6-1 HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1046 of 2189

l.

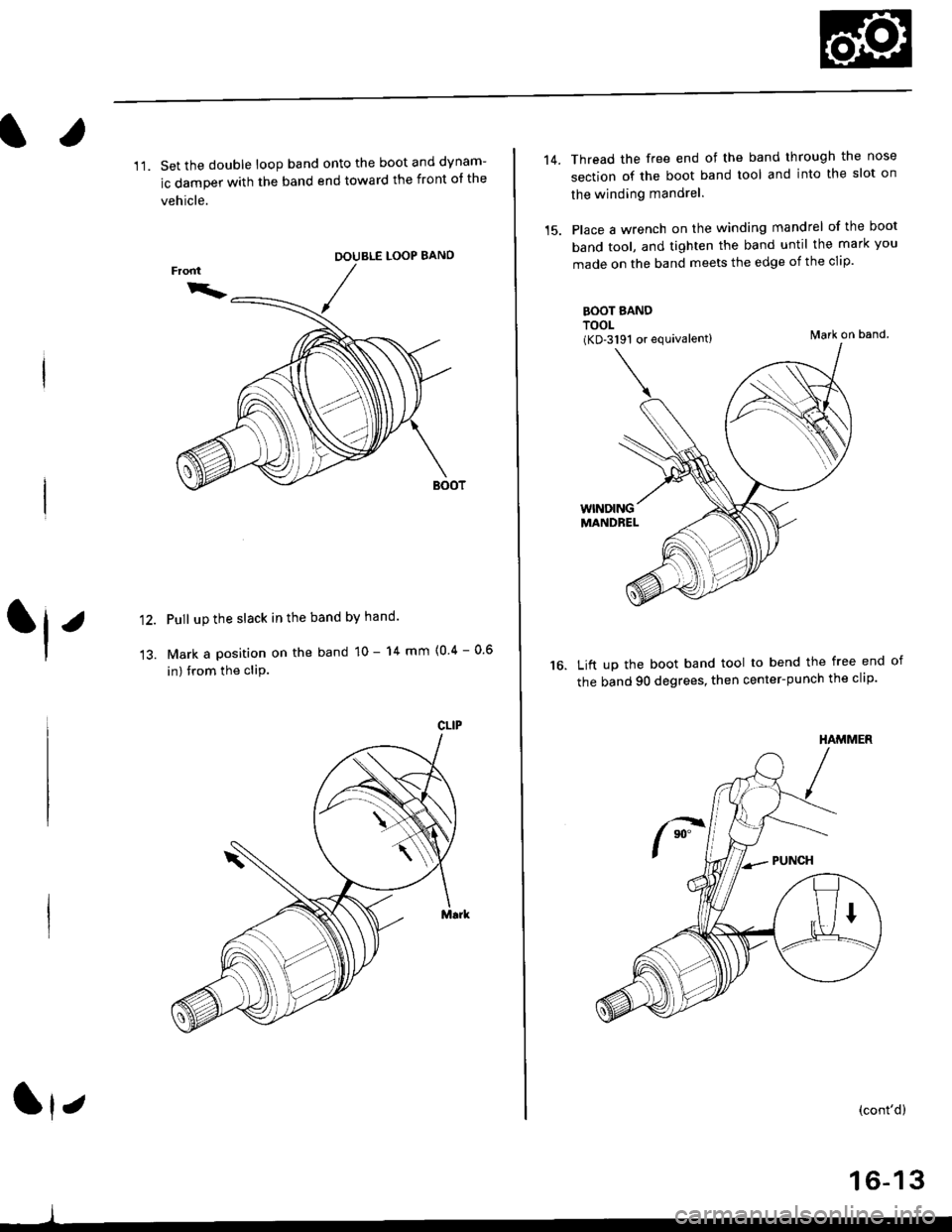

11. Set the double loop band onto the boot and dynam-

ic damper with the band end toward the front ot the

vehicle.

LOOP BANO

Pull up the slack in the band bY hand

Mark a position on the band 10 - 14 mm {0 4 - 0 6

in) from the cliP.

DOUBLE

,

1')

13.

CLIP

Ip

14.

15.

Thread the free end of the band through the nose

section of the boot band tool and into the slot on

the winding mandrel.

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the mark you

made on the band meets the edge of the clip.

Mark on band.

Lift up the boot band tool to bend the free end

the band 90 degrees, then center-punch the clip'16.

(cont'd)

16-13

(KD-3191 or equivalent)

HAMMER

Page 1047 of 2189

Driveshafts

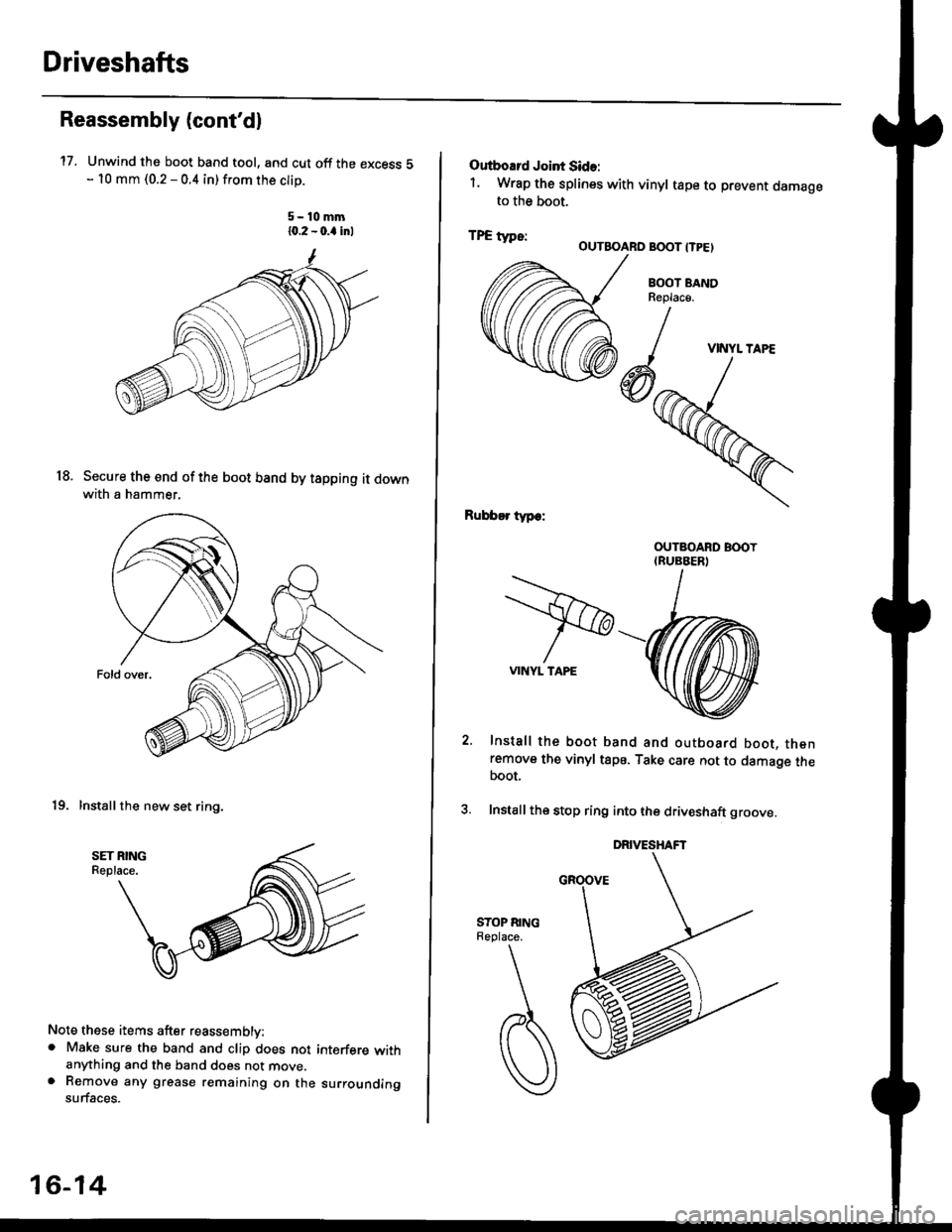

17.

Reassembly (cont'dl

Unwind the boot band tool, and cut off the excess 5- 10 mm (0.2 - 0.4 in) from the clip.

5-10mm10.2 - 0.a inl

Secure the end of the boot band by tapping it downwith a hammer,

19. Installthe new set ring,

18.

Note these items after reassembly:. Make sure the band and clip does notanything and the band does not move.a Remove any grease remaining on thesurfaces.

interfere with

su rrou nding

16-14

Outboard Joint Sid.:

1. Wrap the splines with vinyl tape to prevent damageto the boot.

TPE tvDe:-. OUTBOARO BOOT ITPE)

BOOT BANDReplac€,

Rubber typ.:

Install the boot band and outboard boot, thenremove the vinyl tape. Take care not to damage theboot,

Install the stop ring into the driv€shaft groove.

DRIVESHAFT

>VINYL TAPE

VINYL TAPE

Page 1048 of 2189

J)

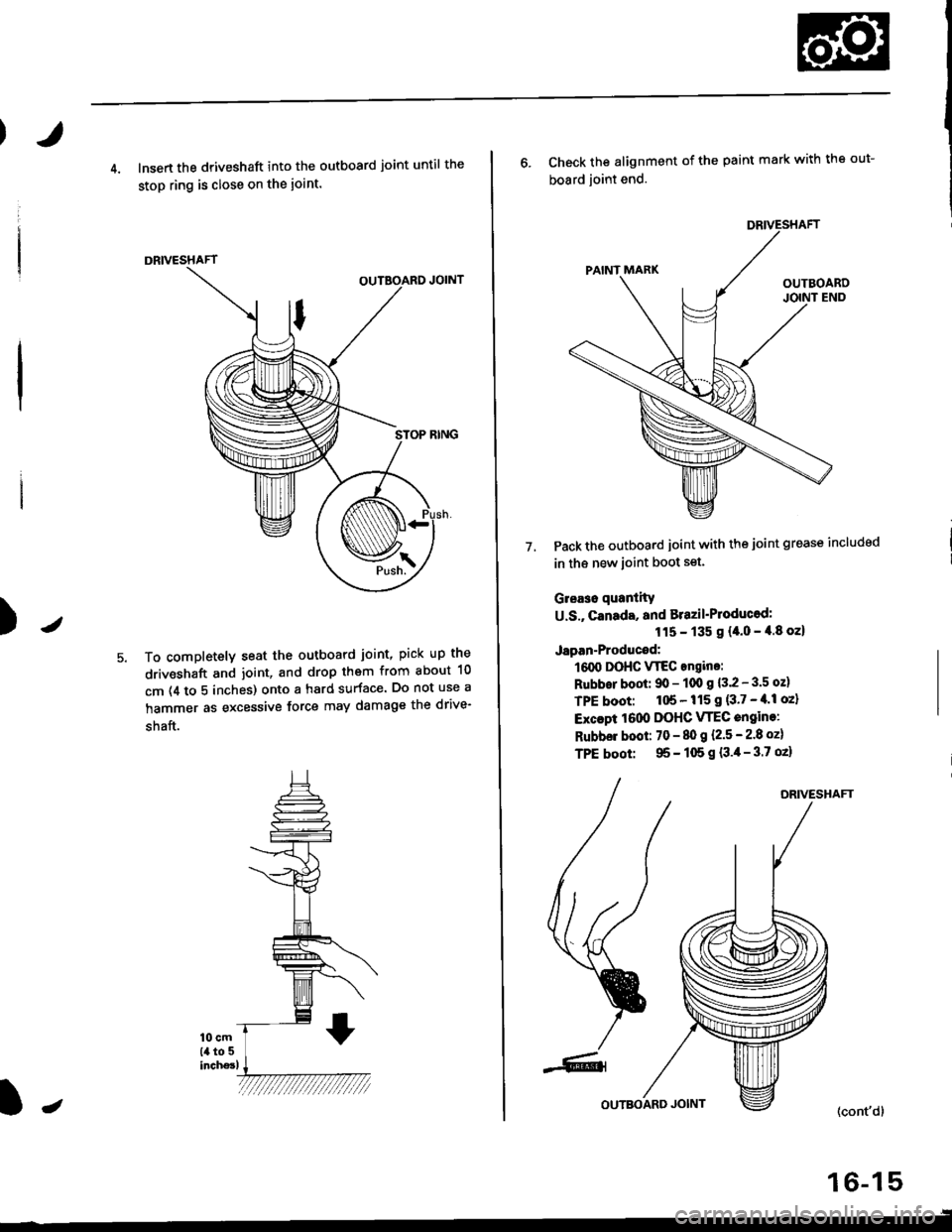

4. lnsert the driveshaft into the outboard joint until the

stop ring is close on the ioint.

DRIVESHAFT

To completely seat the outboard joint, pick up the

driveshaft and joint, and drop them from about 10

cm (4 to 5 inches) onto a hard surface. Do not use a

hammer as excessive force may damage the drive-

shaft.

16-15

J

6. Check the alignment of the paint mark with the out-

board joint end.

Pack the outboard joint with the joint grease includsd

in th€ new ioint boot set.

Gleaso quanlity

U.S., canada, and Brazil'Ploducod:

115 - 135 g {4.0 - 4.8 oz}

Japan-Producod:

161X, DOHC VTEC angino:

Rubbor boot: 90 - 100 g 13.2 - 3.5 oz)

TPE boot: 1tl6 - 115 I {3'7 - tl'l oz}

Excapt 1000 DOHC VTEC engine:

Rubbel boot: 70 - 80 g l.2.5 - 2.8 ozl

TPE boot: 95 - 105 g {3.4- 3.7 oz}

7.

DRIVESHAFT

(cont'd)

Page 1049 of 2189

Driveshafts

Reassembly lcont'd)

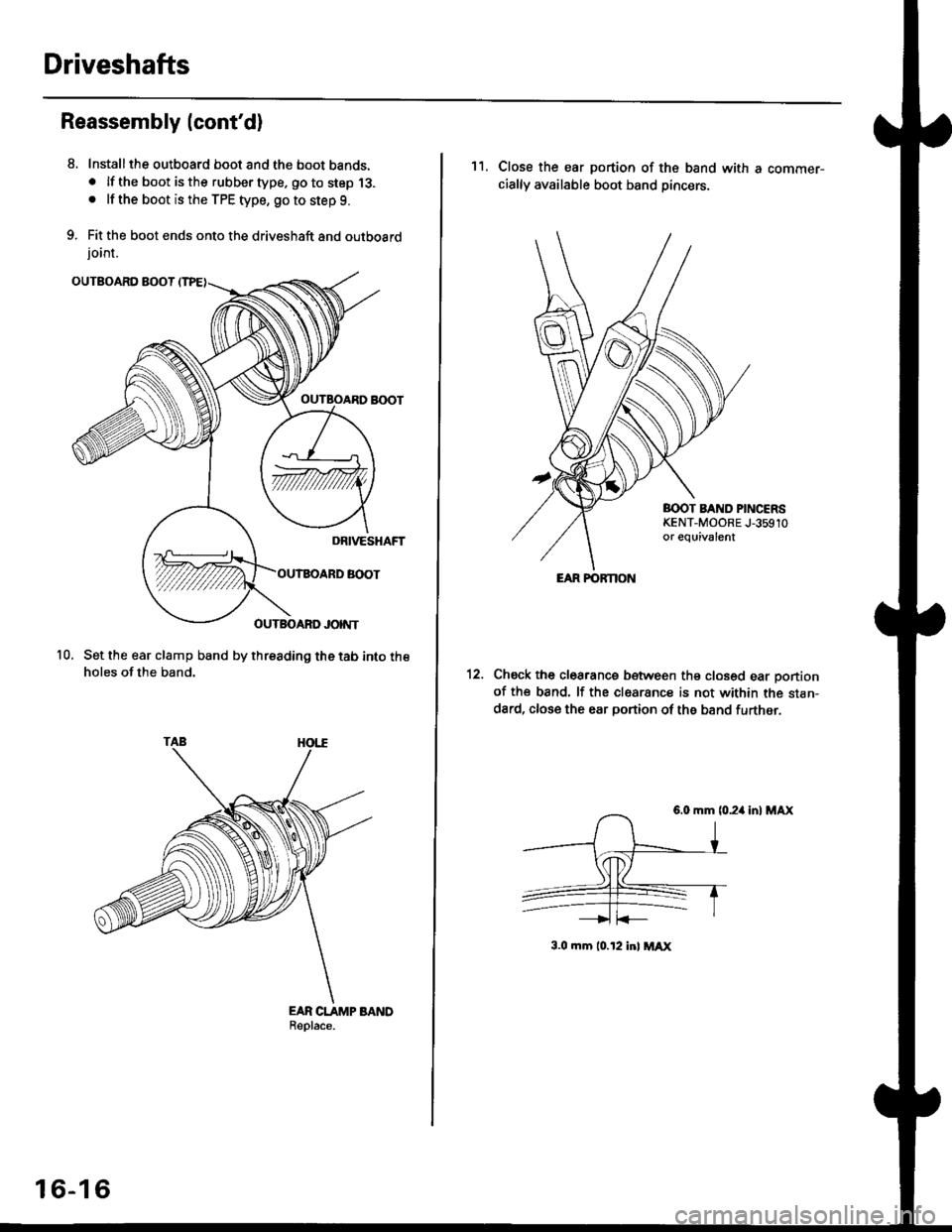

Installthe outboard boot and the boot bands.. lf the boot is the rubber type. go to step 13.. lf the boot is the TPE type, go to step 9.

Fit the boot ends onto the driveshaft and outboard

ioint.

10, Set the ear clamp band by threading the tab into theholes of the band.

EAR CLAMP BANDReolace.

8.

16-16

11. Close the ear portion of the band with a commer-cially available boot band Dincerc.

BOOT BAND PINCERSKENT-MOORE J,35910or eouivalent

Chsck the clearanca between the closed ear oonionof the band. lf the clesrance is not within the stan-

dard, close the ear portion of ths band further.

6.0 mm (0.24 in) MAX

3.0 mm 10.t2 inl MAX

EAR FOFNON

Page 1050 of 2189

I

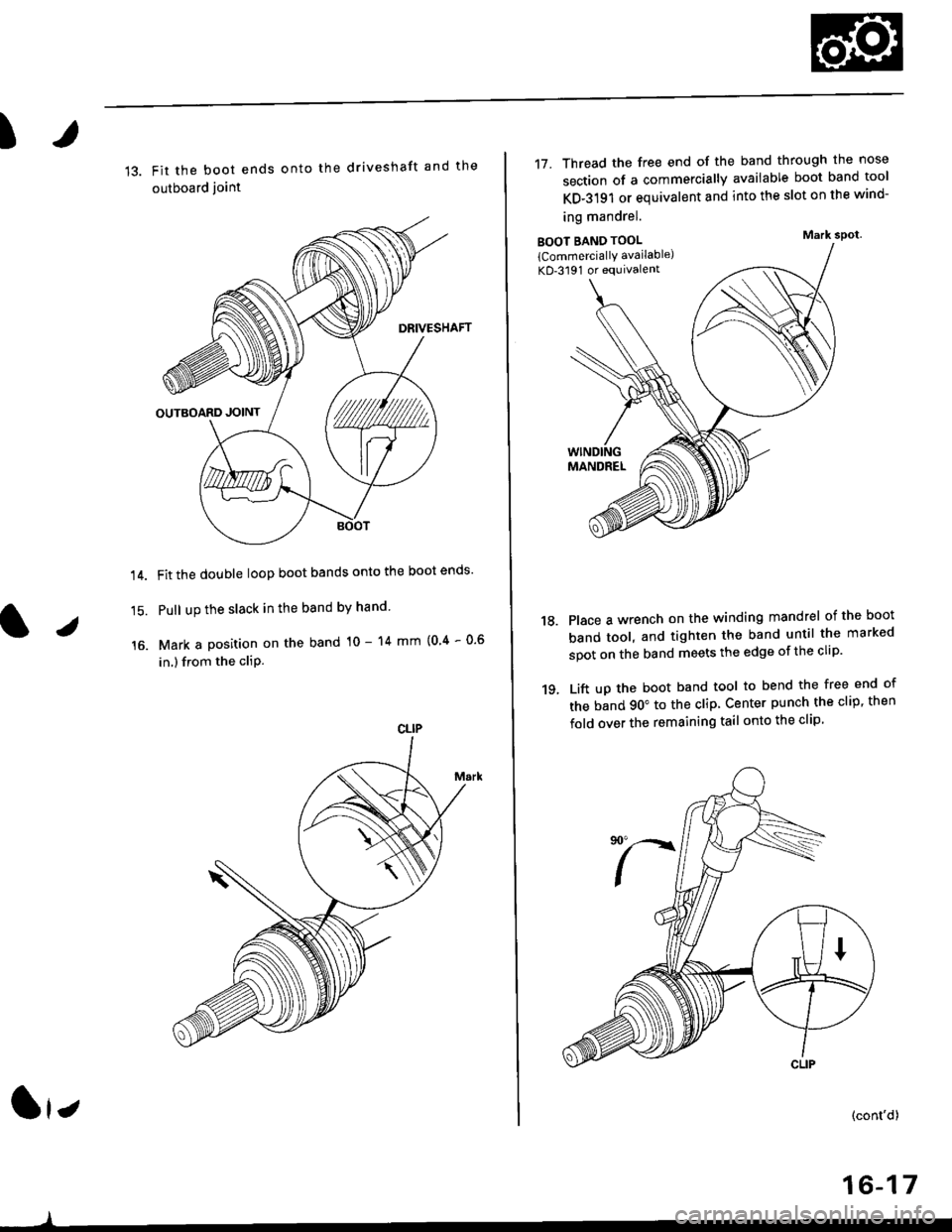

13. Fit the boot ends onto the driveshaft and the

outboard joint

Fit the double loop boot bands onto the boot ends'

Pull up the slack in the band by hand'

Mark a position on the band 10 - 14 mm {0 4 - 0 6

in,) from the cliP.

14.

16.

CLIP

lrz

17. Thread the free end of the band through the nose

section of a commercially avaiiable boot band tool

KD-3191 or equivalent and into the slot on the wind-

ing mandrel.

BOOT BAND TOOL

lCommerciallY available)

KD-3191 or equivalent

MANDREL

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot on the band meets the edge of the clip'

Lift uo the boot band tool to bend the free end of

the band 90" to the clip Center punch the clip, then

fold over the remaining tail onto the clip

Mark spot.

18.

1q

(cont'd)

16-17

Page 1051 of 2189

Driveshafts

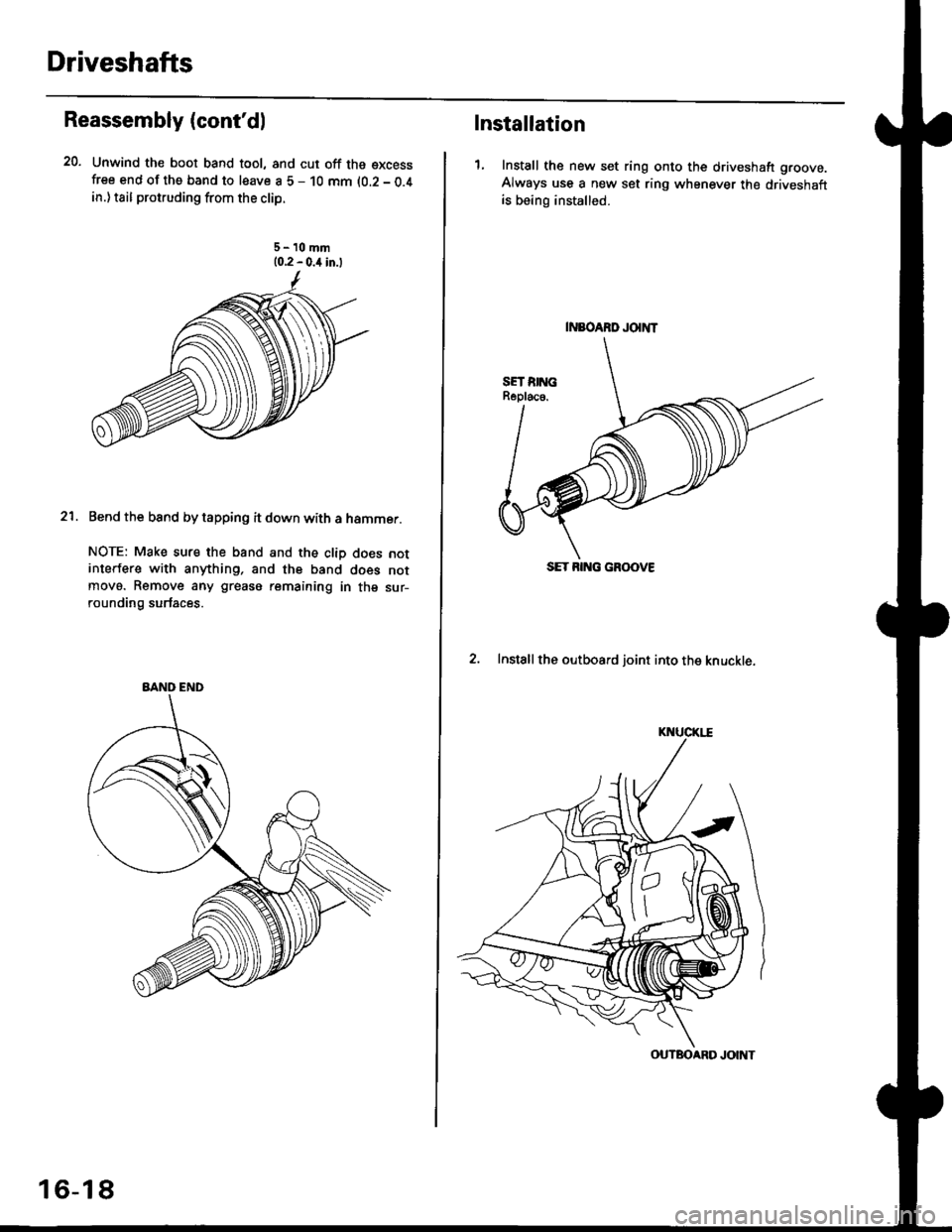

Reassembly (cont'dl

20. Unwind the boot band tool, and cut off the excessfree end of the band to leave a 5 - 10 mm (0.2 - 0.4in.) tail protruding from the clip.

21. Bend the band by tapping it down with a hammer.

NOTE: Maks sure the band and the clip does notinterfere with anything, and the band does notmov6. Remove any grease remaining in the sur-

rounding surtaces.

AANO END

16-18

INBOARD JOiIT

SET RII{G GR(X)VE

Installation

1, Install the new set ring onto the driveshaft groove.

Always use a new set ring whenever the driveshaftis being installed.

2. Install the outboard joint into the knuckte.

OUTBOARD JOINT

KNUCKI.E

Page 1052 of 2189

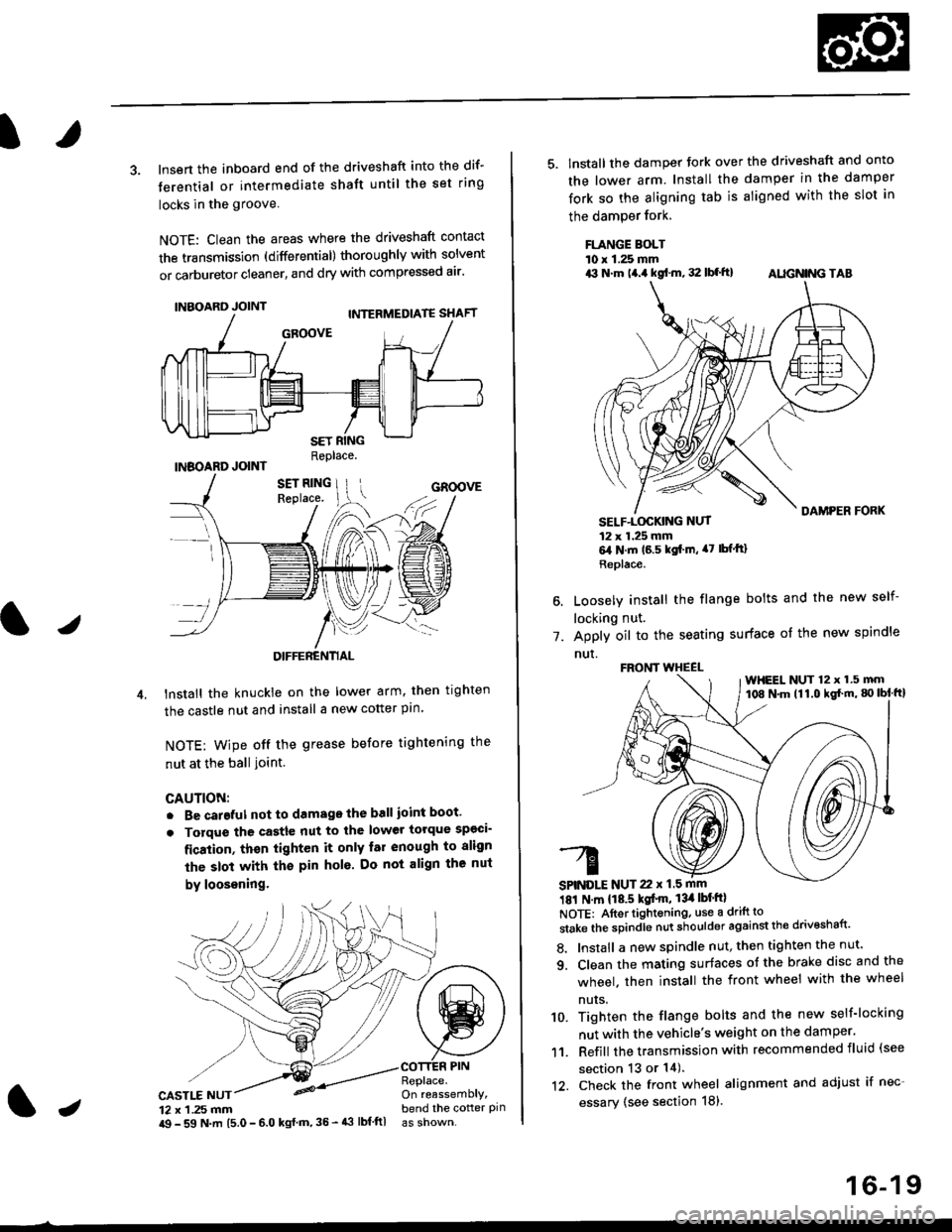

3. lnsert the inboard end of the driveshaft into the dif-

terential or intermediate shaft until the set ring

locks in the groove

NOTE: Clean the areas where the driveshaft contact

the transmission (differential) thoroughly with solvent

or carburetor cleaner, and dry with compressed air'

INBOARD JOINT

INBOARD JOINTReplace.

GROOVE

an

DIFFERENTIAL

lnstall the knuckie on the lower arm. then trghten

the castle nut and install a new cotter pin

NOTE: wipe off the grease before tightening the

nut at the ball ioint.

CAUTION:

. Be careful not to damago the ball ioint boot'

. Torque the castle nut to the lower torque sp€ci-

fication, thsn tighten it only far enough to align

the slot with th€ pin hol6. Do not align the nut

by loosening.

CASTLE NUT12 x 1 .25 mm

COTTER PINReplace.On reassemblY,bend the cotter pinJi$ - 59 N.m 15.0 - 6.0 kgl m,35 - 43 lbf ftl

16-19

5. lnstall the damper tork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damPer fork.

FLANGE BOLTl0 r 1.25 mmrit N.m t4.a kgf.m, 32 lbf.ft) AIIGN|NG TAB

1.

SELF-LOGKING NUT12 x 1.25 mm6,1N.m 16.5 kgi.m, a7 lbfftl

Replace.

Loosely install the flange bolts and the new self-

locking nut.

Apply oil to the seating surface of the new spindle

nut.

181 N m 118.5 kgt'm, 13il lbt'ftl

NOTE: Aftortightening, use a drift to

stake the spindle nut shoulder against the drivoshaft'

8. Install a new spindle nut, then tighten the nut'

9. Clean the mating surfaces ot the brake disc and the

wheel. then install the front wheel with the wheel

nuts.

10. Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

11. Refill the transmission with recommended fluid (see

section 13 or 14).'t2. Check the front wheel alignment and adjust if nec-

essary (see section 18),

FRONT WHEEL

SPINDLE NUT 22 x 1.5 mm

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgl'm, g) lbl ftl

Page 1205 of 2189

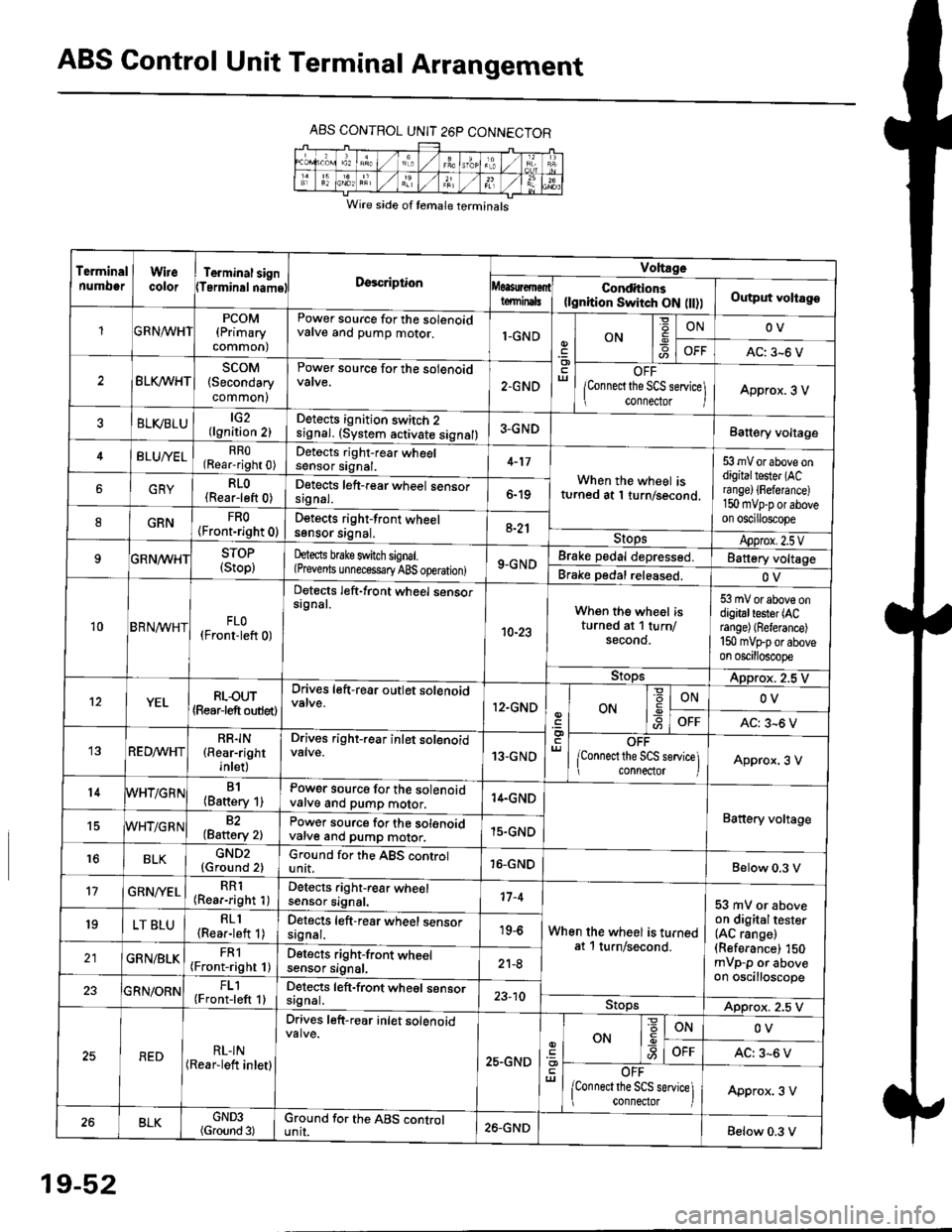

ABS Control Unit Terminal Arrangement

ABS CONTROL UNIT 26P CONNECTOR

Wire side of temale terminals

Terminalnumo0rWirecolorTerminal signTerminalnamoDgscriptionVoltage

Conditions(lgnition Switch ON flt))Output voltagoteminals

PCOM(Primary

common)

Power source for the solenoidvalve and pump motor.1-GNDON

=ONOV

AC: 3-6 V

BLK/WHTscoM(Secondary

common)

Power source for the solenoid

2.GNDOFF

lConnect the SCS service\

conneclor lApprox. 3 V

ELVBLUtG2(lgnition 2)Detects ignition switch 2

!9nal. (system activate signal)3-GNDBatt€ry voltage

BLU/YELRRO(Rear-right 0)Detects right-rear wheelsensor signal.4-17

When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester (ACra nge) {Fefera nce)150 mvp-p or aboveon oscilloscope

6GRYRLO(Rear-left 0)Detects left-rear wheel sensorsrgnal.6-19

8GRNFRO(Front-right 0)D€tects right-front wheelsgnsor srgnal,a-21StopsApprox.2.5VSTOP(Stop)hects brake switch signal.(Prevents unnecess€ry ABS operation)9-GNDBrake pedal depressed.Battery voltage

Brake pedal released.OV

10BRN^/vHTFLO(Front-left 0)

Detects left-front wheel sensorsignal.

10-23

When the wheel isturned at 1 turn/secono.

53 mV or above ondigitaltester (ACrange) (Referance)

150 mVFporaboveon oscilloscope

9!opsApprox. 2.5 V

12YELRLOUT(Rearjeft outlet)

Drives left-rear outlet solenoid

12.GNDON-9ONOV

OFFAC: 3^6 V

REDMHTRR]N(Rear-right

inlet)

Drives right-rear inlet solenoidvalve.13-GNDOFF

lconnect the SCS service]i connector IApprox. 3 V

14B1(Battery 1)Power source for the solenoidvatve and pump motor.14.GND

Battery voltage15WHT/G R N82(Baftery 2)Power source for the solenoidvarve ano pump motor.15.GND

r6BLKGND2{Ground 2)Ground for the ABS controlunit.16-GNDBelow 0.3 V

17GRN/'/ELRR1(Rear-right 1)Detects right-rear wheelsensor signal.17-4

When the wheel is turnedat 1 turn/second.

53 mV or aboveon digitaltester(AC range)(Referance) 150mVp-p or aboveon oscilloscope

19LT BLURLl(Rea.-left 1)Detects left-rear wheel sensorsagnal.19-6

GRN/BLKFRl(Front-right 1)Detects right-front wheelsensor signal.21-8

FL1(Front-left 1)Detects left-front wheel sensorsignal.23-10StopsApprox. 2.5 V

REDRL-IN(Rear-lett inletl

Drives left-r€ar inlet solenoid

25.GND

ut

ON

'6

-9ONOV

OFFAC: 3-6 V

OFF

lconnect the SCS service] connector lApprox. 3 V

BLKGND3(Ground 3)Ground for the ABS cgntrolunit.26.GNDBelow 0.3 V

19-52

Page 1758 of 2189

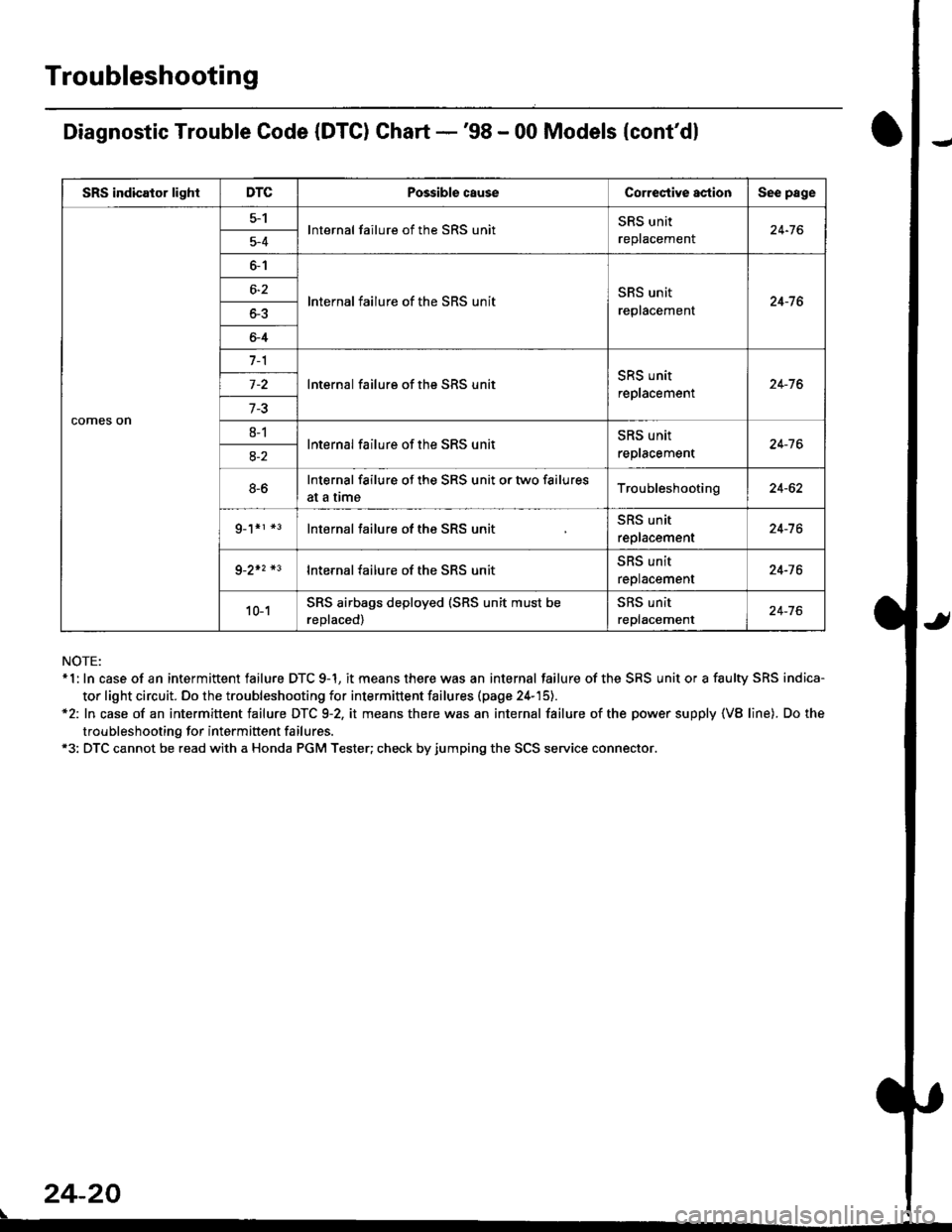

Troubleshooting

Diagnostic Trouble Code (DTC) Chart -'98 - 00 Models {cont'dl

NOTE:* 1: In case of an intermittent failure DTC 9-1, it means there was an internal failure of the SRS unit or a faulty SRS indica-

tor light circuit. Do the troubleshooting for intermittent failures (page 24-'15).*2: In case of an intermittent failure DTC 9-2, it means there was an internal failure of the power supply {VB line). Do the

troubleshooting for intermiftent failures.*3: DTC cannot be read with a Honda PGM Tester; check by jumping the SCS service connector.

24-20

\

SRS indicator lightDTCPossible causeCorrectiYe actionSee page

comes on

5-1lnternal failure of the SRS unitSRS unit

replacemenl24-765-4

6-1

lnternal failure of the SRS unitSRS unit

replacement24-7 66-2

o-5

6-4

7-1

lnternal failure of the SRS unitSRS unit

replacement24-76

7-3

8-1lnternal failure of the SRS unitSRS unit

reptacement24-7 68-2

8-6Internal failure of the SRS unit or two failures

at a trmeTroubleshooting24-62

g_1*r *3lnternal failure of the SRS unitSRS unit

replacement24-7 6

9-2+2 *3lnternal failure of the SRS unit5l|5 Untr

replacement24-76

10-1SRS airbags deployed (SRS unit must be

reDlaced)

SRS unit

replacement24-76

Page 1760 of 2189

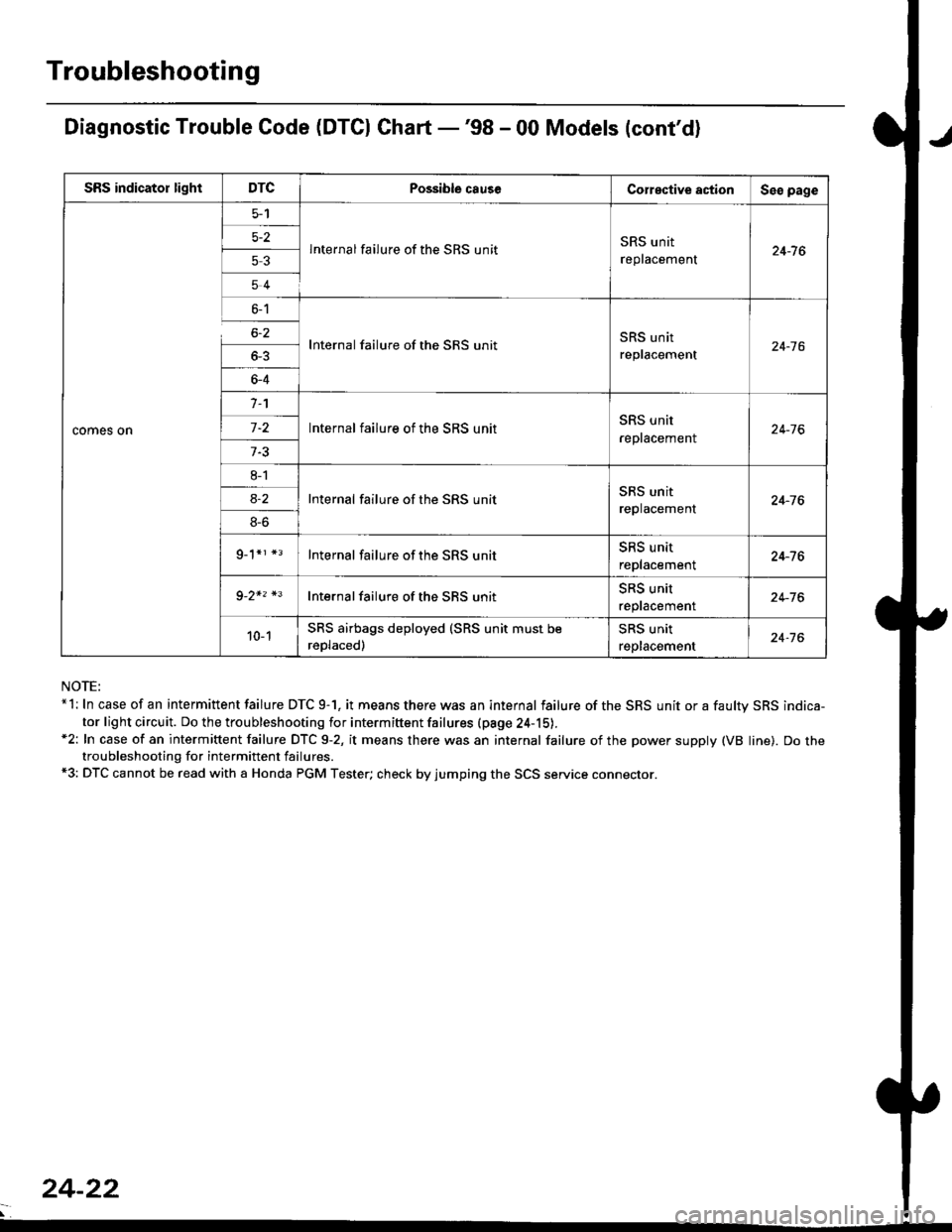

Troubleshooting

Diagnostic Trouble Code (DTCI Ghart -'98 - 00 Models (cont'd)

NOTE:*l: In case of an intermittent failure DTC 9-1. it means there was an internal failure of the SRS unit or a faultv SRS indica-

tor light circuit. Do the troubleshooting for intermiftent failures (pa9e 24-15).*2: In case of an intermittent failure DTC 9-2, it means there was an internal failure of the power supply (VB line). Do thetroubleshooting for intermittent failures.*3: DTC cannot be read with a Honda PGM Tester; check by jumping the SCS service connector.

SRS indicator lightDTCPossible causeCorective actionSeo page

comes on

5-2

53

54

lnternal failure of the SRS unitSRS unit

replacement24-7 6

6-1

6-2

_

64

Internal failure of the SRS unitSRS unit

replacement24-16

n

-

8l

8S

9_1*r *3

Internal failure of the SRS unitSRS unit

reptacement24-76

Internal failure of the SRS unitSRS unit

replacement24-76

Internal failure of the SRS unitSRS unit

replacement24-76

Internal failure of the SBS unitSRS unit

reptacemenr24-76

10-1SRS airbags deployed (SRS unit must be

reDlaced)

SRS unit

replacement24-76

24-22