Iat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1027 of 2189

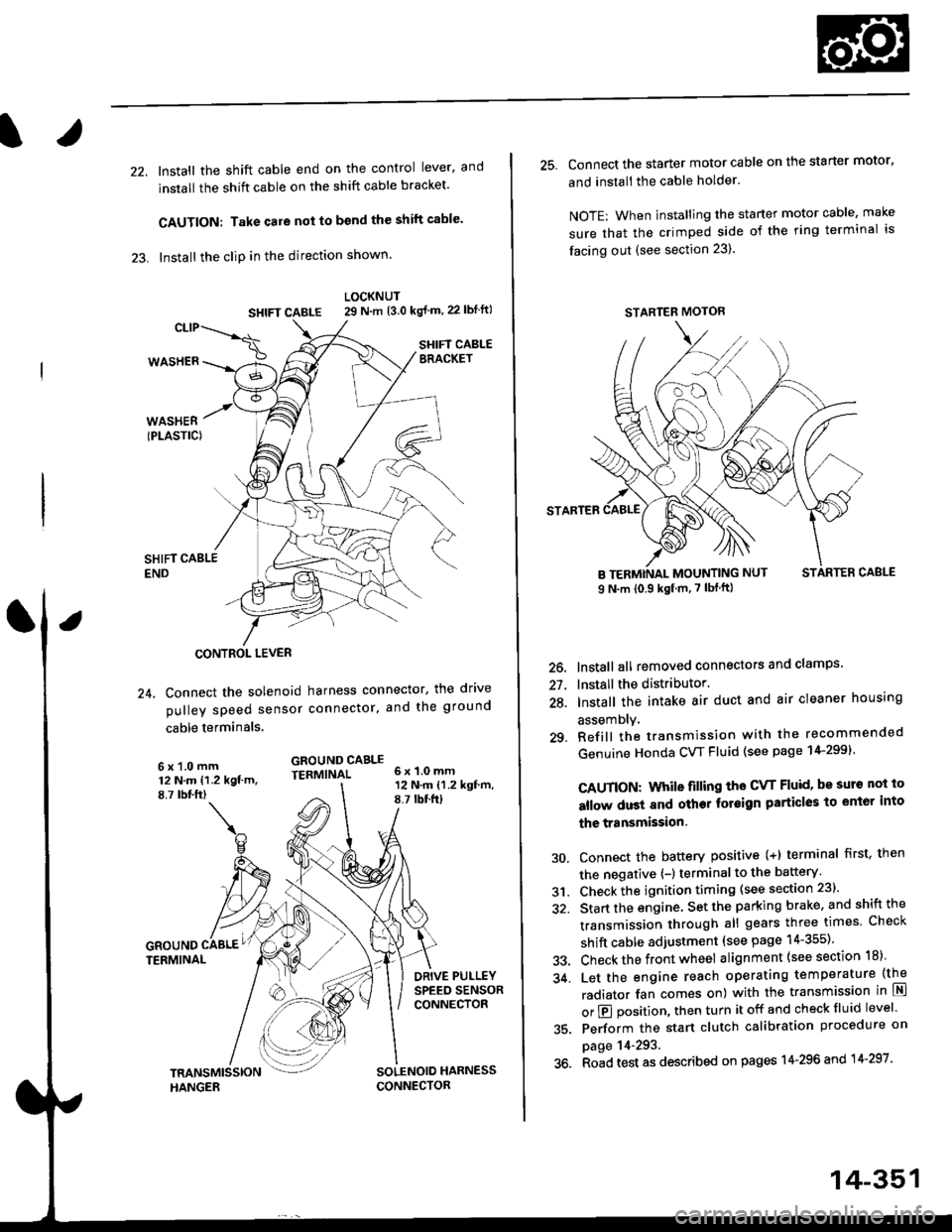

22. Install the shift cable end on the control lever, and

install the shift cable on the shift cable bracket'

CAUTION: Take care not to bend the shift cable'

23. lnstall the clip in the direction shown.

LOCKNUT

SHIFI CABLE 29 N m {3.0 kg{ m, 22lblftl

SHIFT CABLEERACKET

WASHERIPLASTIC)

CONTROL LEVER

24, Connect the solenoid harness connector. the drive

pulley speed sensor connector. and the ground

cable terminals.

6x1.0mm12 N.m {1.2 kgf.m.8,7 rbtft)

GROUND CABLETERMINAL 6x1.0mm

GROUNDTERMINAL

12 N.m {1.2 kgf'm,8.7lbtfrl

DRIVE PULLEYSPEED SENSORCONNECTOR

SOLENOID HARNESS

CONNECTOR

25. Connect the starter motor cable on the starter motor.

and install the cable holder.

NOTE: When installing the staner motor cable. make

sure that the crimped side of the ring terminal is

facing out (see section 23).

STARTEB

BMOUNTING NUT

9 N.m (0.9 kgf m,7 lbf ft)

26. Install all removed connectors and clamps'

27. Install the distributor.

28. Install the intake air duct and air cleaner housing

29.

assemDly.

Refill the transmission with the recommended

Genuine Honda CVT Fluid (see page 14-2991

CAUTION: While filling the CvT Fluid, bs surs not io

allow dust and other fotoign particles to entor into

the transmission.

Connect the battery positive (+) terminal first, then

the negative (-l terminal to the battery'

Check the ignition timing (see section 23).

Start the engine. Set the parking brake, and shift the

transmission through all gears three times Check

shift cable adjustment (see page 14-355).

Check the front wheel alignment (see section 18)

Let the engine reach operating temperature (the

radiator fan comes on) with the transmission in lXl

or E position, then turn it off and check fluid level'

Perform the start clutch calibration procedure on

page 14-293.

Road test as described on pages 14-296 and 14-297

30.

31.

34.

36.

STARTER MOTOR

14-351

Page 1033 of 2189

Shift Indicator PanelATF Gooler/Hoses

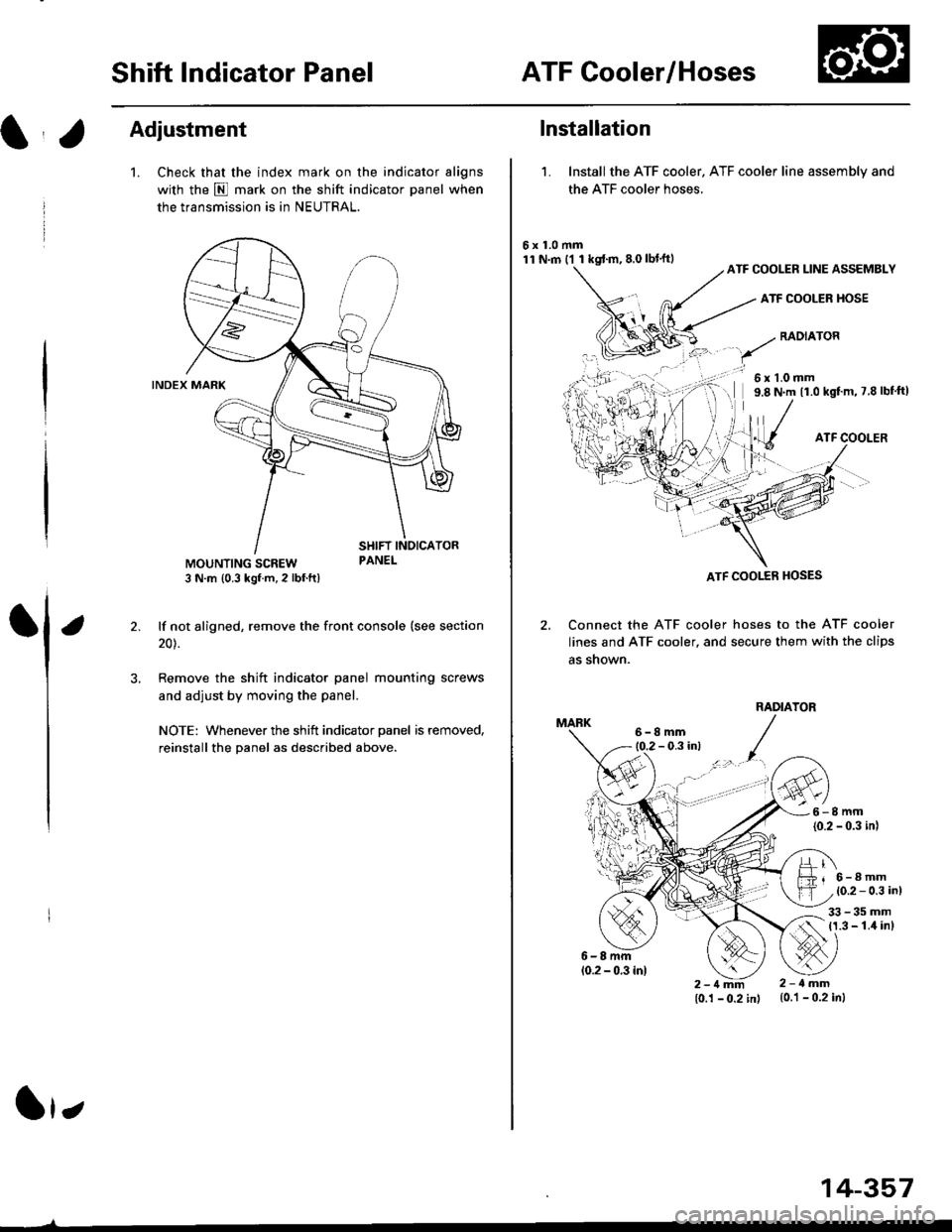

Adjustment

1.Check that the index mark on the indicator aligns

with the E mark on the shift indicator panel when

the transmission is in NEUTRAL.

lf not aligned, remove the front console {see section

20).

Remove the shift indicator panel mounting

and adjust by moving the panel.

NOTE: Whenever the shift indicator panel is removed,

reinstallthe Danel as described above.

It,

14-357

lnstallation

1. Installthe ATF cooler, ATF cooler line assembly and

the ATF cooler hoses.

6x1.0mm11 N.m ('l 1 kgf.m,8.0lbl'ftlATF COOLER LINE ASSEMBLY

ATF COOLER HOSE

RADIATOR

6x1.0mm9.8 N.m 11.0 kgf'm, 7 8 lbf'ft)

ATF COOLER

Connect the ATF cooler

lines and ATF cooler. and

as shown.

hoses to the ATF cooler

secure them with the clips

1l lTf{il.T

6-8mm10.2 - 0.3 in)

33-35mm11.3 - 1.4 inl

2-1mm10.1 - 0.2 in)

2-ilmm{0.1 - 0.2 in)

ATF COOI..ER HOSES

Page 1052 of 2189

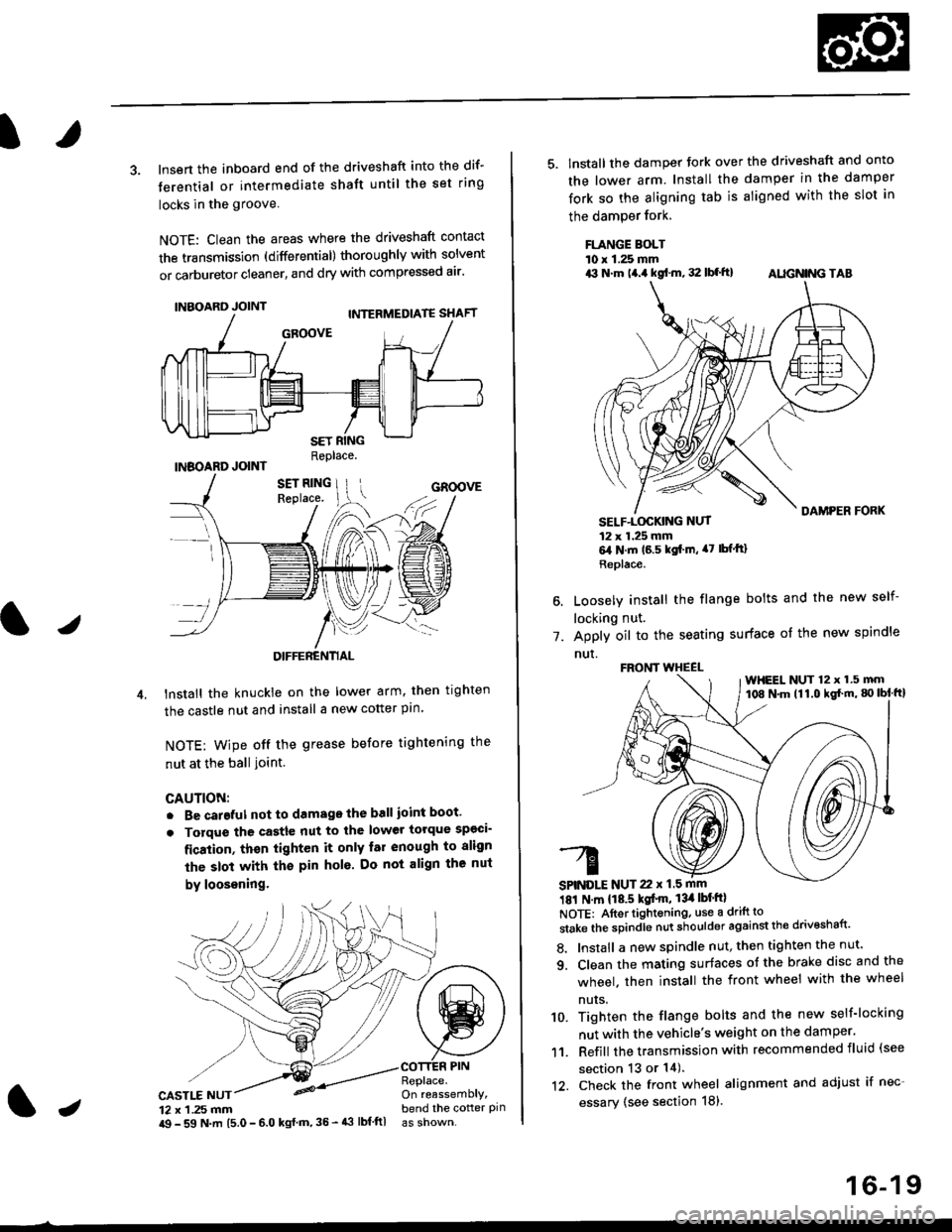

3. lnsert the inboard end of the driveshaft into the dif-

terential or intermediate shaft until the set ring

locks in the groove

NOTE: Clean the areas where the driveshaft contact

the transmission (differential) thoroughly with solvent

or carburetor cleaner, and dry with compressed air'

INBOARD JOINT

INBOARD JOINTReplace.

GROOVE

an

DIFFERENTIAL

lnstall the knuckie on the lower arm. then trghten

the castle nut and install a new cotter pin

NOTE: wipe off the grease before tightening the

nut at the ball ioint.

CAUTION:

. Be careful not to damago the ball ioint boot'

. Torque the castle nut to the lower torque sp€ci-

fication, thsn tighten it only far enough to align

the slot with th€ pin hol6. Do not align the nut

by loosening.

CASTLE NUT12 x 1 .25 mm

COTTER PINReplace.On reassemblY,bend the cotter pinJi$ - 59 N.m 15.0 - 6.0 kgl m,35 - 43 lbf ftl

16-19

5. lnstall the damper tork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damPer fork.

FLANGE BOLTl0 r 1.25 mmrit N.m t4.a kgf.m, 32 lbf.ft) AIIGN|NG TAB

1.

SELF-LOGKING NUT12 x 1.25 mm6,1N.m 16.5 kgi.m, a7 lbfftl

Replace.

Loosely install the flange bolts and the new self-

locking nut.

Apply oil to the seating surface of the new spindle

nut.

181 N m 118.5 kgt'm, 13il lbt'ftl

NOTE: Aftortightening, use a drift to

stake the spindle nut shoulder against the drivoshaft'

8. Install a new spindle nut, then tighten the nut'

9. Clean the mating surfaces ot the brake disc and the

wheel. then install the front wheel with the wheel

nuts.

10. Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

11. Refill the transmission with recommended fluid (see

section 13 or 14).'t2. Check the front wheel alignment and adjust if nec-

essary (see section 18),

FRONT WHEEL

SPINDLE NUT 22 x 1.5 mm

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgl'm, g) lbl ftl

Page 1053 of 2189

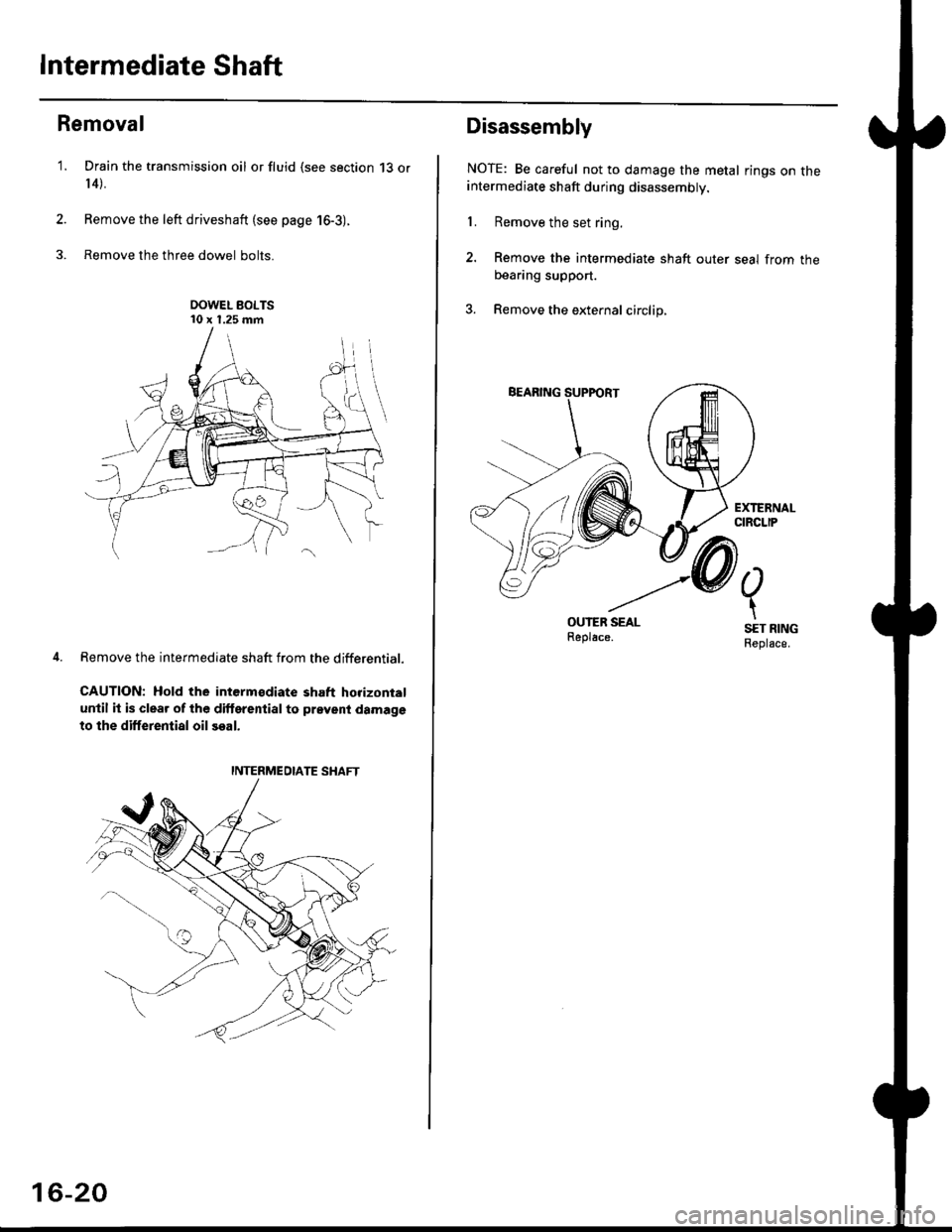

Intermediate Shaft

Removal

Drain the transmission oil or fluid {see section 13 or

r 4).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

OOWEL BOLTS'10 x 1.25 mm

Remove the intermediate shaft from the differential.

CAUTION: Hold the intermsdiate shaft horizontal

until it is clear of lhe dilterential to prevent damage

to the differential oil seal.

'1.

2.

3.

INTERMEDIATE SHAFT

16-20

Disassembly

NOTE: Be careful not to damage the metal rings on theintermediate shaft during disassembly.

1. Remove the set ring.

2. Remove the intermediate shaft outer seal from theDeaflng suppon.

3. Remove the external circlip,

Page 1054 of 2189

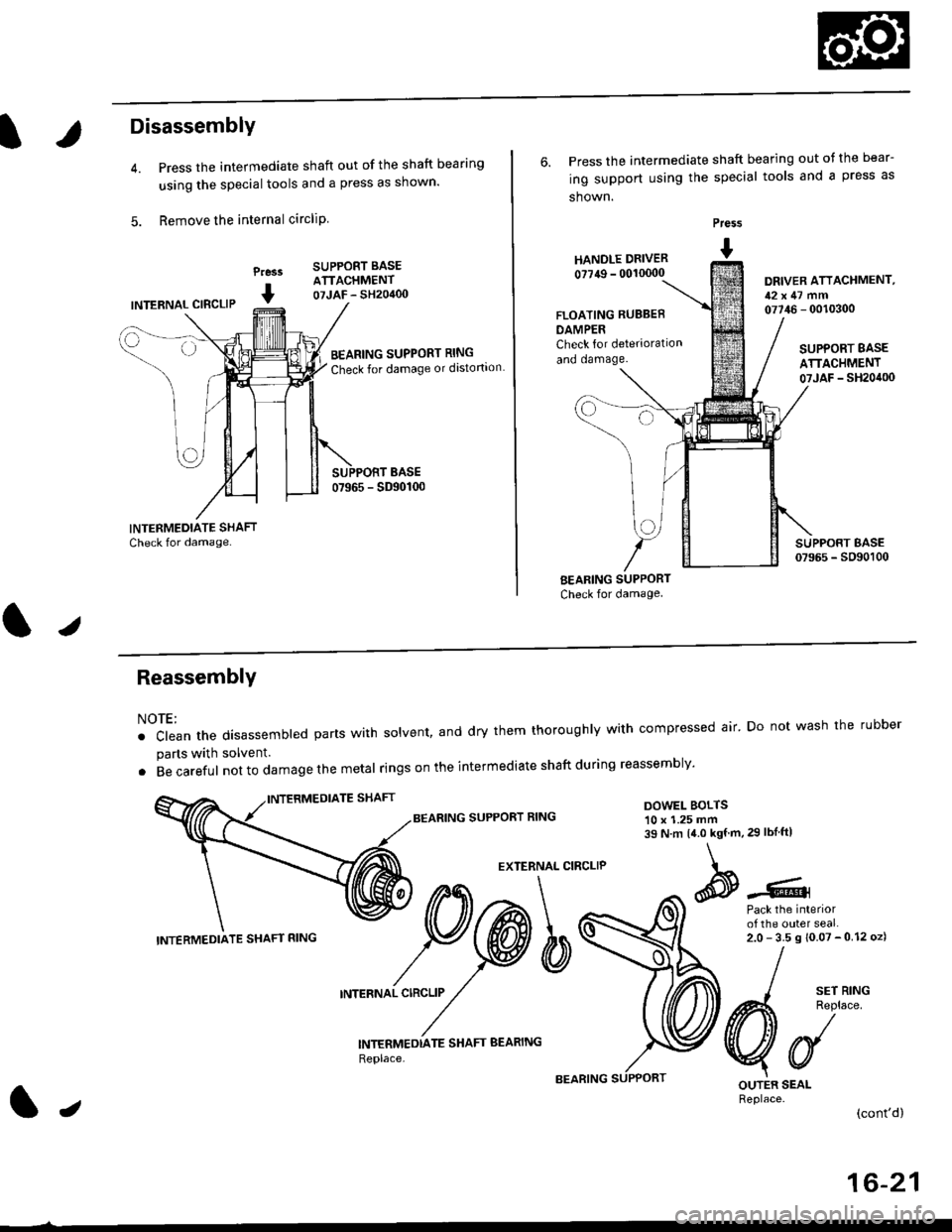

Disassembly

Press the intermediate shaft out of the shaft bearing

using the special tools and a press as shown.

Remove the internal circliP

Press

I

SUPPORT BASEATTACHMENT07JAF - SH20400INTERNAL CIBCLIP

BEARING SUPPORT RING

Check for damage or distortion

6. Press the intermediate shaft bearing out ot the bear-

ing support using the special tools and a press as

shown.

HANOLE DRIVER

0?749 - 00'�10000

Press

I

DRIVER ATTACHMENT,12x47 mm07746 - 0010300FLOATING RUBBEB

DAMPERCheck for deterioration

and oamage.SUPPORT BASE

ATTACHMENT07JAF _ SH20it00

BEARING SUPPORT

Check for damage

I sErR'NG

A4 Reolace

VUOUTER SEALReplace.(cont'd)

ReassemblY

NOTE:

. clean the disassembted parts with solvent, and dry them thoroughly with compressed air' Do not wash the rubber

parts with solvent.

. Becareful not to da mage the metal ringson the intermediate shaftduring reassembly'

BEARING SUPPORT RINGDOWEL BOLTS10 x 1.25 mm39 N.m 14.0 kgf.m,29 lbIftl

EXTERNAL CIRCLIP

Pack the interiorof the outer seal.2.0-35s10.07-012oz)

INTERNAL CIRCLIP

INTERMEDTATE SHAFT BEARING

Replace,

INTERMEDIATE SHAFT RING

lJ

16-21

Page 1055 of 2189

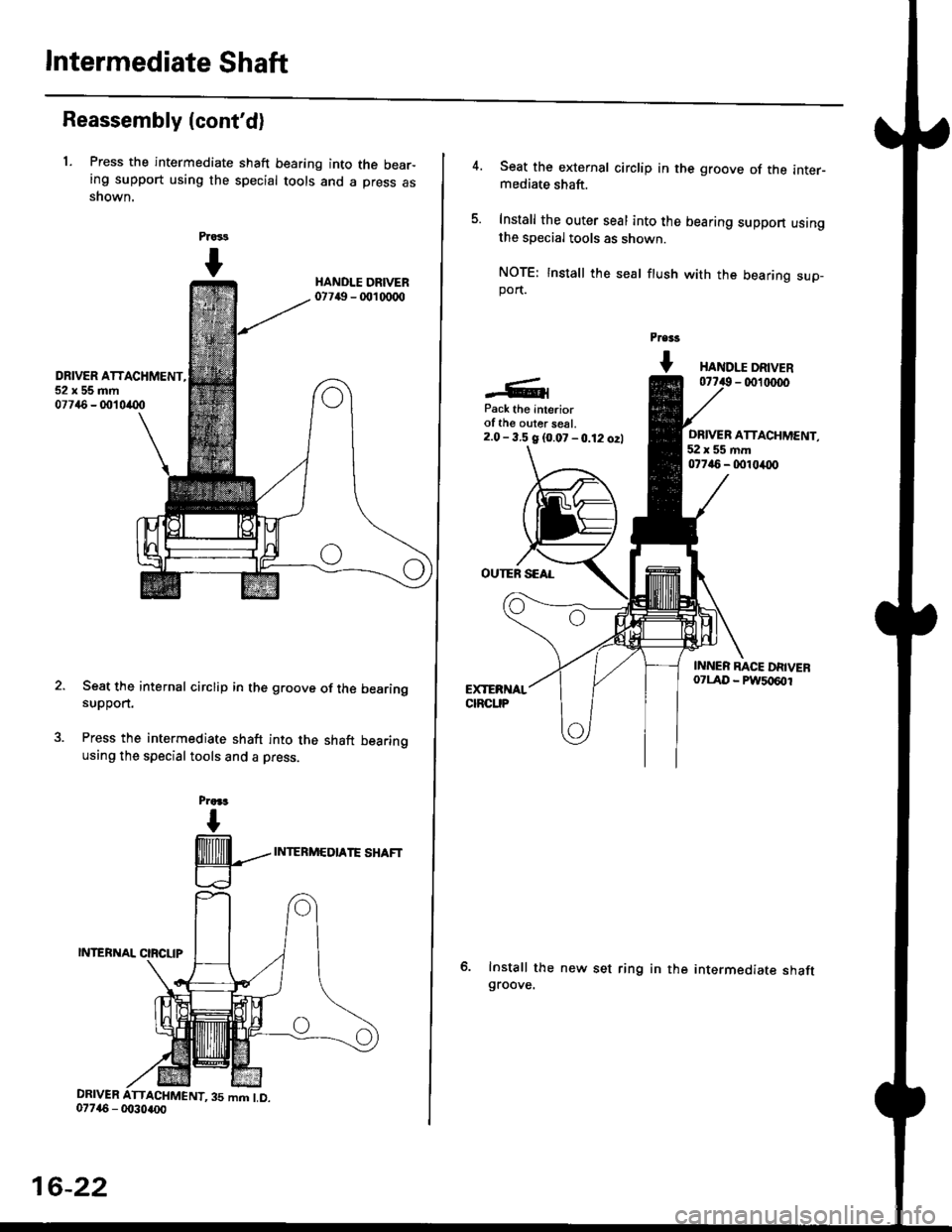

lntermediate Shaft

Reassembly (cont'd)

1. Press the intermediate shaft bearing into the bear-ing support using the special tools and a press asshown.

Prass

I

DRIVER ATTACHMENT,52x55mm07746 - 001 0(X)

Seat the internal circlip in the groove of the bearingsuppon.

Press the intermediate shaft into the shaft bearingusing the special tools and a press.

Praa.r

I

@---

LJ

INTERMEDIATE SHAFT

DRIVER ATTACHMENT,35 mm LD.

16-22

Seat the external circlip in the groove of the inter-mediate shaft.

Install the outer seal into the bearing support usingthe special tools as shown.

NOTE: Install the seal ftush with the bearing sup-port.

Pre$

t HANDr.r DRTVER- 0011r(x)0

Pack the Interiorof the ouler seal.2.0- 3.5 g {0.07 -0.12 ozl

OUTEN SEAL

Install the new set ringgroove.

ORIVER ATTACHMENT,52x55mm077i16 - 0010/O0

in the intermediate shaft

Page 1056 of 2189

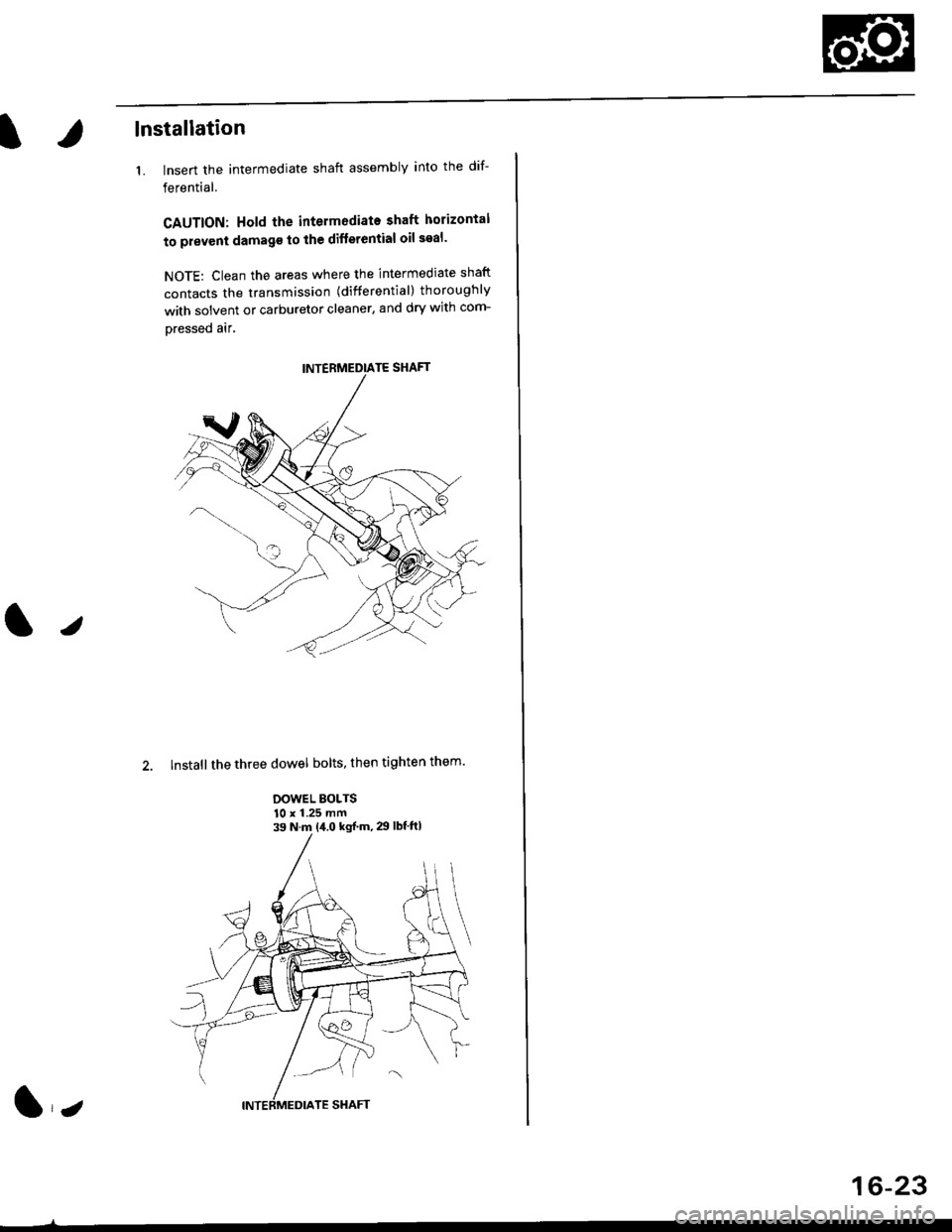

lnstallation

1. lnsert the intermediate shaft assembly into the dif-

ferential.

CAUTION: Hold the intermodiate shaft horizontal

to prevent damag€ to the difterential oil seal'

NOTE: Clean the areas where the intermediate shaft

contacts the transmission (differential) thoroughly

with solvent or carburetor cleaner, and dry with com-

Dressed air,

2. Install the three dowel bolts, then tighten them'

DOWEL BOLTS10 x 1.25 mm39 N.m {i1.0 kgf'm, 29 lbf'ftl

lz

16-23

Page 1090 of 2189

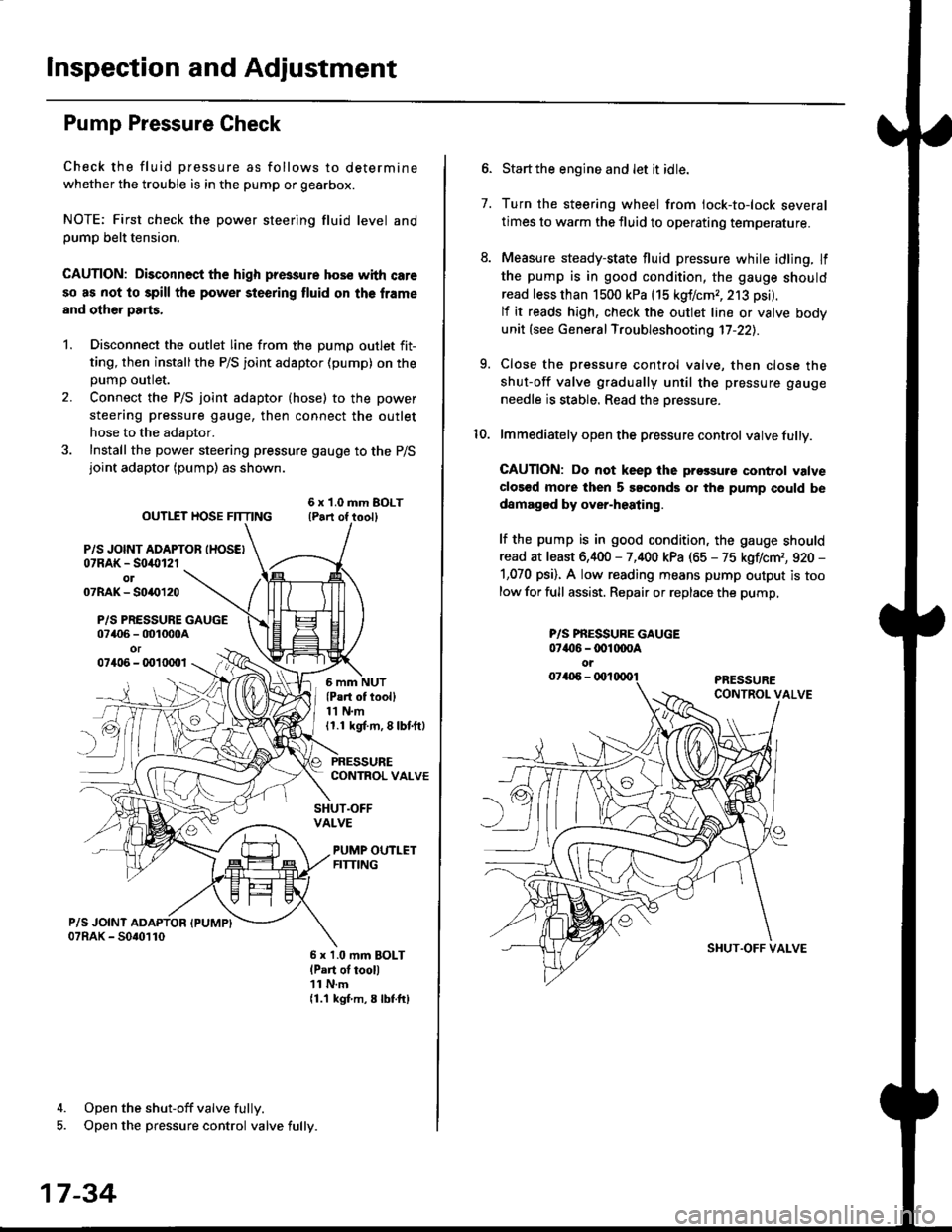

lnspection and Adjustment

Pump Pressure Check

Check the fluid pressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE: First check the power steering fluid level andpump belt tension.

CAUTION: Disconnect the high pr$sure hos€ with care

so as not lo spill the power sieering tluid on tha frame

and other parts.

1. Disconnect the outlet line from the Dumo outlet fit-

ting, then installthe P/S joint adaptor (pump) on the

Dumo outlet.

2. Connect the P/S joint adaptor (hose) to the power

steering pressure gauge, then connect the outlet

hose to the adaptor.

3. Install the power steering pressure gauge to the P/Sjoint adaptor (pump) as shown.

ourlEr HosE FnrNo ,t"ll lrilu"ott

P/S JOINT ADAPTOB IHOSEI07RAK - S0i10l2rol07RAK- 50{{)120

P/S PRESSURE GAUGE07406 - 001000Aor07406 - 0010001

4. Open the shut-off valve fully.

5. Open the pressure control valve fully.

17-34

(Pa.t of tooll11 N.m11.1 kgt m, 8 lbf.ftl

PRESSURECONTROL VALVE

SHUT.OFFVALVE

PUMP OUTLETFITTING

6 x 1.0 mm BOLTlPart of tool)11 N.m11.1 kgf m, 8 lbtftl

7.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. If

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet line or valve body

unit (see General Troubleshooting 17-22).

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable. Read the oressure.

lmmediately open the pressure control valve fully.

GAUTION: Do not keep lhe prossure control valve

clos€d more then 5 soconds or the pump could be

damagod by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm,, 920 -

1,070 psi). A low reading means pump output is too

low for full assist. Repair or replace the pump,

9.

P/S PBESSURE GAUGE07{16 -@1@OA

oi

SI{UT.OFF VALVE

Page 1111 of 2189

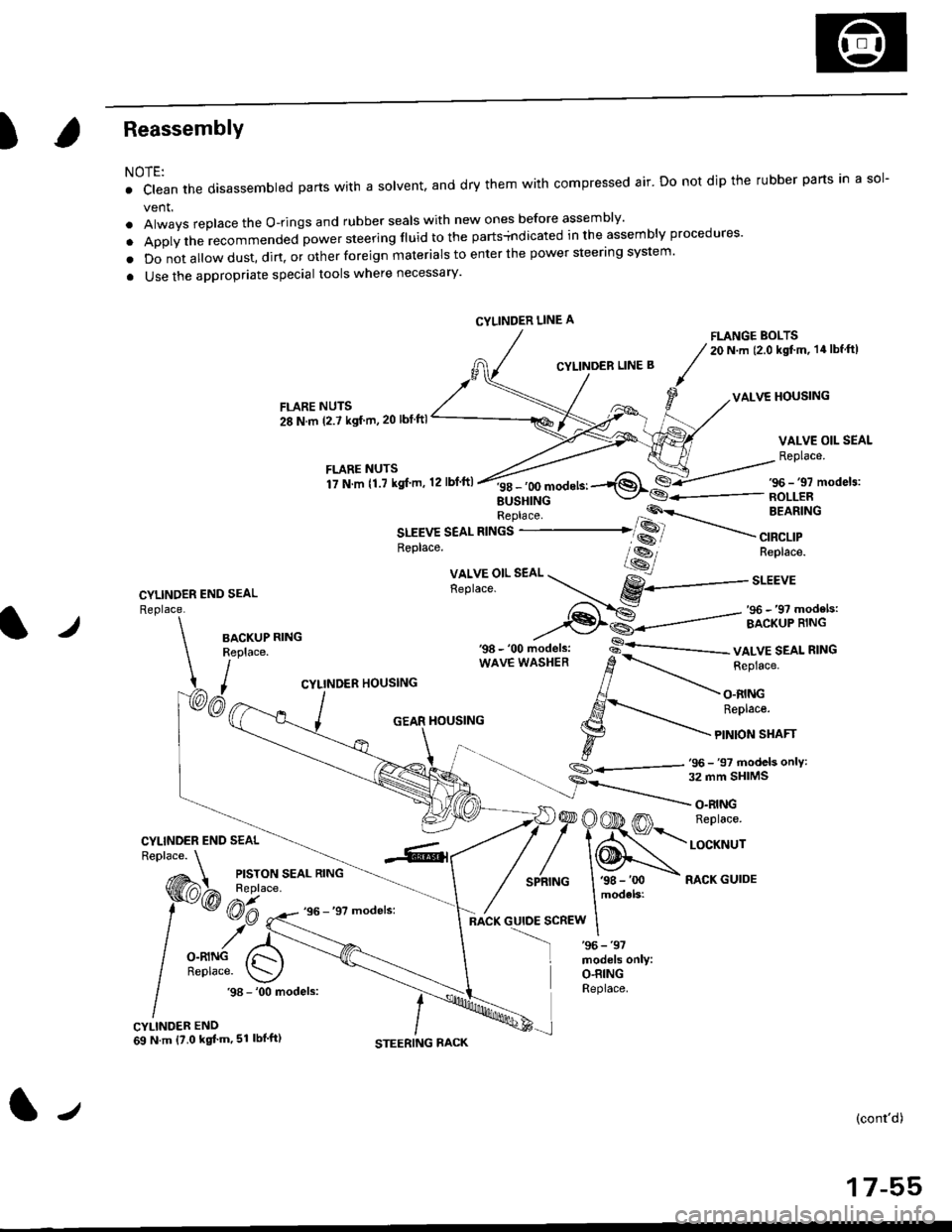

)Reassembly

NOTE:

. clean the disassembled parts wrth a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly'

. Apply the recommended power steering fluid to the parts+ndicated in the assembly procedures'

o Do not a||ow dust, dirt, or other foreign materials to enter the power steering system.

a Use the appropriate special tools where necessary'

FLANGE BOLTS20 N.m (2.0 kgt'm, 14lbf ftl

CYLINDER LINE B

VALVE HOUSINGFLARE NUTS

28 N.m (2.7 ksf m,20 lbf ftl

VALVE OIL SEAL

Replace.

CYLINDER END SEAL

Replace.

f itllTllli".",'r'o,.n,ft

''*^'*-1$*€-/s6-,,mode,3:

EUSHINGReplace 'P'\-- BEARING

SLEEVE SEAL RINGS ..-------......�� SS

.----

",a"a,,

*---

--,

Replace. lss-, Replace.

Xll,Y5"l'.

"o. --r...- gY------..r.u,

,-f-..-S: _ ,96 _,9? models:

--€l€--------=- ircriip'ii.rt'-l./BACKUPReplace.

I,

wAvE wAsHER d

-.-.-r_ i"pru"".

CYLINDER HOUSING // -\-

, AJ - O.RING

/ ,S-'..- ReDtace.

_ j GEAR HouslNG l.g --'\-

\- t F

tonsrnrr

.,_- s

- 'oo ,,iod"t., -s-'--------- vALvE SEAL R'NG

S_.<---,tj- 97 models onlY:

CYLINDER END SEAL

)@OOD m n"prac".

/'\N,."._nrNG I '98 - 'oo - RACK GUIDE

models:

:scREw I

O.RINGReplace..98 - '00 models:

CYLINDER END69 N.m {?.0 kgt'm,51 lbl'ft)

(cont'd)

17-55

CYLINDER LINE A

tJ

Page 1152 of 2189

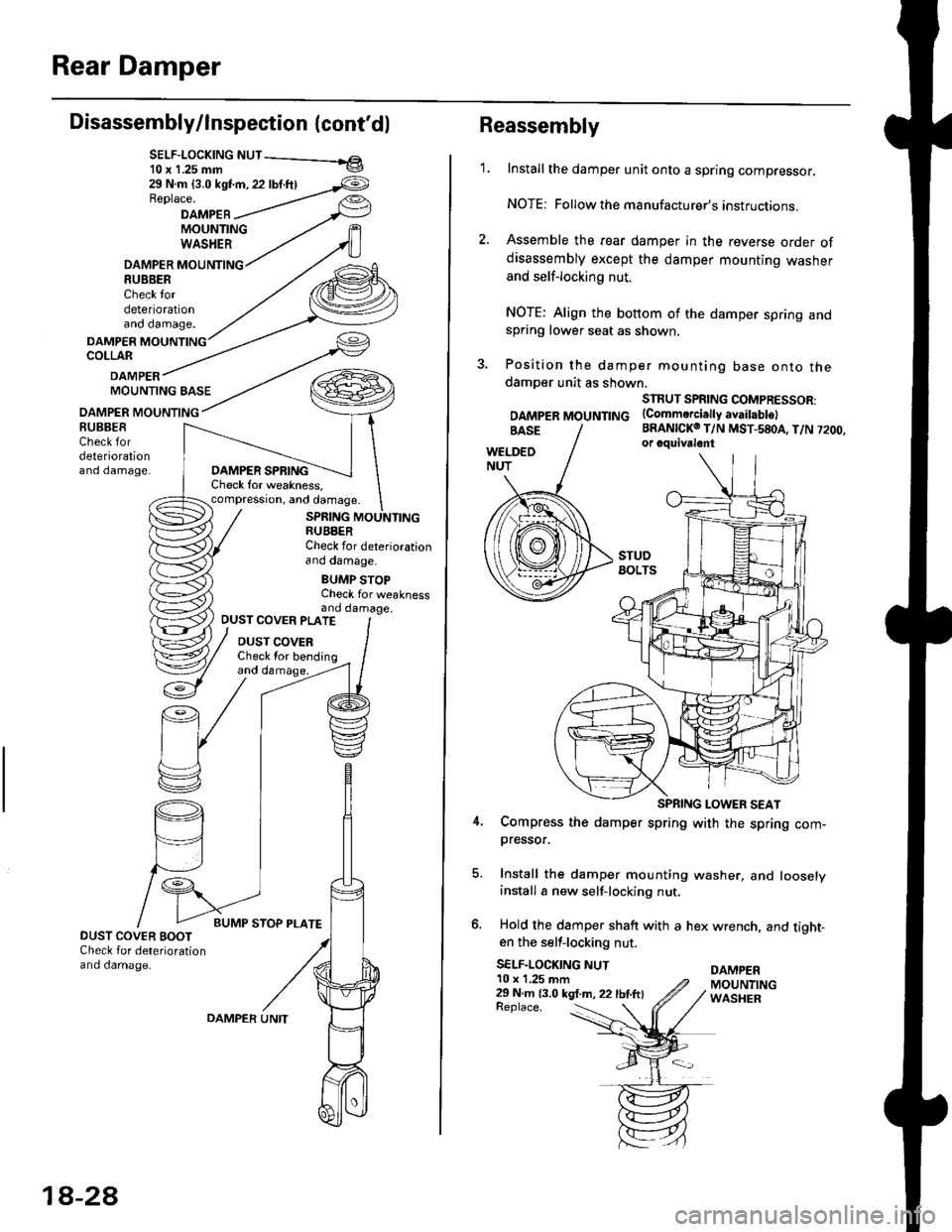

Rear Damper

Disassembly/lnspection (cont'dl

SELF-LOCK|NG NUT - el10 x 1.25 mm v

29 N.m {3.0 kst'm, 22 lbf.ftlReplace.

DAMPEBMOUNTINGWASHER

DAMPER MOUNTING8U8BERCheck tordeteriorationano oamage.

DAMPERCOLLAR

DAMPERMOUNTING BASE

OAMPER MOUNTING

DAMPER SPRINGCheck lor weakness,compression, and damage.

SPRING MOUNTINGRUBBERCheck for deteriorationano oamage.

BUMP STOPCheck for weaknessand damage,

BUBBESCheck fordeteriorationano oamage.

OUST COVER PLATE

DUST COVERCheck lor bending

DUST COVER BOOTCheck for deteriorationand damage.

18-2A

OAMPER UNITReplace. :

Reassembly

1.Install the damper unit onto a spring compressor.

NOTE: Followthe manufacturer's instructions.

Assemble the rear damper in the reverse order ofdisassembly except the damper mounting washer

and self-locking nut.

NOTE: Align the bottom of the damper spring andspring lower seat as shown.

Position the damper mounting base onto thedamoer unit as shown.

SIRUT SPRING COMPRESSOR:

DAMpERMOUNTTNG (Commerciattyavaitabtel

BRANICKO T/N MST-580A, T/N 7200.or cquivalont

Compress the damper spring with the spring com-pressor.

Install the damper mounting washer, and looselyinstall a new self-locking nut.

Hold the damper shaft with a hex wrench, and tight-en the self-locking nut.

SELF-LOCKING NUTDAMPER10 x 1,25 mm29 N m 13.0 kgt.m, 22 lbtftlMOUNTINGWASHER