primary o2 HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 165 of 2189

Remove the cylinder head cover.

NOTE: Refer to page 6-88 when installing the cylin-

der head cover.

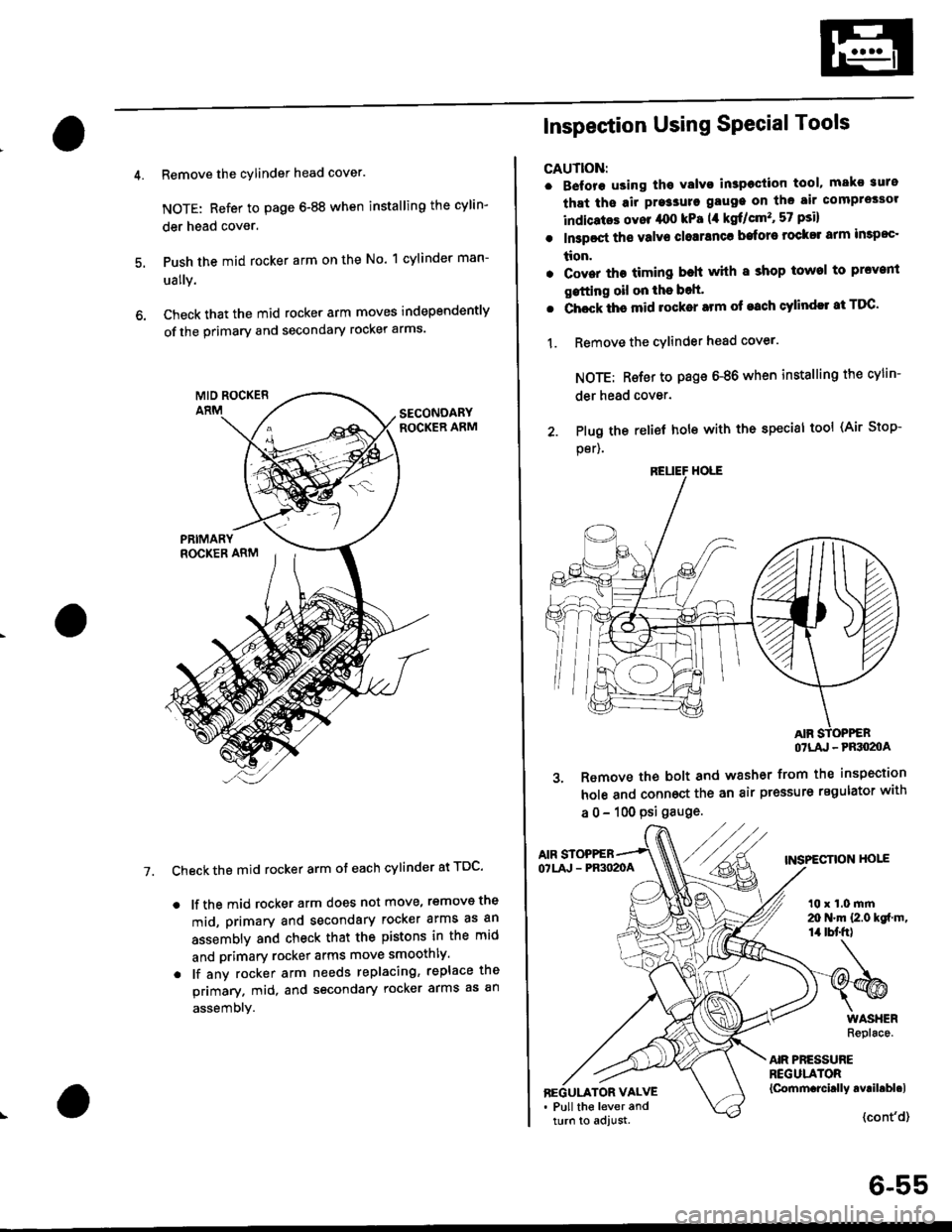

Push the mid rocker arm on the No. 1 cylinder man-

ually.

Check that the mid rocker arm moves independently

of the primary and secondary rocker arms.

Check the mid rocker arm ot each cylinder at TDC'

. lf the mid rocker arm does not move, removs the

mid, primary and secondary rocker arms as an

assembly and check that the pistons in the mid

and primary rocker arms move smoothly.

. lf any rocker arm needs replacing, replace the

primary. mid, and secondary rocker arms as an

assembly.

7.

2. Plug the

per).

Inspection Using SPecial Tools

CAUTION:

. B€fore using tho Yalvo inspeciion tool, mako suro

that ths air pre3sure gauge on the air comprossor

indicatos ovor /rco kPa (,1 kgf/cm'�, 57 psi)

. In3poct ths valve closranca bafore rock$ arm impoc'

tion.

. Cover the timing beh whh I shop towel to prcvenl

gstting oil on the bolt'

. Chock ths mid rocker arm of each cylindll at TDC'

1. Remove the cYlinder head cover.

NOTE: Rsfer to page 6-86 when installing the cylin-

der head cover.

relief hole with the special tool (Air Stop-

OTLA' - PRSO2OA

3. Remove the bolt and washer from the inspection

hole and connoct the an air pressure regulator with

a 0 - 100 psi gauge.

AIF STOPPEBTNSPECTION HOIEOTLA' - PR3O2OA

t0 x 1.0 mrn20 N.m {2.0 kgf m,14 tbt'fr)

AIR PRESSUREREGULATOR{Cornm.rcirlly avril.bl.lBEGULATOR VALVE. Pull the lever andturn to adjust.{cont'd}

6-55

Page 166 of 2189

VTEC Rocker Arms

4.

Inspection Using Special Tools (cont,dl

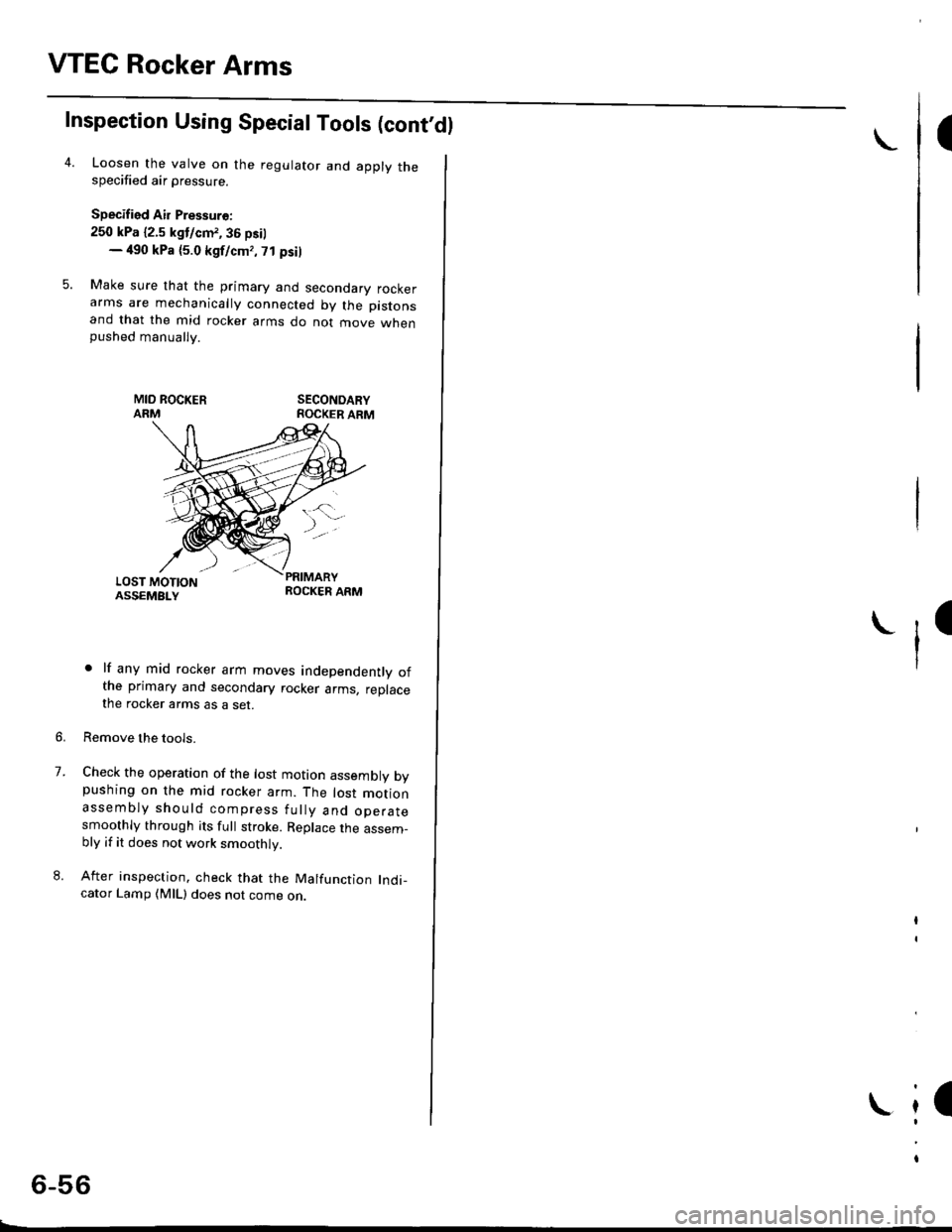

Loosen the valve on the regulator and apply thespecified air pressure.

Specified Air Pressuro:

250 kPa {2.5 kgtlcm,, 36 psil- 490 kPa {5.0 kgtcm,, 7t psil

Make sure that the primary and secondary rockerarms are mechanically connected by the pistonsand that the mid rocker arms do no. move wnenpushed manually.

SECONDARYROCKER ARM

. lf any mid rocker arm moves independently ofthe primary and secondary rocker arms, replacethe rocker arms as a set.

Remove the tools.

Check the operation of the lost motion assembly bypushing on the mid rocker arm. The lost motionassembly should compress fully and operatesmoothly through its full stroke. Replace the assem_bly if it does not work smoothly.

After inspection. check that the Malfunction Indi_cator Lamp {MlL) does not come on.

7.

6-56

I

ll

;l

Page 179 of 2189

WATER BYPASS

HOSE

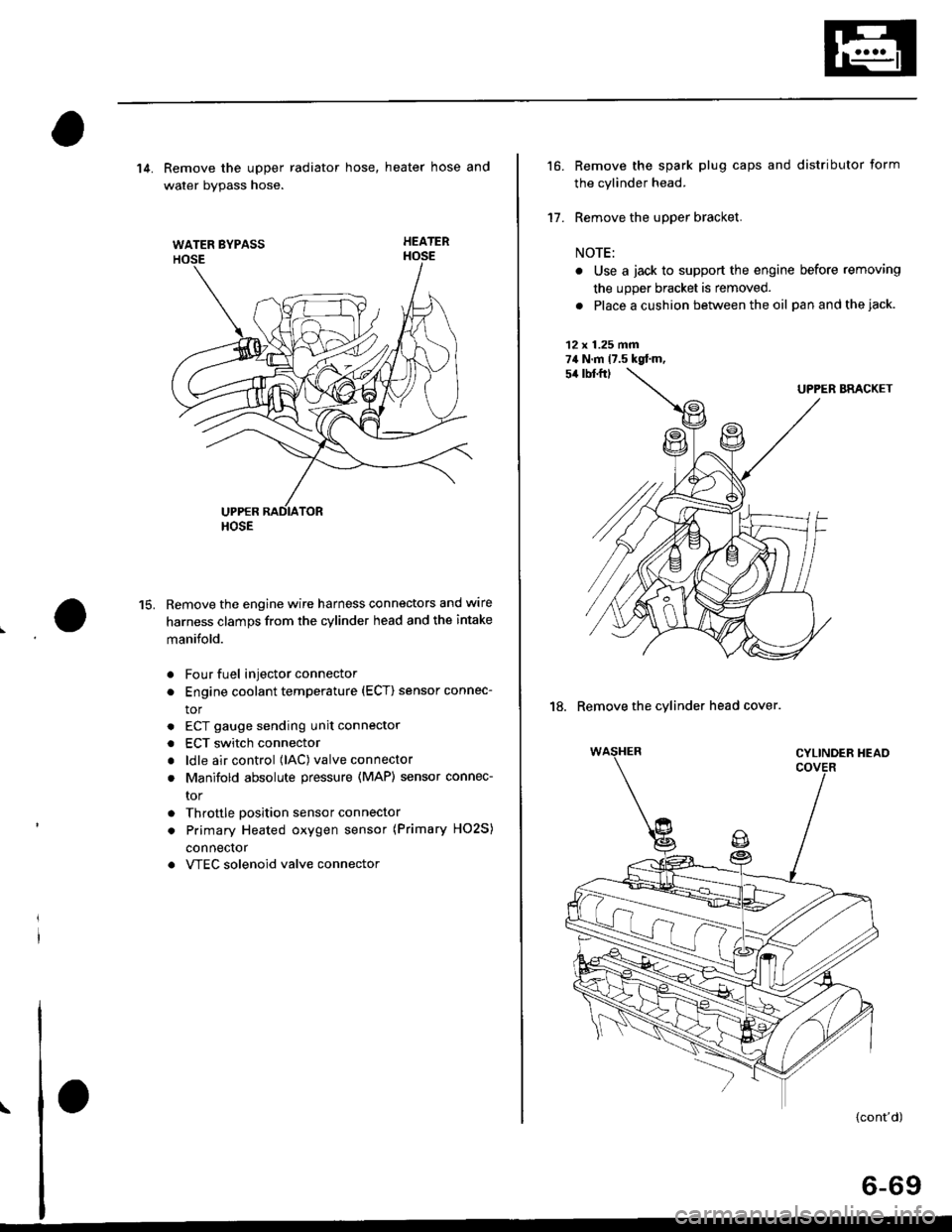

14. Remove the upper radiator hose, heater hose and

water bvpass hose.

HEATER

Remove the engine wire harness connectors and wlre

harness clamps from the cylinder head and the intake

manifold.

Four fuel injector connector

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

ldle air control (lAC) valve connector

Manifold absolute pressure (MAP) sensor connec-

tor

Throttle position sensor connector

Primary Heated oxygen sensor (Primary HO2S)

connecror

VTEC solenoid valve connector

15.

a

a

a

a

a

\

16.

17.

Remove the spark plug caps and distributor form

the cylinder head.

Remove the upper bracket.

NOTE:

. Use a jack to support the engine before removing

the upp€r bracket is removed.

. Place a cushion between the oil panandthejack.

12 x 1.25 fin74 N.m 17.5 kgtm,

UPPER BRACKET

18. Remove the cylinder head cover.

{cont'd)

6-69

Page 183 of 2189

Rocker Arms and Lost Motion Assemblies

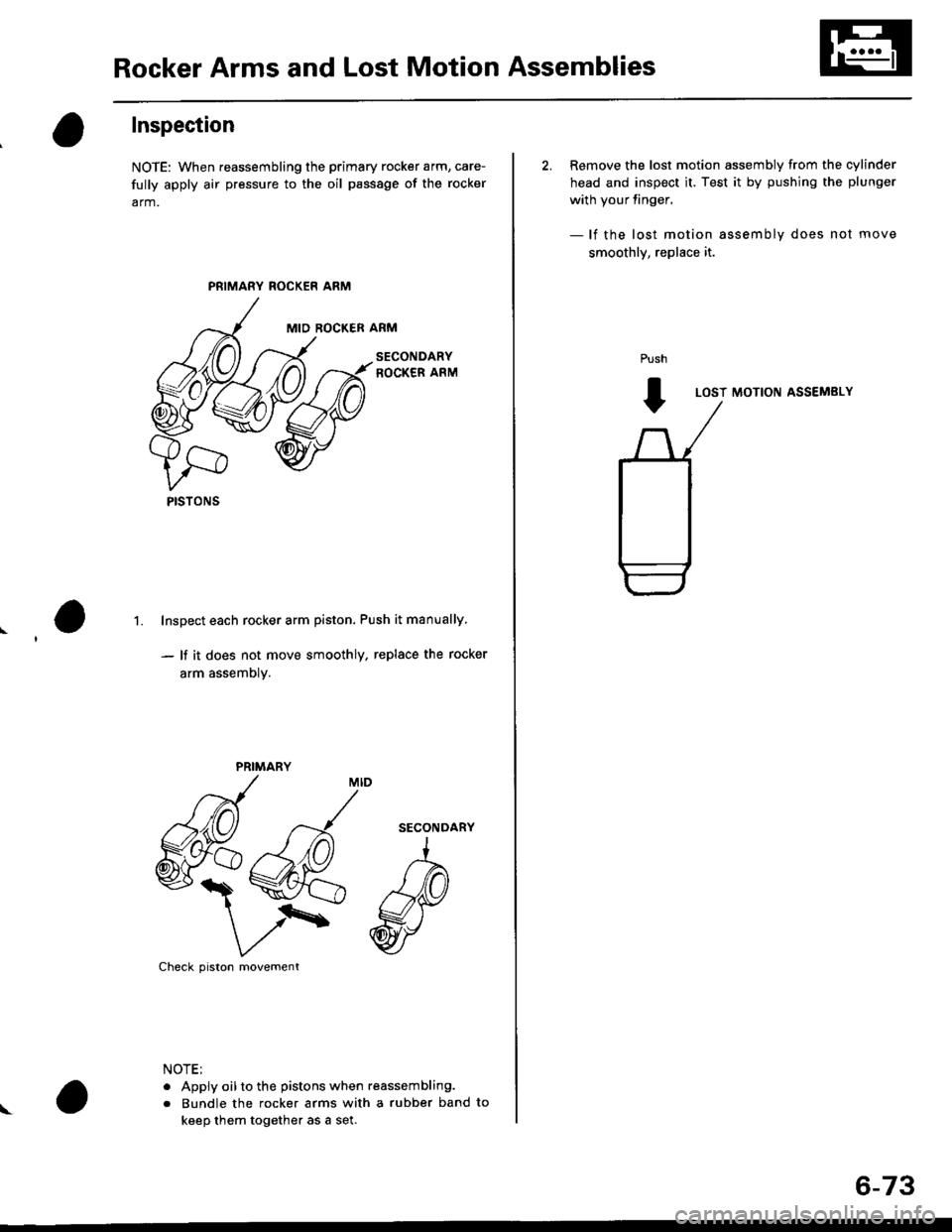

Inspection

NOTE: When reassembling the primary rocker arm, care-

fully apply air pressure to the oil passage of the rocker

arm.

PRIMARY ROCKER ARM

MID ROCKER ARM

Inspect each rocker arm piston. Push it manually

- lf it does not move smoothly. replace the rocker

arm assemDly.

1.

SECONDARY

Check prston movement

NOTE:

. Apply oilto the pistons when reassembling.

. Bundle the rocker arms with a rubber band to

keep them together as a set.

PISTONS

PRIMARY

\

6-73

2. Remove the lost motion assembly from the cylinder

head and inspect it. Test it by pushing the plunger

with your finger,

- lf the lost motion assembly does not move

smoothly, replace it.

LOST MOTION ASSEMBLY

Push

I

Page 184 of 2189

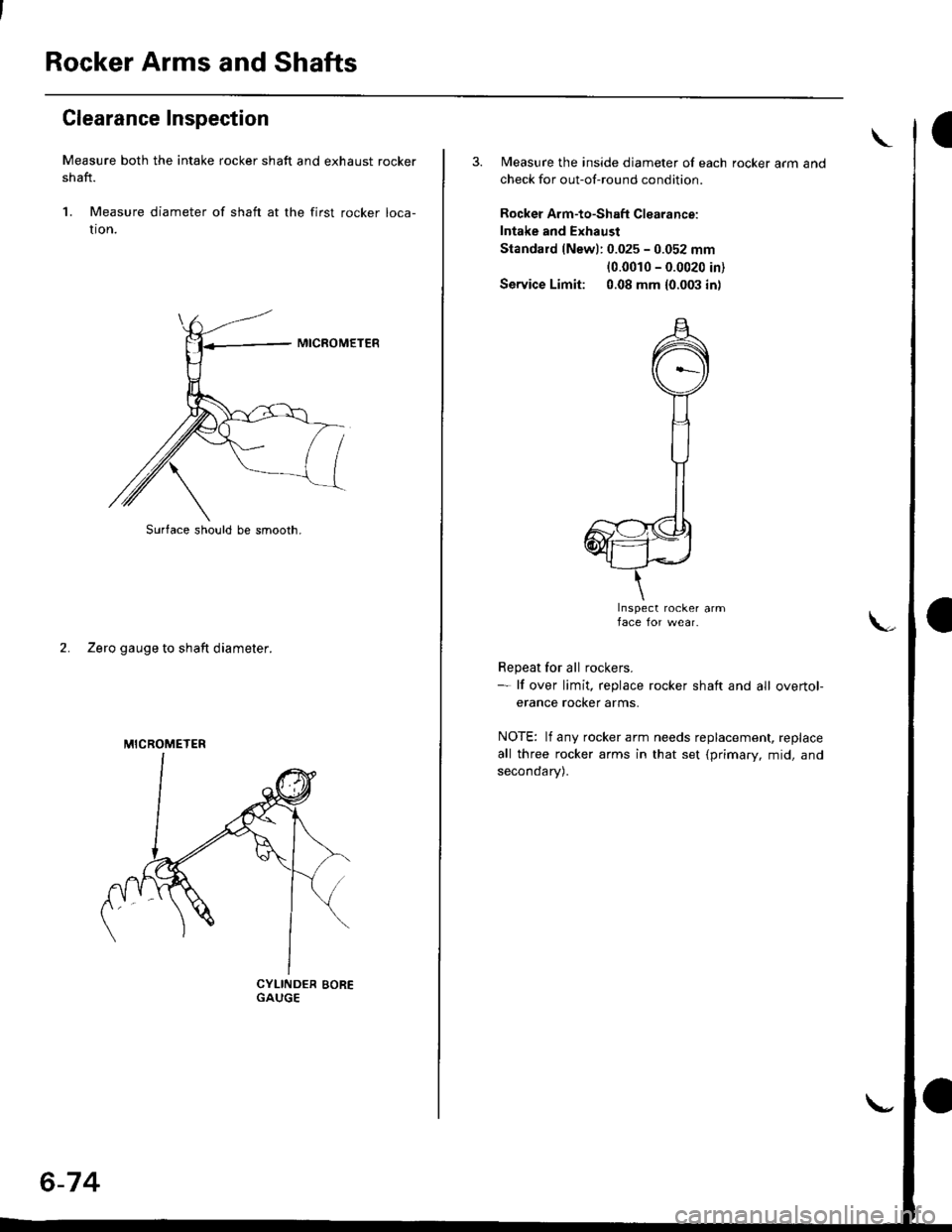

Rocker Arms and Shafts

Clearance Inspection

Measure both the intake rocker shaft and exhaust rocker

shaft.

1. Measure diameter of shaft at the first rocker loca-

tron.

2. Zero gauge to shaft diameter.

Surlace shor/ld be smooth.

MICROMETER

6-74

3. Measure the inside diameter of each rocker arm and

check for out-of-round condition

Rocker Arm-to-Shaft Clearance:

Intake and Exhaust

Standard {Newl: 0.025 - 0.052 mm

{0.0010 - 0.0020 in)

Service Limit: 0.08 mm {0.003 in)

Inspect rocker armface for wear.

Repeat for all rockers.- lf over limit, replace rocker shaft and all overtol-

erance rocker arms.

NOTE: lf any rocker arm needs replacement, replace

all three rocker arms in that set {primary, mid, and

seconoary).

Page 186 of 2189

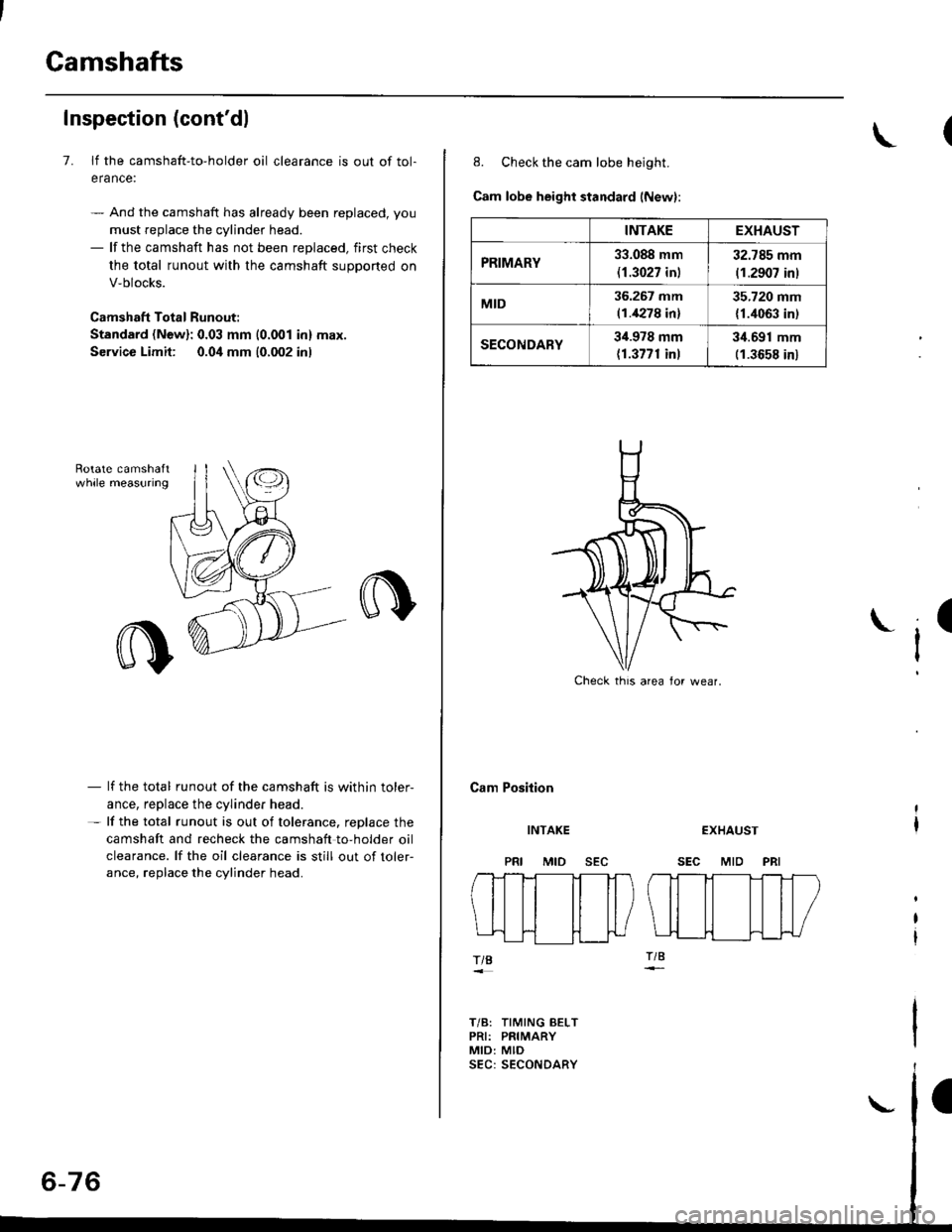

Gamshafts

Inspection (cont'dl

7. lf the camshaft-to-holder oil clearance is out of tol-

erance:

- And the camshaft has already been replaced, you

must replace the cylinder head.- lf the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Camshaft Total Runout:

Standard (New): 0.03 mm {0.001 in} max.

Service Limit: 0.04 mm (0.002 inl

- lf the total runout of the camshaft is within toler,

ance, replace the cylinder head.- lf the total runout is out of tolerance. replace the

camshaft and recheck the camshaft to,holder oil

clearance. lf the oil clearance is still out of toler-

ance, replace the cylinder head.

INTAKEEXHAUST

PRIMARY33.088 mm

{1.3027 in)

32.785 mm

(1.2907 inl

MID36.267 mm(1.4278 in)

35.720 mm

{1.4063 in)

SECONDARY34.978 mm(1.3771 inl

3i1.691 mm(1.3658 in)

8. Check the cam lobe height.

Cam lobe height standard (New):

Cam Position

I

INTAKE

MID

EXHAUST

SEC MID PRI

TIB

T/B: TIMING BELTPRI: PRIMARYMID: MID

Check thrs area lor wear.

Page 247 of 2189

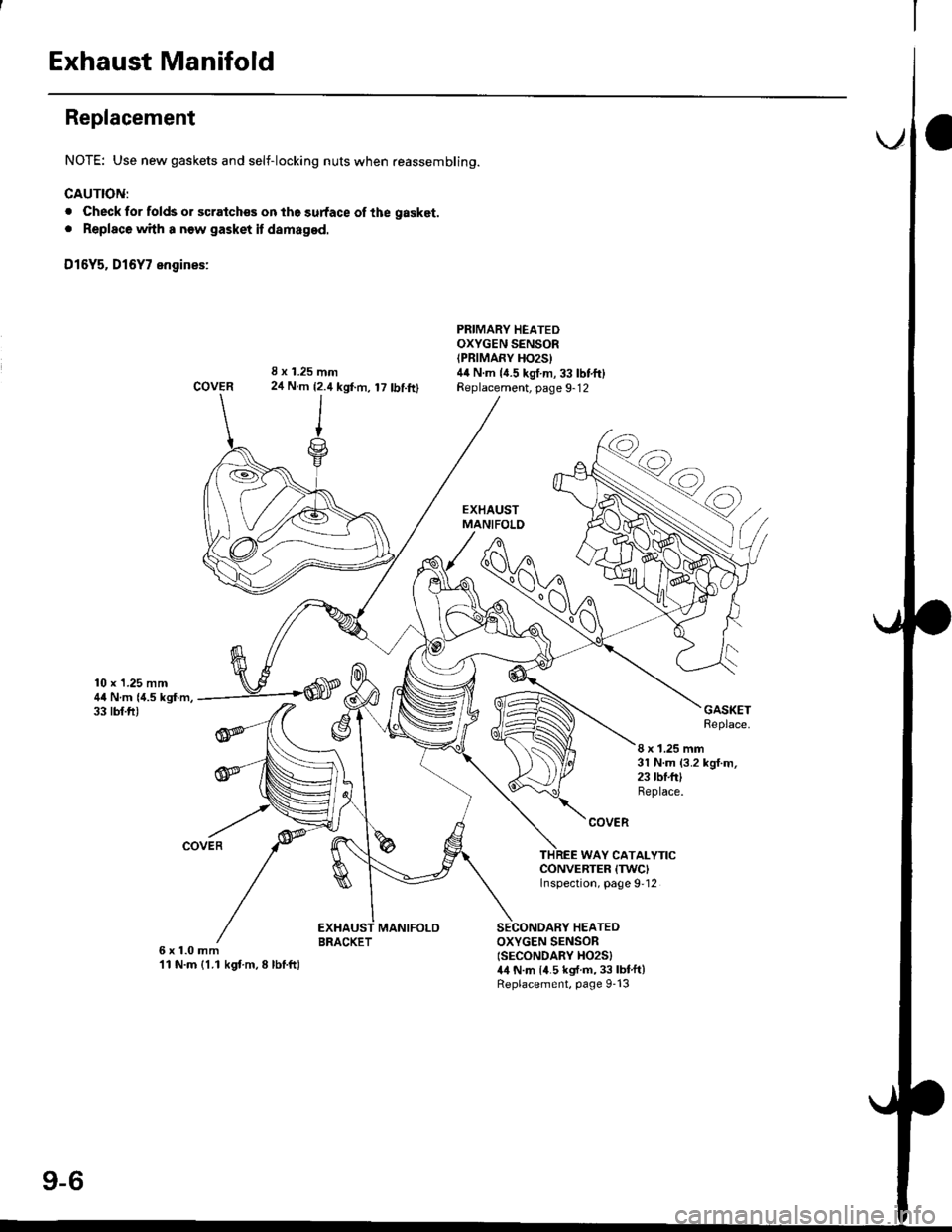

Exhaust Manifold

Replacement

NOTE: Use new gaskets and self-locking nuts when reassembling.

CAUTION:

. Check for folds or scratch€s on the surface of the gasket.

. Replace with a new gasket it damaged.

D16Y5. D16Y7 engines:

I x 1.25 mm24 N.m {2.4 kgt.m, 17 tbtft}

MANIFOLDBRACKET

PRIMARY HEATEDOXYGEN SENSORIPRIMAFY HO2SI44 N.m {4.5 kgf m, 33 lbtft)Replacement, page 9-12

GASKETReplace.

I x 1.25 mm31 N.m (3.2 kgf.m,23 tbf.ft)Beplace.

WAY CATALYTICCONVERTER {TWCIlnspection, page 9'12

6x1.0mm11 N.m {1.1 kgt m,8 lbf.ft)

SECONDARY HEATEDOXYGEN SENSOR(SECONDARY HO2S}44 N.m 14.5 kgf.m,33 lbf.ft)Replacement, page 9-13

9-6

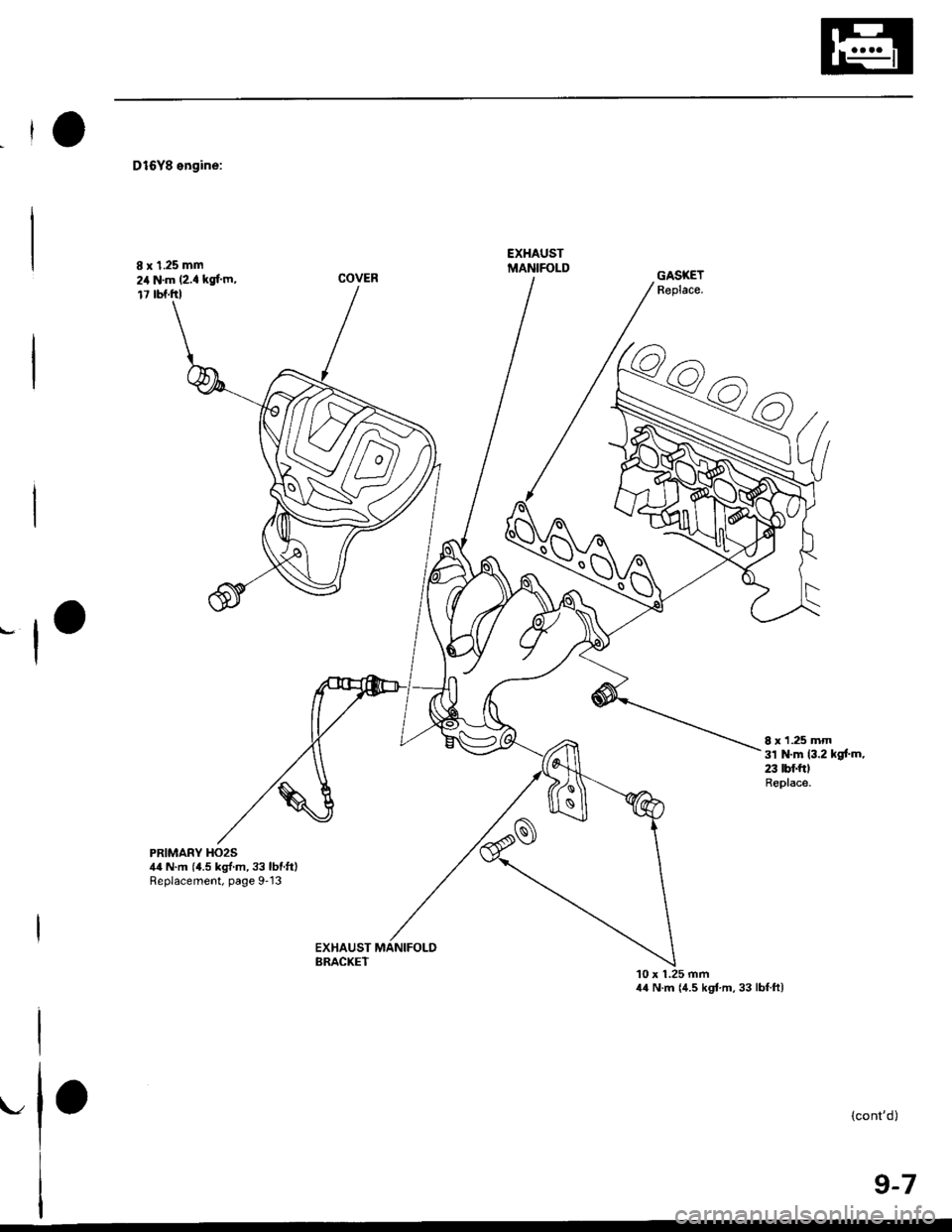

Page 248 of 2189

D15Y8 engine:

8 x 1.25 mm2,1 N.m (2.a kgf'm,

17 tbf.ftl

GASKETReplace.

8 x 1.25 mm31 N.m 13.2 kgf'm,23 lbf.ftlReplace.

PRIMARY HO2S44 N.m (4.5 kgf.m, 33 lbtft)Replacement, page 9-13

EXHAUST MANIFOLDBRACKET10 x 1.25 rnm

(cont'd)

9-7

/r4 N.m {4.5 kgf.m, 33 lbf.ft)

v

Page 252 of 2189

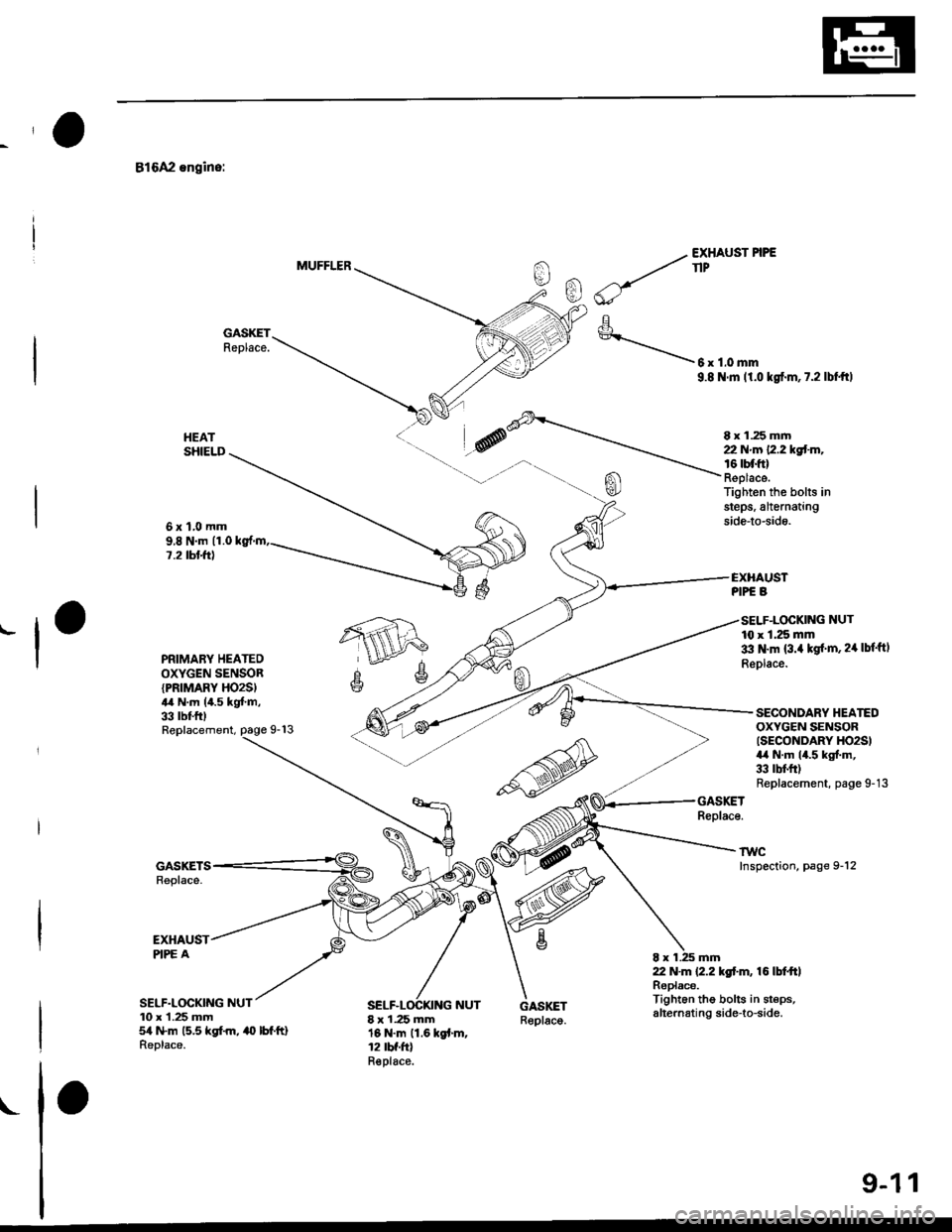

816A2 engino:

MUFFLER_.,. EXHAUST PIPE

-/- tlP

g

\6r1.omm

9.8 N m 11.0 kgf'm, 7.2 lbl'ttl

GASKETReplace.

8 x 1.25 mm2. N'm 12.2 kgl-m,t6 tbtf0Replace.Tighten the bolts insteps, alternatrngside-to-side.6x1,0mm9,8 N.m 11.07.2lbl4rl

SELF-LOCKING NUTl0 x 1.25 mm

3:t N.m {3.4 kgf m,24lbf'ftl

ReDlace.PRIMARY IIEATEDOXYGEN SENSOR{PRIMARY HO2S)ll N.m (4.5 kgl.m,33 tbt f0Replacement,

SECONDARY HEATEDOXYGEN SENSOR{SECONDARY HO2SIlrt N.m 14.5 kgf.m,33 rbl.ft)Replacement, page 9-13

GASKETR€place.

twcInspection, page 9-12GASKEISReplace.

SELF.L(rcKNG NUT10 x 1.25 mm5,r N.m 15.5 kgf.m, ,|{} lbf.ft)ReDlace.

8x1.25mm22 N.m {2.2 kgt m, 16 lbf.ftlReplsce.Tight6n the bolts in st6ps,alternating side-to-side.8 x 1.25 mm16 N.m 11.6 kgt.m,12 rbf.ft)F€pl8ce.

I

Replaca.

9-11

Page 253 of 2189

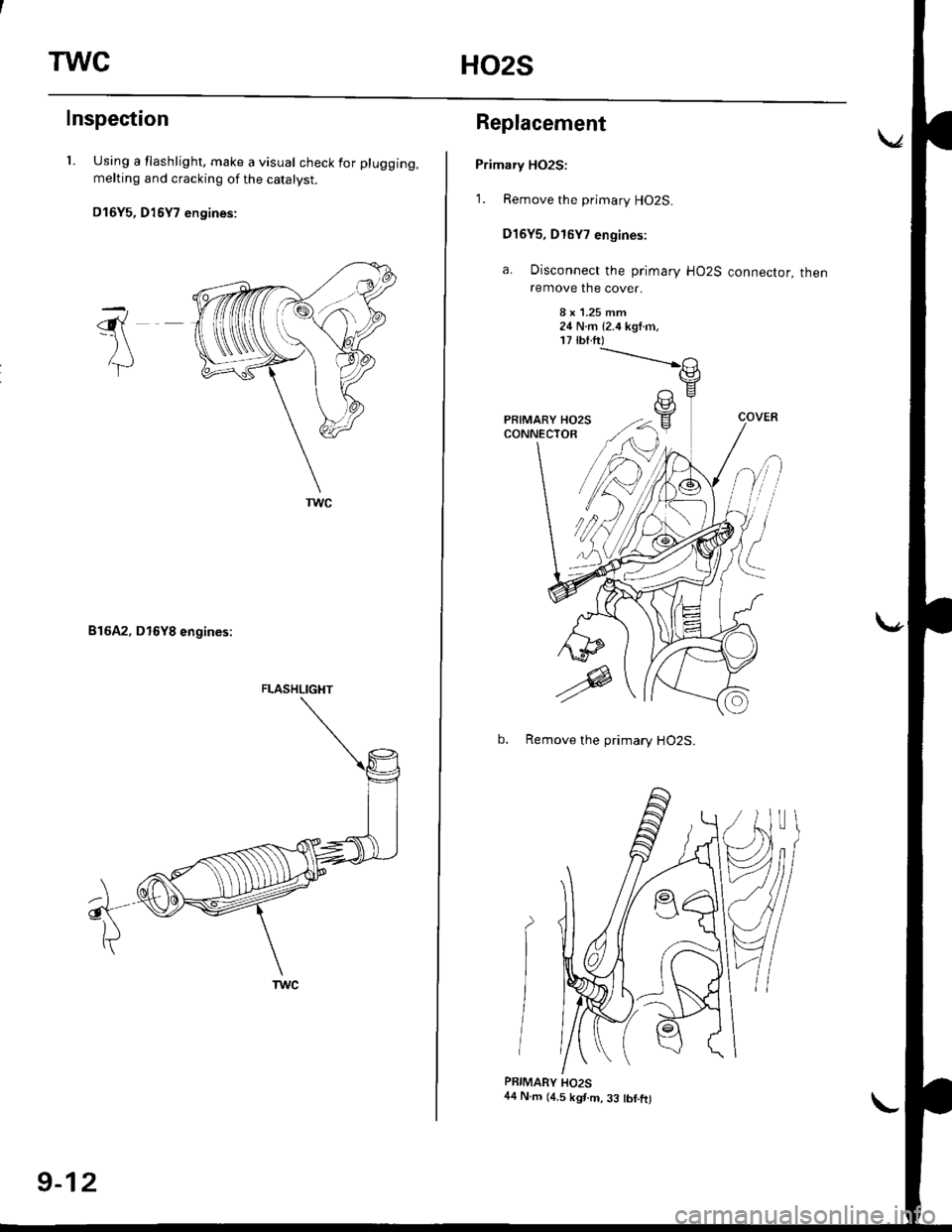

TWCHO2S

Inspection

l. Using a flashlight, make a visual check for plugging,

melting and cracking of the catalyst.

D16Y5, D16Y7 engines:

816A2, D16Y8 engines:

-\6{-)\

lT

a

A

FLASHLIGI{T

9-12

Replacement

Primary HO2S:

1. Remove the primary HO2S.

D16Y5, D15Y7 engines:

a. Disconnect the primary HO2S connector, thenremove the cover.

8 x'1.25 mm24 N.m {2.4 kgl.m,

PRIMARY H02SCONNECTOR

b. Remove the primary HO2S.

| \l ,l(

I bK/l

l llw.

/

(

PBIMARY HO2S44 N m (4.5 kgf.m, 33 tbI.ft)