Dash HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 471 of 2189

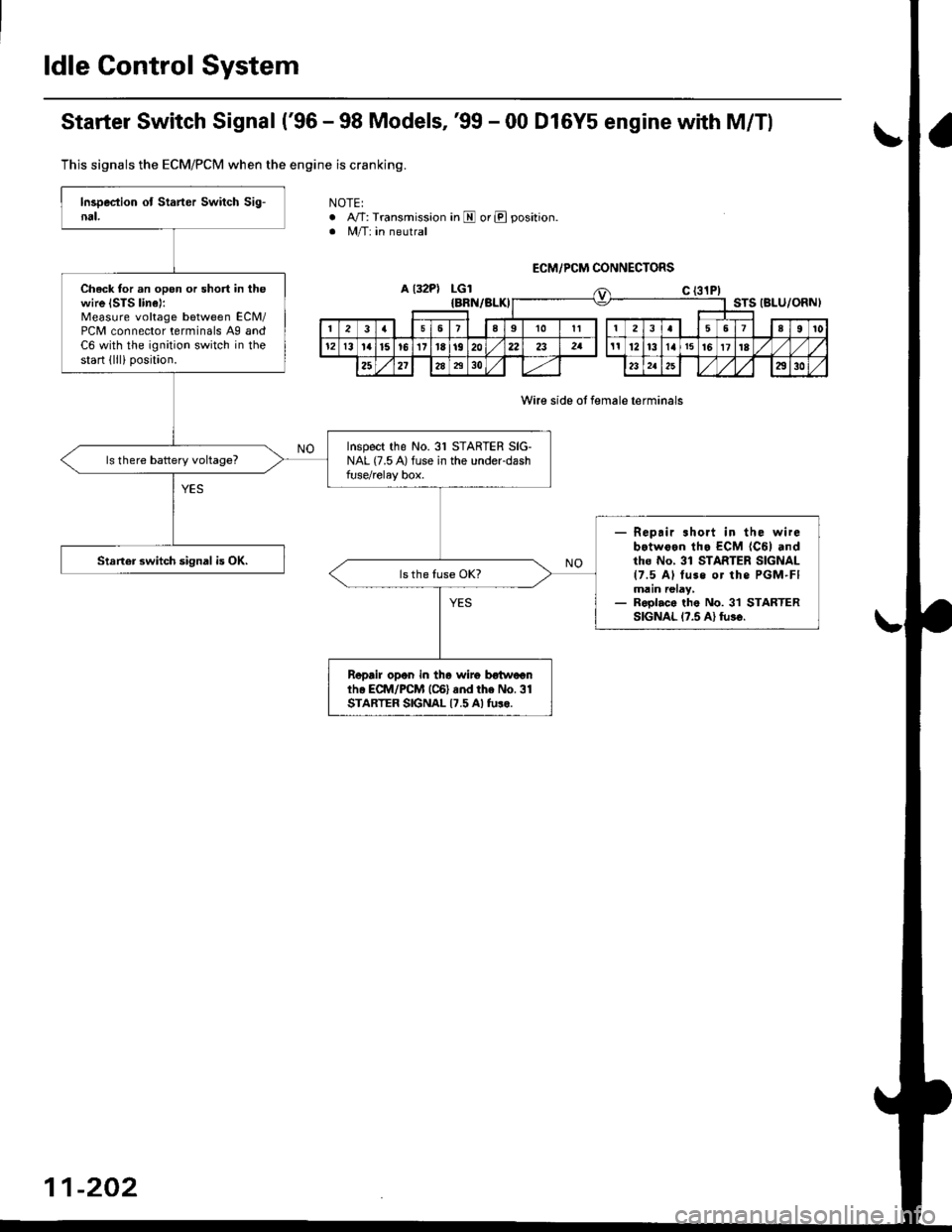

ldle Control System

Starter Switch Signal ('96 - 98 Models,'99 - 00 D16Y5 engine with M/Tl

Thjs signals the ECM/PCM when the engine is cranking.

NOTE:. A/T: Transmission in E or E position. M/T: in neutral

a l32PlLGl

Wire side ot female lerminals

Check tor an open or short in thewire ISTS linel:Measure voltage between ECM/PCM connector terminals A9 andC6 with the ignition switch in thestart lllli position.

Inspect the No. 31 STARTER SIG-NAL (7.5 A) fuse in the underdashfuse/relay box.

- Repair .hort in the wirebotwoen tha ECM {C6l andtho No, 31 STARTER SIGNAL{7.5 Al tuss or the PGM-FImain relay,- Roolac. the No. 3'l STARTERSIGNAL l?.5 Al tu3€.

Staner 3witch signal is OK.

Repair opon in th6 wiro botweanih. ECII4/PCM (C6) and the No.31STARTER SIGNAL {7.5 Al tulo.

ECM/PCM CONNECTORS

{BRN/BLKISTS IBLU/ORNI

216910It3567a9l0

l2l3la15!6171a1920222att12t3l4t5t6171E

252l2A7t30232a2930

11-202

Page 472 of 2189

\

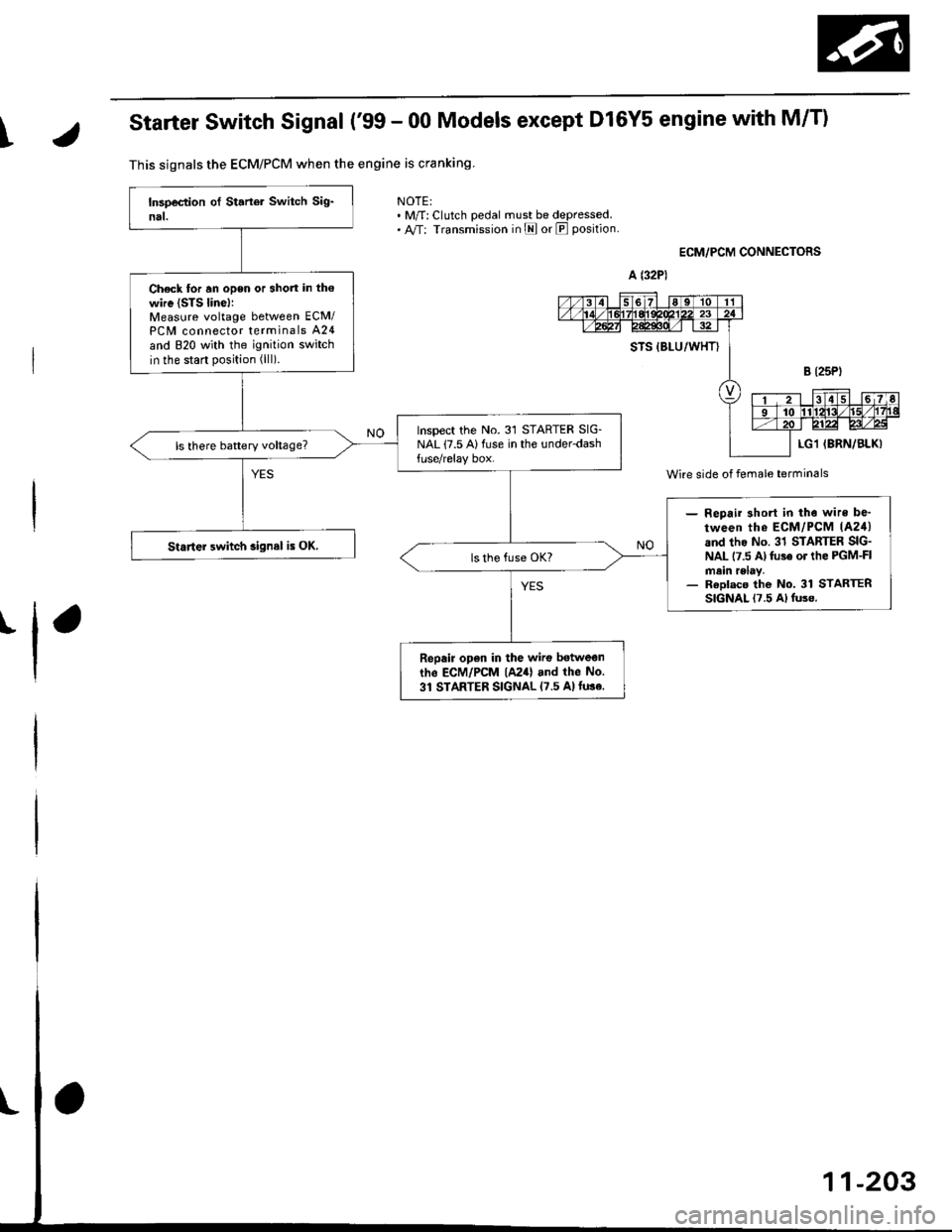

Starter Switch Signal ('99 - 00 Models except Dl6Y5 engine with M/T)

NOTE:. M/f: Clutch pedal must be depressed.. A,/T: Transmission in E or E position

ECM,/PCM CONNECTORS

I

This signals the ECM/PCM when the engine is cranking

Ch€ck for an open or short in the

wire {STS linel:Measure voltage between ECM/PC[/| connector terminals A24

and 820 with the ignition switch

in the start position (lll).

Inspect the No.31 STARTER SIG-NAL (7.5 Alluse in the under-dash

- Repair 3hort in tho wire be'

tween tho ECM/PCM lA24)and tho No. 31 STARTER SIG-NAL 17.5 Al fuse or the PGM-FImein relay.- ReDlaco the No. 31 STARTERSIGNAL 17.5 Al fuse.

Staner 3witch signal is OK.

Repair open in the wirc betwean

the ECM/PCM lA24) and the No.

31 STARTER SIGNAL {7.5 Alfuse.

W;re side of female terminals

Page 508 of 2189

JI

I

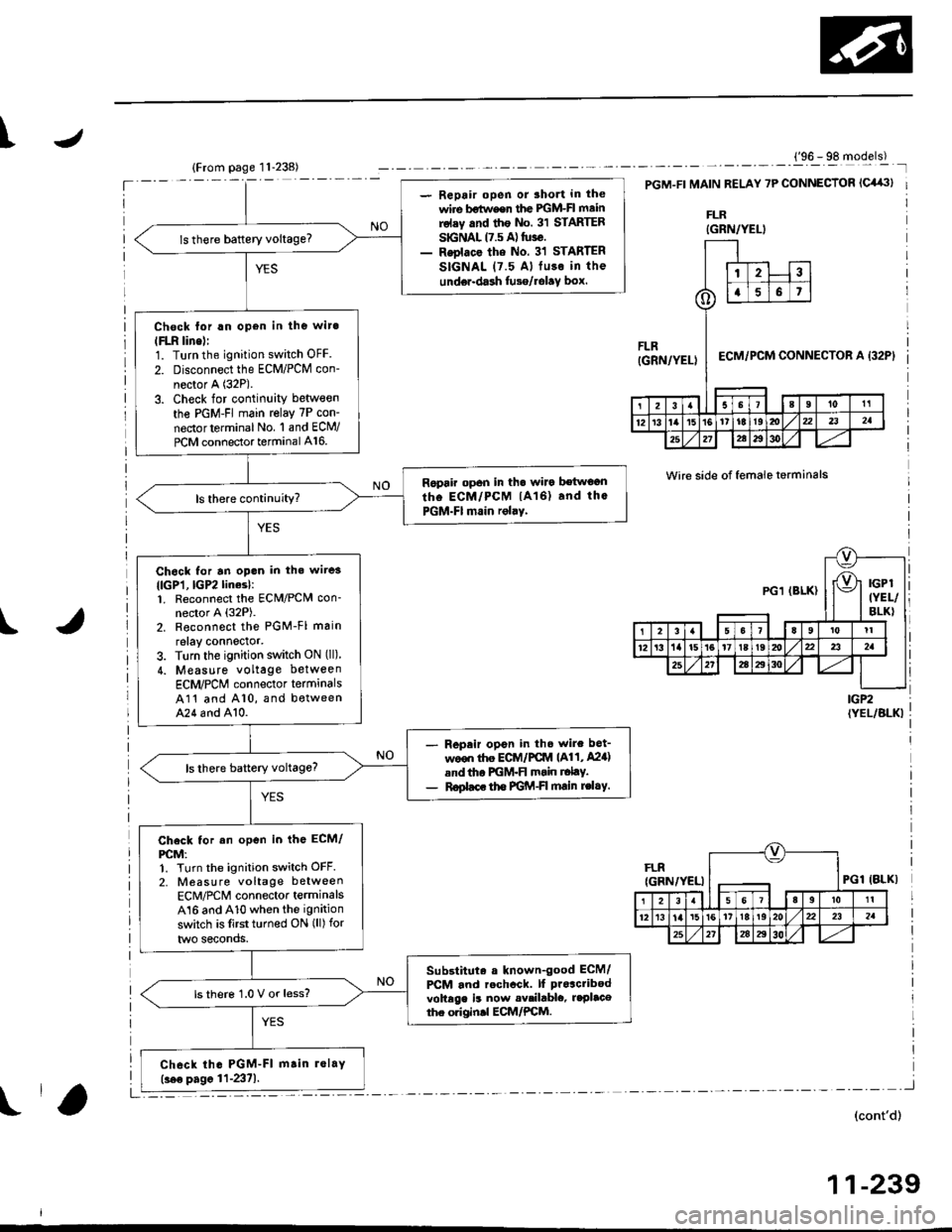

- Repair open or 3hort in the

wire bstw€er the lGM-Fl mainrolsy .nd the No. 31 STARTERSGNAL 17.5 A) tuse.- Reolace the No. 31 STARTER

SIGNAL (7.5 Al fu3o in the

unde.-dash tusg/rolav box.

ls there baftery voltage?

Chock lor !n open in the wit.

lFLn line)l1. Turn the ignition switch OFF

2. Disconnect the ECM/PCM con-

nector A (32P).

3. Check for continuity between

the PGM-FI main relay 7P con-

nectorterminal No. 1 and ECM/

PCM connector terminal A16.

Ropair op6n in th. walo betwoanthe ECM/PCM lA16) and thc

PGM-FI main rolaY.

Ch6ck for an opon in th. wi.e3

llcPl,lGP2linesl:1. Reconnect the ECM/PCN4 con-nector A (32P).

2. Reconnoct the PGM-Fl main

relay connector,3. Turn the ignition switch ON (ll)

4. Measure voltage between

ECM/PCM connector termanals

A11 and A10, and betweenA24 6nd A10.

Repeir opon in th6 wire bet-

ween ttre ECiA /PCM (A11, A24)

and tho PGM-FI msin r.lty.

R€plac. tho FGM-FI main rc|.Y.

Check tor an open in the ECM/

PCM:1. Turn the ignition switch OFF.

2, Measure voltage between

ECM/PCM connector terminalsA16 and A10 when the ignition

switch is lirst turned ON (ll) for

two seconds.

Substituta a known-good ECM/

PCM and rechcck. lf proacribod

voltege is now availablc, r.Placethe originll ECM/PCM.

ls thero 1.0 V or less?

Ch6ck th. PGM-FI m.in lolay(.ee pagc 11-2371.

('96 - 98 models)

t32Pt

Wire side of female terminals

IGP2{YEL/BLKI

FLRIGRN/YELIPGl

3l5 6 7l lslel tl1l

1213'tal5t6't7t8t920221 232a

2527284t

(cont'd)

1 1-239

IBLK)

{GRN/YELI

FLR(GRN/YELI

23

()a6t

ECM/PCM CONNECTOR A

21Il0t1

12r31'al5't61'tti9ml,/x2232a

25212e293ol./

PGl (BLK)

1I

12't/t15t617t8t9zi

25272A4t304l

Page 509 of 2189

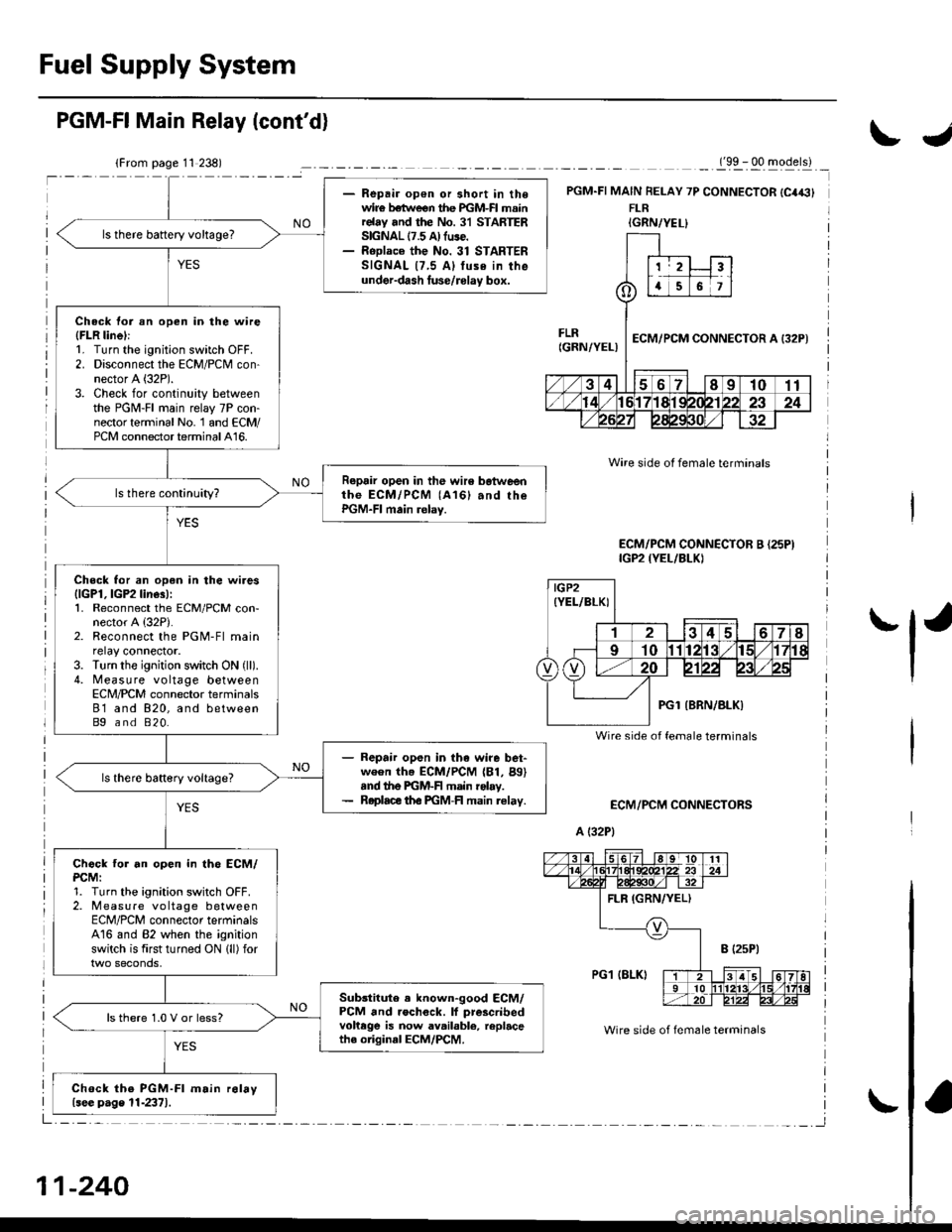

Fuel Supply System

- Repair op€n or short in thewir€ betlveen the PGM-FI mainrelay and the No. 31 STARTERSIGNAL 17.5 A) fuse.- RoDlace the No. 31 STARTERSIGNAL {7,5 Al tuse in theunder-dash luse/rolay box.

ls there battery voltage?

Check tor an open in the wire(FLR linel:1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector A (32P).

3. Check for continuity betweenthe PGM-FI main relay 7P con-nector terminal No. 1 and ECM/PCM connector terminal A16.

Repair open in the wir6 botweenthe ECM/PCM (A161 and rhePGM-FI main relay.

Check for an open in the wires{lGPl, lGP2 line3):1. Reconnect the ECM/PCM con-nector A {32P).2. Reconnect the PGM-Fl mainrelay connector.3. Turn the ignition switch ON (ll).

4. Measure voltage betweenECN4/PCM connector terminals81 and 820, and betweenBg and 820.

- Repair open in the wire bet-ween th. ECM/PCM (81, Bg)snd the PGM-F main rolay.- Roplace th€ PGM-FI main relav.

Chock tor an open in th6 ECM/PCM:1. Turn the ignition switch OFF.2. Measure vo ltage betweenECM/PCM connector terminalsA16 and 82 when the ignitionswitch is first turned ON lll) for

Sub3titute . known-good ECM/PCM and rochock. lf prescribedvohege is now available, replacethe original ECM/PCM.

ls there 1.0 V or less?

Chock the PGM-Fl m.in r6lay{see p.ge 11-2371.

PGM-FI Main Relay (cont'd)

_._(9x . qq -gqerll _

PGM.FI MAIN FELAY 7P CONNECTOR {C4€}FLR

ECM/PCM CONNECTORS

A (32P1

Wire side ot female terminals

Wire side of fem6le terminals

ECM/PCM CONNECTOR B {25PIIGP2 {YEL/BLKI

IGRN/YEL}

IGP2(YEL/BLKI

Wire side of female terminals

11-240

IJ

'l'

Page 544 of 2189

\J

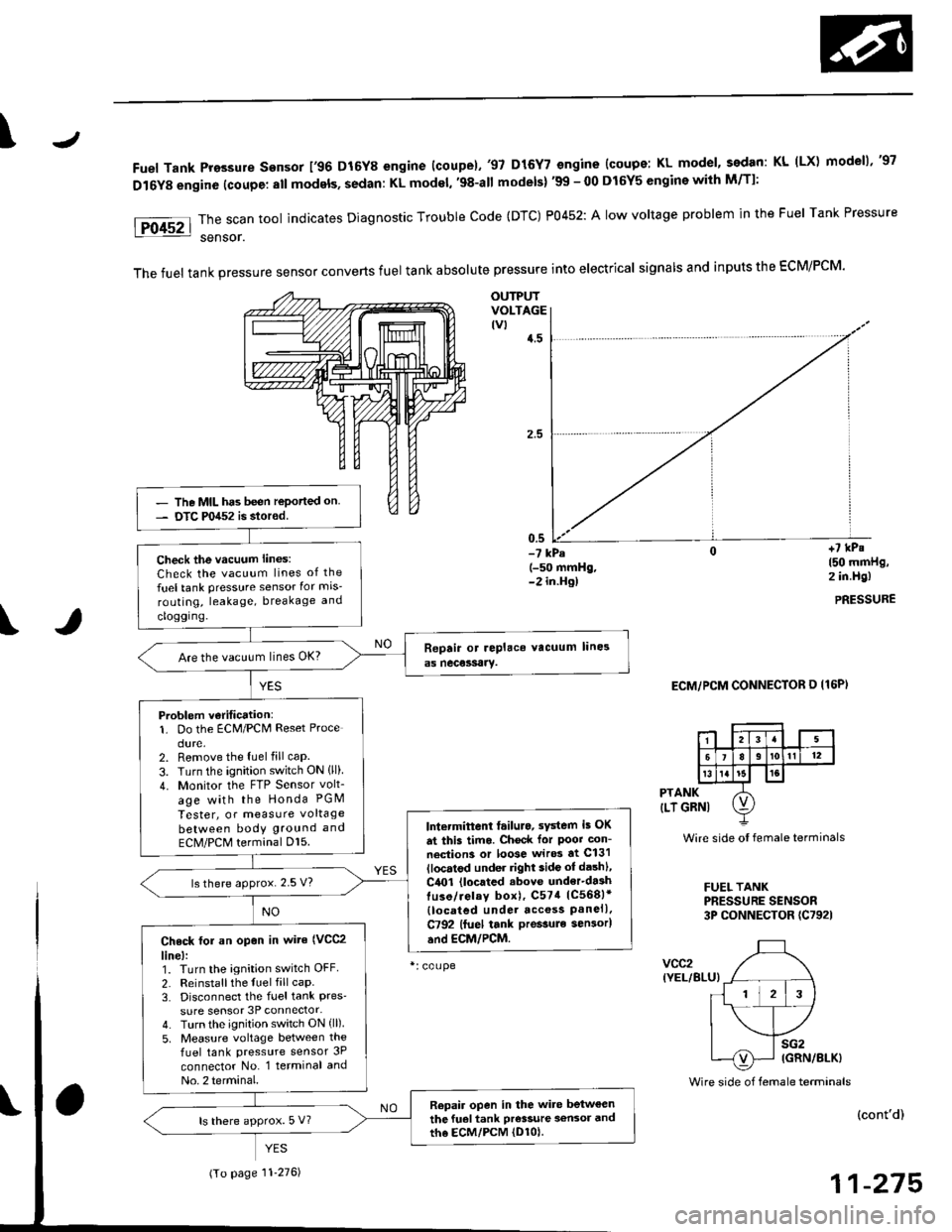

Fuel Tank Pro3sure sensor 196 D16Y8 engine (coupe).'97 D15Y7 engine {coupe: KL model, sedan: KL (LX) modeu,'97

D16Y8 engine (coupe: all models, sedan: KL model, '98-all models) '99 - 00 D16Y5 engine with M/Tl:

\

PTANK

{LT GRNI

vcc2(YEL/BLU}

Wire side oI female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C7921

sG2IGRN/8LK)

Foc2l::il":"toolindicatesDiagnosticTroublecode(DTc)P0452:A|owvo|tageprob|emintheFue|TankPressure

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the EcM/PCM.

OUTPUTVOLTAGEtvt4.5

-? kPa(-50 mmHg,-2 in.Hg)

ECM/PCM CONNECTOR O I16P)

Wire side of female terminals

+7 kPs150 mmHg,2 in.Hg)

PRESSURE

(cont'd)

11-275

- The MIL has been reported on- DTC P0452 is stored.

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum lines OK?

Problem v€ritication:1. Do the ECM/PCM Reset Proce

dure.2. Remove the luel fill caP.

3. Turn the ignition switch ON lll)4. Monitor the FTP Sensor volt_

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM terminal Dl5.lntermittent tailuro, sYstem i5 OK

dt this timo. Chock for Poot con-

neciion3 or loose wir* at C131

llocatod under right side ot dashl,

C4O1 (located .bove under'da3htuso/ielay box), C574 1C568)*

{located under acc€ss Panell.C792 lfuel tank pressule sen3or)

and EcM/PCM.

ls there approx. 2.5 V?

Check tol an op€n in wite (VCC2

line):1. Turn the ignition switch OFF

2. Reinstallthe fuel fill caP.3. Disconnect the fuel tank Pres'sure sensor 3P connector-4. Turn the ignition switch ON (ll)

5, Measure voltage between the

fuel tank pressure sensor 3P

connector No. l terminal and

No. 2 terminal.

Repair open in the wite betweenthe fuel tank Pr€s3ure a€n3or andth6 EcM/PcM (D1ol.ls there approx. 5 V?

(To page 11'276)

Page 546 of 2189

\

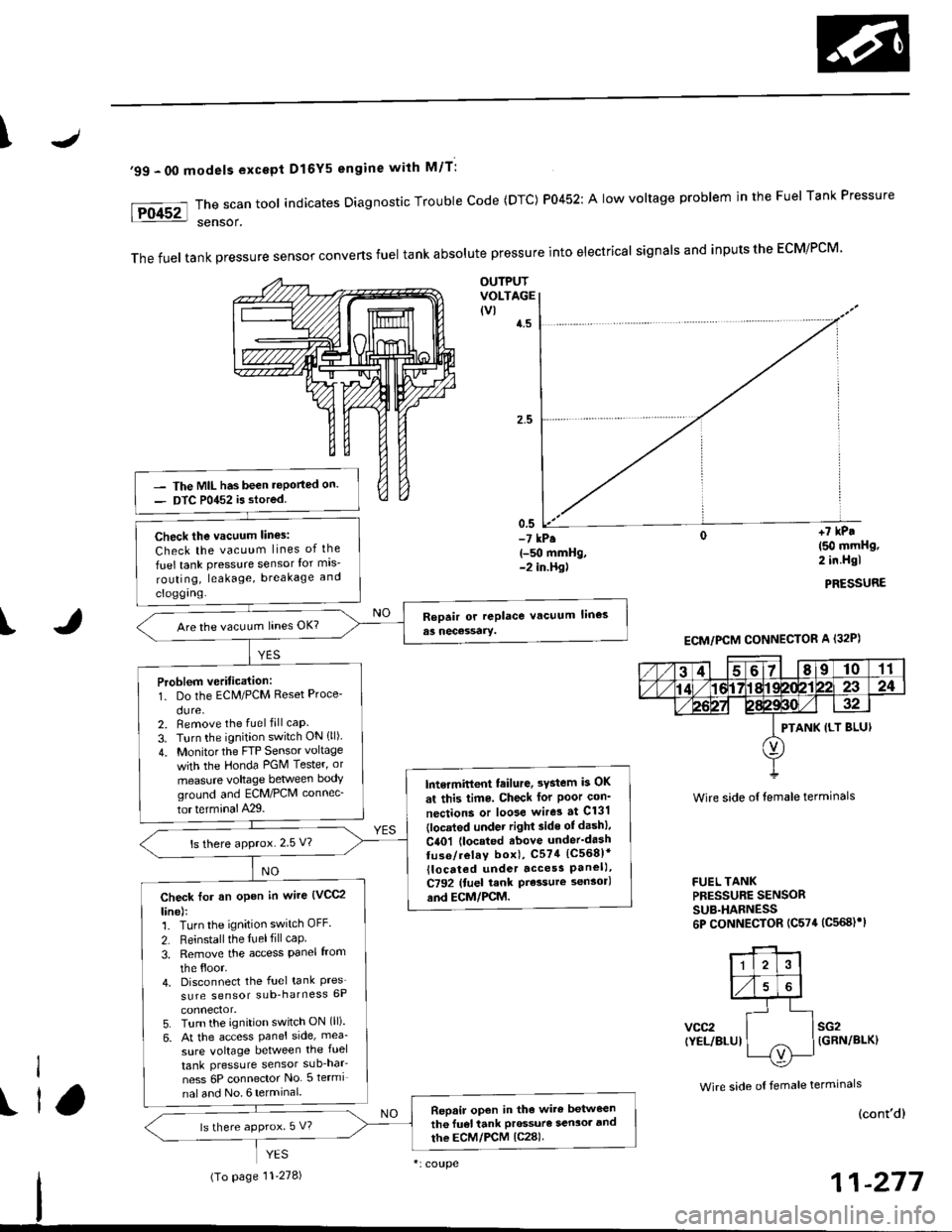

'99 - 00 models excepi Dl6Y5 engine with M/T:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM

OUTPUTVOLTAGE(vlt.5

0.5-7 kP.(-g) mmHg,-2 in.Hgl

+7 kP.

150 mmHg,2 in.Hgl

PRESSURE

I

Wire side of lemale terminals

FUEL TANKPRESSURE SENSORSUB.HARNESS6P CONNECTOR (C574 (C568)rl

vcc2(YEL/BLUIsG2{GRN/BLK}

Wire side o{ temale terminals

The MIL has been .eported on.

DTC P0452 is stored

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum hnes OK?

Problem veritication:1. Do the ECM/PCM Reset Proce-

du re,2. Bemove the fuel fill caP.

3. Turn the ignition switch ON {ll)

4. Monitorthe FTP Sensor voltage

with the Honda PGM Tester' or

measure voltage between body

groLrnd and ECM/PCM connec_

tor terminalA29.

lntermitlent tailure, 3Ystem b OK

at this time. Check for Poor con'

nections or loose wire3 at C131

{located under right side of dash},

C401 {located above under'dash

tuse/relay box), C574 (C568)*

llocdted under access Panel),C792 (tuel rank Prcssure sensorl

and ECM/PCM.

ls there approx.2 5 V?

Check for an open in wire {VCC2

line):1. Turn the ignition switch OFF.

2. Reinstall the ltrel fill caP

3, Remove the access Panel from

the floor.4. Disconnect the fuel tank Pres'sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll).

6. At the access Panel side, mea_

sure voltage between the fuel

tank Pressure sensor sub-nar-

ness 6P connector No 5termi

nal and No. 6 termlnal.

Repair open in tho wire between

th6 fu€l tank Prossuro sen3oa and

the ECM/PCM lc28).ls there approx 5 V?

ECM/PCM CONNECTOR A (32P)

PTANK {LT BLUI

I

ll

(To page '11-278)

(cont'd)

Page 550 of 2189

\

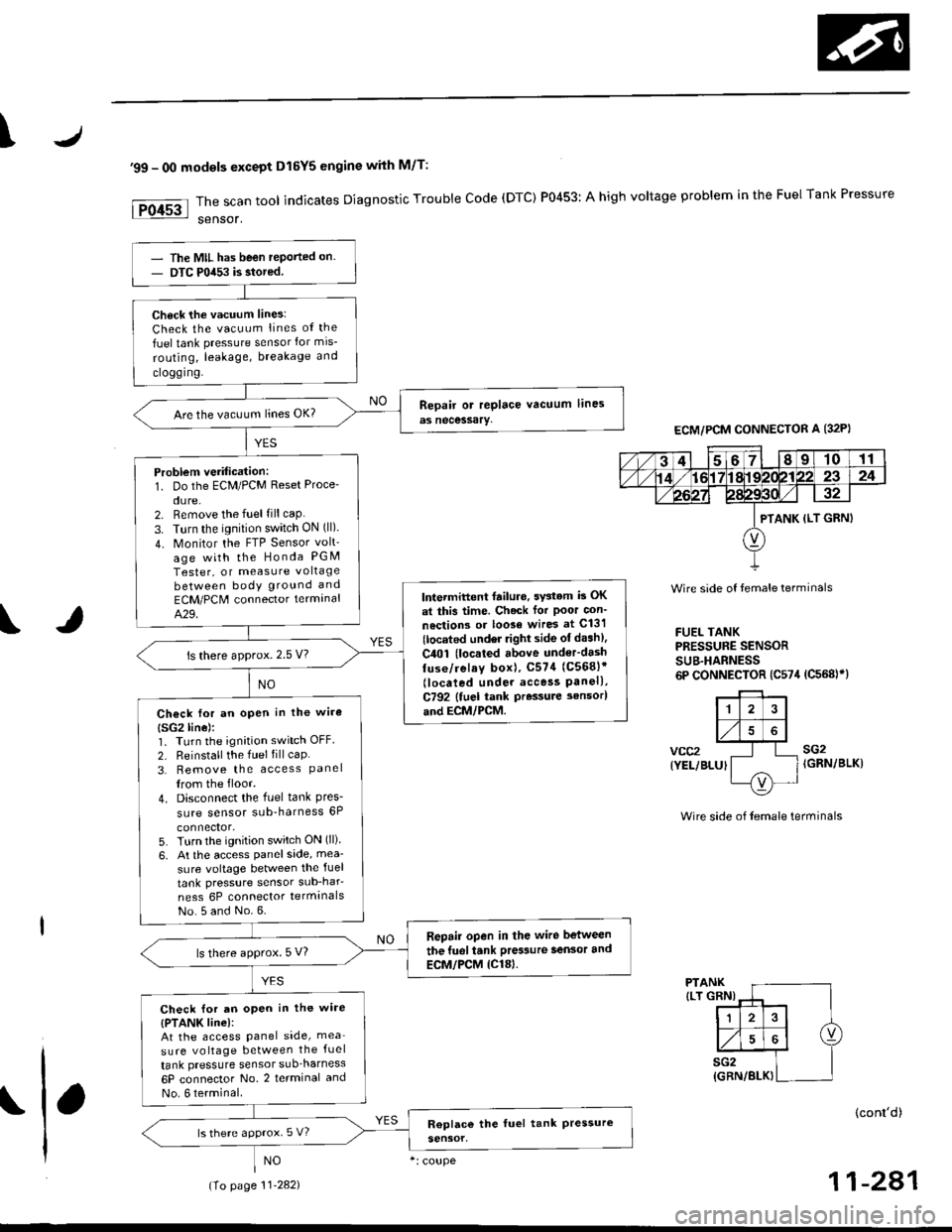

'99 - 0O modols except Dl5Y5 engine with M/T:

rFo45'::n":"tooIindicatesDiagnosticTroub|ecode(DTc)P0453:Ahighvo|tageprob|emintheFUelTankPressure

Wire side of temale terminals

FUEL TANKPRESSUNE SENSOR

SUB.HARNESS6P CONNECTOR {C574 (C568)}}

vcc2{YEL/BLUI

sG2IGRN/BLK)

Wire side of female terminals

PTANK{LT GRNI

(cont'd)

11-281

ECM/PCM CONNECTOR A {32P)

PTANK {LT GRN)

The MIL has been reported on.

DTC P0453 is stored.

Check the vacuum lines:

Check the vacuum lines ot the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verilication:1. Do the ECM/PCM Reset Proce-

du re,2. Remove the fuel fill caP

3. Turn the ignition switch ON (ll).

4. Monitor the FTP Sensor volt'

age with the Honda PGM

Tester, or measure voltage

between body ground and

ECM/PCM connector terminalA.29.

lntermittent failuro. svstem b OK

at this time. Check for Poor con_

noctions or loo3€ wire3 at C131

{located under tight side of dash),

C4Ol {located above underdash

fuse/relay boxl, C57{ (C5681'

llocaled unde. access Panell,C792 {fuel tank Pressure sensorl

aod ECM/PCM.

ls there approx.2.5 V?

Ch€ck for an open in the wira

{SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuel fill caP

3. Remove the access Panellrom the floor.

4. Disconnect the fuel tank Pres-sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll)

6, At the access Panelside, mea-

sure voltage between the fuel

tank pressure sensor sub_har-

ness 6P connector termlnals

No.5 and No.6.

Repair open in the wire between

the fueliank Pres3ure 3ensor and

ECM/PCM {Cl8).ls there approx.5 V?

Check lor an oPen in the wire

{PTANK linel:At the access Panel side, mea

sure voltage between the fuel

tank pressure sensor suo_harness

6P connector No. 2 terminal and

No. 6 terminal.

ls there approx. 5 V?

(To page 11.282)

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 691 of 2189

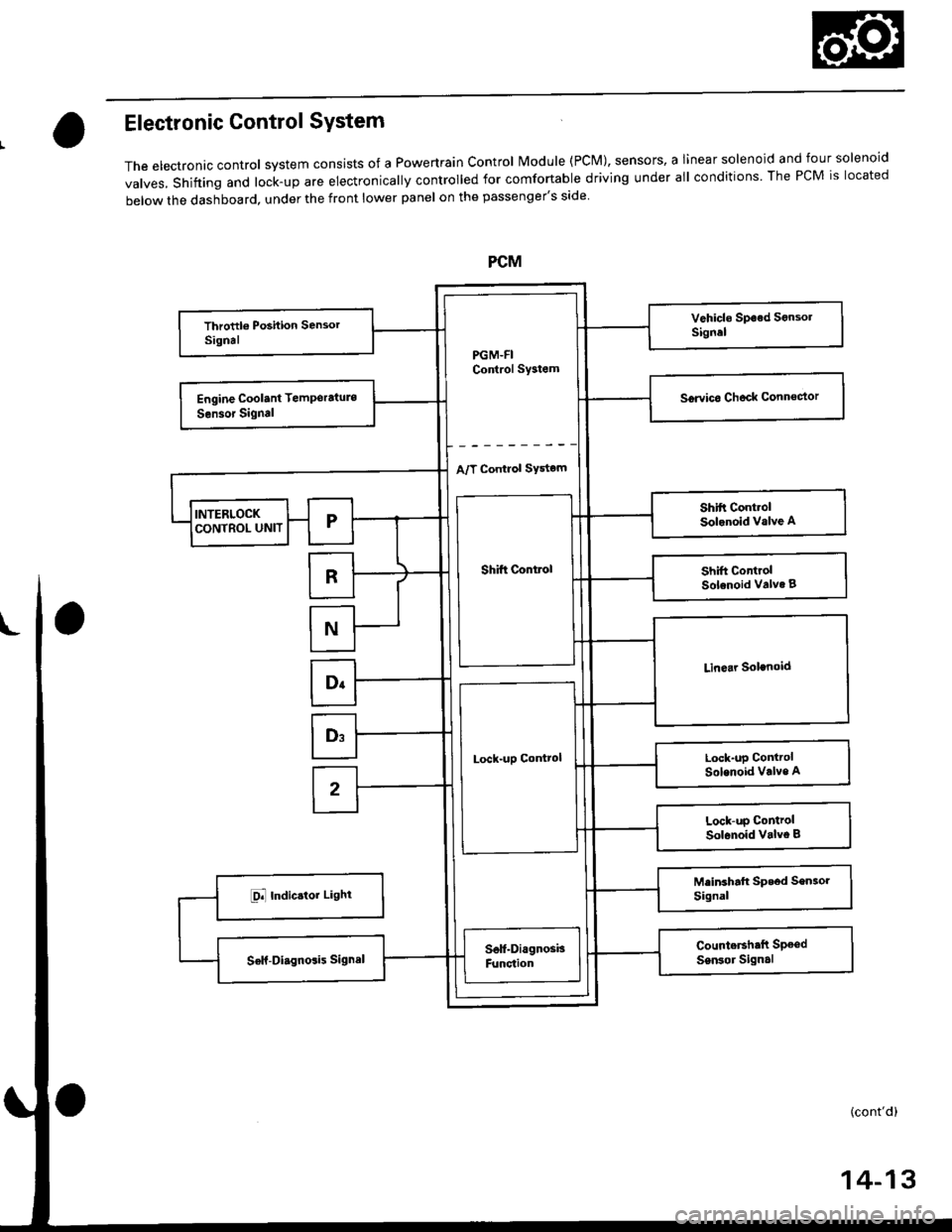

Electronic Control SYstem

The electronac controt system consrsts of a Powertrain control Module (PcM), sensors, a Iinear solenoid and four solenoid

valves, shifting and lock-up are electronically controlled for comfortable driving under all conditions The PCM is located

below the dashboard, under the front lower panel on the passenger's side

PGM-FIControl Sy3tem

A/T Control SYstom

Shift Control

Lock-uD Control

14-13

Page 718 of 2189

![HONDA CIVIC 1999 6.G Owners Manual PGM Gircuit Diagram (A/T Control System: 96 - 98 Modelsl

UNDEfl -HOOD FUSE/RELAY BOX

No.41 (80A1 N0.42 l40A)

No.47 {7.5 A)

No.l3 (15A)

Arp Np lon,^o l r,, lotrr l 6lt l 3]t lot*

UNDER DASHFUSE/REIAY HONDA CIVIC 1999 6.G Owners Manual PGM Gircuit Diagram (A/T Control System: 96 - 98 Modelsl

UNDEfl -HOOD FUSE/RELAY BOX

No.41 (80A1 N0.42 l40A)

No.47 {7.5 A)

No.l3 (15A)

Arp Np lon,^o l r,, lotrr l 6lt l 3]t lot*

UNDER DASHFUSE/REIAY](/img/13/6068/w960_6068-717.png)

PGM Gircuit Diagram (A/T Control System: '96 - 98 Modelsl

UNDEfl -HOOD FUSE/RELAY BOX

No.41 (80A1 N0.42 l40A)

No.47 {7.5 A)

No.l3 (15A)

Arp Np lon,^o l r,, lotrr l 6lt l 3]t lot*

UNDER DASHFUSE/REIAY 8OX

/8LU

c10

YEUBLKBtK

424

Btx

At0423

'96:BLU/BED'97, '98r GFN/BLK

TTTYEL GRN BLULT GRN

BLK/BTU

RED

GRNiELK

F- BTK/BI.U

F_wHr

F- GRN

f- GRN

F- Bru

GRN

BLU

NorE: t :ro5v

T :ro 12v

GAUGE ASSEMBTY

A,T GEAR POSITIONINDICATOR

824 t88 tB17'96: GRN 8LU

'96: BLU/RED al'97,'98: GRN/8LK --