oil HONDA CIVIC 1998 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 170 of 2189

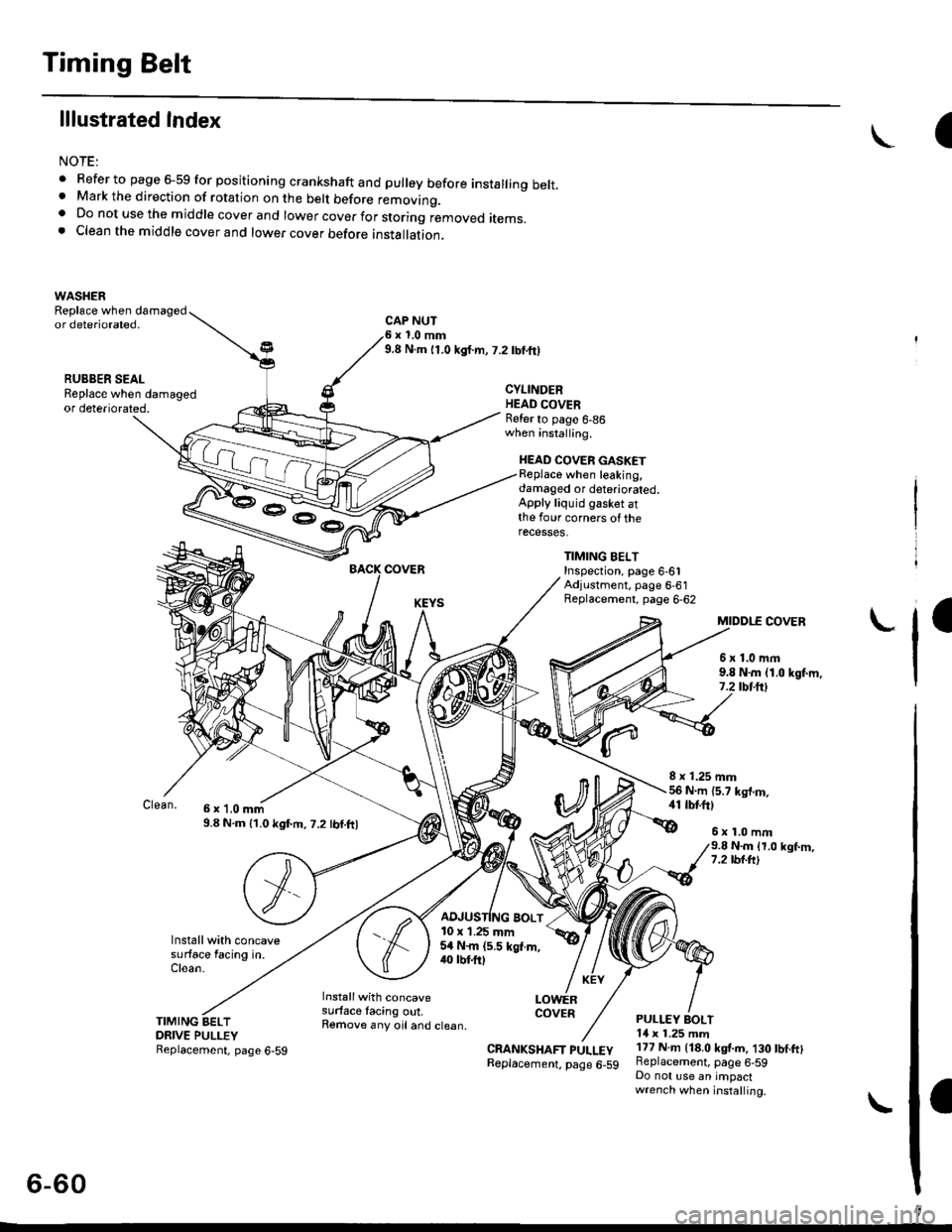

Timing Belt

lllustrated Index

NOTE:

. Refer to page 6-59 for positioning crankshaft and pulley before installing belt.. Mark the direction of rotation on the belt before removino.a Do not use the middle cover and lower cover for storing r'emoved items.. Clean the middle cover and lower cover before installation.

WASHER

I

Replace when damagedor deteriorated.CAP NUTx 1,0 mm9.8 N.m lr.0 kgf.m, 7.2lbtftl

CYLINDERHEAD COVERRefer to page 6-86when installing.

HEAD COVER GASKETReplace when leaking,damaged or deteriorated.Apply liquid gasket atthe four corners ol therecesses,

TIMING BELTInspection, page 6-61Adjustment, page 6-61Replacement, page 6-62

I

6 x '1.0 mm9.8 N.m {1.0 kgf.m, 7.2 lbt.ftl

l0 x 1.25 mm5a N.m {5.5 kgl.m,40 tbt ftt

MIDDTE COVER

6 x 1.0 mrn9.8 N.m {1.0 kgf.m,7.2 tbt-ltl

8 x 1.25 mmN.m {5.7 kgt.m,41 tbt fr)

6x1.0mmN.m 11.0 kgf.m,7.2 tbt.ft'l

PULLEY BOLT14 x 1.25 mm177 N.m {18.0 kgf.m. 130 tbt.ft}Beplacement, page 6-59Do not use an impactwrench when installing.

TIMING BELTDRIVE PULLEY

Installwith concavesurtace facing out.Remove any oil and clean.

LOWERCOVER

CRANKSHAFT PULLEYReplacement, page 6-59

- -o

6-60

Replacement, page 6-59

Page 171 of 2189

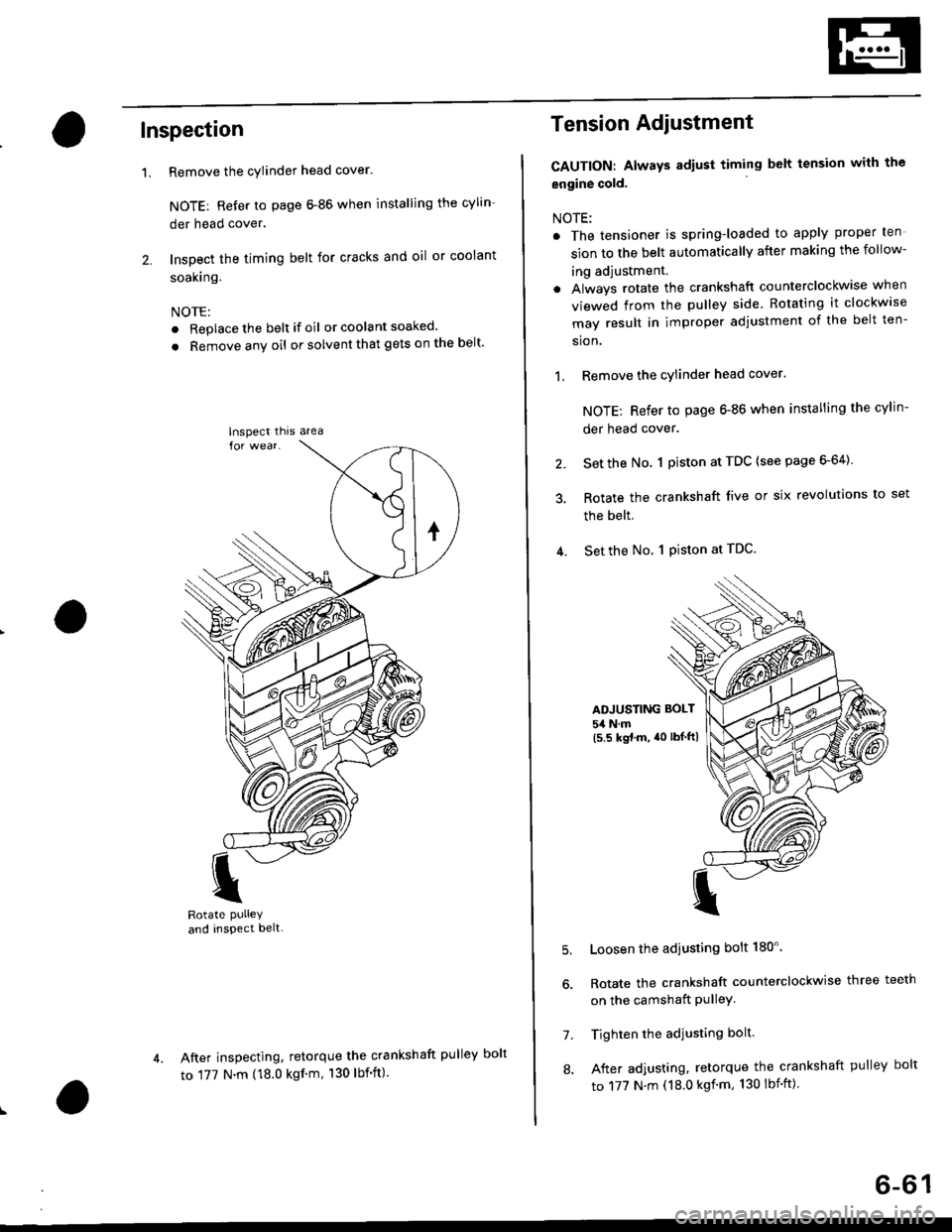

Inspection

Remove the cylinder head cover.

NOTE: Refer to page 6-86 when installing the cylin-

der head cover.

Inspect the timing belt for cracks and oil or coolant

soakrng.

NOTE:

. Replace the belt if oil or coola nt soaked.

. Remove any oil or solvent that gets on the belt'

I

Rotate PUlleYand inspect belt-

After inspecting, retorque the crankshaft pul

to 177 N.m (18.0 kgf'm, 130 lbf'ft)

'L

lnspect thrs area

Tension Adiustment

CAUTION: Always adiust timing belt tension with the

engine cold.

NOTE:

. The tensioner is spring-loaded to apply proper ten

sion to the belt automatically after making the follow-

ing adjustment.

. Always rotate the crankshaft counterclockwise when

viewed from the pulley side. Rotating it clockw'se

may result in improper adjustment of the belt ten-

sion.

1, Remove the cylinder head cover.

NOTE; Refer to page 6-86 when installing the cylin-

der head cover.

2. Set the No. 1 piston at TDC (see page 6-64)

3. Rotate the crankshaft live or six revolutions to set

the belt.

4. Set the No. 1 Piston at TDC

ADJUSTING BOLT

54 N.m(5.5 kgt.m, a0 lbtftl

5.

7.

8.

Loosen the adjusting bolt 180'.

Rotate the crankshaft counterclockwise three teeth

on the camshaft PulleY.

Tighten the adjusting bolt.

After adjusting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgf'm, 130 lbnft)

ley bolt

6-61

Page 172 of 2189

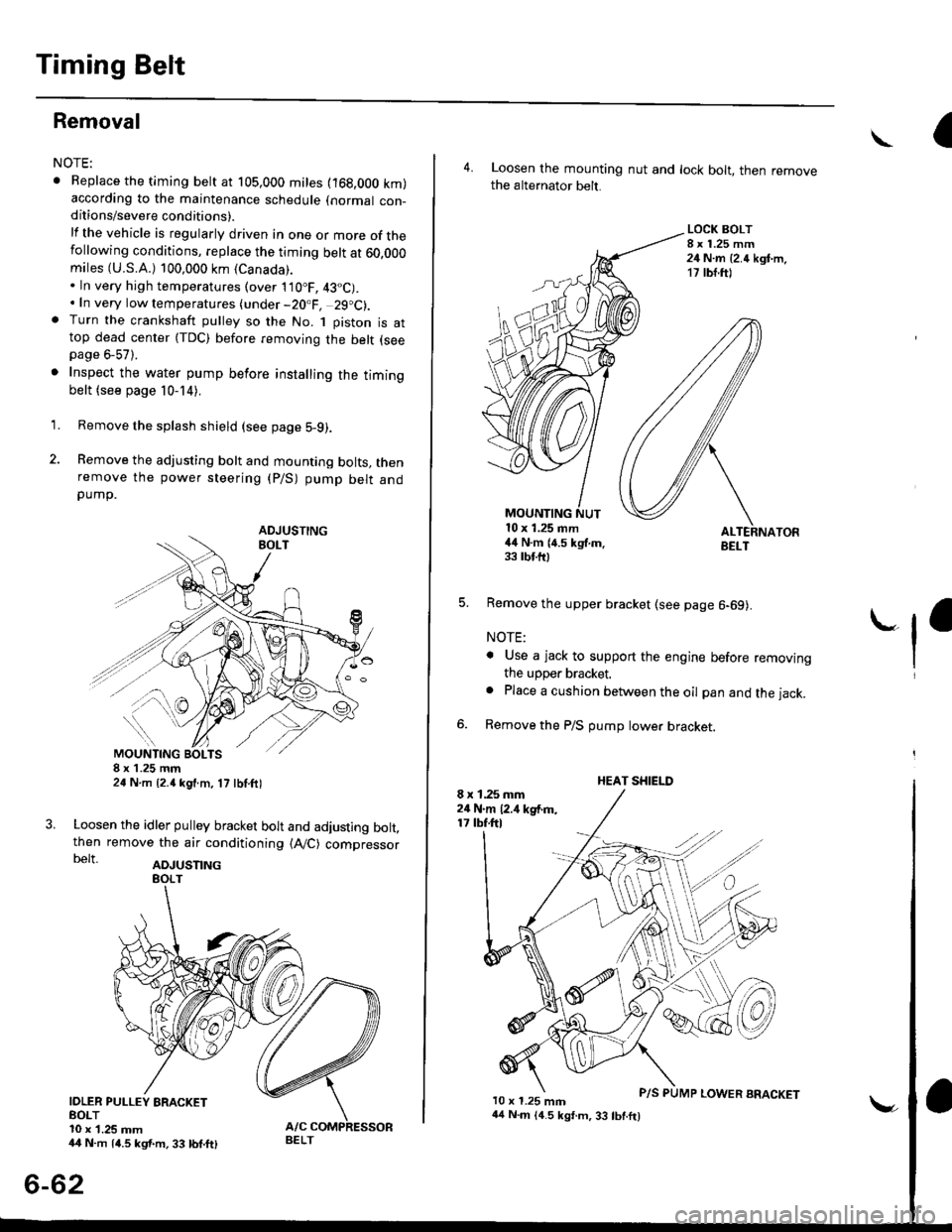

Timing Belt

Removal

NOTE:

. Replace the timing belt at 105,000 mites (168,000 km)according to the maintenance schedule (normal con-ditions/severe conditions).

lf the vehicle is regularly driven in one or more of thefollowing conditions, replace the timing belt at 60,OOOmiles (U.S.A.) 100,000 km {Canada).. In very high temperatures (over 110"F, 43"C).. In very low temperatures (under -20.F, 29.C).. Turn the crankshaft pulley so the No. 1 piston is attop dead center (TDC) before removing the belt (seepage 6-57).

. Inspect the water pump before installing the timingbelt {see page 10-14).

1.

IOLER PULLEY BRACKETEOLT10 x 1.25 mm44 N.m 14.5 kgf.m, 33 bnft)

6-62

Remove the splash shield (see page 5-9).

Remove the adjusting bolt and mounting bolts, thenremove the power steering (P/S) pump belt andpump.

8xL25mm24 N m {2.{ kgf.m, 17 lbf.ft)

Loosen the idler pulley bracket bolt and adjusting bolt,then remove the air conditioning (A,/C) compressorbelt aDJUsnNG

44 N.m 14.5 kgt.m, 33 lbf.ft)

P/S PUMP LOWER ARACKET

a\

4. Loosen the mounting nut and lock bolt, then removethe alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgt.m.17 rb{.ftl

5. Remove the upper bracket (see page 6-69).

NOTE:

. Use a jack to support the engine before removingthe upper bracket.

o Place a cushion between the oil pan and the jack.

Remove the P/S pump lower bracket

8 x 1.25 mm24 N.m 12.,1 kgf.m,17 tbf.ftl

l0 x 1.25 mm

'-f'

MOUNTING10 x 1.25 mm44 N.m (4.5 kgf.m.33 rbf.fttBELT

HEAT SHIELD

Page 173 of 2189

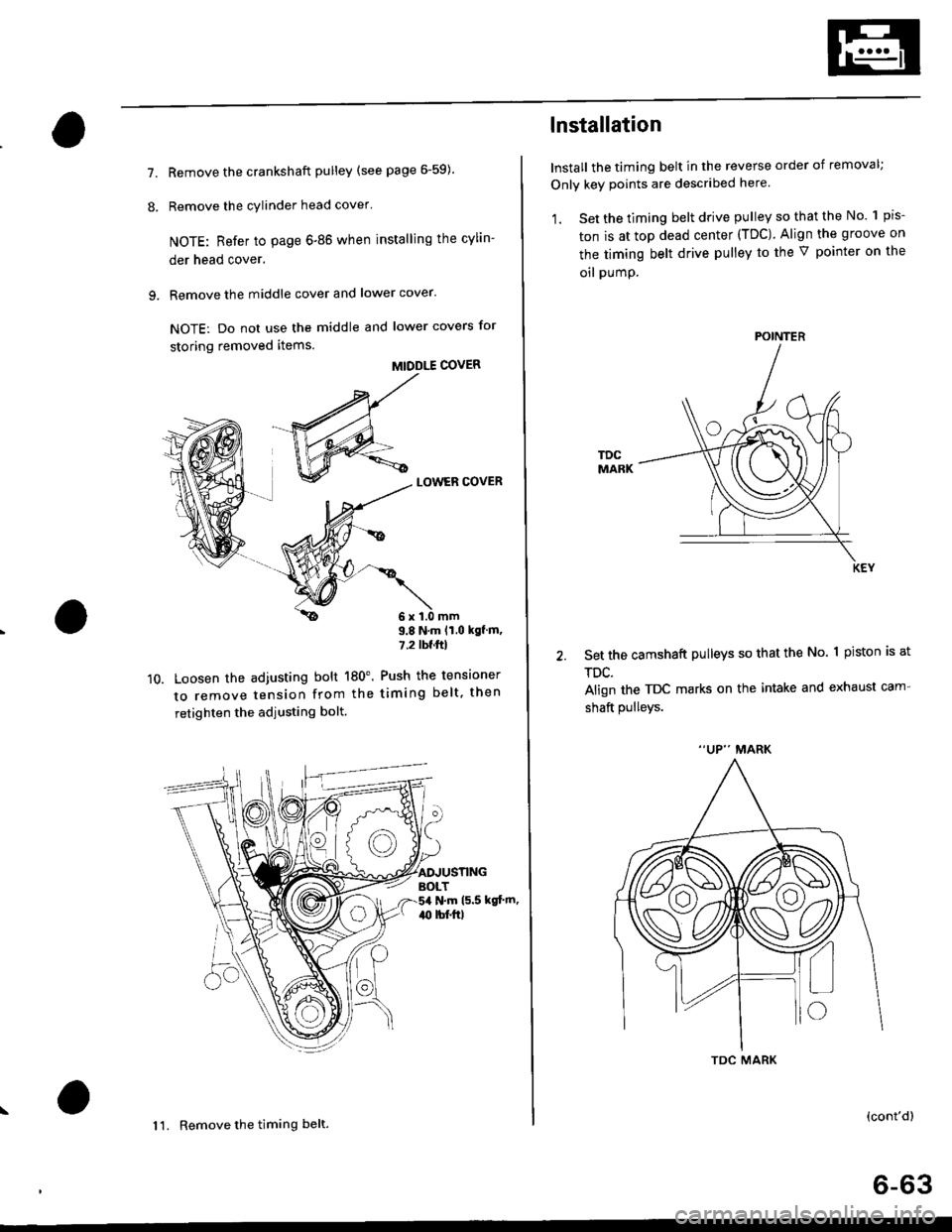

7.

8.

Remove the crankshaft pulley (see page 6-59).

Remove the cylinder head cover'

NOTE: Refer to page 6-86 when installing the cylin-

der head cover.

Remove the middle cover and lower cover.

NOTE: Do not use the middle and lower covers for

storing removed items.

MIDDLE COVER

LOWER COVER

9.

10.Loosen the adjusting bolt 180'.

to remove tension from the

retighten the adjusting bolt.

9.8 N.m lt.o kgf m,

7.2lw'ftl

Push the tensioner

timing belt, then

N.m (5.5 kgt'm,

1 1. Remove the timing belt.

TDC

lnstallation

Install the timing belt in the reverse order of removal;

Only key points are described here.

1. Set the timing belt drive pulley so that the No. 1 pis'

ton is at top dead center (TDC). Align the groove on

the timing belt drive pulley to the V pointer on the

oil pumP.

set the camshaft pulleys so that the No. 1 piston is at

TDC.

Align the TDC marks on the intake and exhaust cam-

shaft pulleys.

MARK

(cont'd)

6-63

POINTER

Page 175 of 2189

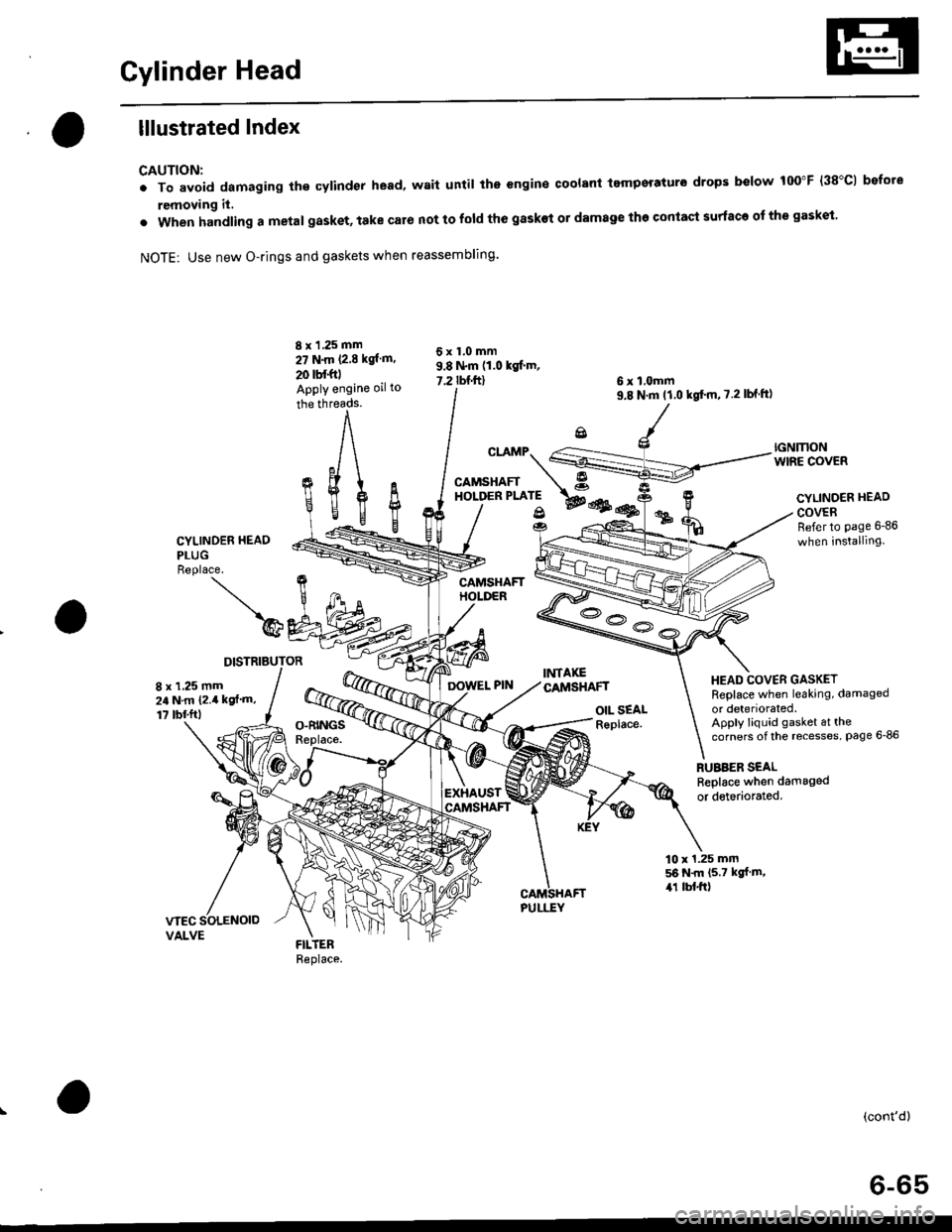

Cylinder Head

lllustrated Index

CAUTION:

. To avoid damaging the cylinder head, wait until the engine coolant tempsraturo drops below 100"F (38"C1 bofote

removing it,

. when handling a metal gasket, take caro not to fold the gaskot or damage the contact surface of the gasket.

NOTE: Use new O-rings and gaskets when reassembling.

CYLINDER HEAO

PLUGReplace.

)@

DISTRIBUTOR

8 x 1 ,25 mm

27 N.m P.E kgl m.

20 tbf.foApply engine oil to

the threads.

cr.rMp.S

CAMSHAFT A"o''*t*'; wes@

OIL SEALReplace.

6 x l,omm9.8 N'm tl.0 kgt'm,7.2lbf ft)

RUBBER SEALReplace when damaged

or detedorated.

6x1.0mm9.8 N.m (1.0 kgf'm,

7.2 rbnftl

fi%

IGNMONWIRE COVER

CYLINOER HEAD

COVERRefer to page 6-86

when installing

HEAD COVER GASKETReplace when leaking, damaged

or deteriorated.Apply liquid gasket at thecorners of the recesses, Page 6-86

8 x 1,25 mm24 N.m {2.4 kgf'm,

1? tbf.ftl

EXHAUST

10 x 1.25 mm56 N.m (5.7 kgf m,,r1 lbl.ft)

(cont'd)

6-65

Page 176 of 2189

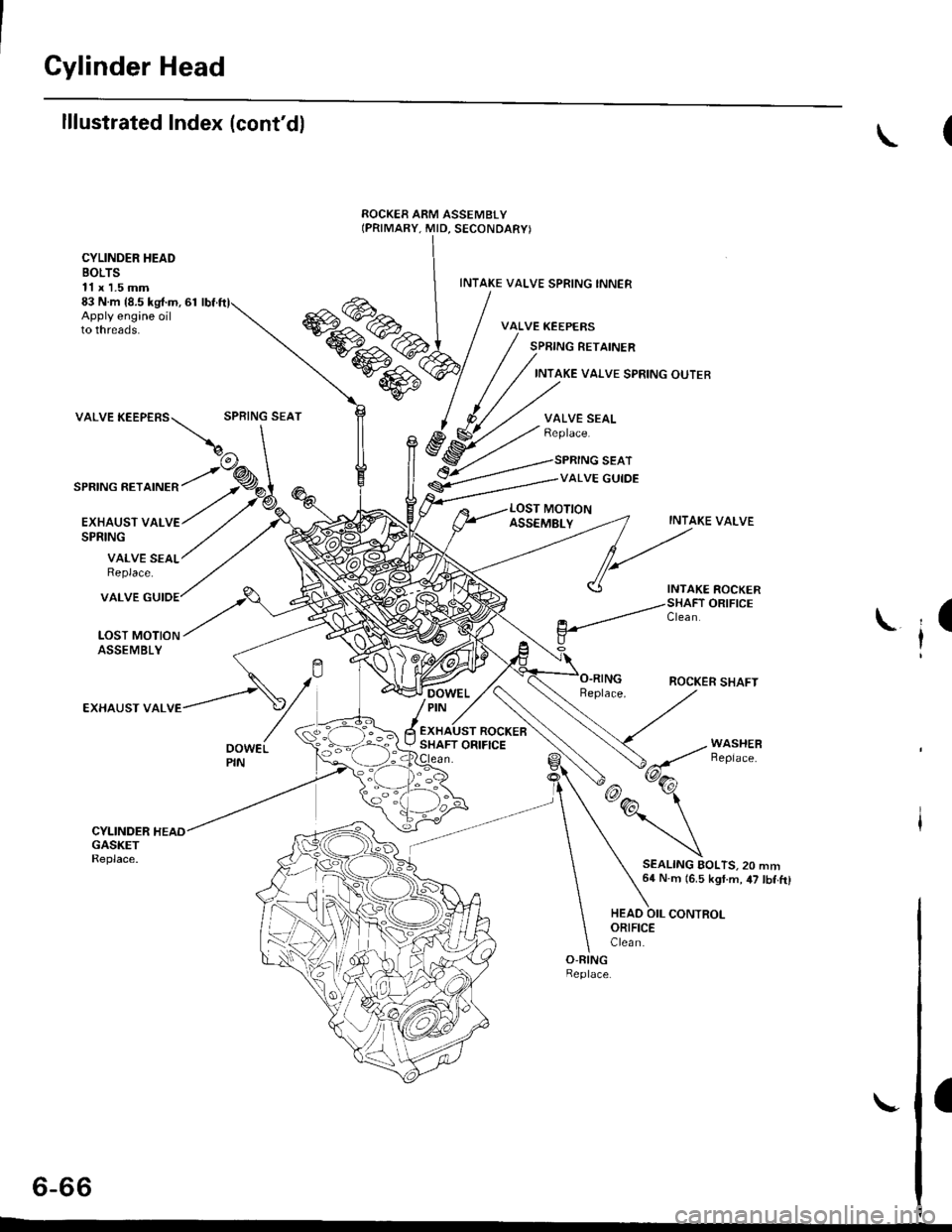

Cylinder Head

lllustrated Index (cont'dl

CYLINDER HEADBOLTS11 x 1.5 mm83 N.m {8.5 kg{.m, 61Apply engine oilto threads.

INTAKE VALVE SPRING INNER

VALVE KEEPERS

SPRING RETAINER

INTAKE VAI.VE SPRING OUTER

valvEKEEPEBS\:""j"*'

SPRING RETAINER

EXHAUST VALVESPRING

VALVE SEALReplace.

VALVE

LOST MOTIONASSEMBLY

EXHAUST VAL

VALVE SEALReplace.

SPRING SEAT

VALVE GUIDE

INTAKE VALVE

ROCKER SHAFT

SEALING AOLTS.20 mm64 N.m (6.5 kgt.m, 47 tbf.ft)

t

il

HEAO OIL CONTROLORIFICEClea n.

a

6-66

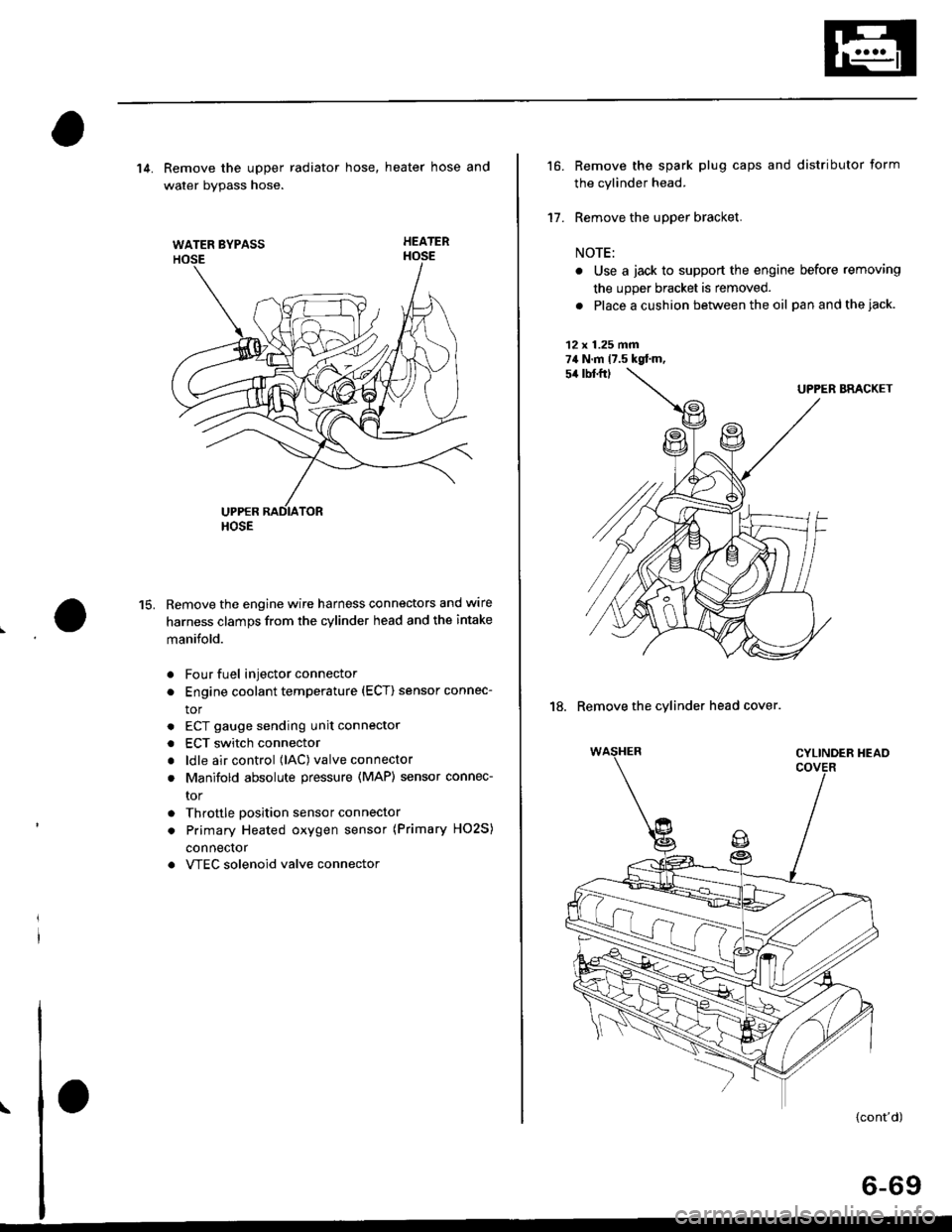

Page 179 of 2189

WATER BYPASS

HOSE

14. Remove the upper radiator hose, heater hose and

water bvpass hose.

HEATER

Remove the engine wire harness connectors and wlre

harness clamps from the cylinder head and the intake

manifold.

Four fuel injector connector

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

ldle air control (lAC) valve connector

Manifold absolute pressure (MAP) sensor connec-

tor

Throttle position sensor connector

Primary Heated oxygen sensor (Primary HO2S)

connecror

VTEC solenoid valve connector

15.

a

a

a

a

a

\

16.

17.

Remove the spark plug caps and distributor form

the cylinder head.

Remove the upper bracket.

NOTE:

. Use a jack to support the engine before removing

the upp€r bracket is removed.

. Place a cushion between the oil panandthejack.

12 x 1.25 fin74 N.m 17.5 kgtm,

UPPER BRACKET

18. Remove the cylinder head cover.

{cont'd)

6-69

Page 181 of 2189

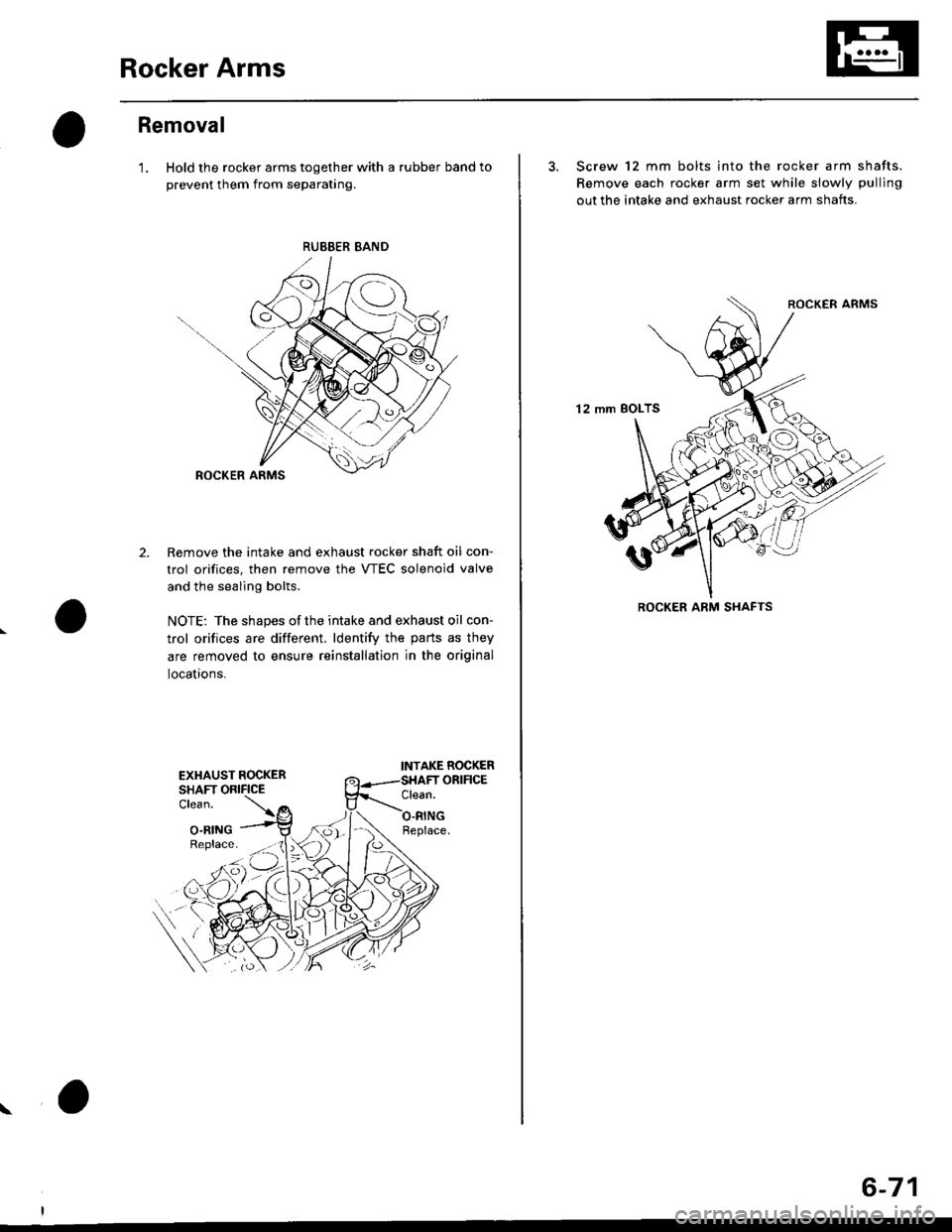

Rocker Arms

Removal

'1. Hold the rocker arms together with a rubber band to

prevent them from separating.

Remove the intake and exhaust rocker shaft oil con-

trol orifices, then remove the VTEC solenoid valve

and the sealing bolts.

NOTE: The shapes ofthe intake and exhaust oil con-

trol orifices are different, ldentify the parts as they

are removed to ensure reinstallation in the original

locauons.

2.

EXHAUST ROCKERSHAFT ORIFICE

INTAKE ROCKERORIFIGEClean.Clean.

O.RINGO.RINGReplace.

RUEBER BAND

Replace. _ (lX

-dJ'v-l-

6-71

3. Screw 12 mm bolts into the rocker arm shafts.

Remove each rocker arm set while slowly pulling

out the intake and exhaust rocker arm shafts.

12 mm BOLTS

ROCKER ARM SHAFTS

Page 183 of 2189

Rocker Arms and Lost Motion Assemblies

Inspection

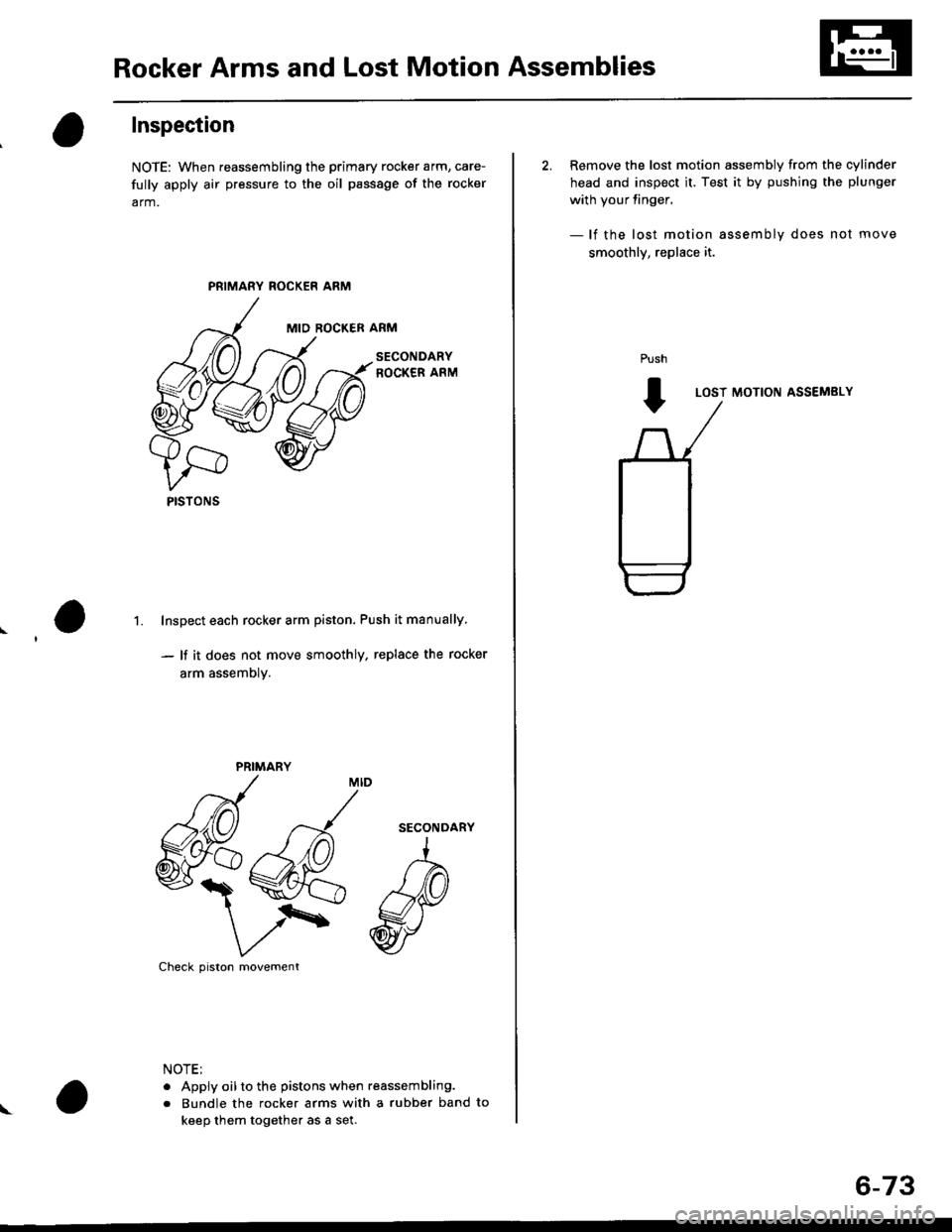

NOTE: When reassembling the primary rocker arm, care-

fully apply air pressure to the oil passage of the rocker

arm.

PRIMARY ROCKER ARM

MID ROCKER ARM

Inspect each rocker arm piston. Push it manually

- lf it does not move smoothly. replace the rocker

arm assemDly.

1.

SECONDARY

Check prston movement

NOTE:

. Apply oilto the pistons when reassembling.

. Bundle the rocker arms with a rubber band to

keep them together as a set.

PISTONS

PRIMARY

\

6-73

2. Remove the lost motion assembly from the cylinder

head and inspect it. Test it by pushing the plunger

with your finger,

- lf the lost motion assembly does not move

smoothly, replace it.

LOST MOTION ASSEMBLY

Push

I

Page 185 of 2189

Camshafts

Inspection

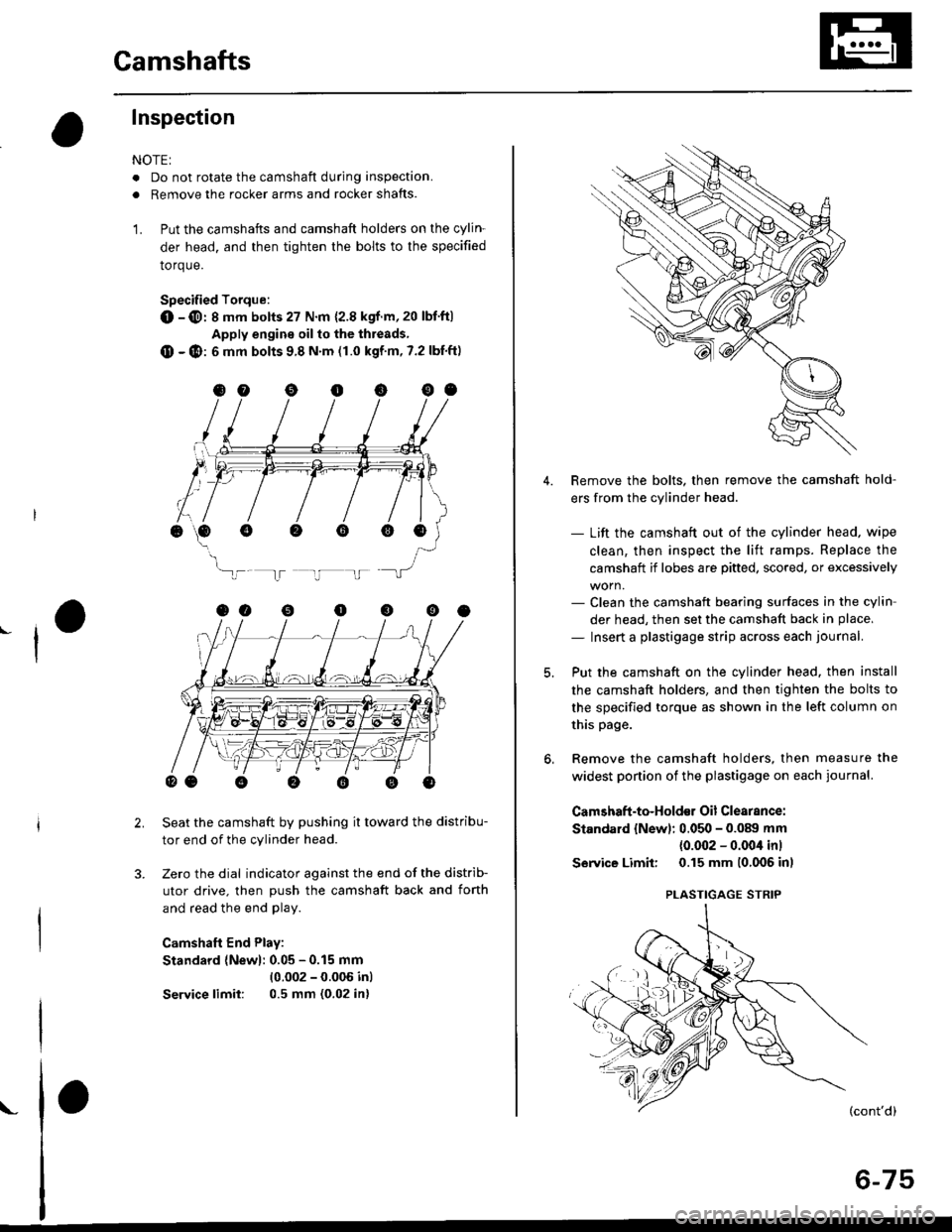

NOTE:

. Do not rotate the camshaft during inspection.

. Removg the rocker arms and rocker shafts.

'L Put the camshafts and camshaft holders on the cylin-

der head. and then tighten the bolts to the specified

torque.

Specified Torque:

O -@: 8 mm botts 27 N.m {2.8 kgf.m,20 lbt'ft)

Apply engine oil to the threads,

O - @: 6 mm bolts 9.8 N.m (1.0 kgf m, 7.2 lbf'ft)

Seat the camshaft by pushing it toward the distribu-

tor end of the cylinder head.

Zero the dial indicator against the end of the distrib-

utor drive. then push the camshaft back and fonh

and read the end play.

Camshaft End Play:

Standard {New}: 0.05 - 0.15 mm

{0.002 - 0.006 inl

Service limil: 0.5 mm (0.02 in)

ooooooo

ooooo

\-

4.Remove the bolts. then remove the camshaft hold-

ers from the cylinder head.

- Lift the camshaft out of the cylinder head, wipe

clean, then inspect the lift ramps. Replace the

camshaft if lobes are pitted, scored, or excessively

- Clean the camshaft bearing surfaces in the cylin

der head, then set the camshaft back in place,

- Insert a plastigage strip across each iournal.

Put the camshaft on the cylinder head. then install

the camshaft holders, and then tighten the bolts to

the specified torque as shown in the left column on

this page.

Remove the camshaft holders, then measure the

widest portion of the plastigage on each journal.

Camshaft -to-Hold€1 Oil Clearsnce:

Standard {Newl: 0.050 - 0.089 mm

{0.002 - 0.004 inl

S6rvice Limit: 0.15 mm 10,006 inl

(cont'd)

6-75

PLASTIGAGE STRIP