ESP HONDA CIVIC 1998 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1115 of 2189

)

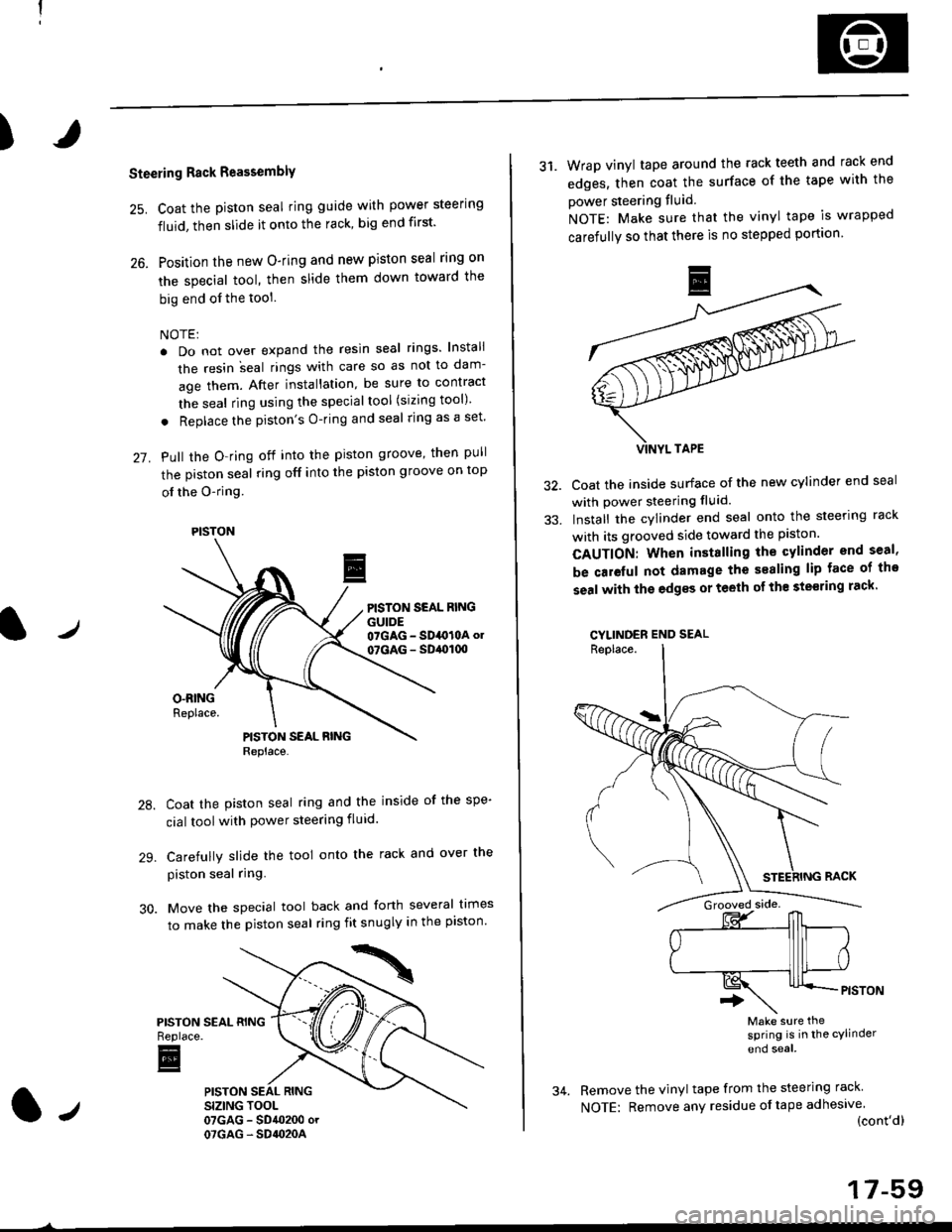

Steering Rack Reassembly

25. Coat the piston seal ring guide with power steering

fluid, then slide it onto the rack, big end first'

26. Position the new O-ring and new piston seal rlng on

the special tool, then slide them down toward the

big end of the tool

NOTE:

. Do not over expand the resin seal rings lnstali

the resin ;eal rings with care so as not to dam-

age them. After installation, be sure to contract

the seal ring using the specialtool (sizing tool)

. Replace the piston's O-ring and seal ring as a set'

27. Pull the O-ring off into the piston groove, then pull

the piston seal ring off into the piston groove on top

ol the O-ring

PISTON SEAL RINGGUIDE07GAG - SD4O10A ol

07GAG - SD,ol(xt

Coat the piston seal ring and the inside of the spe-

cial toolwith power steering fluid.

Carefully slide the tool onto the rack and over the

piston seal ring.

Move the special tool back and forth several times

to make the piston seal ring fit snugly in the piston'

PISTONReplace.

E

PISTON

31. Wrap vinyl tape around the rack teeth and rack end

edges, then coat the surface of the tape with the

power steering fluid

NOTE: Make sure that the vinyl tape is wrapped

carefully so that there is no stepped portion

Coat the inside surface of the new cylinder end seal

with power steering fluid.

Install the cylinder end seal onto the steering rack

with its grooved side toward the piston.

CAUTION: When installing the cylinder end seal,

be caieful not damage the sealing lip face of tho

seal with the edgss or teeth of th€ ste€ring rack'

CYLINDER END SEAL

Make sure thesPring is in the cylinder

end soal

Remove the vinyl tape from the steering rack

NOTE: Remove any residue oftape adhesive(cont'dl

17-59

Page 1117 of 2189

)

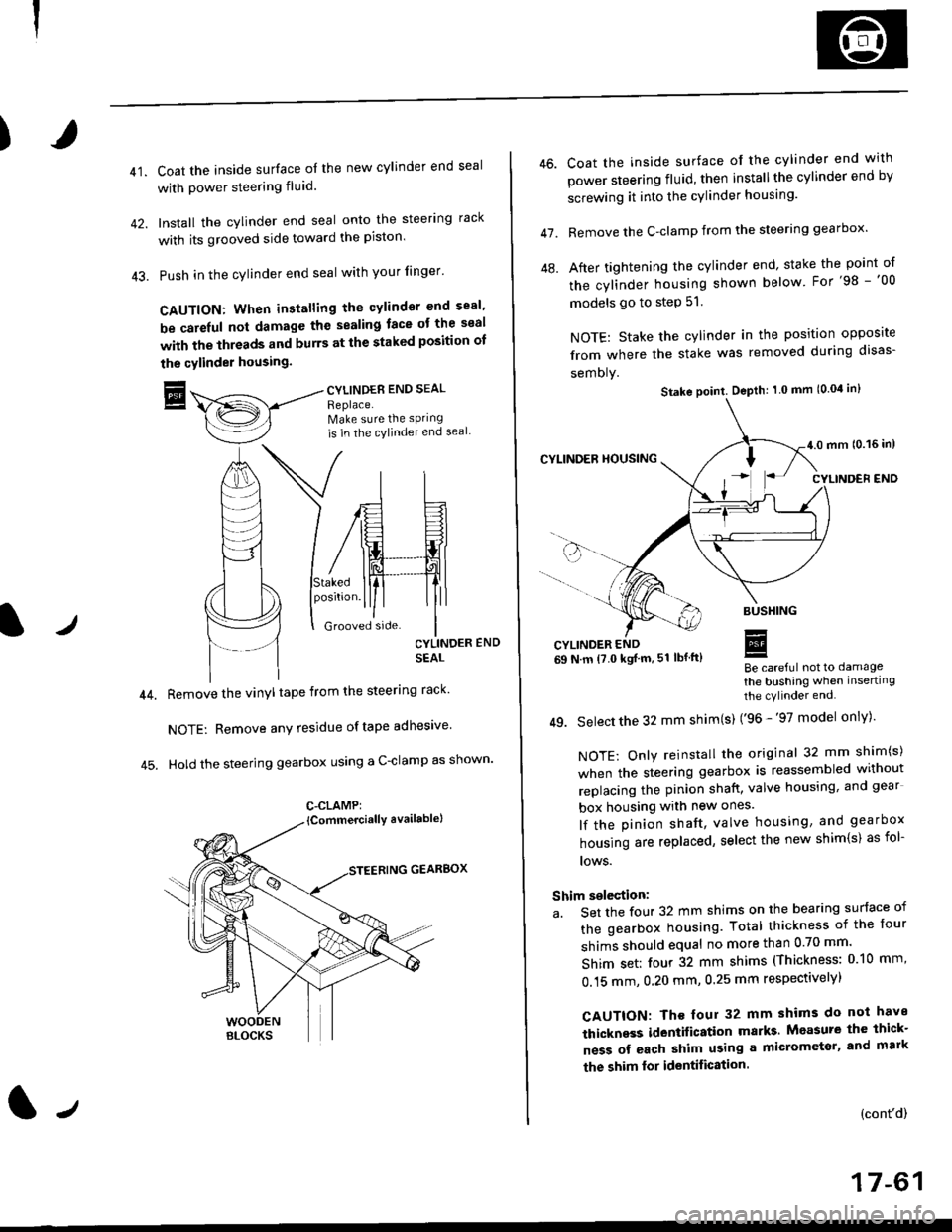

41.Coat the inside surface of the new cylinder end seal

with power steering fluid.

Install the cylinder end seal onto the steering rack

with its grooved side toward the piston'

Push in the cylinder end seal with your finger'

CAUTION: When installing the cylinder end sesl'

be carelul not damage the sealing face ot the seal

with the threads and burrs at the staked position oI

the cylinder housing.

trCYLINDES END SEAL

Replace.Make sure the sPring

is in the cylincler end seal

CYLINDER END

SEAL

Remove the vinyl tape from the steering rack'

NOTE: Remove any residue oftape adhesive

Hold the steering gearbox using a C-clamp as shown'

GEARBOX

C-CLAMP:

l-,

46.

47.

Coat the inside surface of the cylinder end with

power steering fluid, then installthe cylinder end by

screwing it into the cylinder housang.

Remove the C-clamp from the steering gearbox'

After tightening the cylinder end' stake the point of

the cylinder housing shown below For'98 -'00

models go to step 51.

NOTE: Stake the cylinder in the position opposite

from where the stake was removed during disas-

semoly.

Be careful not to damage

the bushing when inserting

the cylinder end.

49. Select the 32 mm shim(s) ('96 -'97 model only)'

NOTE: Only reinstall the original 32 mm shim(s)

when the steering gearbox is reassembled without

replacing the pinion shatt, valve housing, and gear

box housing with new ones.

lf the pinion shaft, valve housing, and gearbox

housing are replaced, select the new shim{s) as fol-

lows.

Shim selection:

a. Set the four 32 mm shims on the bearing surface of

the gearbox housing. Total thickness of the four

shims should equal no more than 0 70 mm'

Shim set: four 32 mm shims (Thickness: 010 mm'

0.15 mm, 0.20 mm, 0.25 mm respectivelyl

CAUTION: Th€ four 32 mm shims do not have

thickness identification marks Measure the thick-

ness of each shim using a micrometsr, and mark

the shim lor identification.

(cont'd)

17-61

Stake point. Depth: 1 0 mm (0.04 in)

Page 1134 of 2189

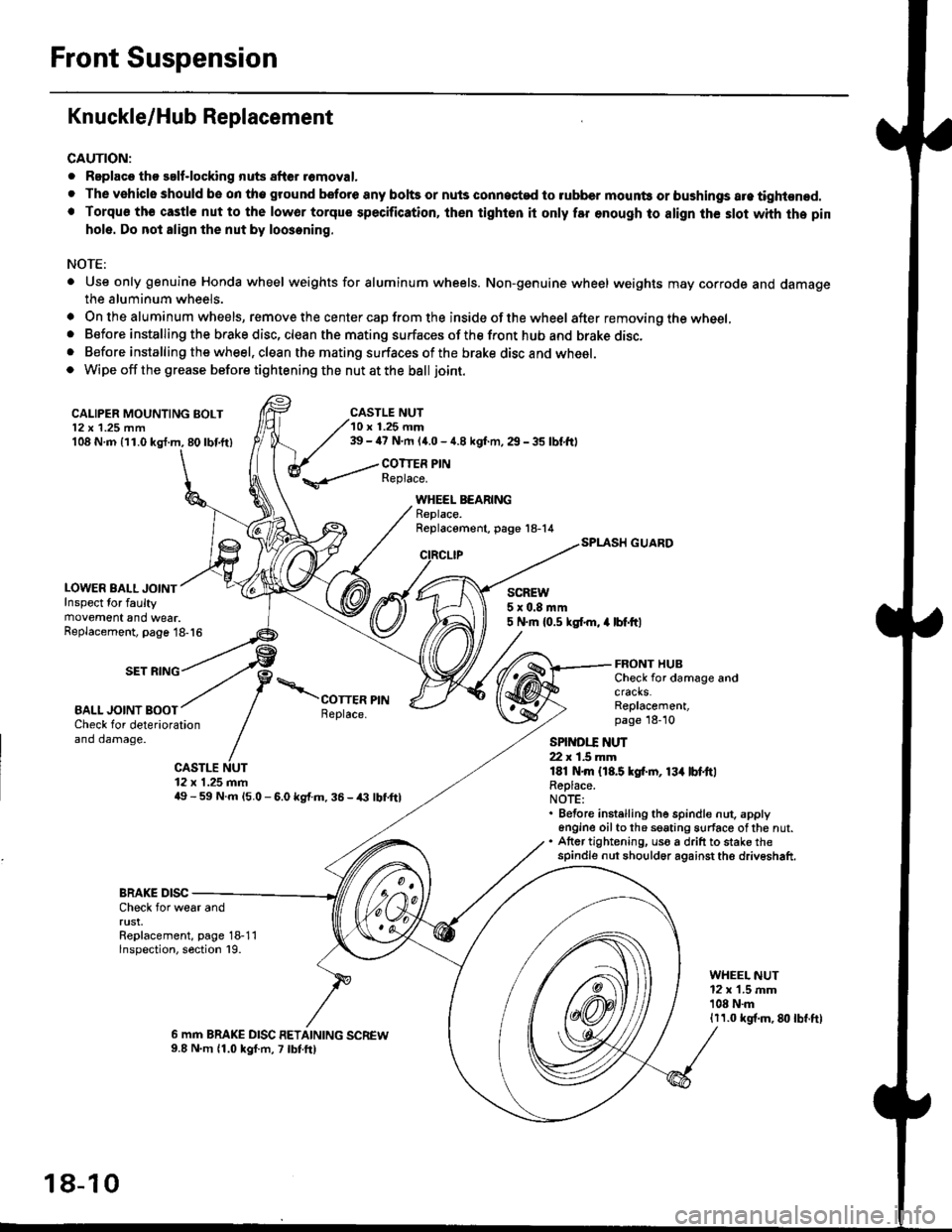

Front Suspension

Knuckle/Hub Replacement

CAUTION:

. Replaco tho salf-locking nuts after romoval.

. The vehiclo should be on tho ground bsfore any bohs or nuls connected to rubber mounb or bushings are tightened.. Torqu€ th€ castle nut to the lowor torque specification, ihen tighton it only far enough to align th€ slot whh the pin

hole. Do not align the nut by loosening.

NOTE:

. Use only genuine Honda wheel weights for aluminum wheels. Non-genuine wheel weights may corrode and damagethe aluminum wheels.

. On the aluminum wheels, remove the center cap from the inside of the wheel after removing the wheel,. Before installing the brake disc, clean the mating surfaces of the front hub and brake disc,. Before installing the wheel, clean the mating surfaces of the brake disc and wheel.o Wipe off the grease before tightening the nut at the ball joint.

CALIPER MOUNTING BOLT12 x 1.25 mm108 N.m {11.0 kgl.m, 80lbf.ft)

LOWER BALL JOINTInspect for faultymovement and wear.

CASTLE NUT10 r 1.25 mm39 - ia7 N.m (4.0 - 4.8 kgf.m, 29 - 35 lbf,ftl

COTTER PINReplace.

WHEEL BEARINGReplace.Replacement, page 18-14

CIRCLIP

SCREW5x0.8mm5 N.m {0.5 ksl.m, 4 lbf.ftlReplacement, page 18-16

SET RING

BALL JOINT BOOT

FRONT HUBCheck for damage andcracks.Replacement,page 18-10Check for deteriorationand damage.

CASTLE NUT12 x 1.25 mm49 - 59 N.m l5.O - 6.0 kg{.m. 36 - /(} lbf,ftl

SPINDI.T ]{UT22 r 1.5 mmlEl N.m {18.5 kgf.rn, 13{ lbl.ttlReplace.NOTE:. Before instelling the spindle nut. apply6n9ine oilto th6 seating surface ofthe nut.. Atter tightening, uso a drift to stake thespindle nut should6r against the driveshaft.

BRAKE DISCCheck for wear andrust.Replacement, page 18-11lnspection, section 19.

WHEEL NUT12 x 1.5 mm'108 N.m1r1.0 kgf.m, 8lt lbf.ft)

6 mm BRAKE DISC RETAINING SCREW9.8 N.m 11.0 kgf.m, 7 lbtft)

18-10

Page 1176 of 2189

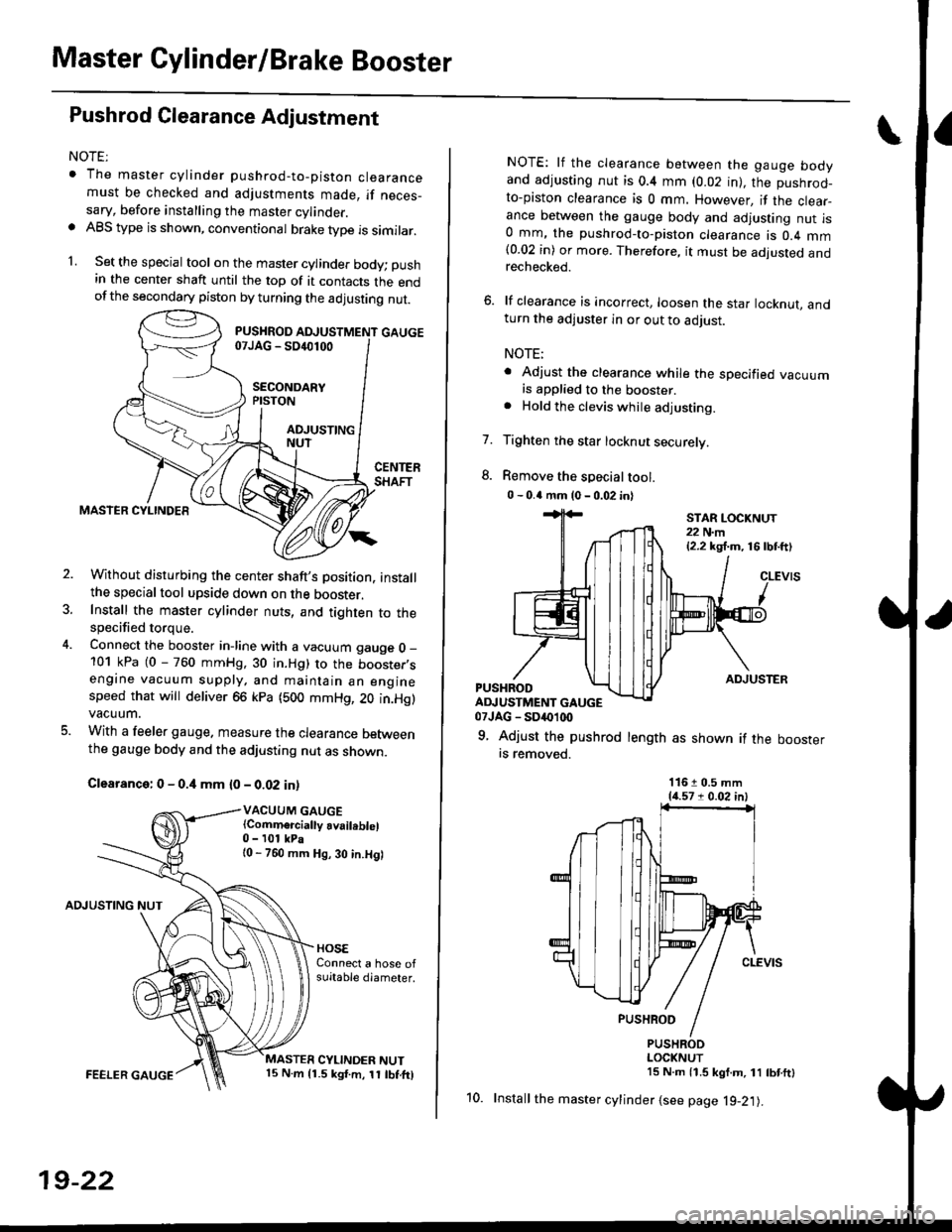

Master Cylinder/Brake Booster

Pushrod Glearance Adjustment

NOTEr

. The master cylinder pushrod-to-piston clearancemust be checked and adjustments made, if neces_sary, before installing the master cylinder.. ABS type is shown, conventional brake type is similar.

1. Set the special tool on the master cylinde. body; push

in the center shaft until the top of it contacts the endofthe secondary piston by turning the adjusting nut.

Without disturbing the center shaft's Dosition, installthe specialtool upside down on the booster.Install the master cylinder nuts, and tighten to thespecified torque.

Connect the booster in-line with a vacuum gauge O _

101 kPa (0 - 760 mmHg, 30 in.Hg) to the booster,sengine vacuum supply, and maintain an enginespeed that will deliver 66 kpa (500 mmHg, 20 in.Hg)vacuum.

With a feeler gauge. measure the clearance Detweenthe gauge body and the adjusting nut as shown.

Clearance: 0 - 0.4 mm {0 - 0.02 in)

VACUUM GAUGE(Comm€rcially availeblel0 - 101 kPa{0 - 760 mm Hg, 30 in.Hg)

AOJUSTING NUT

FEELER GAUGE

19-22

10.

NOTE: lf the clearance between the gauge bodyand adjusting nut is 0.4 mm (0.02 in), the pushrod-to-piston clearance is 0 mm. However, if the clear_ance between the gauge body and adjusting nut is0 mm, the pushrod-to-piston clearance is 0.4 mm(0.02 in) or more. Therefore, it must be adjusted andrechecked.

6. lf clearance is incorrect, loosen the star locknut, andturn the adjuster in or out to adjust.

NOTE;

. Adjust the clearance while the specified vacuumis applied to the booster.. Hold the clevis while adjusting.

Tighten the star locknut securely.

Remove the special tool.

0 - 0.4 mm (0 - 0.02 in)

7.

ADJUSTERPUSHRODADJUSTMENT GAUGE07JAG - SD('1(x)

9. Adjust the pushrod length as shown if the boosterrs removed.

STAR LOCKNUT22 N.m{2.2 kg,f.m, 16lbtft)

11610.5 mm{{.571 0.02 in)

PUSHRODLOCKNUT15 N.m 11.5 kgf.m, 11 tbtftl

Install the master cylinder {see page l9-21).

Page 1182 of 2189

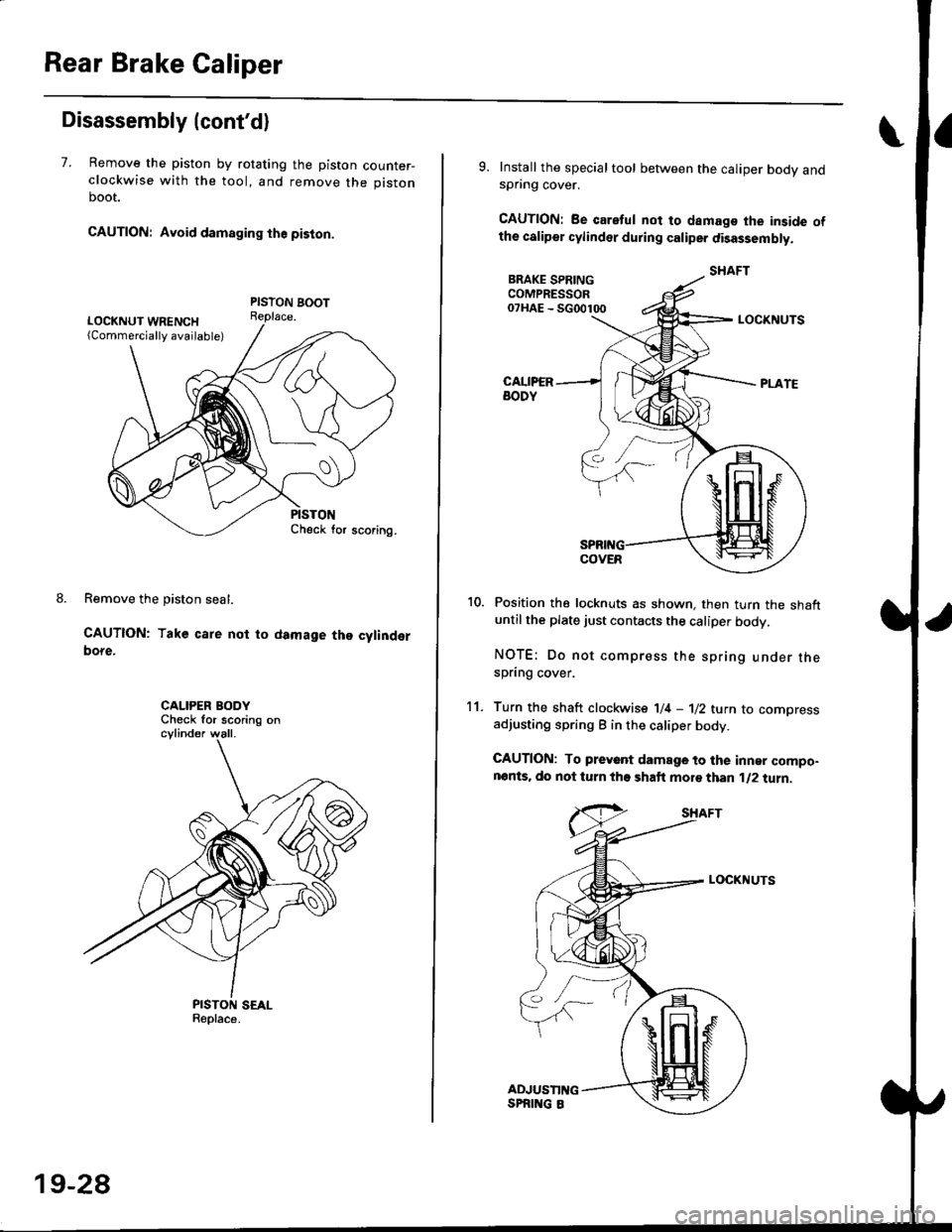

Rear Brake Galiper

Disassembly (cont'd)

7. Remove the piston by rotating the piston counter-clockwise with the tool, and remove the piston

boot.

CAUTION: Avoid damaging the piston.

PISTON BOOTReplace.

Remove the piston seal.

CAUTION: Take care not to damage the cylinderbore.

CALIPER BODYCheck for scoring on

9. Install the special tool between the caliper bodv andspnng cover.

CAUTION: Be caretul not to damags the inside ofthe caliper cylinder during caliper disassembty.

BRAKE SPRINGCOMPRESSOR07HAE - SG00100

11.

LOCKNUTS

Position the locknuts as shown. then turn the shaftuntil the plate just contacts the caliper body.

NOTE: Do not compress the spring under thespring cover.

Turn the shaft clockwise 1/4 -'ll2 tu.n to comoressadjusting spring B in the caliper body.

CAUTION: To preyant damage to the inner compo-nonts. do not turn the shaft mor€ than 1/2 turn.

SHAFT

LOCKNUTS

PISTON SEALReplace.

ADJUSTII{GSPRING 8

19-28

Page 1246 of 2189

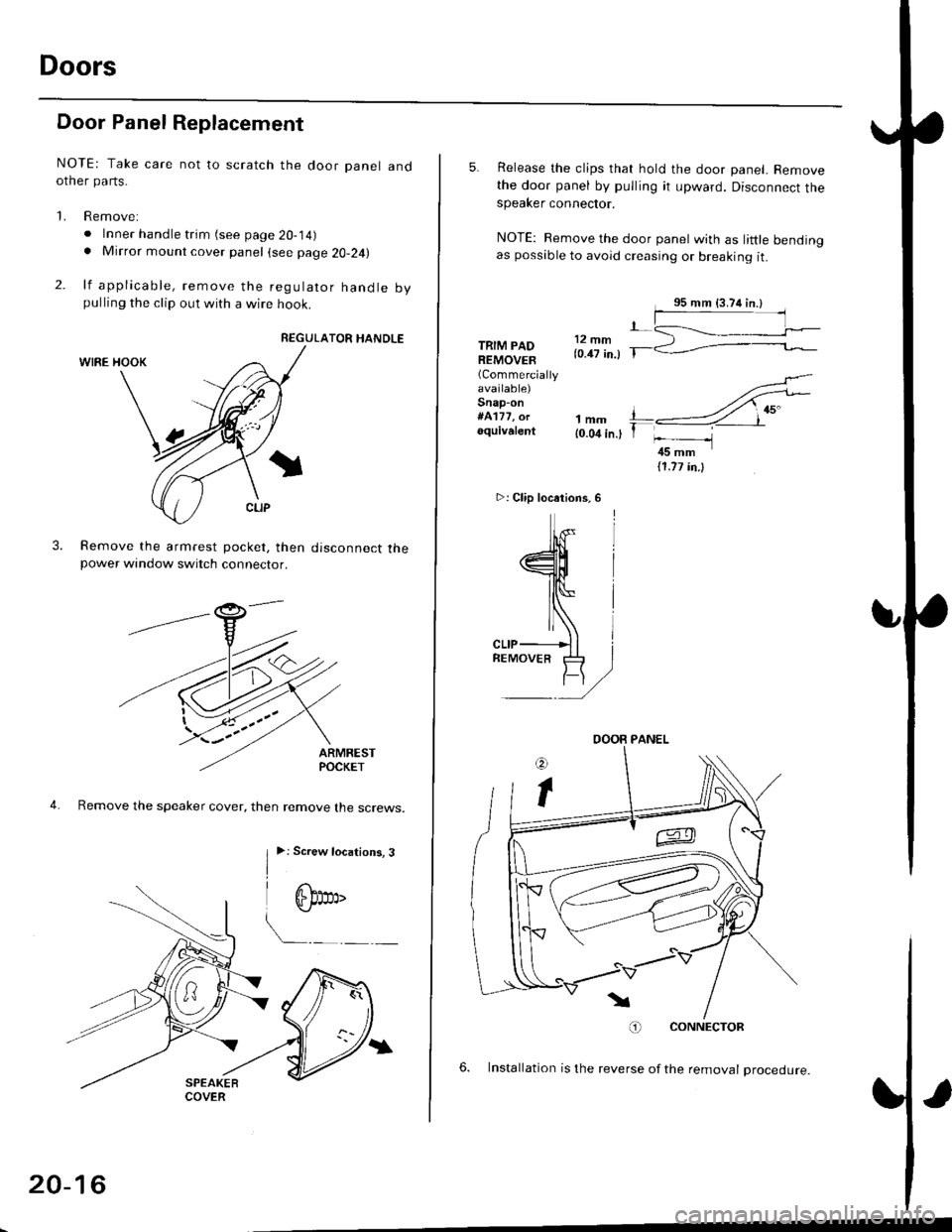

Doors

Door Panel Replacement

NOTE: Take care not to scratch the door panel andother pa rts.

'1. Remove:

. Inner handle trim (see page 20-14). Mirror mount cover panel (see page 20-24)

2. lf applicable, remove the regulator handle bypulling the clip out with a wire hook.

REGULATOR HANDLE

WIRE HOOK

Remove the armrest pocket, then disconnect thepower window switch connector.

ARMRESTPOCKET

4. Remove the speaker cover, then remove lhe screws.

3.

I

>: Screw locations, 3

| 6b:a,'

L"_

COVER

20-16

TRIM PADREMOVER(Commercially

available)Snap-on#A'177, orequivalent1mm{0.04 in.)

5. Release the clips that hold the door panel. Removethe door panel by pulling it upward. Disconnect thespeaker connector.

NOTE: Remove the door panel with as little bendingas possible to avoid creasing or breaking it.

.L12 fim(0.47 in.) T-

>: Clip locations,

l^

J[

=l$

ll,\*

atr-

,,)

REMoVER tl-)

11.77 in.l

O) CONNECTOR

6. lnstallation is the reverse of the removat oroceoure.

DOOR PANEL

Page 1253 of 2189

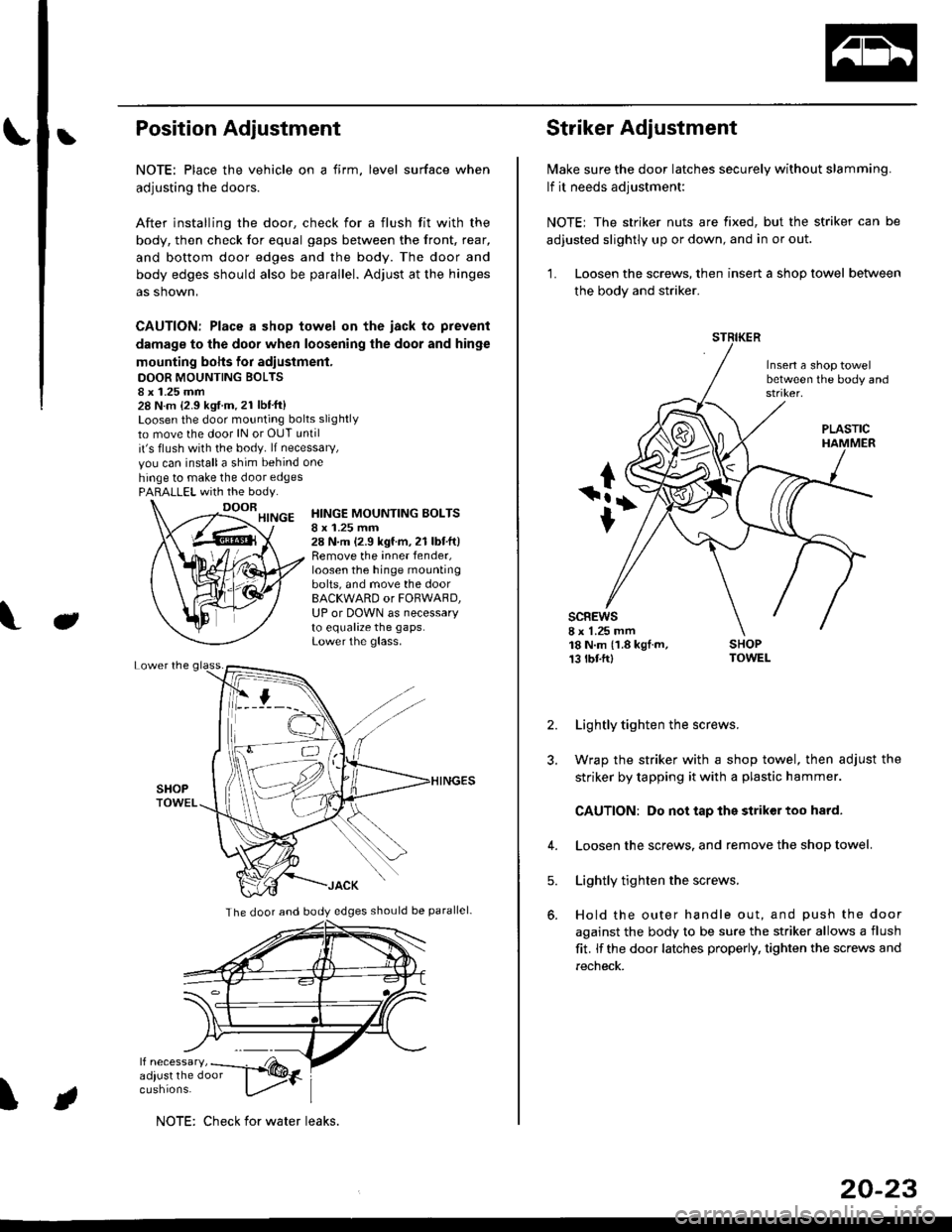

bPosition Adjustment

NOTE: Place the vehicle on a firm, level surface when

adjusting the doors.

After installing the door, check for a flush fit with the

body, then check for equal gaps between the front, rear,

and bottom door edges and the body. The door and

body edges should also be parallel. Adjust at the hinges

as shown,

CAUTION: Place a shop towel on the iack to prevent

damage to the door when loosening the door and hinge

mounting bohs for adiustment.

DOOR MOUNTING BOLTS8 x 1.25 mm28 N.m {2.9 kgf.m.21 lbt'ft}Loosen the door mounting bolts slightly

to move the door lN or OUT until

it's flush with the body. lf necessary,

vou can installa shim behind one

hinge to make the door edgesPARALLEL with the body.

J

HINGE MOUNTING BOLTSI x 1.25 mm28 N.m (2.9 kgf.m,21 lbtft)Remove the inner fender,loosen the hinge mountingbolts, and move the doorBACKWARD or FORWARD,UP or DOWN as necessaryto equalize the gaps.Lower the glass.

\

The door and body edges should be parallel-

ifF t

NOTE: Check for water leaks.

20-23

Striker Adjustment

lvlake sure the door latches securely without slamming.

lf it needs adjustment:

NOTE; The striker nuts are fixed, but the striker can be

adjusted slightly up or down, and in or out.

'L Loosen the screws, then insert a shop towel between

the body and striker.

Insert a shop towelbetween the body and

sc8Ews8 x 1.25 mm18 N.m (1.8 kgf.m,13 tbtftl

PLASTIC

2. Lightly tighten the screws.

3. Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striker too hard.

4. Loosen the screws. and remove the shop towel.

Lightly tighten the screws.

Hold the outer handle out, and push the door

against the body to be sure the striker allows a flush

fit. lf the door latches properly, tighten the screws and

recheck.

5.

Page 1371 of 2189

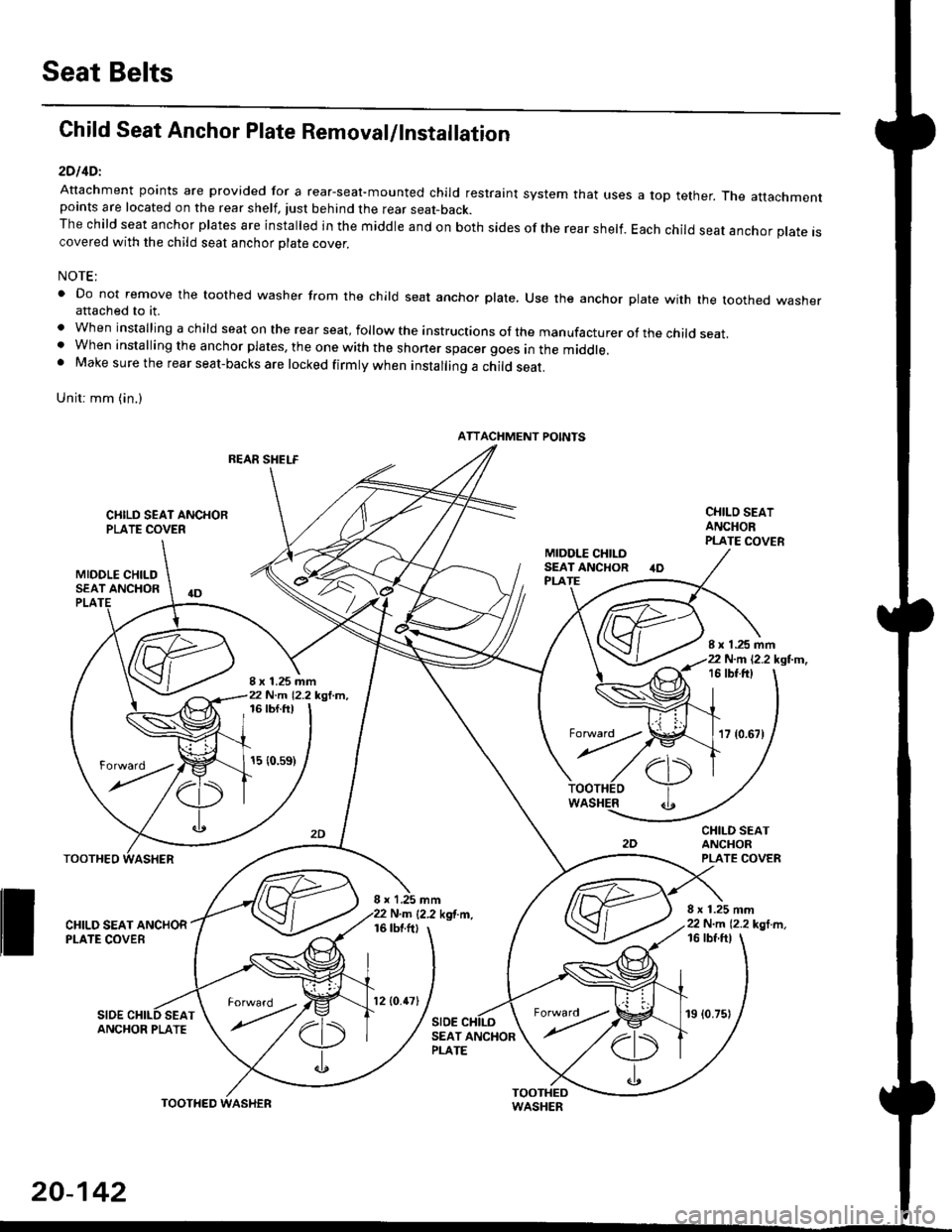

Seat Belts

Child Seat Anchor Plate Removal/lnstallation

2DllDl

Attachment points are provided for a rear-seal-mounted child restraint system that usespoints are located on the rear shelf, tust behind the rear seat-back.The child seat anchor plates are installed in the middle and on both sides of the rear shelf.covered with the child seat anchor olate cover.

a top tether. The attachment

Each child seat anchor plate is

NOTE:

' Do not remove the toothed washer from the child seat anchor plate, Use the anchor plate with the toothed washerattached to it.

. When installing a child seat on the rear seat, follow the instructions of the manufacturer of the child seat.. When installing the anchor plates, the one with the shoner spacer goes in the middle.. Make sure the rear seat-backs are locked firmly when installing a child seat.

Unit: mm (in.)

REAR SHELF

CIIILD SEAT ANCHORPLATE COVER

MIDOLE CHILDSEAT ANCHOR

CHILO SEATANCHORPLATE COVER

CHILD SEATANCHORPLATE COVER

8 x 1.25 mm22 N.m 12.2 kgl m,

PLA

8 x 1.25 mm22 N.m 12.2 kgl.m,

I x 1.25 mm22 N.m 12.2 kgl.m,16 tbt.ftt

17 {0.67)

16 tbf.ft)

15 {0.s9)

WASHER

rl)

.t

TOOTHEO

ll ff*,".rd,',i"'"o*

SIDESEAT

I x 1,25 mmN.m {2.2 kgf.m.16 tbtftl

SIDE

16 tbf ftl

ANCHOR PLATESEAT ANCHORPLATE

ATTACHMENT POINTS

torward .

20-142

TOOTHED

12lO.47l19 (0.75)

Page 1474 of 2189

Troubleshooting

Tips and Precautions (cont'dl

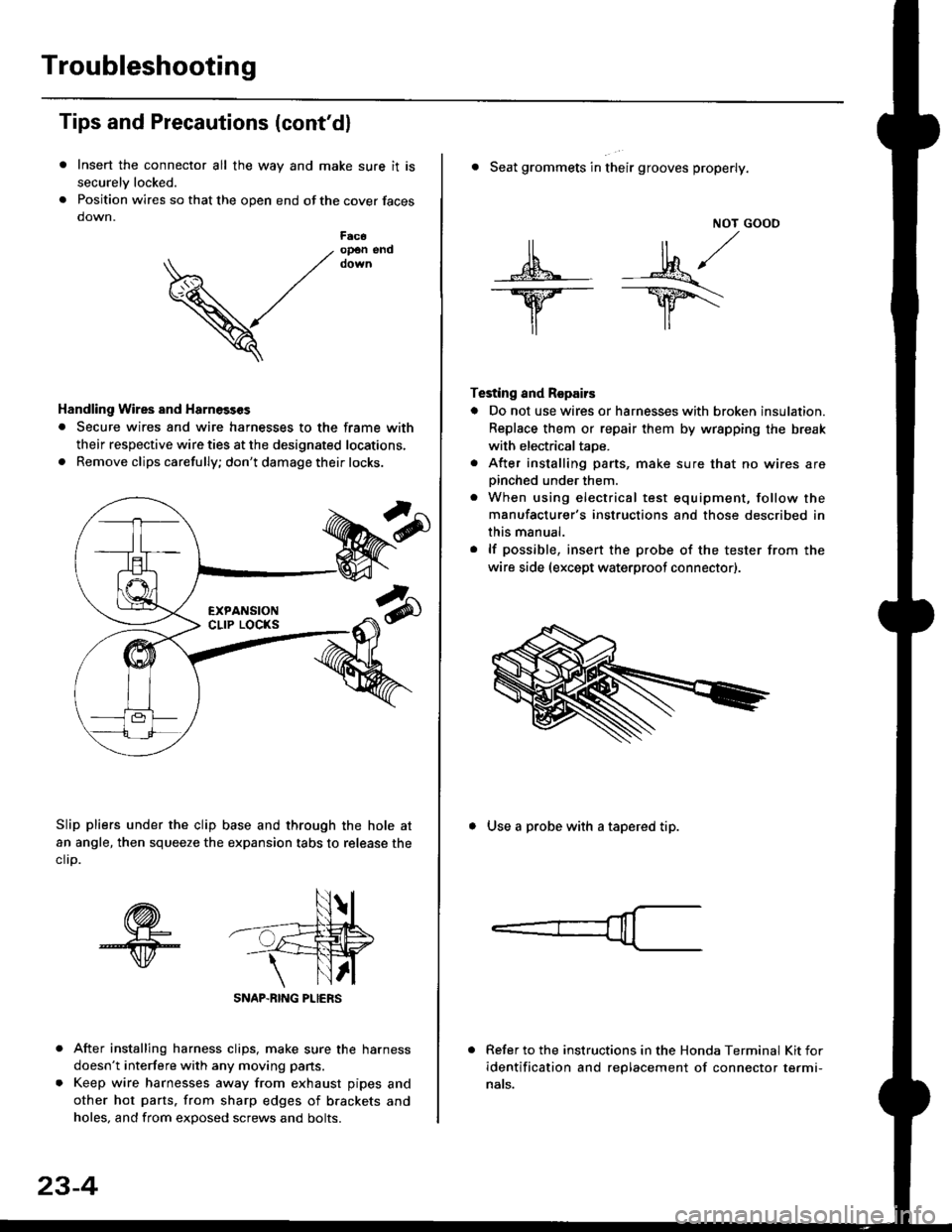

Insert the connector all the way and make sure it is

securelv locked.

Position wires so that the open end of the cover faces

down.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts. from sharp edges of brackets and

holes, and from exDosed screws and bolts.

V

F6c6op€n end

Handling Wires and Harnosscs

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations,

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrp.

SNAP-BING PLIERS

23-4

NOT GOOO

ll il,/

s*' -.1}8."/_Y--_Y5\

il ,,

Testing and Repairs

o Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrspping the break

with electricaltaoe.

. After installing parts, make sure that no wires arepinched under them.. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nats.

Page 1819 of 2189

How To Use This Manual

Circuit Schematics

oa

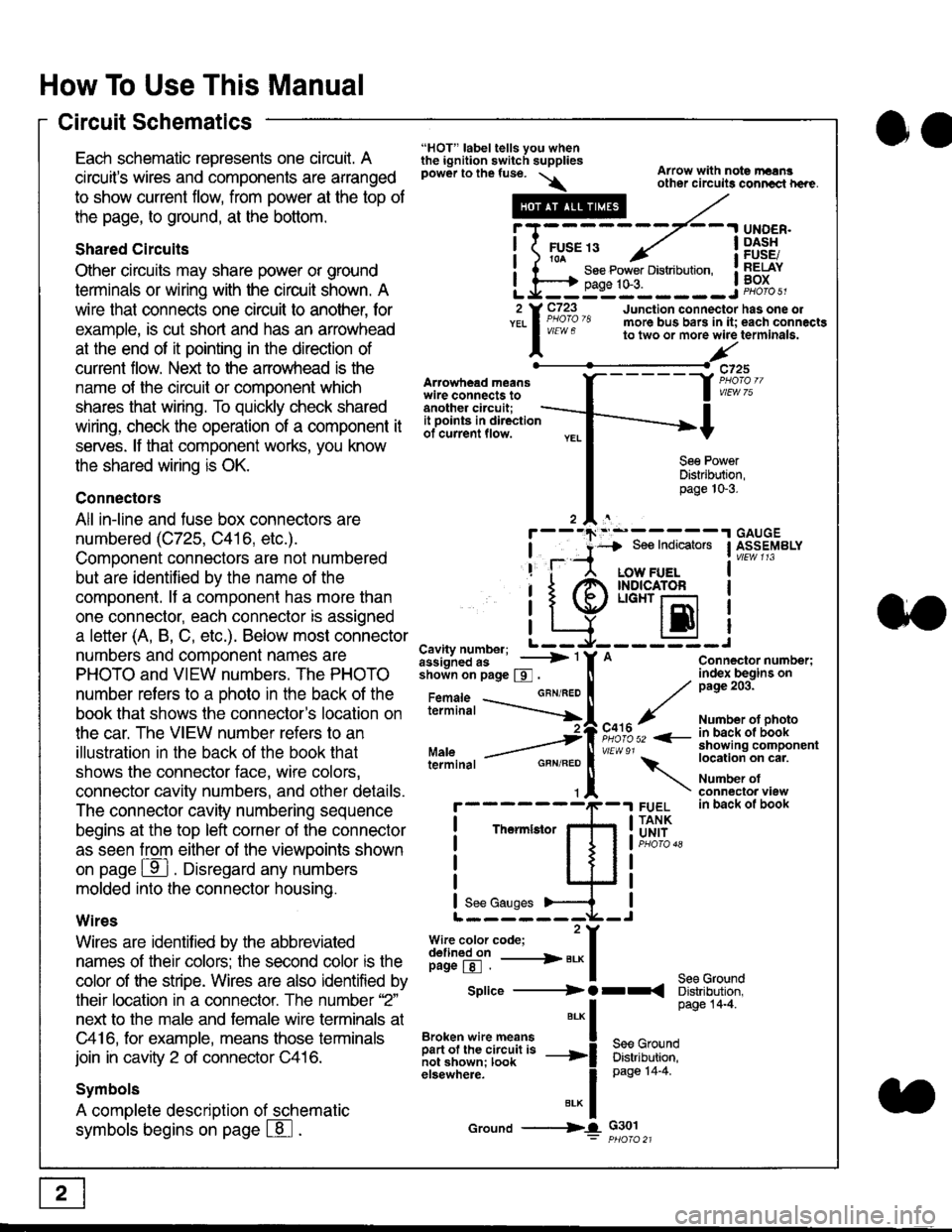

Each schematic represents one circult. A

circuit's wires and components are arranged

to show current flow, from power at the top of

the page, to ground, at the bottom.

Shared Circuits

Other circuits may share power or ground

terminals or wiring with the circuit shown. A

wire that connects one circuit to another, for

example, is cut short and has an arrowhead

at the end of it pointing in the direction of

current flow. Nelit to the anowhead is the

name o{ the circuil or comoonent which

shares that wiring. To quickly check shared

wiring, check the operation of a component it

serves. lf that component works, you know

the shared wiring is OK.

Connectors

All in-line and fuse box connectors are

numbered (C725, C416, etc.).

Component connectors are not numbered

but are identiJied by the name of the

component. lf a componenl has more than

one connector, each connector is assigned

a letter (A, B, C, etc.). Below most connector

numbers and comDonent names are

PHOTO and VIEW numbers. The PHOTO

number refers to a Dhoto in the back of the

book that shows lhe conneclor's location on

the car. The VIEW number refers to an

illustration in the back of the book that

shows the connector face, wire colors,

connector cavity numbers, and other details.

The connector cavity numbering sequence

begins at the top left corner oJ the connector

as seen from either of the viewooints shown

on page ffl . Disregard any numbers

molded into the connector housino.

Wires

Wires are identilied by the abbreviated

names of their colors; the second color rs the

color of the stripe. Wires are also identified by

their location in a connector. The number '2"

next to the male and female wire terminals at

C416, for example, means those terminals

join in cavity 2 of connector C416.

Symbols

A complete description of schematic

symbols begins on page | 8

"HOT" label tells you whenthe ignition switch suppliespower to the fuse. \

Artowhead meanswire connects toanother circuit;

Arrow with note rErngother circuils conncct h€re.

it .a

llu":: ^,{ ii t See Power Distribution, .I t----t oaqe tO-3. IL*--:--------J2 Y C723 Junction connectorYEL I Pao'o'8 more bus bars in it;

I - " " to two or more wire

l,/

-t>?

See PowerDistribution,page 10-3.

UNDER.DASHFUSE/RELAYBOX

has one oleach connactgterminala.

it ooints in directionof current flow.

TheImletor

t_I

Cavity number; L ---

Jiili'iJi!--' -----> '

shoin on page S .

Maleterminal

L?*?l?,-

"'"'I

c725

vlEUt/ 75

Connector number;index begins onpage 203.

Number ot photoin back ol bookshowing componentlocation on cat.

Number ofconneclor viewin back of book

7

GBN/FEO

See Ground

Soe Indicators I ASSEMBLY

:-------J

LOW FUELINDICATOFLIGHT r-l

EI

A

"o'r"/PHOTO 52 <-

\

FUELTANKUNIT

Splice ---------) O rr

".* I Page 14'4'

IBroken wire means | --^ -

iar";J.'It,;,rJ;ii; -----i Bffi,Bili*l

elsewhere. I 0a0e tn-a

IBrK Icround --->lL c301: ptioro 21