Lug nut HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1104 of 2189

Steering Gearbox

Removal {cont'dl

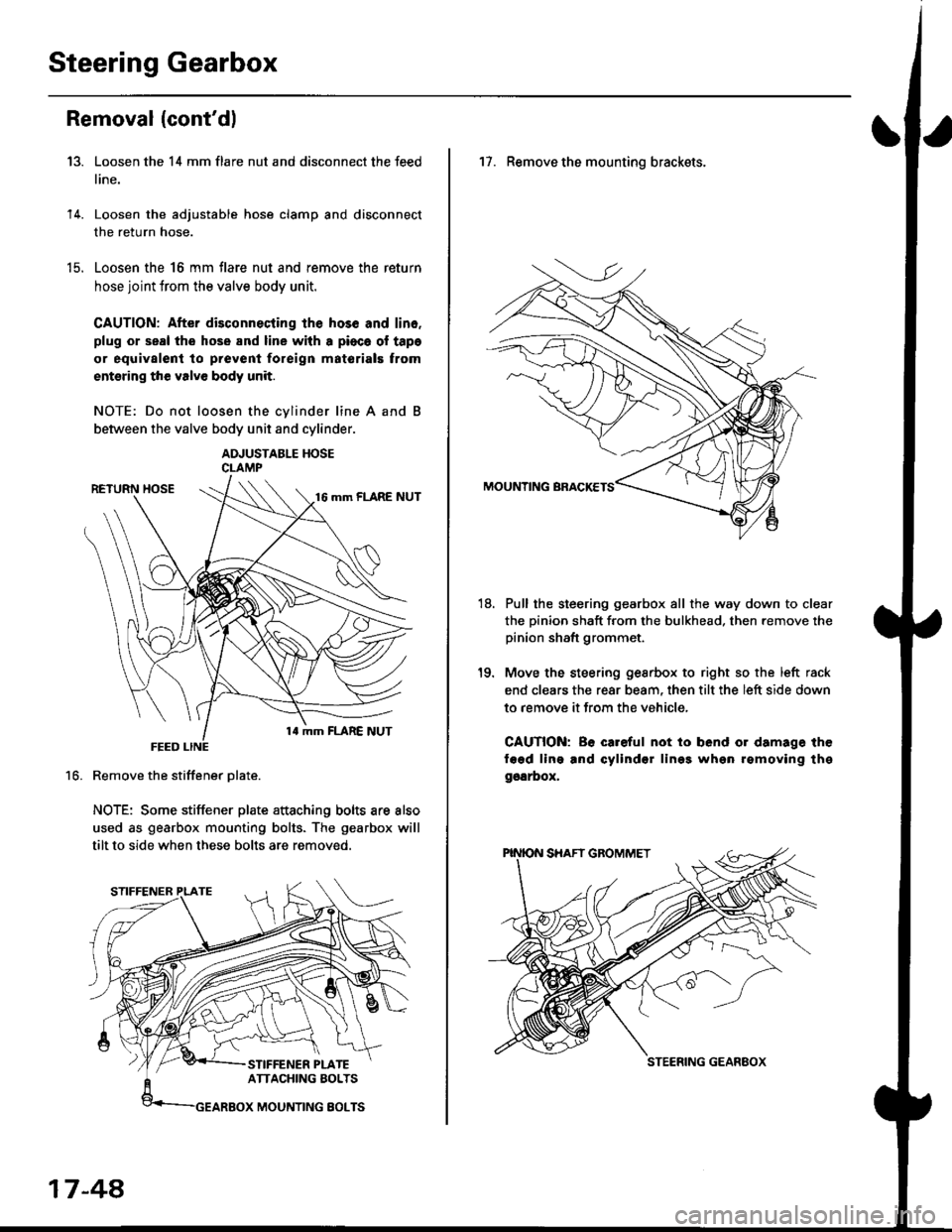

Loosen the 14 mm flare nut and disconnect the feed

line.

Loosen the adjustable hose clamp and disconnect

the return hose.

Loosen the 16 mm flare nut and remove the return

hose joint trom the valve body unit.

CAUTION: After disconnecting lhe hos6 and lin6.

plug or seal the hose and line with a pioca ol tapa

or equivalent to prevenl foreign matorials trom

entsring the valve body unit.

NOTE: Do not loosen the cvlinder line A and

between the valve body unit and cylinder.

ADJUSTABLE HOSECLAMP

Remove the stiffener Dlate.

NOTE: Some stiffener plate attaching bolts are also

used as gearbox mounting bolts. The gearbox will

tilt to side when these bolts are removed.

13.

14.

t9.

16.

17-48,

17. Remove the mounting brackets.

Pull the steering gearbox all the way down to clear

the pinion shaft from the bulkhead. then remove the

pinion shaft grommet.

Move the steering gesrbox to right so the left rack

end clears the rear beam, then tilt the left side down

to remove it from the vehicle,

CAUTION: Be careful not io bend or damage the

fagd ling and cylindsr lin99 whgn rgmoving thg

ggarbox,

18.

STEERING GEANEOX

Page 1139 of 2189

I

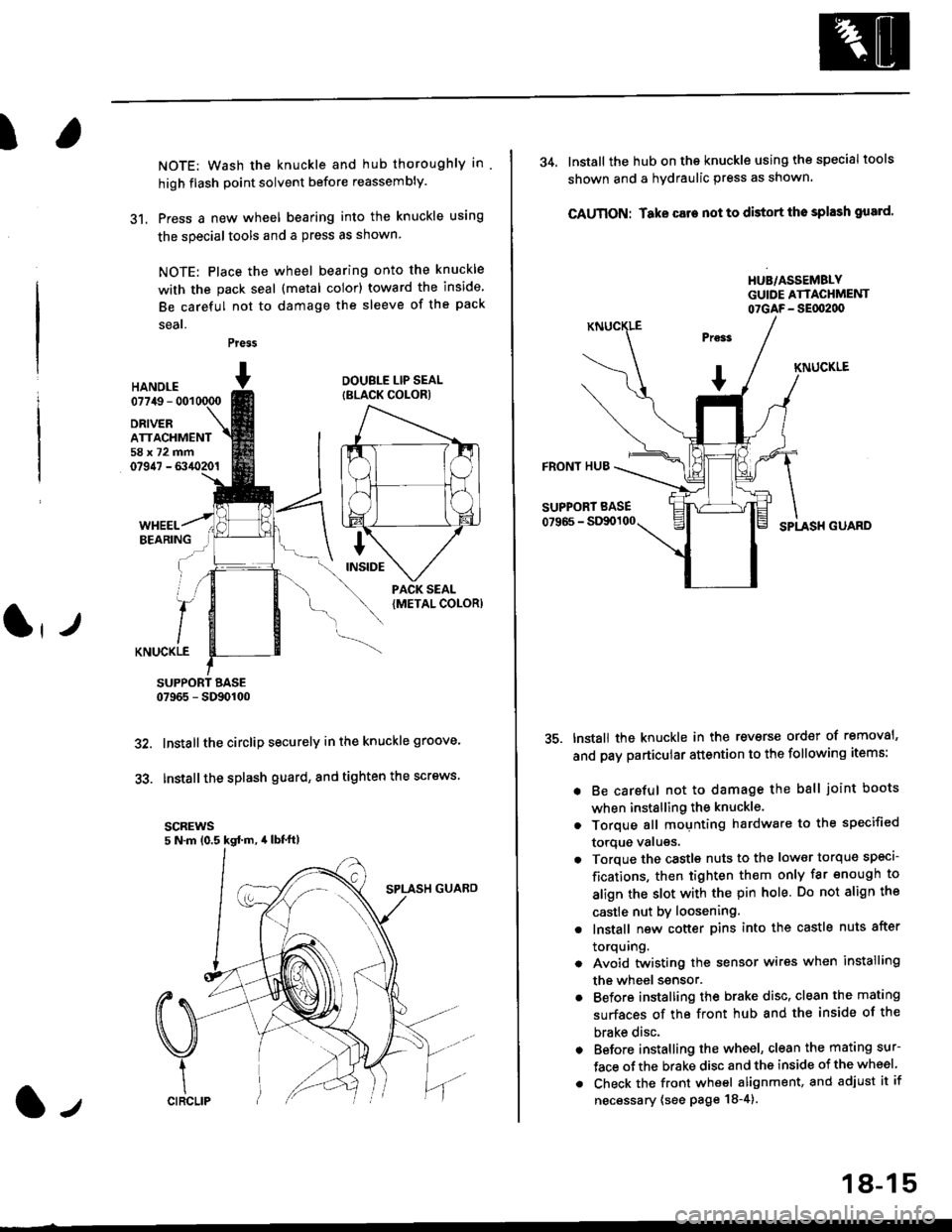

NOTE: Wash the knuckle and hub thoroughly in

high flash point solvent before reassembly.

31. Press a new wheel bearing into the knuckle using

the specialtools and a press as shown

NOTE: Place the wheel bearing onto the knuckle

with the pack seal (metal color) toward the inside

Be careful not to damage the sleeve of the pack

seal.

Press

HANOI.E07749 - 001

DRIVERATTACHMENT58x72mm07947 - 6340201

DOUBLE LIP SEAL

{BLACK COLOR)

KNUCKLE

SUPPORT BASE07965 - SD90100

Installthe circlip securely in the knuckle groove'

Installthe splash guard, and tighten the screws.

scREws5 N.m (0.5 kgd m, 4lbt'ft)

32.

33.

l-,

18-15

34. lnstall the hub on the knuckle using the specialtools

shown and a hydraulic press as shown.

CAUTION: Take care not to distort tho splash gusrd'

HUB/ASSEMBLYGUIDE ATTACHMENT07GAF- SEflt2d)

KNUCKLE

FRONT HUB

SUPPORT BASE

07966 - StXx)100SPLASH GUARD

tnstall the knuckle in the reverse order of removal'

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

. Torque all mounting hardware to the specified

torque valugs.

. Torque the castls nuts to the low€r torque specl-

fications, then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. lnstall new cotter pins into the castle nuts after

torquing.

. Avoid twistin0 the sensor wires when installing

the wheel ssnsor.

. Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the wheel, clean the mating sur-

face ofthe brake disc and the inside of the wheel

. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

Page 1228 of 2189

\il

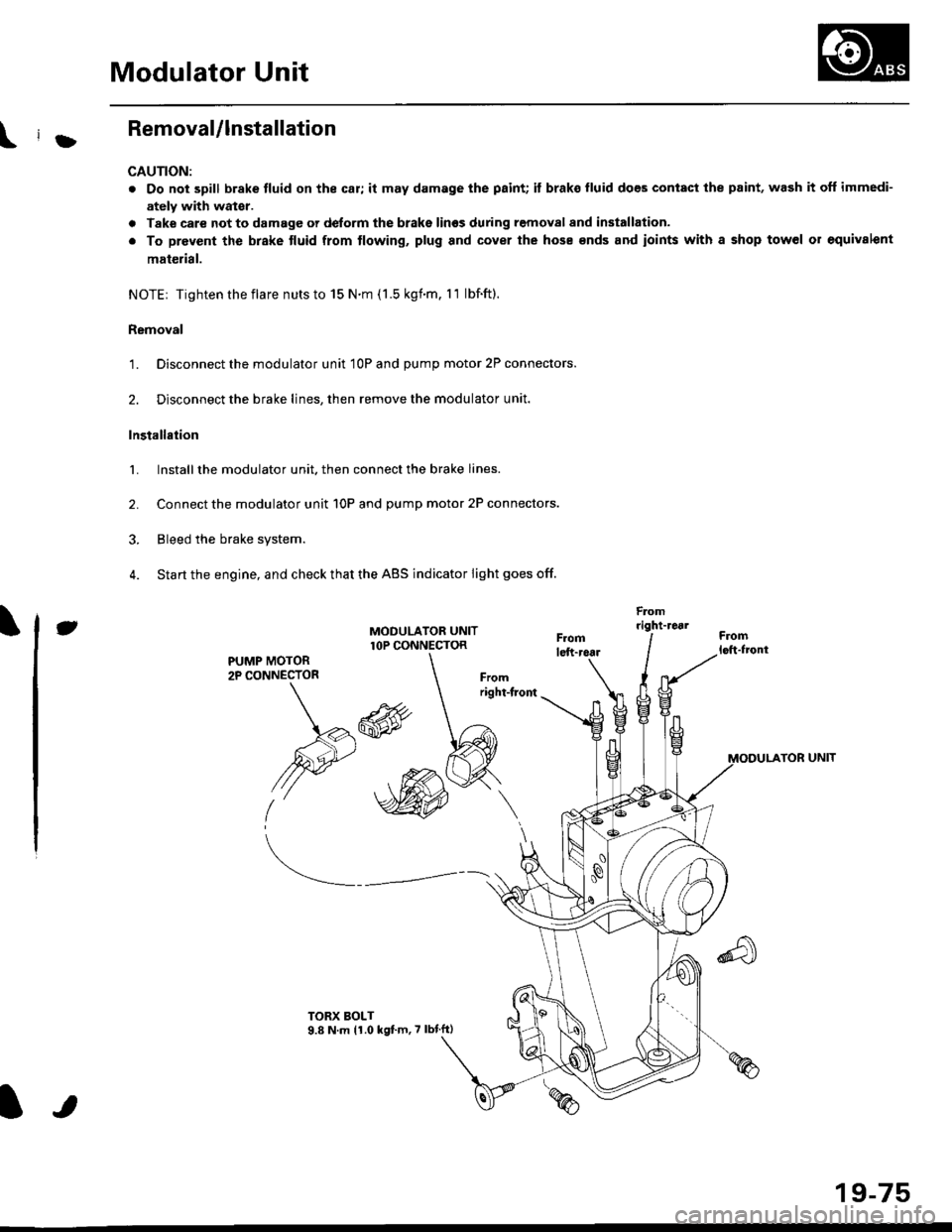

Modulator Unit

RemovaUlnstallation

CAUTION:

. Do not spill brake tluid on the car; it may damage the paint; it brako lluid does contact the paint, wash it off immedi-

ately with wator.

a Take care not to damage or delorm the brake lin€s during removal and installation.

. To prevent the brake tluid from tlowing, plug and cover the hose €nds and ioints with a shop tow6l or equivalent

mat€rial.

NOTE| Tightentheflare nutsto 15 N.m (1.5 kgnm. l1 lbf.ft).

Removal

'1. Disconnect the modulator unit 10P and Dump motor 2P connectors.

2. Disconnect the brake lines, then remove the modulator unit.

Installaiion

1. Install the modulator unit. then connect the brake lines.

2. Connect the modulator unit 10P and oumD motor 2P connectors.

3. Bleed the brake system.

4. Start the engine, and check that the ABS indicator light goes off.

Fomright-1461

PUMP MOTOR2P CONNECTOR

J

-R

/2e'

t'

TOR UNIT

tt

19-75

Page 1452 of 2189

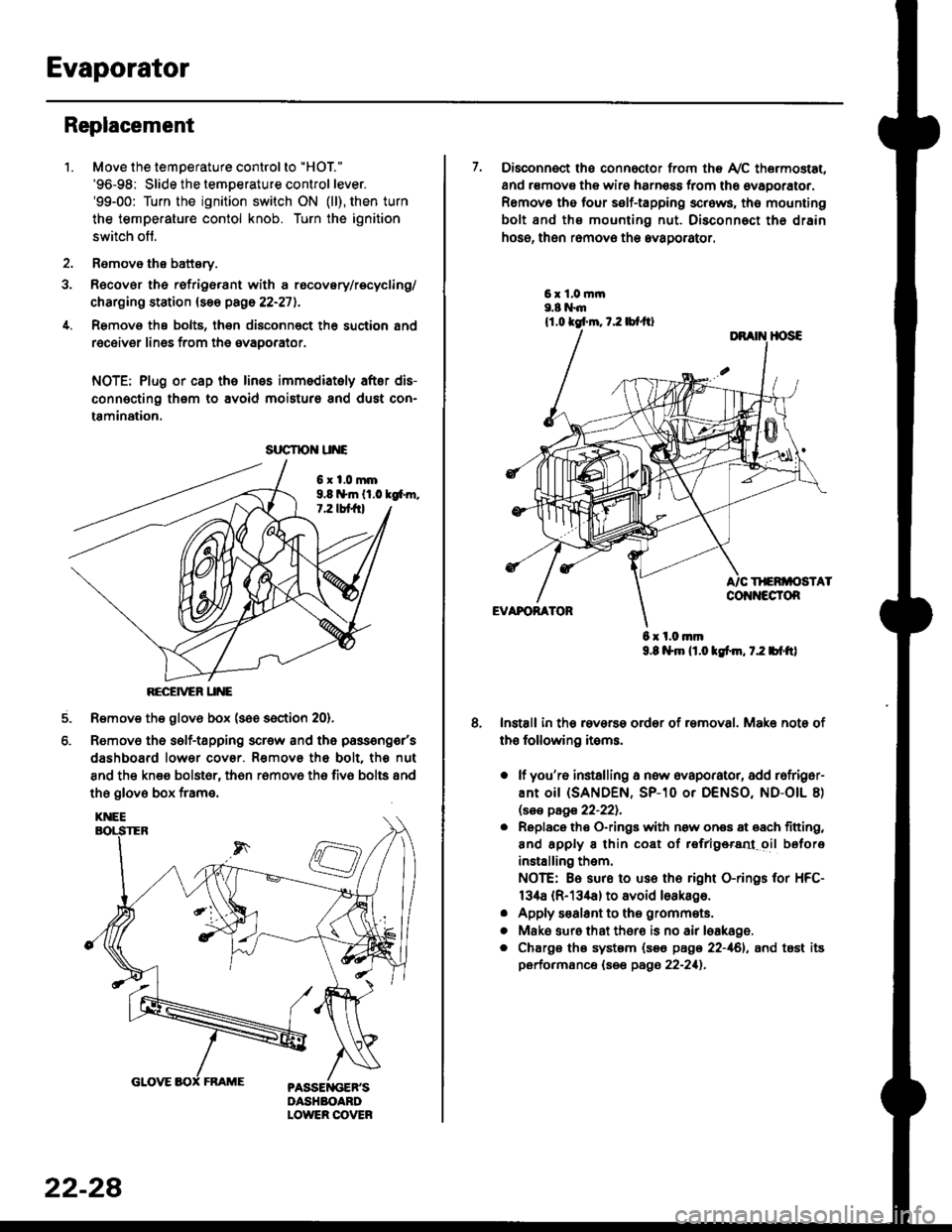

Evaporator

1.

Replacement

4.

Move the temperature control to "HOl"

'96-98: Slide the temoerature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off.

Remove the battsry.

Rgcover the refrigerant with a rocovery/recycling/

charging station (see page 22-271.

Remove the bolts, then disconnect th6 suction 8nd

receiver lines from th6 evaoorator.

NOTE: Plug or cap the lines imm€diatoly after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm9.8 n*ln ll.0 tg6m.7.2 lbt frl

RECEiVER UNE

Remove the glov6 box (see section 20).

Removo the self-tapping scr€w and the passeng€r's

dashboard lower cover. Removs the bolt. the nut

8nd the kn€e bolst6r, th6n r6mov6 th6 fiv6 bolts and

the glove box frame.

6.

srrcrrc u E

22-28

7. Disconnect the connector from th€ Ay'C thermostat,

and r€movs the wire harness from the ovaporator.

Remov6 tho four self-tapping screws, tho mounting

bolt and ths mounting nut. Disconnect th€ drain

hose, then remov€ th6 avagorator.

6 x l.0.nm9.8 l$m lt.o ldm, 7.2 bl.tt)

Install in the reverse order of removal. Make note of

th€ following items.

o lf you'r6 installing a new evaporator, add rofriger-

ANt OiI {SANDEN, SP-10 Or DENSO, ND-OIL 8)

lsas page 22-221.

. Replace the O-rings with now ones 8t 68ch titting,

and apply 8 thin coat of r€frlgersd oil before

installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid loakago.

. Apply s€alant to tha grommets.

. Mske sure that ther€ is no air leakage.

. Chargs ths system {s€€ page 22-161, and tost its

performance (see pags 22-211.

Page 1454 of 2189

Compressor (SANDENI

Replacement

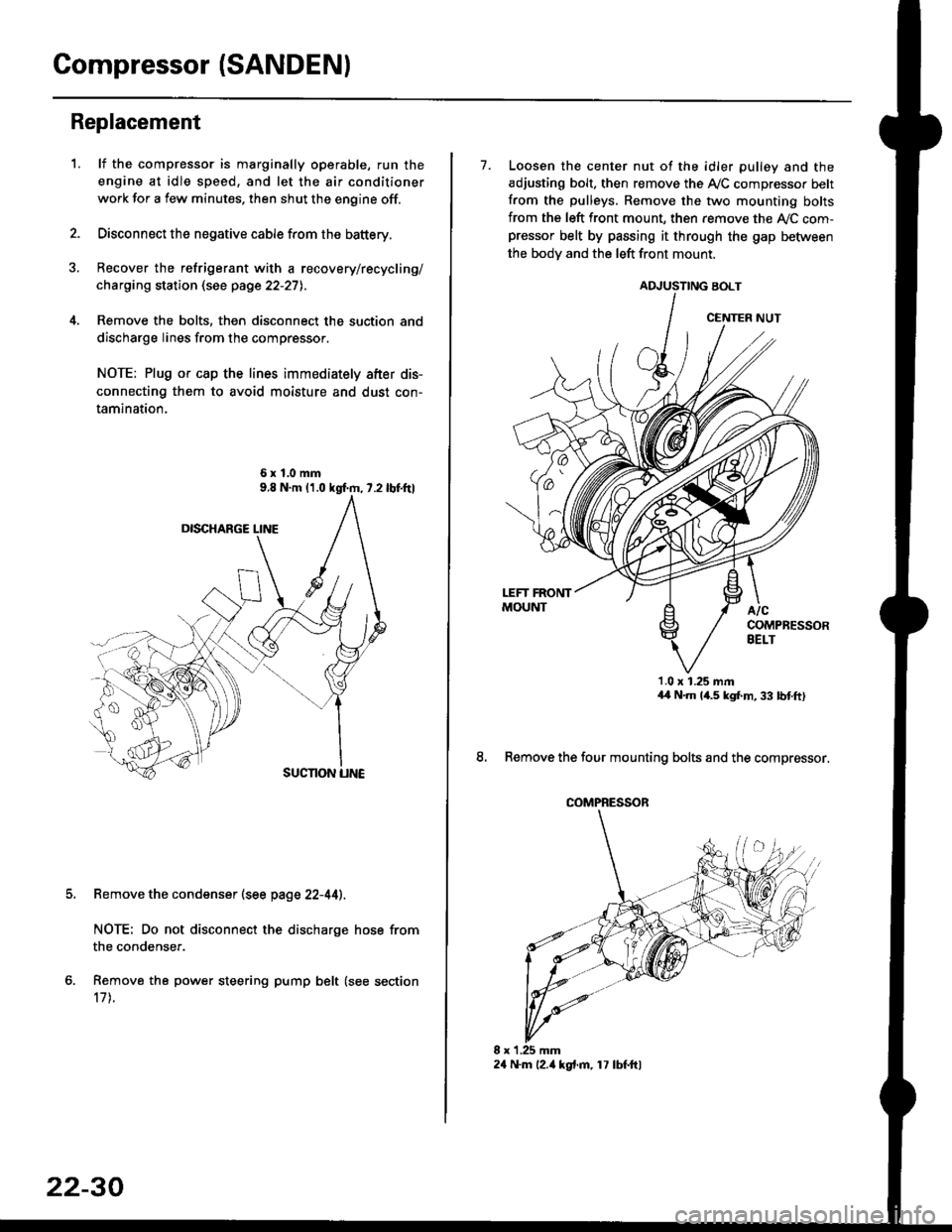

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-27l..

Remove the bolts, then disconnect the suction and

discharge lines from the compressor.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm

Remove the condenser (see page 22-44).

NOTE: Do not disconnect the discharge hose from

the condenser.

Remove the power steering pump belt (see section

17 t.

22-30

24 N.m l2.ia kgt.m, 17 lbf.ftl

7. Loosen the center nut of the idler pulley and the

adjusting bolt. then remove the A,/C compressor belt

from the pulleys. Remove the two mounting bolts

from the left front mount, then remove the ly'C com-pressor belt by passing it through the gap befiiveen

the bodv and the left front mount.

ADJUSTING BOLT

1.0 x 1.25 mmaa N.m 14.5 kgf,m, 33 bnft)

8. Remove the four mounting bolts and the compressor.

CENTER NUT

COMPRESSOR

Page 1461 of 2189

Compressor (DENSO)

Replacement

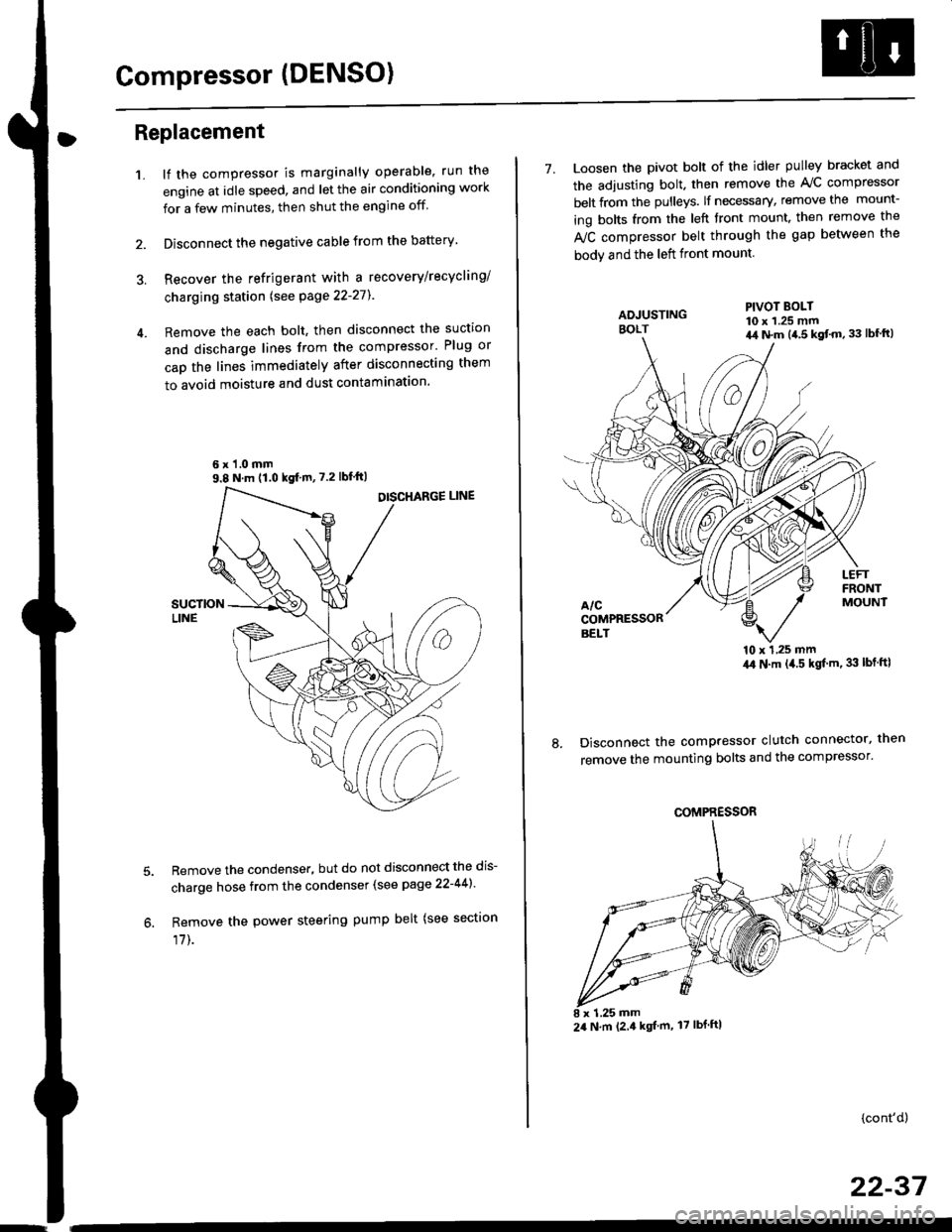

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning work

for a few minutes, then shut the engine off

Disconnect the negative cable from the battery'

Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271

Remove the each bolt, then disconnect the suction

and discharge lines from the compressor' Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contaminatlon.

6 x '1.0 mm9.8 N.m (1.0 kgf m,7.2 lbfft)

Remove the condenser, but do not disconnect the dis-

charge hose from the condenser (see page 22-441'

Remove the power steering pump belt (see sectron

17]-.

7. Loosen the pivot bolt of the idler pulley bracket and

the adjusting bolt. then remove the A,/C compressor

belt from the pulleys. lf necessary, remove the mount-

ing bolts from the left front mount. then remove the

fuC compressor belt through the gap between the

bodv and the left front mount.

'10 x 1,25 mm4,0 N.m (,1.5 kgf'm. 33 lbt ftl

Disconnect the compressor clutch connector, then

remove the mounting bolts and the compressor'

PIVOT BOLT10 x 1.25 mm4,1 N.m (4.5 kgt'm,33 lbfft)

COMPRESSOR

24 N.m (2.4 kgf m, 17 lbf ftl

(cont'd)

22-37