1

(cont'd)

24-27

check the sRs indicator light circuit:1. Disconnect the dashboard wire harness 5P connector

from the gauge assembly.2. Connect a voltmeter between the No. 1 terminal (+) of

the 5P connector and ground.

3. T!rn the ignition switch ON 1ll), and meas!re voltage.

ls there 8.5 V or loss lor six seconds atter the ignition

swilch has been turned ON {lll?

YESNO

Faulty SRS indicator light circuit in the gauge e$embly;

replace the SRS printed circuit boa.d in tho gauge

ass€mblY.

Check the wire harness otthe SRS indicator light circuil {1):'1. Turn the ignition switch OFF.2. Disconnect the main wire harness 24P connector from

the dashboard wire harness.

3. Connect a voltmeter between the No. 5 terminal {+) of

the main wire harness 24P connector and 9round4. Turn the ignition ON (ll), and measure voltage.

ls thore 8.5 V or lcss tor tix second3 .Itor the ignition

switch has b6en turned ON lll)?

YESNO

Short to oower in the BLU wire ol the dashboald wiroharness; rgpaii the ham€ss.

To page 24-28

ar