Recover HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1450 of 2189

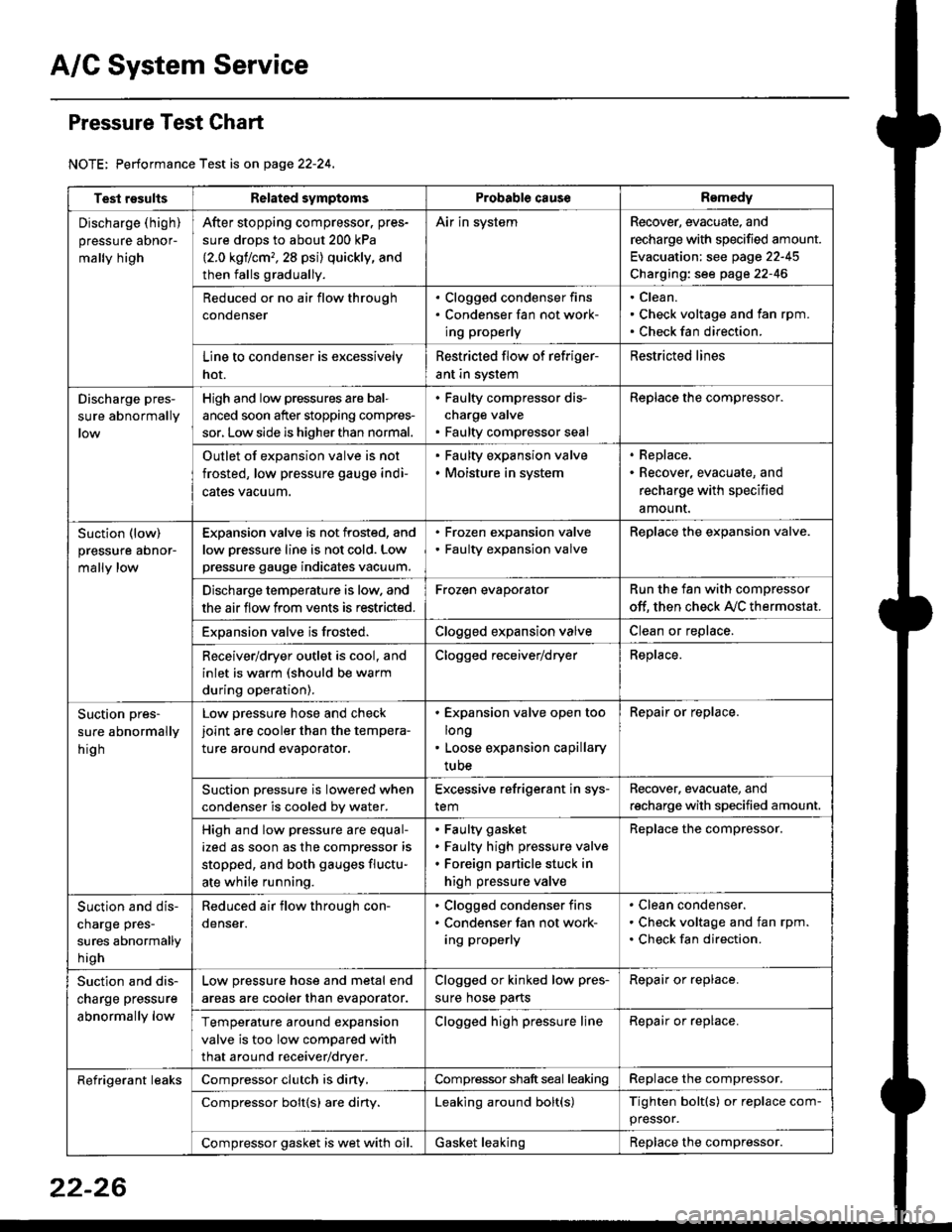

A/C System Service

Pressure Test Chart

NOTE: Performance Test is on page 22-24,

Test resultsRelated symptomsProbabl€ causeRemedy

Discharge (high)

pressure aDnor-

mally high

After stopping compressor. pres-

sure drops to about 200 kPa

{2.0 kgflcm,,28 psi) quickly, and

then falls gradually.

Air in systemRecover, evacuate, and

recharge with specified amount.

Evacuation: see page 22-45

Charging: see page 22-46

Reduced or no air flow through

condenser

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean.

Check voltage and fan rpm.

Check fan direction.

Line to condenser is excessively

hot.

Restricted flow of refriger-

ant in system

Restricted lines

Discharge pres-

sure abnormally

High and low pressures are bal-

anced soon after stopping compres-

sor, Low side is higher than normal.

. Faulty compressor dis-

charge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is not

frosted, low pressure gauge indi-

cales vacuum.

. Faulty expansion valve. Moisture in system

. Replace,. Recover, evacuate, and

recharge with specified

amount.

Suction (low)

pressure abnor-

mally low

Expansion valve is not frosted, and

low oressure line is not cold. Low

pressure gauge indicates vacuum.

. Frozen expansion valve. Faulty expansion valve

ReDlace the exoansion valve.

Discharge temperature is low. and

the air flow from vents is restricted.

Frozen evaporatorRun the fan with compressor

off. then check A,/C thermostat.

Exoansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool, and

inlet is warm (should be warm

during operation).

Clogged receiver/dryerReplace.

Suction pres-

sure abnormally

hig h

Low pressure hose and check

joint are cooler than the tempera-

ture around evaporator.

. Expansion valve open too

long. Loose expansion capillary

tube

Repair or replace.

Suction oressure is lowered when

condenser is cooled bv water.

Excessive refrigerant in sys-

tem

Recover. evacuate, and

recharge with specified amount.

High and low pressure are equal-

ized as soon as the compressor is

stopped, and both gauges fluctu-

ate while running.

Faulty gasket

Faulty high pressure valve

Foreign particle stuck in

high pressure valve

Replace the compressor.

Suction and dis-

charge pres-

sures abnormally

h igh

Reduced air flow through con-

denser.

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean condenser.

Check voltage and fan rpm.

Check fan direction.

Suction and dis-

charge pressure

abnormally low

Low pressure hose and metal end

areas are cooler than evaporator.

Clogged or kinked low pres-

sure hose parts

Repair or replace.

Temperature around expansion

valve is too low compared with

that around receiver/dryer.

Clogged high pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny,Compressor shaft seal leakingReplace the compressor.

Compressor bolt{s) are diny.Leaking around bolt(s)Tighten bolt(s) or replace com-

pressor.

Compressor gasket is wet with oil.Gasket leakingReplace the compressor.

22-26

Page 1451 of 2189

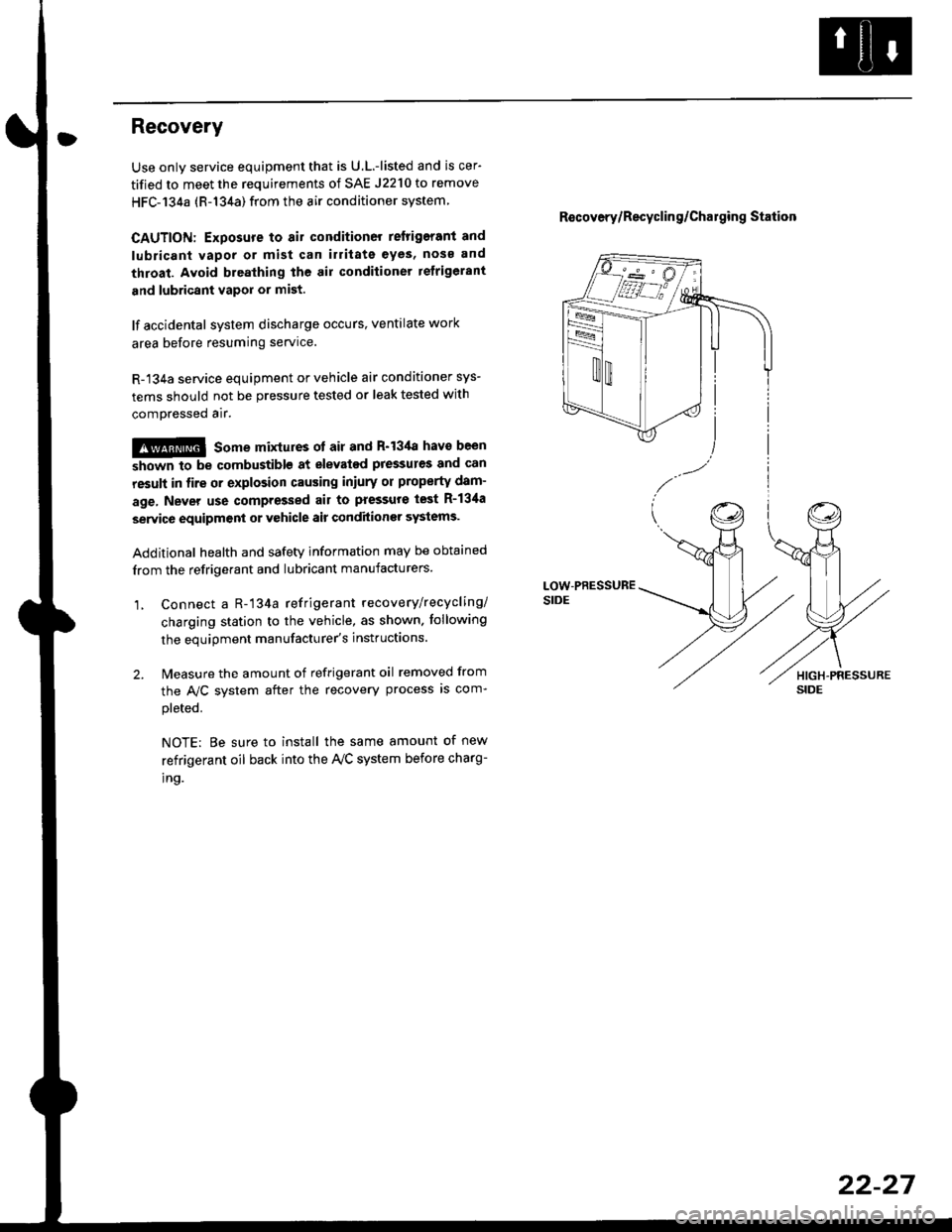

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system

CAUTION: Exposure to air conditioner relrigerant and

lubricant vapor or mist can illitate eyes, noss and

throat. Avoid breathing the ail conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed air.

!@@ some mixtures ot air and R'13'[a havo been

strown to be combustiblg at elevated pressures and Gan

resuh in fire or explosion causing iniury or property dam-

age, Never use compressed air to pressure test R-134a

service equipment or vehicle air conditioner systems.

Additional health and safetv information may be obtained

from the refrigerant and lubricant manufacturers.

1, Connect a R-'134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown. tollowing

the equipment manufacturer's instluctions.

2. Measure the amount of refrigerant oil removed from

the A/C svstem after the recovery process is com-

pleted.

NOTE: Be sure to install the same amount of new

refrigerant oil back into the Iy'C system before charg-

tno.

R€covery/Recyclin g/Cha19ing Station

22-27

Page 1454 of 2189

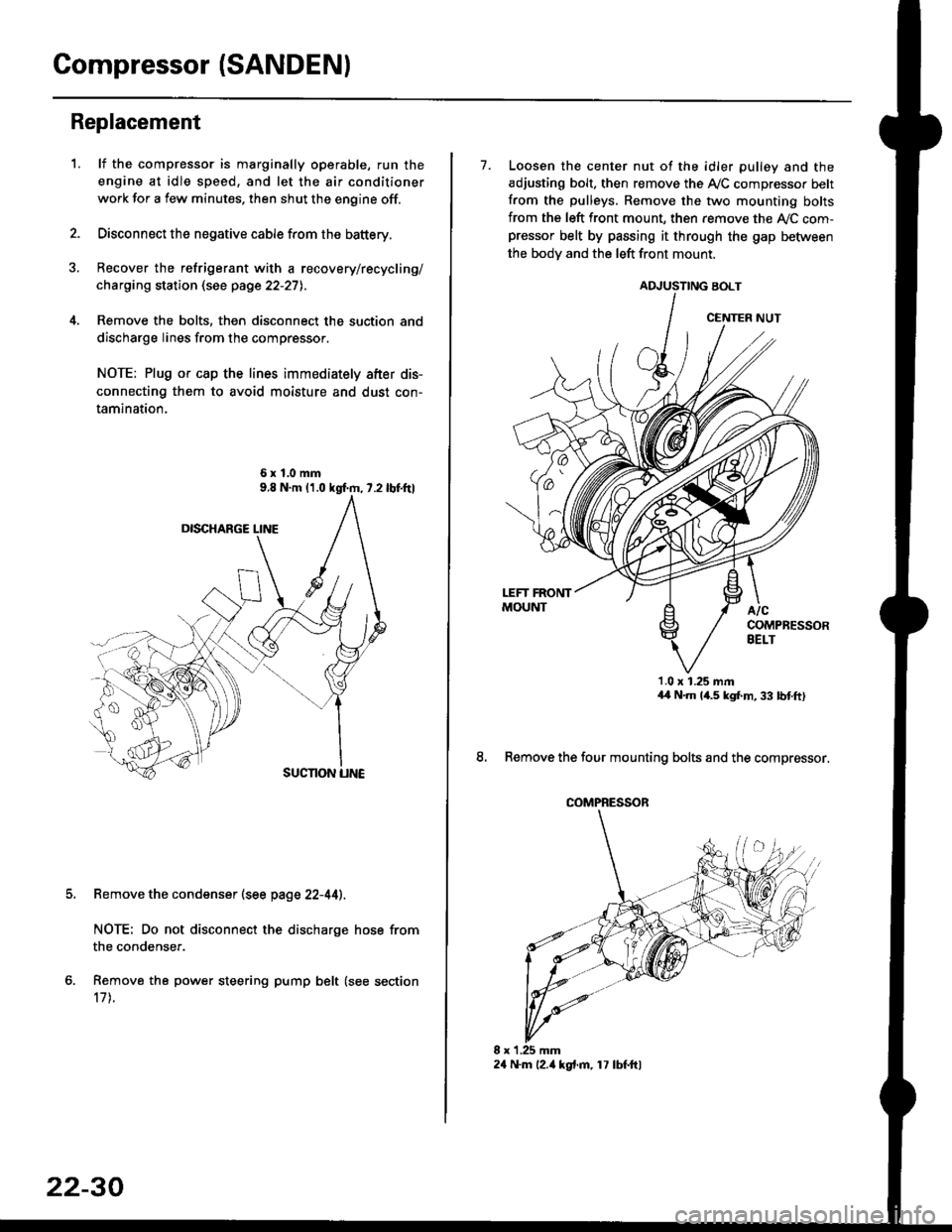

Compressor (SANDENI

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-27l..

Remove the bolts, then disconnect the suction and

discharge lines from the compressor.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm

Remove the condenser (see page 22-44).

NOTE: Do not disconnect the discharge hose from

the condenser.

Remove the power steering pump belt (see section

17 t.

22-30

24 N.m l2.ia kgt.m, 17 lbf.ftl

7. Loosen the center nut of the idler pulley and the

adjusting bolt. then remove the A,/C compressor belt

from the pulleys. Remove the two mounting bolts

from the left front mount, then remove the ly'C com-pressor belt by passing it through the gap befiiveen

the bodv and the left front mount.

ADJUSTING BOLT

1.0 x 1.25 mmaa N.m 14.5 kgf,m, 33 bnft)

8. Remove the four mounting bolts and the compressor.

CENTER NUT

COMPRESSOR

Page 1461 of 2189

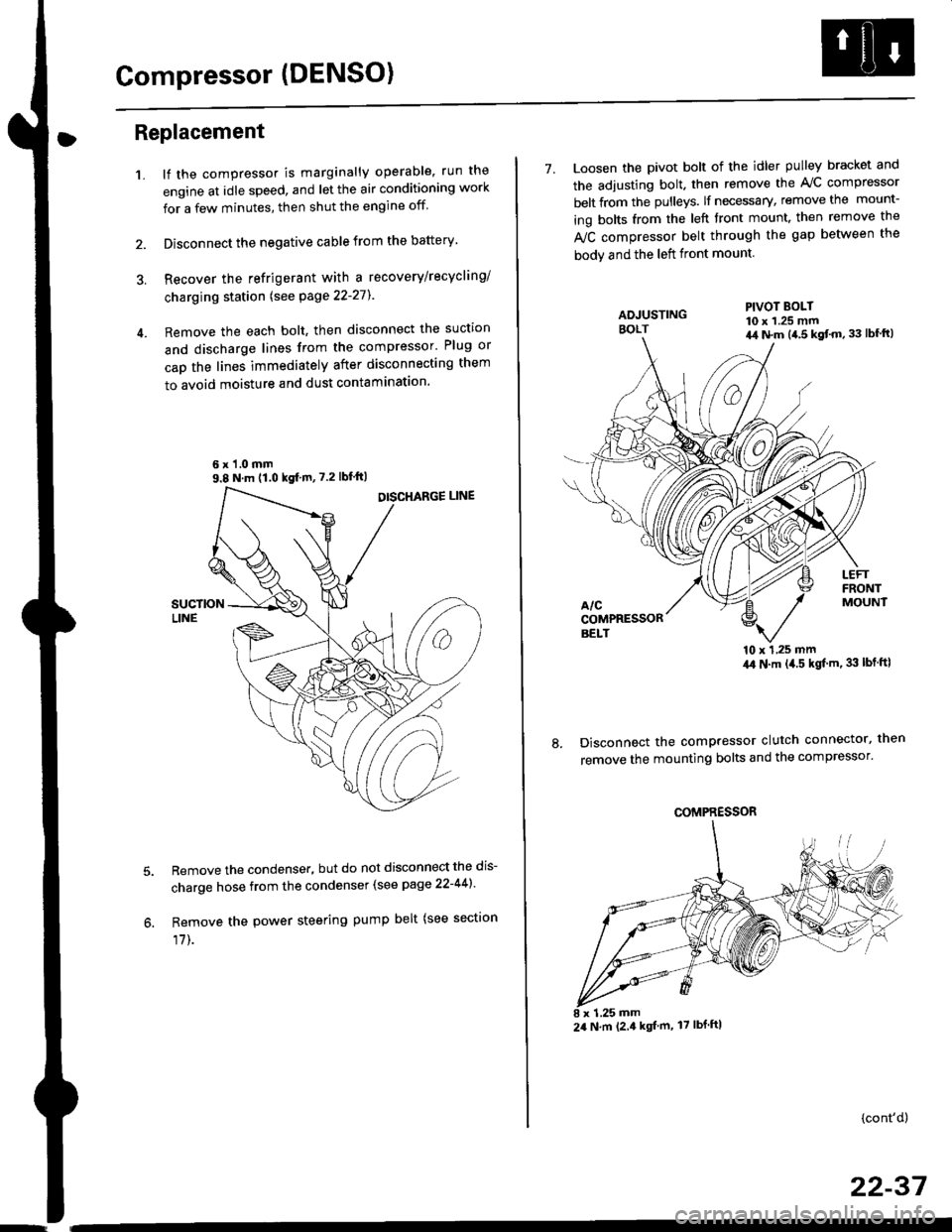

Compressor (DENSO)

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning work

for a few minutes, then shut the engine off

Disconnect the negative cable from the battery'

Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271

Remove the each bolt, then disconnect the suction

and discharge lines from the compressor' Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contaminatlon.

6 x '1.0 mm9.8 N.m (1.0 kgf m,7.2 lbfft)

Remove the condenser, but do not disconnect the dis-

charge hose from the condenser (see page 22-441'

Remove the power steering pump belt (see sectron

17]-.

7. Loosen the pivot bolt of the idler pulley bracket and

the adjusting bolt. then remove the A,/C compressor

belt from the pulleys. lf necessary, remove the mount-

ing bolts from the left front mount. then remove the

fuC compressor belt through the gap between the

bodv and the left front mount.

'10 x 1,25 mm4,0 N.m (,1.5 kgf'm. 33 lbt ftl

Disconnect the compressor clutch connector, then

remove the mounting bolts and the compressor'

PIVOT BOLT10 x 1.25 mm4,1 N.m (4.5 kgt'm,33 lbfft)

COMPRESSOR

24 N.m (2.4 kgf m, 17 lbf ftl

(cont'd)

22-37

Page 1466 of 2189

Compressor (DENSO)

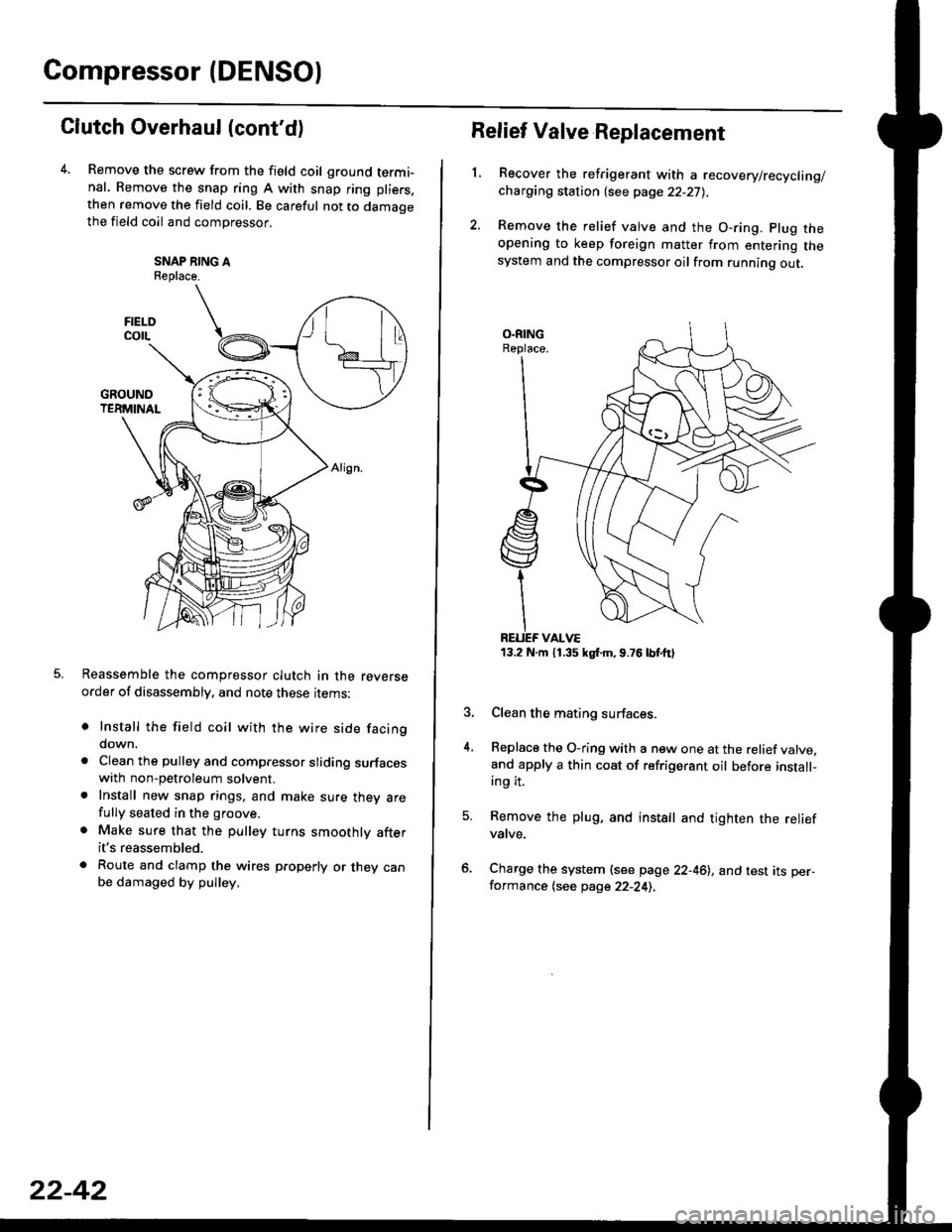

Clutch Overhaul (cont'd)

Remove the screw from the field coil ground termi-nal. Remove the snap ring A with snap ring pliers.

then remove the field coil. Be careful not to damaoethe field coil and compressor.

SNAP NING AReplace.

Reassemble the compressor clutch in the reverseorder of disassembly, and note these rrems:

o Install the field coil with the wire side facingdown.

a Clean the pulley and compressor sliding surfaceswith non-petroleum solvent.. Install new snap rings, and make sure thev arefully seated in the groove.

. Make sure that the pulley turns smoothly afterit's reassembled.

. Route and clamp the wires p.operly or they canbe damaged by pulley.

FIELOcorL

22-42

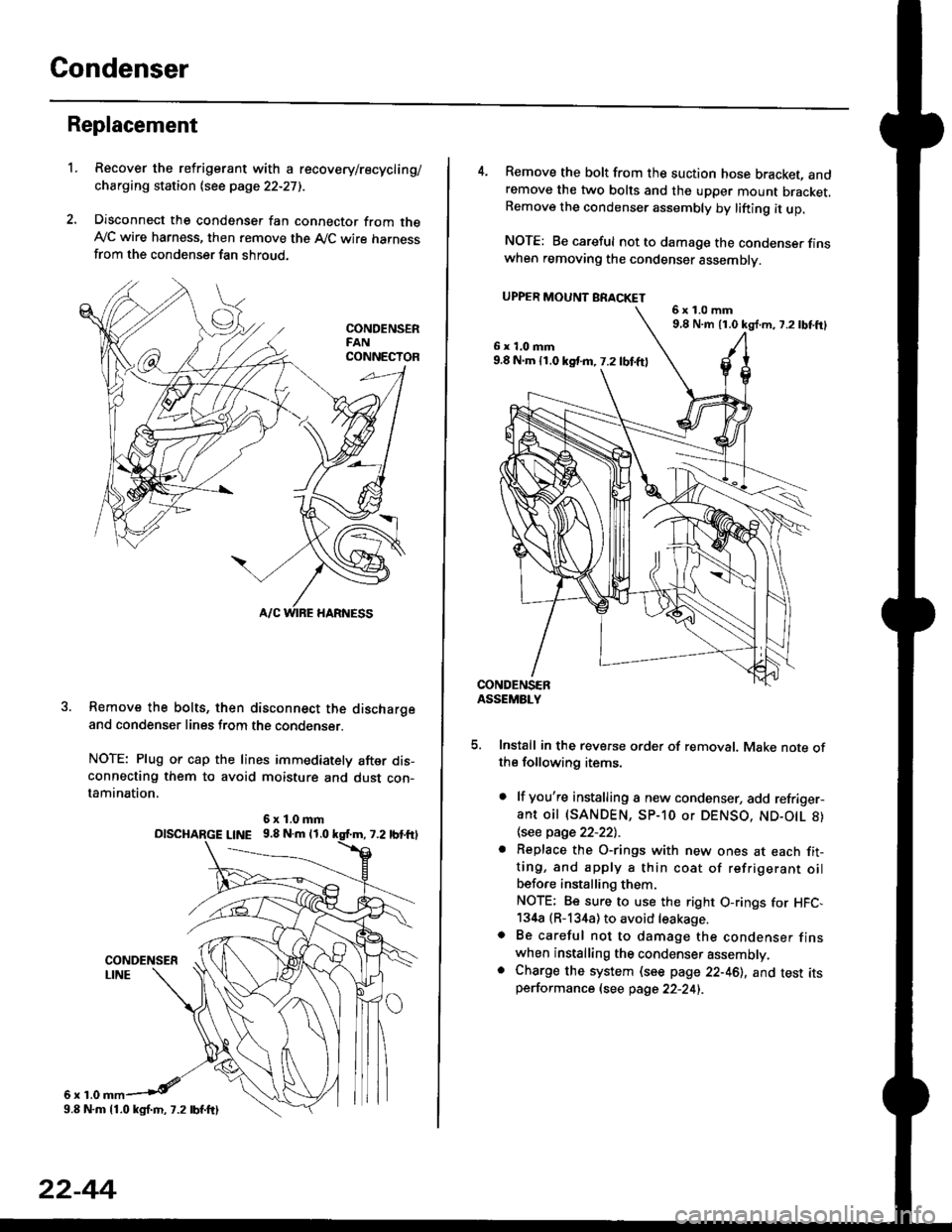

13.2 N.m 11.35 kgt m,9.76lbtttl

Relief Valve Replacement

L

4.

Recover the refrigerant with a recovery/recycling/charging station {see page 22-27),

Remove the relief valve and the O-ring. plug theopening to keep foreign matter from entering thesystem and the compressor oilfrom running out.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil before install-ing it.

Remove the plug, and install and tighten the reliefvatve.

Charge the system (see page 22-46), and test its per-formance (see page 22-24),

Page 1468 of 2189

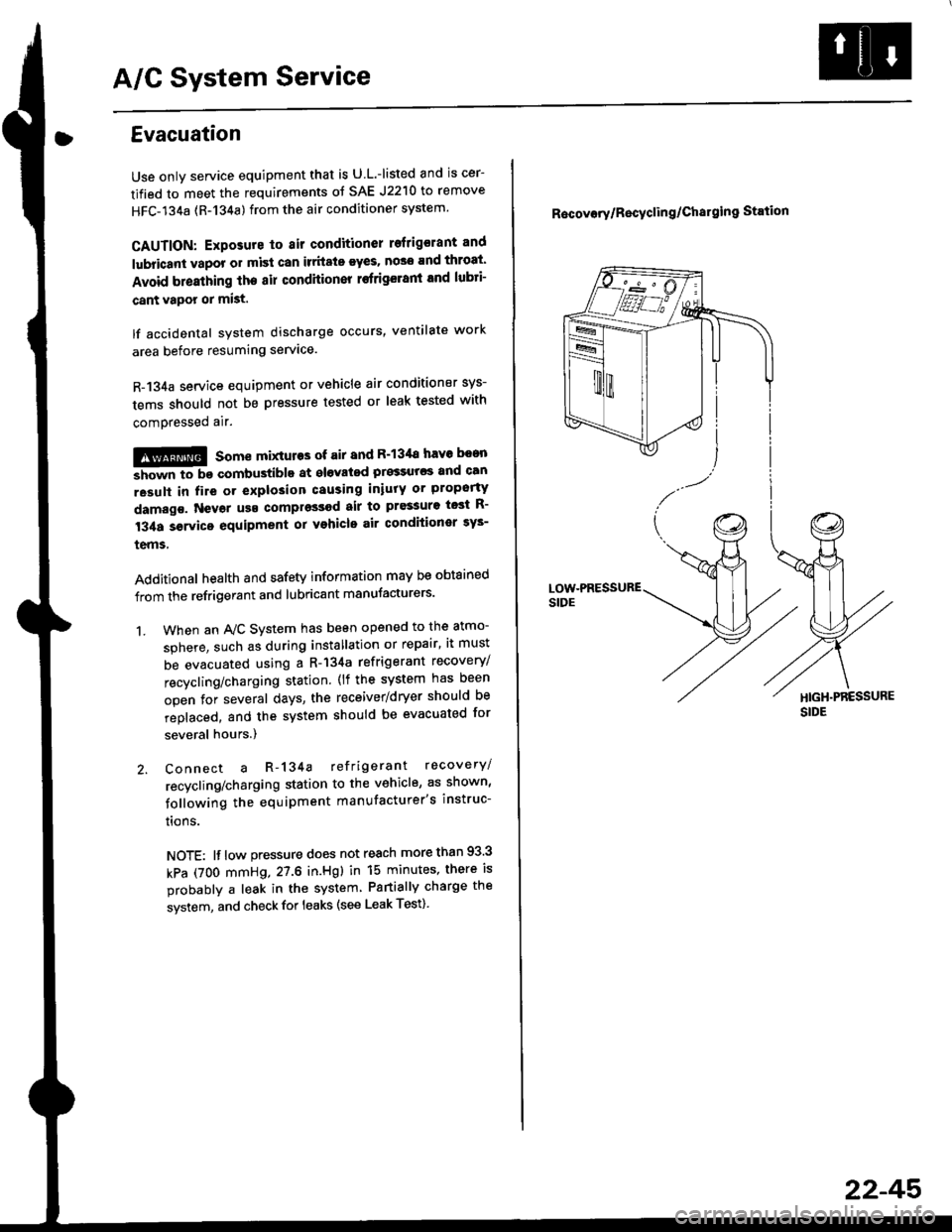

Condenser

Replacement

1.Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271.

Disconnect the condenser fan connector from theAy'C wire harness, then remove the A,/C wire harnessfrom the condenser fan shroud.

Remove the bolts, then disconnect the dischargeand condenser lines from the condenser.

NOTE: Plug or cap the lines immediately after dis-connecting them to avoid moisture and dust con-tamination,

6r1.0

6x1.0mmolscHARGE L|NE 9.8 N.m 11.0

9.8 N.m 11.0 kgl.m, 7.2 lbf.ftl

22-44

4. Remove the bolt from the suction hose bracket, andremove the two bolts and the upper mount bracket.Remove the condenser assembly by lifting it up.

NOTE: Be careful not to damage the condenser finswhen removing the condenser assembly.

UPPER MOUNT BRACKET

5. Install in the reverse order of removal. Make note ofthe following items.

. lf you're installing a new condenser, add refriger-ant oil (SANDEN, SP-10 or DENSO, ND-O|L 8)

\see page 22-22l.-

. Replace the O-rings with new ones at each fit-ting, and apply a thin coat of refrigerant oilbefo.e installing them.

NOTE; Be sure to use the right O-rings for HFC,134a (R-134a) to avoid leakage.o Be careful not to damage the condenser finswhen installing the condenser assembly.. Charge the system (see page 22-46), and test itsperformance (see page 22-24i.

6x1.0mm9,8 N.m 11.0 kg{.m, 7.2lbtft}

6x1.0mm9.8 N.m 11.0 kst m, 7.2 lbf.ftl

Page 1469 of 2189

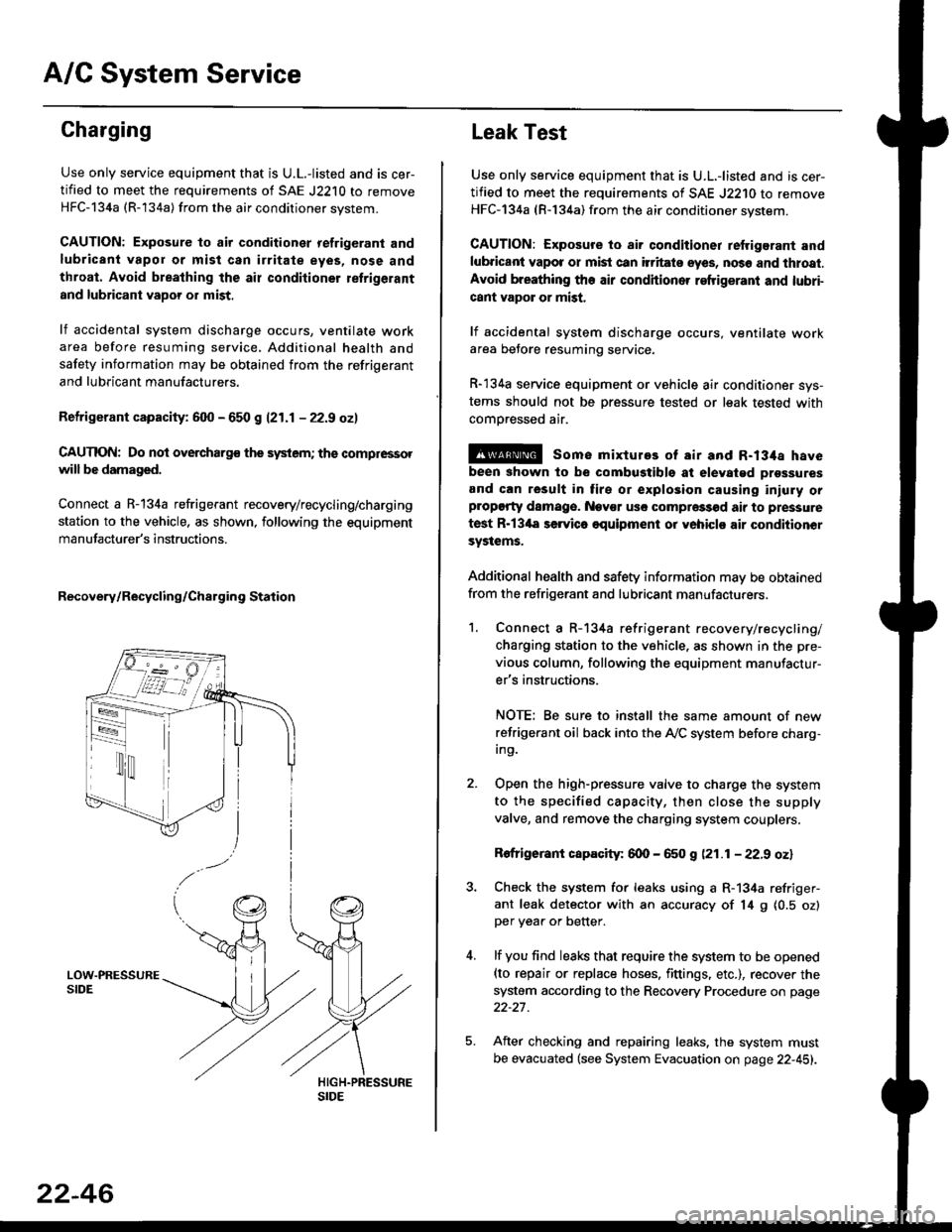

A/C System Service

Evacuation

Use only service equipment that is U L.-listed and is cer-

tified to meet the requirements oJ SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system'

CAUTION: Exposure to air conditioner reftig€lant and

lubricant vapor or misi can irrhaie eyes. noso and throat'

Avoid breathing the ail condhioner lefrigelant and lubri

cant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming servace.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comDressed air.

!!@@ some mixtures of air and R-13'[8 haYo boon

ffiiE-n to be "ombustible at elovatod pressurcs and can

result in fire or explosion causing iniury or propsrtY

damag€. Never uso complsssod air to pre3surs tost R-

1344 ssrvico equipment or vehicle air conditioner sy3-

tems,

Additional health and safety information may be obtained

from the refrigerant and lubricant manuJacturers'

When an A,/C System has been opened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant recovery/

recycling/charging station. (lf the system has been

open for several days, the receiver/dryer should be

replaced, and the system should be evacuated for

several hours.)

Connect a R-134a refrigerant recovery/

recycling/charging station to the vehicle, as shown'

following the equipment manufacturer's instruc-

trons.

NOTE: lf low pressure does not reach more than 93 3

kPa (7OO mmHg,27.6 in.Hgl in 15 minutes, there is

probably a leak in the system Partially charge the

system, and check for leaks (see Leak Test)

1.

R6covory/Recyclin g/Chal9ing Station

22-45'

Page 1470 of 2189

A/C System Service

Charging

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritale eyes, nose and

throat. Avoid breathing the air conditioner retrigerant

and lubricant vaoor or mist,

lf accidental system discharge occurs, ventilate workarea before resuming service, Additional health and

safety information may be obtained from the refrigerant

and lubricant manufacturers.

Refrigerant capacityt 600 - 650 g 121.1 - 22.9 ozl

CAUnON: Do not overcharg€ the system; the comprcssor

will be damaged.

Connect a R-134a refrigerant recovery/recycling/charging

station to the vehicle, as shown, following the equipment

manufacturer's instructions.

Recovery/Recycling/Charging Station

22-46

Leak Test

Use only service equipment that is U.L,-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure io air conditioner refrigerant and

lubricant vapot or mist can itritats eyes, no36 and thtoat.

Avoid breathing the air conditioner refrigeranl and lubri-

cant vapor or mist,

lf accidental system discharge occurs, ventilate workarea betore resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

@ some mixtures of air and R-134a have

been shown to be combugtibls at elevatgd prossures

and can result in tire or explosion causing iniuly orplopgrty damage. Nev€r usc compre33od air to pressure

test R-13'la servica oquipment or yohiclo air conditionor

systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

NOTE; Be sure to install the same amount of new

refrigerant oil back into the A,/C system before charg-In9.

Open the high-pressure valve to charge the system

to the specified capacity, then close the supply

valve, and remove the charging system couplers.

Rofrigerant capacity: 600 - 650 g (21.1 - 22.9 oz)

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 9 10.5 ozlper yea. or better.

lf you find leaks that require the system to be opened(to repair or replace hoses. fittings. etc.), recover the

system according to the Recovery Procedure on page

22-27.

After checking and repairing leaks. the system must

be evacuated (see System Evacuation on page 22-451.

Page 1561 of 2189

Battery

Test

@l. Battery lluid lelectrolytel contalns sulfuric acid. lt may cause severe burns it it gets on your skin ol in your eyes Wear

protective clothing and a face shield.

- It eleqtlolyte gets on your skin or clothes, rinse it off with watel immediately

- lf electrolyte gets in your eyes, flush it out by splashing water in your eyes for at least 15 minutes; call a physician

immediately.

. A battery gives off hydrogen gas. lf ignited, the hydrogen will explode and could crack the battery case and splatter

acid on you. Keep sparks, flames, and Gigarettes away from the battery'

o Overchaiging will raise the temperature oI the electrolyte. This may force electrolyte to spray out ot ths battery vents'

Follow the charger manufacturel's instrustions, and chalge the battery at a propcr rate.

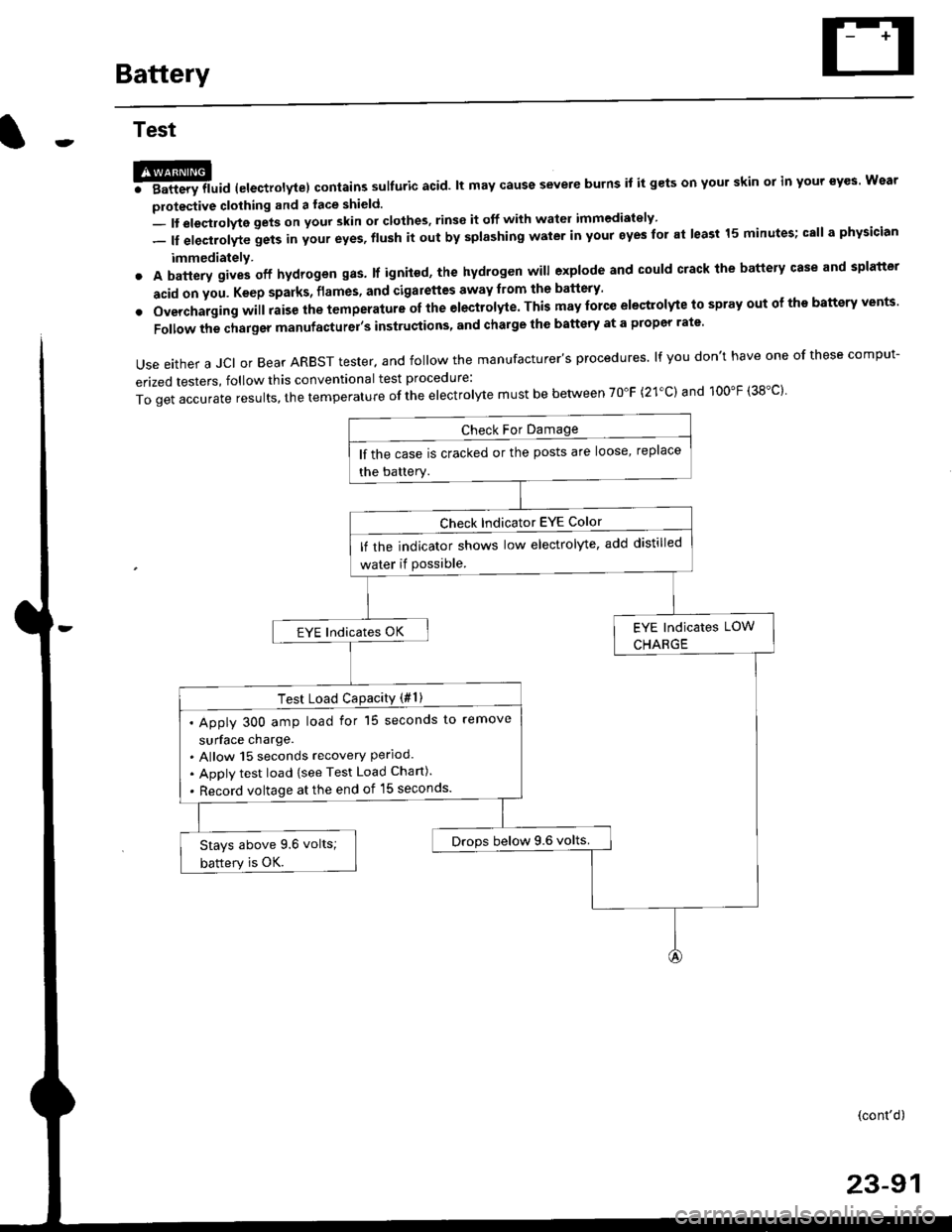

Use either a JCI or Bear ARBST tester. and follow the manufacturer's procedures. lf you don't have one of these comput-

erized testers, follow this conventional test procedure:

ToqetaccurateresuIts,thetemperatureoftheeIectro|ytemustbebetweenT0"F(21.c)and100"F(38.c}'

lf the case is cracked or the posts are loose, replace

the battery.

lf rhe indicator shows low electrolyte, add distilled

water if Possible.

EYE lndicates OK

Test Load CaPacitY (#l )

. Apply 300 amp load for 15 seconds to remove

surface charge.. Allow 15 seconds recovery Perloo.. Apply test load {see Test Load Chan).

. Record voltage at the end of l5 seconds.

Drops below 9.6 volts.Stays above 9.6 volts;

battery is OK.

(cont'd)

23-91

Page 1562 of 2189

Battery

Test (cont'd)

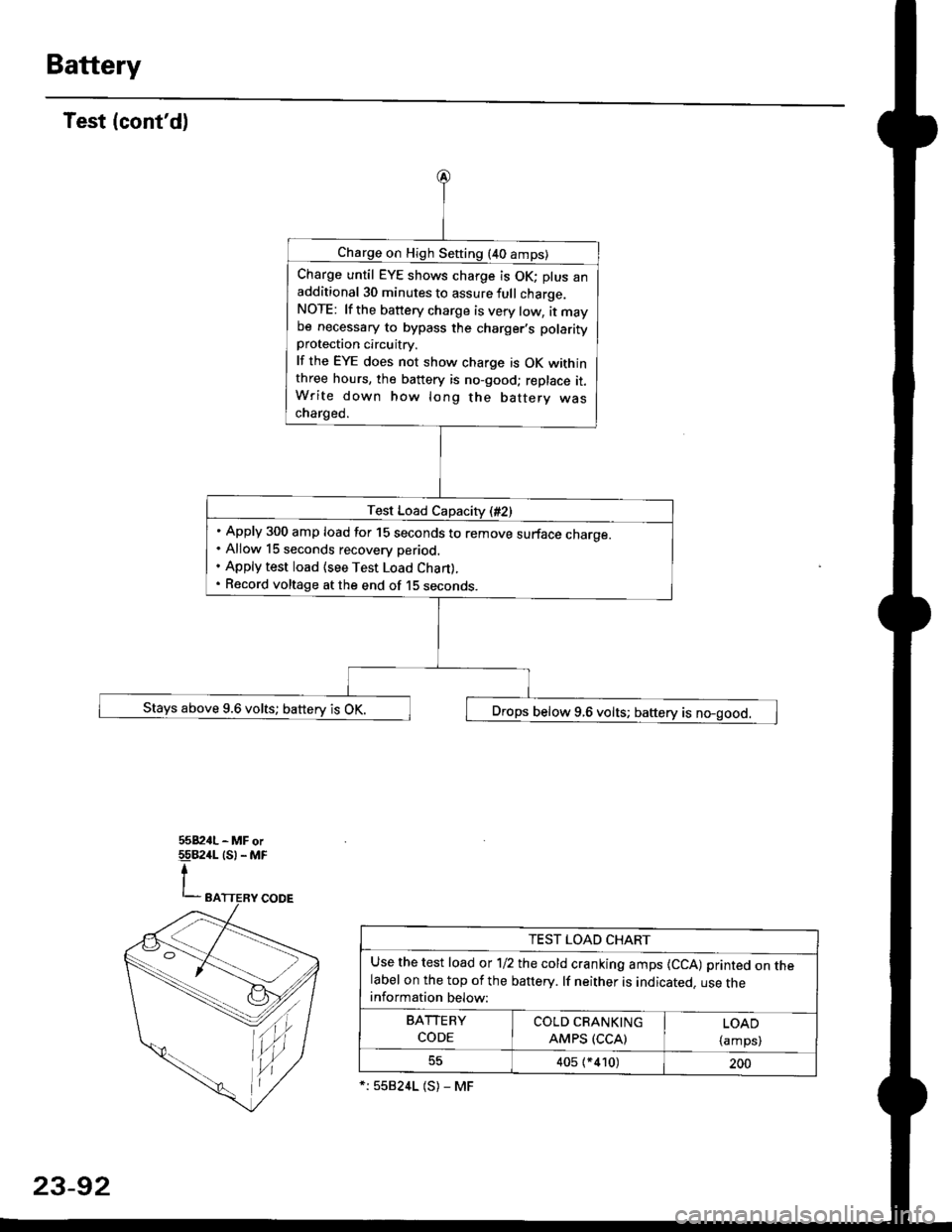

Charge on High Sefting (40 amps)

Charge until EYE shows charge is OK; plus anadditional 30 minutes to assure full charge.NOTE: lf the battery charge is very tow, it maybe necessary to bypass the charger,s polarityprotection circuitry.

lf the EYE does not show charge is OK withinthree hours, the battery is no-good; replace it.Write down how long the battery wascharged.

Test Load Capacity (#2)

Apply 300 amp load for 15 seconds to remove surface charoe.Allow 15 seconds recovery period.

Apply test load {see Test Load Chan).

Record voltage at the end of 15 seconos.

Stays above 9.6 volts; battery is OK. ,] Drops below 9.6 volts; baftery is no-good.

tu,

TEST LOAD CHART

Use the test load or 1/2 the cold cranking amps {CCA) printed on thelabel on the top of the banery. lf neither is indicated. use theinformation below:

BArrERy coLb@

coDE I AMps (ccAl | {amps)

405 (*410)200

*:558241 (S) - MF

23-92