ac system HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 898 of 2189

Description

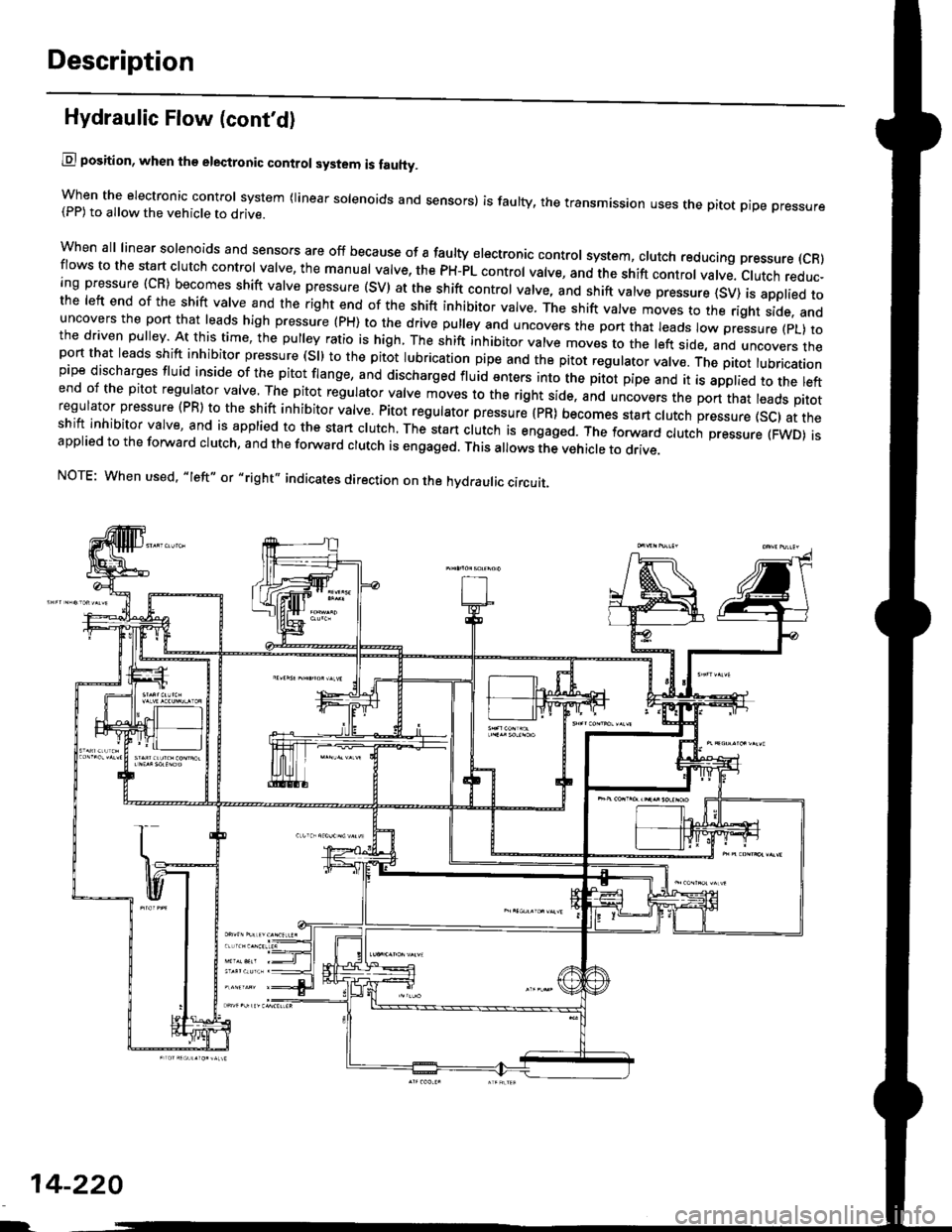

Hydraulic Flow (cont'd)

lll position, when th€ electronic control system is fauhy.

when the electronic control svstem (linear solenoids and sensors) is faulty, the transmission uses the pitot pipe pressure(PP) to 311o- rh" u"hicle to drive.

when all linear solenoids and sensors are off because of a faulty electronrc control system, clutch reducing pressure (cR)flows to the start clutch control valve, the manual valve, the PH-PL control valve, and the shift control valve. clutch reduc-ing pressure (cR) becomes shift varve pressure (sV) at the shift contror varve, and shift varve pressure {sv) is appried tothe left end of the shift valve and the right end of the shift inhibitor valve. The shift valve moves to the right side. anduncovers the pon that leads high pressure (PH) to the drive pulley and uncovers the po.t tlr"t r""1" ro,,"-pressure (pL) tothe driven pulley At this time, the pulley ratio is high, The shift inhibitor valve moves to the left side, and uncovers theport that leads shift inhibitor pressure (Sll to the pitot lubrication pipe and the pitot regulator valve. tne prtot lubricationpipe discharges fluid inside of the pitot flange, and discharged fluid enters into the pitot pipe and it is applied to the leftend of the pitot regulator valve. The pitot regulator valve moves lo the right side, and uncovers the port that leads pitotregulator pressure (PR) to the shift inhibitor valve. Pitot regulator pressure {pR) becomes start clutch pressure {sc1 at theshift inhibitor valve, and is applied to the stan clutch. The stan clutch rs engaged. The forward clutch pressure (FWD) isapplied to the forward crutch, and the forward crutch is engaged. This alows the vehicre to drive.

NOTE: When used. "|eft" or ,,right', indicates direction on the hydraulic circuit.

14-220

I.

Page 899 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual E] position, when the elestronic Gontrol system is faulty

The flow of tluid up to the drive pulley, the driven pulley and the start clutch is the same as in El position

The manual valve is shifted i HONDA CIVIC 1999 6.G Workshop Manual E] position, when the elestronic Gontrol system is faulty

The flow of tluid up to the drive pulley, the driven pulley and the start clutch is the same as in El position

The manual valve is shifted i](/img/13/6068/w960_6068-898.png)

E] position, when the elestronic Gontrol system is faulty'

The flow of tluid up to the drive pulley, the driven pulley' and the start clutch is the same as in El position

The manual valve is shifted into the lE position' and it uncovers the port that leads reverse brake pressure {RVS} to the

reverse inhibitor valve. Reverse ,"nlu-i,"ip*r""i" (Rl) is applied to.the right end of the reverse inhibitor valve because of

afaultyinhibitorsolenoid.The'"t'",""inftiUito'valvemovestotheleftside'anduncoverstheportthatleadsreverse

brake pressure {RVS) to the ,"u"r." ir"t"- cru,ch reducing pressure (cR) becomes reverse brake pressure (RVS) at the

manual valve, and,lows to the ,e

"rs" lr"re. ttre reverse brake is engaged and locks the ring gear' This allows the vehi-

cle to drive in reverse.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit'

14-221

Page 905 of 2189

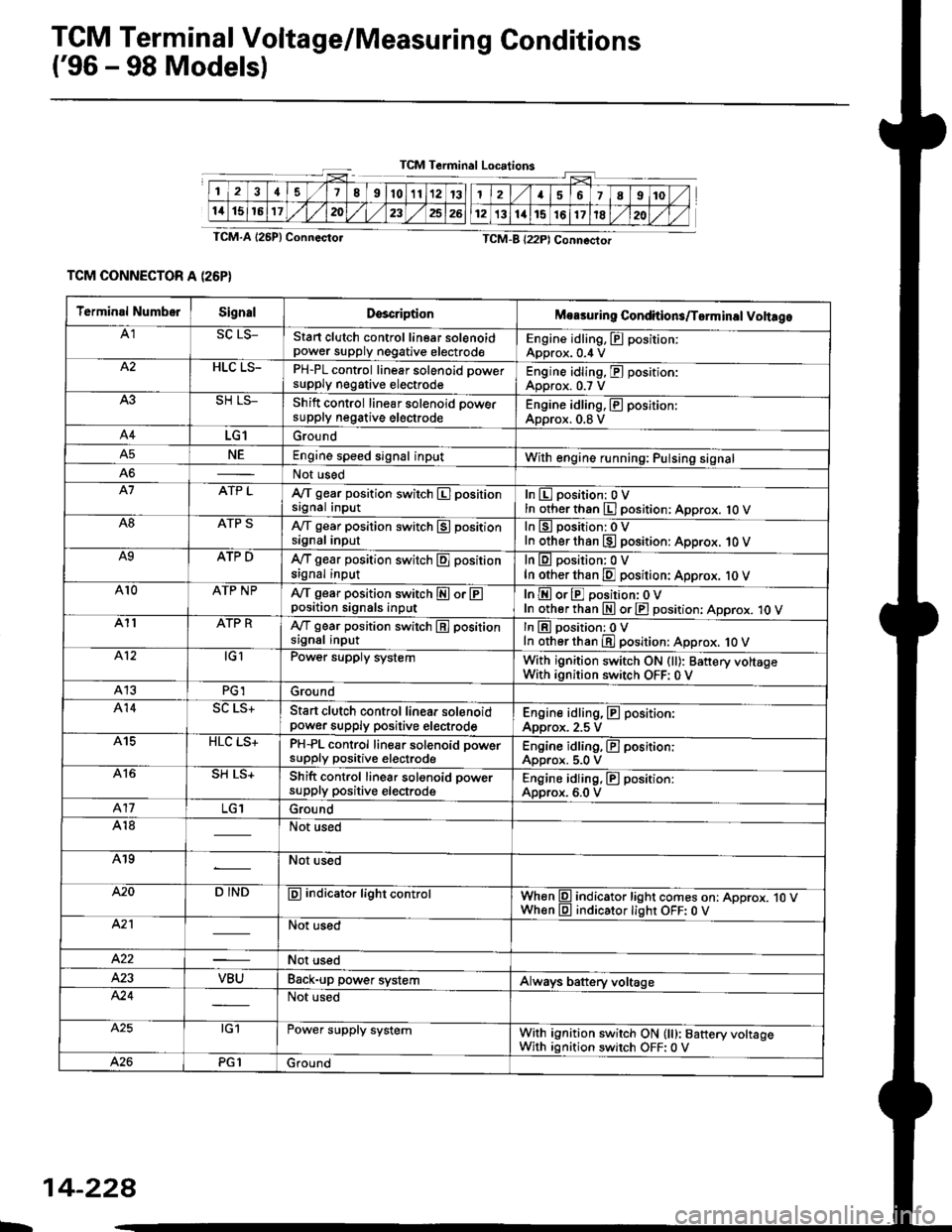

TCM Terminal Voltage/Measuring Gonditions

('96 - 98 Modelsl

TCM Terminal Loc.tions

TCM-A l25P) Connecto.

TCM CONNECTOR A (26P}

TCM-B (22P) Connectot

2418910111213

1115161720232526

Terminal NumbetSignalDsscriptionMoasuring Conditions/Torminsl Vohrgo

A1SC LS_Stan clutch control linear solenoidpower supply negative electrodeEngine idling, E position:Approx. 0.4 VHLC LS-PH-PL control linear solenoid Dowersupply negative electrodeEngine idling, E position:Approx. 0.7 V

Shift control linear solenoid oowersupply negative electrodeEngine idling, E position:Approx. 0.8 V

A4LG1Ground

NEEngine speed signal inputWith engine running: Pulsing signalA6Not used

A7ATP LA/f gear position switch El positionsignal inputInEposition:OVIn other than El position: Approx. 1O VA8ATP Sly'T gear position switch E positionsignal inputIn lg position: 0 VIn other than E position: Approx. 10 VA9ATP DA{/T gear position switch E positionsignal inputIn lll position: 0 VIn other than E position: Approx. 10 VAr0ATP NPA,/T gear position switch E or Eposition signals inputInEorEposition:oVIn otherthan E orE position: Approx. 1O VA11ATP RA,/T gear position switch E positionsignal inputIn lE position: 0 VIn other than E position: Approx. 1O VA.12tGlPower supply systemWith ignition switch ON (ll): Banery voltsgeWith ignition switch OFF: 0 VA13PG1Ground

414Start clutch control linea. solenoidpower supply positive electrodeEngine idling, E position:Approx. 2.5 VA15HLC LS+PH-PL control line8|. solenoid powersupply positive electrodeEngine idling, El position:Approx. 5.0 VA16SH LS+Shift control linear solonoid oowersupply positive electrodeEngine idling, E position:Approx. 6.0 V417Ground

A18Not used

A19Not used

420D INDE indicator light controlWhen l9l indicator light comes on: Approx. jO VWhen lll indicator lighr OFF: 0 VA2'lNot used

422Not used

VBUBack-up power systemAlways battery voltage424Not used

A.25tG1Power supply systemWith ignition switch ON (lt): Baftery voltageWith ignition switch OFF:0 VPG1Ground

L

14-228

Page 907 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual PCM Circuit Diagram (A/T Control System: gg - 00 Models)

UADEF DSIFUSSFEUY 8OXr{o.2s (7 5A)

tGNtTtc{lSWTCHUNDER.OASNFUSF]NEUY 8OI

iPrE: T ro sv

INlD

,:--

^1 GETB POSITIoi{

14-230 HONDA CIVIC 1999 6.G Workshop Manual PCM Circuit Diagram (A/T Control System: gg - 00 Models)

UADEF DSIFUSSFEUY 8OXr{o.2s (7 5A)

tGNtTtc{lSWTCHUNDER.OASNFUSF]NEUY 8OI

iPrE: T ro sv

INlD

,:--

^1 GETB POSITIoi{

14-230](/img/13/6068/w960_6068-906.png)

PCM Circuit Diagram (A/T Control System: 'gg - 00 Models)

UADEF D'SIFUSSFEUY 8OXr{o.2s (7 5A)

tGNtTtc{lSWTCHUNDER.OASNFUSF]NEUY 8OI

iPrE: T ro sv

INlD

,:--

^1 GETB POSITIoi{

14-230

Page 909 of 2189

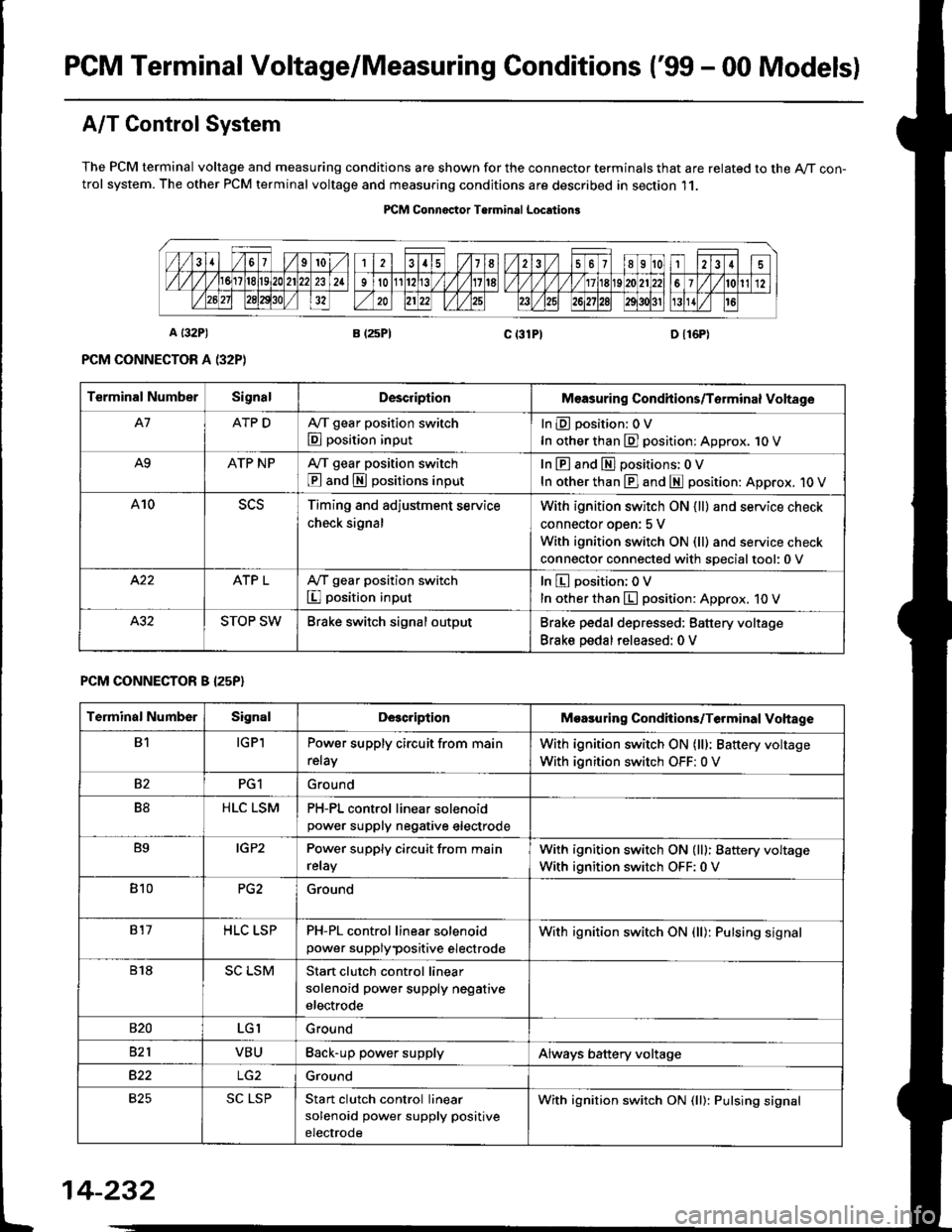

PGM Terminal Voltage/Measuring Conditions ('99 - 00 Modelsl

A/T Control System

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A/T con-trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

PICM Connoctor Terminrl Location3

Terminal NumberSignalDescriplionMeasuring Condhions/Torminal Voltage

A7ATP DA,/T gear position switch

E position input

InEposition:OV

In other than E] position: Approx. 1O V

A9ATP NPA/T gear position switch

@ and S positions input

In E and El positions: 0 V

In other than E] and E position: Approx. 1O V

A10Timing and adjustment service

check signal

With ignition switch ON {ll} and service check

connector oDen: 5 V

With ignition switch ON (ll) and service check

connector connected with soecialtool:0 v

ATP LA,/T gear position switch

I position input

In E position; OV

In other than E position: Approx. 10 V

STOP SWBrake switch signal outputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

PCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMoasuring Condhions/Terminal Vohage

B1IGPlPower supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF: 0 V

82PG1Ground

B8HLC LSMPH-PL control linear solenoidpower supply neqative electrode

B9IGP2Power supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF:0 V

810PG2Ground

817HLC LSPPH-PL control linear solenoid

power supplypositive electrode

With ignition switch ON {ll): Pulsing signal

818SC LSMStart clutch control linear

solenoid power supply negative

electrode

s20LGIGround

821VBUBack-up power supplyAlways battery voltage

B22Ground

825SC LSPStan clutch control linear

solenoid power supply positive

electrode

With ignition switch ON (ll): Pulsing signal

t

14-232

Page 911 of 2189

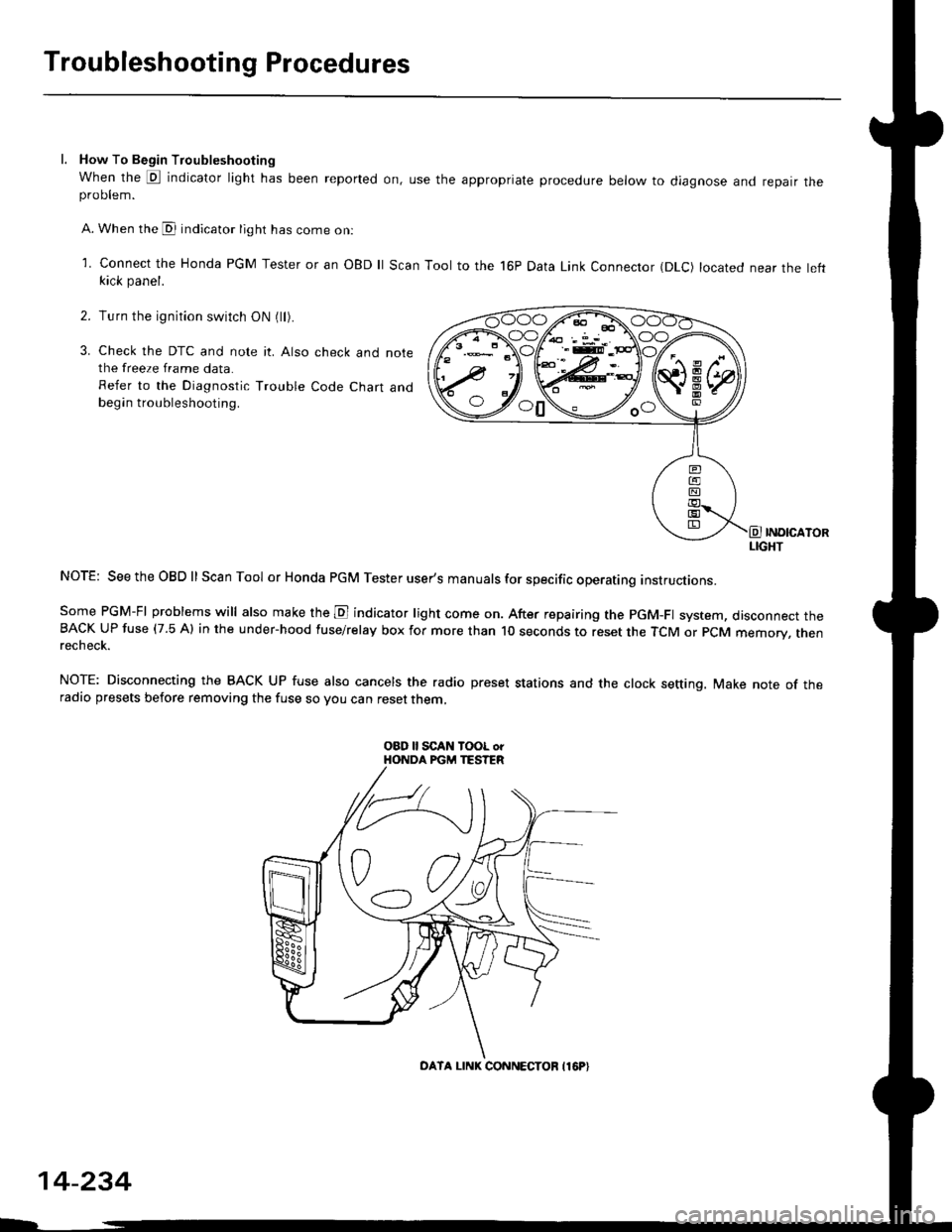

Troubleshooting Procedures

l. How To Begin Troubleshooting

When the E indicator light has been reported on, use the appropriate procedure below to diagnose and repatr theproDlem.

A. When the @ indicator light has come on:

l connect the Honda PGM Tester or an oBD ll Scan Tool to the 16P Data Link Connector (DLc) located near the leftkick panel.

Turn the ignition switch ON (ll).

Check the DTC and note it. Also check and notethe freeze frame data.

Refer to the Diagnostic Trouble Code Chart andbegin troubleshooting.

INOICATORLIGHT

NOTE: SeetheOBDll Scan Tool or Honda PGM Tester user's manuals for specific operating instructions.

Some PGM-FI problems will also make the E indicator light come on. After repairing the pGM-Fl system, disconnect theBACK UP fuse (7.5 Al in the under-hood fuse/relay box for more than l0 seconds to reset the TCM or PCM memory, rnenrecheck.

NOTE: Disconnecting the BACK UP fuse also cancels the radio preset stations and the clock setting. Make note of theradio presets before removing the fuse so you can reset them,

2.

3.

o0\e--loo

OATA LINK CONNECTOB I16P}

14-234

Page 912 of 2189

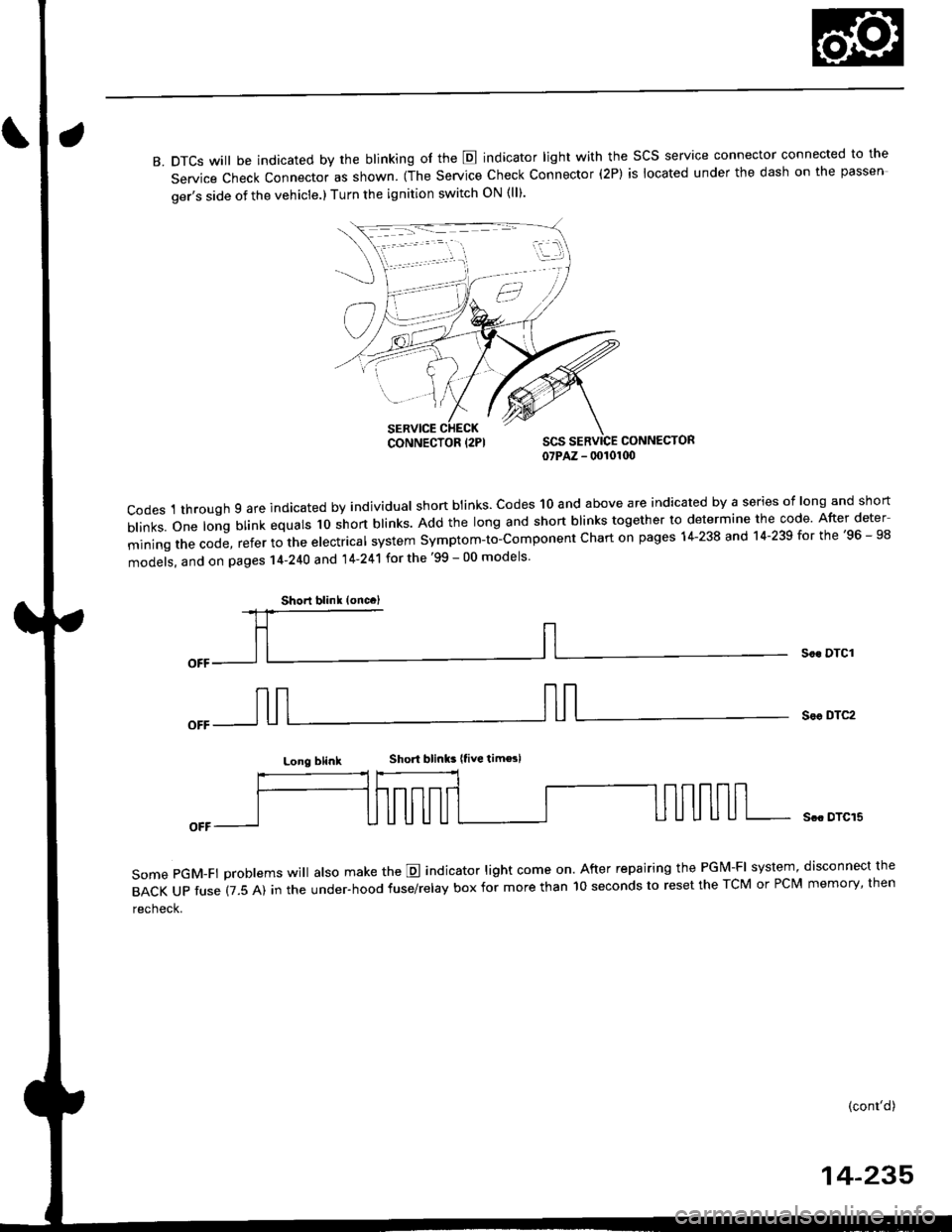

B. DTCS will be indicated by the blinking of the E indicator light with the SCS service connector connected to the

Service Check Connector as shown. (The Service Check Connector (2P) is located under the dash on the passen

ger's side of the vehicle.) Turn the ignition switch ON (ll).

CONNECTOR07PAZ - 00101(x)

codes 1 through 9 are indicated by individual shon btinks. codes 10 and above are indicated by a series of long and short

b|inks.one|ongblinkequa|sloshortb|inks.Addthe|ongandshortb|inkstogethertodeterminethecode.Afterdeter

miningthecode,refertothee|ectrica|systemsymptom-to-componentchartonpagesl4-238and14.239forthe,96_98

models, and on pages 14-240 and 14'241 for the '99 - 00 models

Soc DTCI

Sor DTC2

Long blinkShort blinks |tive tim€sl

some pGM-Ft problems wi

atso make the E indicator light come on. After repairing the PGM-FI system, disconnect the

BACKUPfuse(7.5A)intheUnder.hoodfuse/re|ayboxformorethanl0secondstoresettheTcMorPcMmemory,then

recheck.

Scc DTCI5

(cont'd)

14-235

iii:j

,,,/

CONNECTOR {2PI

Shorl blink (oncc)

Page 913 of 2189

Troubleshooting Procedures

(cont'd)

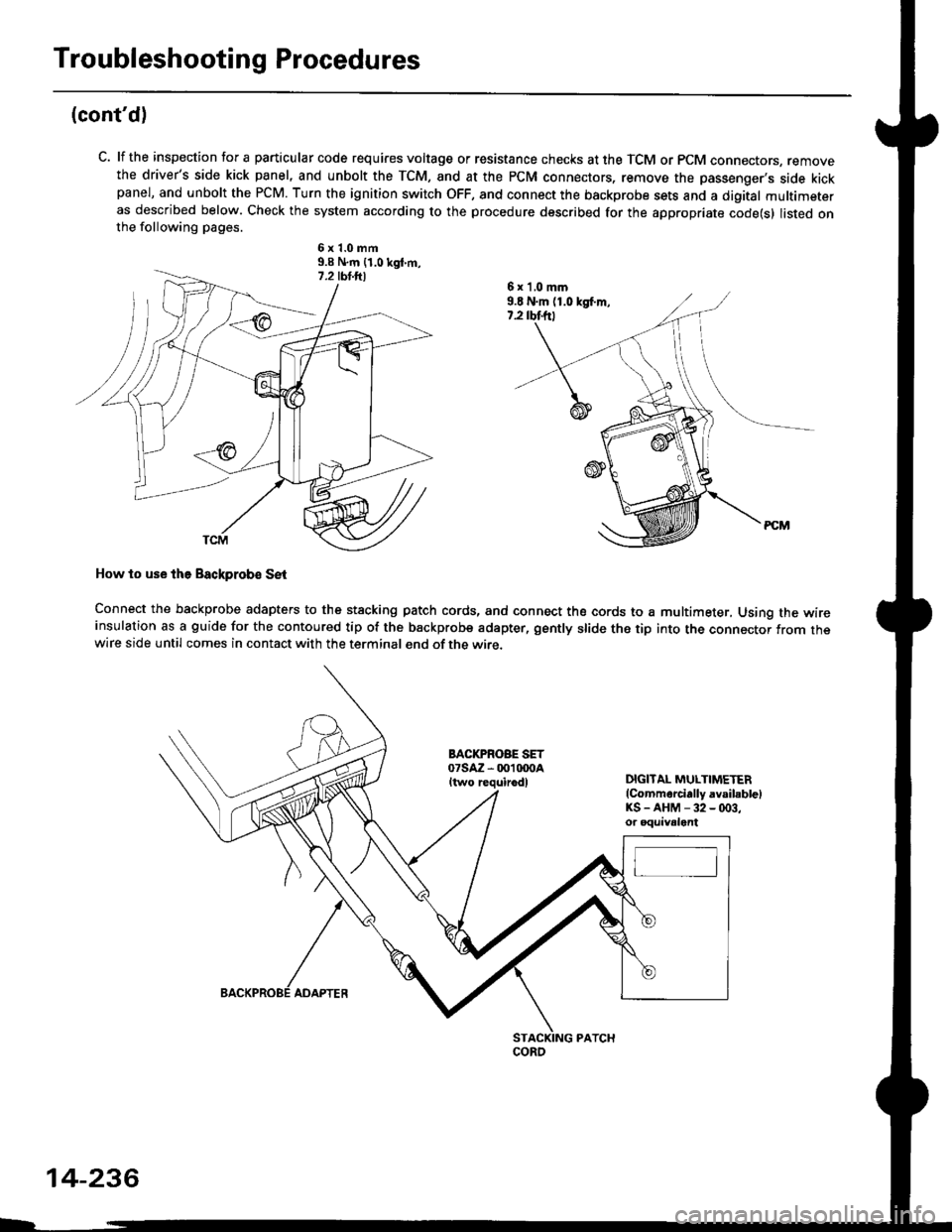

C. lf the inspection for a particular code requires voltage or resistance checks at the TCM or PCM connectors, removethe driver's side kick panel, and unbolt the TCM, and at the PCM connectors, remove the passenger's side kickpanel, and unbolt the PCM. Turn the ignition switch OFF, and connect the backprobe sets and a digital multimeteras described below. Check the system according to the procedure described for the appropriate code(s) listed onthe following pages.

6x1.0mm9.9 N.m {1.0 kgt m,

How to use lhe Backprob€ SE{

Connect the backprobe adapters to the stacking patch cords, and connect the cords to a multimeter, Using the wireinsulation as a guide for the contoured tip of the backprobe adapter, gently slide the tip into the connector from thewire side until comes in contact with the terminal end of the wire.

BACI(PROBE SET07saz - 001 txtoaItwo requirodlDIGITAL MULTIMETER(Commarcially avsibblelKS-AHM-32-(x)3,or oquivalent

6 x 'l,0 mm9.E N.m (1.0 kgf.m,7.2 rbtftt

coRo

14-236

ADAPTER

Page 915 of 2189

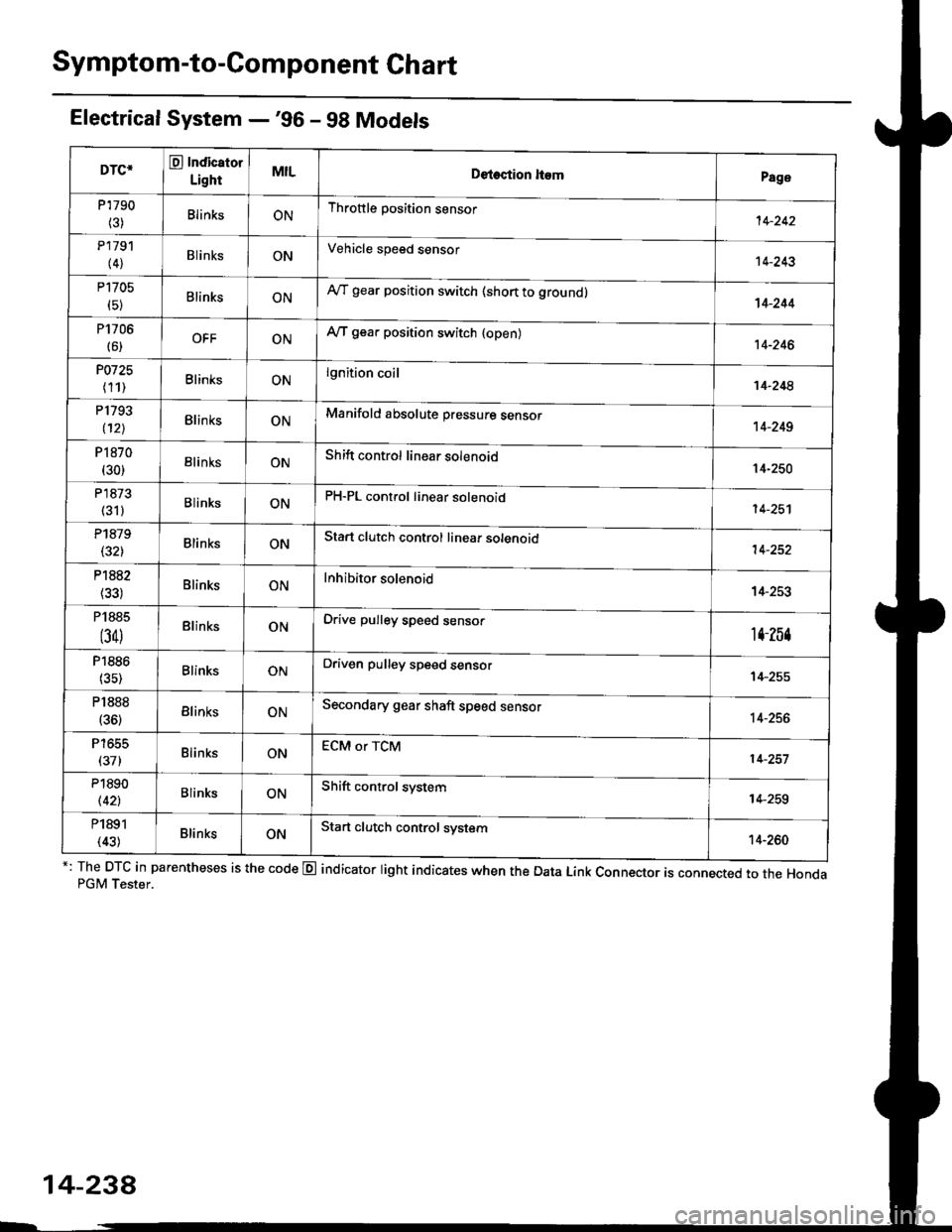

Symptom-to-Component Chart

Electrical System -'96 - 98 Models

*: The DTC in parentheses is the code @ indicator light indicates when the Data Link Connector is connected to the HondaPGM Tester.

DTC*O Indicator

LightMILDetection ltemPage

P1790

(3)BlinksONThrottle position sensor14-242

P179'l

(4)BlinksONVehicle speed sensor14-243

P1705

(5)BlinksONAy'T gear position switch (short to groundl't 4-244

P1706

(6)OFFONA/T gear position switch {open)14-246

P0725

(11)BlinksONlgnition coil14-248

P1793

112lBlinksONManifold absolute pressure sensor14-249

P 1870(30)BlinksONShift control linear solenoid14-250

P'1873

(311BlinksONPH-PL control linear solenoid14-25'l

P1879(32)BlinksONStart clutch control linear sotenoid14-252

P1882BlinksONInhibitor solenoid14-253

P1885

(34)BlinksONDrive pulley speed sensor1l-Zb4

P1886(35)BlinksONDriven pulley speed sensor14-255

P1888

(36)BlinksONSecondary gear shaft speed sensor14-256

T to55

(37)BlinksONECM or TCM14-257

P1890

l42lBlinksONShift control system14-259

P1891

(43)BlinksONStart clutch control svstem14-260

14-23a

Page 916 of 2189

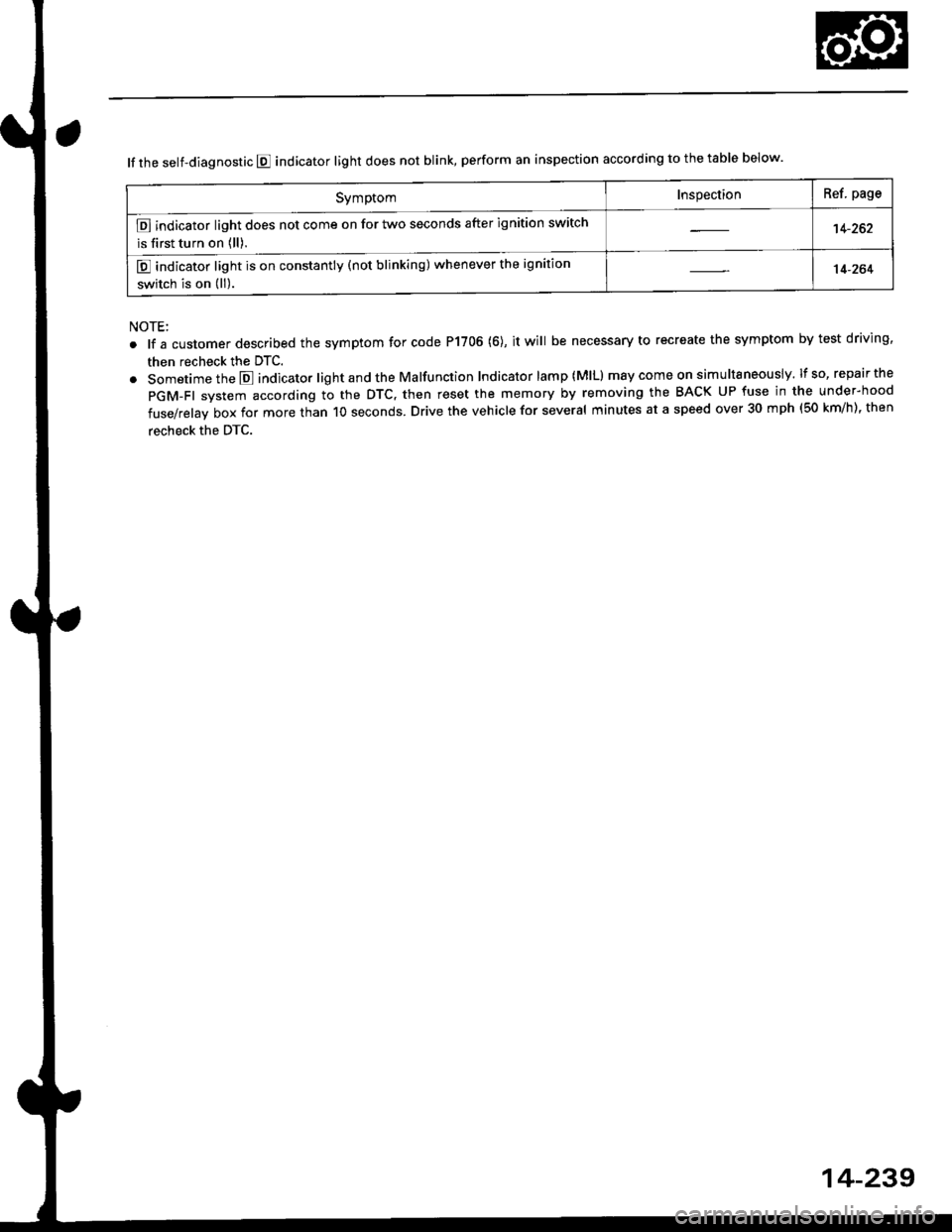

lf the self-diagnostic E indicator light does not blink, perform an inspection according to the table below.

SymptomInspectionRef. page

E indicator light does not come on for two seconds after ignition switch

is first turn on (ll).14-262

E indicator light is on constantly (not blinking) whenever the ignition

switch is on (ll).14-264

NOTE:

. lf a customer described the symptom for code P1706 (6), it will be necessary to recreate the symptom by test driving,

then recheck the DTC.

. Sometime the E indicator light and the Malfunction Indicator lamp (MlL) may come on simultaneously. lf so, repair the

pGM-Fl system according to the DTc, then reset the memory by removing the BACK uP fuse in the under-hood

fuse/relay box for more than 10 seconds. Drive the vehicle for several minutes at a speed over 30 mph (50 km/h)' then

recheck the DTC.

14-239