no. 25 HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1067 of 2189

It

12.

13.

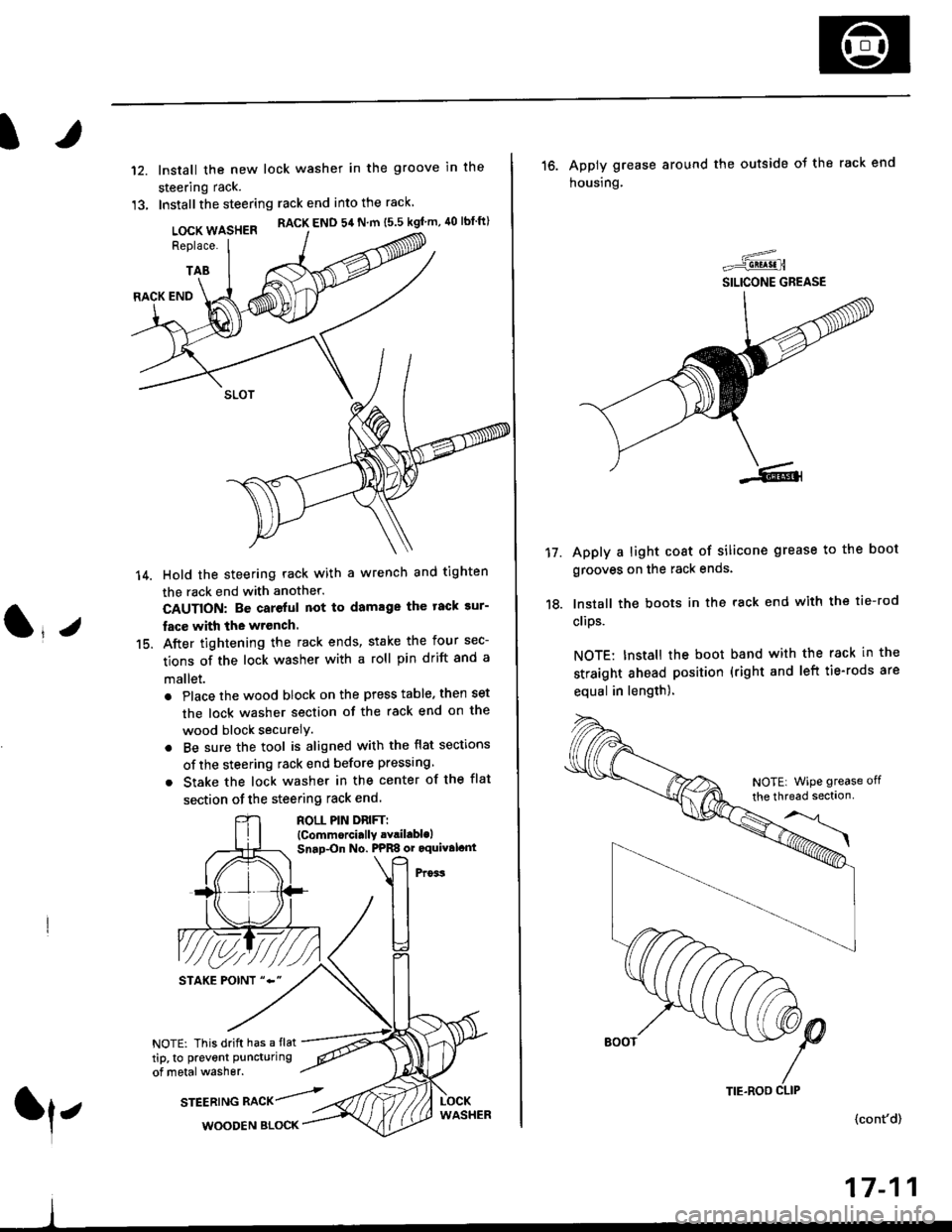

lnstall the new lock washer in the groove in the

steering rack.

Installthe steering rack end into the rack

LOCK WASHER RACK END 54 N m ts.s kgf'm, 40 lbtft)

Replace.

TAB

(l*v

14.

15.

RACK END

Hold the steering rack with a wrench and tighten

the rack end with another.

CAUTION: Be careful not to damage the tack sur-

fac€ with the wrench.

After tightening the rack ends, stake the four sec-

tions of the lock washer with a roll pin drift and a

mallet.

. Place the wood block on the press table. then set

the lock washer section of the rack end on the

wood block securelY.

. Be sure the tool is aligned with the flat sections

of the steering rack end before pressing

. Stake the lock washer in the center of the flat

section of the steering rack end.

ROLL PIN DnlFTl(Commorci.lly .Yril.blolSnap-On No. PPRS or oquival.nt

NOTE: This drift has a flat

tip, to prevent puncturing

of metal washer.

srEEatruG nlCr/rl,WOODEN BLOCK

TIE.ROO CLIP

16. Apply grease around the outside ot the rack end

housing.

Apply a light coat of silicone grease to the boot

grooves on the rack ends.

lnstall the boots in the rack end with the tie-rod

clips.

NOTE: Install the boot band with the rack in the

straight ahead position (right and left tie-rods are

equal in length).

=-..r=-q!q!!.n

SILICONE GREASE

17.

(cont'd)

17-11

NOTE| WiPe grease off

the thread sectlon

Page 1114 of 2189

Steering Gearbox

Reassembly (cont'd)

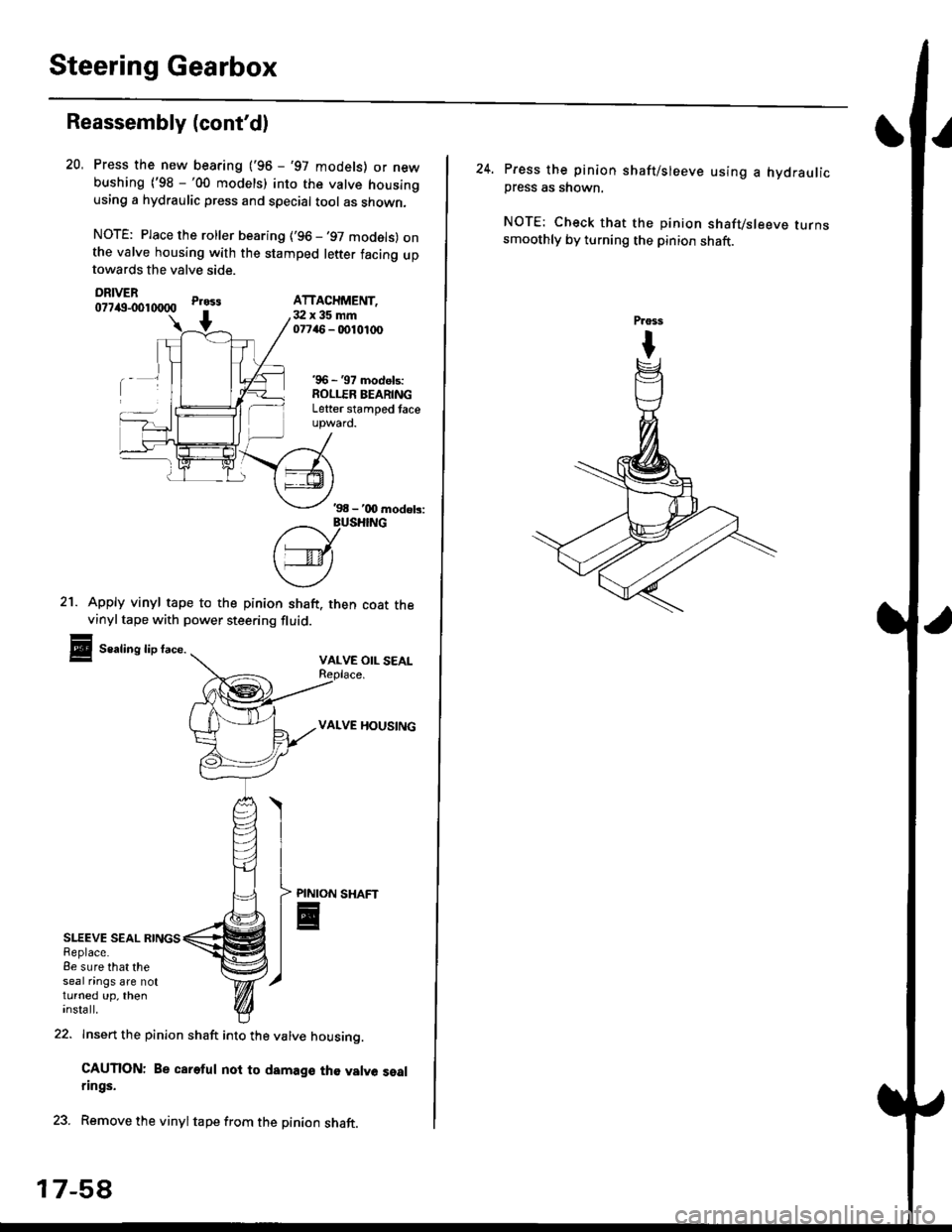

SLEEVE SEAL RINGSReplace.8e sure that theseal nngs are notturned up, theninsta ll.

21. Apply vinyl tape to the pinion shaft. then coat thevinyltape with power steering fluid.

Sealing lip face.VALVE OIL SEAL

VALVE HOUSING

Press the new bearing ('96 - '97 models) or newbushing ('98 -'00 models) into the valve housingusing a hydraulic press and special tool as shown,

NOTE: Place the roller bearing ('96 -'97 models) onthe valve housing with the stamped letter facing uptowards the valve side.

DRIVER077itg-001tXlOO

22. Insert the pinion shaft into the valve housino.

CAUTION: Be careful noi to damage th€ valve sealrings.

23. Remove the vinyltape from the pinion shaft.

20.

Pr033

+3:Ix35mm07746 - 0010,t(x)

'96 - '97 models:ROLLER BEARINGLetter stamped taceupward.

ATTACHMENT,

'98 - '00 modob:

?/_vusHrNG

['---v-lt

\4)

PINION

E

17-5A

24. Press the pinion shaft/sleeve using a hydraulicpress as shown.

NOTE: Check that the pinion shafvsleeve turnssmoothly by turning the pinion shaft.

Page 1126 of 2189

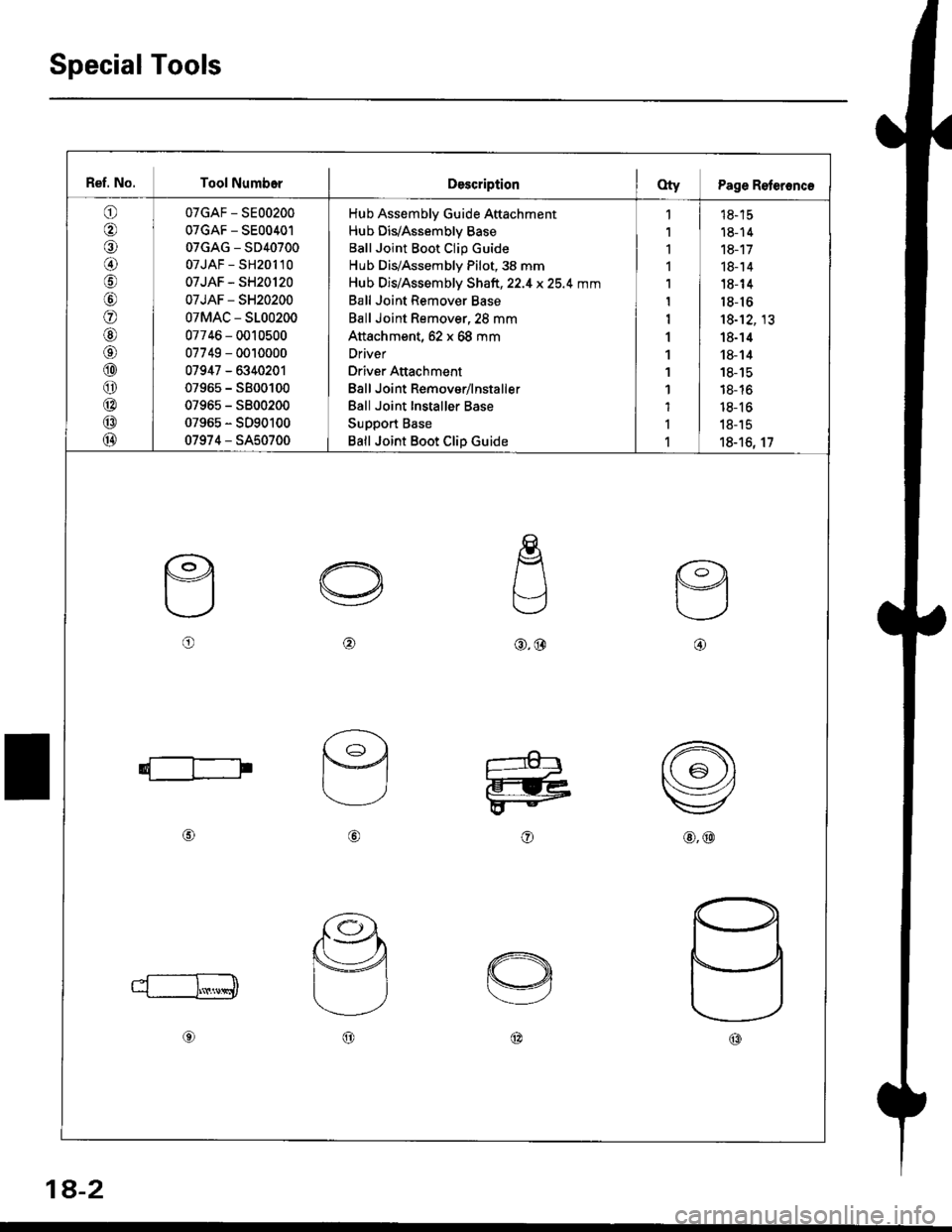

Special Tools

Ref. No. Tool NumborDescriptionOty Page Reteronc€

o

€)

@

\9

o

@aa\

@

o

@

@

@

07GAF - SE00200

07GAF - SE00401

07GAG - SD40700

07JAF - SH201 l0

07JAF - SH20120

07JAF - SH20200

07MAC - S100200

07746 - 0010500

07749 - 0010000

07947 - 6340201

07965 - SB00100

07965 - 5800200

07965 - SD90100

07974 - SA50700

Hub Assembly Guide Attachment

Hub DivAssembly Base

Ball Joint Boot Clip Guide

Hub Dis/Assembly Pilot, 38 mm

Hub Dis/Assembly Shaft,22.4 x25.4 mm

Ball Joint Remover Base

Ball Joint Remover,2S mm

Attachment, 62 x 68 mm

Driver

Driver Attachment

Eall Joint Remover/lnstaller

Ball Joint Installer Base

Support Base

Ball Joint Boot Clip Guide

,|

1

1

1

1

1

1

1

1

1

1

1

I

1

td- tc

18- 14

18-17

18- 14

18- 14

18-16

18-12, 13

18-14

18- 14

18- 15

18- 16

18- 16

18-15

18-16, 17

o@@.@@

@

o@

1a-2

Page 1156 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual Special Tools

Ref. No. I Tool Numbo]DescriplionOty I Page Reference

o07HAE - SG00100

07JAG - SD40100

07914 - SA50001

Brake Spring Compressor

Pushrod Adjustment Gauge

Snap Ring Pliers

19-28, 33

19-22

o HONDA CIVIC 1999 6.G Workshop Manual Special Tools

Ref. No. I Tool Numbo]DescriplionOty I Page Reference

o07HAE - SG00100

07JAG - SD40100

07914 - SA50001

Brake Spring Compressor

Pushrod Adjustment Gauge

Snap Ring Pliers

19-28, 33

19-22

o](/img/13/6068/w960_6068-1155.png)

Special Tools

Ref. No. I Tool Numbo]DescriplionOty I Page Reference

o07HAE - SG00100

07JAG - SD40100

07914 - SA50001

Brake Spring Compressor

Pushrod Adjustment Gauge

Snap Ring Pliers

19-28, 33

19-22

o@

19-2

Page 1197 of 2189

Special Tools

Ret. No. I Tool Number I Description I O,V I page Reference

(!) I 07PM- 0010100 I SCS Service Connector t I 19_s6

19-44

Page 1205 of 2189

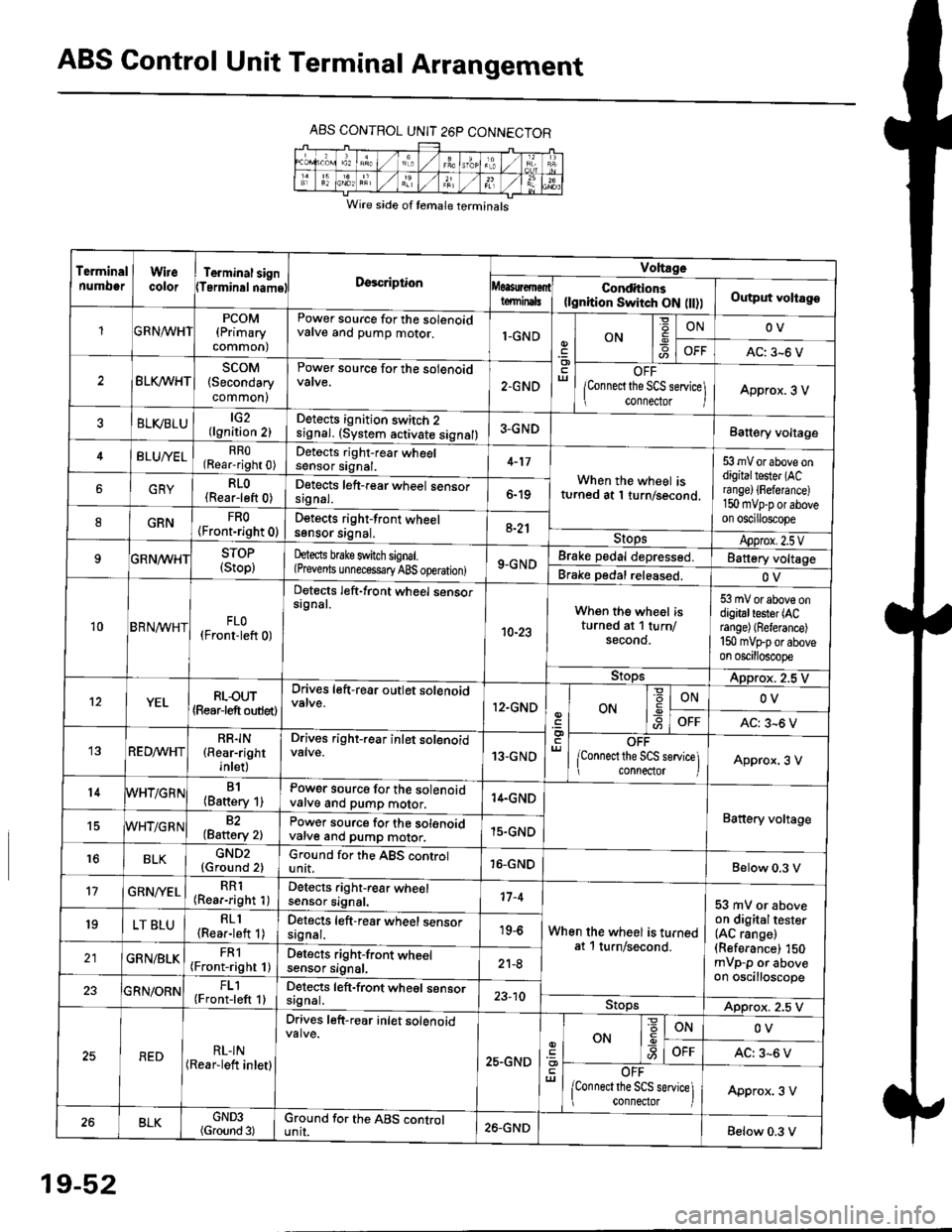

ABS Control Unit Terminal Arrangement

ABS CONTROL UNIT 26P CONNECTOR

Wire side of temale terminals

Terminalnumo0rWirecolorTerminal signTerminalnamoDgscriptionVoltage

Conditions(lgnition Switch ON flt))Output voltagoteminals

PCOM(Primary

common)

Power source for the solenoidvalve and pump motor.1-GNDON

=ONOV

AC: 3-6 V

BLK/WHTscoM(Secondary

common)

Power source for the solenoid

2.GNDOFF

lConnect the SCS service\

conneclor lApprox. 3 V

ELVBLUtG2(lgnition 2)Detects ignition switch 2

!9nal. (system activate signal)3-GNDBatt€ry voltage

BLU/YELRRO(Rear-right 0)Detects right-rear wheelsensor signal.4-17

When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester (ACra nge) {Fefera nce)150 mvp-p or aboveon oscilloscope

6GRYRLO(Rear-left 0)Detects left-rear wheel sensorsrgnal.6-19

8GRNFRO(Front-right 0)D€tects right-front wheelsgnsor srgnal,a-21StopsApprox.2.5VSTOP(Stop)hects brake switch signal.(Prevents unnecess€ry ABS operation)9-GNDBrake pedal depressed.Battery voltage

Brake pedal released.OV

10BRN^/vHTFLO(Front-left 0)

Detects left-front wheel sensorsignal.

10-23

When the wheel isturned at 1 turn/secono.

53 mV or above ondigitaltester (ACrange) (Referance)

150 mVFporaboveon oscilloscope

9!opsApprox. 2.5 V

12YELRLOUT(Rearjeft outlet)

Drives left-rear outlet solenoid

12.GNDON-9ONOV

OFFAC: 3^6 V

REDMHTRR]N(Rear-right

inlet)

Drives right-rear inlet solenoidvalve.13-GNDOFF

lconnect the SCS service]i connector IApprox. 3 V

14B1(Battery 1)Power source for the solenoidvatve and pump motor.14.GND

Battery voltage15WHT/G R N82(Baftery 2)Power source for the solenoidvarve ano pump motor.15.GND

r6BLKGND2{Ground 2)Ground for the ABS controlunit.16-GNDBelow 0.3 V

17GRN/'/ELRR1(Rear-right 1)Detects right-rear wheelsensor signal.17-4

When the wheel is turnedat 1 turn/second.

53 mV or aboveon digitaltester(AC range)(Referance) 150mVp-p or aboveon oscilloscope

19LT BLURLl(Rea.-left 1)Detects left-rear wheel sensorsagnal.19-6

GRN/BLKFRl(Front-right 1)Detects right-front wheelsensor signal.21-8

FL1(Front-left 1)Detects left-front wheel sensorsignal.23-10StopsApprox. 2.5 V

REDRL-IN(Rear-lett inletl

Drives left-r€ar inlet solenoid

25.GND

ut

ON

'6

-9ONOV

OFFAC: 3-6 V

OFF

lconnect the SCS service] connector lApprox. 3 V

BLKGND3(Ground 3)Ground for the ABS cgntrolunit.26.GNDBelow 0.3 V

19-52

Page 1213 of 2189

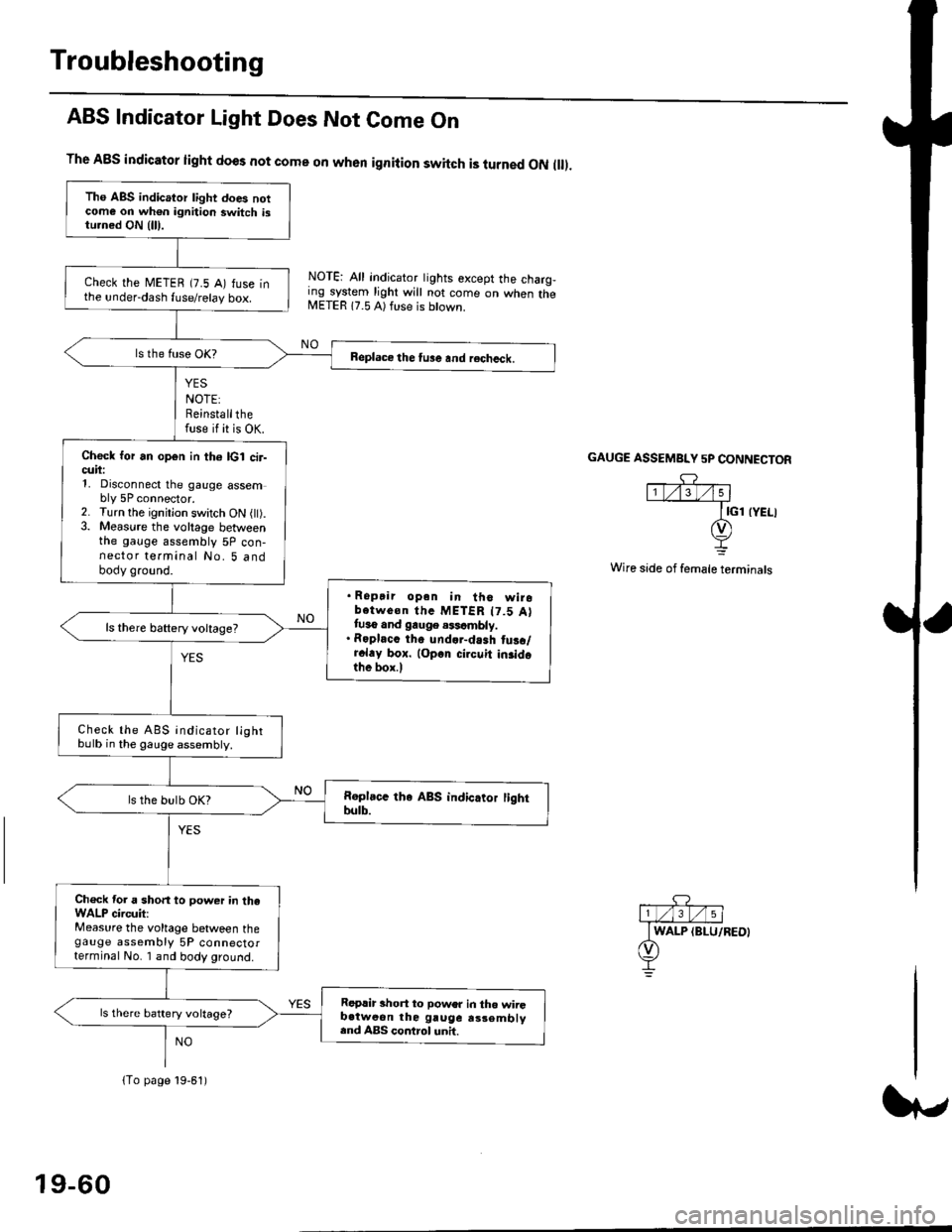

Troubleshooting

ABS Indicator Light Does Not Come On

YES

NOTE:Reinstallthefuse if it is OK.

The A8S indicator light does not come on when ignition switch is turned ON ll.

NOTE: All indicator tights except the charg,ing system light will not come on when theMETER 17.5 A) ft se is btown.

NO

GAUGE ASSEMBI"Y 5P CONNECTOR

Wire side of female terminals

Tho ABS indicator light does notcome on wh€n ignition switch istu.ned ON {lll.

check the METEB (7.5 A) fuse inthe under-dash fuse/relay box.

Beplace the tu3e and recheck.

Check for an open in th6 lcl cir-cuii:1, Disconnect the gauge assembly 5P connector.2. Turn the ignitjon switch ON l).3. Measure the voltage betweenthe gauge assembly 5P con-nector terminal No. 5 andbody ground.

. Ropair opan in tho wirobotwe€n thc METER t7.5 Attuso and gauge .$cmbly.. Roplacc th. und.r-dash tus./r.l.y box. lop.r cirouit in3idothe box.l

ls there baftery voltage?

Check the ABS indicator lightbulb in the gauge assembly.

ls the bulb OK?

Ch€ck tor a short to power in theWALP circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. I and body ground.

Replir short to power in tho wiiGb.tweon the gruge rs3embly.nd ABS control unh.

ls there battery voltage?

lTo page 19-61)

19-60

Page 1214 of 2189

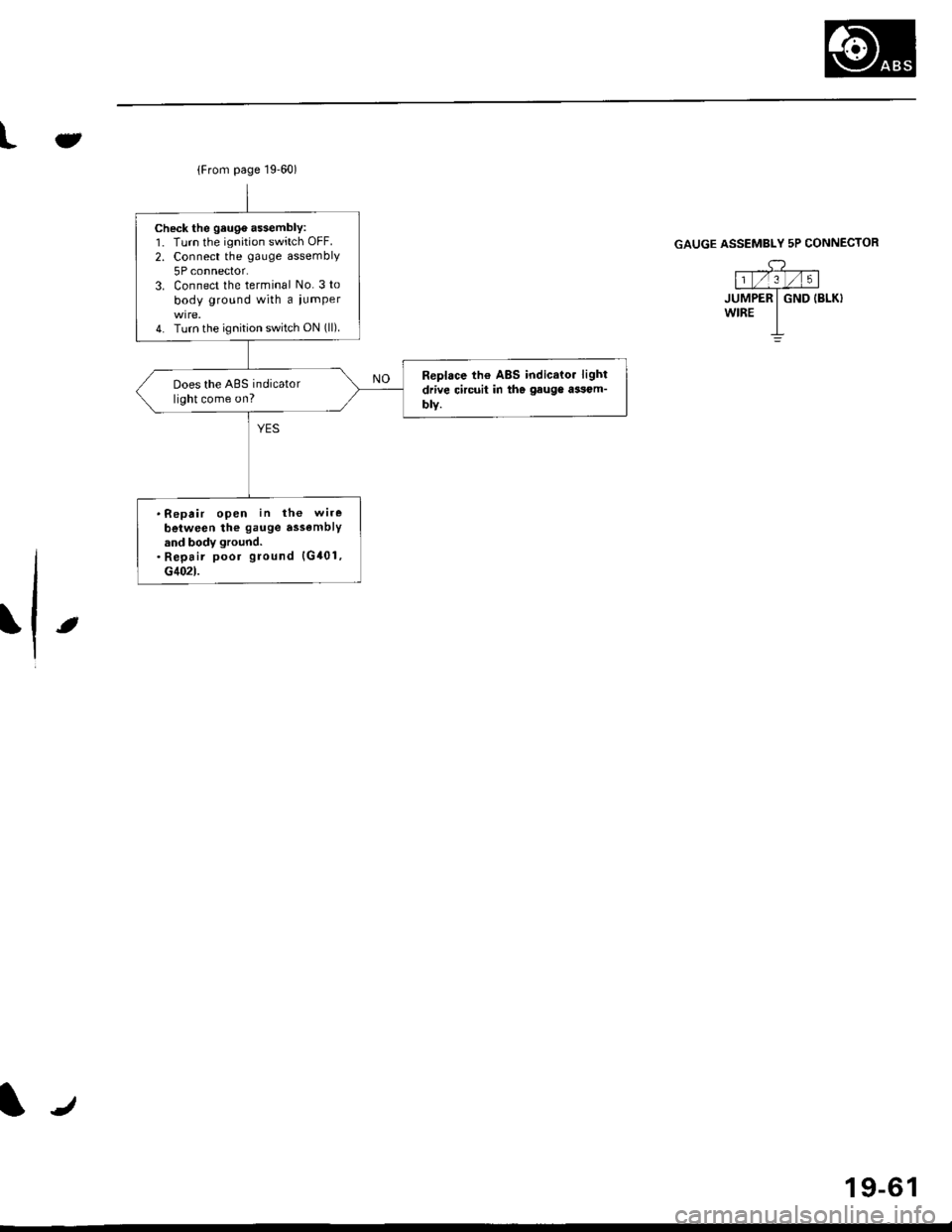

{From page 19.60)

Check the geuge a$embly:1. Turn the ignition switch OFF.

2. Connect the gauge assembly

5P connector.3. Connect the terminal No. 3 to

body ground with a iumper

4. Turn the ignition switch ON (ll).

Replace th€ ABS indicato. light

drive circuit in the gauge ai3om-

blY.

Does the ABS indicatorlight come on?

.Repair open in the wire

beiween the gauge assemblYand body ground.. Repair poor ground {G401,G402t.

Jt

GAUGE ASSEMBLY 5P CONNECTOR

,c? "l1t/'.lt/t5 |

JUMPER I GND IBLK}wrRE I-L

t

19-61

Page 1215 of 2189

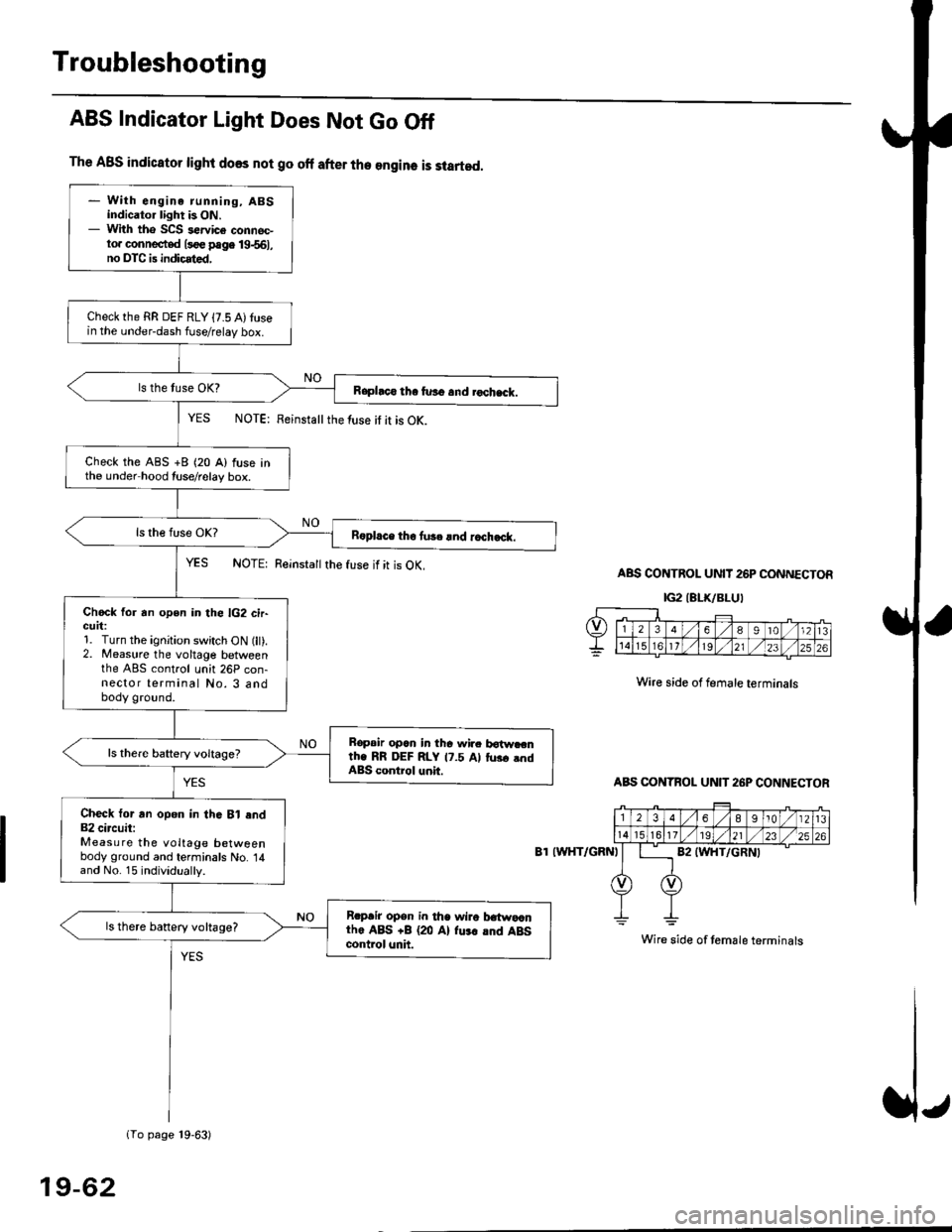

Troubleshooting

The ABS indicator light does not go off after the engine is started.

- With engine running, ABSindicator light is ON.- With tho SCS sewice connec-to. connected l3oe page 19-561,no DTC is indicated,

Checkthe RR DEF RLY {7.5 A)tusein the under-dash fuse/relay box.

Raphco tha furo and rochack.

Check the ABS +B (20 A) fuse inthe under hood tuse/relay box.

R6pl.ce tho tu3c lnd r.ch.ck.

Chock for an open in the lG2 cir-GUrt:1. Turn the ignition switch ON (lt).2. Measure the voltage betweenthe ABS control unh 26P con-nector terminal No. 3 andbody ground.

Bopair opcn in tha wir. botw.cnth. RR DEF RLY 17.5 Al tus. .ndABS control unit.

Check tor an opon in thG Bl end82 circuit:Measure the voltage betweenbody ground and terminals No. 14and No. 15 individually.

Rrpair opsn in tha wiro t atwa,anthe ABS +B (20 Al fu.r .nd ABScontrol unh.

ls there banery voltage?

1To page 19-63)

ABS Indicator Light Does Not Go Off

YES NOTE: Feinstattthe luse it it is OK.

YES NOTE: Reinsta

the fuse if it is OK.ABS CONTROL UNIT 26P CONNECTOR

IG2IELK/BLUI

Wire side of female terminals

ABS CONTBOL UN]T 26P CONNECTOR

8T IWHT/GRNI

Wire side of temale terminals

19-62

Page 1216 of 2189

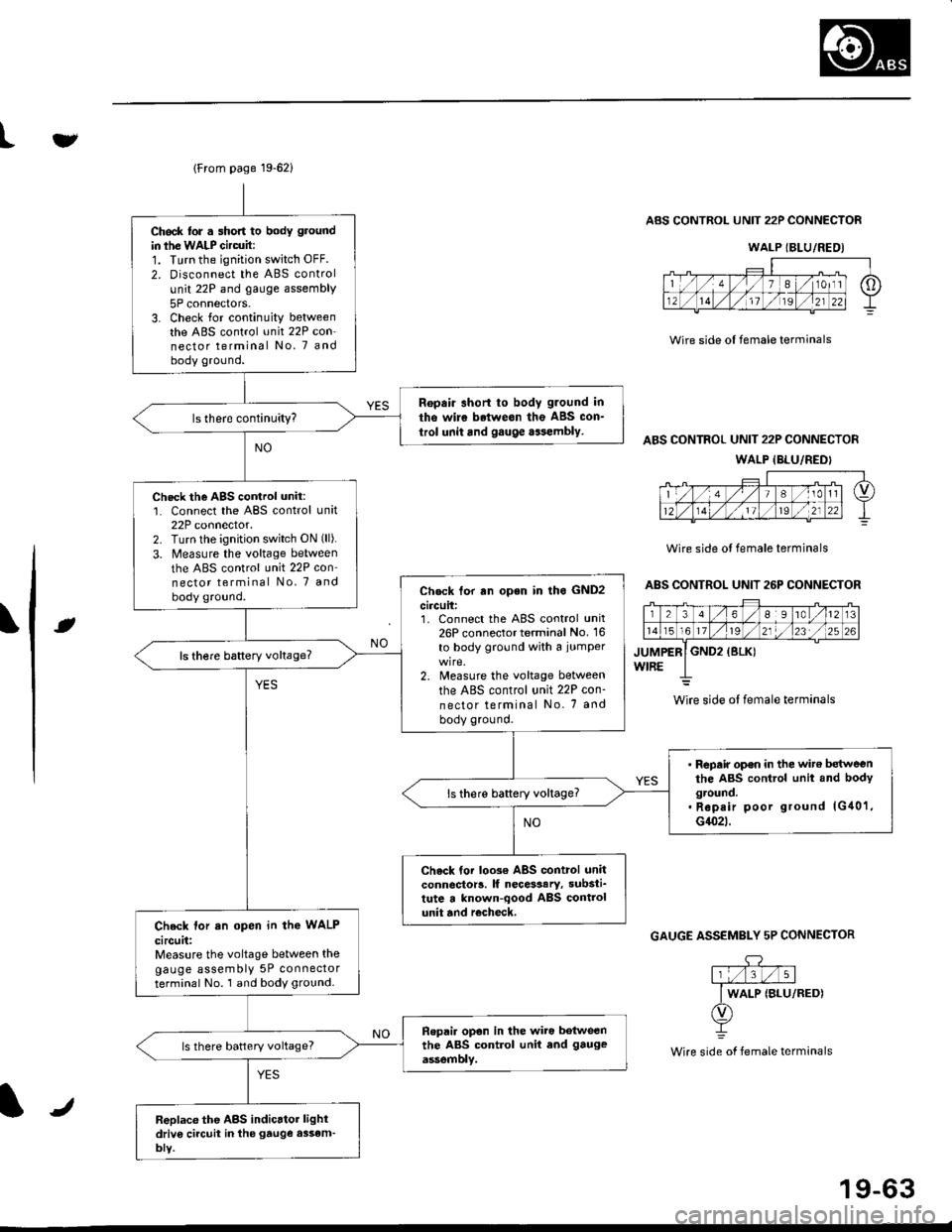

lFrom page 19-621

Ch6ck lor . short to body ground

in ihe WALP Gircuit:1. Turn the ignition switch OFF.

2. Disconnect the ABS control

unit 22P and gauge assembly

5P connectors.3. Check for continuity betweenthe ABS control unit 22P con-nector terminal No. 7 andbody ground.

Ropair short to body g.ound in

tho wire betweon the ABS con_

trol unit and gauge aasembly.

Check the AgS cortrol unit:1. Connect the ABS control unit22P connector.2. Turn lhe ignition switch ON (ll).

3. Measure the voltage between

the ABS control unit 22P con'nector terminal No, 7 and

body ground.Check tor rn open in lho GND2

circuit:1. Connect the ABS control unit26P connector terminal No. 16

to body ground with a iumper

2. Measure the voltage between

the ABS control unit 22P con-

nector terminal No. 7 and

body ground.

ls there baftery voltage?

' Repair op€n in the wit€ betweenthe ABS control unit and bodyground.. Rep.ir poor ground lG40'1,G1(}2t.

ls there battery voltage?

Check tor loo3€ ABS control unitconnector!. lf necesaary, substi_tute a known-qood ABS controlunit and r€check,Check lor an open in the WALP

circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. 1 and body ground.

Ropai. opon in the wiro botweenthe ABS control unit end gauge

assemblv.ls there battery voltage?

Replace the ABS indicrtor lightdriv6 ci.cuit in the gtuge assem-bly.

tv

Wire side ol female terminals

ABS CONTROL UNIT 22P CONNECTOR

ABS CONTROL UNIT 22P CONNECTOR

WALP {BLU/REDI

Wire side ol female terminals

ABS CONTROL UNIT 26P CONNECTOR

rt

GAUGE ASSEMBLY 5P CONNECTOR

.DY

Wire side of female terminals

WALP {BLU/REDI

wire side ol female terminals

J

19-63