Recover HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 290 of 2189

![HONDA CIVIC 1998 6.G Workshop Manual D16Y5 engine (99 - 00 modelsl:

O) PRIMARY HEATED OXYGEN SENSOR (PBIMARY HO2S,

SENSOR 1)

O SECONDARY HEATEO OXYGEN SENSOR {SECONDARY

HO2S. SENSOR 2)

6] MANIFOLD ABSOLUTE PRESSURE IMAPI SENSOR

rO CruCI HONDA CIVIC 1998 6.G Workshop Manual D16Y5 engine (99 - 00 modelsl:

O) PRIMARY HEATED OXYGEN SENSOR (PBIMARY HO2S,

SENSOR 1)

O SECONDARY HEATEO OXYGEN SENSOR {SECONDARY

HO2S. SENSOR 2)

6] MANIFOLD ABSOLUTE PRESSURE IMAPI SENSOR

rO CruCI](/img/13/6068/w960_6068-289.png)

D16Y5 engine ('99 - 00 modelsl:

O) PRIMARY HEATED OXYGEN SENSOR (PBIMARY HO2S,

SENSOR 1)

O SECONDARY HEATEO OXYGEN SENSOR {SECONDARY

HO2S. SENSOR 2)

6] MANIFOLD ABSOLUTE PRESSURE IMAPI SENSOR

rO CruCIruC COOUruT TEMPERATURE IECTI SENSOR

o rrurlxe ln ETUpERATURE 0AT) SENSOR

.d KNOCK SENSOR (KS}

O CN,NruXSXITT SP:ED FLUCTUATION (CKFI SENSOR

@ rou an corurnoL 0Ac) valvE

O THROTTLE BODY (TB)

@ FUEL INJECTOR

E) FUEL PULSATION OAMPER

t? FUEL FILTER

G) FUEL PRESSURE REGULATOR

OI FUEL PUMP (FP)

Gi FUEL TANK

G) AIR CLEANERfi? RESONATOR

Gl posmvr cnglrcAsE VENTILATION (PCV) VALVE

@ EXHAUST GAS RECIRCULATION IEGR} CONTROL

SOLENOID VALVE6 EXHAUST GAS RECTRCULATION (EGR) VAI-VE

rf exxlust cls nectRcuLATloN IEGR) vALvE LIFT

SENSOR@ EVAPORATIVE EMISSION (EVAPI PURGE CONTNOL

SOLENOID VALVE

O} PURGE JOINTio :vaponanve eutssloN (EVAP) coNTRoL cANlsrER

d rvlponlrtve EmtsstoN tEvAPl BYPASS soL-eNolD

VALVE

6 EVAPORATIVE EMISSION {EVAP) CONIROL CANISTER

FILTER

@ EVAPORATIVE EMISSION (EVAPI CONTROL CANISTER

VENT SHUT VALVEOA FUEL TANK PRESSURE SENSOR

6 :vlponlnvg er,/tlssloN tEvAPl TWO WAY VALVE

6 oNgoano nerueltNc vAPoR REcovERY {onvRl VENT

SHUT VALVE

€!) ONBOARD REFUELING VAPOR RECOVERY (ORVRI VAPOR

RECIBCULATION VALVE

@ THREE WAY CATALYTIC CONVERTER (TWCI

(cont'd)

11-21

L

Page 293 of 2189

![HONDA CIVIC 1998 6.G Workshop Manual System Description

Vacuum Connections (contdl

D16Y8 engine l99 - 00 modetsl:

(]-i PAIMARY HEATEO OXYGEN SENSOR {PRIMARY HO2S,SENSOR 1)..2r SECONOARY HEATEO OXycEN SENSOB ISECONDARYHO2S, SENSOR 2li3) HONDA CIVIC 1998 6.G Workshop Manual System Description

Vacuum Connections (contdl

D16Y8 engine l99 - 00 modetsl:

(]-i PAIMARY HEATEO OXYGEN SENSOR {PRIMARY HO2S,SENSOR 1)..2r SECONOARY HEATEO OXycEN SENSOB ISECONDARYHO2S, SENSOR 2li3)](/img/13/6068/w960_6068-292.png)

System Description

Vacuum Connections (cont'dl

D16Y8 engine l'99 - 00 modetsl:

(]-i PAIMARY HEATEO OXYGEN SENSOR {PRIMARY HO2S,SENSOR 1)..2r SECONOARY HEATEO OXycEN SENSOB ISECONDARYHO2S, SENSOR 2li3) MANIFOLD ABSOLUTE PBESSURE {MAPI SENSORO ENGINE cooLANT TEMPERATURE (ECTI sENsoR(5) INTAKE AIR TEMPERATURE {IAT} sENsoRG] KNOCK SENSOR IKSI?r CRANKSHAFT SPEEo FLUCTUATTON {CKF) SENSOR.O IDLE AIR coNTRoL {IAc)vALvEi-9] THROTTLE BOOY {TB)(O FUEL INJECToRI]'i FUEL FILTER.O FUEL PRESSURE REGULAToR[t FUEL PUMP {FPl.D FUEL TANKil' AIR CLEANERTD RESONATORO FUEL TNJEC oN AtR tFtA) coNTRoL vAt_vE.19 POSITIVE CRANKCASE VENTILATION {PCVI VALVE

.19) EVAPORATIVE EMIssIoN {EVAP) PURGE coNTBoLSOLENOID VALVE€g PURGE JorNTtj EVApoRATtvE EMtsstoN {Evap} coNTRoL cANtsTERC4 EVAPONANVE EMISSION (EVAP) BYPASS SOLENOIDVALVE

?3 EVAPORATIVE EMISSION {EVAP} CONTROL CANISTERFILTERA4 EVAPoBATIVE EMIssIoN (EVAP) coNTRoL CANISTERVENT SHUT VALVEC! FUEL TANK PRESSURE sENsoREO EVAPOBATIVE EMISSION (EVAP) TWO WAY VALVEe? oNBoARD REFUELtiIG vApoR REcovERy {oRvR} VENTSHUT VALVE@ oNBoARD REFUELTNG vapoR REcovERy (oRvR) vapoRRECIRCULATION VALVEiP THREE WAY CATAI.YTIC CONVEBTER {TWCI

'- *o'*- -

COOLANT

]L

nrl

L

ii8'x'", *

--j IIM TTI ^n 14 [l(2i)-fr l-1ry|

11-24

Page 296 of 2189

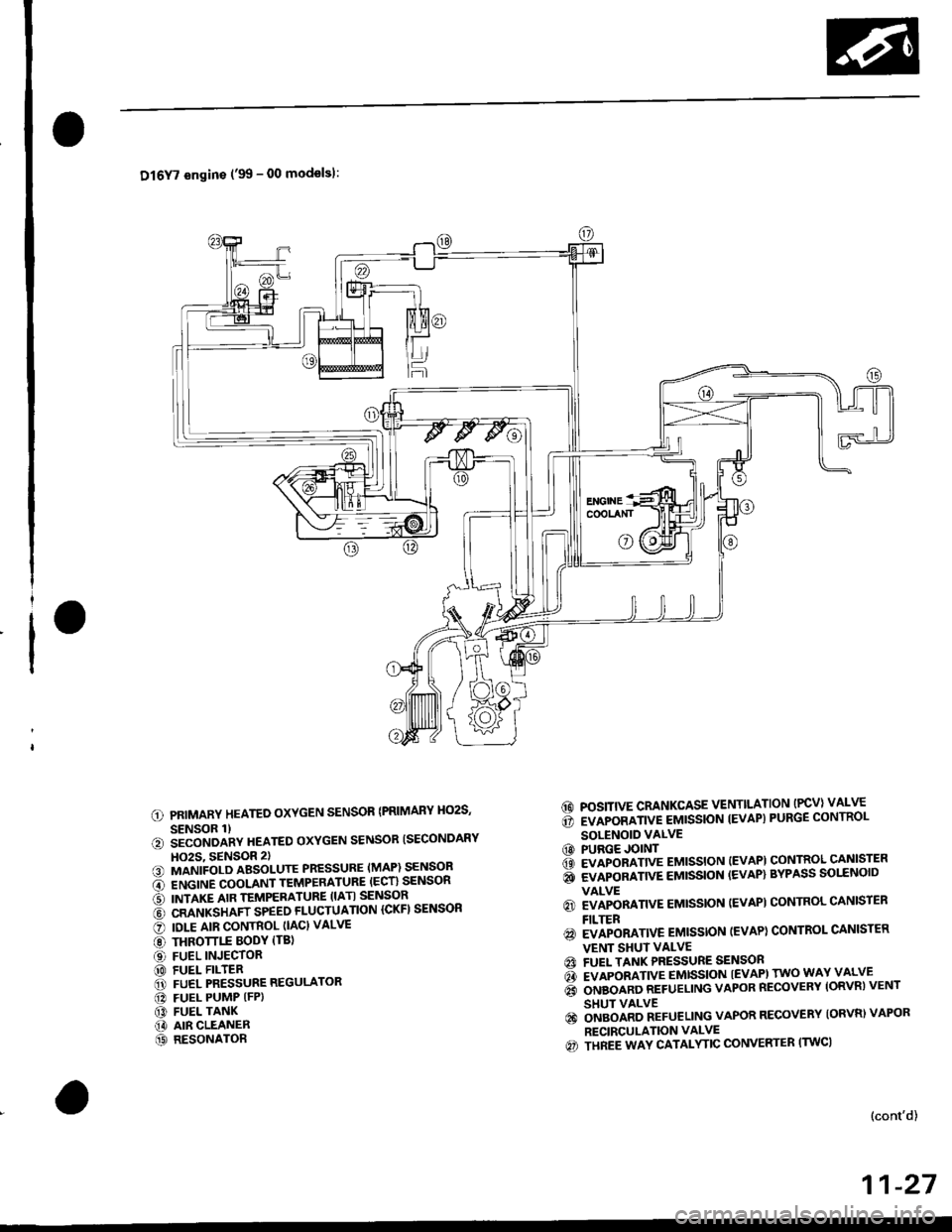

Dl6Y7 engins ('99 - 00 modelsl:

PRIMARY HEATED OXYGEN SENSOR {PRIMARY HO2S,

SENSOR 1)iiconoanv neareo oxYGEN sENsoR ISECoNDARY

HO2S, 9ENSOR 2)MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

ENGINE COOLANT TEMPERATURE (ECT} SENSOR

INTAKE AIR TEMPERATURE (IATI SENSOR

CRANKSHAFT SPEED FLUCTUATION ICKFI SENSOR

IOLE AIR CONTROL (IAC} VALVE

THROTTLE BODY (TBl

FUEL INJECTORFUEL FILTERFUEL PRESSURE REGULATOR

FUEL PUMP (FP)

FUEL TANKAIR CLEANERRESONATOR

6d POSITIVE CRANKCASE VENTILATION (PCV) VALVE

6 rvapoamve eutssloN tEvAP) PURGE coNTRoL

SOLENOID VALVECO PURGE JOINT6 evlponnnve eutssloN (EvAPl coNTRoL cANlsrER

i evlponnnve eussloN {EVAP} BYPASS solrNolD

VALVE

6) EVAPORATIVE EMISSION (EVAPI CONTROL CANISTEN

FILTER

@ EVAPORATIVE EMISSTON (EVAP) CONTROL CANISTER

VENT SHUI VALVEA FUEL TANK PRESSURE SENSON

d rvlpoamve emtsstoN tEvAPl rwo wAY vALvE

6 orueonno nerueLING vAPoR REcovERY loRvnl vENT

SHUT VALVE

€) ongolno neruellNc VAPOR RECOVERY {ORVR) VAPOR

RECIRCULATION VALVE

€) THREE WAY CATALYTIC CONVERTER (TWC)

a

6t

@!.,

o@ao

@@

(}

@@

(cont'd)

11-27

Page 297 of 2189

I

a

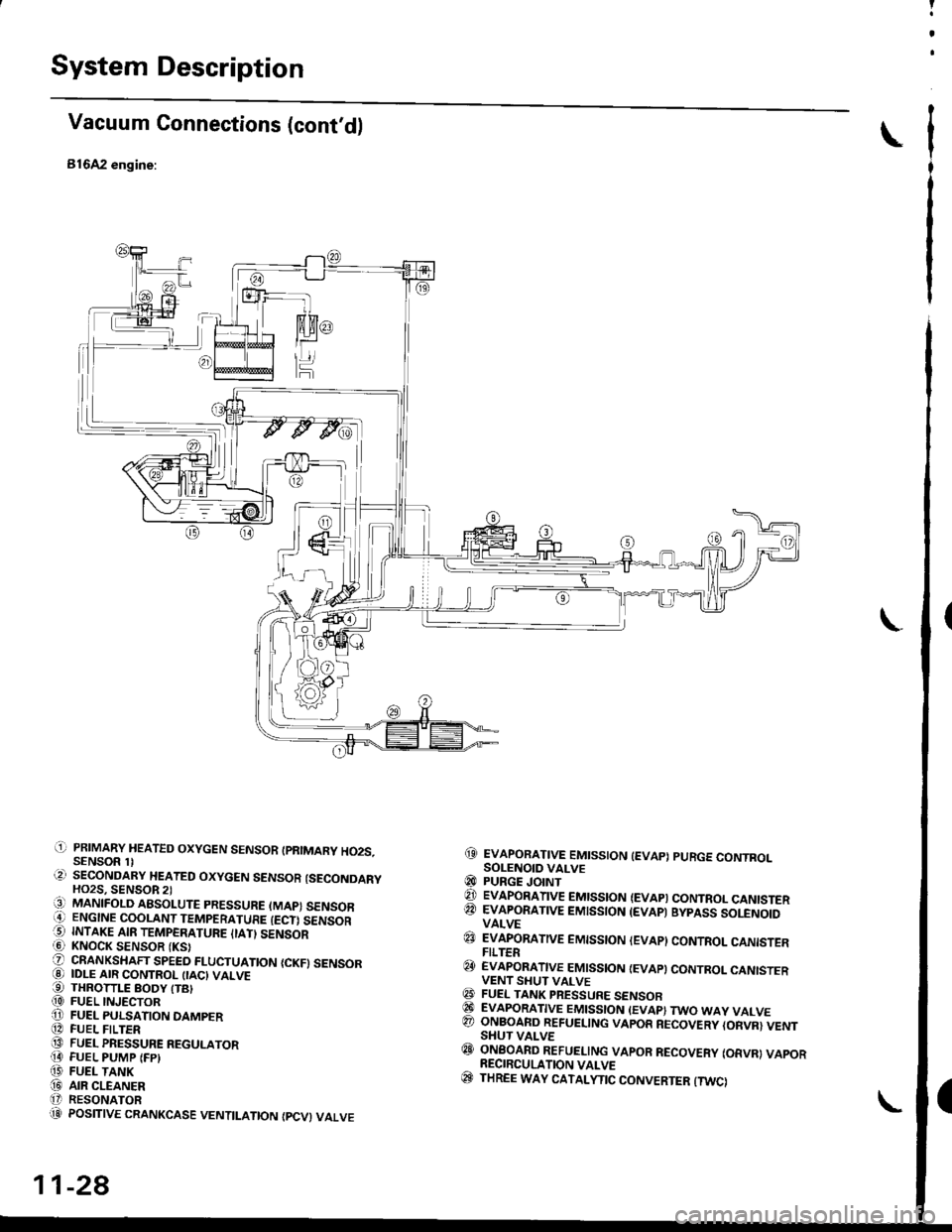

System Description

Vacuum Connections (cont'd)

816A2 engine:

@ EvApoRATtvE EMtsstoN tEvAp) puRGE coNTRoLSOLENOID VALVE@ PURGE JoINT€t EvApoRATtvE EMtsstoN (EVApt coNTRoL caNtsTERQA EVAPORATIVE EMISSION (EVAP) BYPASS SOLENOIDVALVE

@ EVApoRATtvE EMtsstoN lEvApl coNTRoL caNtsrERFILTER@ EvApoRATtvE EMtsstoN {EvApt coNrRoL cANtsrERVENT SHUT VALVE@ FUEL TANK PRESSURE sENsoRGI EVAPORATIVE EMISSION (EVAP} TWO WAY VALVE@ ONBOARD REFUETING VAPOR RECOVERY {ORVR} VENTSHUT VALVE@ oNBoAnD REFUELING vApoR REcovERy (oRvRl vApoR. RECIRCULATION VALVE(c} THREE WAY CATALYTIC CONVERTER {TWCI

(' PRIMARY HEATED OXYGEN SENSOR IPRIMARY HO2S.SENSOR 1l.?) SECONDARY HEATED OXYGEN SENSOR {SECONDARYHO2S, SENSOR 2)13] MANIFOLD ABSoLUTE PRESSURE (MAP) sENsoBi' ENGINE COOLANT TEMPERATURE IECT) SENSORO INTAKE AIR TEMPERATURE ITATI SENSORi6l KNOCK SENSOR {KS}O oRANKSHAFT SPEED FLUCTUATIoN {cKF} sENsoR@ IDLE AIR coNTRoL (IAc} VALVE€) THRoTTLE BoDy trB|(D FUEL INJECToRO FUEL PULSATIoN DAMPER[D FUEL FILTER@ FUEL PRESSURE REGULAToR!I FUEL PUMP IFP)f,' FUEL TANK(iD ArR CLEANERt' RESONAToR'.1]i POSITIVE cRANKcAsE VENTILATIoN {Pcv} VALVE

11-28

Page 536 of 2189

1\

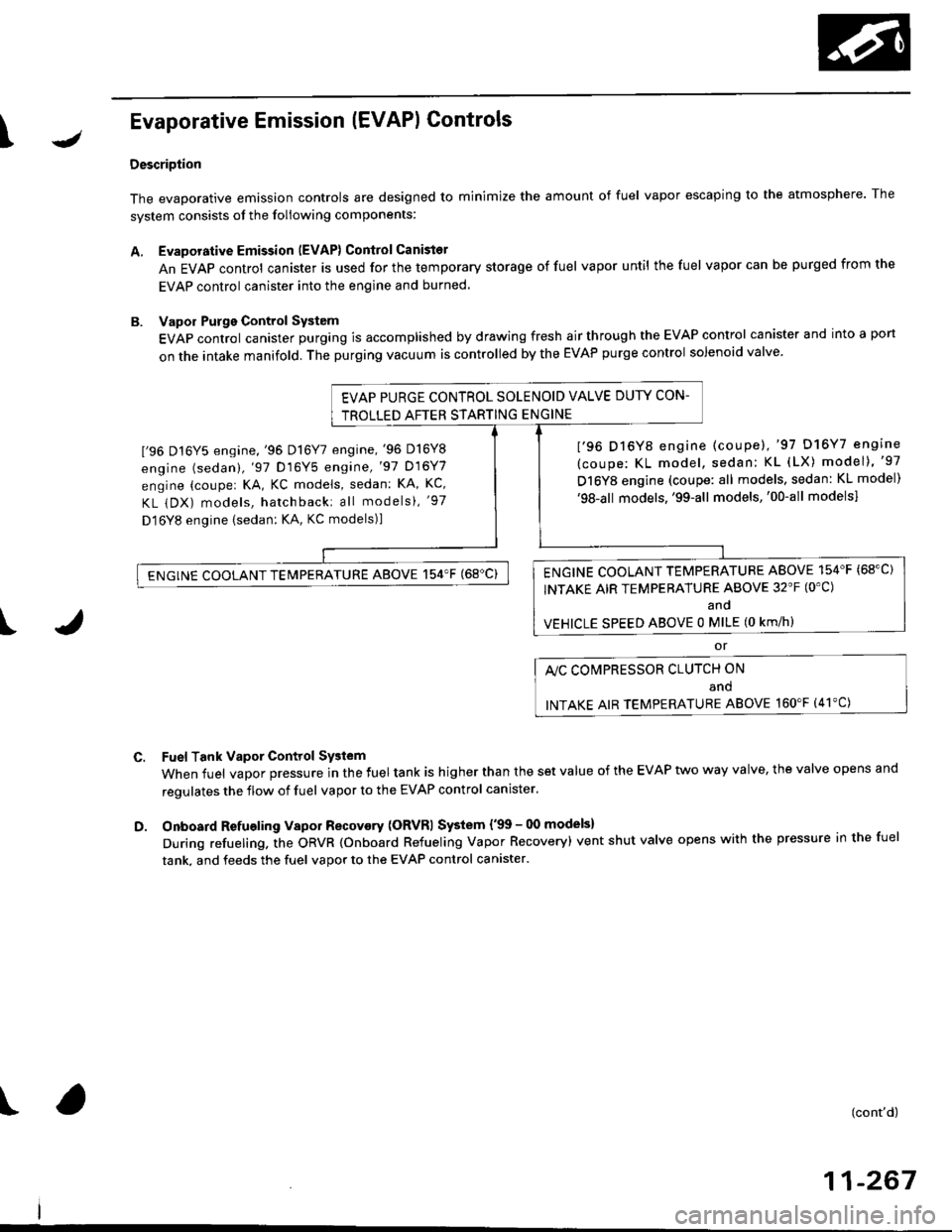

Evaporative Emission (EVAPI Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the foliowing components:

A. Evaporative Emission (EVAP) Control Canisto]

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

I'96 D16Y5 engine,'96 Dl6Y7 engine,'96 D16Y8

engine (sedan),'97 D16Y5 engine,'97 D16Y7

engine (couper KA, KC models, sedan: KA, Kc'

KL iDX) models, hatchback: all models), '97

D 16Y8 engine (sedan: KA, KC models)l

I'96 D16Y8 engine (coupe),'97 D16Y7 engine

(coupe: KL model, sedan: KL (LX) model)"97

D16Y8 engine (coupe: all models, sedan: KL model)'98-all models,'99-all models,'00-all modelsl

I

c.

D.

or

l'lc COMPRESSOR CLUTCH ON

and

INTAKE AIR TEMPERATURE ABOVE 160"F (41'C)

Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

Onboard Refueling Vapor Recovery (ORVRI System {'99 - 00 models}

During refueling. the oRVR {onboard Refueling Vapor Recovery) vent shut valve opens with the pressure in the fuel

tank. and feeds the fuel vapor to the EVAP control canister.

t(cont'd)

11-267

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154'F {68"C)

INTAKE AIR TEMPERATURE ABOVE 32'F (O'C)

and

VEHICLE SPEED ABOVE O MILE (O KM/h}

ENGINE COOLANT TEMPERATURE ABOVE 154'F (68'C)

Page 539 of 2189

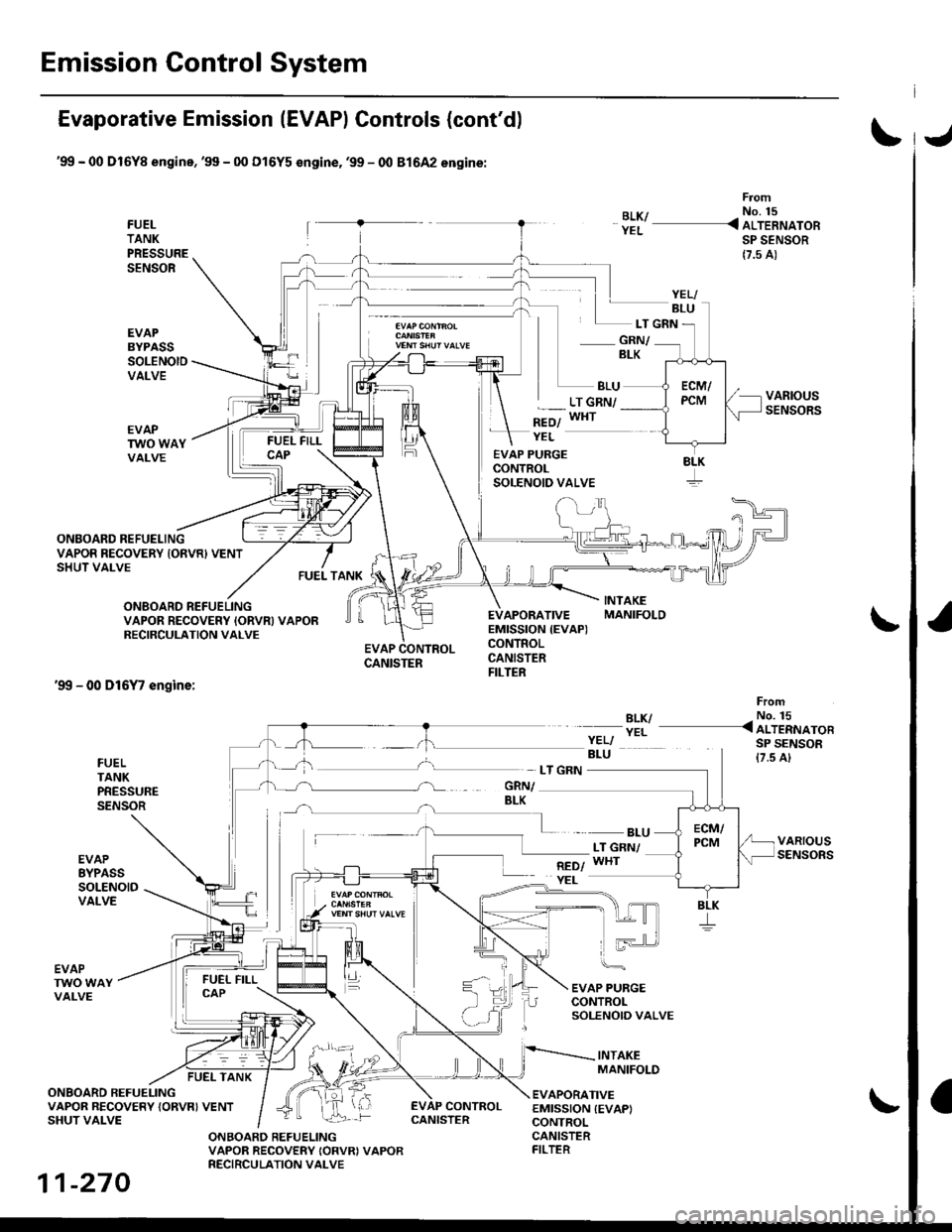

Emission Control System

Evaporative Emission (EVAPI Controls (cont'd)

'99 - 00 Dl6Yg engine,'99 - 00 Dl6Y5 €ngine,'99 - 00 81642 engine:

FUELTANKPRESSURESENSOR

EVAPBYPASSSOLENOIDVALVE

From

BLK/ - No. 15

YEL _ ALTERNATORSP SENSOR

{7.5 A)

- GRN/BLK

BLU

*=ol

LT GRN/WHT

ONBOARD REFUELING

FUEL TANK

EVAP PURGECONTROLSOLENOID VALVE

EVAPORATIVEEMISSION {EVAP)CONTROLCANISTERFILTER

YEL

LT GRN

VAPOR RECOVERY IONVR) VENTSHUT VALVE

ONBOARD REFUELINGVAPOR RECOVERY IORVN} VAPORRECIRCULATION VALVE

'99 - 00 D16Y7 engine:

EVAP CONTROLCANISTER

BLK/YEL

FromNo. 15< ALTERNATORSP SENSOR{7.5 A}FUELTANKPRESSURESENSOR

EVAPEYPASSSOLENOIDVALVE

- BLULT GNN/WHT

EVAP PURGECONTROLSOLENOIO VALVE

INTAKEMANIFOLD

EVAPTWO WAYVALVE

FUEL TANK

ONBOARD REFUELINGVAPOR RECOVERY {ORVRI VENTSHUT VALVE

EVAPORATIVEEMISSION {EVAPICONTROL

EVAP CONTROL

ONBOARD REFUELINGVAPOR RECOVERY IORVRI VAPORRECIRCULATION VALVE

CANISTERFILTER

YELI

8LK

11-270

CANISTER

Page 1425 of 2189

Air Conditioning

Speciaf Tools ......'.....' 22-2

f f f ustrated f ndex ......................... ".......' 22-3

Wiring/Connector Locations'.........'.... 22'4

Description

Outfine ............ .......22-s

Circuit Diagram

'96 - 98 Models ......"..........".......'.... 22-6

'99 Modef """""""' 22-7

Troubleshooting

Symptom Chart ".'......""................. 22-8

Flowcharts

Condenser Fan .........".................,..'. 22-9

Compressor .....""" 22-12

A/C System .........'.22'17

A/C Thermostat

Test ........'.......' """'22'21

Relays

Test ....."'......... ..""'22-21

A/C Service Tips and Precautions ......22-22

A/C System Torque Specifications '...22-23

A/C System Service

Performance Test ... '."......... ".... ....'..22-24

Pressure Test Chart .................. .... "' 22-26

Recovery ...".........," 22-27

Evaporator

Replacement .....",' 22'24

Overhauf .....-.....""' 22'29

Compressor {SANDEN}

Repf acement ......'.' 22-30

fffustrated fndex ......"..................'.... 22'32

Cf utch Inspection ......... "............ ...... 22-33

Clutch Overhau I ........................ ....... 22-34

Thermal Protector Replacement .... 22-36

Relief Valve Replacement ......'..."". 22-36

Compressor (DENSO)

Repfacement ..""',' 22-37

lf lustrated Index ............................... 22-39

Clutch lnspection ............."'...... "'.... 22-40

Cf utch Overhaul .....................'......... 22-41

Ref ief Valve Replacement'..'......"'.. 22-42

A/C Compressor Belt

Adiustment ............22'43

Condenser

Repfacement .......,,22'44

A/C System Service

Evacuation ...,,,.......22-45

Charging '..........--'..22'46

Leak rest """""""'22-46

Page 1429 of 2189

Description

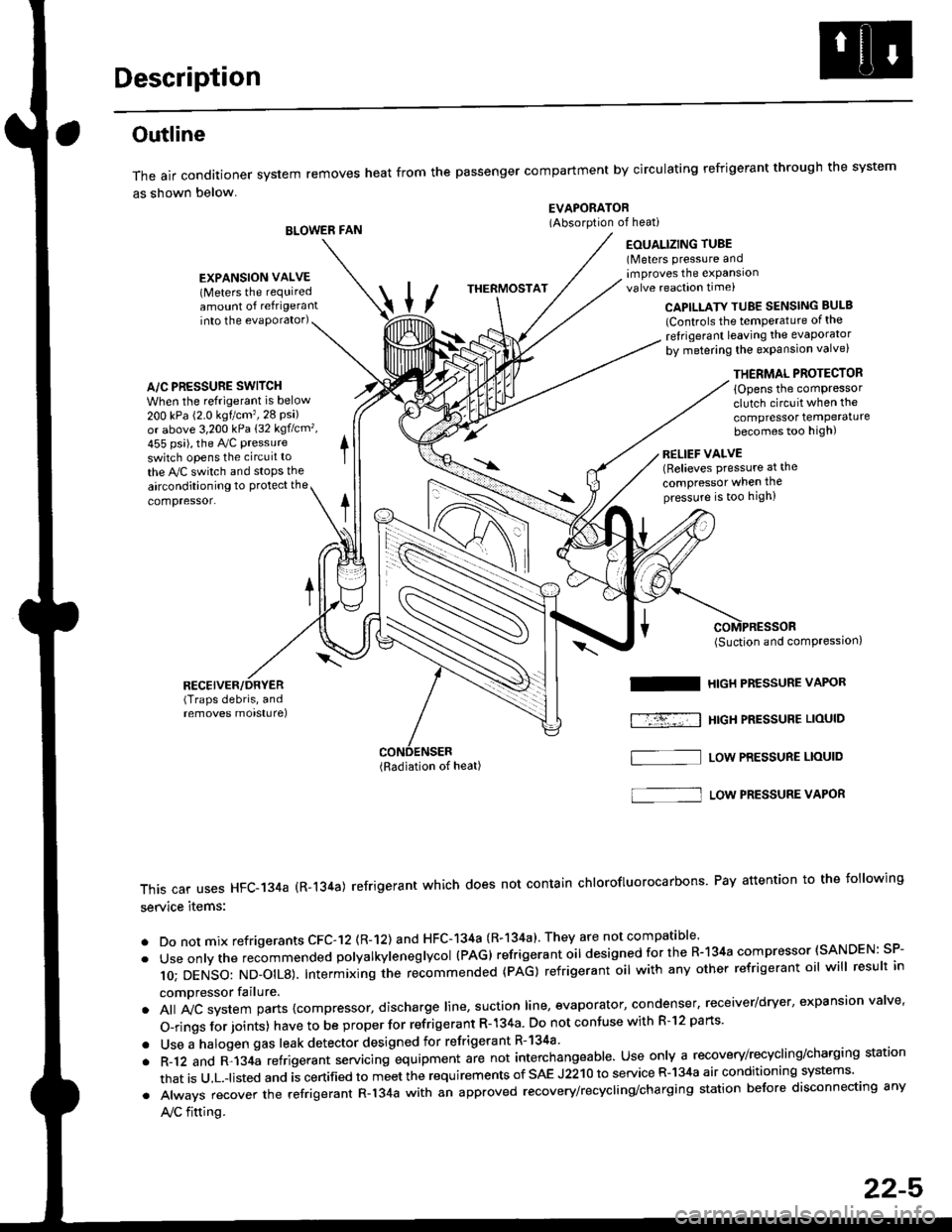

Outline

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

BLOWER FAN

EVAPORATOR(Absorption of heati

EOUALIZING TUBE(Meters pressure andimproves the expansionvalve reaction time)

into the evaporator)CAPILLATY TUBE SENSING BULB

lControls the temPerature of the

ref rigerant leaving the evaporator

by metering the expansion valve)

/\

THERMOSTAT

A/C PRESSURE SWITCH

When the refrigerant is below

200 kPa (2.0 kgtcm'�,28 Psi)or above 3,200 kPa 132 kgflcm',

455 psi), the Ay'C pressure

switch opens the circuit to

the A,/C switch and stops the

EXPANSION VALVE(Meters the requiredamount of refrigerant

airconditioning to Protect the

compressor.

RECEIVER/DRYER(Traps debris, andremoves morsturel

THERMAL PROTECTOR

{Opens the comPressorclutch circuit when the

compressor temPeraturebecomes too high)

RELIEF VALVE(Relieves pressure at the

compressor when thepressure is too high)

(Radiation of heat)

I

f-r-�-; I

(Suction and comPression,

HIGH PRESSURE VAPOR

HtGH PRESSUBE LIOUID

LOW PRESSURE LIOUID

This car uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons Pay attention to the following

service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a)' They are not compatible'

. Useonlythe recommended polyalkyieneglycol (PAG) refrigerant oil designedforthe R-134a compressor (SANDEN: SP-

10; DENSO: ND_OIL8). Intermixing ihe re-commended (pAG) refrigerant oil with any other refrigerant oil will result in

compressor failure.

. All A,,ic system parts {compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve'

O-rings for joints) have to be proper for refrigerant R- 134a Do not confuse with R-l2 parts'

. Use a halogen gas leak detector designed for refrigerant R-134a

. R-12 and R-134a refrigerant servacing equipment are not interchangeable. Use only a recovery/recycling/charging station

that is u,L.-listed and is certified to meet the requirements of sAE J2210 to service R-134a air conditioning systems'

. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting any

A,/C fitting.

S]

22-5

Page 1446 of 2189

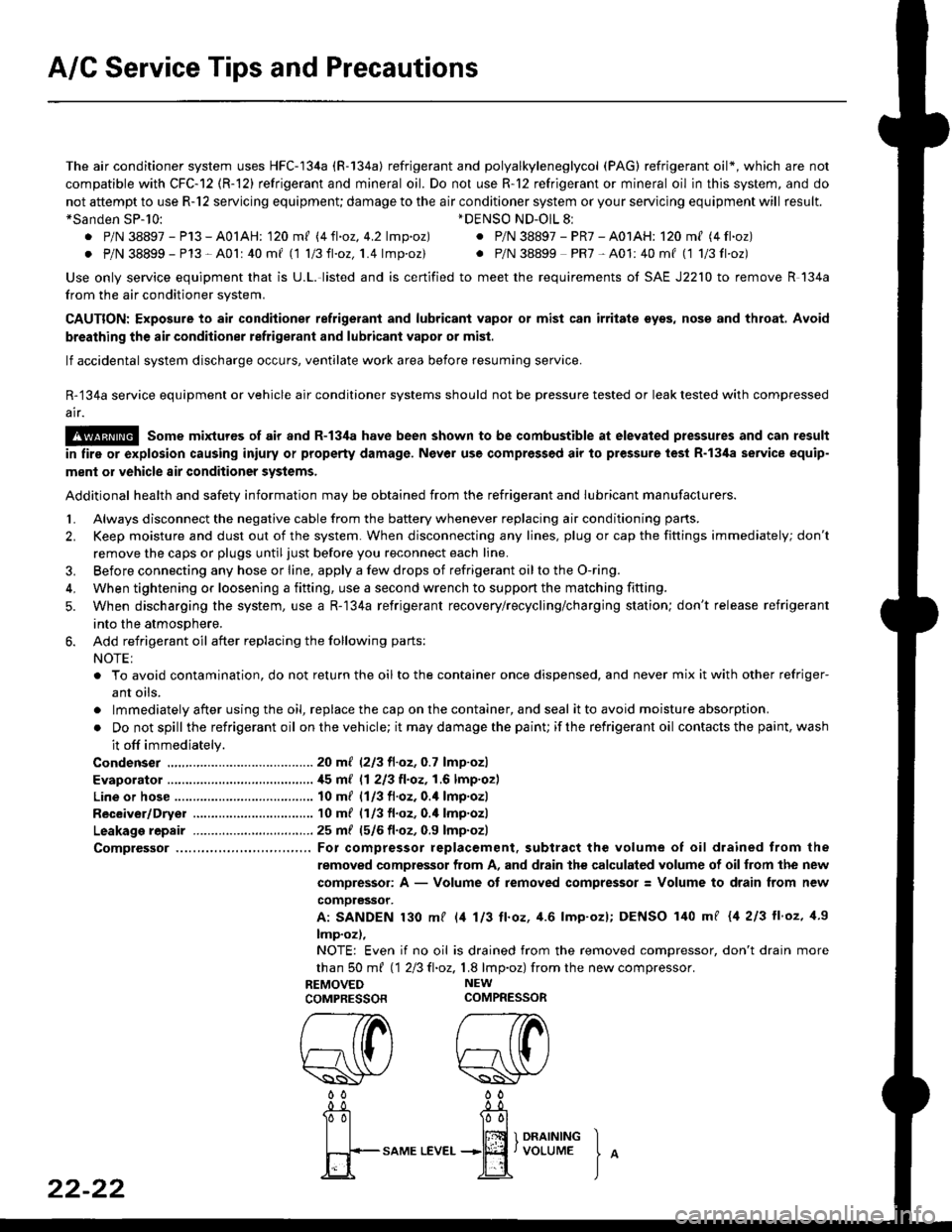

A/C Service Tips and Precautions

The air conditioner system uses HFC-134a (R-134a) refrigerant and polyalkyleneglycol (PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenU damage to the air conditioner system or your servicing equipment will result.*Sanden SP-10:

. P/N 38897 - P13 - A0lAH: 120 ml 14ll.oz, 4.2lmp.oz)

. P/N 38899 - P13 - A0l | 40 mf 11 1/3ll.oz,1.4 lmp'oz)

Use only service equipment that is U.L. listed and is certified to meet the requirements of SAE J2210 to remove R 134a

from the air conditioner system.

CAUTION: Exposure to air conditioner ref;ige;ant and lubricant vapol or mist can irritate syes, nose and throat, Avoid

breathing the air conditioner refrigerant and lubricant vapor or misl.

lf accidental system discharge occurs, ventilate work area before resuming service.

R-'134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

ai.

!@@ some mixtures of air and R-t3ila have been shown to be combustible at elevated pressures and can result

in tire or explosion causing iniury or property damage. Never use compressed air lo pressure tesl R-134a service equip-

ment or vehicle 8ir conditioner systoms.

Additional health and safety information may be obtained from the refrigerant and Iubricant manufacturers.

L Always disconnect the negative cable from the battery whenever replacing air conditioning pans.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line, apply a few drops of refrigerant oilto the O-ring.

4, When tightening o. loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R-134a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere,

6. Add refrigerant oil after replacing the following parts:

NOTE:

. To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the paint; if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser .......2o ml (2/3 fl.oz, 0.7 lmp.ozl

Evaporator .,.,.,. i[5 m{ 11 213 tl.oz,1,6lmp.ozl

Line or hose ..... 10 mf (1/3 fl.oz, 0.4 lmp.ozl

Receiver/Dryer 10 m{ (1/3 fl.oz,0.'l lmp.ozl

Leakage repair 25 m{ (5/6 fl.oz, 0.9 lmp.ozl

Comptessor ... For compressor replacement. subtract the volume of oil drained trom the

removed compressor from A, and drain the calculated volume of oilfrom the new

compressor: A - Volume of removed compressor: Volume to drain from new

comoressor.

A: SANDEN 130 mf l/t 113 ll.oz, 4.6 lmp'ozl; DENSO 140 mf {4 213 ll'oz, 1.9

lmp.oz),

NOTE: Even if no oil is drained from the removed compressor, don't drain more

than S0 m{ 112Ell.oz,1.8 lmp.oz) fromthe new compressor.

REMOVED NEW

COMPRESSORCOMPRESSOR

*DENSO ND-OlL 8l

. P/N 38897 - PR7 - A01AH: 120 ml (4 fl.oz)

. P/N 38899 PR7-A01:40mf (1 1/3fl'oz)

rereW W0000

22-22

-0_!- -0_a

Tol l00l

| | lffi 1 onrrrutrc I

fi+-sAME

LEvEr...+jEf,voLUME

J

^

Page 1448 of 2189

A/C System Service

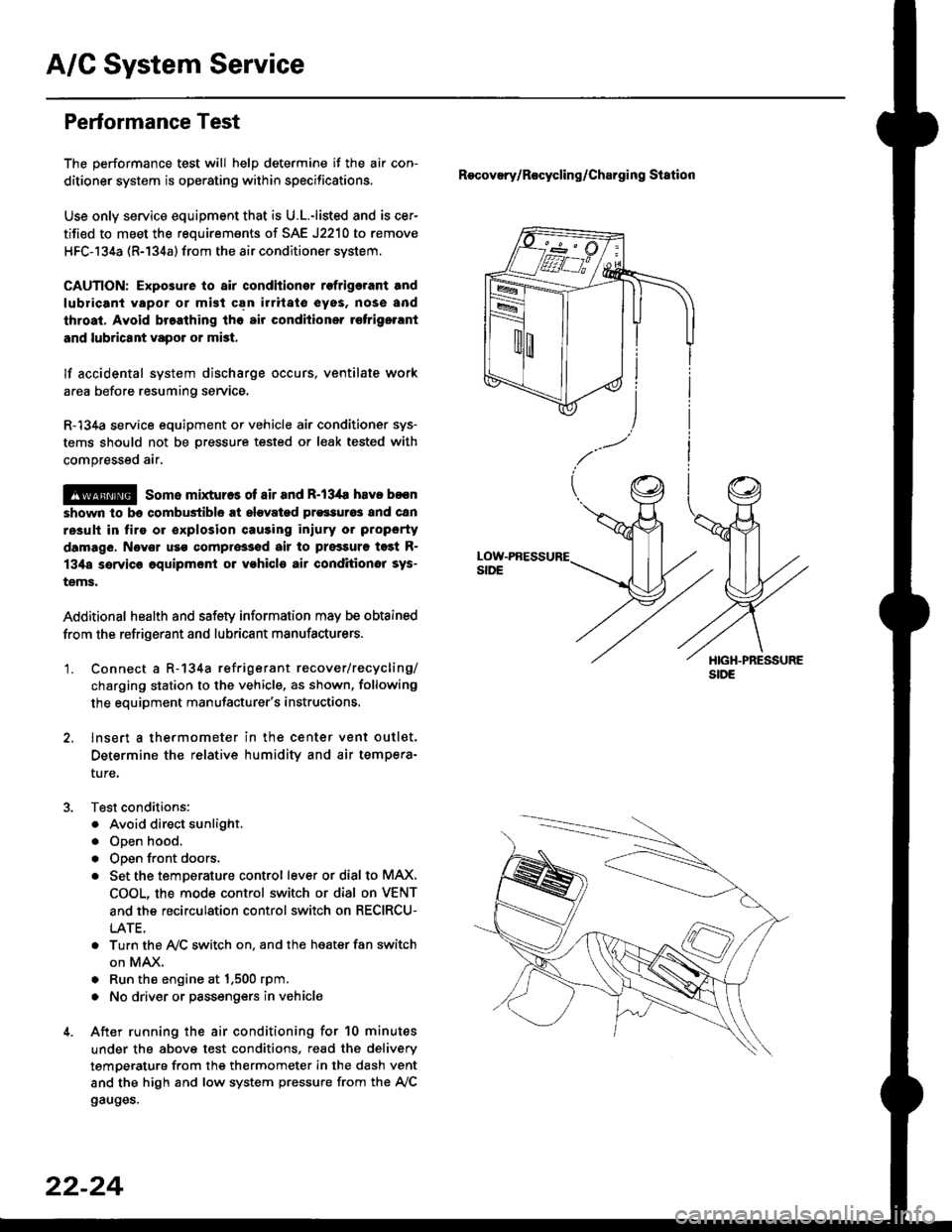

Performance Test

The performance test will help determine if the air con-

ditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is cer-

tified to meet the reouirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditionor rofrigerant and

lubricant vapor or mist can irrilalo €yes, nose and

throat. Avoid breathing tho air conditioner rstrigerrnt

and lubricant vapor or mist,

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

@ some mixtur$ of air and R-134a have been

shown lo b9 combustible rt glgvatad pr€ssur63 and can

resull in tire 01 oxplosion causing inlury ot property

damage. Never uao compre33ed air to pressure t99t R-

134a ssrvico 6quipmsnt or vohicla air conditioner sys-

tems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

'1. Connect a R-134a refrigerant recover/recycling/

charging station to the vehicle, as shown, following

the equipment manufacturer's instructions.

2. lnsert a thermometer in the center vent outlet.

Determine the relative humidity and air tempera-

ture,

Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open front doors.

. Set the temDerature control lever or dial to MAX,

COOL, the mode control switch or dial on VENT

and the recirculation control switch on RECIRCU-

LATE.

. Turn the A,/C switch on. and the heater fan switch

on MAX.

. Run the engine at 1,500 rpm.

. No driver or passengers in vehicle

After running the air conditioning for 10 minutes

under the above test conditions, read the delivery

temperature from the thermometer in the dash vent

and the high and low system pressure from the A,/C

gauges.

Recovery/Rocycling/Charging Station

22-24