Brake HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1205 of 2189

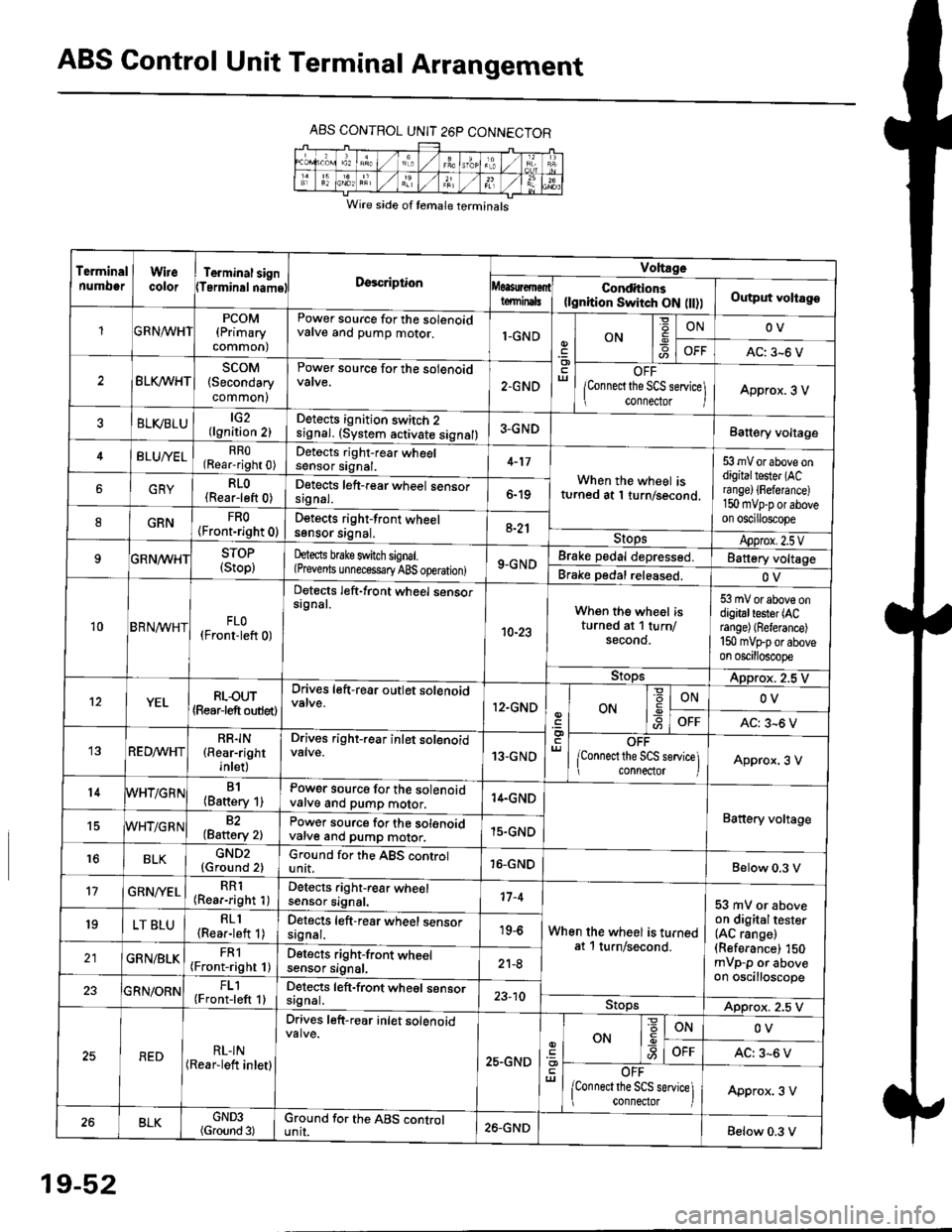

ABS Control Unit Terminal Arrangement

ABS CONTROL UNIT 26P CONNECTOR

Wire side of temale terminals

Terminalnumo0rWirecolorTerminal signTerminalnamoDgscriptionVoltage

Conditions(lgnition Switch ON flt))Output voltagoteminals

PCOM(Primary

common)

Power source for the solenoidvalve and pump motor.1-GNDON

=ONOV

AC: 3-6 V

BLK/WHTscoM(Secondary

common)

Power source for the solenoid

2.GNDOFF

lConnect the SCS service\

conneclor lApprox. 3 V

ELVBLUtG2(lgnition 2)Detects ignition switch 2

!9nal. (system activate signal)3-GNDBatt€ry voltage

BLU/YELRRO(Rear-right 0)Detects right-rear wheelsensor signal.4-17

When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester (ACra nge) {Fefera nce)150 mvp-p or aboveon oscilloscope

6GRYRLO(Rear-left 0)Detects left-rear wheel sensorsrgnal.6-19

8GRNFRO(Front-right 0)D€tects right-front wheelsgnsor srgnal,a-21StopsApprox.2.5VSTOP(Stop)hects brake switch signal.(Prevents unnecess€ry ABS operation)9-GNDBrake pedal depressed.Battery voltage

Brake pedal released.OV

10BRN^/vHTFLO(Front-left 0)

Detects left-front wheel sensorsignal.

10-23

When the wheel isturned at 1 turn/secono.

53 mV or above ondigitaltester (ACrange) (Referance)

150 mVFporaboveon oscilloscope

9!opsApprox. 2.5 V

12YELRLOUT(Rearjeft outlet)

Drives left-rear outlet solenoid

12.GNDON-9ONOV

OFFAC: 3^6 V

REDMHTRR]N(Rear-right

inlet)

Drives right-rear inlet solenoidvalve.13-GNDOFF

lconnect the SCS service]i connector IApprox. 3 V

14B1(Battery 1)Power source for the solenoidvatve and pump motor.14.GND

Battery voltage15WHT/G R N82(Baftery 2)Power source for the solenoidvarve ano pump motor.15.GND

r6BLKGND2{Ground 2)Ground for the ABS controlunit.16-GNDBelow 0.3 V

17GRN/'/ELRR1(Rear-right 1)Detects right-rear wheelsensor signal.17-4

When the wheel is turnedat 1 turn/second.

53 mV or aboveon digitaltester(AC range)(Referance) 150mVp-p or aboveon oscilloscope

19LT BLURLl(Rea.-left 1)Detects left-rear wheel sensorsagnal.19-6

GRN/BLKFRl(Front-right 1)Detects right-front wheelsensor signal.21-8

FL1(Front-left 1)Detects left-front wheel sensorsignal.23-10StopsApprox. 2.5 V

REDRL-IN(Rear-lett inletl

Drives left-r€ar inlet solenoid

25.GND

ut

ON

'6

-9ONOV

OFFAC: 3-6 V

OFF

lconnect the SCS service] connector lApprox. 3 V

BLKGND3(Ground 3)Ground for the ABS cgntrolunit.26.GNDBelow 0.3 V

19-52

Page 1208 of 2189

tJ

t\

Kickback

1. The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder

causing kickback at the brake pedal.

2. TheABScontrol unit operates the solenoid valve when the brake pedal is released afterthe initial diagnosis Youmay

hear the faint solenoid valve operation sound at this time. but it is normal.

Pump Motor

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the faint operation sound

at this time. but it is normal.

Brake Fluid Replacament/Air Blsading

1. Brake fluid replacement and air bleeding procedures are the same as for conventional brakes

Troubleshooting

1. The troubleshooting flowcharts explain the procedures on the assumption that the cause of the problem is still pre-

sent and the ABS indicator light is still on.

Note that troubleshooting following the flowchart when the ABS indicator light does not come on can result in incor-

rect judgment.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

self,diagnosis is made at various times such as the initial diagnosis, except ABS control. during ABS control, during

acceleraiion, during the specified vehicle speed, etc. Therefore, the symptom cannot be checked unless the check

conditions match with the problem conditions

3. When the ABS indicator light does not come on during the test drive, but the troubleshooting is performed based on

the DTC, check for the loose connectors. poor contact of the terminals, etc, before troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the car. Be sure that the ABS indicator light does not come on.

5. The connector illustrations show the female connectors with a single outline and the male connectors with a double

ouflrne.

6. The connector terminal cavities containing female terminals are always numbered by looking at the connector from

the wire side. and the cavities containing male terminals are always numbered by looking at the connector from the

terminal side.

r'

19-55

Page 1209 of 2189

Diagnostic Trouble Code (DTCI

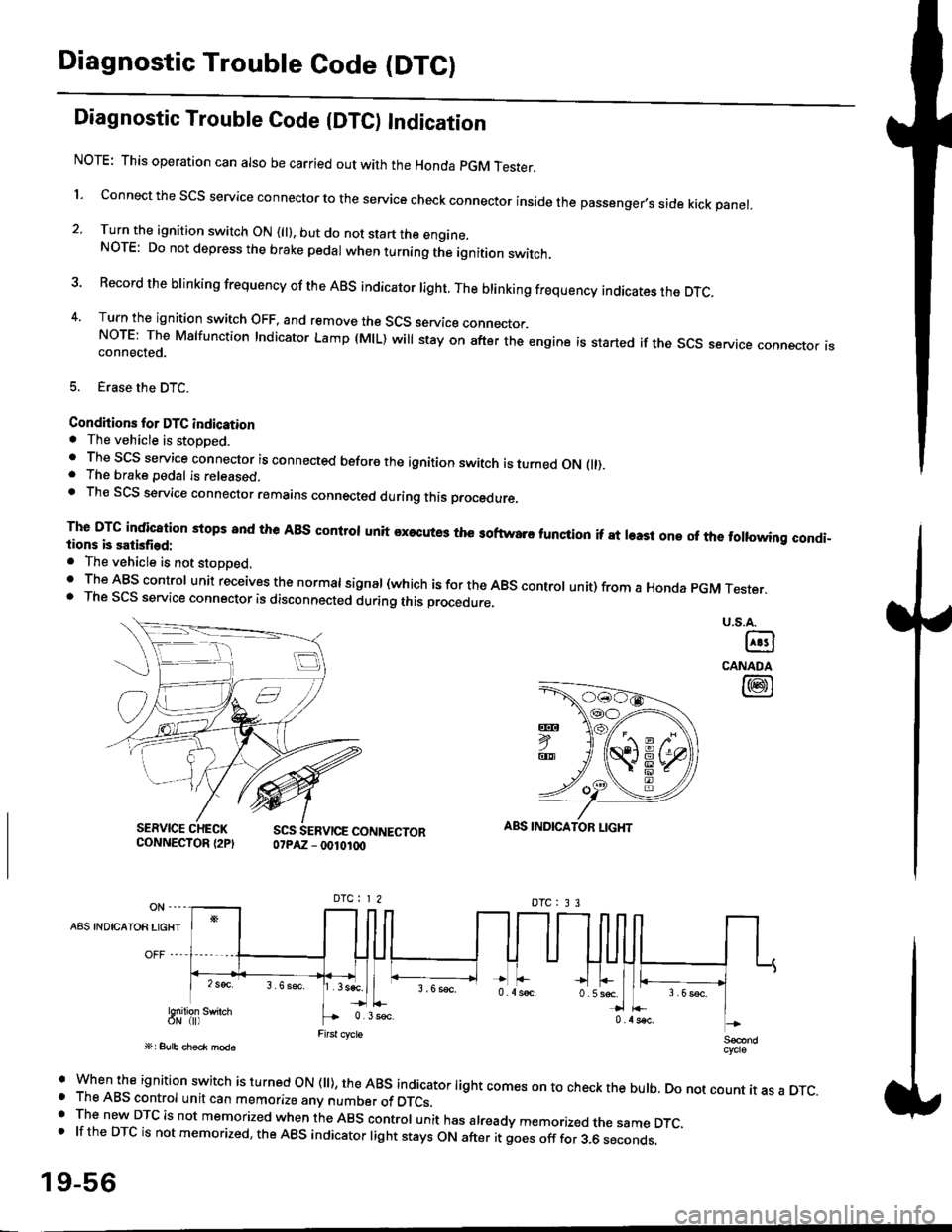

Diagnostic Trouble Code {DTC) Indication

NOTE: This operation can also be carried out with the Honda pGM Tesrer.

l connect the scs service connector to the service check connector inside the passenger,s side kick panel.

2. Turn the ignition switch ON (||). but do not start the engine.NOTE: Do not depress the brake pedal when turning the ignition switch.

3 Record the brinking frequency of the ABS indicator right. The brinking frequency indicates the DTc.

4, Turn the ignition switch OFF, and remove the SCS service connector.NorE: The Mslfunction Indicator Lamp (MlL) will stay on after the engine is started if the scs service connector isconnected.

5. Erase the DTC.

Condhions for DTC indication. The vehicle is stoDDed.. The SCS service connector is connected before the ignition switch is turned ON fll).. The brake pedal is released.. Th€ SCS service connector remains connected during this procedure

The DTG indication stops 8nd the ABs conltol unit executes the softwaro tunqtion if at least one of the following condi-tions b satisfied:

o The vehicle is not stoDoed.' The ABS control unit receives the normat signal (which is for the ABS controt unit) from a Honda pGM Tester.. The SCS service connector is disconnected during this procedu.e,

u.s.A.

@

CANADA

@

SERVICE CHECKCONNECTOR {2PISCS SERVICE CONNECTOR07PAZ - 0010100

ABS INDICATOR LIGHT

DTC : 3 3

A8S INDICAIOR LIGHT

Snilion swirch

' when the ignition switch is turned oN (ll), the ABs indicator light comes on to check the bulb. Do not count it as a DTc.o The ABS control unit can memorize any number of DTCs.. The new DTC is not memorized when the ABS control unit has already memorized the same DTC,.lftheDTCisnotmemorized,theABSindicatorlightstaysONafteritgoesofffor3.6seconds.

19-56

Page 1210 of 2189

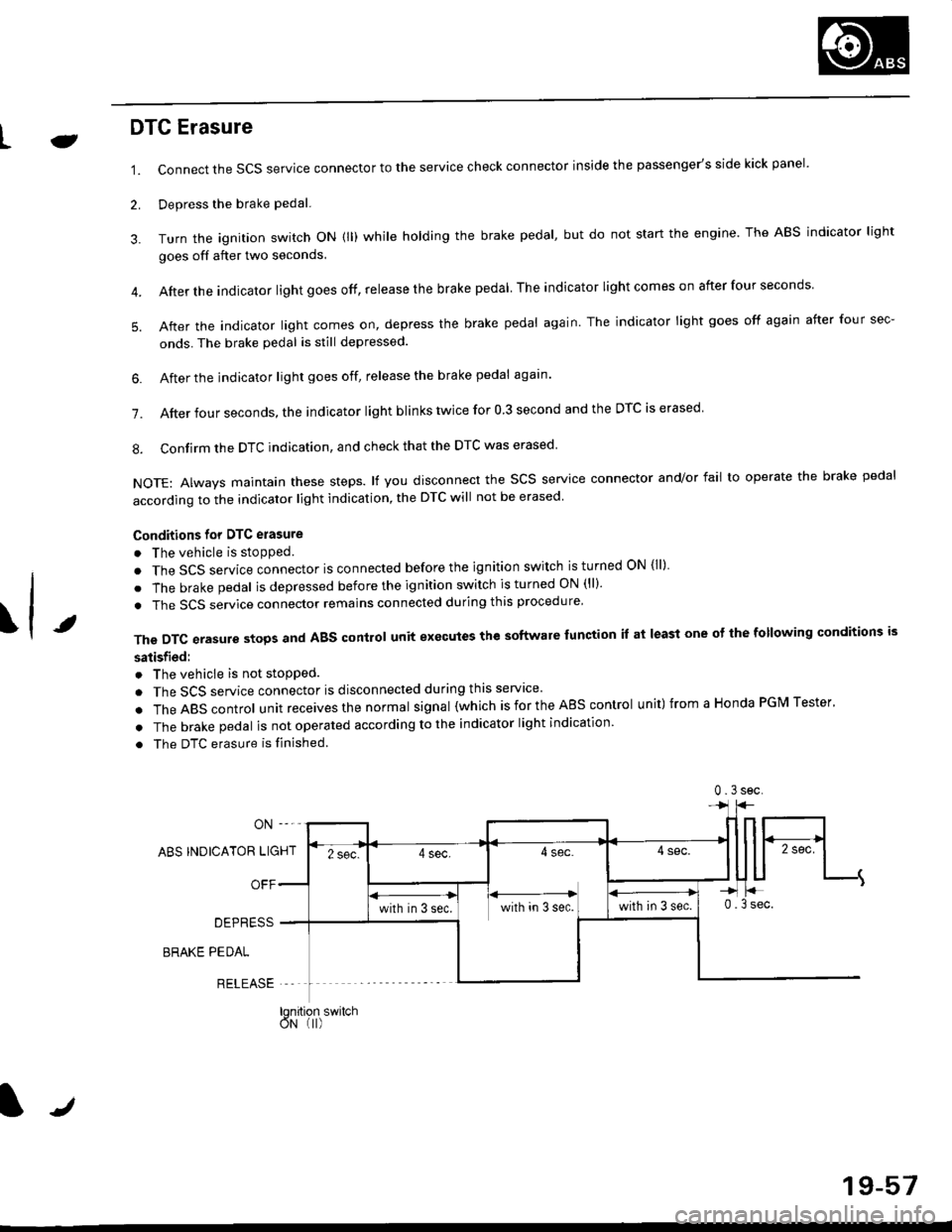

LJDTG Erasure

1.

2.

Connect the SCS service connector to the service check connector inside the passenger's side kick panel.

Depress the brake pedal.

Turn the ignition switch oN (ll) while holding the brake pedal, but do not start the engine. The ABS indicator light

goes off after two seconds.

After the indicator light goes off, release the brake pedal The indicator lightcomeson after four seconds

After the indicator light comes on, depress the brake pedal again. The indicator light goes off again after four sec-

onds. The brake pedal is still depressed.

4.

5.

\t

6. After the jndicator light goes off, release the brake pedal again'

7. After four seconds, the indicator light blinks twice for 0 3 second and the DTC is erased

8. Confirm the DTC indication, and check that the DTC was erased

NOTE: Always maintain these steps. lf you disconnect the scs service connector and/or fail to operate the brake pedal

according to the indicator light indication, the DTC will not be erased

Conditions for DTC erasure

o The vehicle is stopped.

. The SCS service connector is connected before the ignition switch is turned ON {ll)

. The brake pedal is depressed before the ignition switch is turned ON (ll)'

. The SCS service connector remains connected during this procedure

The DTC erasure stops and ABS control unit executes the software lunction it at least one ot the following conditions is

satisfied:

o The vehicle is not stopped.

. The SCS service connector is disconnected during this servace'

.TheABscontro|unitreceivesthenormaIsigna|(whichisfortheAEscontro|unit)fromaHondaPGMTester'

. The brake pedal is not operated according to the indicator light indication

. The DTC erasure is finished

ABS INDICATOR LIGHT

OFF

DEPRESS

BRAKE PEDAL

RELEASE

0.3sec

lqnition switchoN (I)

J

19-57

Page 1228 of 2189

\il

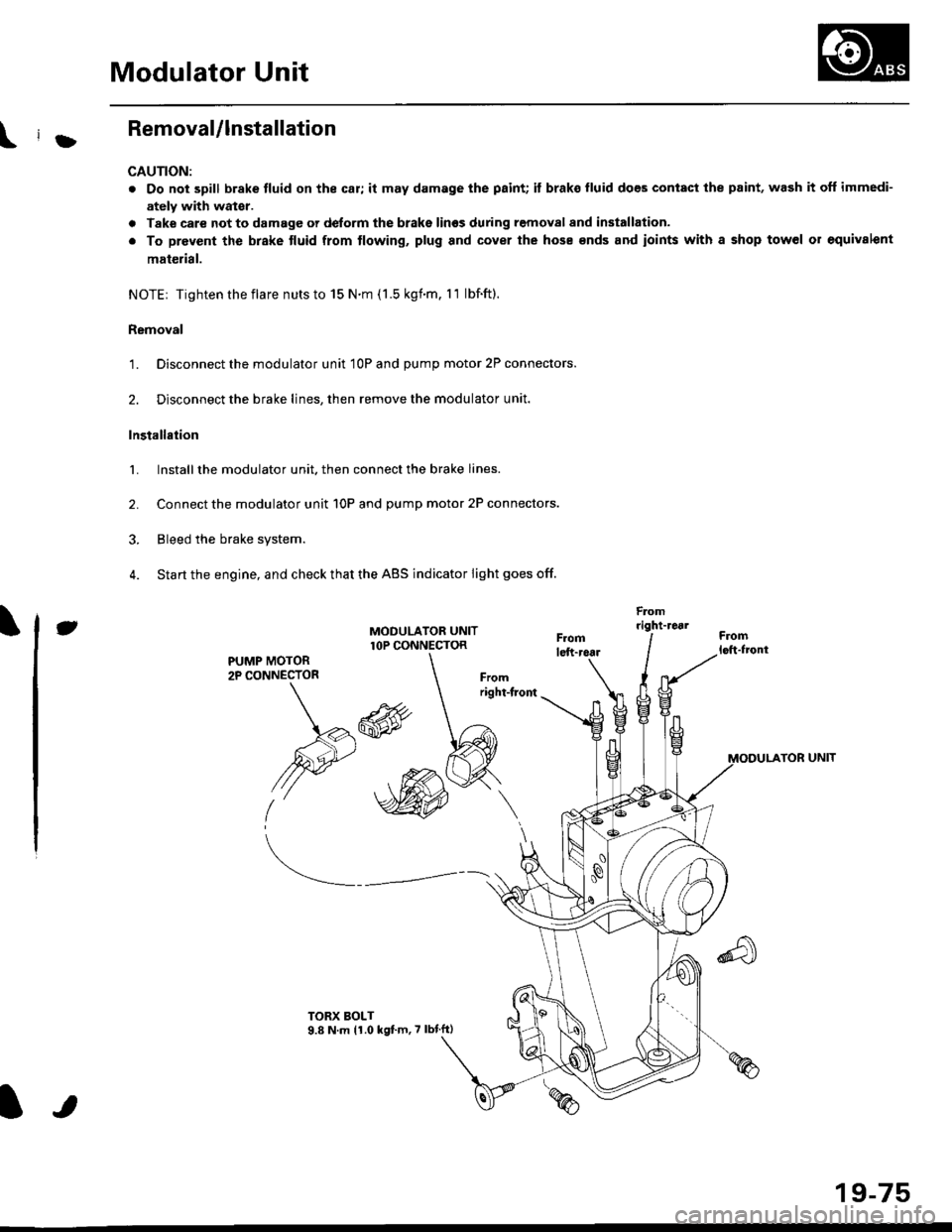

Modulator Unit

RemovaUlnstallation

CAUTION:

. Do not spill brake tluid on the car; it may damage the paint; it brako lluid does contact the paint, wash it off immedi-

ately with wator.

a Take care not to damage or delorm the brake lin€s during removal and installation.

. To prevent the brake tluid from tlowing, plug and cover the hose €nds and ioints with a shop tow6l or equivalent

mat€rial.

NOTE| Tightentheflare nutsto 15 N.m (1.5 kgnm. l1 lbf.ft).

Removal

'1. Disconnect the modulator unit 10P and Dump motor 2P connectors.

2. Disconnect the brake lines, then remove the modulator unit.

Installaiion

1. Install the modulator unit. then connect the brake lines.

2. Connect the modulator unit 10P and oumD motor 2P connectors.

3. Bleed the brake system.

4. Start the engine, and check that the ABS indicator light goes off.

Fomright-1461

PUMP MOTOR2P CONNECTOR

J

-R

/2e'

t'

TOR UNIT

tt

19-75

Page 1229 of 2189

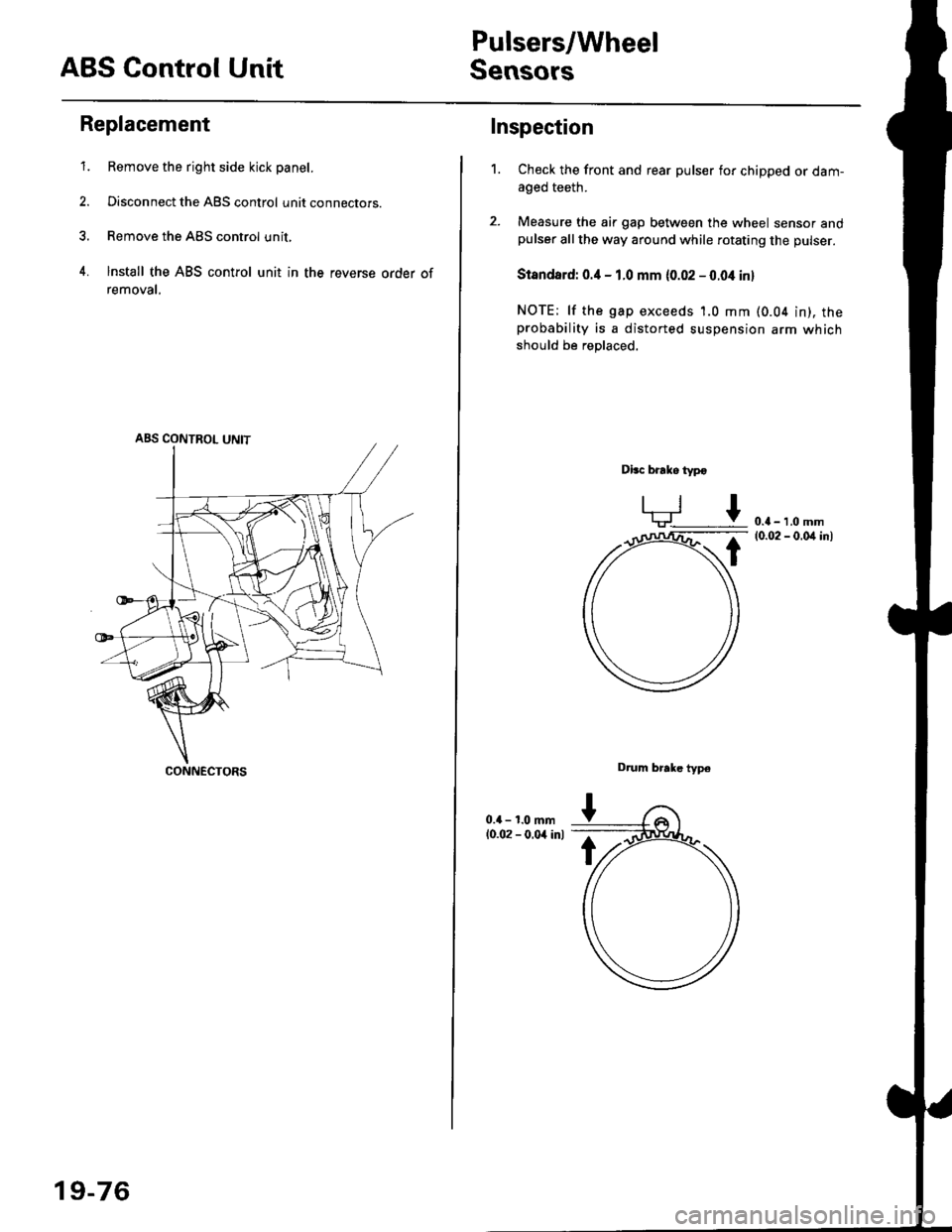

ABS Control Unit

Pulsers/Wheel

Sensors

Replacement

1. Remove the right side kick panel.

2. Disconnect the ABS control unit connecrors.

3. Remove the ABS control unit,

4. lnstall the ABS control unit in the reverse order of

removal,

CONNECTORS

19-76

Inspection

Check the front and rear pulser for chipped or dam-aged teeth.

Measure the air gap between the wheel sensor andpulser all the way around while rotating the pulser.

Slandard: 0.4 - 1.0 mm (0.02 - 0.04 in,

NOTE; lf the gap exceeds 1.0 mm (0.04 in), theprobability is a distorted suspension arm which

should be replaced.

Dbc brake typo

0.{ - 1.0 mm(0.02 - 0.04 in)

Drum brake typ6

1.

Page 1230 of 2189

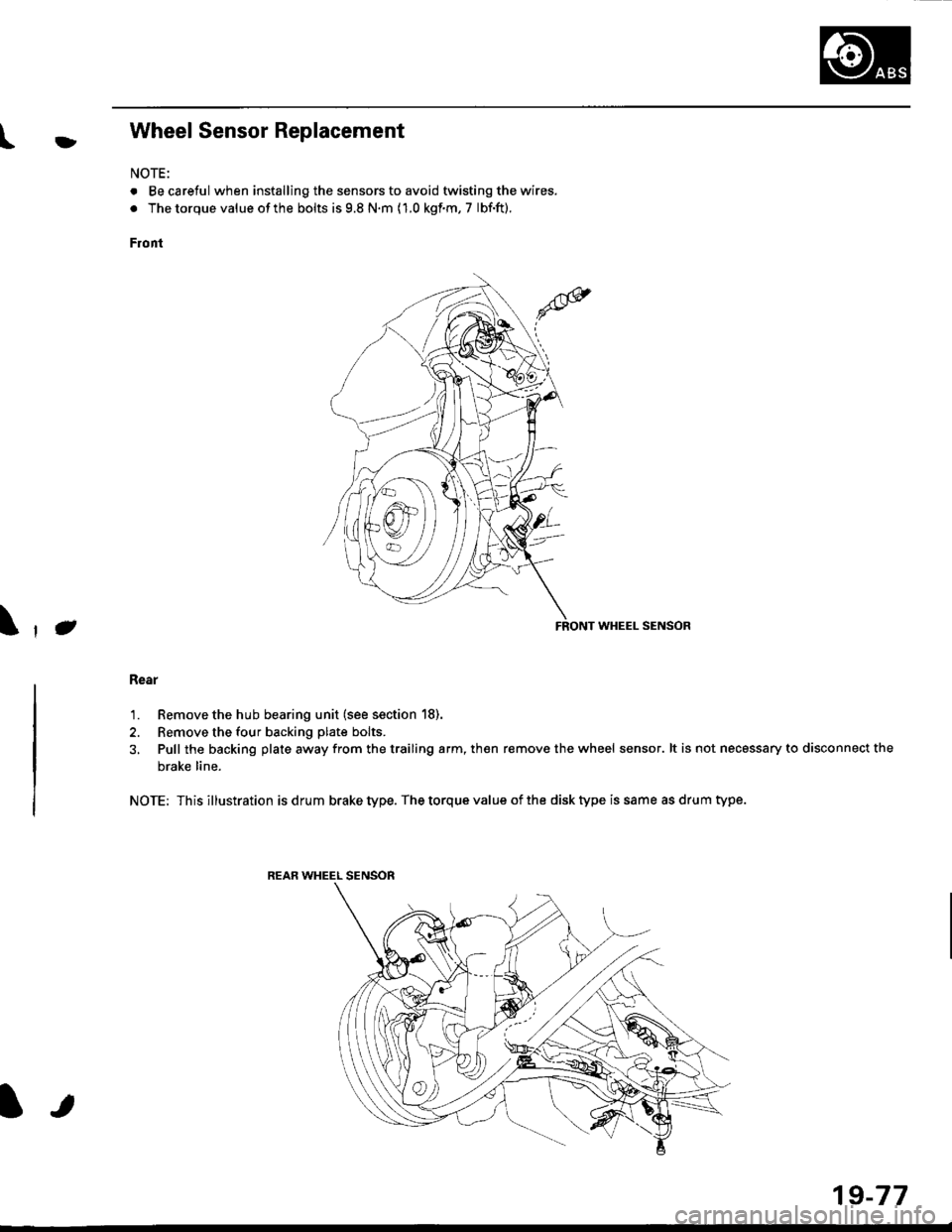

l}tWheel Sensor Replacement

NOTE:

. Becareful when installingthe sensors to avoid twisting the wires.

. The torque value of the bolts is 9.8 N.m (1.0 kgf.m, 7 lbf.ft).

Front

FRONT WHEEL SENSOR

Rear

1. Remove the hub bearing unit (see section 18).

2. Remove the four backing plate bolts.

3, Pull the backing plate away from the trailing arm, then remove the wheel sensor. lt is not necessary to disconnect the

brake line.

NOTE: This illustration is drum brake type. The torque value of the disk type is same as drum type.

REAR WHEEL SENSOR

J\

It

19-77

Page 1289 of 2189

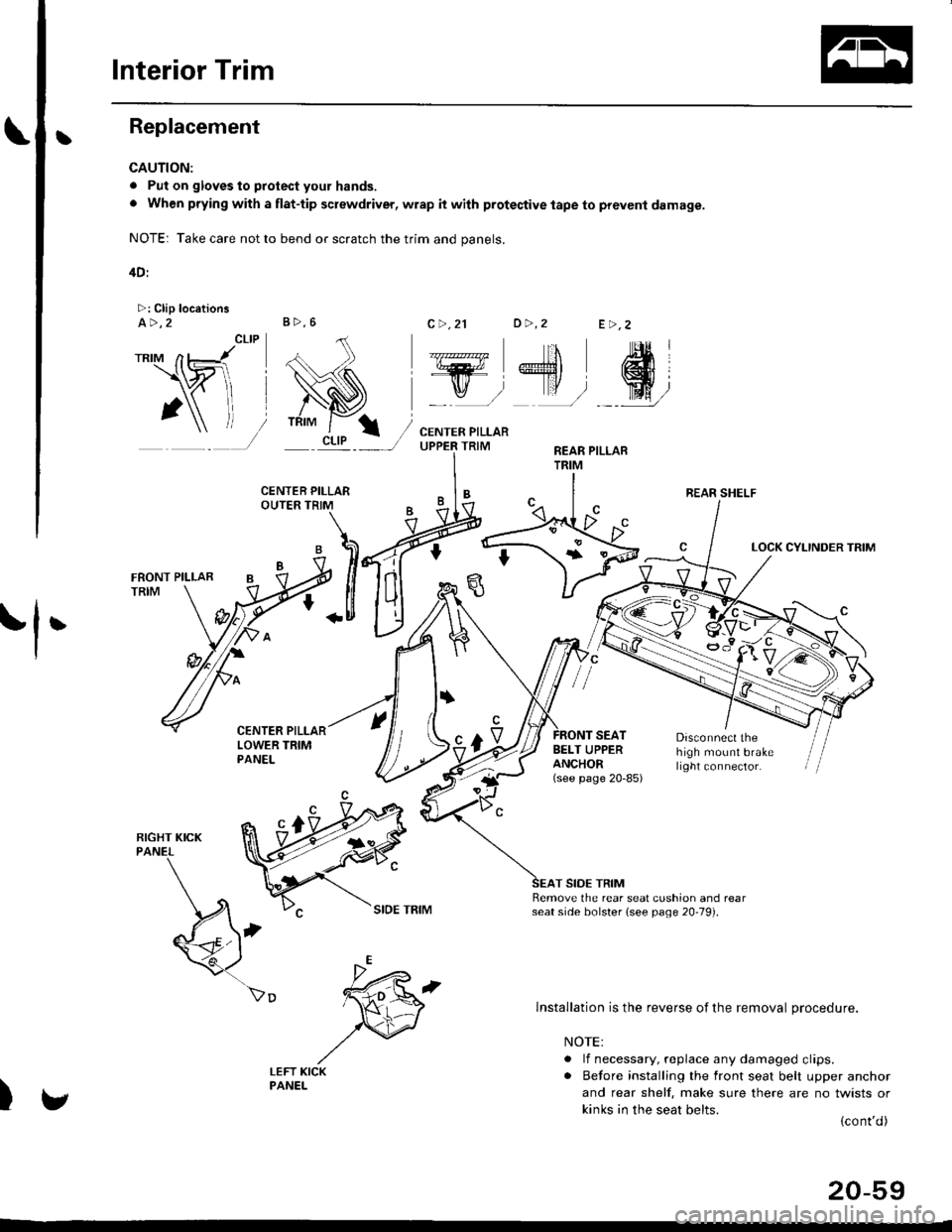

Interior Trim

tReplacement

CAUTION:

. Put on gloves to protect your hands.

o When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage.

NOTE: Take care not to bend or scratch the trim and panels.

4D:

>: Clip locationsa>,2c >,2'lo >,2E >,2

r*'" n t-lt't

\wi, i

' l ll/

_tr* @,

CENTER PILLARUPPER TRIMREAR PILLARTRIM

LOCK CYLINDER TRIM

tl'

I

E'vBELT UPPERANCHOR(see page 20-85)

Disconnect thehigh mount brakelrght connector.

T SIDE TRIMRemove the rear seat cushion and rearseat side bolster lsee page 20-19]'.

)

lnstallation is the reverse of the removal procedure.

NOTE:

. lf necessary, replace any damaged clips.. Before installing the front seat belt upper anchor

and rear shelf. make sure there are no twists or

kinks in the seat belts.(cont'd)

B>,6

REAR SHELF

k"si

fEFT KICKPANEL

20-59

Page 1291 of 2189

Il

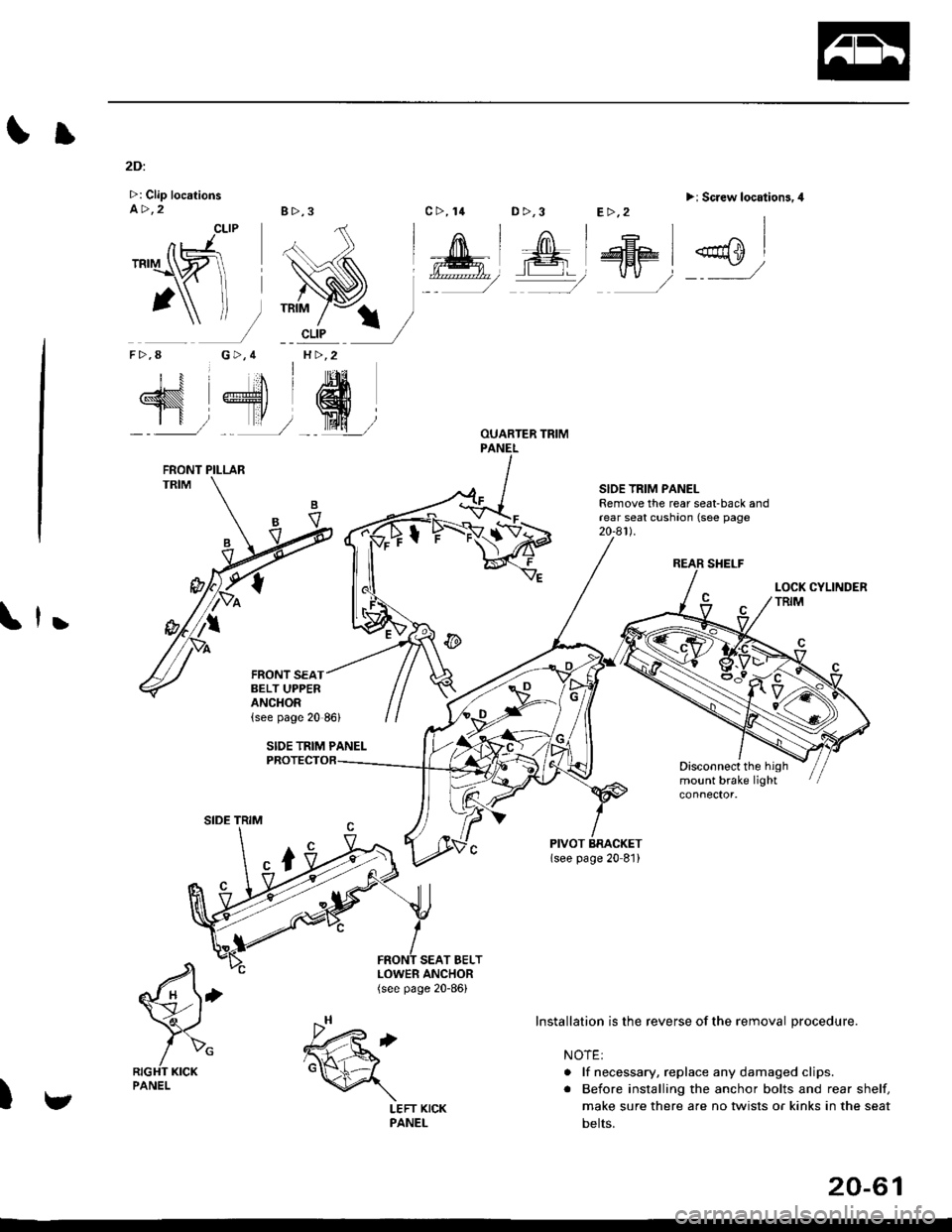

2Di

>: Clip locationsa>,28>,3

CLIP

G>,4H >,2

D >,3>i Screw location3.4

REAR SHELF

SIOE TRIM PANELRemove the rear seat-back andrear seat cushaon (see page20-a1l.

,

Disconnect the highmount brake light

SEAT BELT

€'

/>"RIGHT KICKPANEL

)

TRIM

nJ'.'rI\ZI

1\f-

F>,8

N 4'dr

SIDE TRIM

LOWER ANCHOR(see page 20-86)

c>, 14E>,2

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary, replace any damaged clips.

. Before installing the anchor bolts and rear shelf,

make sure there are no twists or kinks in the seat

belts.

FRONT PILLAR

FRONT SEATBELT UPPERANCHOR

v

.h,'t6d

\

LEFT KICKPANEL

20-61

Page 1296 of 2189

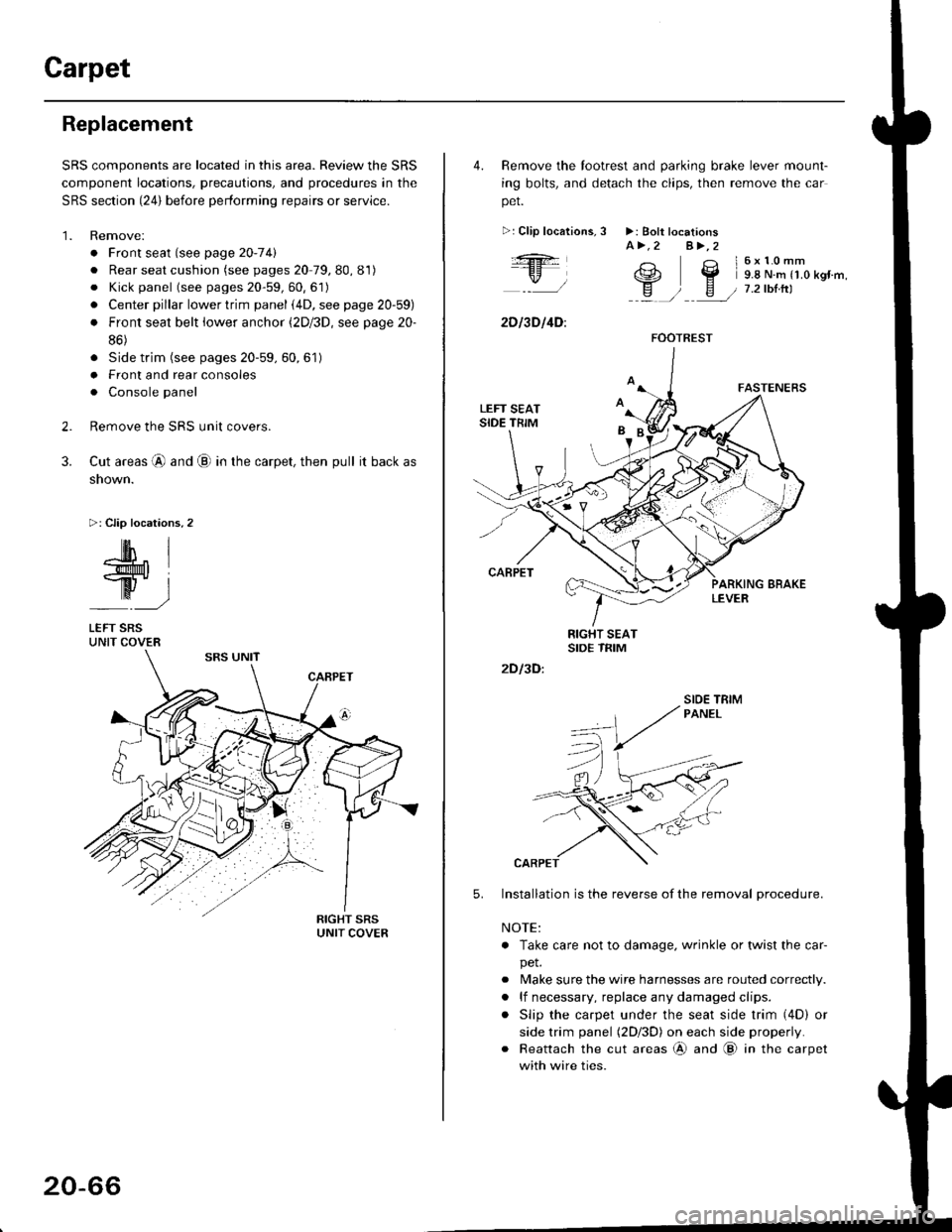

Carpet

Replacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24} before performing repairs or service.

1. Remove:

. Front seat (see page 2O-7 4l

. Rear seat cushion (see pages 20 79, 80, 81)

o Kick panel (see pages 20-59, 60, 61)

o Center pillar lowertrim panel i4D, see page 20-59)

. Front seat belt iower anchor (2Dl3D, see page 20-

86)

. Side trim (see pages 20-59, 60,61)

o Front and rear consoles

. Console panel

Remove the SRS unit covers.

Cut areas @ and @ in the carpet, then pull it back as

snown.

>: Clip locations,2

2.

3.

-lM- IlMt l

ry-l

LEFT SRSUNIT COVER

20-66

4. Remove the tootrest and parking brake lever mount-

ing bolts, and detach the clips, then remove the car

pet.

>:Clip localions,

:ft

\/l

2D l3D l4D:

3 >: Bolt locationsA>.2 A>,2

3 l6x10mm

e2 Y 9.8 N.m r1.o kgr'm,

H ) E / 7.2tbtrtl::a /

5.

2D I3D:

Installation is the reverse of the removal procedure.

NOTE:

. Take care not to damage. wrinkle or twist the car-

pet.

. Make sure the wire harnesses are routed correctly.

. lf necessary, replace any damaged clips.

. Slip the carpet under the seat side trim (4D) or

side trim panel (2Dl3D) on each side properly.

. Reattach the cut areas @ and @ in the carpet

with wire ties.

FOOTREST

SIOE TBIM