Battery HONDA CIVIC 1998 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 739 of 2189

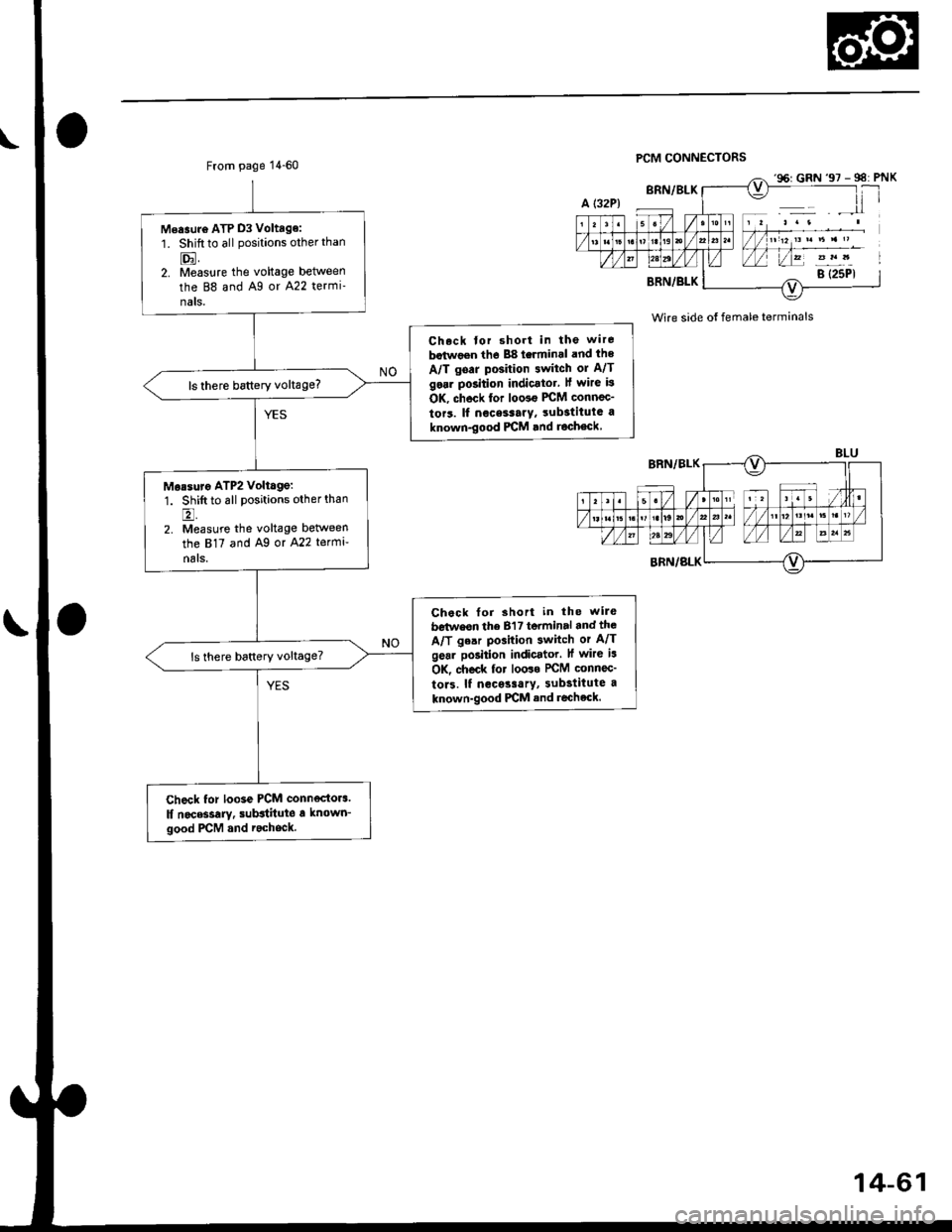

From page 1 4-60PCM CONNECTORS

Wire side ot female terminals

Measuro ATP D3 Voltage:

1. Shift to all positions other than

tr.2. Measure the voltage between

the 88 and A9 or A22 termi-

nals.

Ch.ck tor short in the wire

botwoen tho 88 terminal and ihe

A/T goar position 3witch ol A/T

gosr position indicator, ll wirc is

OK, chock for loo3€ PCM connec-

tor3. lf nece3rary, substituta a

known-good PCM lnd roch€ck

ls there battery voltage?

Morsuro ATP2 Voltage:

1. Shift to all positions other than6t

2. Measurc the voltage between

the 817 and Ag or A22 terml-

n6ls.

Check for short in the wile

b€twesn the B'l 7 terminal and the

A/T ge.r pGition switch or A/T

gear po3ition indicator. lf wire i3

OK, check for loo3o rcM connec'

to13. lf necossarY, substitute a

known-good PICM and recheck.

ls there battery voltage?

check for loose PCM connectors.

lf noc*sarY. sub3titute a known_

good PCM and r.chock.

'96: GRN'97 - 98: PNX

B (25P1

14-61

Page 757 of 2189

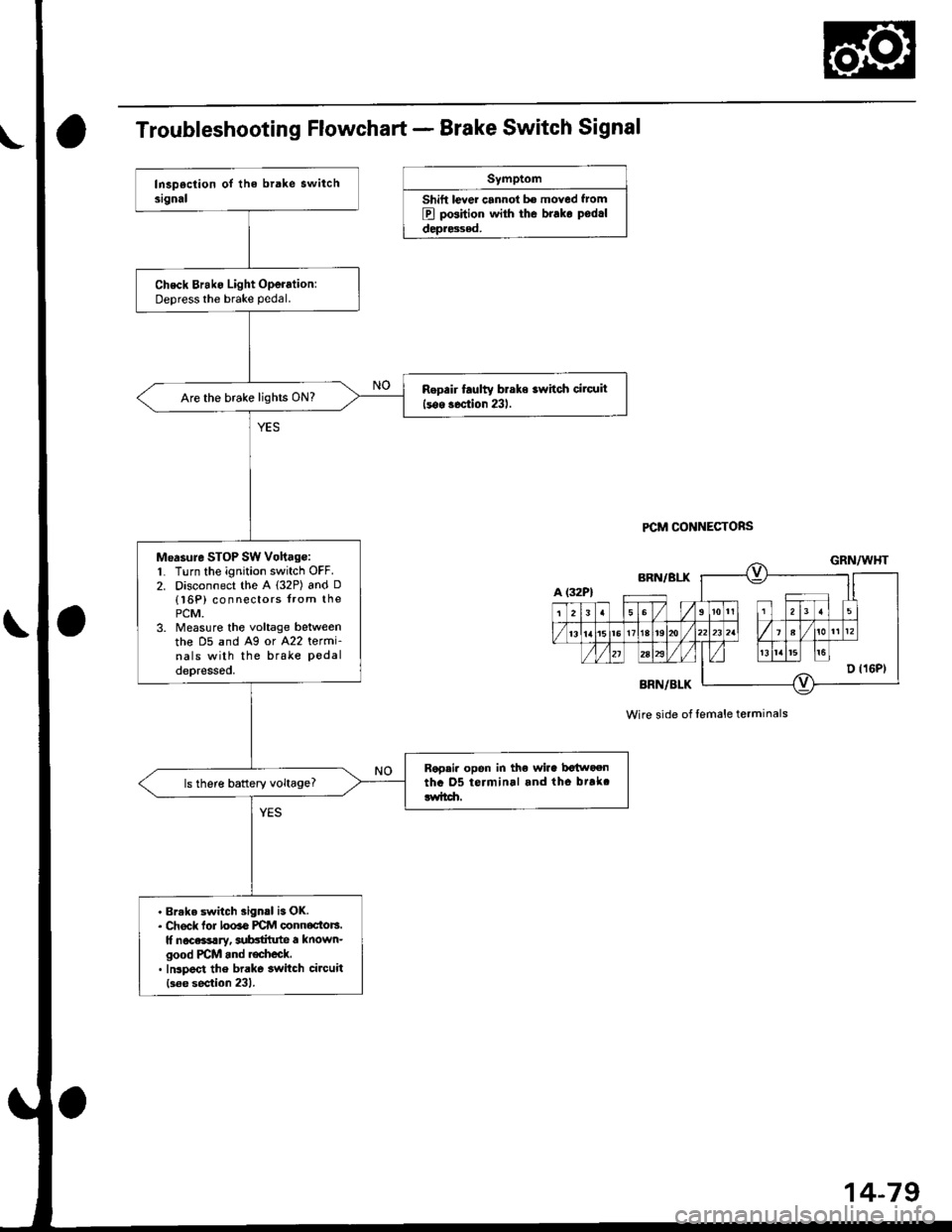

Troubleshooting Flowchart - Brake Switch Signal

Symptom

Shift lever cannol b€ moved f.om

B pGition with the brako podrl

depr8sed.

PCM CONNECTORS

Check Brako Light Operation:Deoress the brake pedal.

Rop.ir faulty braks switch cilcuit

lsos soction 231.Are the brake lights ON?

Measure SToP SW Vohag€:1. Turn the ignition switch OFF.2. Disconnect the A l32P) and D

{l6P) connectors from thoPCM.3. Measure the voltage belweenthe D5 and A9 or A22 termi-nals with the brake Pedaldepressod.

Rap.i. opon in the wira bctn oentha 05 terminal and tho btrkclwitdr.ls there battery voltage?

. Brake switch 3ign.l is OK.. Ch6ck lor looao PCM oonnoctors.It nocassary, aubctilute a known-good PCM and r€check.. Inspoct the brake switch circuit

{s6e section 231.

Wire side of lemale terminals

Page 760 of 2189

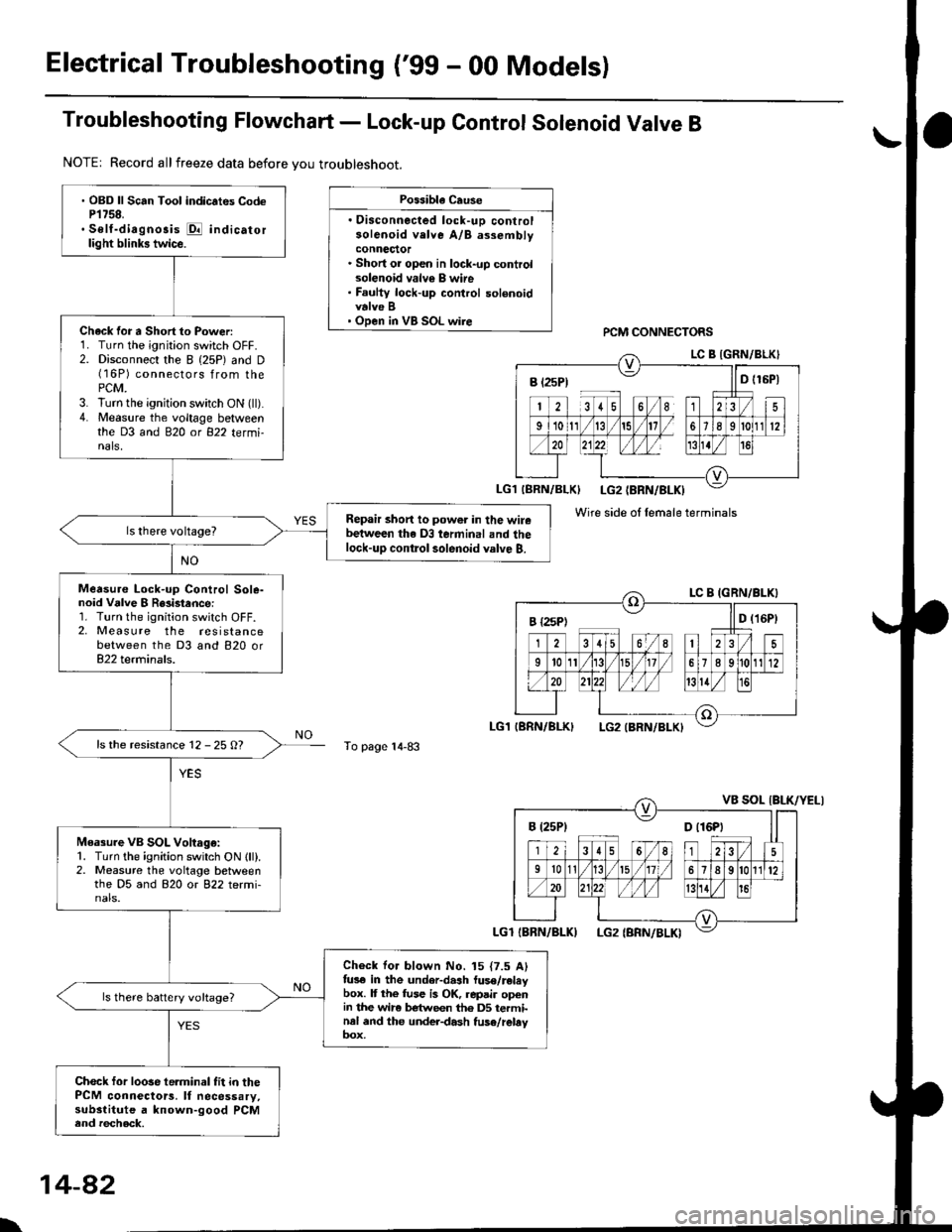

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve B

NOTE| Record allfreeze data before you troubleshoot.

Possibla Cause

. Oisconnected lock-uD controlsolenoid velve A/B assemblyconnector. Short or open in lock-up controlsolenoid valv€ B wire. Faulty lock-up control solenoidvalve B' Open in VB SOL wirercM CONNECTORS

To page 14-83

' OBD ll Scan Tool indic.tes CodeP1758.. Self-diagnosis E indicatorlight blinks twice.

Chack for a Short to Power:1. Turn the ignition switch OFF.2. Disconnect the I (25P) and D(16P) connectors from thePCM.3. lurn the ignition switch ON (ll).4. Measure the voltage betweenthe D3 and 820 ot 822 tetmi-nals,

Repair short to power in the wirebetween the D3 terminal and thelock-up contlol solenoid valve B.

Measure Lock-up Control Sole-noid Vdlve I R8i3tance:1. Turn the ignition switch OFF.2, Measure the resistancebetween the D3 and 820 or822 terminals.

ls the resistance 12 - 25 O?

Measure VB SOL Voltago:1. Turn the ignition switch ON lll).2. Measure the voltage betweenthe D5 and 820 or 822 termi-nals.

Check for blown No. 15 {7.5 Alfus€ in the under-dash luse/releybox. It the fuse is OK, repair openin the wir6 between th6 DS terminal and the under-dash fuse/rebyoox,

ls there battery voltage?

Chock for loose te.minal fit in thePCM connectors. It necessary,substitute a known-good PCMend recheck.

B t2sP) ll D t15P)

Wire side ol female terminals

I {2sPt ll D (16Pt

B (25P1 D t16Pt

\

14-82

Page 762 of 2189

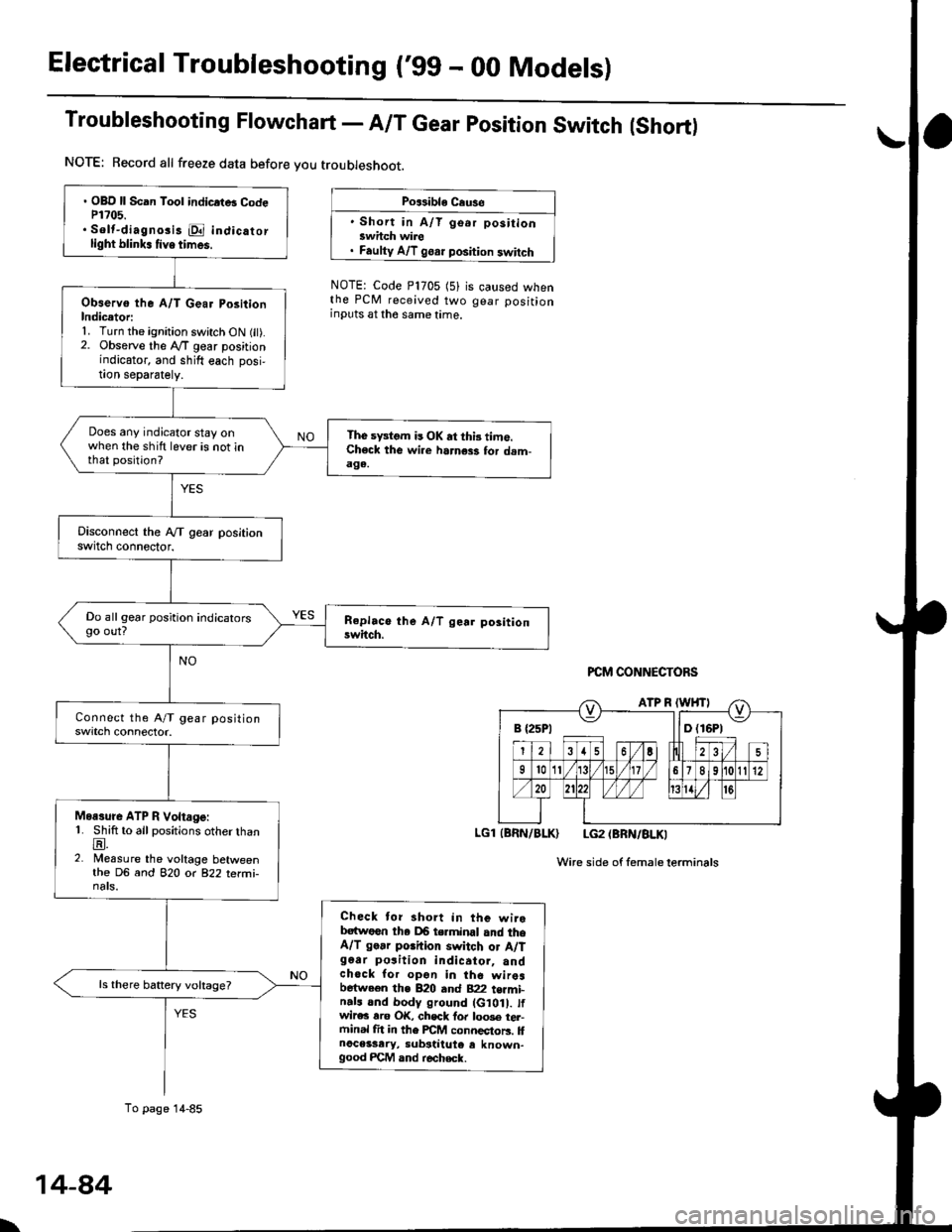

Electrical Troubleshooting ('gg - 00 Models)

Troubleshooting Flowchart - A/T Gear position Switch (Short)

NOTE: Record all freeze data before you troubleshoot.

Po$ible Cause

' Short in A/T go.r positionswhch wire. Faulty A/T goar position switch

NOTE: Code P1705 (5)the PCM received twoinputs at the same time.

is caused whengear position

PCM CONNECTORS

LGl (BRN/BLK) LG2 (BRN/BLKI

Wire side of femaleterminals

B {25P1 llD (16P1

. OBD ll Scan Tool indicrtB CodeP1?05.. Solt-diagno3i3 E indicatorlight blink. tive times.

Observo the A/T Gear PositionIndicetori1. Turn the ignition switch ON fit).2. Observe the lVT gear positionindicator, and shift each posi,!on separately.

Does any indicator stay onwhen the shift lever is not inthat position?

The sFtom is OK at thi3 time.Check the wi.e harness for dam-aga.

Do all gear position indicatorsgo out?

Moasure ATP R Voltage:1. Shift to all positions otherthanE.2. Measure the voltage betweenthe DG and 82O o( 822 terfii-nats.

Check tor short in the wirebatwoen tha DB terminal and theA/T go.r porhion switch or A/Tg6ar po3ition indicator, andchock for opon in the wiresbetween the B20 and B22 t€rmi-n.ls and body ground (G10 . tfwir€c rro OK, chsck fo. loo3e tel-ftinal fit in the FCM connectors. llnoceisary, substiiute e known-good FCM and r€check.

ls there battery voltage?

To page 14-85

\

14-84

Page 763 of 2189

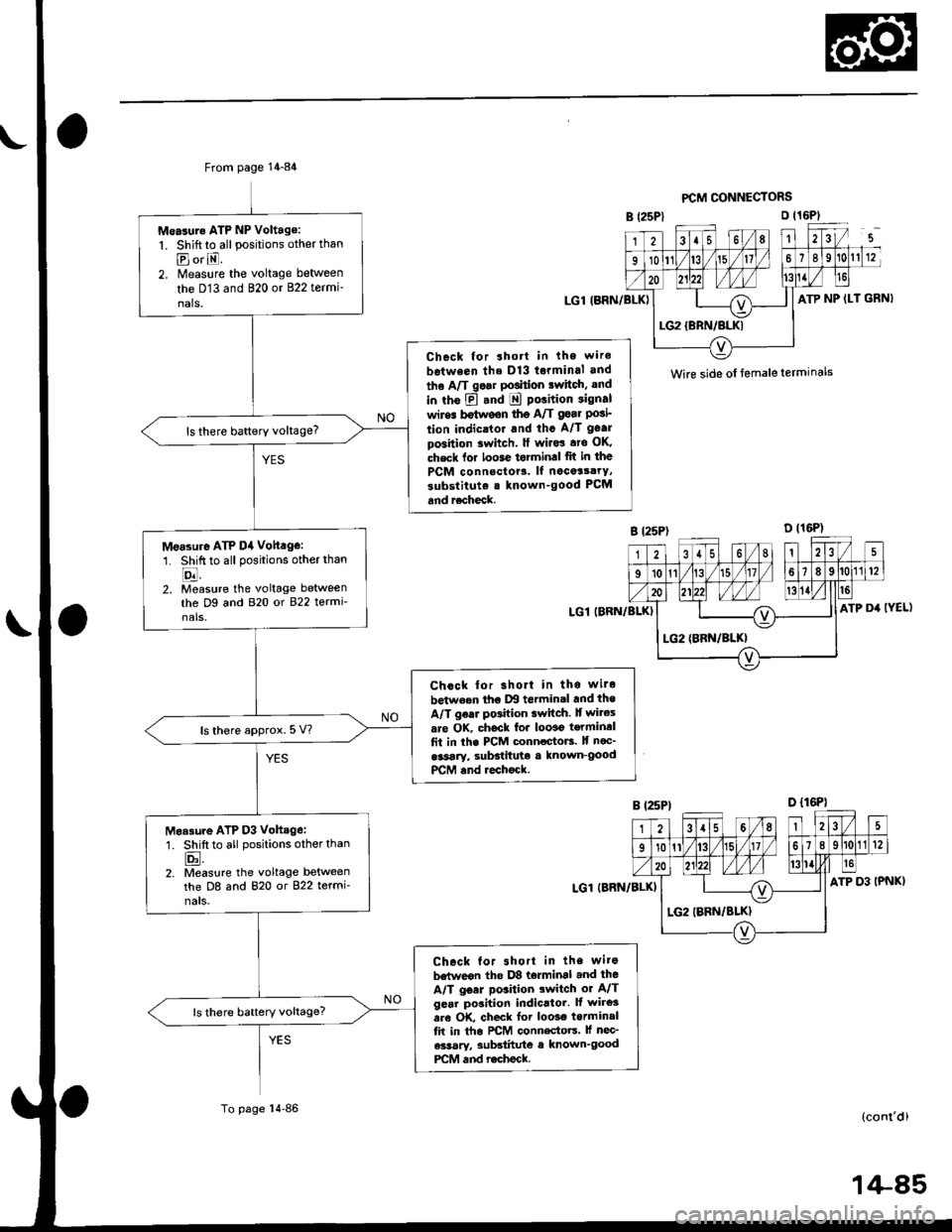

From page 14-84

Measule ATP NP Voltage:

1. Shift to all positions other thanpl or E.2. Measure the voltage between

the D13 and 820 or 822 termi-

nals.

Check for ahott in lhe wire

between ths D13 torminal and

tho A/T go.r PGition iwitci, and

in rho E .nd E polition signal

wires Mwgon tho A/T gsar Posi'tion indicrtor and th. A/T gGar

po3ition 3witch. ll wiJ.! .ro OK,

check lor loose torminal fit in the

PCM connoctor3. lf nocet3.rY,

substitute . known-good PCM

and r6check.

ls there baftery voltage?

Measure ATP D4 voh.g€:

1. Shiftto all positions otherthan

E2. Measure the voltage between

the Dg and 820 or 822 termi-nals.

Ch.ck lor 3hort in ths wilo

betweon tho lxl termin.l and tho

A/T ge.r pGhion switch. It wites

are OK. chock fo. looao t€rminal

fit in the PCM conn.ctoB. lf noc_

.*sary, sulFtitute a known-goodPCM .nd rechock.

ls there approx. 5 V?

Moa3ure ATP D3 Vohsge:

1. Shift to all positions other than

tr.2. Measure the voltage betweenthe D8 and 820 or 822 termi-

nals.

Check tor 3hort in the wits

betweon the D8 torminal and the

A/T goer position switch or A/Tgcar position indicltor. It wires

are OK, check for loo3€ torminalfit in tho FCM conn€ctoG. lf nec_

a3$ry, 3ubatitute e known'goodPCM and r.check.

ls there battery voltage?

To page l4'86

PCM CONNECTORS

o t16PlB {25P)

LGl (BRN/BLK)

g t25P)

LGl (BRN/8IJ()

LGl IBRN/BLK)

GRN)

D t16P)

IYEL)

231115 l68 112tV-s-

10n\/t7/ 167I910 t12

I

o zlzz /l/1,/ 113TIL---{O--l\=/LG2{BRN/BLKI

,/t\_

\a t9

ATP NP (LT

Wirc side o{ female termlnals

31158ll25

910111/t6l/17ls lt la112

20) W Wl/l '3111/ll

+LG2 (BBN/BLKI

-<_

ATP D4

LG2 (BRN/BLK}

14-85

Page 764 of 2189

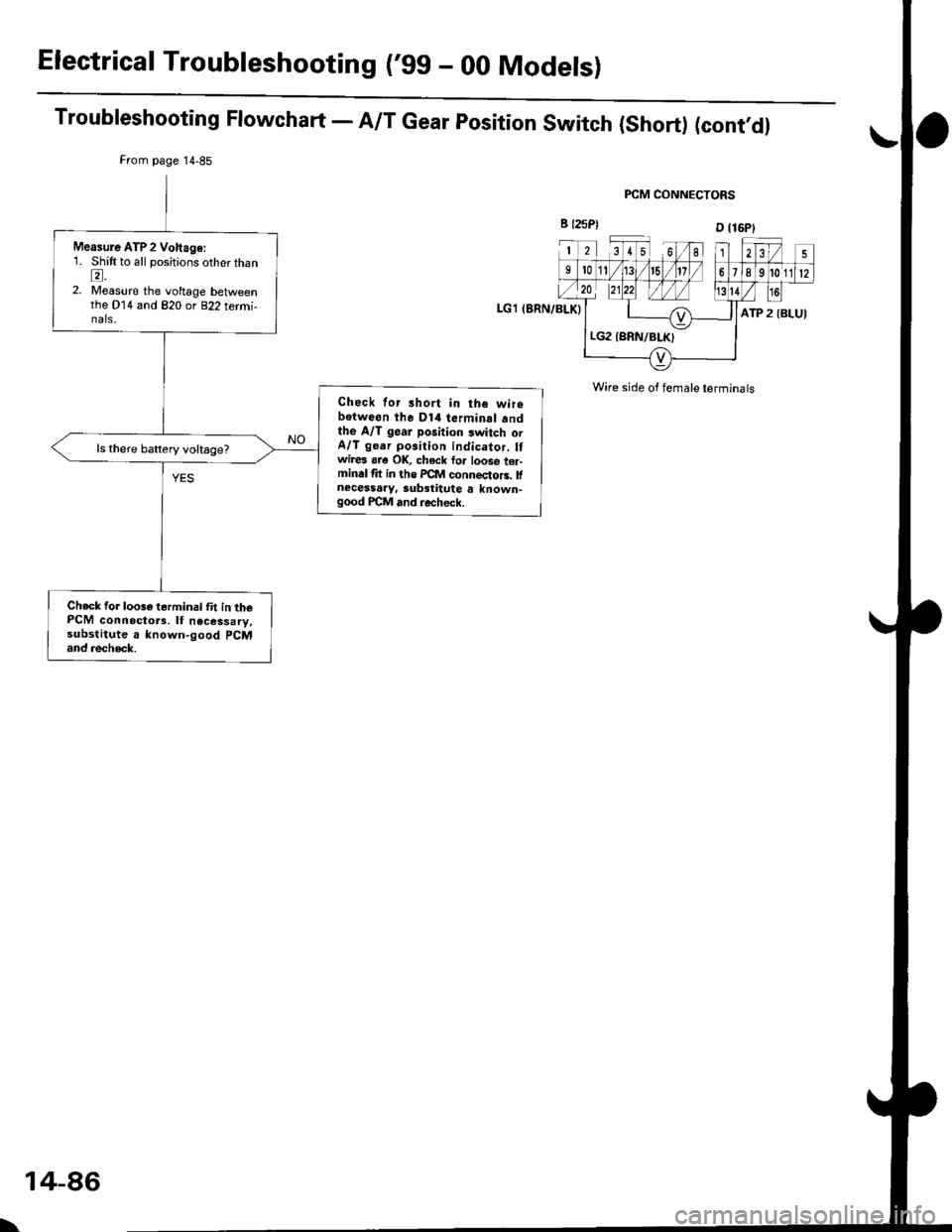

ElectricalTroubleshooting ('gg - 00 Models)

Troubleshooting Flowchart - A/T Gear position Switch (Short) (cont,dl

LGl (BRN/BLK}

FCM CONNECTORS

B {25P)D l16Pl

12[Ll81235

9101/113/ 151/)11789t0112,/ 20

ATP 2 {BLUI

Wire side of female terminals

Measule ATP 2 Vohage:1. Shift to all positions other thanl

2. Measure the voltage betweenthe D14 and 820 or 822 termi-nals,

Check for short in the wirebetween the D14 terminal andthe A/T gear position switch orA/T ge.r position indicator. Itwires aae OK, check loa loose ter-minal th in ths PCM connectors. llnecessary, substitute a known-good FCM and recheck.

ls there battery voltage?

Ch6ck for loose terminal fit in thePCM connoctors. lf necessary,substitute a known-good PCMand recheck.

\

14-86

Page 769 of 2189

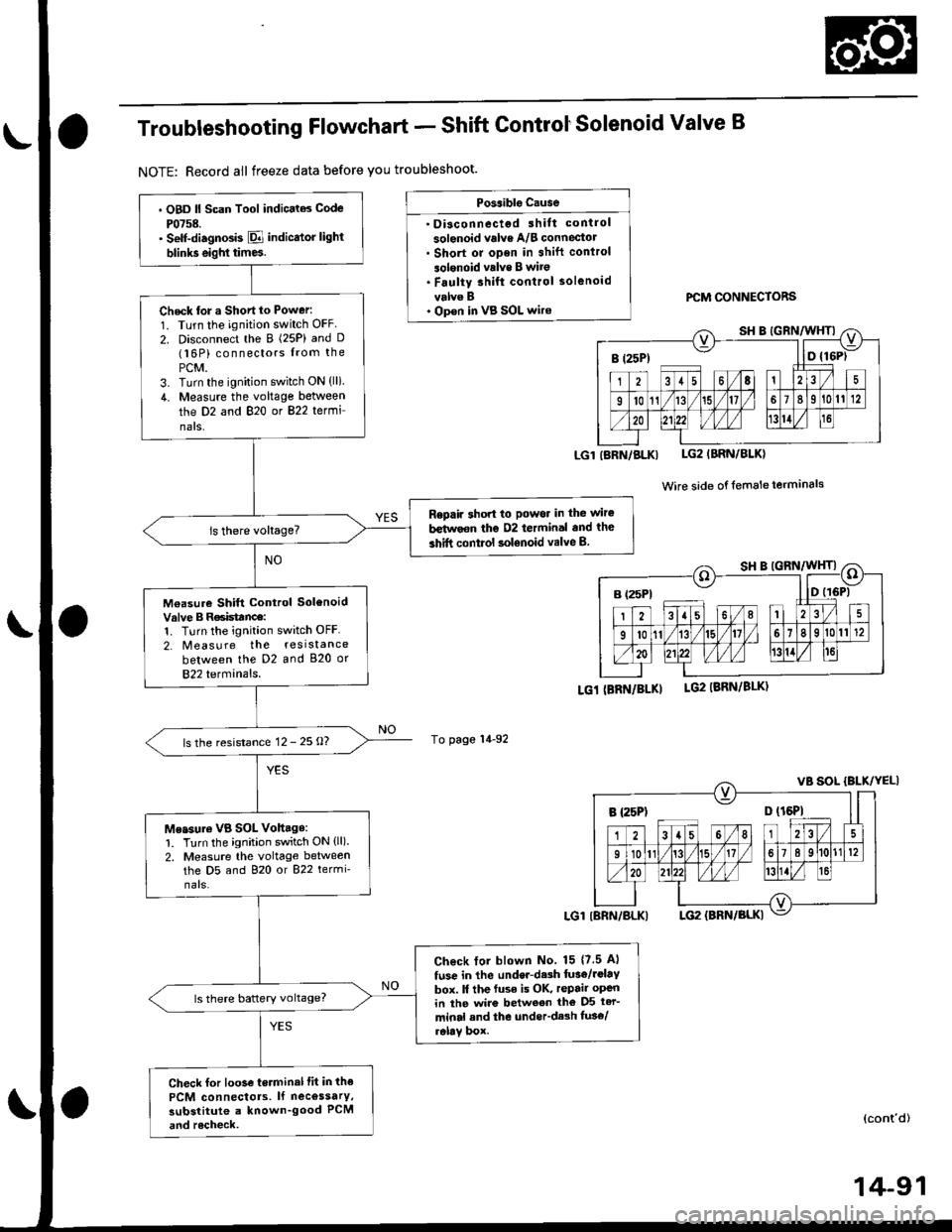

Troubleshooting Flowchart - Shift ControtSolenoid Valve B

NOTE: Record all freeze data before you troubleshoot.

Possiblg Cause

. Disconnectgd ihilt control

solenoid valve A/B conneciotr Short or oDen in shift conlrol

3olgnoid vrlve B wito. Faulty 3hift control solenoid

velve B. Op€n in VB SOL wirercM CONNECTORS

LGlIBRN/BLKI LG2IBRN/BLK)

Wire side of {emale terminals

LGi (BRi|/BLKILG2 IBRN/8LK)

To page 14-92

(cont'd)

14-91

. OBD ll Scan Tool indic.l6 Code

P0758.' Self-diagnosb El indicator light

blinks eighl tim6.

Check tor a Shortto Power:

1. Turn the ignition switch OFF

2. Disconnect the B (25P) and D(16P) connectors from the

PCM.3. Turn the ignition switch ON (lli.

4. Measure the voltage between

the D2 and 820 or 822 termi

nals,

Repaft 3hon to Powor in the wir€

b€tirvoon the D2 termin.l and the

3hift control solenoid valve B.

M€asure Shift Control SolenoidValve B R6isttnce:1. Turn the ignition switch OFF

2. Measure the resistance

between the D2 and 820 or

822 terminals.

ls the resistance 12 - 25 O?

Me.sure VB SOL Vohage:1. Turn the ignition switch ON (ll).

2. Measure the voltage betweenthe D5 and 820 or 822 termi'

nars.

Check lol blown No 15 {7.5 Al

fuse in the under-d.sh luae/rolav

box. ll the fuse is OK, repair open

in ihe wire between tho D5 ter-

minal and the under'dash fus€/relav box.

ls there battery voltage?

Check for loo3e terminal fit in the

PCM connectols. lf necossarY,

substitute a known_good PCM

and rocheck,

B (25Pt - I lD {16P)

B {25P1 D (t6Pl

Page 782 of 2189

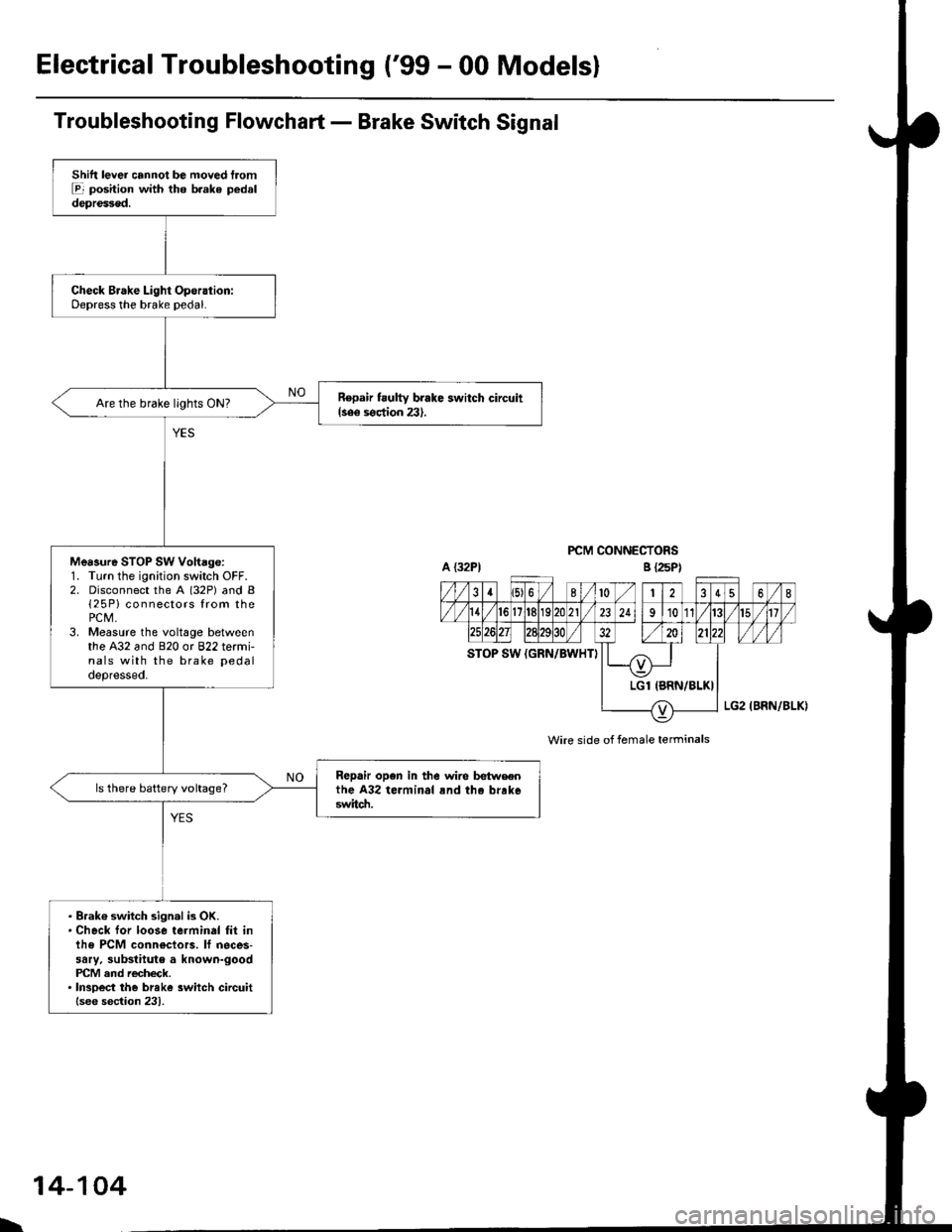

ElectricalTroubleshooting ('99 - 00 Modelsl

Troubleshooting Flowchart - Brake Switch Signal

PCM CONNECTORS

Wire side of female terminals

Shift lever cannot be moved tromE position with tho b.ake pedaldepressod.

Check Brake Light Operation:Depress the brake pedal.

Repair t ulty brake switch circuit{see s€ction 23}.Are the brake llghts ON?

Mea3ure STOP SW Vohage:1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B{25P} connectors from thePCM,3. Measure the voltage betweenthe A32 and 820 or 822 termi-nals with the brake pedal

depressed.

Repair open in the wire betwsenthe A32 terminal rnd tho brrk6switch.

ls there battery voltage?

. Brak€ switch sign.l is OK.. Check for loose terminal fil inlhe PCM conn€ctors. lf neces-sary. substitute a known-goodPICM and recheck.. InsDect the breke 3witch circuitlsee section 231.

B {25P)

\

14-104

Page 783 of 2189

Lock-up Gontrol Solenoid Valve A/B Assembly

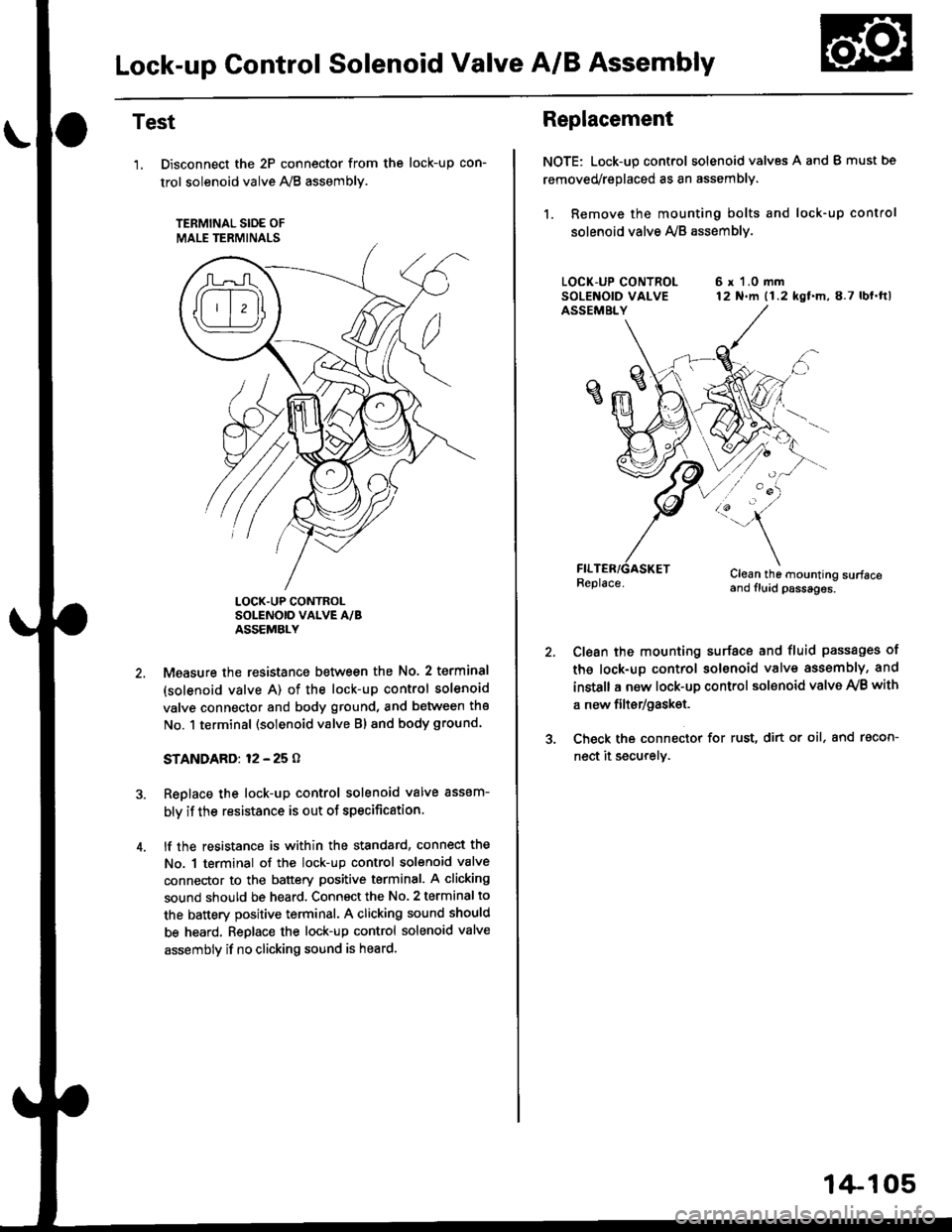

Test

'1, Disconnect the 2P connector from the

trol solenoid valve 1y'8 assembly.

TERMINAL SIOE OF

MALE TERMINALS

tocK-up con-

LOCK.UP CONTROLSOLENOID VALVE A/BASSEMBLY

Measure the resistance between the No. 2 terminal

(solenoid valve A) of the lock-up control solenoid

valve connector and body ground, and between the

No. 1 terminal (solenoid valve Bl and body ground.

STANDARD: 12 - 25 O

Replace the lock-up control solenoid valve assem-

bly if the resistance is out of specification.

lf the resistance is within the standard, connect the

No. 1 terminal of the lock-up control solenoid valve

connector to the battery positive terminal. A clicking

sound should be heard. Connsct the No. 2 terminal to

the battery positive terminal. A clicking sound should

be heard. Replace the lock-up control solenoid valve

assembly if no clicking sound is heard.

Replacement

NOTE: Lock-up control solenoid valves A and I must bs

removed/replaced as an assembly.

1. Remove the mounting bolts and lock-up control

solenoid valve Ay'B assemblv.

6 r 1.0 mm12 N.m (1.2 kgf.m,8.7 lbl.ftl

/:'-

Clean the mounting surfaceand fluid psssages.

Clean the mounting surface and fluid passages of

th6 lock-up control solenoid valve assembly, and

instsll a new lock-up control sol€noid valve Ay'B with

a new filtsr/gask€t.

Check the connector for rust, dirt or oil, and racon-

nect it securely.

1+105

Page 784 of 2189

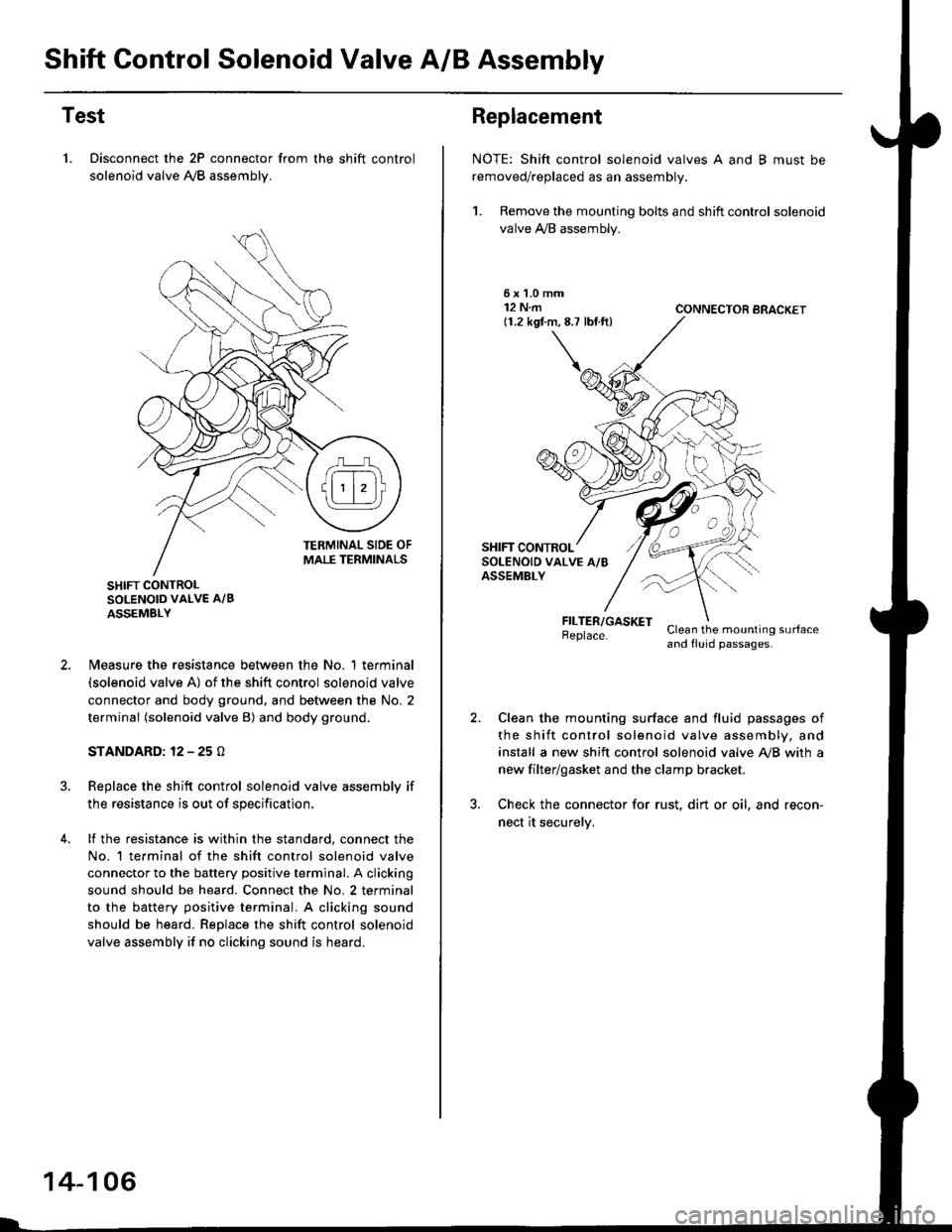

Shift Control Solenoid Valve A/B Assembly

Test

1. Disconnect the 2P connector from the shift control

solenoid valve A,/B assemblv.

SHIFT CONTROLSOLENOID VALVE A/B

ASSEMBLY

N4easure the resistance between the No. 1 terminal(solenoid valve A) of the shift control solenoid valve

connector and body ground, and between the No. 2

terminal (solenoid valve B) and body ground.

STANDARD: 12 - 25 O

Replace the shift control solenoid valve assembly if

the resistance is out of specification,

lf the resistance is within the standard, connect the

No. 1 te.minal of the shift control solenoid valve

connector to the battery positive terminal. A clicking

sound should be heard. Connect the No. 2 terminal

to the battery positive terminal. A clicking sound

should be heard. Replace the shift control solenoid

valve assembly if no clicking sound is heard.

14-106

Replacement

NOTE: Shift control solenoid valves A and B must be

removed/replaced as an assembly.

1. Remove the mounting bolts and shift control solenoid

valve A,/B assembly.

5xL0mm12 N.m(1.2 kgf.m,8.7 lbf.ft)CONNECTOR BRACKET

FILTER/GASKETBeplace.Clean the mounting surfaceand fluid passages.

Clean the mounting surface and fluid passages of

the shift control solenoid valve assembly, and

install a new shift control solenoid valve Ay'B with a

new filter/gasket and the clamp bracket.

Check the connector for rust. dirt or oil. and recon-

nect it securelv,