Head bolts HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 185 of 2189

Camshafts

Inspection

NOTE:

. Do not rotate the camshaft during inspection.

. Removg the rocker arms and rocker shafts.

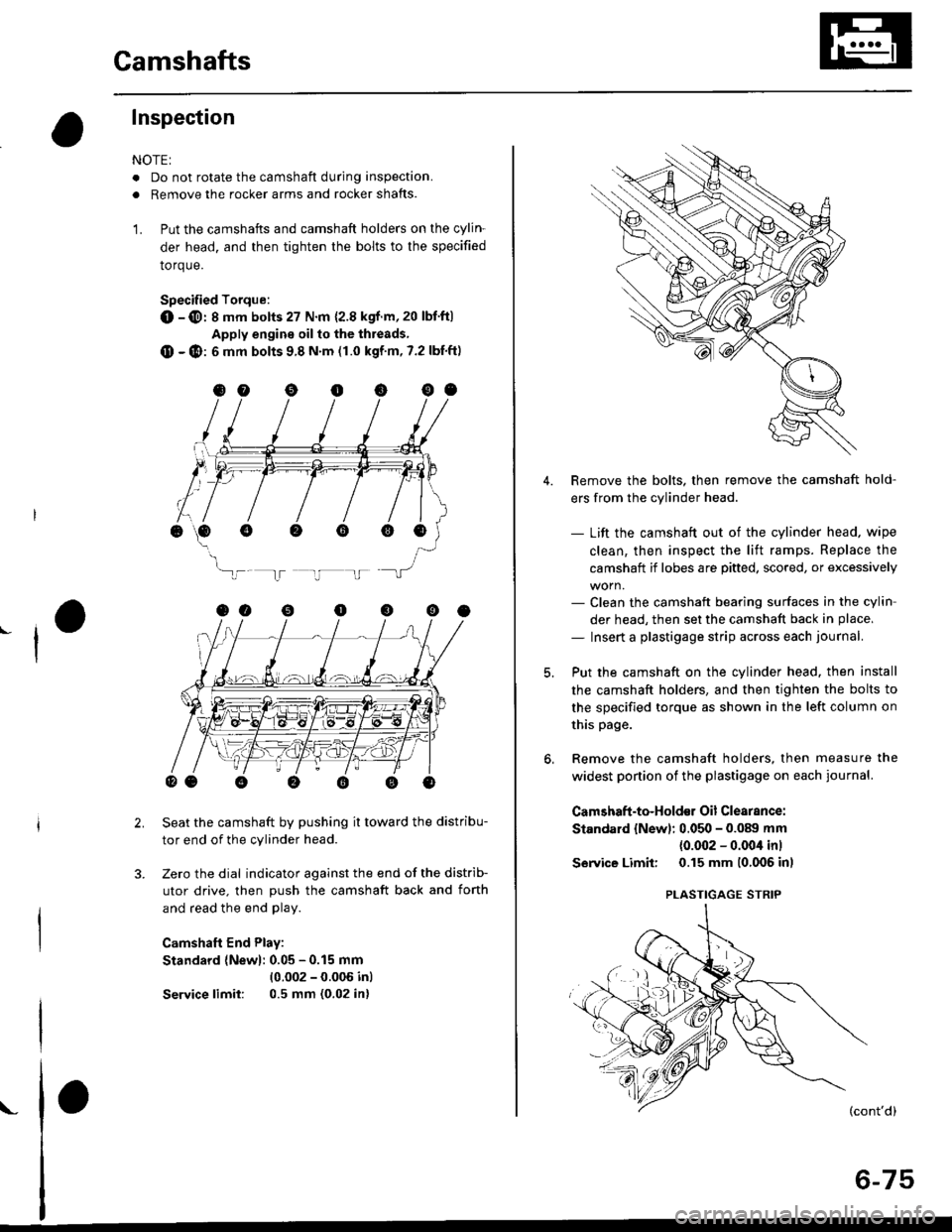

'L Put the camshafts and camshaft holders on the cylin-

der head. and then tighten the bolts to the specified

torque.

Specified Torque:

O -@: 8 mm botts 27 N.m {2.8 kgf.m,20 lbt'ft)

Apply engine oil to the threads,

O - @: 6 mm bolts 9.8 N.m (1.0 kgf m, 7.2 lbf'ft)

Seat the camshaft by pushing it toward the distribu-

tor end of the cylinder head.

Zero the dial indicator against the end of the distrib-

utor drive. then push the camshaft back and fonh

and read the end play.

Camshaft End Play:

Standard {New}: 0.05 - 0.15 mm

{0.002 - 0.006 inl

Service limil: 0.5 mm (0.02 in)

ooooooo

ooooo

\-

4.Remove the bolts. then remove the camshaft hold-

ers from the cylinder head.

- Lift the camshaft out of the cylinder head, wipe

clean, then inspect the lift ramps. Replace the

camshaft if lobes are pitted, scored, or excessively

- Clean the camshaft bearing surfaces in the cylin

der head, then set the camshaft back in place,

- Insert a plastigage strip across each iournal.

Put the camshaft on the cylinder head. then install

the camshaft holders, and then tighten the bolts to

the specified torque as shown in the left column on

this page.

Remove the camshaft holders, then measure the

widest portion of the plastigage on each journal.

Camshaft -to-Hold€1 Oil Clearsnce:

Standard {Newl: 0.050 - 0.089 mm

{0.002 - 0.004 inl

S6rvice Limit: 0.15 mm 10,006 inl

(cont'd)

6-75

PLASTIGAGE STRIP

Page 194 of 2189

I

Cylinder Head

Installation

lnstall the cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.. The cylinder head gasket is a metal gasket, Take carenot to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC (seepage 6-63).

. Do not use the middle cover and lower cover forstorang removed items.. Clean the middle cover and lower cover before instal_lation.

o Replace any washers that are damaged or deteriorated.

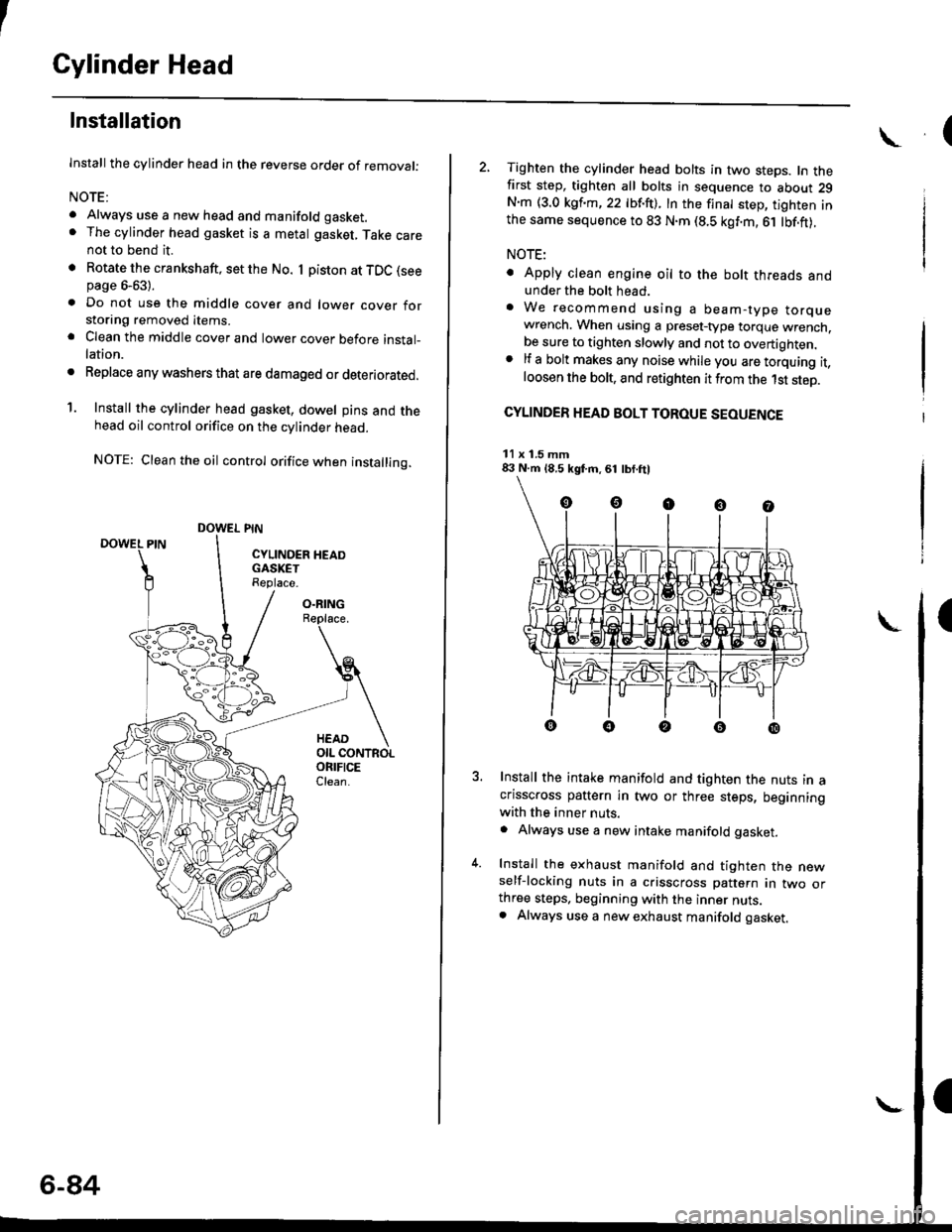

1. Install the cylinder head gasket, dowel pins and thehead oil control orifice on the cylinder head.

NOTE: Clean the oil control orifice when installing.

DOWEL PIN

6-84

2, Tighten the cylinder head bolts in two steps. In thefirst step, tighten all bolts in sequence to about 29N.m (3.0 kgf.m, 22 tbf.ftl. ln the final step, tighten inthe same sequence to 83 N.m (8.S kgf.m,6t lbf.ft).

NOTE:

. Apply clean engine oil to the bolt threads andunder the bolt head.. We recommend using a beam-type torquewrench. When using a preset-type torque wrench,be sure to tighten slowly and not to overtighten.. lf a bolt makes any noise while you are torquing it,loosen the bolt, and retighten it from the 1st step.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11x 1.5 mm83 N.m 18.5 kgf.m, 61 tbf.ftl

Install the intake manifold and tighten the nuts in acflsscross pattern in two or three steps, beginningwith the inner nuts.. Always use a new intake manifold gasket.

Install the exhaust manifold and tighten the newself-locking nuts in a crisscross pattern in two orthree steps. beginning with the inner nuts.. Always use a new exhaust manifold gasket.

4.

Page 587 of 2189

12.

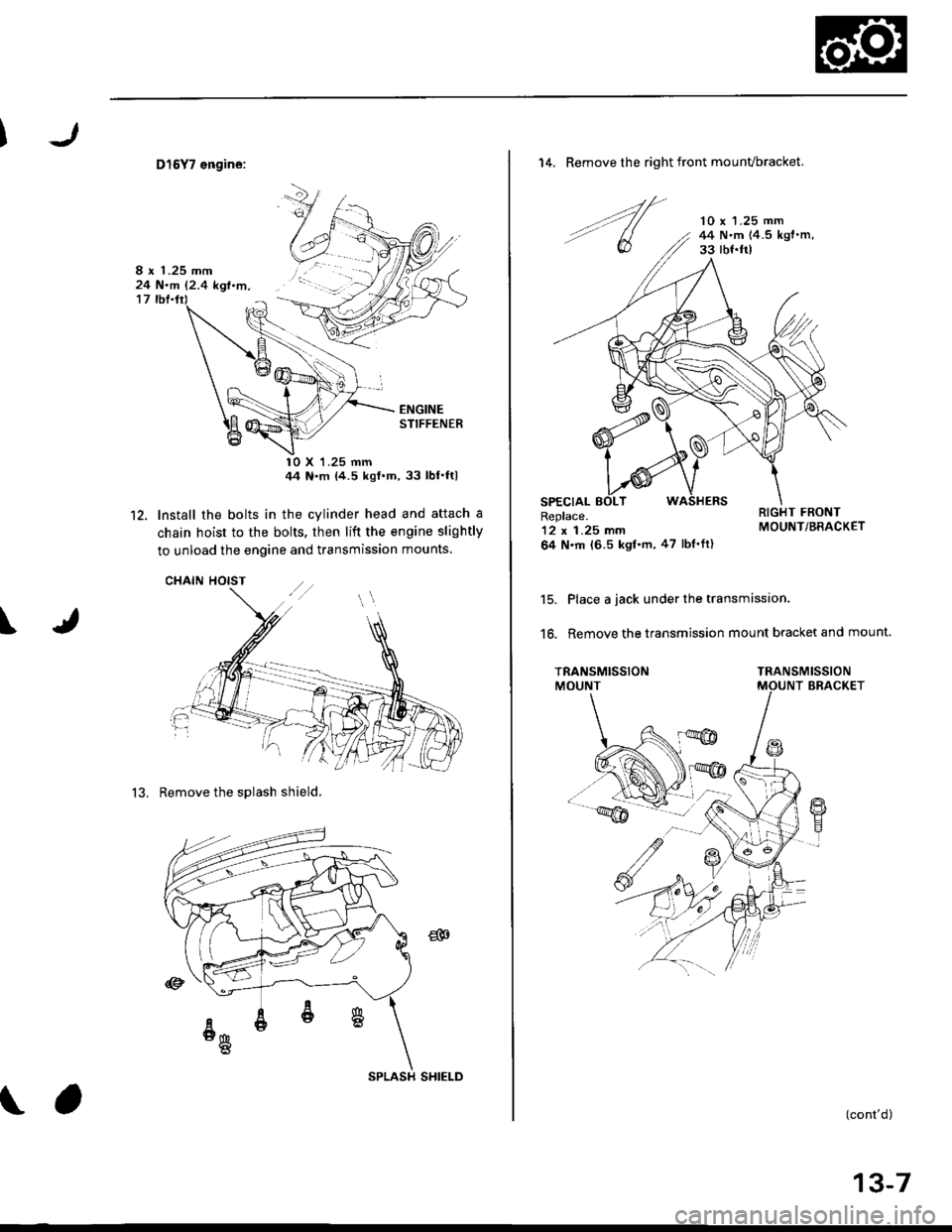

D16Y7 engine:

ENGINESTIFFENER

10 X 1.25 mmIt4 N'm (4.5 kqf'm,33 lbf'ltl

Install the bolts in the cylinder head and attach a

chain hoist to the bolts, then lift the engine slightly

to unload the engine and transmission mounts.

CHAIN HOIST

13. Remove the sDlash shield,

\

8 x 1.25 mm24 N.m {2.4 kgl.m,

SPLASH SHIELD

14. Remove the right front mounvbracket.

'lO x 'l.25 mm44 N'm (4.5 kgl.m,33 rbf.frl

Replace.12 x 1.25 mm

64 N.m t6.5 kgf.m,47 lbf'ft)

Place a jack under the transmission.

Remove the transmission mount bracket and mount.16.

TRANSMISSIONMOUNTTRANSMISSIONBRACKET

(cont'd)

13-7

Page 857 of 2189

17.

18.

19.

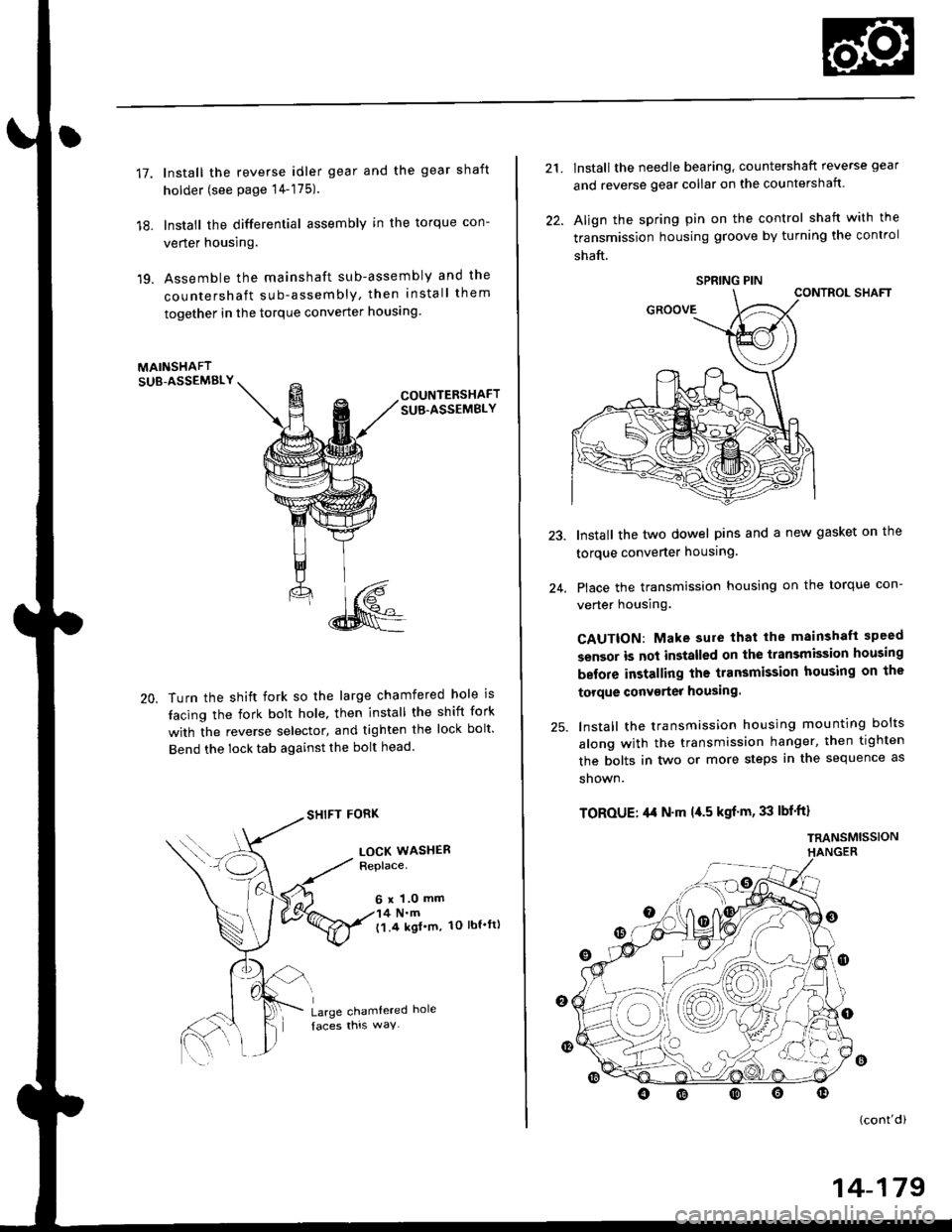

lnstall the reverse idler gear and the gear shaft

holder (see page 14-175).

lnstall the differential assembly in the torque con-

verter housing.

Assemble the mainshaft sub-assembly and the

countershaft sub-assembly, then install them

together in the torque converter houslng

MAINSHAFTSUB-ASSEMBLY

20,

COUNTERSHAFTSUB.ASSEMBLY

Turn the shift fork so the large chamfered hole is

tacing the fork bolt hole, then install the shift fork

with the reverse selector, and tighten the lock bolt'

Bend the lock tab against the bolt head

SHIFT FORK

LOCK WASHERReplace.

6 x 1.0 mm4 N.m('l.4 kgl'm, 1O lbt'ft)

Large chamtered hole

21.

22.

lnstall the needle bearing, countershaft reverse gear

and reverse gear collar on the countershaft.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

CONTROL SHAFT

Install the two dowel pins and a new gasket on the

torque converter housing.

Place the transmission housing on the torque con-

verter housing.

CAUTION: Make sure that lhe mainshaft speed

sensor is not installed on the transmission housing

before installing the transmission housing on the

torque conv€rter housing.

lnstall the transmission housing mounting bolts

along with the transmission hanger, then tighten

the bolts in two or more steps in the sequence as

shown.

TOROUE: ,l,t N'm l{.5 kgf'm, 33 lbf'ft}

TRANSMISSIONHANGER

24.

o

(cont'di

SPRING PIN

14-179

Page 1060 of 2189

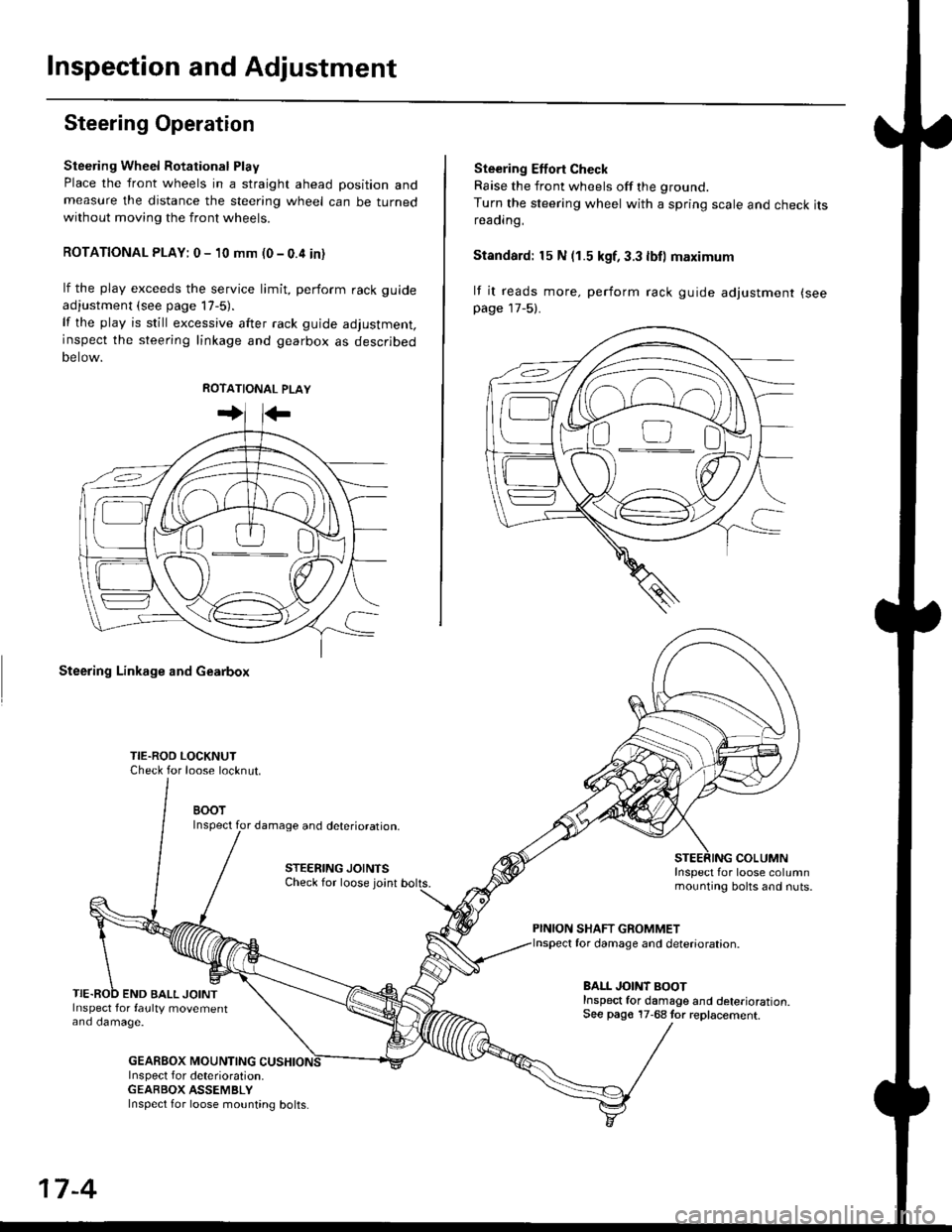

Inspection and Adjustment

Steering Operation

Steering Wheel Rotational Play

Place the front wheels in a straight ahead position andmeasure the distance the steering wheel can be turnedwithout moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.4 in)

lf the play exceeds the service limit, perform rack guide

adjustment (see page lT-5).

lf the play is still excessive after rack guide adjustment,inspect the steering linkage and gearbox as descrjbed

Detow.

Steering Linkage and Gearbox

TIE.ROO LOCKNUTCheck for loose locknut.

BOOTInspect for damage and deterioration.

STEERING JOINTSCheck for loose joint

END BALL JOINTInspect for faulty movementano oamage.

GEABBOX MOUNTINGInspect f or deterioration.GEABBOX ASSEMBLY

Ste€ring Effort Check

Raise the front wheels off the ground.

Turn the steering wheel with a spring scale and check itsreaorng,

Standard: 15 N (1.5 kgf, 3.3 lbll maximum

lf it reads more. perform rack guide adjustment (see

page 17-5).

COLUMNInspect for loose columnmounting bolts and nuts.

PINION SHAFT GROMMETfor damage and deterioration.

BALL JOINT BOOTInspect for damage and deterioration.See pago 17-68 tor replacement.

ao-\---------U

17-4

Inspect for loose mounting bolts.

Page 1069 of 2189

)

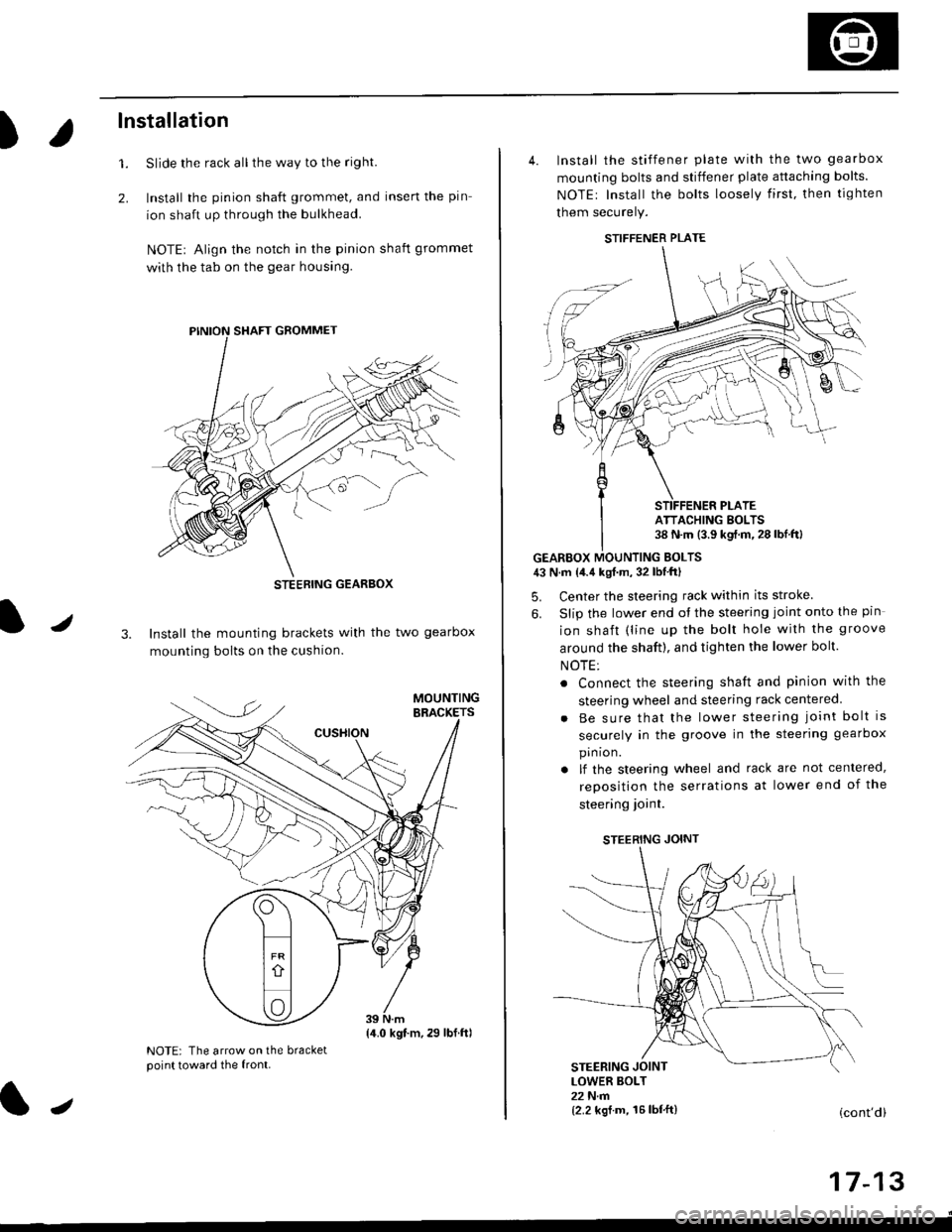

lnstallation

Slide the rack all the way to the righl

Install the pinion shaft grommet, and insert the pin

ion shaft up through the bulkhead.

NOTE| Align the notch in the pinion shaft grommet

with the tab on the gear housing.

1.

2.

J3. Install the mounting brackets with the two gearbox

mounting bolts on the cushion.

NOTE: The arrow on the bracketpoint toward the front.

STEEBING GEARBOX

{4.0 kgt.m,29 lbf.ftl

J

4. Install the stiffener plate with the two gearbox

mounting bolts and stiffener plate attaching bolts.

NOTEr Install the bolts loosely first. then tighten

them securely.

GEARBOX MOUNTING EOLTS43 N.m {4.4 kgf.m, 32 lbf'ftl

5. Center the steering rack within its stroke

6. Slip the lower end ot the steering joint onto the pin

ion shaft (line up the bolt hole with the groove

around the shaft), and tighten the lower bolt.

NOTE:

. Connect the steering shaft and pinion with the

steering wheel and steering rack centered

Be sure that the lower steering joint bolt is

securely in the groove in the steering gearbox

pin ion.

lf the steering wheel and rack are not centered,

reposition the serrations at lower end of the

steering ioint.

STEERING JOINT

STEERING JOINTLOWER BOLT22 N.m{2.2 kgf.m, 16lbf'ft}(cont'd)

I t- t5

STIFFENER PLATE

ATTACHING BOLTS38 N.m (3.9 kgf.m.28lbf.ftl

Page 1104 of 2189

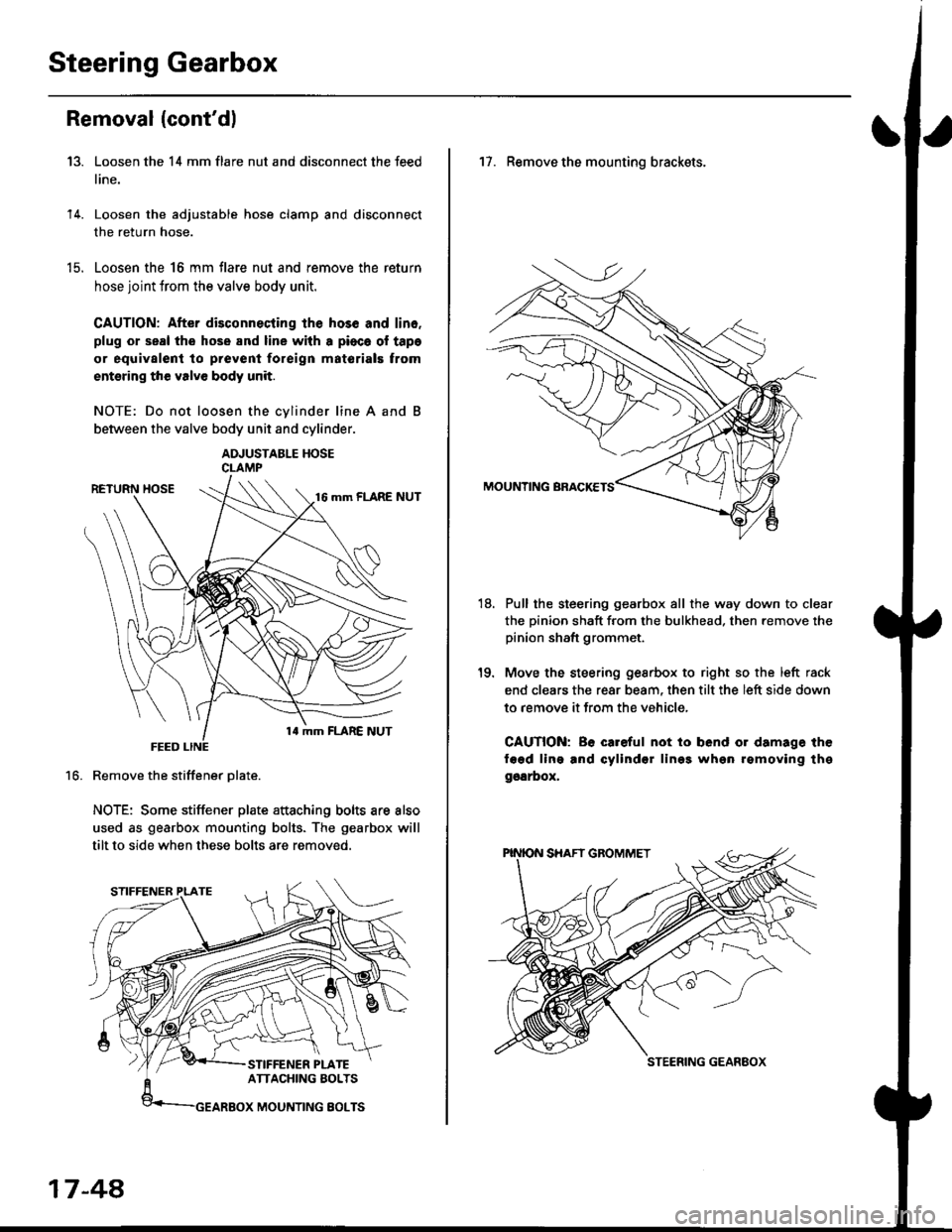

Steering Gearbox

Removal {cont'dl

Loosen the 14 mm flare nut and disconnect the feed

line.

Loosen the adjustable hose clamp and disconnect

the return hose.

Loosen the 16 mm flare nut and remove the return

hose joint trom the valve body unit.

CAUTION: After disconnecting lhe hos6 and lin6.

plug or seal the hose and line with a pioca ol tapa

or equivalent to prevenl foreign matorials trom

entsring the valve body unit.

NOTE: Do not loosen the cvlinder line A and

between the valve body unit and cylinder.

ADJUSTABLE HOSECLAMP

Remove the stiffener Dlate.

NOTE: Some stiffener plate attaching bolts are also

used as gearbox mounting bolts. The gearbox will

tilt to side when these bolts are removed.

13.

14.

t9.

16.

17-48,

17. Remove the mounting brackets.

Pull the steering gearbox all the way down to clear

the pinion shaft from the bulkhead. then remove the

pinion shaft grommet.

Move the steering gesrbox to right so the left rack

end clears the rear beam, then tilt the left side down

to remove it from the vehicle,

CAUTION: Be careful not io bend or damage the

fagd ling and cylindsr lin99 whgn rgmoving thg

ggarbox,

18.

STEERING GEANEOX

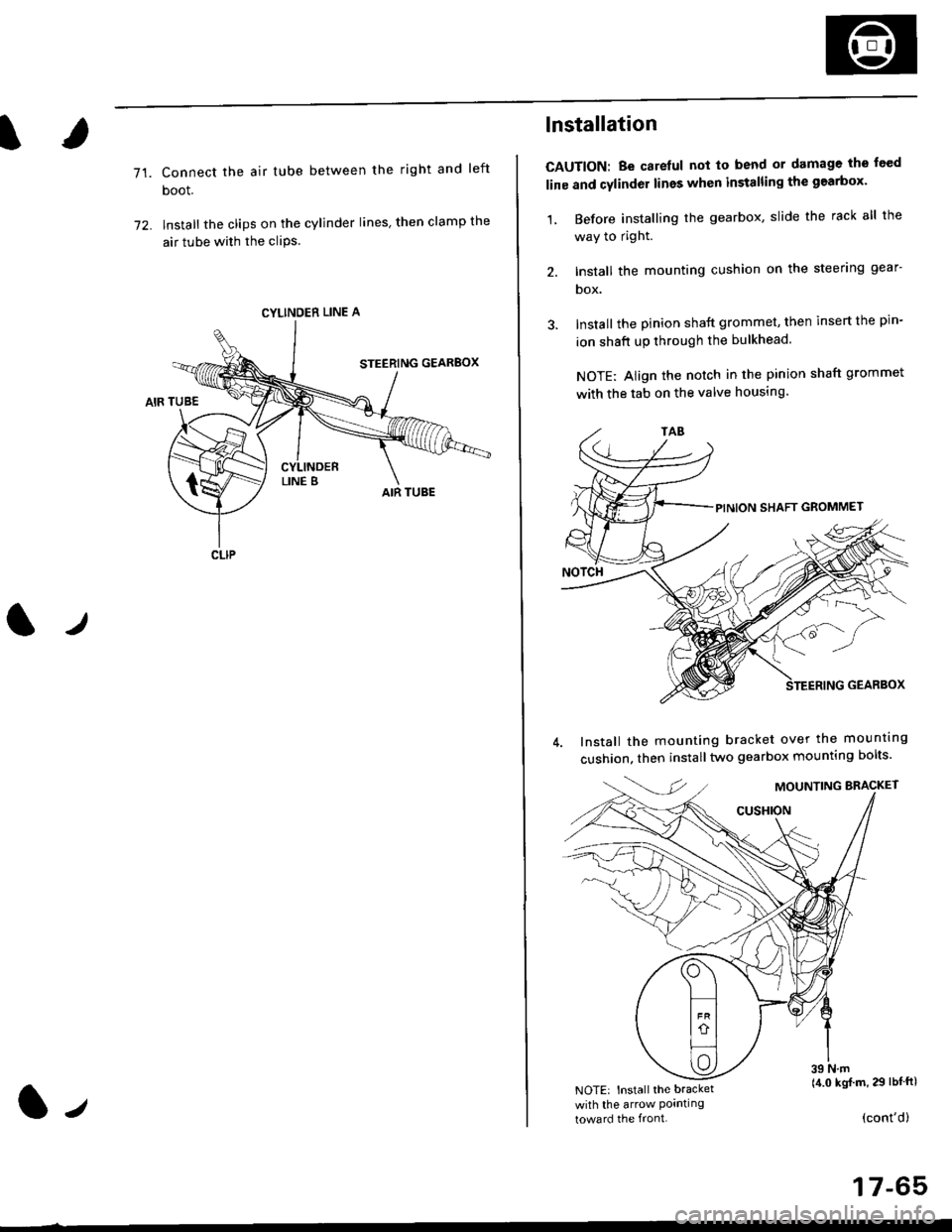

Page 1121 of 2189

71.Connect the air tube between the right and left

boot.

lnstall the clips on the cylinder lines' then clamp the

air tube with the cliPs.

l./

CYLINDER LINE A

CLIP

l-,

lnstallation

CAUTION: Be carelul not to bend or damage the feed

line and cylinder lines when installing the gearbox'

1, Before installing the gearbox, slide the rack all the

way to right.

2. Install the mounting cushion on the steering gear-

DOX.

Install the pinion shaft grommet, then insert the pin-

ion shaft up through the bulkhead.

NOTE: Align the notch in the pinion shaft grommet

with the tab on the valve housing.

Install the mounting bracket over the mounttng

cushion, then installtwo gearbox mounting bolts'

MOUNTING BRACKET

cusHroN

39 N.m(4.0 kgj m, 29 lbtftlNOTE: Install the bracket

with the arrow Pornllngtoward the front.(cont'd)

17-65

Page 1129 of 2189

?

Front Toe Inspection/Adiustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the tire pressure.

Center steering wheel spokes.

Check the toe with the wheels pointed straight

a head.

Front toe: lN 1 1 2 mm llN l/16 r 1/16 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equrpmenr.

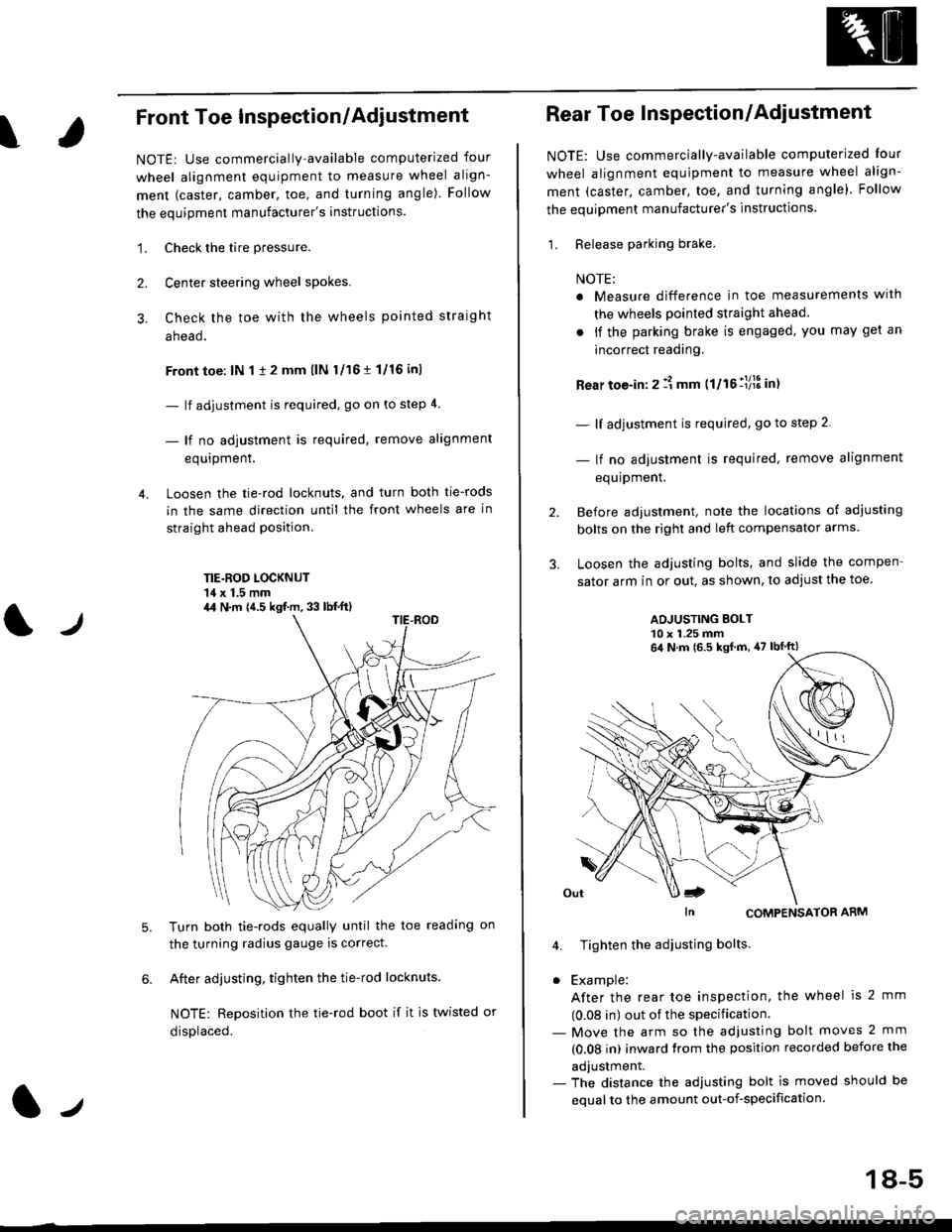

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are in

straight ahead position.

TIE.ROD LOCKNUT'14 x 1.5 mm

4.

tJ

6.

Turn both tie-rods equally until the toe readang on

the turning radius gauge is correct.

After adjusting, tighten the tie-rod locknuts.

NOTE: Reposition the tie-rod boot if it is twisted or

displaced.

4,1 N.m {4.5 kgf.m, 33 lb{.ft)

2.

Rear Toe Inspection/Adiustment

NOTE: Use commercially-available computerjzed Iour

wheel alignment equjpment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Release parking brake.

NOTE:

a Measure difference in toe measurements wlth

the wheels pointed straight ahead.

. if the parking brake is engaged, you may get an

incorrect readang,

Rear toe-in: 2 11 mm ttltollllS int

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adiusting

bolts on the right and left compensator arms

Loosen the adjusting bolts, and slide the compen

sator arm in or out. as shown, to adjust the toe

ADJUSTING BOLT10 x 1.25 mm

In CoMPENSAToR ARM

4. Tighten the adiusting bolts

. Example:

After the rear toe inspection, the wheel is 2 mm

(0.08 in) out of the specification.- Move the arm so the adjusfing bolt moves 2 mm

(0.08 in) inward trom the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

64 N.m 16.5 ksf m, 47 lbtft)

18-5

Page 1284 of 2189

Moonroof

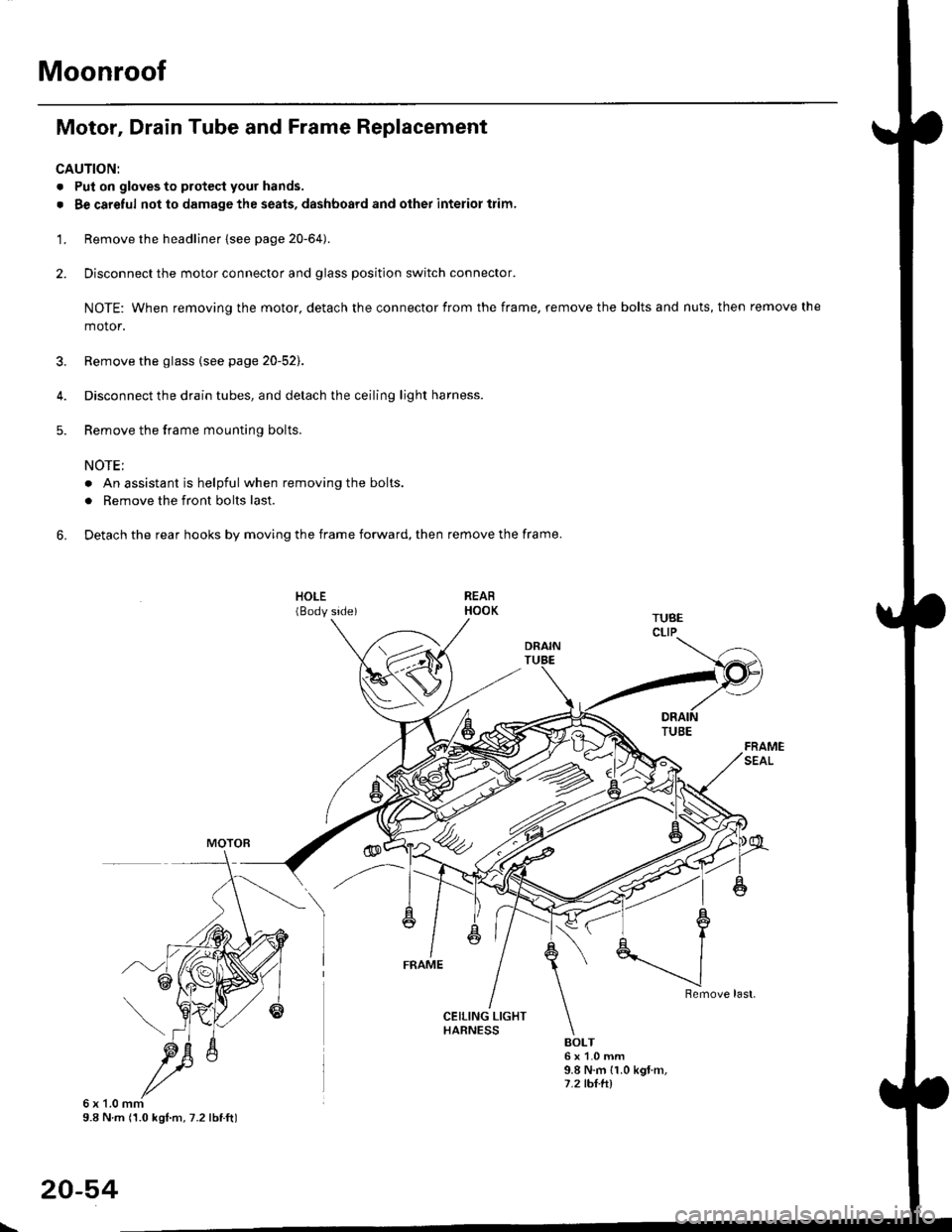

Motor, Drain Tube and Frame Replacement

CAUTION:

. Put on gloves to protecl your hands.

. Be careful not to damage the seats, dashboard and other interior trim.

'1. Remove the headliner {see page 20-64).

2. Disconnect the motor connector and glass position switch connector.

NOTE: When removing the motor, detach the connector from the frame, remove the bolts and nuts, then remove the

motor.

3. Remove the glass {see page 20-52).

4. Disconnect the drain tubes, and detach the ceiling light harness.

5. Remove the frame mounting bolts.

NOTE;

. An assistant is helpful when removing the bolts.

. Remove the front bolts last.

6. Detach the rear hooks by moving the frame forward, then remove the frame.

BOLT6x1.0mm9.8 N.m {1.0 kgt m,7.2 tht.hl

6x1.0mm9.8 N m (1.0 kgl.m, 7.2 lbtft)

20-54

\