PC box HONDA CIVIC 1998 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 948 of 2189

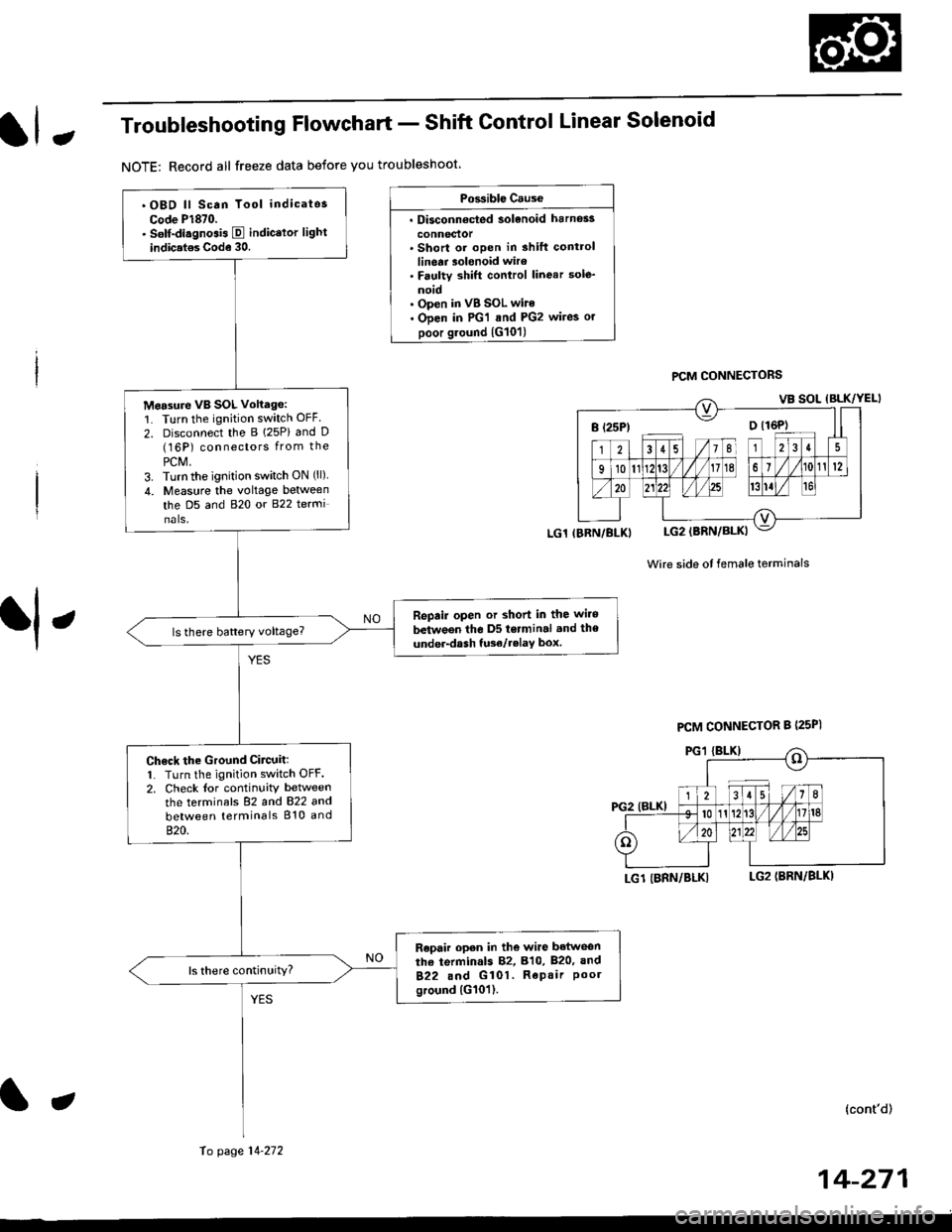

JTroubleshooting Flowchart - Shift Control Linear Solenoid

NOTE: Record all freeze data before you troubleshoot

Possiblc Cause

. Disconn€cted solenoid harnos3

connectol. Short or oDen in shilt controllinetr solonoid wiro. Faulty shift control linear sole_

noid. Op€n in VB SOL wite. ODen in PG'l and PG2 wires or

poor ground {G10'l)

f,

wire side ot female terminals

LG1 IBRN/BLKILG2IBRN/BLK)

{cont'd)

14-271

PCM CONNECTORS

B(25P) - Dll6P)

.OBD ll Scan Tool indicatos

Code P1870.. Solf-diagnosis E indic.lor light

indic.t€s Code 30.

M6a3ure VB SOL voltage:1. Turn the ignition switch OFF.

2. Disconnect the B 125P) and D(16P) connectors from the

PCM,3. Turn the ignition switch ON (ll).

4. Measure the voltage between

the D5 and 820 or 822 terminals.

Repair open or shod in the wire

between the D5 terminal and the

under-dash tuso/telay box.

Check the Ground Circuitl1. Turn the ignition switch OFF.2. Check lor continuity between

the terminafs 82 and 822 and

between terminals 810 and

820.

Repair open in the wi.e betwoen

the termin.ls 82, B10, B20, and

822 and G101. Repair Poolground (G101).

LG1 IBRN/BLKI

PCM CONNECTOR B PsPI

PG,I IBLK)

10 page 14-272

a

Page 950 of 2189

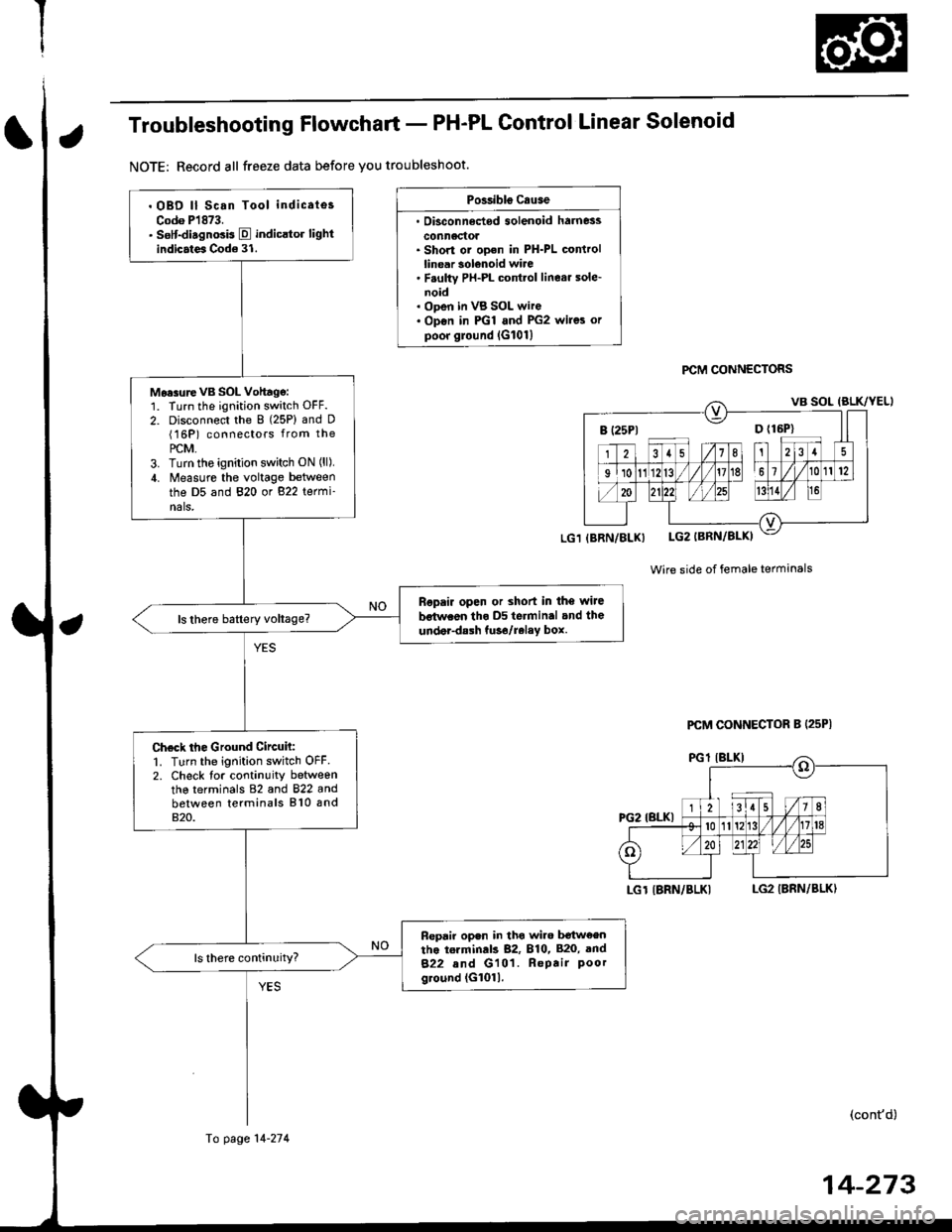

Troubleshooting Flowchart - PH-PL Control Linear Solenoid

NOTE: Record all freeze data before you troubleshoot.

Possibls c.use

. Oisconn6dod solenoid harness

conn6ctol. Short or ooen in PH-PL controllinear solenoid wire. F.ulty PH-PL cont.ol linear sole-noid. ODen in VB SOL wire. Op€n in PGl and PG2 wires orpoor ground lG101l

PCM CONNECTORS

Wire side of female terminals

LGT IBRN/BLKILG2 IBRN/BLK)

(cont'd)

B (25P1 D {16P}

. OBD ll Scan Tool indicates

Codo P1873.. sslt-disgnosis E indicltor lightindicates Code 31.

Mo.surevB SOL Vohagg:1. Turn the ignition switch OFF.

2. Disconnect the 8 (25P) and D(16P) connectors from the

PCM,3. Turn tho ignition switch ON (ll),

4. Measure the voltage between

the D5 and 820 or 822 termi-nals,

Ropair open or shod in the wiJe

bstwaon tho D5 terminal and the

under-dalh tuso/relay box.

Check the Ground Circuh:1. Turn the ignition switch OFF2. Check tor continuity betweenthe terminals 82 and 822 andbetween terminals 810 and820.

Fepair open in tho wiro b€tw€entho torminds 82, 810, 820, and

822 and G101. Repair Poorground (G1011.

(BRN/BLX)

Fo page 14-274

PCM CONNECTOR B (25P|

14-273

Page 952 of 2189

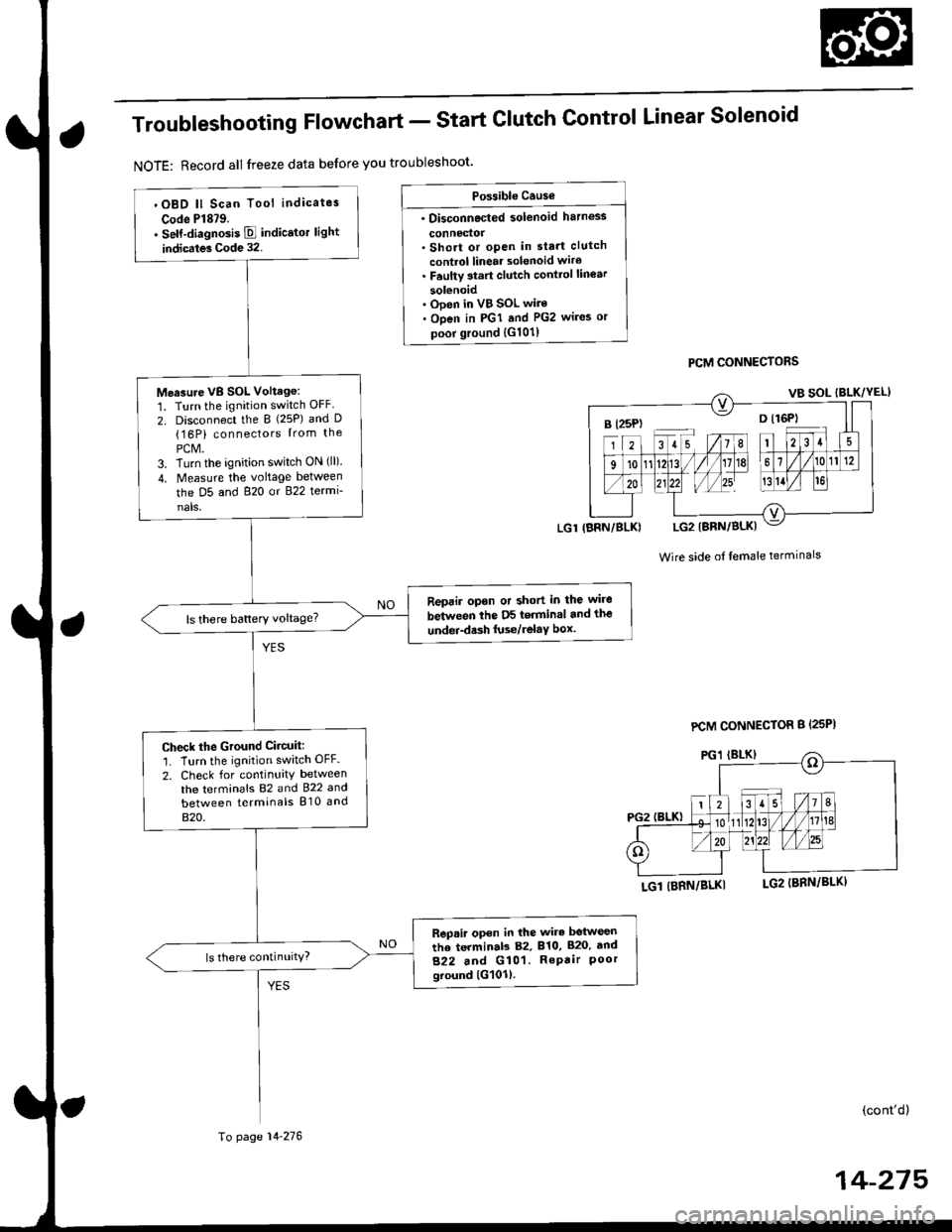

Troubleshooting Flowchart - Start

NOTE: Record all freeze data before you troubleshoot'

Clutch Control Linear Solenoid

PCM CONNECTORS

Wire side of lemale terminals

LGl (BRN/BLKI

(cont'd)

14-215

Po$ible Cause

. Disconnected solenoid harness

connedol. Short or open in sta.t clutch

control linear solenoid wiro. Faulty 3tart clutch conttol lin€ar

solenoid' Ooen in VB SOL wire. Open in PGI and PG2 wires or

poor ground {G101)

B l25P) -- o l16P)

'OBD ll Scan Tool indicates

Code Pl879.. self-diagnosis E indicstor light

indicates Code 32.

Measure VB SOL Voltag6:

1. Turn the ignition switch OFF

2. Disconnect the B {25P) and D(16P) connectors {rom the

PCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage between

the D5 and 820 or 822 termi-

nals,

Reprir opon or short in the wire

between the D5 terminal and the

undei-d.sh luse/relaY box.ls there battery voltage?

Check the Ground Ciicuit:'1. Turn the ignition switch OFF.

2. Check for continuity between

the terminafs 82 and 922 and

between terminals 810 and

820.

Rep.ir open in the wire betwesn

the terminab 82, 810, 820. tnd

822 and G101. RePair Poorground lG101l.

ls there continuity?

LGl IBRN/BLK)

To page 14-276

PCM CONNECTOR B {25PI

Page 954 of 2189

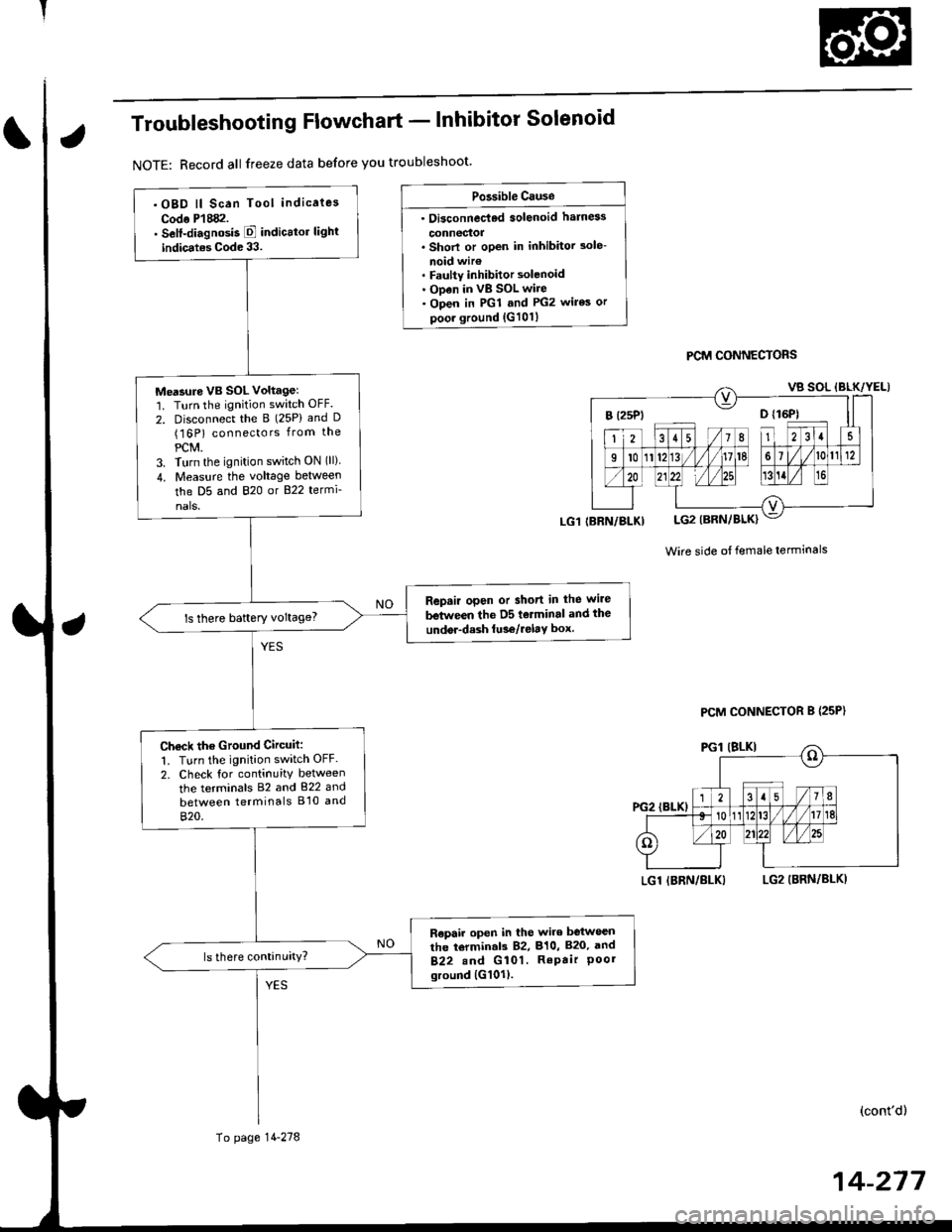

Troubleshooting Flowchart - lnhibitor Solenoid

NOTE: Record all freeze data before you troubleshoot'

Po3sible Cause

. Oi3connec'ted solenoid harn6s

connectoa. Shorl or open in inhibitor 3ole-

noid wir€. Faulty inhibitor solenoid. ODen in vB SOL wire. Open in PGl and PG2 wires or

poor ground {G101}

PCM CONNECTORS

Wire side ot female terminals

LGl IBRN/BLKILG2 (BRN/BLKI

(cont'd)

14-217

.OBD ll Scan Tool indicaies

Codo P'l882.. Self-diagnosis E indicttor light

indic.tes Code 33.

Me'sure VB SOL voltagel'1. Turn the ignition switch OFF.

2. Disconnect the B (25P) and D(16P) connectors from the

PCM.3. Turn the ignition switch ON (ll)

4. Measu.e the voltage between

the D5 and 820 or B22 termi-

nals.

Repair open or short in the wire

between the D5 tolminal and the

undor-dash lu36/relay box.ls there baftery voltage?

Ch€ck the Ground Circuit:

1. Turn the ignition switch OFF.

2. Check tor continuity between

the terminals 82 and 822 and

between terminals B'10 and

820.

R€pair open in the wire between

the torminal3 82, 810, B20, and

B22.nd G 101. RePair Poorground {G101).

(BRN/BLKI

To page 14-278

PCM CONNECTOR B {25P}

Page 965 of 2189

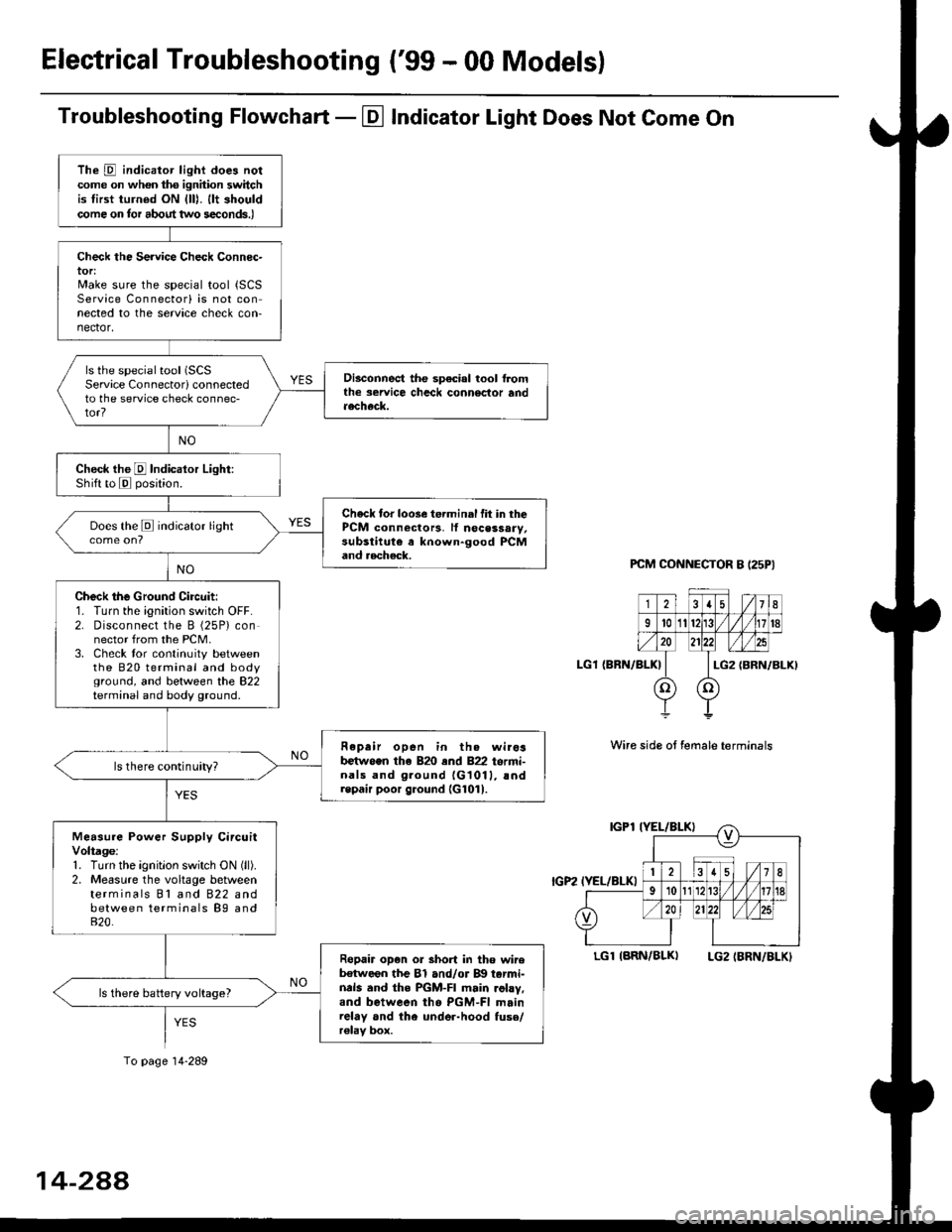

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - El Indicator Light Does Not Come On

PCM CONNECTOR B I25PI

LGl {BRN/BLK)

Wire side ot female terminals

LGlIARN/BLK) LG2IBRN/BLKI

The D indicator light does notcome on whon ths ignhion switchis tirst turned ON {lll. llt shouldcome on tor about two s€conds.)

Check the Service Check Connec-tor:Make sure the special tool {SCSService Connectorl is not connected to the service check con-nector,

ls the special tool (SCS

Service Connectorl connectedto the service check connec-tor?

Disconnect the sp€cial tool f]omthe seruice chcck connoclor andaecheck.

Check the E Indicalor Light:Shift to E posjtion.

Check tor loose te.minal fit in thePCM connectors, lf nocessary,substitute a known-good PCMand aecheck.

Does the E indicator light

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) connector from the PCM.3. Check tor continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Fepair open in th. wirosb€tw.en the 820 end 822 termi-nals and ground {G1011, !ndrepair poor ground {G1011.

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignitlon switch ON (ll).

2. Measure the voltage betweenterminals Bl and 822 andbetween terminals B9 and820.

Ropair op€n or short in tho wireb€tween the Bl and/or B!| tarmi-nds and the PGM-FI main .ohy,and between tho PGM-FI mainrelay and the under-hood fuso/r€lav box.

ls there battery voltage?

To page 14-289

14-2AA

Page 1057 of 2189

l.

t

Steering

Speciaf Tools ....."'.....17-2

Manual Steering

Component Locations

lndex ................ ....... 17-3

Inspection and Adiustment

Steering Operation "'......"............... 17-4

Rack Guide Adiustment ................... 17-5

*Steering Wheel

(See power steering section)

*Steering Column

(See power steering sectionl

Steering Gearbox

Removal ................. 17-5

Disassembly ......."" 17-7

ReassemblY ..'......... 17-9

lnstallation ............. 17-13

Power Steering

Component Locations

lndex "......."..... """' 17-15

System DescriPtion

Fluid Flow Diagram .........""............. 17'16

Steering Pump ............'... "........"'...-- 17 -17

Steering Gearbox .".................'...'.'.' 17-20

Troubleshooting

Generaf Troubleshooting ..........--.... 17'22

Noise and Vibration ......................... 17 -26

Ffuid Leaks .............17-28

Inspection and Adiustment

Steering Operation'......."'........'...... 1 7-30

Power Assist Check

With Vehicle Parked .."................ 17-30

Steering Linkage and Gearbox ....." 17-31

Pump Beft ...--.""".. 17-32

Rack Guide Adiustment .'.......'.......'. 17'33

Fluid Replacement .....'.."................. 17-33

Pump Pressure Check .............'....-. " 17 -34

'Steering Wheel

Removal .."'........'... 17-35

lnstallation ............. 17-35

Disassembly/Reassembly ......'.....'.' 17-36

*Steering Column

Removal/lnstallation ....'........... ---.... 17'37

lnspection .............. 17'38

Power Steering Hoses, Lines

Fluid Leakage Inspeetion ............'.... 17-39

Replacement ......".. 17-39

Power Steering PumP

Removal/lnstallation .'.'..'..'............. 17-40

Disassembly ".........17-41

fnspection .......---'." 17'42

Reassembly ..'.........17-44

Steering Gearbox

Removal ....'........."' 17'47

DisassemblY ..........' 17-49

Reassembly '........... 17-55

lnstallation ............. 17-65

Ball Joint Boot Replacement .......'.. 17-68

Ir/

lp

Page 1059 of 2189

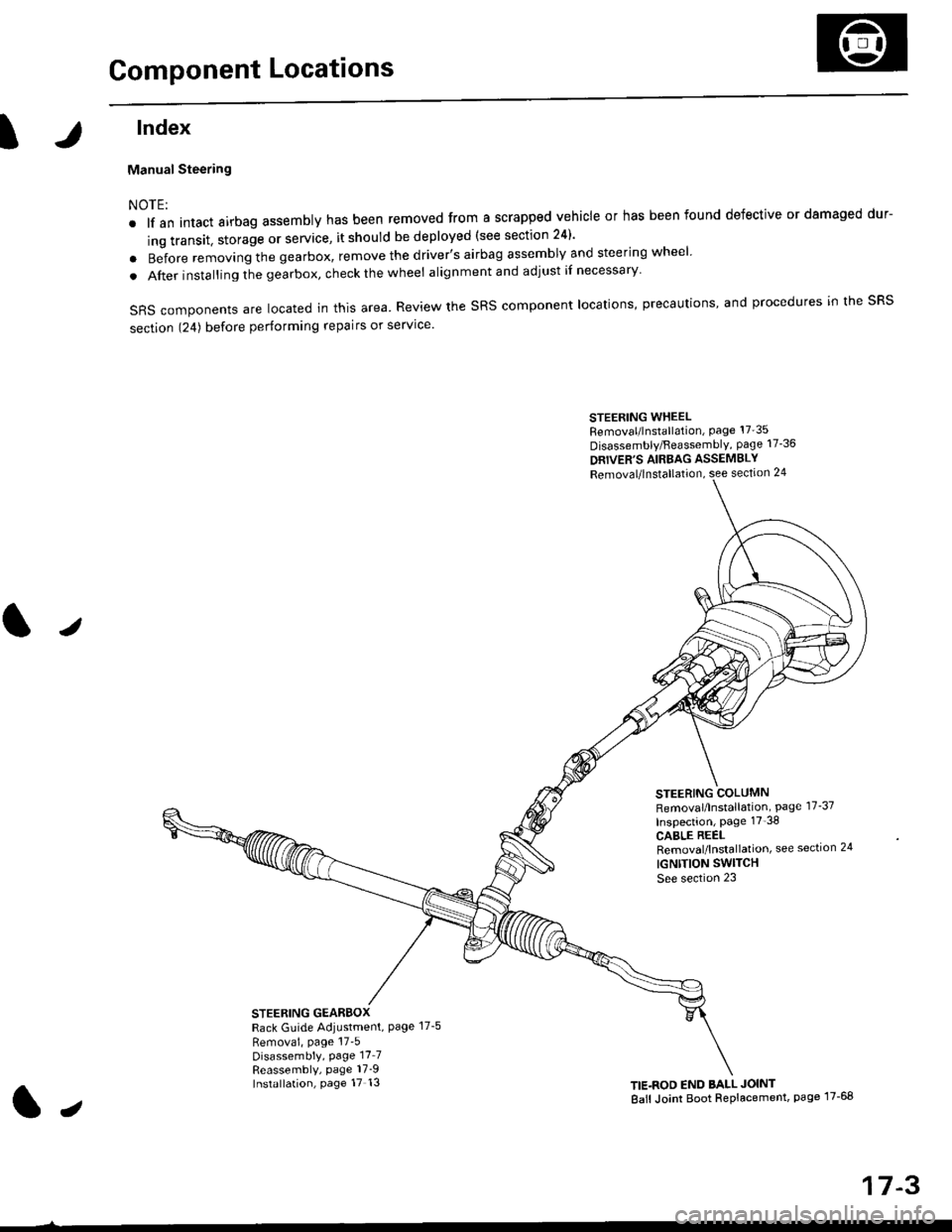

Component Locations

tlndex

Manual Steering

NOTE:

. lf an intact airbag assembly has been removed from a scrapped vehicle or has been found defective or damaged dur-

ing transit. storage or service, it should be deployed (see section 24)'

o Before removing the gearbox, remove the driver's airbag assembly and steering wheel

. After insta lling the gearbox, check the wheel alignmentand adjust if necessary

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section 124) before performing repairs or service'

STEERING WHEELRemoval/lnstallation, Page 17'35

Disassembly/FeassemblY, page 17-36

DRIVER'S AIRBAG ASSEMBLY

Removal/lnstallation, see section 24

STEERING COLUMNRemoval/lnstallation, Page 17-37

Inspection, page 17'38

CABLE REELRemoval/lnstallation, see section 24

IGNTTION SWITCH

See section 23

STEERING GEARBOXRack Guide Adiustment, Page 17-5

Removai, page 17'5Disassembly, Page 17_7Reassembly, page 17_9Installation, page 17 13TIE.ROD END BALL JOINT

Ball Joint Boot Replacement, page 17-68

J

t,

17-3

Page 1060 of 2189

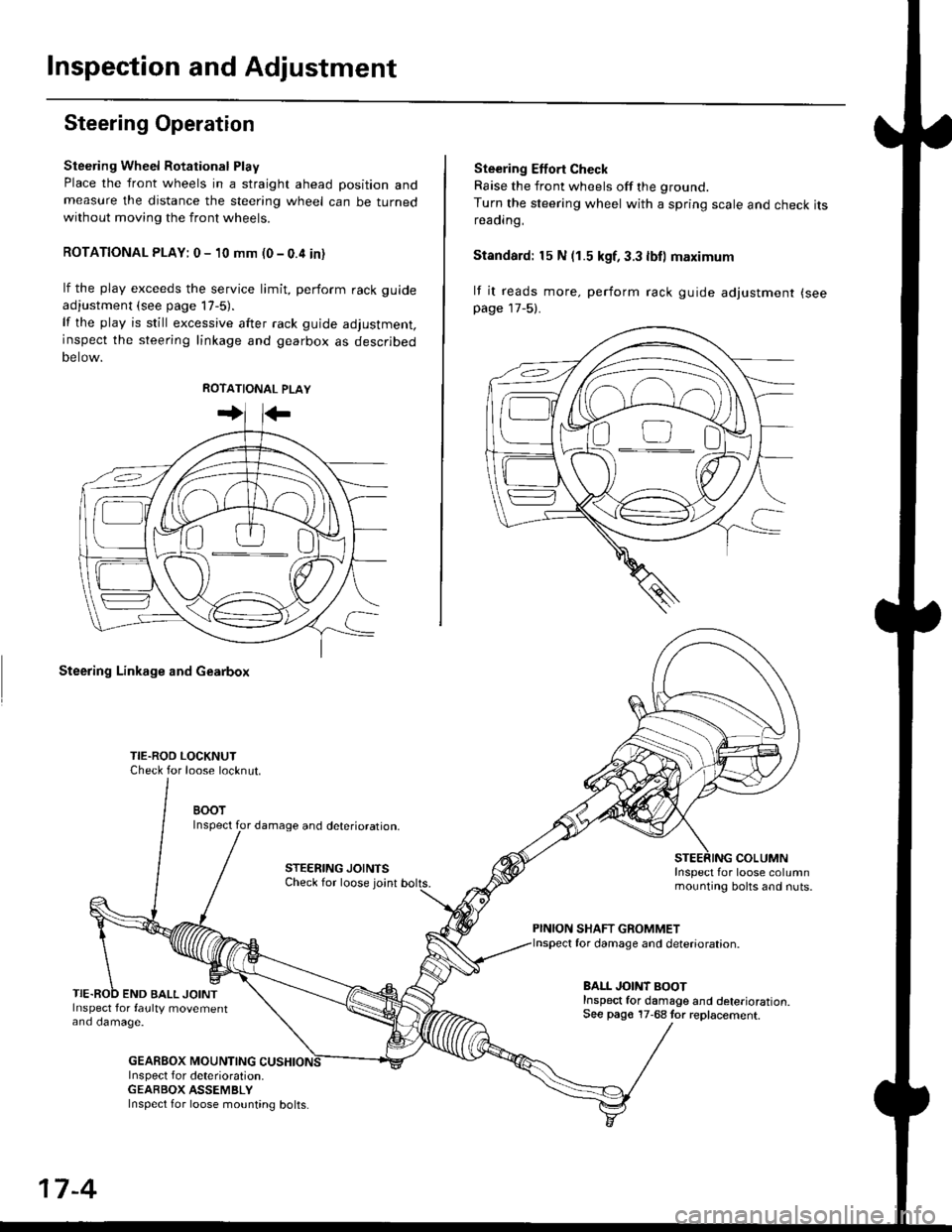

Inspection and Adjustment

Steering Operation

Steering Wheel Rotational Play

Place the front wheels in a straight ahead position andmeasure the distance the steering wheel can be turnedwithout moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.4 in)

lf the play exceeds the service limit, perform rack guide

adjustment (see page lT-5).

lf the play is still excessive after rack guide adjustment,inspect the steering linkage and gearbox as descrjbed

Detow.

Steering Linkage and Gearbox

TIE.ROO LOCKNUTCheck for loose locknut.

BOOTInspect for damage and deterioration.

STEERING JOINTSCheck for loose joint

END BALL JOINTInspect for faulty movementano oamage.

GEABBOX MOUNTINGInspect f or deterioration.GEABBOX ASSEMBLY

Ste€ring Effort Check

Raise the front wheels off the ground.

Turn the steering wheel with a spring scale and check itsreaorng,

Standard: 15 N (1.5 kgf, 3.3 lbll maximum

lf it reads more. perform rack guide adjustment (see

page 17-5).

COLUMNInspect for loose columnmounting bolts and nuts.

PINION SHAFT GROMMETfor damage and deterioration.

BALL JOINT BOOTInspect for damage and deterioration.See pago 17-68 tor replacement.

ao-\---------U

17-4

Inspect for loose mounting bolts.

Page 1061 of 2189

Steering Gearbox

l.r

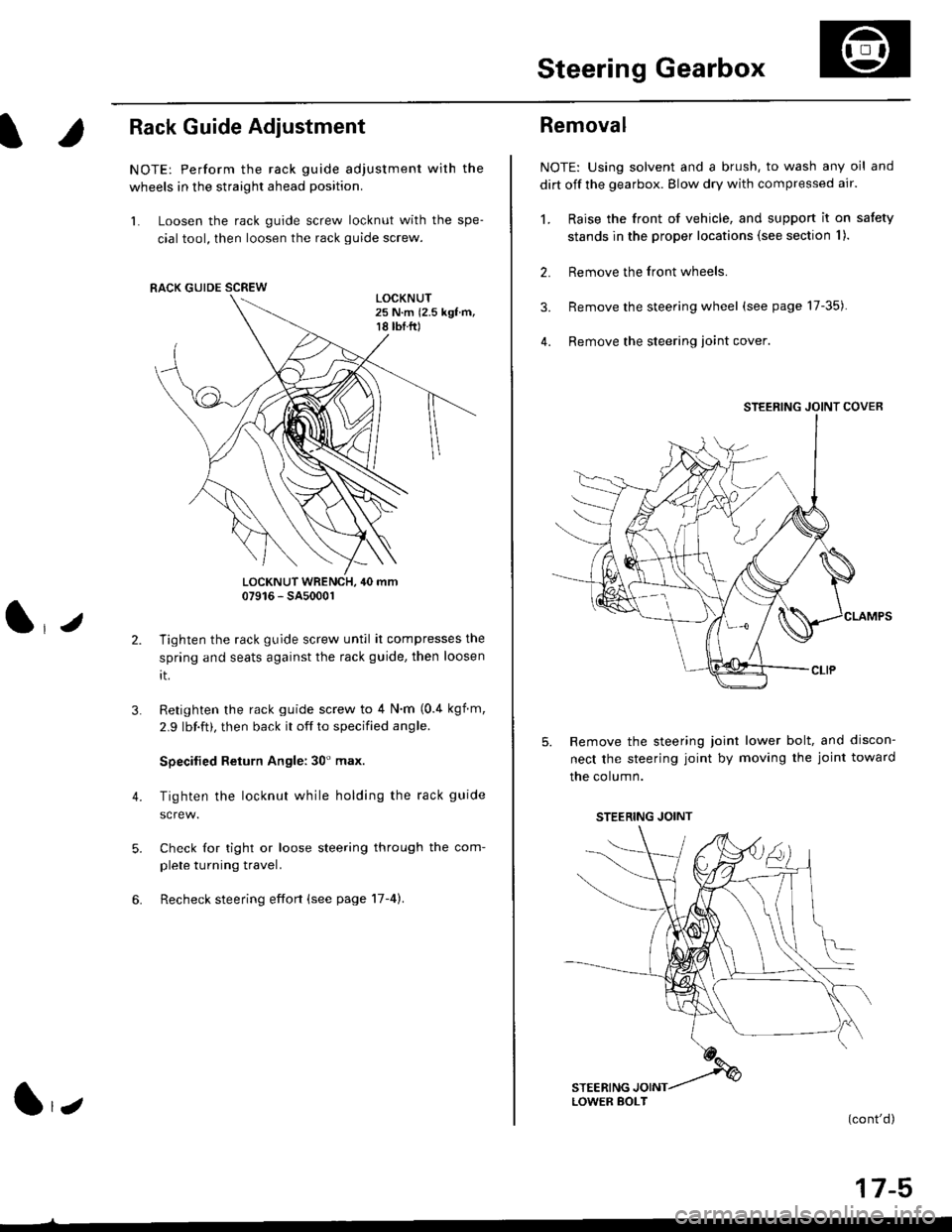

Rack Guide Adjustment

NOTE: Perform the rack guide adjustment with the

wheels in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cial tool, then loosen the rack guide screw.

LOCKNUT WRENCH, 40 mm07916 - SA5000r

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

rt.

Retighten the rack guide screw to 4 N'm (0.4 kgf m,

2.9 lbf.ft), then back it off to specified angle.

Specilied Return Angle: 30' max.

Tighten the locknut while holding the rack guide

Check for tight or loose steering through the com-

plete turning travel.

Recheck steering effort (see page 17-4).

4.

RACK GUIDE SCREW

l,z

Removal

NOTE: Using solvent and a brush, to wash any oil and

dirt off the gearbox. Blow dry with compressed air.

1. Raise the front of vehicle, and support it on satety

stands in the proper locations (see section I ).

2. Remove the front wheels.

3. Remove the steering wheel (see page 17-35).

4. Remove the steering loint cover

Remove the steering joint lower bolt, and discon-

nect the steering joint by moving the joint toward

the column.

(cont'd)

17-5

STEERING JOINT COVER

LOWER BOLT

STEERING JOINT

Page 1062 of 2189

Steering Gearbox

Removal(cont'd)

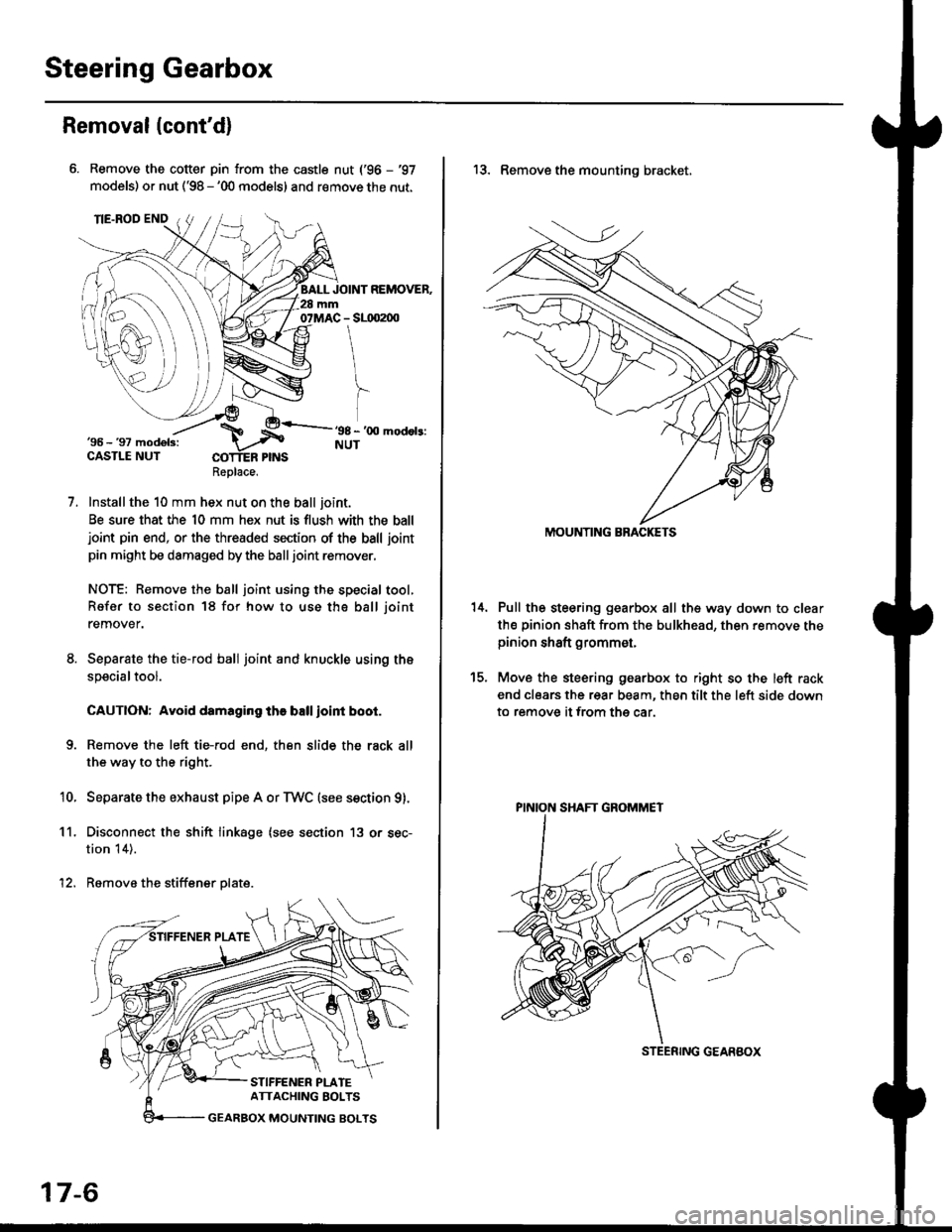

Remove the cotter pin from the castle nut ('96 - '97

models) or nut ('98 - '00 models) and remove the nut.

Installthe 10 mm hex nut on the ball joint.

Be sure that the 10 mm hex nut is flush with the balljoint pin end, or the threaded section of the ball joint

pin might be damaged by the balljoint remover.

NOTE: Remove the ball joint using the special tool,

Refer to section 18 for how to use tho ball joint

remover.

Separate the tie-rod ball joint and knuckle using the

specialtool.

CAUTION: Avoid damaging the ball ioint boot.

Remove the left tie-rod end, then slide the rack all

the way to the right.

Separate the exhaust pipe A or TWC (see section g).

Disconnect the shift linkage (see section 13 or sec-

tion 14).

Remove the stiffener plate.

7.

'10.

11.

12.

Replace.

17-6

13. Remove the mounting bracket,

Pull the steering gearbox all the way down to clear

th€ pinion shaft from the bulkhead, then remove thepinion shaft grommet,

Move the steering gearbox to right so the left rack

end clears the rear beam, then tilt the left side down

to remove it from the car.

t5.

STEENING GEARBOX

PINION SHAFT GROMMET