Fan switch HONDA CIVIC 1998 6.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 975 of 2189

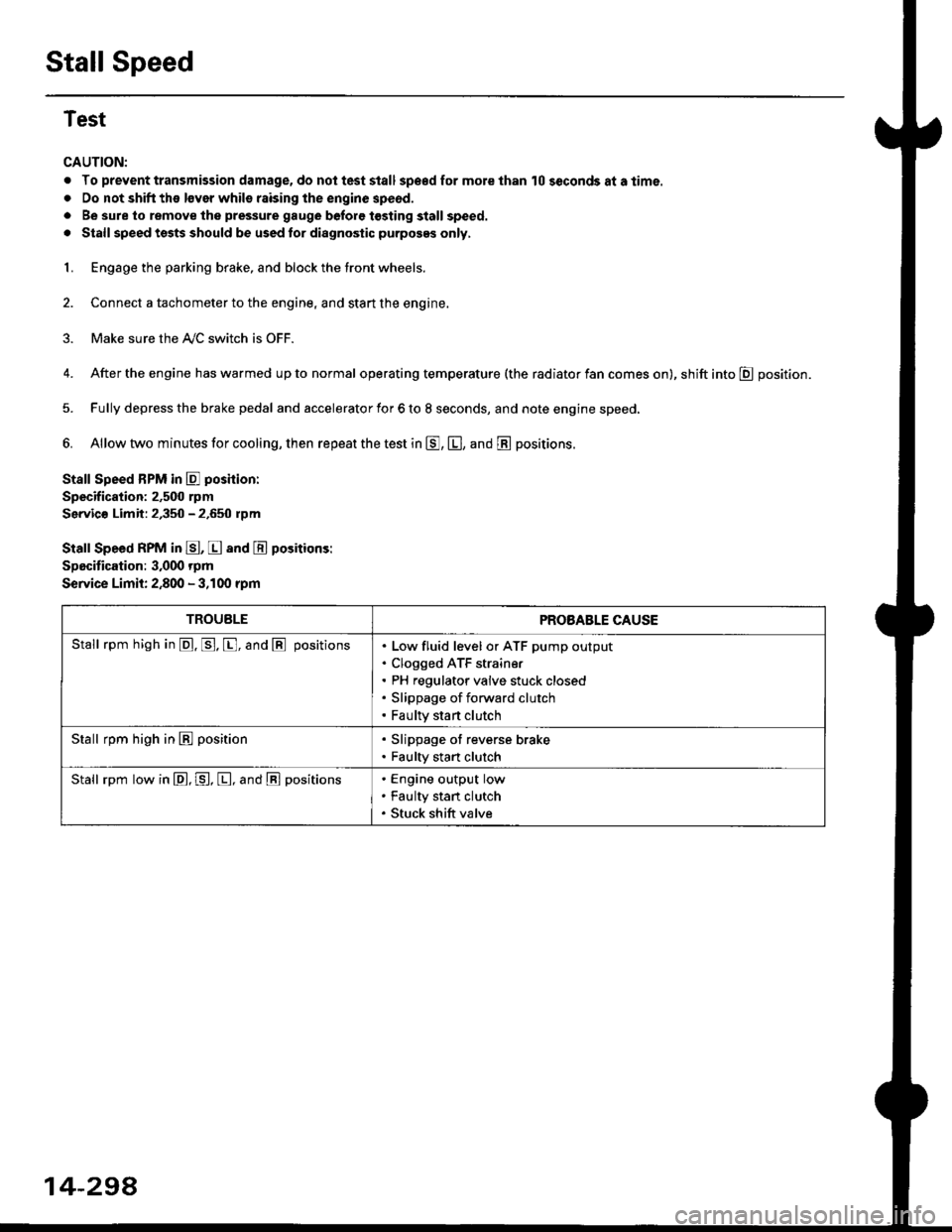

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not test stall sp€€d for mole than 10 seconds at a time.

. Do not shift the lsver whils raising the engine speod.

. Be sure lo remove the pressure gauge before tosting stall speed.

. Stall speed tssts should be used tor diagnostic purposes only,

1. Engage the parking brake, and block the tront wheels.

2. Connect a tachometer to the engine, and stan the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed,

6. Allow two minutes for cooling, then repeat the test in E, E, and E positions.

Stall Speed BPM in E poshion:

Specification: 2,500 rpm

Servic€ Limit: 2,350 - 2.650 rpm

Stall Speed RPM in E, E and E positions:

Specitication: 3,000 rpm

Service Limit: 2,800 - 3,100 rpm

TROUBLEPROBABLE CAUSE

Stall rpm high in @. p. [, and @ positionsLow fluid level or ATF pump output

Clogged ATF strain€r

PH regulator valve stuck closed

Slippage of forward clutch

Faulty start clutch

Stall rpm high in E position. Slippage of reverse brake. Faulty start clutch

Stall rpm low in E, P, [, and @ positionsEngine output low

Faulty stan clutch

Stuck shift valve

14-294

Page 1375 of 2189

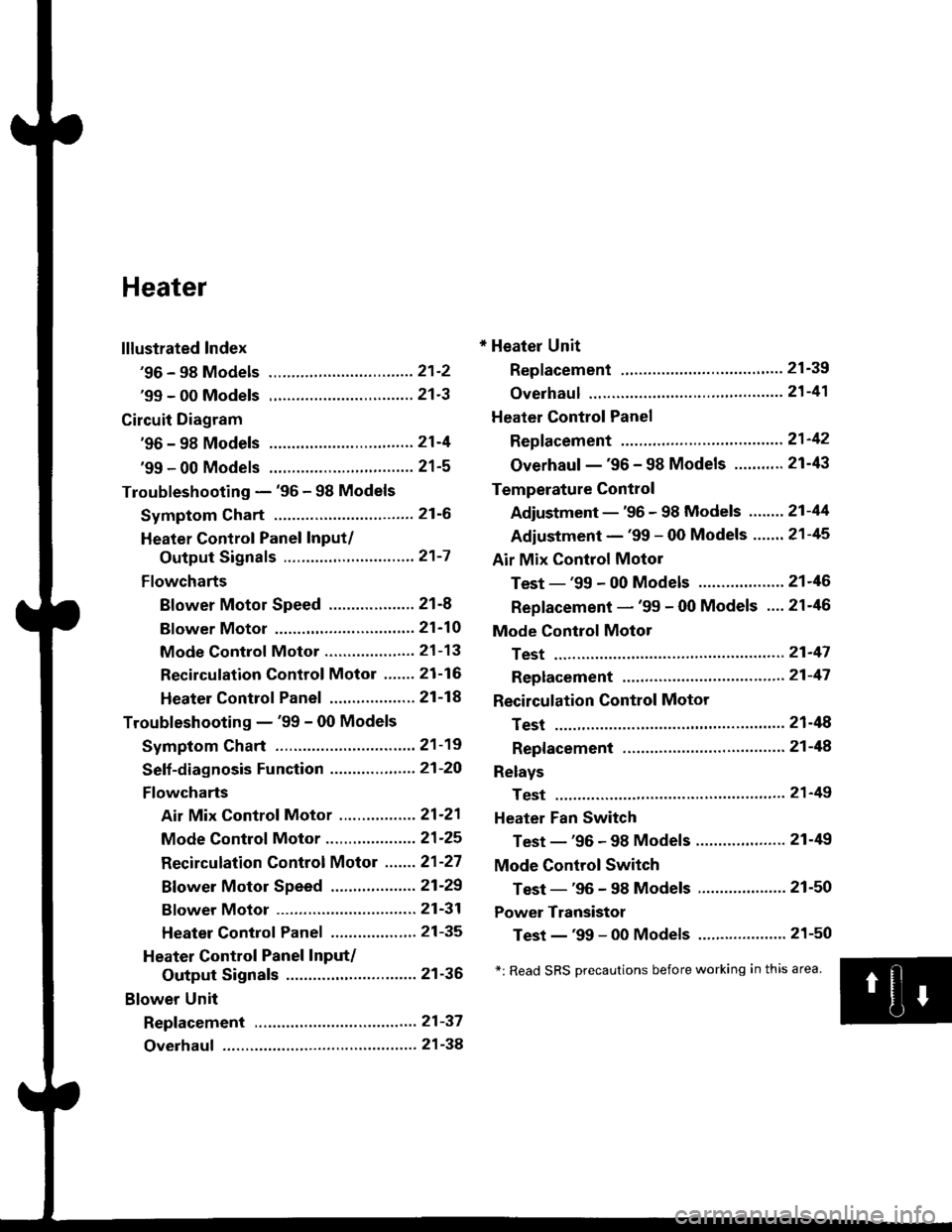

Heater

lllustrated Index

'96 - 98 Models ................................ 21'2

'99 - 00 Models ................................ 21'3

Circuit Diagram

'96 - 98 Models .....21-4

'99 - 00 Models ................................ 21-5

Troubleshooting - '96 - 98 Models

Symptom Chart ............................... 21-6

Heater Control Panel Input/

Output Signals ..............,.............. 21-7

Flowcharts

Blower Motor Speed ................... 21-8

Bf ower Motor ,...21'10

Mode Control Motor ............... ,.'.' 21-13

Recirculation control Motor ....... 21-16

Heater Control Panel ................ ... 21 -14

Troubleshooting - '99 - 00 Models

Symptom Chart ............................... 21-19

Seff-diagnosis Function ............,,,.... 21-20

Flowcharts

Air Mix Control Motor ......,.......... 21-21

Mode Control Motor ............... ..... 21 -25

Recirculation Control Motor ....... 21-27

Bf ower Motor Speed .............. .....21'29

Bf ower Motor ....21-31

Heater Control Panel ................,.. 21-35

Heater Control Panel Input/

Output Signals ............................. 21-36

Blower Unit

Repf acement .........21-37

Overhaul ................ 21-38

* Heater Unit

Replacement ....'....21-39

overhaul """" """' 21-4'l

Heater Control Panel

Repfacement .........21'42

Overhaul -'96 - 98 Models ........... 21-43

Temperature Control

Adjustment - '96 - 98 Models """" 21-44

Adiustment - '99 - 00 Models .......21-45

Air Mix Control Motor

Test - '99 - 00 Models ...........' .......21'46

Replacement - '99 - 00 Models ....21'46

Mode Control Motol

Test ................, .,...'.21'47

Replacement '.'."...21-47

Recirculation Control Motor

Test ................. .......21-48

Repf acement ......." 21-48

Relays

Test ................. .......2'l-49

Heater Fan Switch

Test - '96 - 98 Models ............. .......21-49

Mode Control Switch

Test -'96 - 98 Models ..........."....... 21-50

Power Transistor

Test - '99 - 00 Models ....'........ ....".21-50

*: Read SRS Drecautions before working in this area.

Page 1377 of 2189

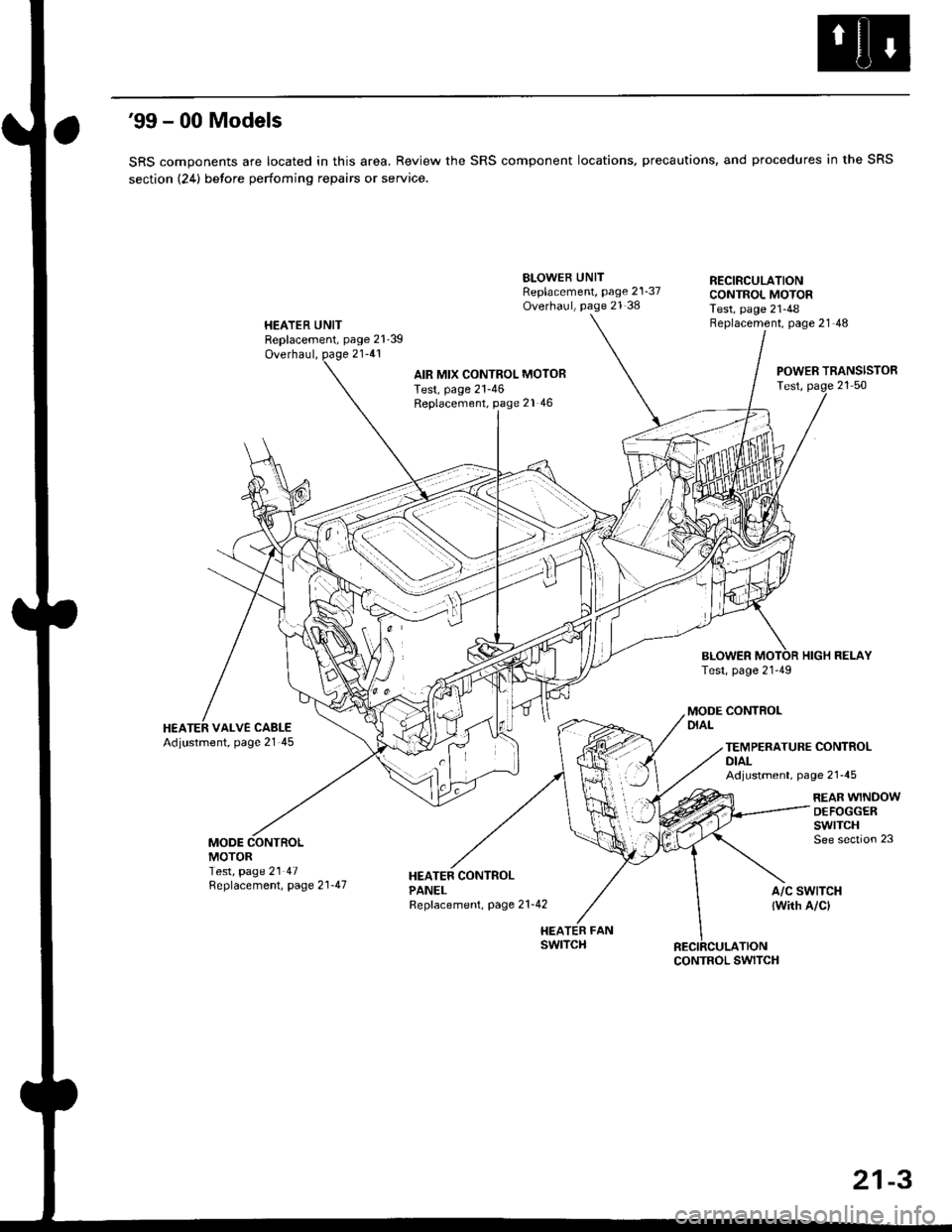

'99 - 00 Models

SRS components are located in this area, Review the SRS component locations, precautions, and procedures in the SRS

section (24) betore perfoming repairs or service.

HEATER UNITReplacement, page 21'39

Overhaul, page 21-41

BLOWEB UNITReplacement, page 21-37Overhaul, page 21 38

HEATER FANswtTcH

RECIRCULATIONCONTROL MOTORTest, page 21-48Beplacement, page 21-48

AIR MIX CONTROL MOTOBTest, page 21-46Replacement, page 21 46

BLOWERTest, page 21-49

POWER TRANSISTORTest, page 21 50

HIGH RELAY

MODE CONTROLDIALHEATER VALVE CABLEAdjustment, page 21 45TEMPERATURE CONTROLDIALAdjustment, page 21-45

REAR WINDOWDEFOGGERswtrcHSee section 23MODEMOTORTest, page 21 47Replacement, page 2 l-47A/C SWTTCH

lwith A/cl

CONTROL SWITCH

21-3

Page 1381 of 2189

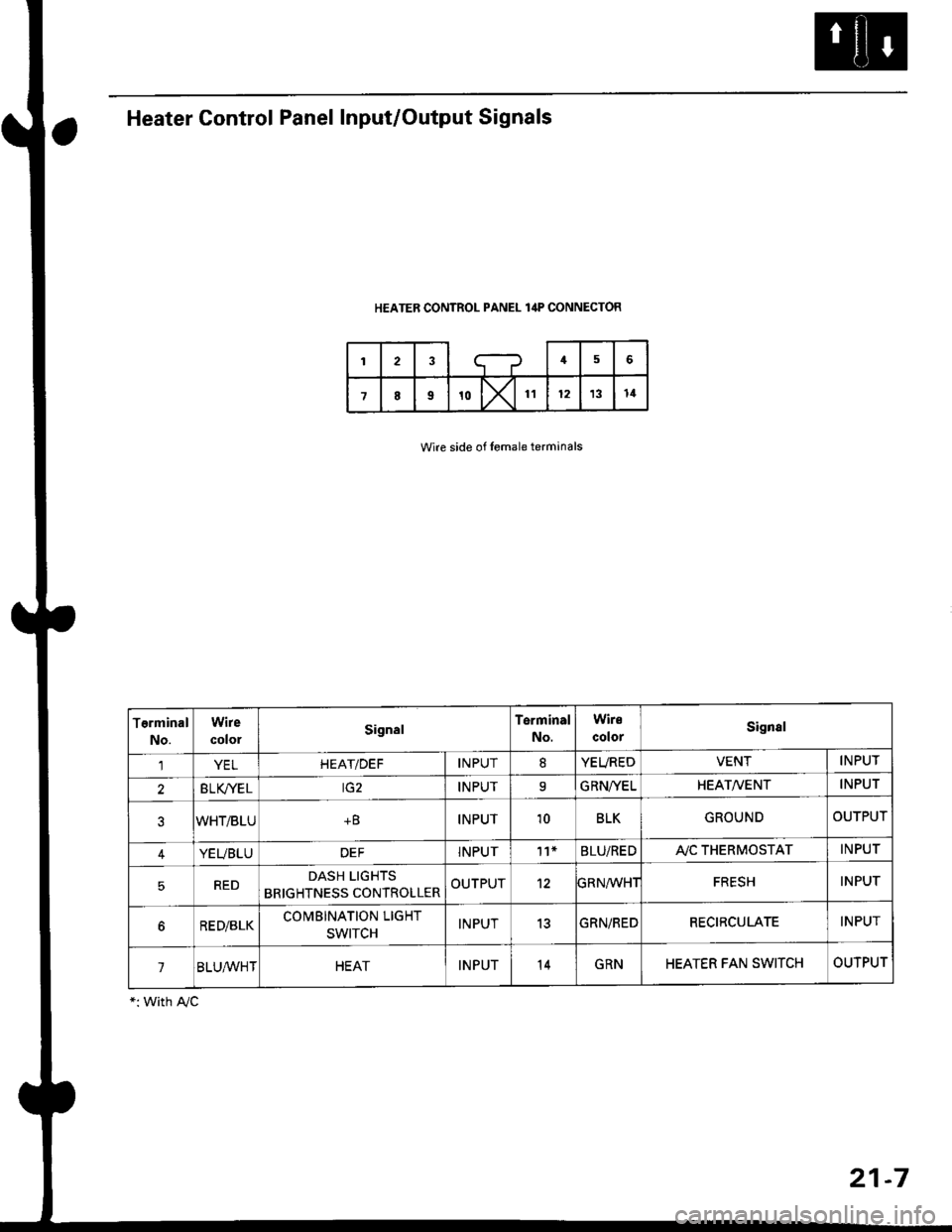

Heater Control Panel Input/Output Signals

HEATER CONTROL PANEL lilP CONNECToR

Wire side of lemale terminals

21-7

Terminal

No.

Wire

colorSignalTerminal

No.

Wire

colorSignal

1YELHEAT/DEFINPUT8YEVREDVENTINPUT

BLfiELINPUT9G RNI/ELHEATIr'ENTINPUT

WHT/BLU+BINPUT'10BLKGROUNDOUTPUT

4YEUBLUDEFINPUT11*BLU/REDA./C THERMOSTATINPUT

5REDDASH LIGHTS

BRIGHTNESS CONTROLLEROUTPUT12GRN/WHTFRESHINPUT

6RE D/8LKCOMBINATION LIGHT

SWITCHINPUT13GRN/REDRECIRCULATEINPUT

1BLUMHTHEATINPUT14GRNHEATER FAN SWITCHOUTPUT

Page 1382 of 2189

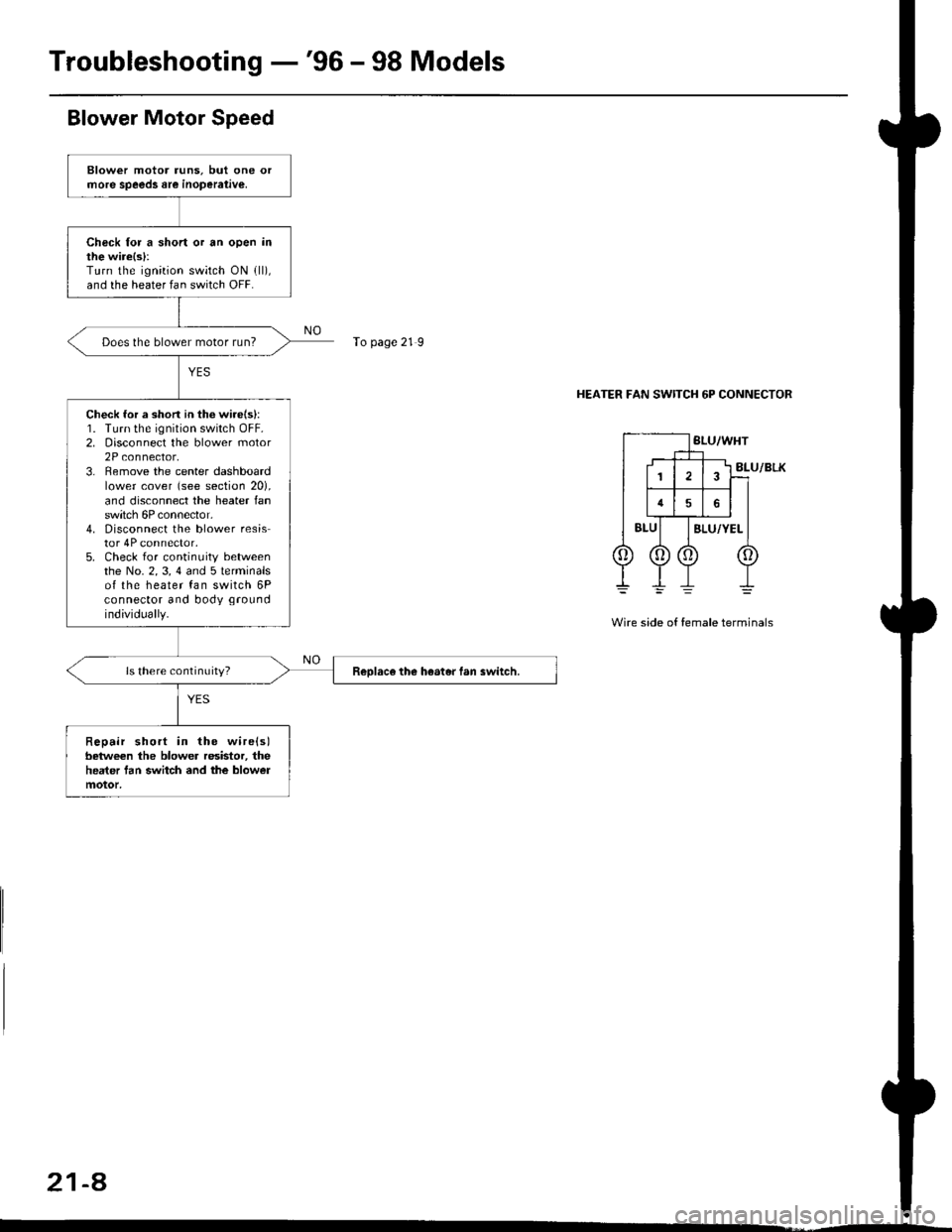

Troubleshooting -'96 - 98 Models

Blower Motor Speed

HEATER FAN SWITCH 6P CONNECTOR

Wire side of female terminals

21-a

Blower motor runs. but one orrnore speeds are inoperative,

Chsck for a short or an open inthe wire{s}:Turn the ignition switch ON {ll),and the heater fan switch OFF.

Does the blower motor run?

Check for a shon in th6 wirels):1. Turn the ignition switch OFF.2. Disconnect the blower motor2P connector,3. Remove the center dashboardlower cover (see section 20),and disconnect the heater lanswitch 6P connector,4. Disconnect the blower resistor 4P connector,5. Check for continuity betweenthe No. 2,3, 4 and 5lerminalsof the heater fan switch 6Pconnector and body ground

individually.

ls there continuity?Reolace the heater fan switch,

Repair short in the wire(s)beiween the blower resistor, theheater tan switch and the blowermotor,

To page 21 9

Page 1383 of 2189

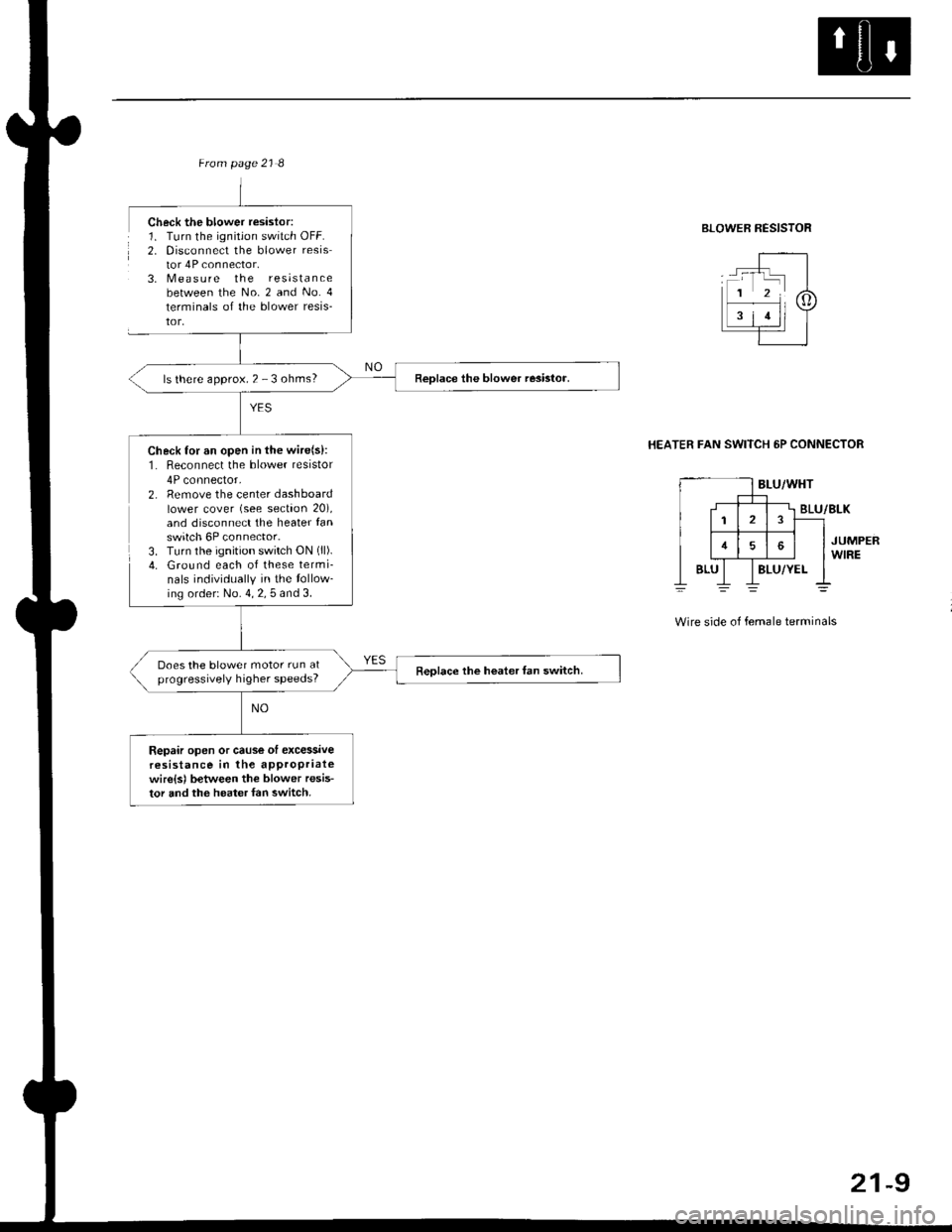

ls there approx. 2 - 3 ohms?

Check for an open in the wire(s):1. Reconnect the blower resistor

4P connector,2. Remove the center dashboardlower cover (see section 20),and disconnect the heater fanswitch 6P connector.3. Turn the ignition switch ON (ll).

4. Ground each of these termi-nals individually in the tollow_ing order: No. 4, 2, 5 and 3.

Does the blower motor run atprogressively higher speeds?Reolace the hoater fan switch.

Repair open or cause ol excessiveresistance in the appropriatewire{sl between the blower resis-tor and the heater {an switch.

Check the blower resislor:1. Turn the ignitjon switch OFF.2. Disconnect the blower resistor 4P connector.3, N4easure the resistancebetween the No. 2 and No. 4

terminals of the blower resis-tor,

BLOWER RESISTOR

HEATER FAN SWITCH 6P CONNECTOR

BLU/WHT

2

16

BLUBLU/YEL

BLU/BLK

JUMPERWIRE

Wire side of female terminals

21-9

Page 1385 of 2189

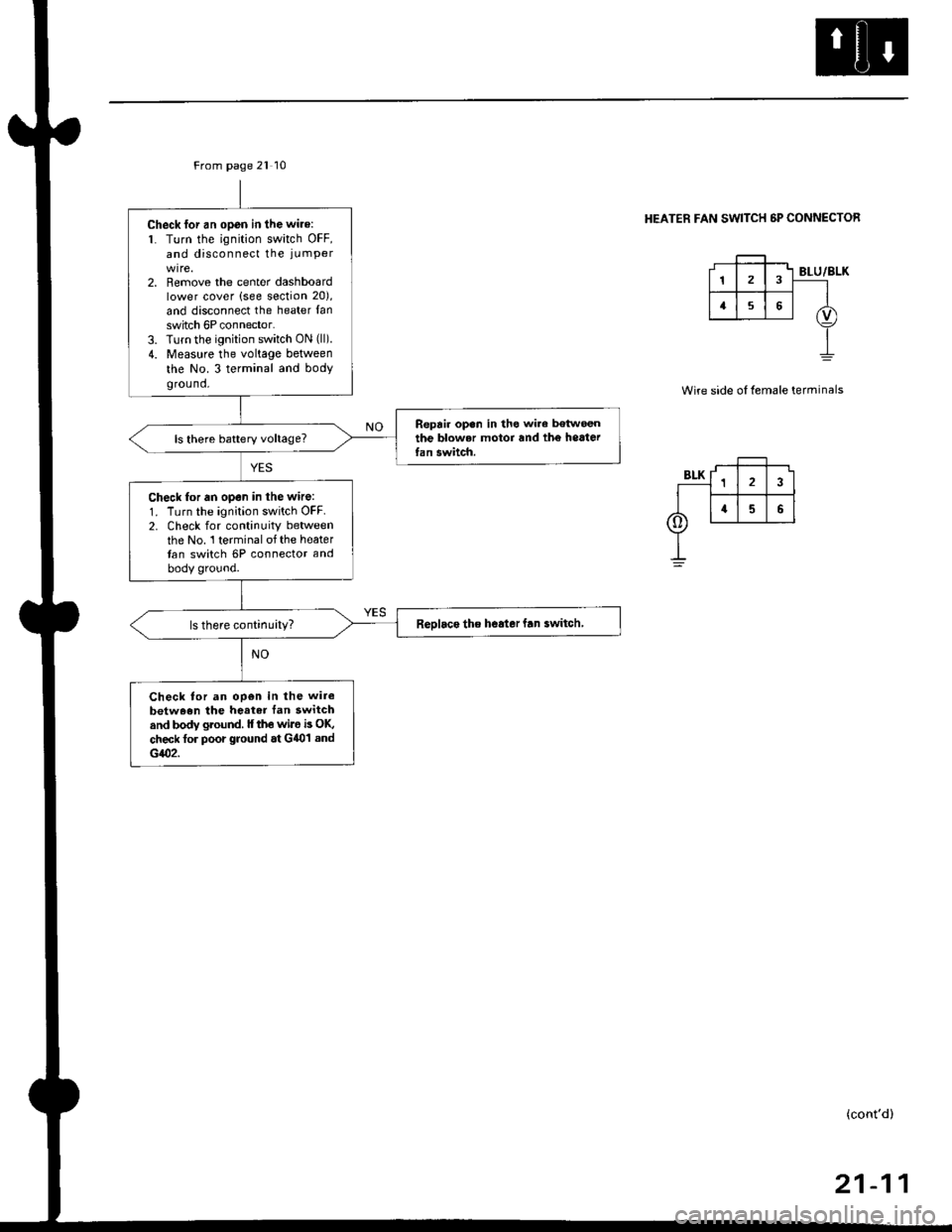

From page 2l 10

Check for an open in the wire:

1. Turn the ignition switch OFF,and disconnect the iLrmPer

2. Remove the center dashboardlower cover (see section 20),

and disconnect the heater fanswitch 6P connector.3. Turn the ignition switch ON (ll).

4. Measure the voltage between

the No. 3 terminal and bodygrou nd.

Repair op.n in th6 wiro betw€enthe blower motor and tho heaterfan switch.

Check for an open in the wire:

1. Turn the ignition switch OFF.2. Check for continuity between

the No. 1 terminal of the heatertan switch 6P connector and

body ground.

Reolaco tho heater fan iwitch

Check tor an op€n in the wire

betw.en the heater tan switchand body ground. ll th€ wilo b OK,

check tor poor ground at G401 and

G102.

HEATER FAN SWITCH 5P CONNECTOR

Wire side oI female terminals

(cont'd)

21-11

Page 1417 of 2189

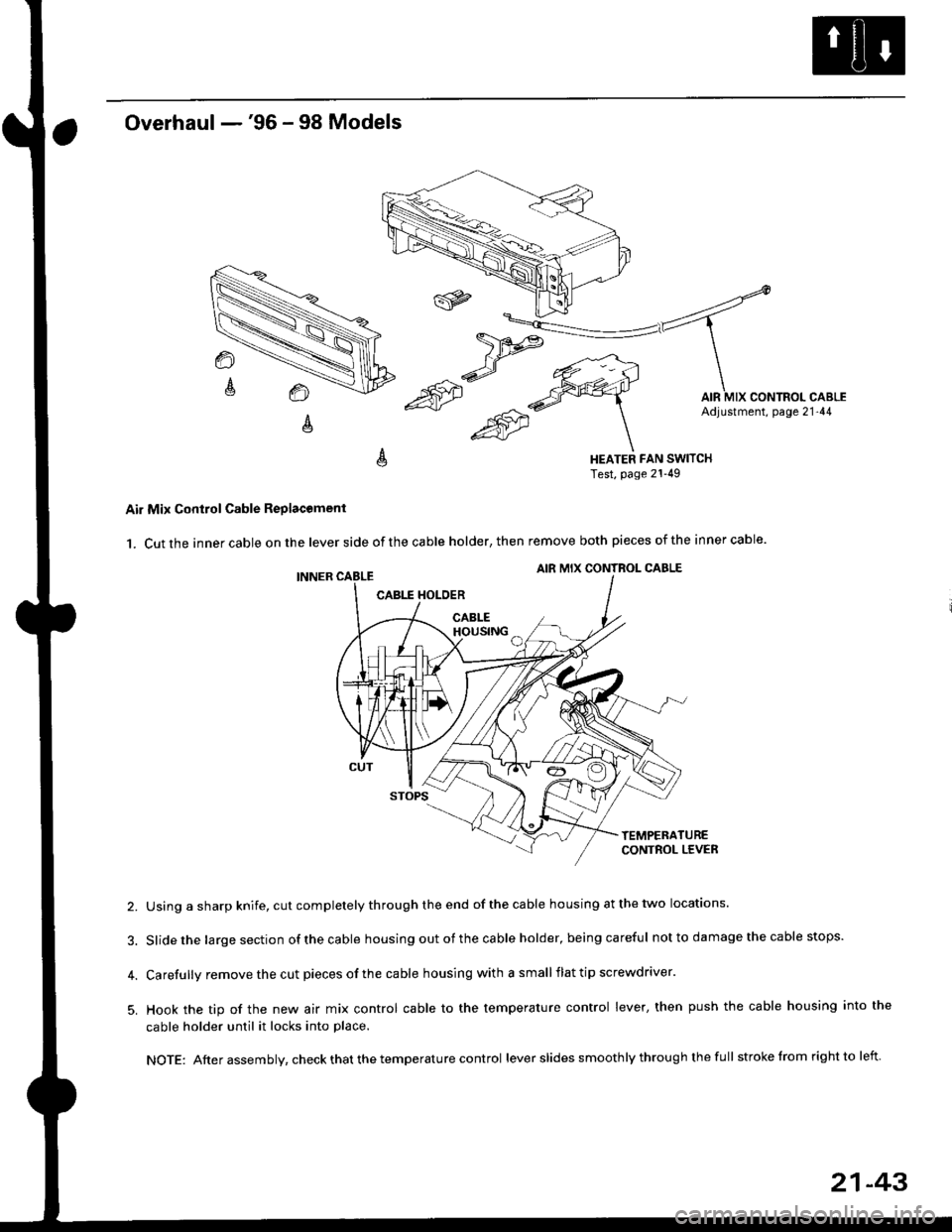

Overhaul -'96 - 98 Models

HEATER FAN SWITCHTest, page 21-49

Air Mix Control Cable Replacomenl

1. Cut the inner cable on the lever side of the cable holder, then remove both pieces of the inner cable.

2. Using a sharp knife, cut completely through the end of the cable housing at the two locations.

3. Slidethe largesection ofthecable housing outofthe cable holder, being careful not to da mage the cable stops.

4. Carefully remove the cut pieces of the cable housing with a small flat tip screwdriver.

5. Hook the tip of the new air mix control cable to the temperature control lever, then push the cable housing into the

cable holder until it locks into place.

NOTE: After assembly, check that the temperature control lever slides smoothly through the full stroke lrom right to left.

21-43

Page 1423 of 2189

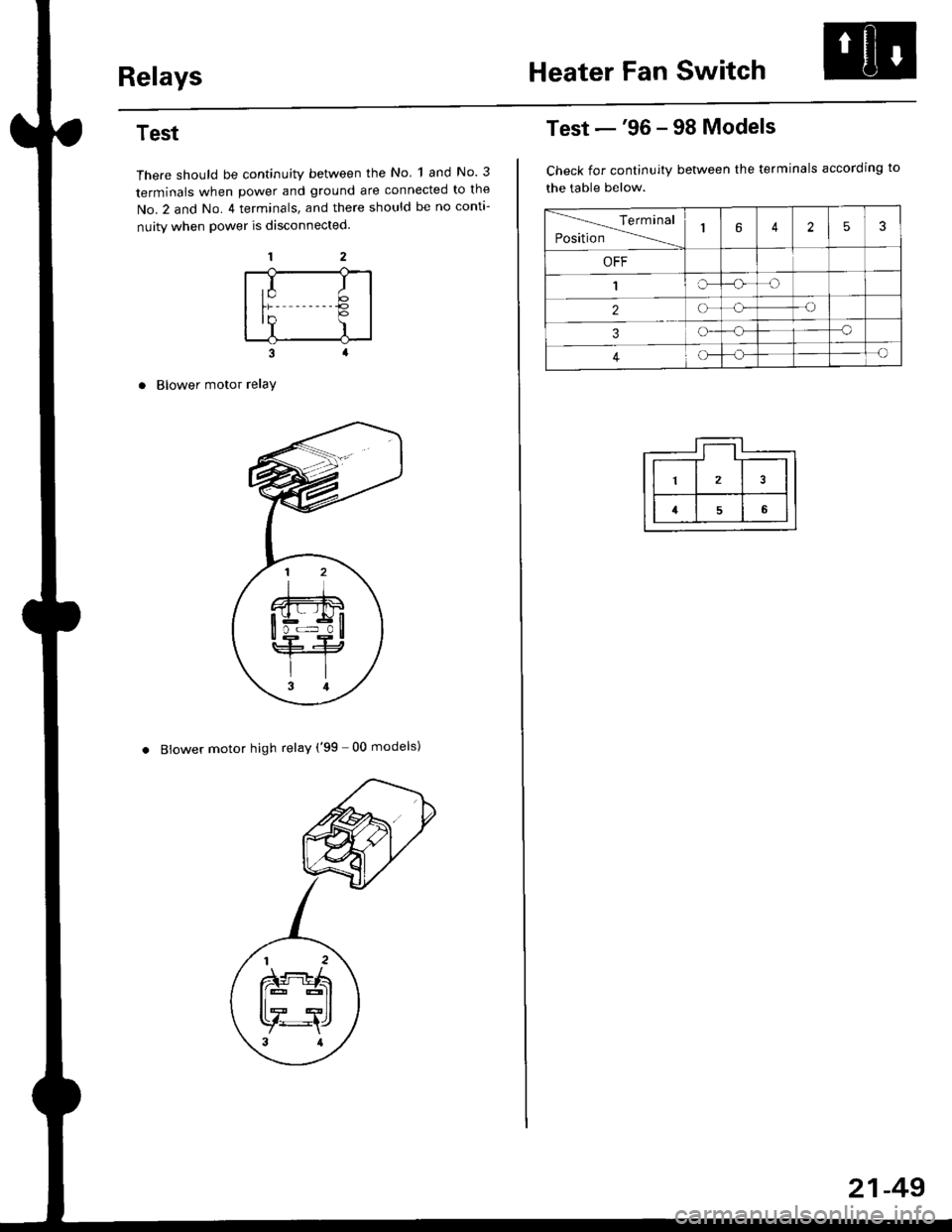

RelaysHeater Fan Switch

Test

There should be continuity between the No 1 and No. 3

terminals when power and ground are connected to the

No.2 and No. 4 terminals, and there should be no conta-

nuity when power is disconnected.

Blower motor relaY

. Blower motor high relay ('99 00 models)

,I It;€'Y )

Test -'96 - 98 Models

Check for continuity between the terminals according to

the table below.

lerminal

Position14253

OFF

1I�rJ

2o-o

3o-a

4c)-{

21-49

Page 1429 of 2189

Description

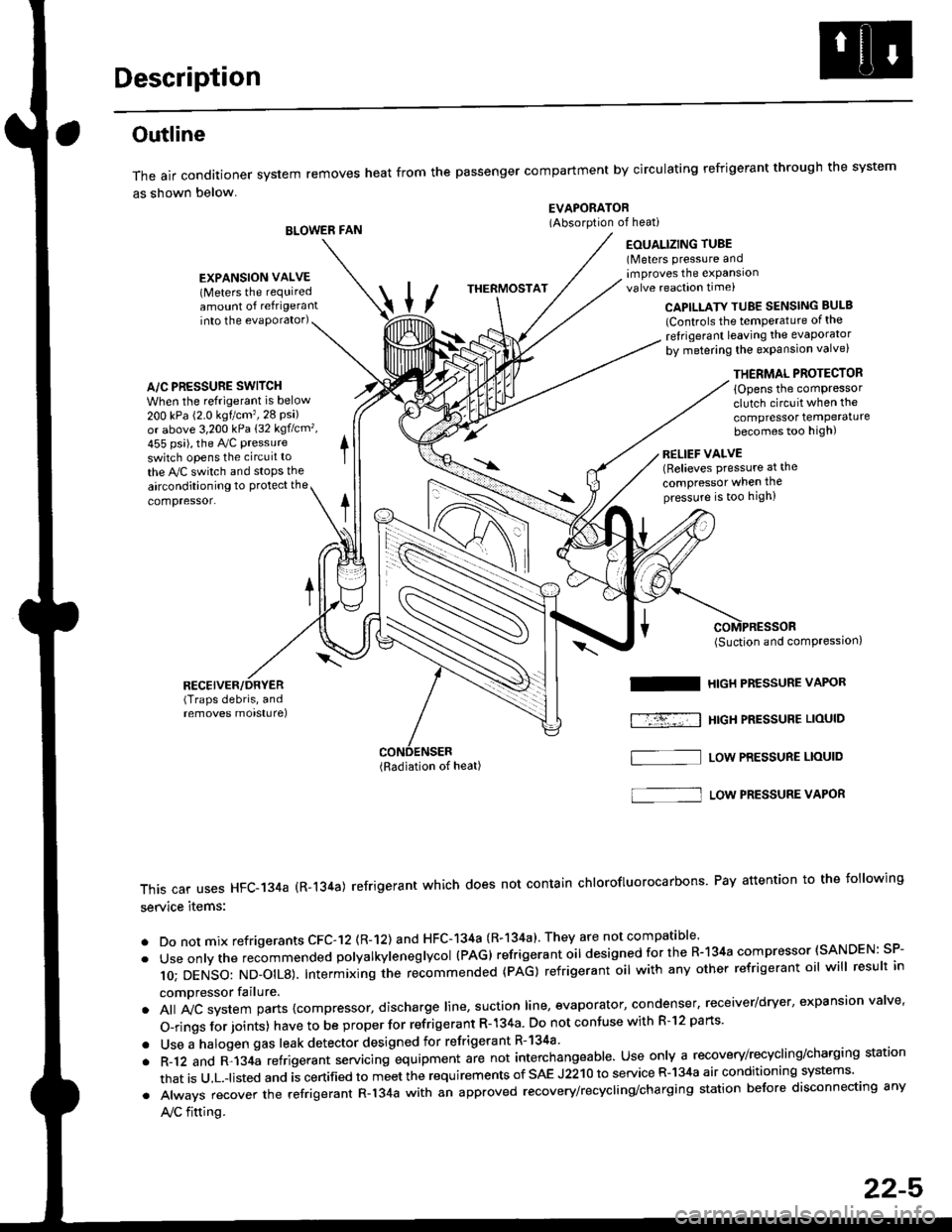

Outline

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

BLOWER FAN

EVAPORATOR(Absorption of heati

EOUALIZING TUBE(Meters pressure andimproves the expansionvalve reaction time)

into the evaporator)CAPILLATY TUBE SENSING BULB

lControls the temPerature of the

ref rigerant leaving the evaporator

by metering the expansion valve)

/\

THERMOSTAT

A/C PRESSURE SWITCH

When the refrigerant is below

200 kPa (2.0 kgtcm'�,28 Psi)or above 3,200 kPa 132 kgflcm',

455 psi), the Ay'C pressure

switch opens the circuit to

the A,/C switch and stops the

EXPANSION VALVE(Meters the requiredamount of refrigerant

airconditioning to Protect the

compressor.

RECEIVER/DRYER(Traps debris, andremoves morsturel

THERMAL PROTECTOR

{Opens the comPressorclutch circuit when the

compressor temPeraturebecomes too high)

RELIEF VALVE(Relieves pressure at the

compressor when thepressure is too high)

(Radiation of heat)

I

f-r-�-; I

(Suction and comPression,

HIGH PRESSURE VAPOR

HtGH PRESSUBE LIOUID

LOW PRESSURE LIOUID

This car uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons Pay attention to the following

service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a)' They are not compatible'

. Useonlythe recommended polyalkyieneglycol (PAG) refrigerant oil designedforthe R-134a compressor (SANDEN: SP-

10; DENSO: ND_OIL8). Intermixing ihe re-commended (pAG) refrigerant oil with any other refrigerant oil will result in

compressor failure.

. All A,,ic system parts {compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve'

O-rings for joints) have to be proper for refrigerant R- 134a Do not confuse with R-l2 parts'

. Use a halogen gas leak detector designed for refrigerant R-134a

. R-12 and R-134a refrigerant servacing equipment are not interchangeable. Use only a recovery/recycling/charging station

that is u,L.-listed and is certified to meet the requirements of sAE J2210 to service R-134a air conditioning systems'

. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting any

A,/C fitting.

S]

22-5