rear seal HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1188 of 2189

Rear Brake Caliper

Reassembly (cont'dl

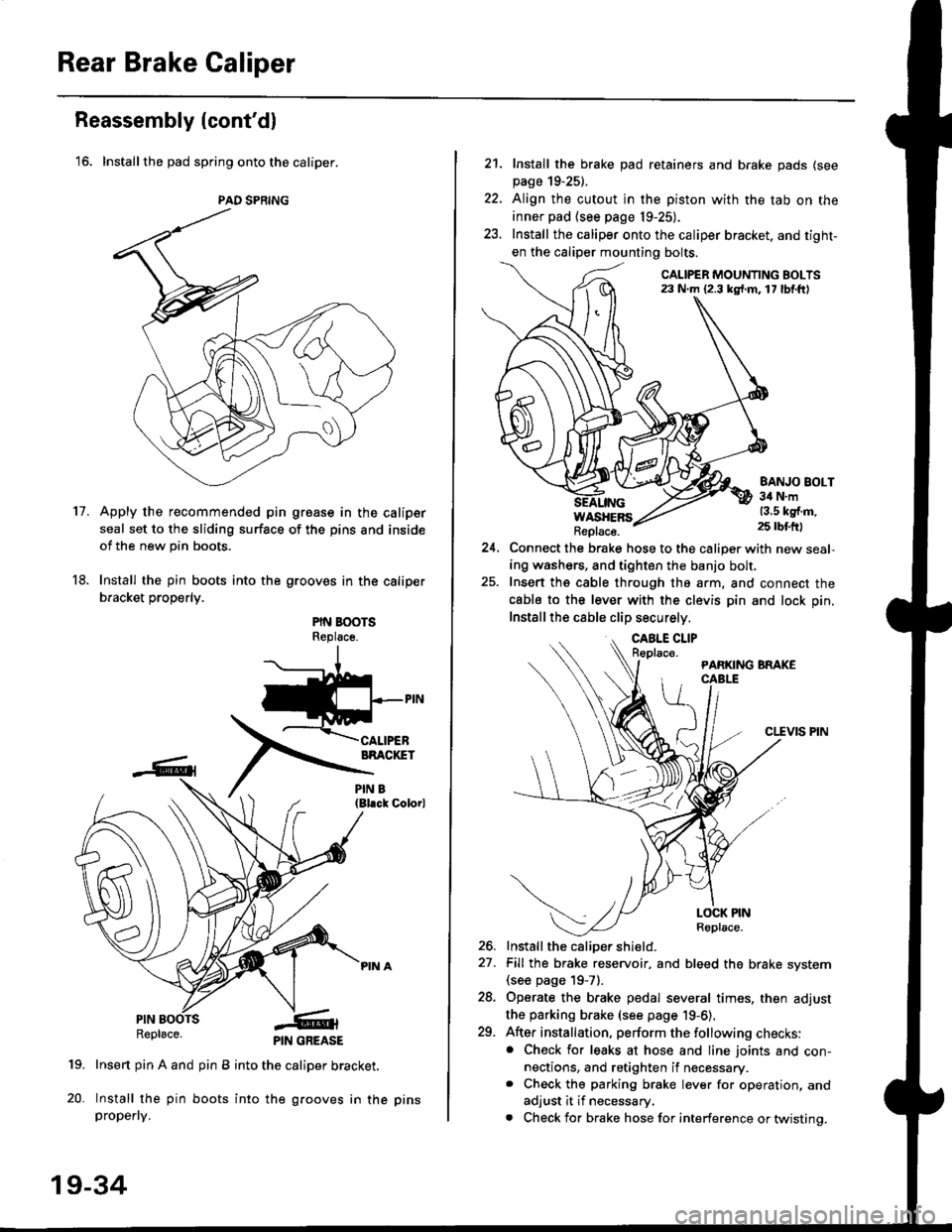

'16. Installthe pad spring onto the caliper.

Apply the recommended pin groase in the caliper

seal set to the sliding surface of the pins and inside

of the new pin boots.

Install the pin boots into the grooves in the caliper

bracket properly.

PIN BOOTSReplsce.

(Bl.ck Colorl

PINRepl6ce.

19. Insert pin A and pin B into the caliper bracket.

20. Install the pin boots into the grooves in thepropefly.

PAD SPRING

11.

PIN GREASE

19-34

pr ns

22.

21. Install the brake pad retainers and brake pads (see

page 19-25).

Align the cutout in the piston with the tab on the

inner pad (see page 19-25).

Install the caliper onto the caliper bracket. and tight-

en the caliper mounting bolts.

CALIPER MOUNTING BOLTS23 N.m {2.3 kg{.m. 17 lbf.ft)

WASHERSReplace.

BANJO BOLT34 N.m13.5 kg{.m.25 rbtft)

24.Connect the brake hose to the caliper with new seal,

ing washers, and tighten the banjo bolt,

Insert ths cable through the arm, and connect the

cabls to the lever with the clevis pin and lock pin.

Install the cable clip securely.

CLEVIS PIN

-t

//t

LOCK PINRoplace.

26. Install the caliDer shield.

27. Fill the brake reservoir, and bleed the brake svstem(see page 19-71.

28. Operate the brake pedal several times, then adjust

the parking brake (see page 19-6).

29. After installation, perform the following checks:. Check for leaks at hose and line joints and con-nections, and retighten if necessary.. Check the parking brake lever for operation, and

adjust it if necessary.

. Check for brake hose for interference or twistinq.

Page 1255 of 2189

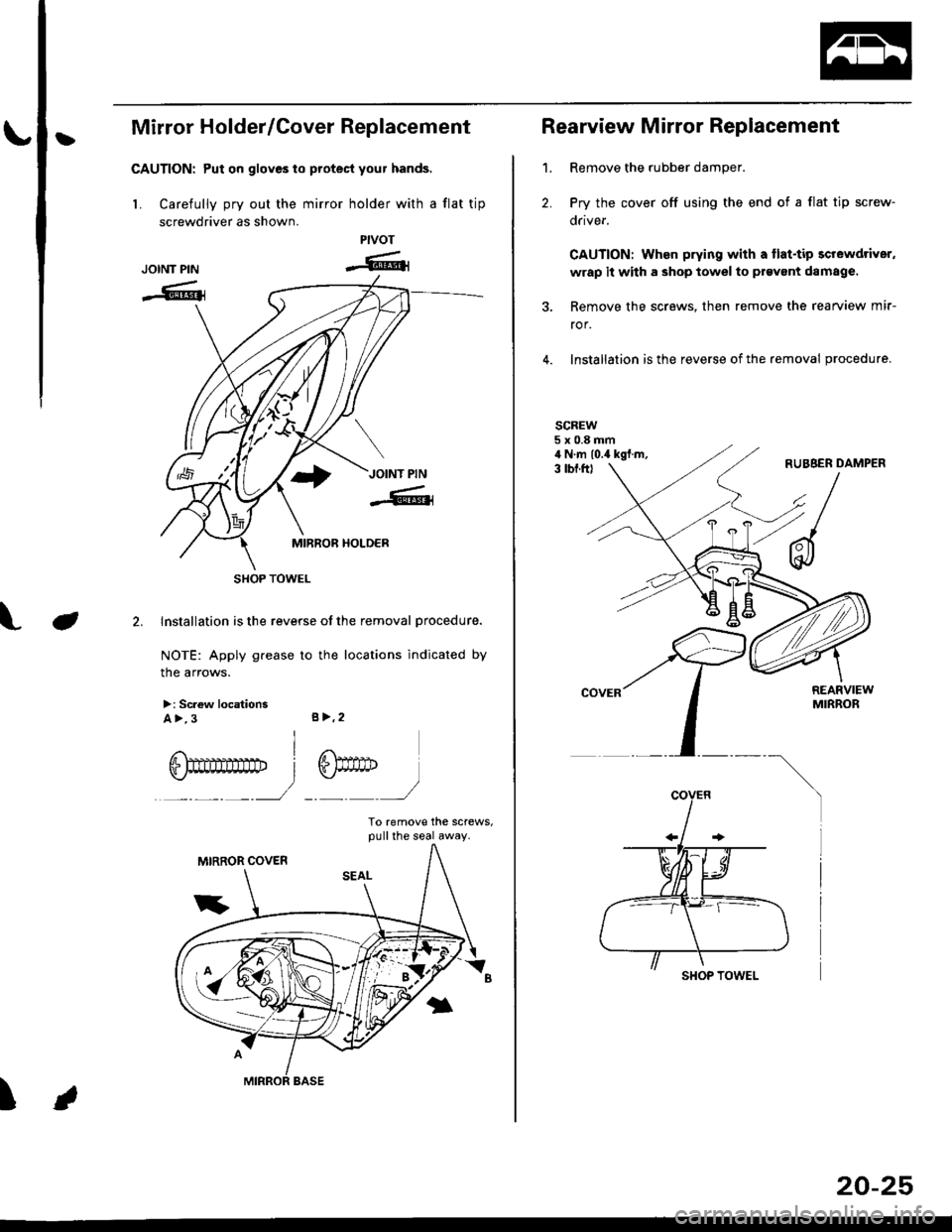

|}Mirror Holder/Cover Replacement

CAUTION: Put on gloves to protecl your hands.

L Carefully pry out the mirror holder with a flat tip

screwdriver as shown.

Installation is the reverse of the removal procedure.

NOTE: Apply grease to the locations indicated by

the arrows.

>: Sc.ew locationsA >, 3 s>,2

I

ry

To remove the screws,pull the seal away.

PIVOT

-6rJOINT PIN

-G{

J

6)drD

)

I

SHOP TOWEL

Rearview Mirror Replacement

1. Remove the rubber damper.

2. Pry the cover off using the end of a flat tip screw-

drivef.

CAUTION: When prying with a flat-tip screwdriver,

wrap it with a shop towel to prgvant damage.

3. Remove the screws, then remove the rearview mir-

ror,

4. Installation is the reverse of the removal procedure.

SCREW5x0.8mmil N.m lo.a kgf.m,3 lbf.ftl

SHOP TOWEL

20-25

Page 1257 of 2189

b

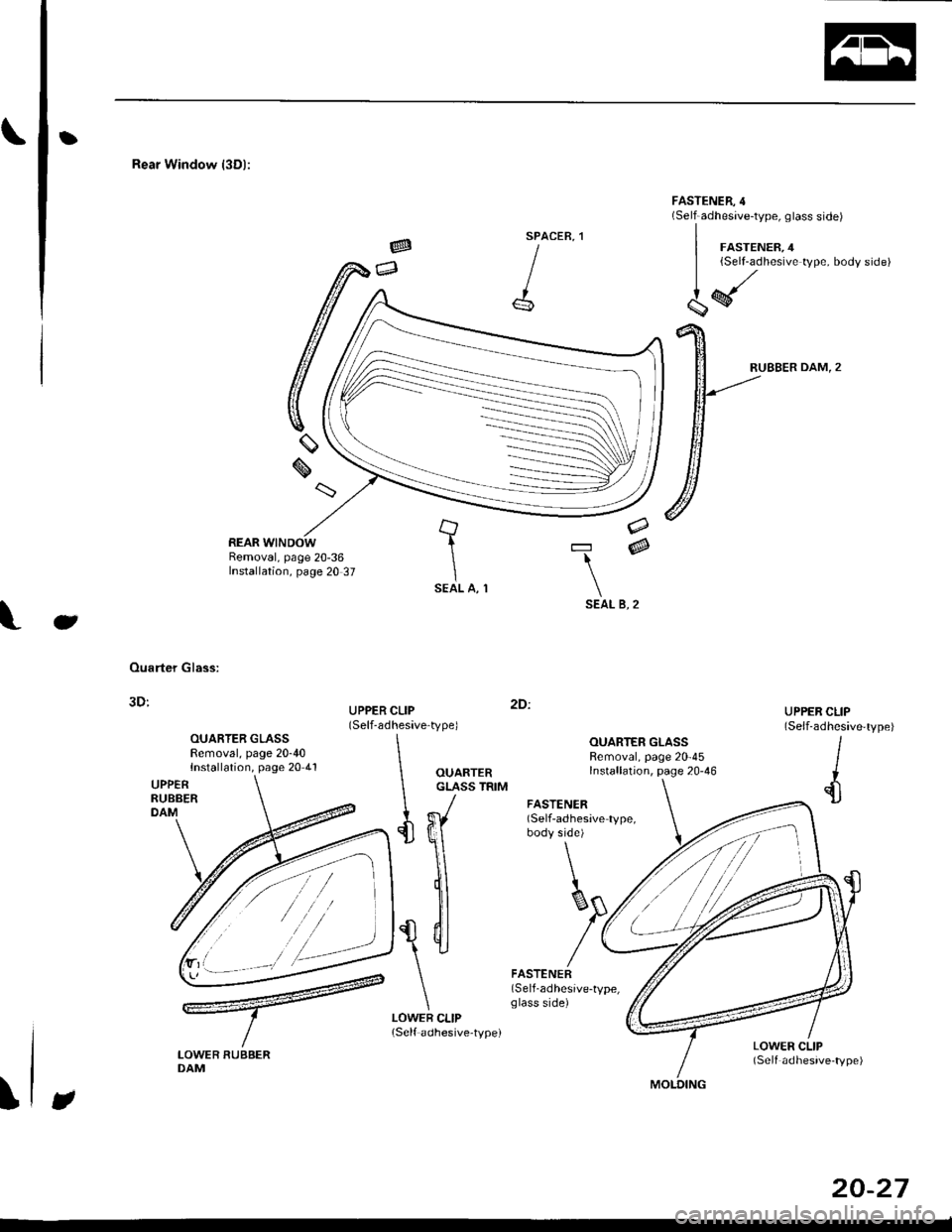

Rear Window l3Dl:

SPACER,

I

| ,o"r.".". o

{ff*'*'YPe

bod'side)

FASTENER,4(Self-adhesive-type, glass side)

RUBBER DAM,2

tIISEAL A, 1

=@

SEAL B, 2

e

Ouarter Glass:

3D:

OUARTER GLASSRemoval, page 20-40Installation, page 20 4lOUARTERGLASS TRIM

LOWER CLIPlSelf adhesive'type)

2D:

FASTENER(Self-adhesive-type,glass side)

FASTENER(Self-adhesave type,body side)

\

\

)f\

n,

$(

\il]

LOWER RUBBERDAM

LOWER CLIP(Self adhesive-type)

J

20-27

Page 1261 of 2189

3

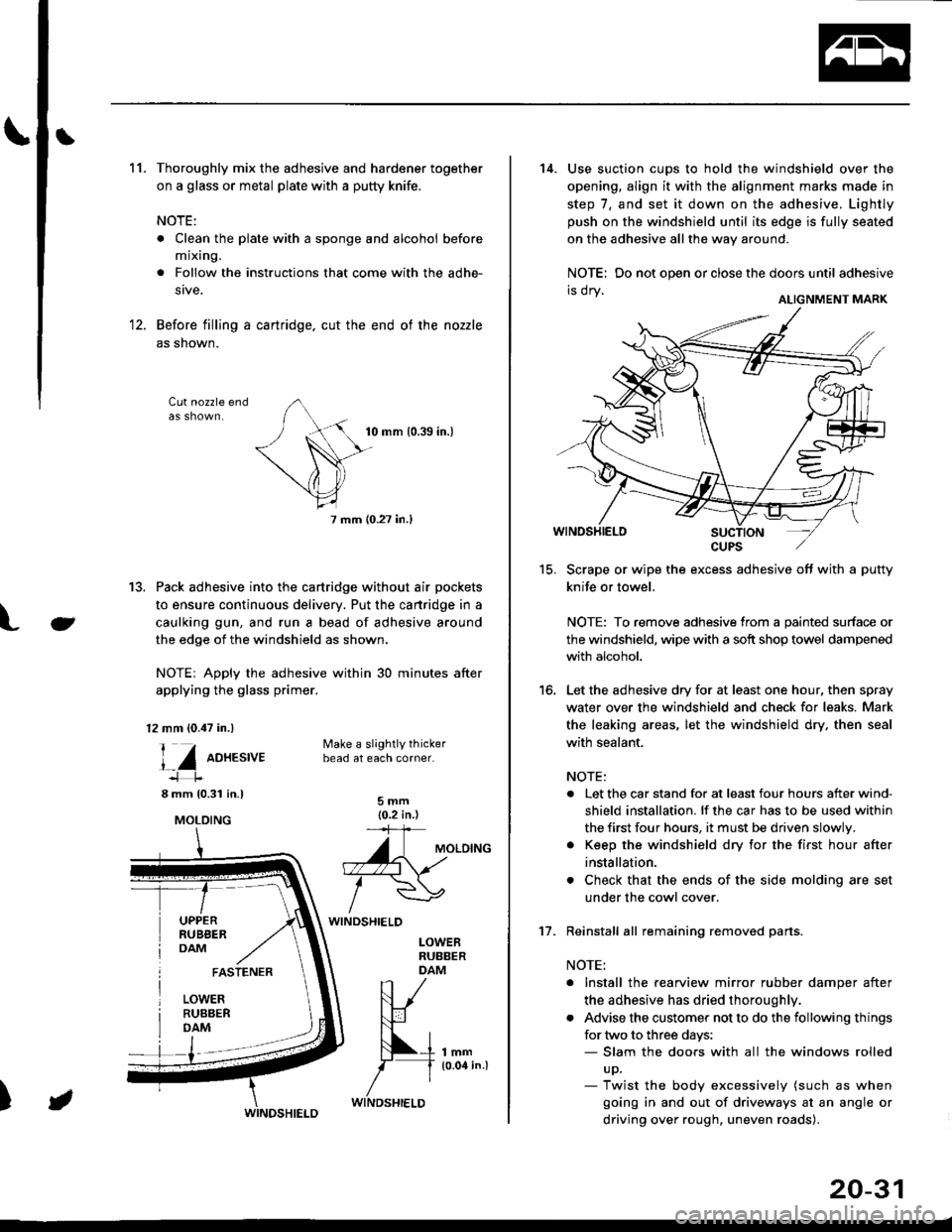

11.Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that come with the adhe-

stve.

Before filling a cartridge. cut the end of the nozzle

as shown.

Cut nozzle end

tu

10 mm 10.39 in.)

7 mm (0.27 in.l

13. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (0.47 in.)

l_Z oo*.t,ut

8 mm 10.31 in.l

UPPERRUBBERDAM

Make a slightly thickerbead at each corner.

5mm(0.2 in )='+

A\uloto^o. -.\

/wWINDSHIELD

LOWEBRUBBERDAM

lmm10.04 in.l

FASTENER

LOWERRUBBERDAM

)

MOLDING

WINDSHIELD

20-31

15.

16.

14. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTE: Do not open or close the doors until adhesive

ri vI Y ALTGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface or

the windshield, wipe with a soft shop towel dampened

with alcohol.

Let the adhesive dry for at least one hour, then spray

water over the windshield and check for leaks. Mark

the leaking areas, let the windshield dry, then seal

with sealant.

NOTE:

. Let the car stand for at least four hours after wind-

shield installation. lf the car has to be used within

the first four hours, it must be driven slowly.

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl',.

. Advise the customer not to do the following things

for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excessively (such as when

going in and out of driveways at an angle or

driving over rough, uneven roads).

't7.

Page 1265 of 2189

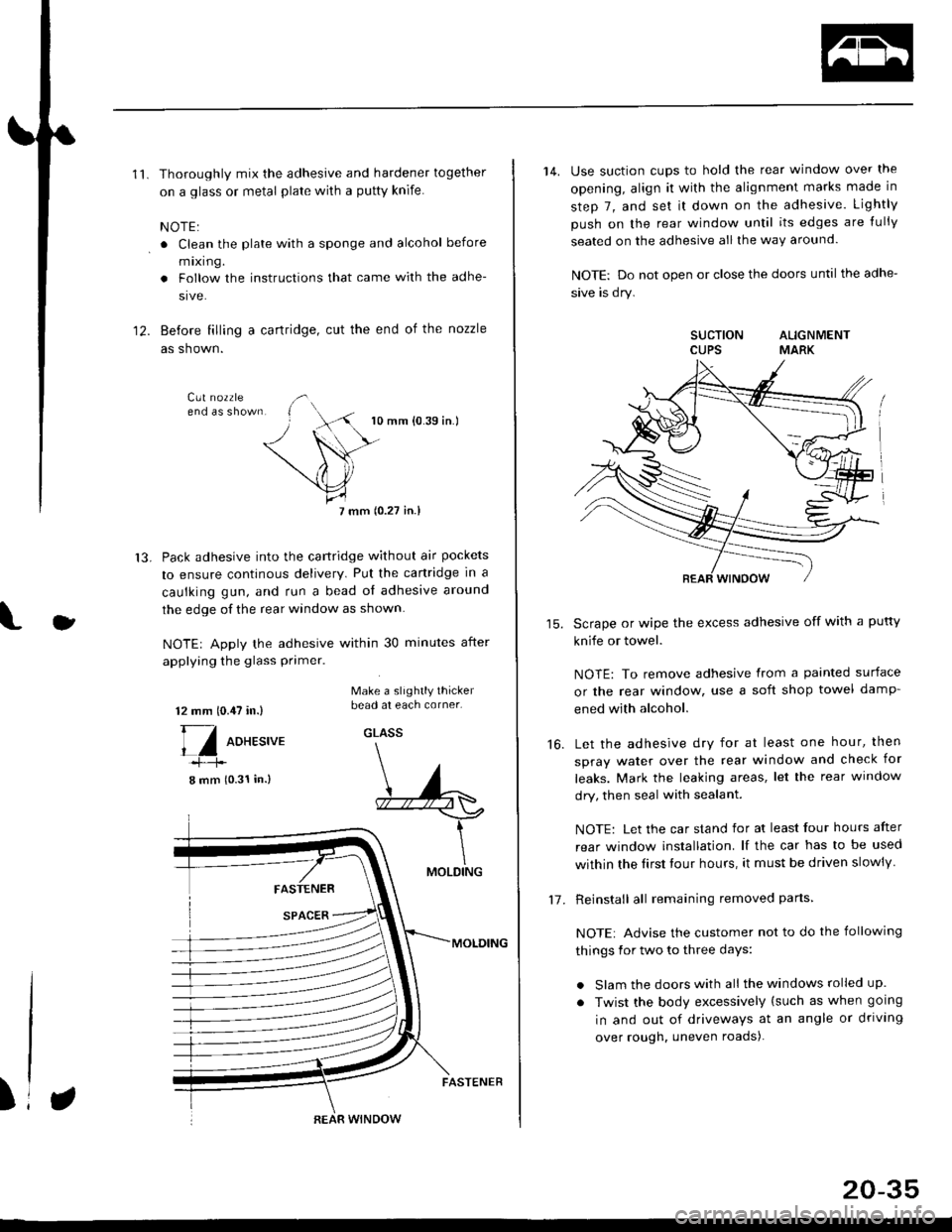

'11.Thoroughly mix the adhesive and hardener together

on a glass or metal plate wilh a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that came with the adhe-

sive.

Before filling a cartridge, cut the end of the nozzle

as shown.

10 mm {0.39 in.)

7 mm (0.27 in.l

Pack adhesive into the cartridge without air pockets

to ensure continous delivery. Put the canridge in a

caulking gun, and run a bead ol adhesive around

the edge of the rear window as shown.

NOTE| Apply the adhesive within 30 minutes after

applying the glass primer.

12.

13.

J

12 mm 10.,U in.)

[/ oo*r.,u.

8 mm (0.31 in.)

Make a slightly thickerbead at each corner.

GLASS

FASTENER

SPACER

MOLDING

MOLDING

)REAR WINDOW

FASTENER

20-35

14. Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly

push on the rear window until its edges are {ully

seated on the adhesive all the way around.

NOTE: Do not open or close the doors until the adhe-

sive is dry.

SUCTION ALIGNMENTCUPS MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the rear window, use a soft shop towel damp-

ened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the rear window and check for

leaks. Mark the leaking areas, let the rear window

dry, then seal with sealant.

NOTE: Let the car stand for at least four hours after

rear window installation. lf the car has to be used

within the Iirst tour hours, it must be driven slowly

Reinstall all remaining removed parts

NOTE: Advise the customer not to do the following

things for two to three days:

. Slam the doors with all the windows rolled up.

. Twist the body excessively (such as when going

in and out of driveways at an angle or driving

over rough. uneven roads).

16.

1-7 .

Page 1267 of 2189

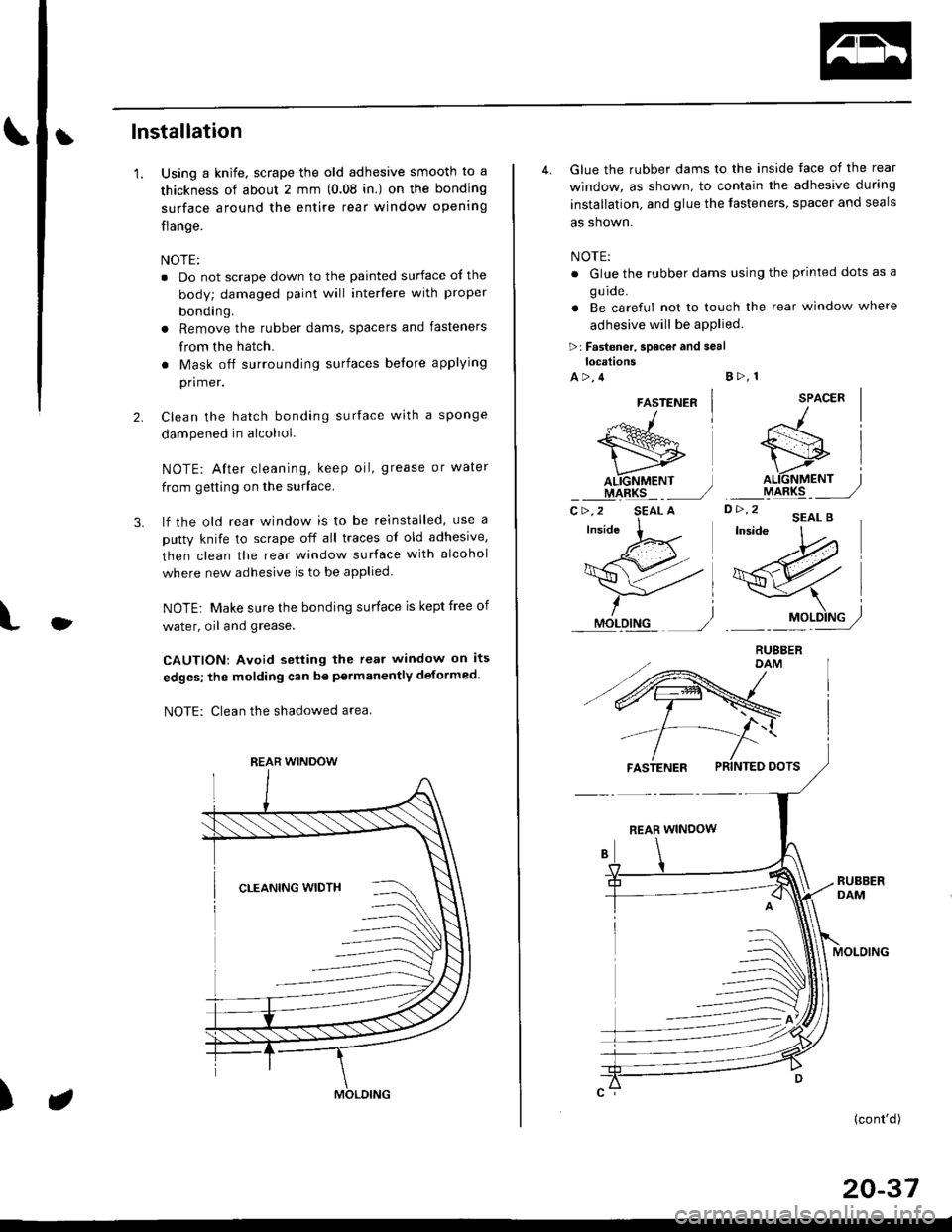

tlnstallation

'1.

3.

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire rear window opening

flange.

NOTE:

. Do not scrape down to the painted surface ol the

body; damaged paint will interfere with proper

bonding.

a Remove the rubber dams, spacers and fasteners

from the hatch.

. Mask off surrounding surfaces before applying

primer.

Clean the hatch bonding surface with a sponge

dampened in alcohol.

NOTE: After cleaning, keep oil, grease or water

from getting on the surface.

lf the old rear window is to be reinstalled, use a

putty knife to scrape off all traces of old adhesive,

then clean the rear window surface with alcohol

where new adhesive is to be applied.

NOTE; Make sure the bonding surface is kept free of

water, oil and grease.

CAUTION: Avoid setting the rear window on its

edges; the molding can be permanently deformed.

NOTE: Clean the shadowed area

2.

O

)

REAR WINDOW

4. Glue the rubber dams to the inside face of the rear

window, as shown, to contain the adhesive during

installation, and glue the fasteners, spacer and seals

as shown.

NOTE:

. Glue the rubber dams using the printed dots as a

g u ide.

. Be careful not to touch the rear window where

adhesive will be aPPlied

>r Fastener, spacor and seallocations

A>,4B>, 1

SPACER

D> '2 'EAL B'W

/l

si

o.\6fif,", j

ryt48rq _ _ ,,/

-\l

19Pry/

FASTENER PRINTED DOTS

REAR WINDOW

MOLOING

(cont'd)

20-37

FASTENER

"-*^1

wAL.IGNMENT ]IIARKS _ _,/C>,2 SEAL A

Page 1270 of 2189

Rear WindowOuarter Glass

Installation {cont'd)

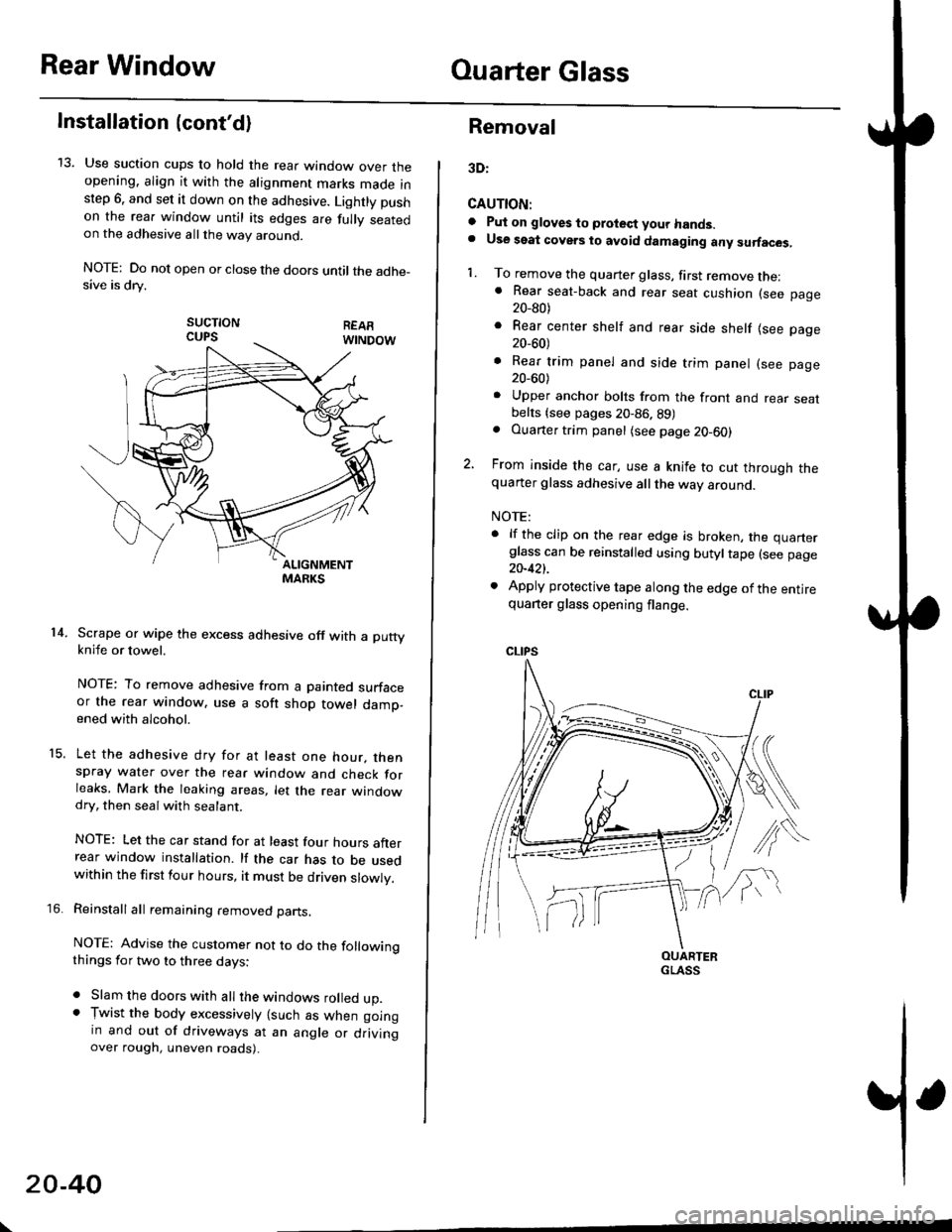

13. Use suction cups to hold the rear window over theopening. align it with the alignment marks made inslep 6. and set it down on the adhesive. Lightly pushon the rea. window until its edges are fully seatedon the adhesive allthe way around.

NOTE: Do not open or close the doors until the adhe_sive is drv.

sucTtoNCUPS

Scrape or wipe the excess adhesive off with a puttyknife or towel.

NOTE: To remove adhesive from a painted surfaceor the rear window. use a soft shop towel damp-ened with alcohol.

Let the adhesive dry for at least one hour. thenspray water over the rear window and check forleaks, Mark the leaking areas, let the rear windowdry, then seal with sealant.

NOTE: Let the car stand for at least four hours afterrear window installation. lf the car has to be usedwithin the first four hours, it must be driven slowly.

Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the followingthings for two to three days:

. Slam the doors with all the windows rolled up.. Tr,vist the body excessively lsuch as when goingin and out of driveways at an angle or drivingover rough, uneven roads).

14.

15.

\

20-40

Removal

3D:

CAUTION:

a Pul on gloves to protect your hands.. Use seat covers to avoid damaging any surfaces,

1. To remove the quarter glass, first remove the:. Rear seat-back and rear seat cushion (see page20_80)

. Rear center shelf and rear side shelf lsee page20_60)

. Rear trim panel and side trim panel (see page20_60)

. Upper anchor bolts from the front and rear seatbelts {see pages 20-86. 89). Ouarter trim panel (see page20-60)

2, From inside the car, use a knife to cut through thequarter glass adhesive all the way around.

NOTE:

. lf the clip on the rear edge is broken, the quarterglass can be reinstalled using butyltape (see page20-421.

. Apply protective tape along the edge of the entirequarter glass opening flange.

OUARTERGLASS

Page 1272 of 2189

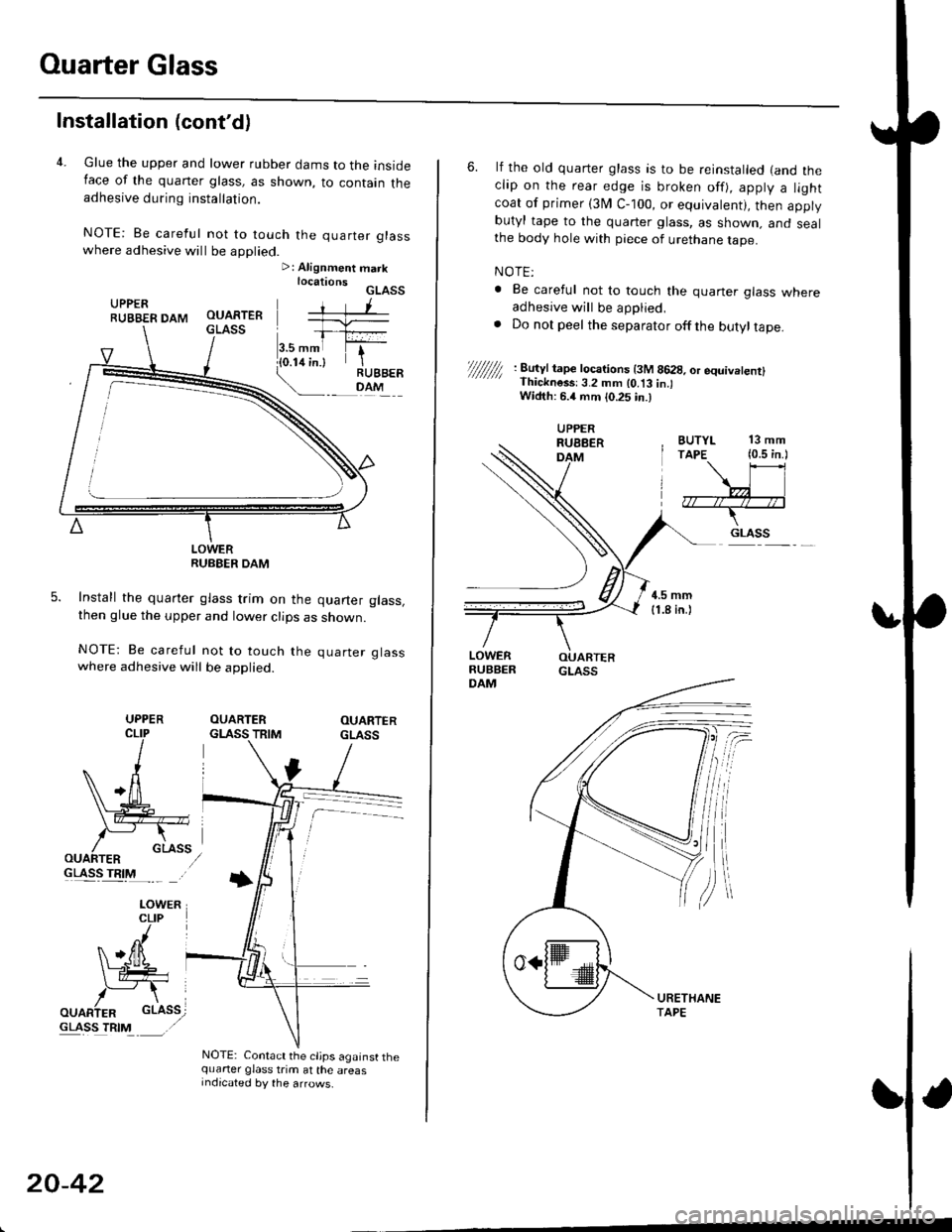

Quarter Glass

Installation (cont'd)

4. Glue the upper and lower rubber dams to the insideIace of the quaner glass, as shown, to contain theadhesive during installation.

NOTE: Be careful not to touch the quarter glasswhere adhesive will be applied.>: Alignment marklocationsGLASSUPPERRUBBER DAM

LOWERRUBEER DAM

Install the quarter glass trim on the quarter glass,then glue the upper and lower clips as shown.

NOTE: Be careful not to touch the quarter glasswhere adhesive will be applied.

OUARTERGLASS TRIMOUARTERGLASS

GLASS TRIM

NOTE: Contact the cljps against thequarter glass trim at the areasIndicated by the arrows.

UPPER

20-42

6. lf the old quarter glass is to be reinstalled (and theclip on the rear edge is broken off), apply a lightcoat of primer (3I/ C-100, or equivalent), then applybutyl tape to the quarter glass, as shown. and sealthe body hole with piece of urethane tape.

NOTE:

. Be careful not to touch the quaner glass whereadhesive will be applied,. Do not peel the separator offthe butyltape.

//////// '. 8�u'Jt tape tocarions t3M 8628, or equivetenrl' Thickness:3.2 mm lo.t3 in.lWidth: 6.4 mm {0.25 in.)

BUTYL 13 mmTAPE (0.5 in.l

\\l

,7r--/r4--;*--T-

.. GLASS

UPPERRUEBERDAM

Page 1281 of 2189

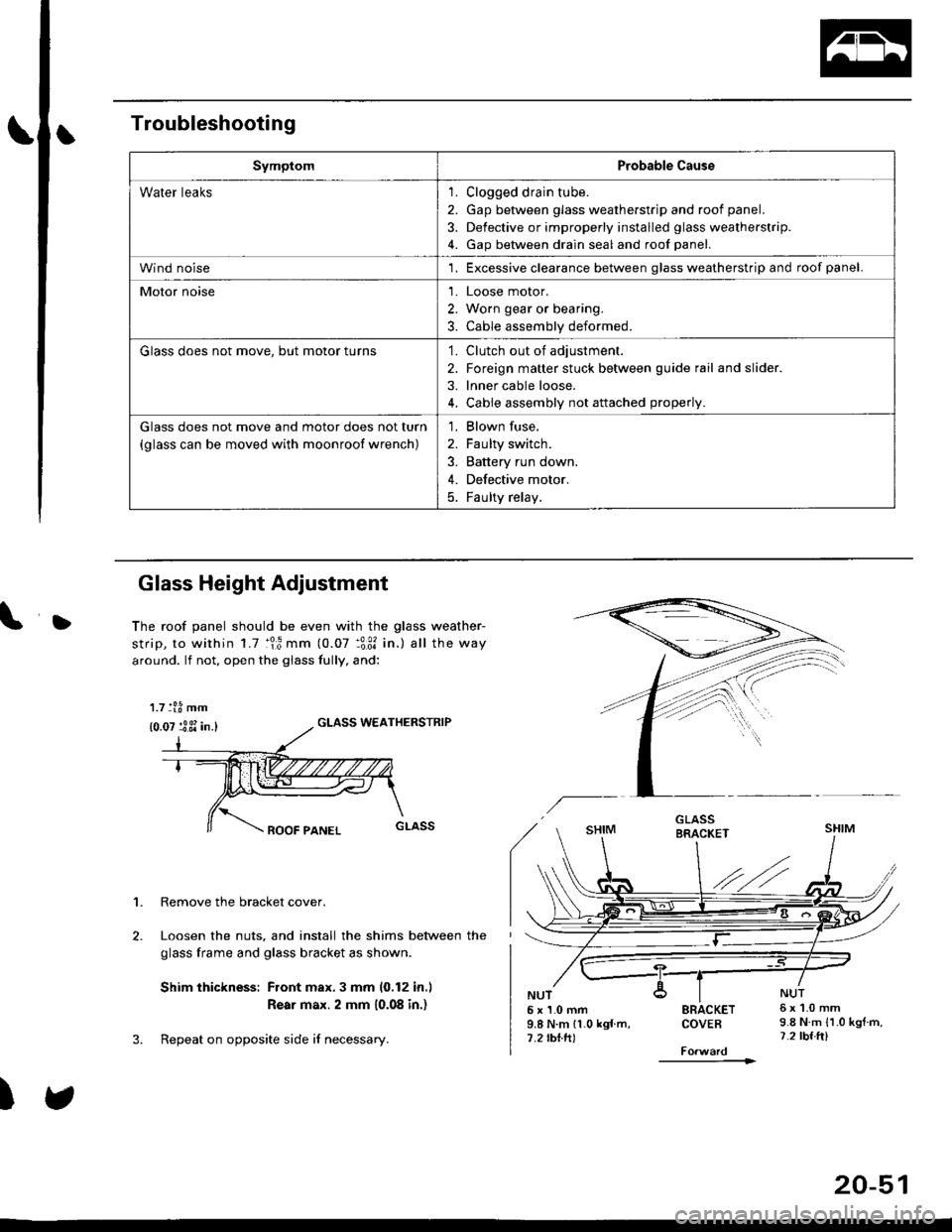

Troubleshooting

SymptomProbable Cause

Water leaks1. Clogged drain tube.

2. Gap between glass weatherstrjp and roof panel.

3. Defective or improperly installed glass weatherstrip.

4. Gap between drain seal and roof panel.

Wind noise'1. Excessive clearance between glass weatherstrip and roof panel.

Motor noise1. Loose motor.

2. Worn gear or bearing.

3. Cable assembly deformed.

Glass does not move, but motor turns'1. Clutch out of adjustment.

2. Foreign matter stuck between guide rail and slider.

3. lnner cable loose.

4. Cable assembly not attached properly.

Glass does not move and motor does not turn

{glass can be moved with moonroof wrench)

1. Blown fuse,

2. Faulty switch.

3. Battery run down.

4. Defective motor.

5. Faulty relay.

D

Glass Height Adjustment

The roof panel should be even with the glass weather-

strip, to within 1.7 :lr3 mm (0.07 :3:31 in.) all the way

around. lf not, open the giass fully, and:

GLASS WEATHERSTRIP

1. Remove the bracket cover.

Loosen the nuts, and install the shims between the

glass frame and glass bracket as shown.

Shim thickness: Front max.3 mm 10,12 in.l

Rear max. 2 mm 10.08 in.)

Repeat on opposite side i{ necessary.

)

5x1.0mm9.8 N.m 11.0 kgf m,7.2 rbtft)

SRACKETCOVEB

----------1>

6x1.0mm9.8 N.m {1.0 kgtm,7.2 tbf.ft)

1.7 tl.8 mm

{0.07 :3 3i in.}

20-51

Page 1285 of 2189

L

L

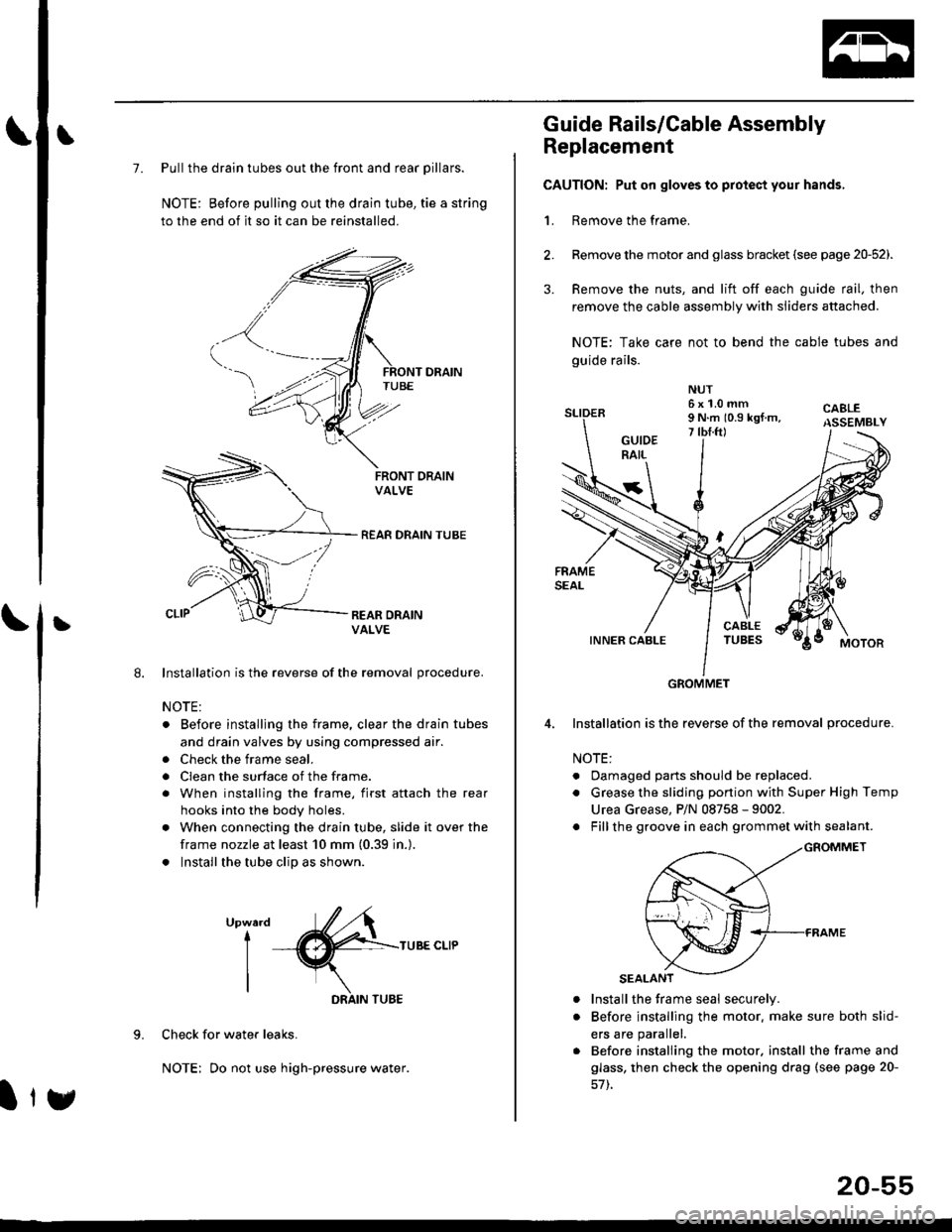

7. Pull the drain tubes out the front and rear pillars.

NOTE: Before pulling out the drain tube, tie a string

to the end of it so it can be reinstalled.

Installation is the reverse of the removal procedure.

NOTE:

. Before installjng the frame, clear the drain tubes

and drain valves by using compressed air.

. Check the frame seal.

. Clean the surface of the frame.

. When installing the frame, first attach the rear

hooks into the body holes.

. When connecting the drain tube, slide it over the

frame nozzle at least 10 mm (0.39 in.).

. Install the tube clip as shown.

UpwardI

I

I

TUBE CLIP

Check for water leaks.

NOTE: Do not use high-pressure water.

DRAIN TUBE

Ity

20-55

Guide Rails/Cable Assembly

Replacement

CAUTION: Put on gloves to protect your hands,

1. Remove the frame.

Remove the motor and glass bracket (see page 20-52).

Remove the nuts, and lift off each guide rail, then

remove the cable assembly with sliders attached.

NOTE: Take care not to bend the cable tubes and

guide rails.

Installation is the reverse of the removal procedure.

NOTE:

. Oamaged parts should be replaced.

. Grease the sliding portion with Super High Temp

Urea Grease, P/N 08758 - 9002.

. Fillthe groove in each grommet with sealant.

a

a

Install the frame seal securely.

Before installing the motor. make sure both slid-

ers are parallel.

Before installing the motor. install the frame and

glass, then check the opening drag (see page 20-

GROMMET