Iat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1498 of 2189

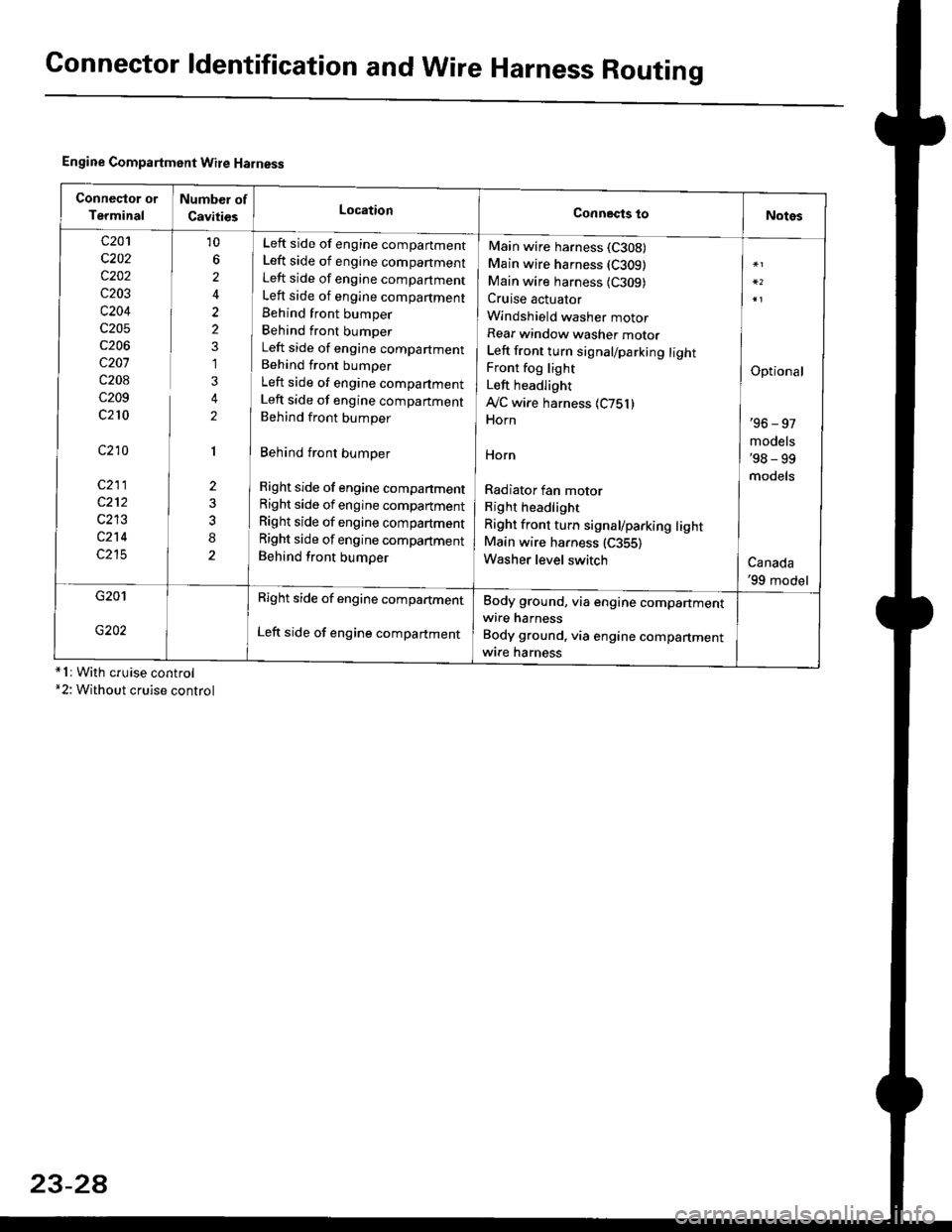

Connector ldentification and WireHarness Routing

Engine Compartment Wire Harness

conneqtor of

Terminal

Number of

CavitiesLocationConnects toNotes

c201

c202

c202

c203

c204

c205

c206

c207

c208

c209

c210

c210

c211

c212

c213

c214

c215

10

6

2

2

2

1

3

2

1

2

8

Left side of engine companment

Left side of engine companment

Left side of engine companment

Left side of engine compartment

Behind front bumper

Behind front bumper

Left side of engine compartment

Behind front bumper

Left side of engine compartment

Left side of engine companment

Behind front bumper

Behind front bumper

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Behind front bumper

Main wire harness (C308)

Main wire harness (C309)

Main wire harness {C309)Cruise actuator

Windshield washer motor

Rear window washer motor

Left front turn signal/parking lightFront fog light

Left headlight

Ay'C wire harness 1C751)Horn

HOrn

Radiator fan motor

Right headlight

Right front turn signal/parking lightMain wire harness (C355)

Washer level switch

Optional

'96 - 97

models'98 - 99

models

Canada'99 model

G201

G202

Right side of engine compartment

Left side of engine compartment

Body ground, via engine compartmentwire harness

Body ground, via engine compartmentwrre harness*1r With cruise control*2: Without cruise control

23-2A

Page 1529 of 2189

'

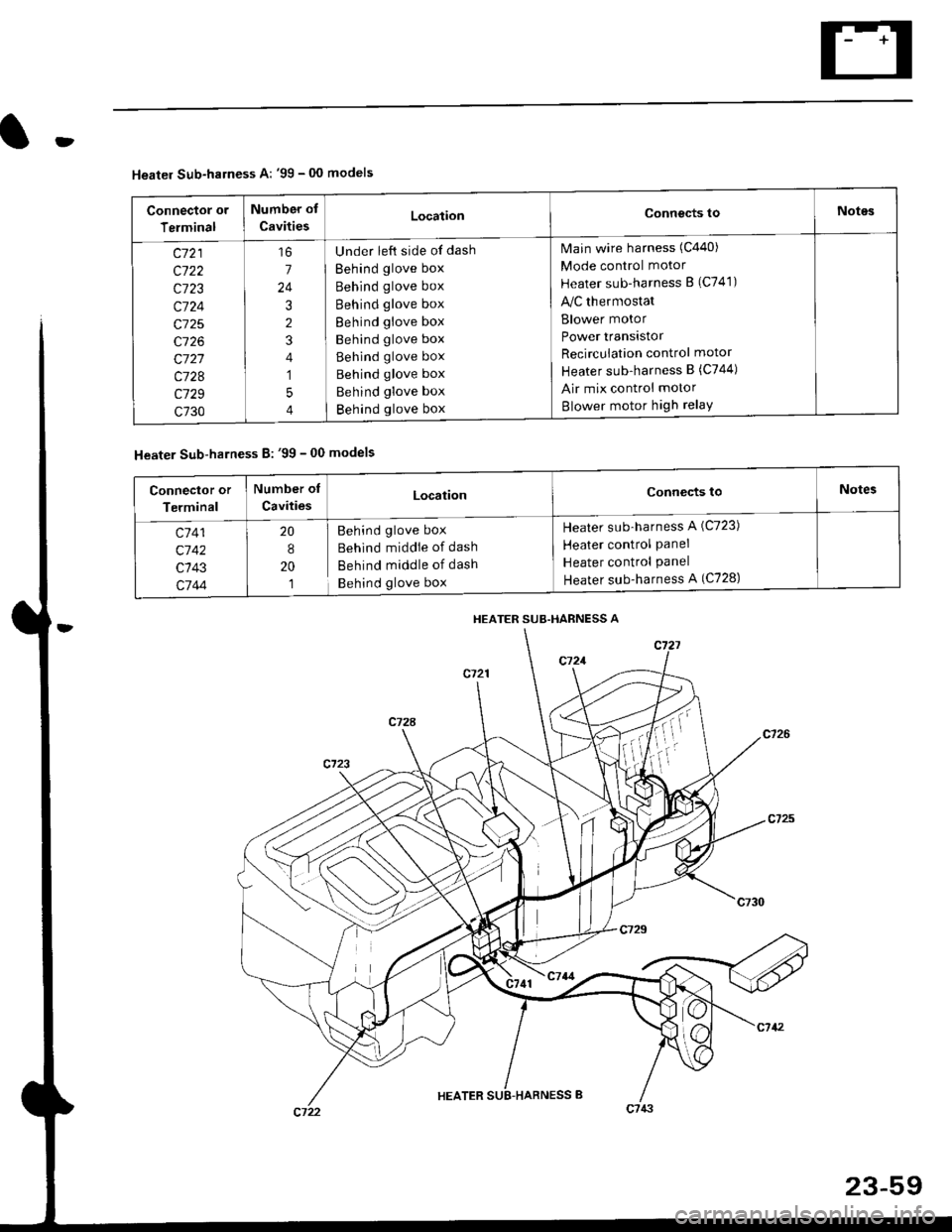

Heater Sub-harness A: '99 - 00 models

Connector or

Terminal

Number of

CavitiesLocationConnects toNotes

c721

c722

c723

c724

c725

c726

c727

c728

c729

c730

7

24

3

2

4

1

5

4

Under left side of dash

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Main wire harness (C440)

Mode control motor

Heater sub-harness B (C741)

lilc thermostat

Blower motor

Power transistor

Recircuiation control motor

Heater sub-harness B (C744)

Air mix control motor

Blower motor high relaY

Heater Sub-harness B: '99 - 00 models

HEATER SUB.HARNESS A

Connector or

Terminal

Number of

CavitiesLocationConnects toNotes

c7 41

c'742

c143

c744

20

8

20

1

Behind glove box

Behind middie of dash

Behind middle of dash

Behind glove box

Heater sub-harness A (C723)

Heater control Panel

Heater control Panel

Heater sub-harness A (C728)

Page 1533 of 2189

(l'-

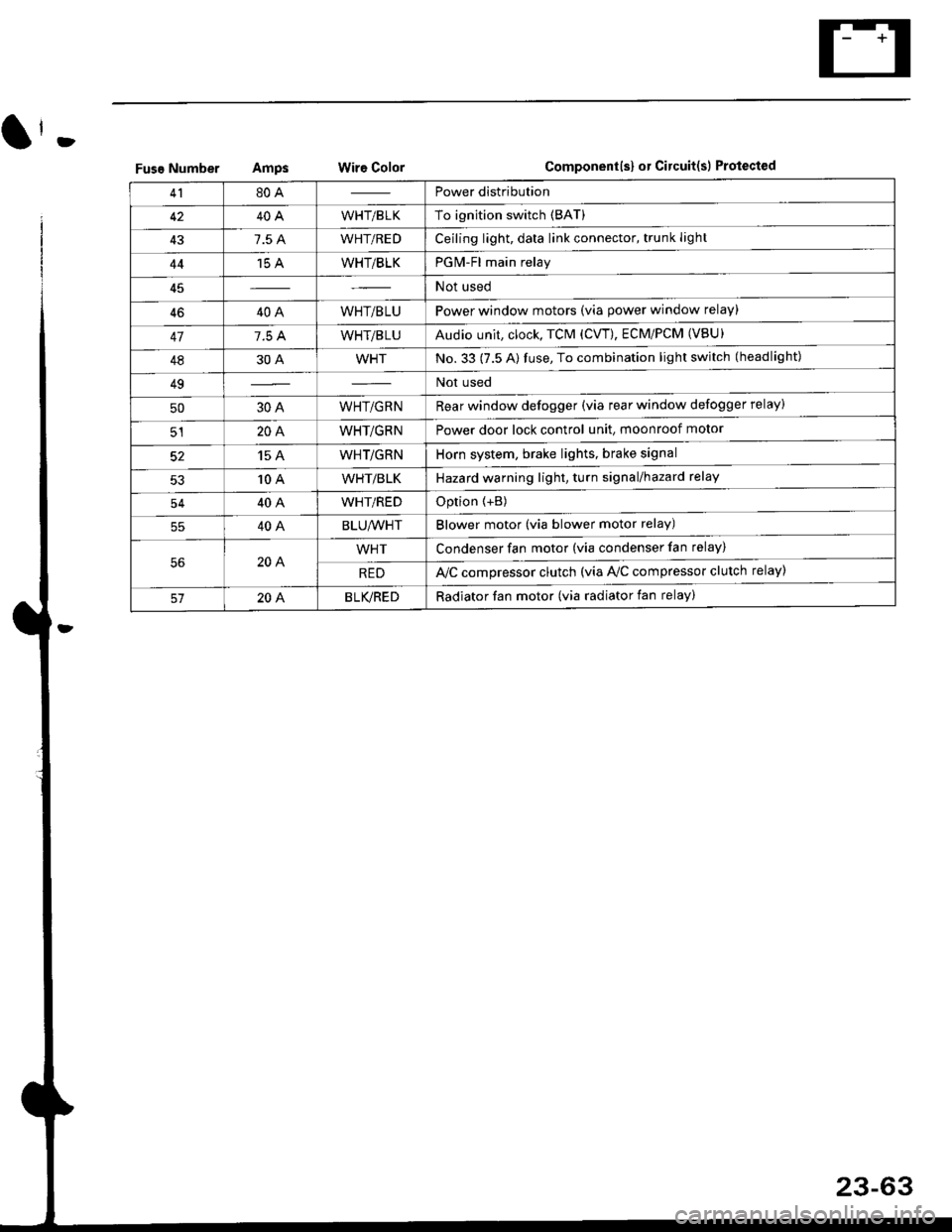

Fuse NumberAmpswire ColorComponent(s) or Circuitlsl Protect€d

4180APower distribution

4240AWHT/BLKTo ignition switch (BAT)

437.5 AWHT/REDCeiling light, data link connector, trunk light

4415 AWHT/BLKPGM-Fl main relay

Not used

4640AWHT/BLUPower window motors (via power window relay)

477.5 AWHT/BLUAudio unit, clock, TCM (CVT), ECM/PCM (VBU)

4830AWHTNo.33 (7.5 A) fuse, To combination light switch (headlight)

49Not used

5030AWHT/GRNRear window defogger (via rear window defogger relay)

cl20AWHT/GRNPower door lock control unit, moonroof motor

15 AWHT/GRNHorn system, brake lights, brake signal

10 AWHT/BLKHazard warning light, turn signal/hazard rclay

54404WHT/REDOption {+B)

5540ABLU,A/VHTBlower motor (via blower motor relay)

204WHTCondenser fan motor (via condenser fan relay)

REDl'lc compressor clutch (via IVC compressor clutch relay)

204BLVBEDRadiator fan motor (via radiator fan relay)

23-6

Page 1538 of 2189

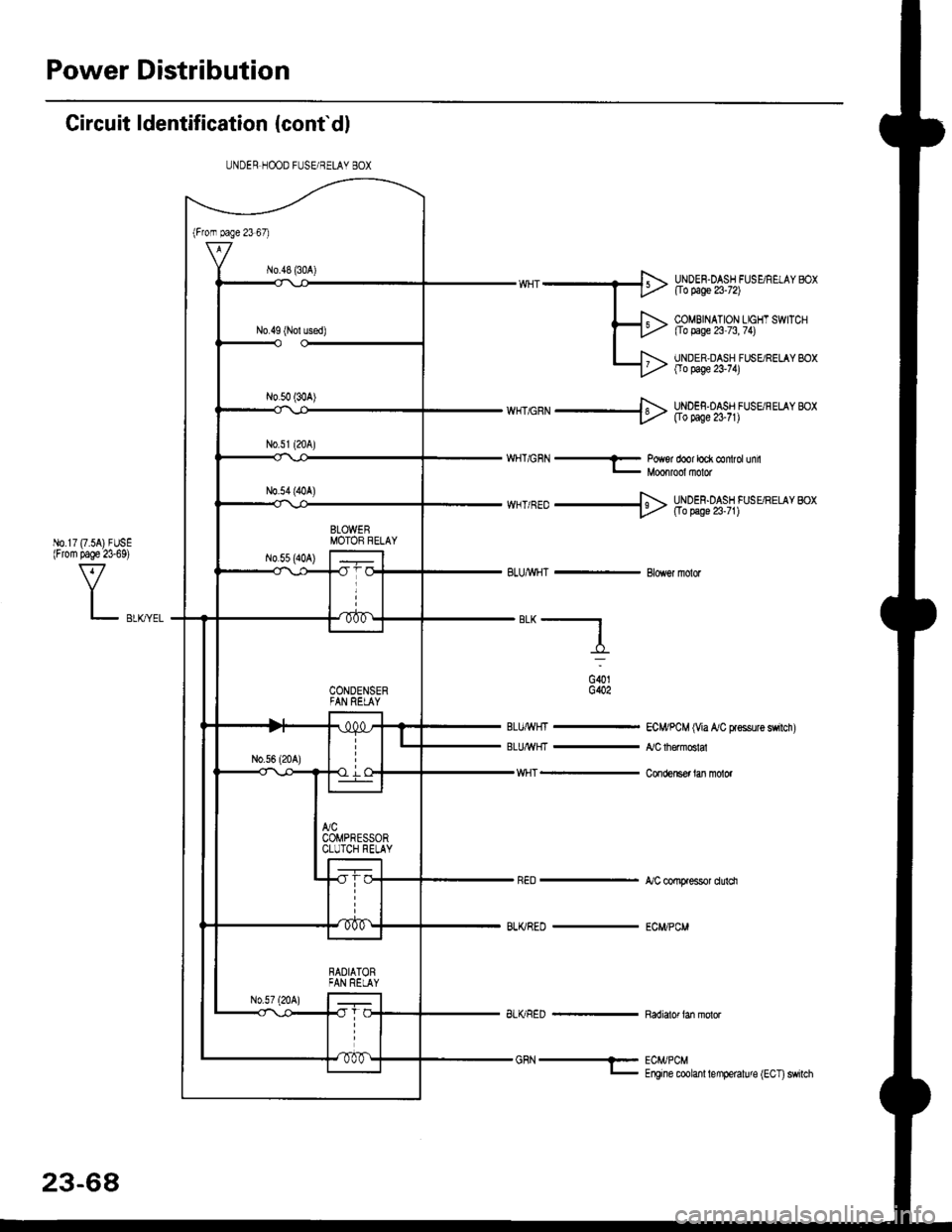

Power Distribution

Circuit ldentification (conf dl

ECI4/PCM (Via A/C Fsssure switch)

,VC th€modA

Con(,ensef lan molor

A/C comFessor dulci

ECWPCM

UNDER HOOD FUSE/BELAY BOX

"*-f_

v{HT -

BLI(/RED -

UNDEN.DASH FUSE/REIAY BOXflo page 23-72)

COMBINATION LIGHT SWITCH[Io page 23 73, 74)

UNDER,DASH FUSgRELAY BOXOo page 23'74)

wnc'N ---}> Hlgl;%,s,1 lsu'r"' *,

wHT/GnN-Po#sr door lock control unilMoonrool molor

*HT/RED + Hoo5f;oA'.j1fu,uttto" *t

BLUMHT - Blowor fiolor

G()1G402

BLu/rrit{t -

BLU/lf {I -

23-68

BLI(RED - Radiator tan molor

Page 1557 of 2189

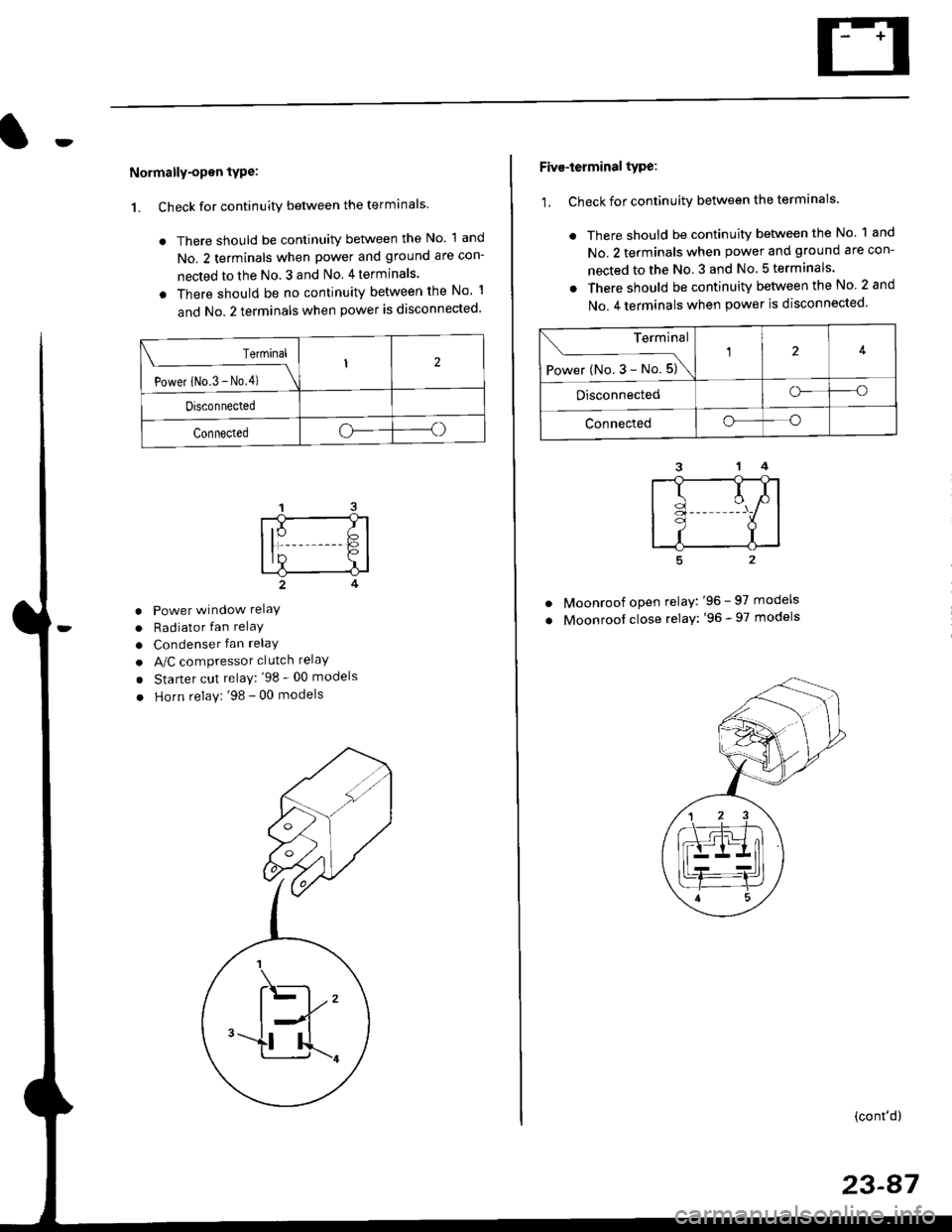

Normally-opsn tYPe:

1. Check for continuity between the terminals

. There should be continuity between the No. 1 and

No. 2 terminals when power and ground are con-

nected to the No. 3 and No 4terminals.

o There should be no continuity between the No 1

and No.2 terminals when power is disconnected'

Terminal

Power iNo.3 - No,4) \

I2

Disconnected

Connectedoo

a

a

a

Power window relaY

Radiator fan relaY

Condenser fan relaY

A/C compressor clutch relaY

Starter cut relay: '98 - 00 models

Horn relay: '98 - 00 models

Five-ierminal type:

1. Check for continuitv between the terminals.

. There should be continuity betlveen the No. 1 and

No. 2 terminals when power and ground are con-

nected to the No. 3 and No 5terminals.

. There should be continuity between the No 2 and

No. 4 terminals when power is disconnected'

--1

I

II

t

Moonroof open relay: '96 - 97 models

Moonroof close relay: '96 - 97 models

(cont'd)

23-87

Terminal

Power (No. 3 - No. 5)\

4

Disconnectedo--o

Connectedo--o

Page 1561 of 2189

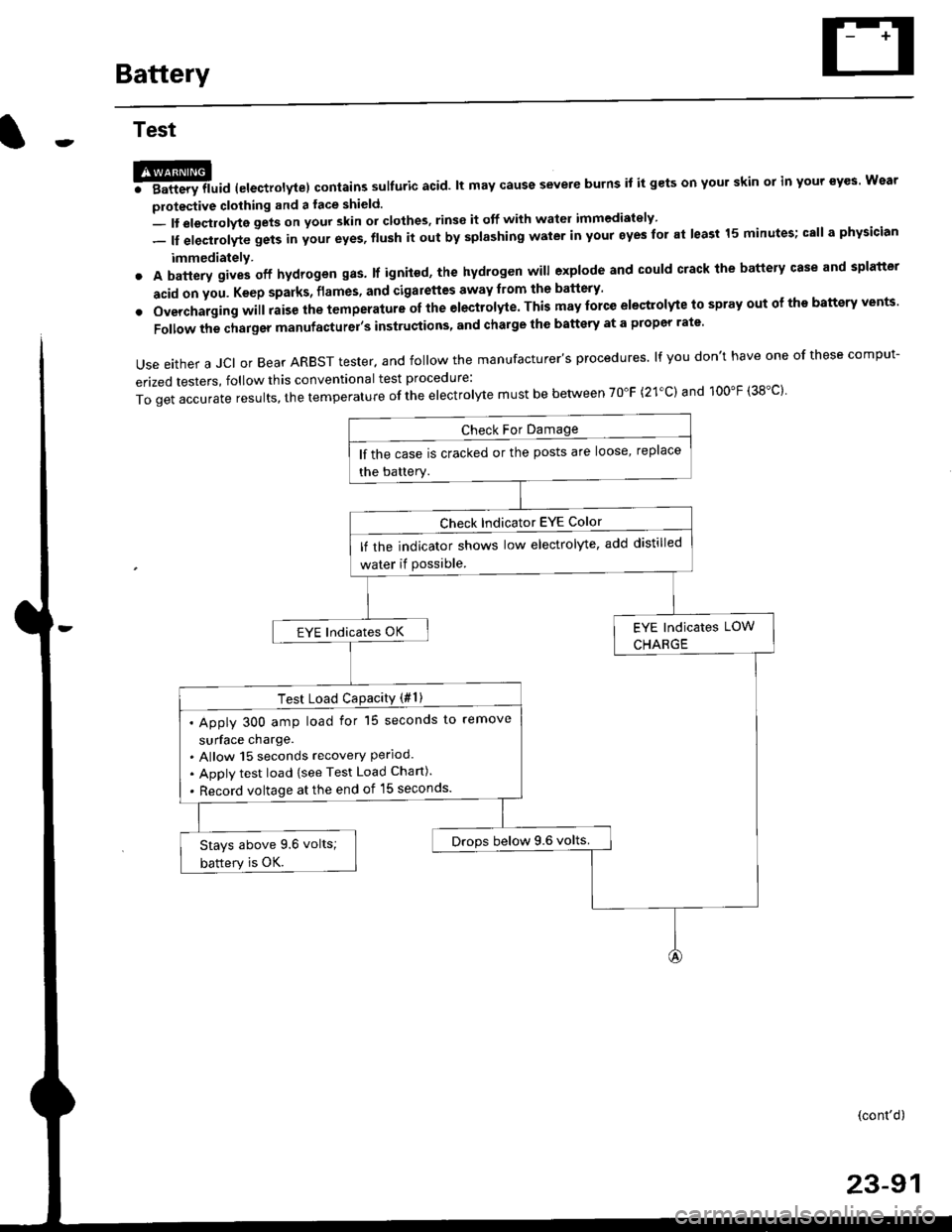

Battery

Test

@l. Battery lluid lelectrolytel contalns sulfuric acid. lt may cause severe burns it it gets on your skin ol in your eyes Wear

protective clothing and a face shield.

- It eleqtlolyte gets on your skin or clothes, rinse it off with watel immediately

- lf electrolyte gets in your eyes, flush it out by splashing water in your eyes for at least 15 minutes; call a physician

immediately.

. A battery gives off hydrogen gas. lf ignited, the hydrogen will explode and could crack the battery case and splatter

acid on you. Keep sparks, flames, and Gigarettes away from the battery'

o Overchaiging will raise the temperature oI the electrolyte. This may force electrolyte to spray out ot ths battery vents'

Follow the charger manufacturel's instrustions, and chalge the battery at a propcr rate.

Use either a JCI or Bear ARBST tester. and follow the manufacturer's procedures. lf you don't have one of these comput-

erized testers, follow this conventional test procedure:

ToqetaccurateresuIts,thetemperatureoftheeIectro|ytemustbebetweenT0"F(21.c)and100"F(38.c}'

lf the case is cracked or the posts are loose, replace

the battery.

lf rhe indicator shows low electrolyte, add distilled

water if Possible.

EYE lndicates OK

Test Load CaPacitY (#l )

. Apply 300 amp load for 15 seconds to remove

surface charge.. Allow 15 seconds recovery Perloo.. Apply test load {see Test Load Chan).

. Record voltage at the end of l5 seconds.

Drops below 9.6 volts.Stays above 9.6 volts;

battery is OK.

(cont'd)

23-91

Page 1571 of 2189

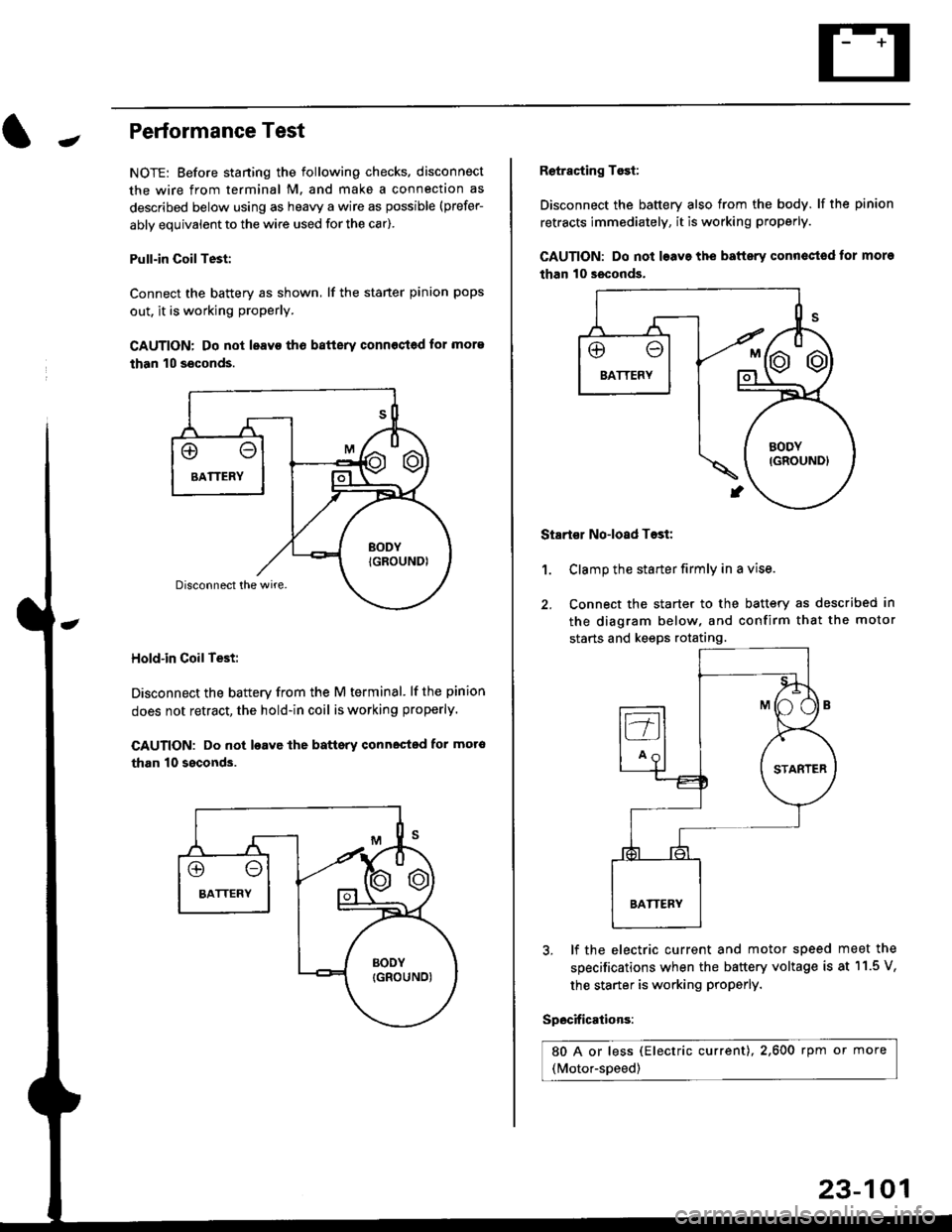

-Performance Test

NOTE: Before staning the following checks. disconnect

the wire from terminal M. and make a connection as

described below using as heavy a wire as possible (prefer-

ably equivalent to the wire used for the car).

Pull-in CoilTest:

Connect the battery as shown, lf the staner pinion pops

out. it is working proPerly.

CAUTION: Do not leavo tho batterv connost€d for more

than 10 seconds.

Hold-in Coil Test:

Disconnect the battery from the M terminal' lf the pinion

does not retract, the hold-in coil is working properly.

CAUTION: Do not loavc lhe battsry connected for mot6

than 10 ssconds.

Retracting Tosi:

Disconnect the battery also from the body. lf the pinion

retracts immediately, it is working properly.

GAUTION: Do not loave the baftery conn€ctod tor more

than 10 seconds.

Startor No-load Tost:

Clamp the starter firmly in a vise.

Connect the starter to the battery as described in

the diagram below, and confirm that the motor

starts and keeps rotating.

1.

3, lf the electric current and motor speed

specifications when the battery voltage is

the starter is working ProPerly.

Specifications:

80 A or less (Electric current),2,600 rpm or more

(Motor-speed)

meet the

at 11.5 V,

23-101

Page 1575 of 2189

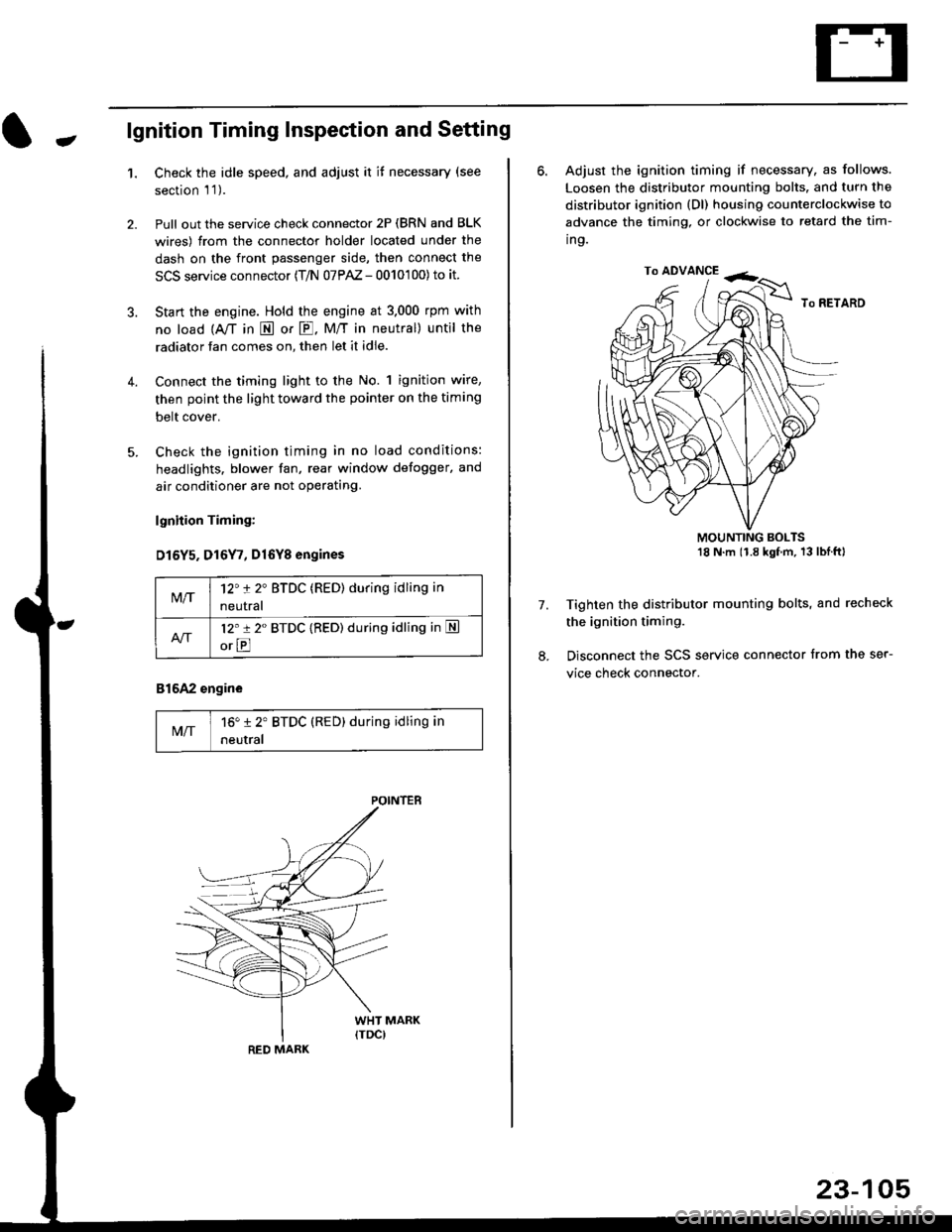

-lgnition Timing Inspection and Setting

1.Check the idle speed, and adjust it it necessary (see

section 'l '1 ).

Pull out the service check connector 2P (BRN and BLK

wires) from the connector holder located under the

dash on the front passenger side, then connect the

SCS service connector (T/N 07PAZ - 0010'100) to it.

Start the engine. Hold the engine at 3.000 rpm with

no load {A,/T in E or E. M/T in neutral) until the

radiator fan comes on, then let it idle.

Connect the timing light to the No. 1 ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights. blower fan, rear window defogger, and

air conditioner are not operating.

lgnhion Timing:

D15Y5. D16Y7, Dl6Yg engines

816A2 engine

MIT16" 12' BTDC (RED) during idling in

neutral

M/T12't 2" BTDC (RED) during idling in

neutral

l2'r 2" BTDC {RED) during idling in S

orE

POINTEB

RED MARK

23-105

ro ADVANCE -<;,

6. Adjust the ignition timing if necessary, as follows.

Loosen the distributor mounting bolts. and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing, or clockwise to retard the tim-

ing.

MOUNTING BOLTS18 N'm (1.8 kgfm, 13lblftl

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

7.

Page 1588 of 2189

Charging System

Troubleshooting (cont'd)

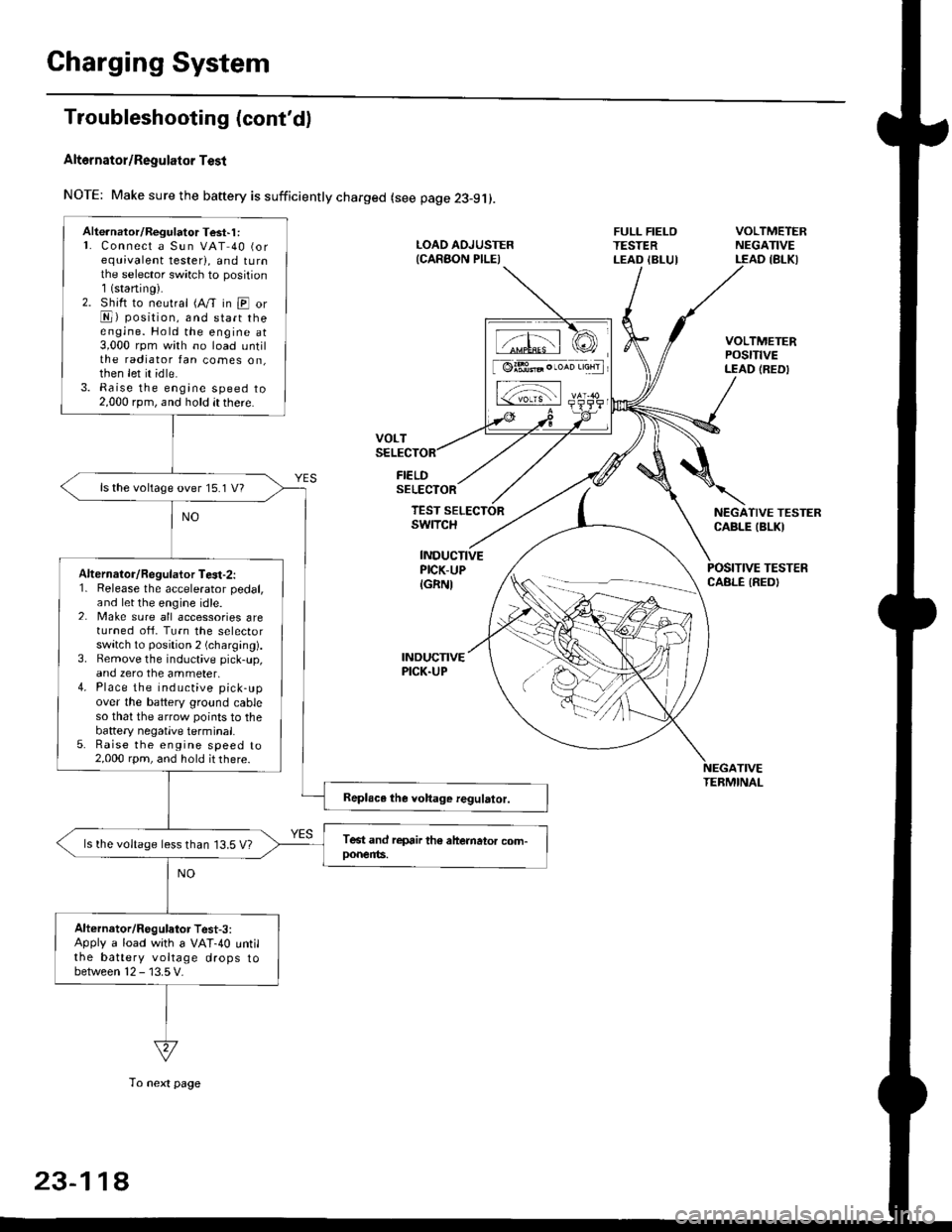

Alt6rnator/Regulator Test

NOTE: Make sure the baftery is sufficiently charged (see page 23-9j).

FIELDSELECTOR

LOAD AOJUSTER{CARAON PILEI

FULL FIELOTESTERLEAD IBLUI

VOLTMETERNEGATIVELEAD IBLKI

VOLTMETERPOStTtVELEAD (REDI

NEGATIVE TESTERCABLE IBLKI

POSITIVE TESTERCABLE IREDI

TEST SELECTORswrTcH

INDUCTIVEPICK-UP

IGRNI

INDUCNVEPICK.UP

TIVETEBMINAL

Alte.nator/Regulator Test'1 :L Connect a Sun VAT 40 (orequivalent tester), and tu rnthe selector sw;tch to position1(staning).2. Shift to neutral (A/T in E orE) position, and start theengine. Hold the engine at3,000 rpm with no load untilthe radiator fan comes on,then let it idle.3. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

Alternalor/Regulator Te3t-2:1. Release the accelerator pedal,and let the engine idle.2. Make sure all accessories areturned ofi. Turn the selectorswitch to position 2 (charging).3. Bemove the inductive pick-up,and zero the ammeter,4. Place the inductive pick-upover the battery ground cableso that the arrow points to thebattery negatlve terminal.5. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage less than 13.5 V?

Alternator/Regulator Test-3:Apply a load with a VAT-40 untilthe battery voltage drops tobetween 12 - 13.5 V.

tffil rCI

[ @lBt* . ,*n 'aHrl

L-;-;l rs-

23-11A

To next page

Page 1594 of 2189

Gharging System

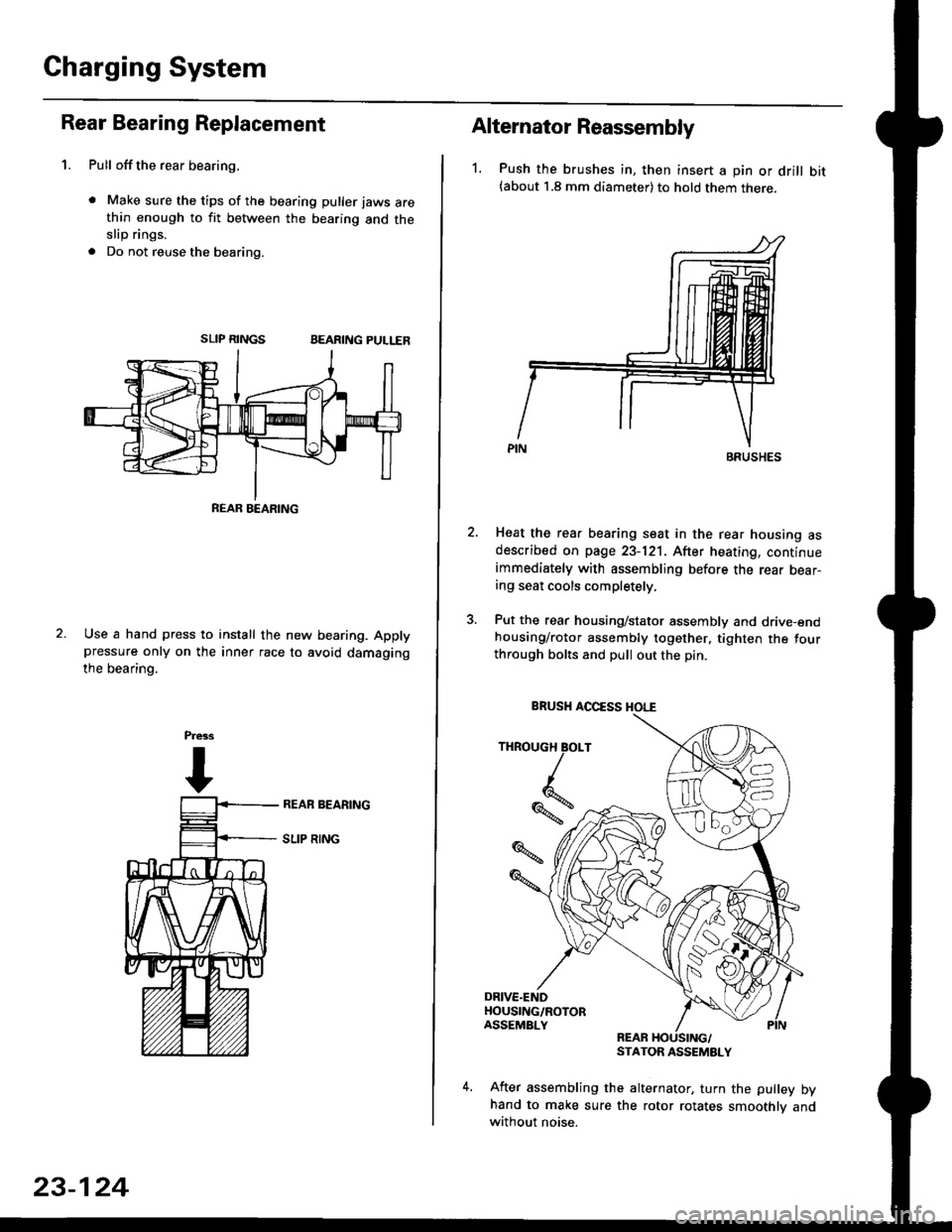

Rear Bearing Replacement

1. Pull offthe rear bearing,

. Make sure the tips of the bearing puller jaws arethin enough to fit between the bearing and theslip rings.

. Do not reuse the bearing.

SLIP RINGSBEARING PULLER

Use a hand press to install the new bearing. Applypressure only on the inner race to avoid damaging

the bearino.

REAB BEARING

23-124

Alternator Reassembly

1. Push the brushes in, then insert a pin or drill bit(about 1.8 mm diameter) to hold them there.

Heat the rear bearing seat in the rear housing asdescribed on page 23-121. After heating, continueimmediately with assembling before the rear bear-ing seat cools completely,

Put the rear housing/stator assembly and drive-endhousing/rotor assembly together. tighten the fourthrough bolts and pull out the pin.

REARSTATOR ASSEMBLY

After assembling the alternator, turn the pulley byhand to make sure the rotor rotates smoothlv andwithout noise.

BRUSHES

THROUGH BOLT

Iq

%*z

BRUSH AOCESS HOI."E