service indicator HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 912 of 2189

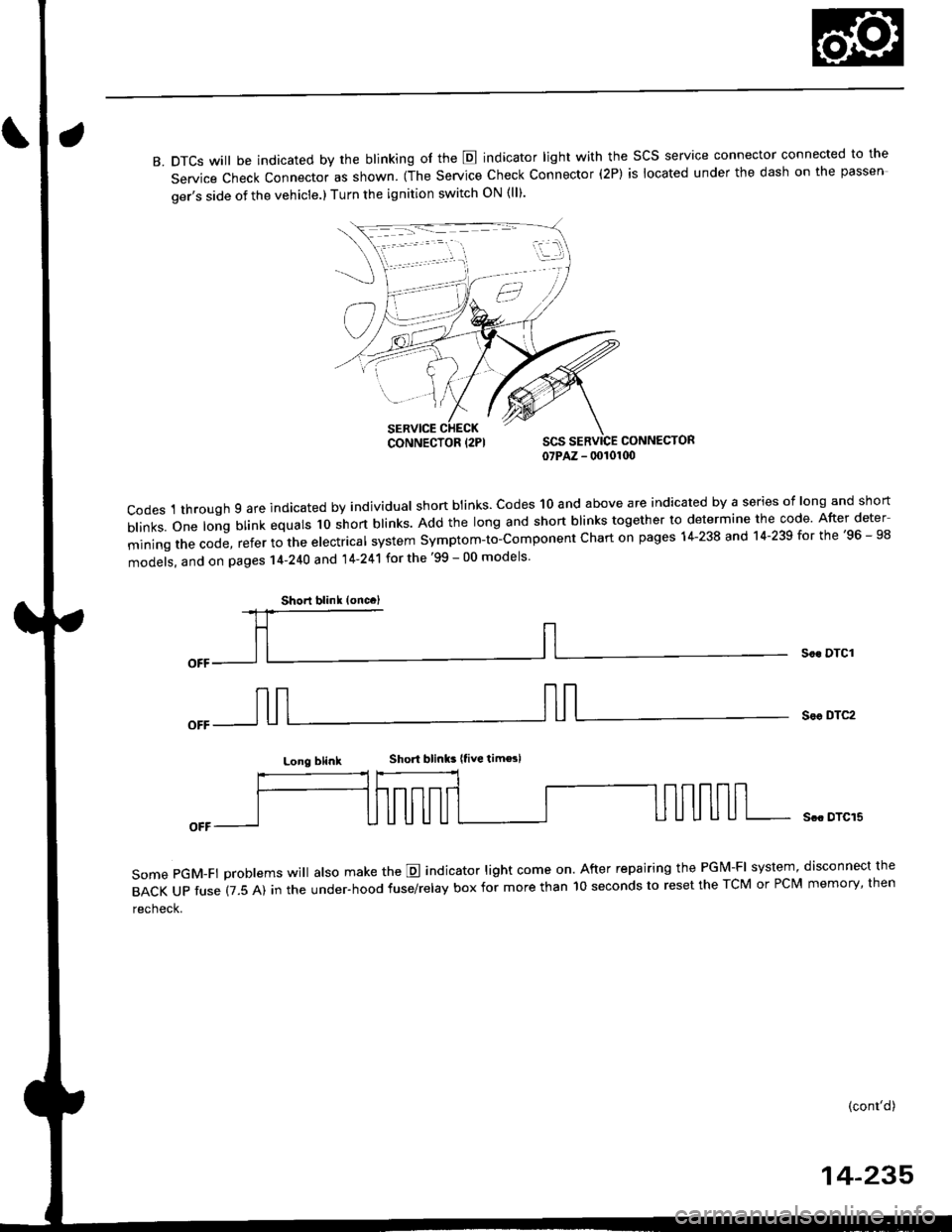

B. DTCS will be indicated by the blinking of the E indicator light with the SCS service connector connected to the

Service Check Connector as shown. (The Service Check Connector (2P) is located under the dash on the passen

ger's side of the vehicle.) Turn the ignition switch ON (ll).

CONNECTOR07PAZ - 00101(x)

codes 1 through 9 are indicated by individual shon btinks. codes 10 and above are indicated by a series of long and short

b|inks.one|ongblinkequa|sloshortb|inks.Addthe|ongandshortb|inkstogethertodeterminethecode.Afterdeter

miningthecode,refertothee|ectrica|systemsymptom-to-componentchartonpagesl4-238and14.239forthe,96_98

models, and on pages 14-240 and 14'241 for the '99 - 00 models

Soc DTCI

Sor DTC2

Long blinkShort blinks |tive tim€sl

some pGM-Ft problems wi

atso make the E indicator light come on. After repairing the PGM-FI system, disconnect the

BACKUPfuse(7.5A)intheUnder.hoodfuse/re|ayboxformorethanl0secondstoresettheTcMorPcMmemory,then

recheck.

Scc DTCI5

(cont'd)

14-235

iii:j

,,,/

CONNECTOR {2PI

Shorl blink (oncc)

Page 939 of 2189

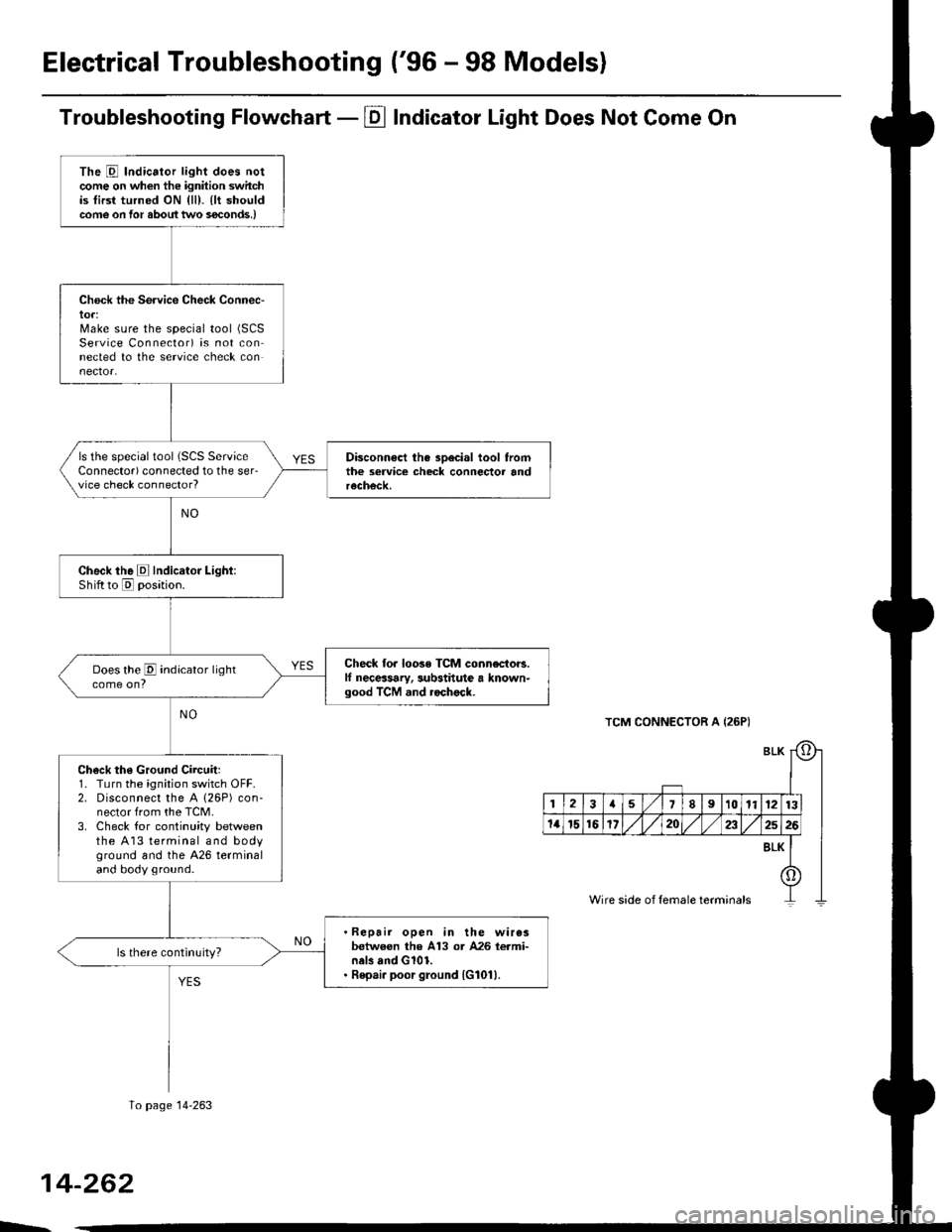

Electrical Troubleshooting ('96 - 98 Modelsl

Troubleshooting Flowchart - Pl Indicator Light Does Not Gome On

TCM CONNECTOR A {26P)

BLI

l-I

123a589101t12nl

1a151617202325rt

o

8LK

Wire side of female terminals

The E Indicator light does notcome on when the ignition switchis tirst turned ON {ll). {lt shouldcome on for aboul two s€conds,)

Chock the Service Check Connec-lot:Make sure the special tool (SCS

Service Connector) is not connected to the seryice check connector,

ls the special tool (SCS ServiceConnector) connected to the ser-vice check connector?

Disconn€ct the sDecial tool fromthe seruice check connector andrecheck.

Check the E Indicator Light:Shift to [5] oosition.

Check fo. loose TCM connectors.lf neceasary, substitute a known-good TCM .nd rochock.

Does the E indicator lightcome on?

Ch€ck th6 Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the A 126P) con-nector from the TCM.3. Check tor continuity betweenthe A13 terminal and bodyground and the 426 terminaland body ground.

.Repair open in the wiresbetwoon lhe A13 or A26 termi-nel3 and G101.. Repai. poor ground {G1011.

To page 14-263

14-262

>.

Page 965 of 2189

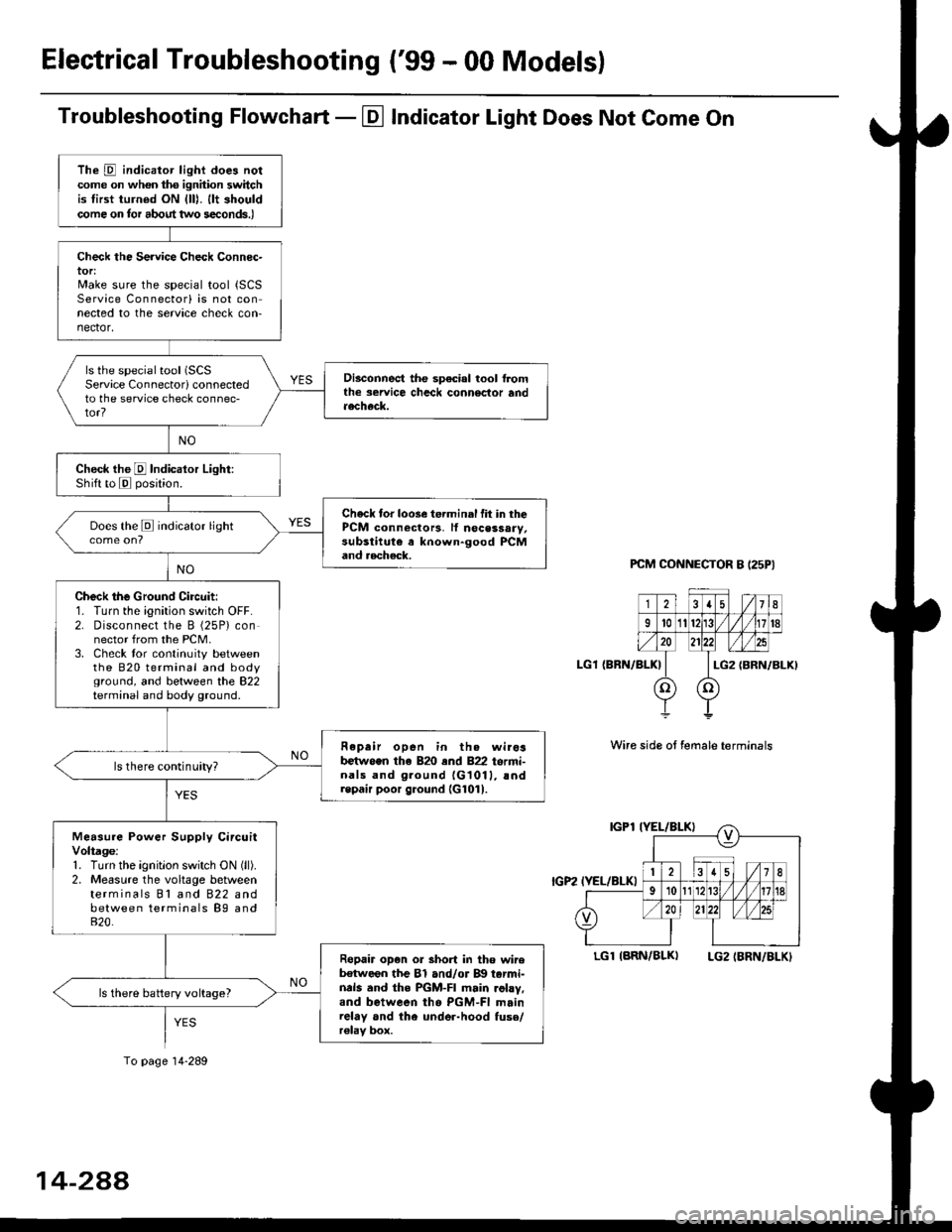

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - El Indicator Light Does Not Come On

PCM CONNECTOR B I25PI

LGl {BRN/BLK)

Wire side ot female terminals

LGlIARN/BLK) LG2IBRN/BLKI

The D indicator light does notcome on whon ths ignhion switchis tirst turned ON {lll. llt shouldcome on tor about two s€conds.)

Check the Service Check Connec-tor:Make sure the special tool {SCSService Connectorl is not connected to the service check con-nector,

ls the special tool (SCS

Service Connectorl connectedto the service check connec-tor?

Disconnect the sp€cial tool f]omthe seruice chcck connoclor andaecheck.

Check the E Indicalor Light:Shift to E posjtion.

Check tor loose te.minal fit in thePCM connectors, lf nocessary,substitute a known-good PCMand aecheck.

Does the E indicator light

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) connector from the PCM.3. Check tor continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Fepair open in th. wirosb€tw.en the 820 end 822 termi-nals and ground {G1011, !ndrepair poor ground {G1011.

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignitlon switch ON (ll).

2. Measure the voltage betweenterminals Bl and 822 andbetween terminals B9 and820.

Ropair op€n or short in tho wireb€tween the Bl and/or B!| tarmi-nds and the PGM-FI main .ohy,and between tho PGM-FI mainrelay and the under-hood fuso/r€lav box.

ls there battery voltage?

To page 14-289

14-2AA

Page 1166 of 2189

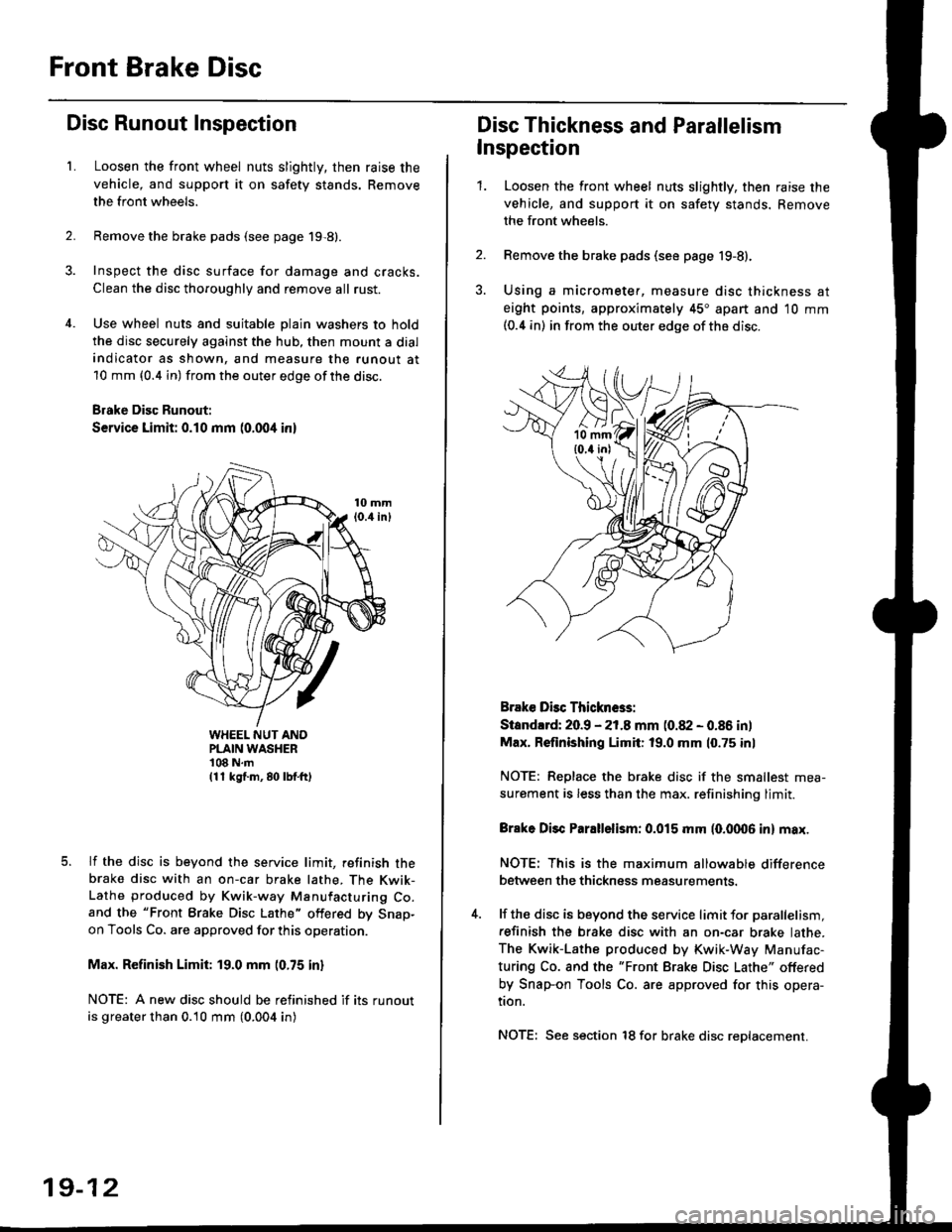

Front Brake Disc

Disc Runout Inspection

L

2.

Loosen the front wheel nuts slightly, then raise the

vehicle, and support it on safety stands. Remove

the front wheels.

Remove the brake pads (see page 19,8).

Inspect the disc surface for damage and cracks.

Clean the disc thoroughly and remove all rust.

Use wheel nuts and suitable plain washers to hold

the disc securely against the hub, then mount a dial

indicator as shown, and measure the runout at

10 mm (0.4 in) from the outer edge of the disc.

Brake Disc Runout:

Service Limit: 0.10 mm (0.004 inl

WHEEL NUT ANOPLAIN WASHER'108 N.m(11 kg{.m, 80 lbf.ft)

lf the disc is beyond the service limit, refinish thebrake disc with an on-car brake lathe, The Kwik-Lathe produced by Kwik-way Manufacturing Co.and the "Front Brake Disc Lathe" offered by Snap-on Tools Co. are approved for this operation.

Max. Refinish Limit: 19.0 mm (0.75 in)

NOTE: A new disc should be refinished if its runout

is greater than 0.10 mm (0.004 in)

19-12

Disc Thickness and Parallelism

Inspection

1.Loosen the front wheel nuts slightly, then raise the

vehicle, and support it on safety stands. Remove

the front wheels.

Remove the brake pads (see page 19-8).

Using a micrometer, measure disc thickness at

eight points, approximately 45" apart and 10 mm(0.4 in) in from the outer edge of the disc.

Brake Dbc Thickn6s:

Standlrd: 20.9 - 21.8 mm (0.82 - 0.86 in)

Max. Refinishing Limit: 19.0 mm 10.75 inl

NOTE: Replace the brake disc if the smallest mea-

surement is less than the max. refinishinq limit.

Brake Disc Parallelism: 0.015 mm (0.fit06 in) max.

NOTE: This is the maximum allowable difference

between the thickness measurements.

lf the disc is beyond the service limit for parallelism,

refinish the brake disc with an on-car brake lathe.

The Kwik-Lathe produced by Kwik-Way Manufac-

turing Co. and the "Front Brake Disc Lathe" offered

by Snap-on Tools Co. are approved for this opera-

tion.

NOTE: See section 18 for brake disc reDlacement.

Page 1180 of 2189

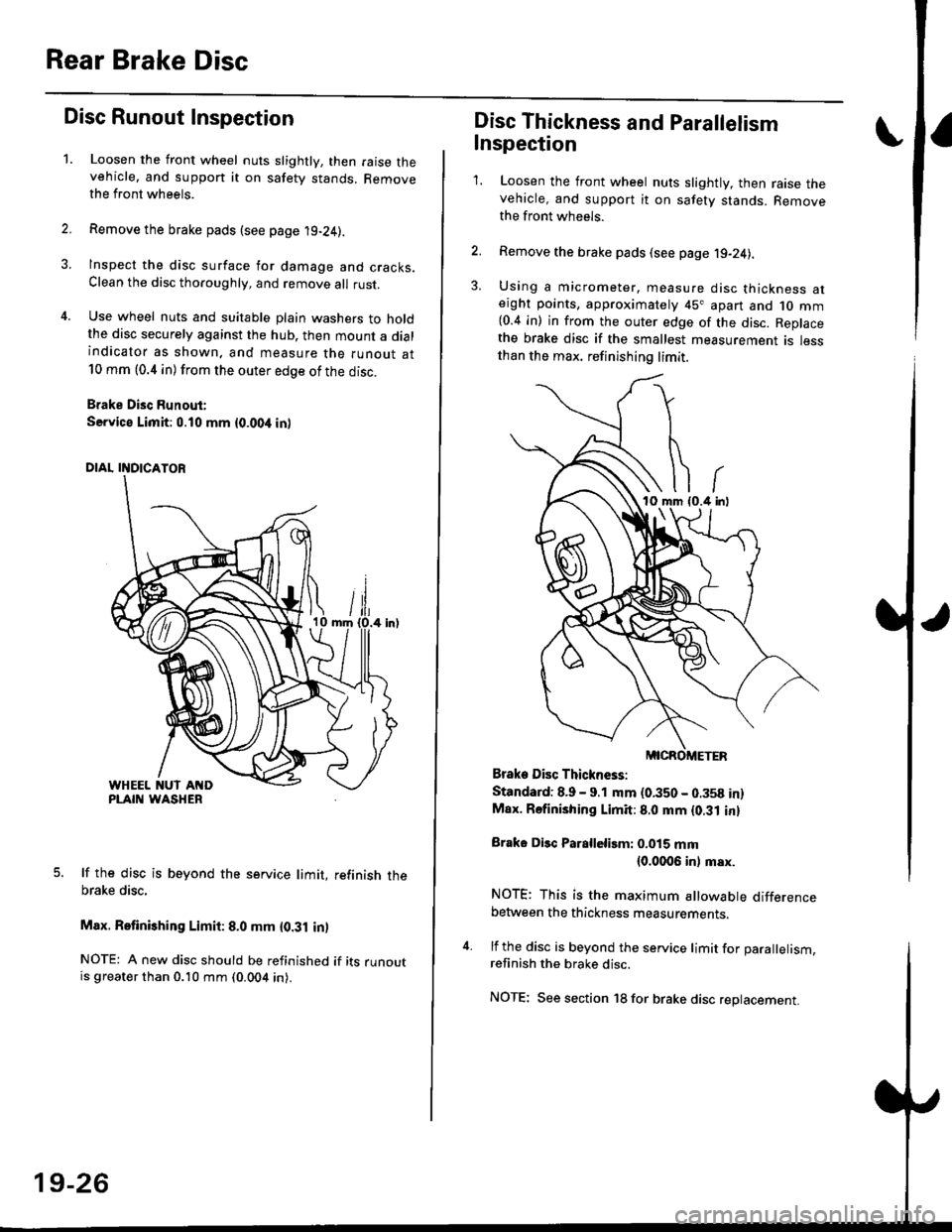

Rear Brake Disc

Disc Runout Inspection

1.Loosen the front wheel nuts slightly, then raise thevehicle, and suppon it on safety stands. Removethe front wheels.

Remove the brake pads (see page 19-24).

Inspect the disc surface for damage and cracks.Clean the disc thoaoughly, and remove a

rust.

Use wheel nuts and suitable plain washers to holdthe disc securely against the hub. then mount a dialindicator as shown. and measure the runout at10 mm (0.4 in) from the outer edge of the disc.

Brake Disc Runout:

Service Limit:0.10 mm {0.00,t in)

5. lf the disc is beyond the service limit, refinish thebrake disc,

Max. Retinishing Limit: 8.0 mm {0.31 in)

NOTE: A new disc should be refinished if its runoutis greater than 0.10 mm (0.004 in).

19-26

Disc Thickness and Parallelism

Inspection

1. Loosen the front wheel nuts slightly, then raise thevehicle, and support it on safety stands. Removethe front wh6els.

2. Remove the brake pads (see page j9-24).

3. Using a micrometer. measure disc thickness aterght points, approximately 45" apart and 1o mm{0.4 in) in from the outer edge of the disc. Replacethe brake disc if the smallest measurement is lessthan the max. refinishing limit.

Brake Disc Thickness:

Standard: 8.9 - 9.1 mm (0.350 - 0.358 in)Max. Rsfinishing Limit: 8.0 mm {0.31 in}

Brake Disc Parallelirm: 0.015 mm(0.0006 inl msx.

NOTE; This is the maximum allowable differencebetween the thickness measurements.

4. lf the disc is beyond the service limit for Darallelism.refinish the brake disc.

NOTE; See section 18 for brake disc replacement.

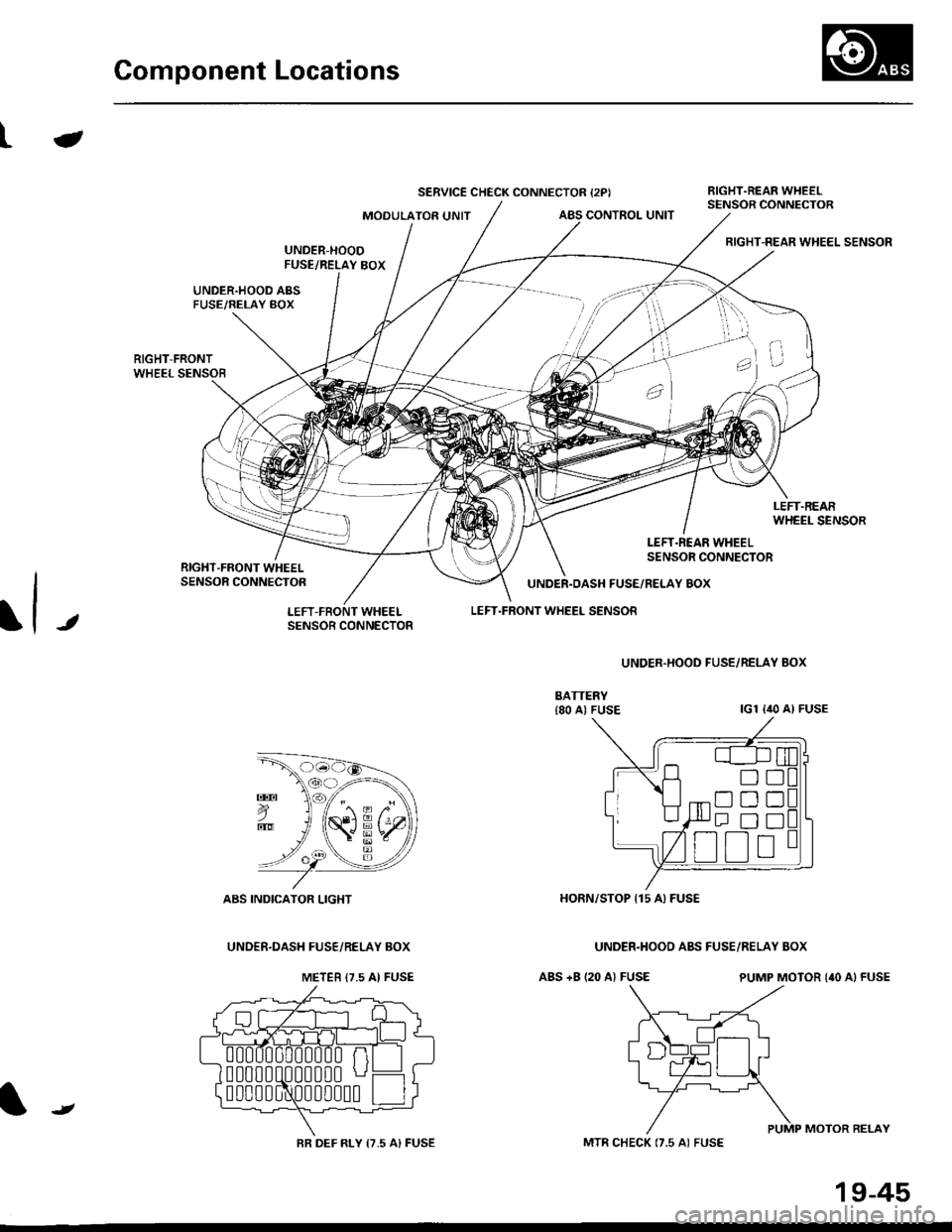

Page 1198 of 2189

Component Locations

ta

SERVICE CHECK CONNECTOR {2PIBIGHT.REAR WHEELSENSOR CONNECTORMOOULATOR UNITABS CONTROL UNIT

RIGHT-REAR WHEEL SENSOR

LEFT.R€AR WHEELSENSOR CONNECTOR

J

UNDER.DASH FUSE/RELAY 8OX

LEFT.FRONT WHEEL SENSOR

ABS +B (20 A) FUSE

UNDER.HOOD FUSE/RELAY BOX

lcl lilo Al FUSE

ABS INDICATOR LIGHT

UNOEF.DASI{ FUSE/RELAY BOX

HORN/STOP I15 A) FUSE

UNDER.HOOO ABS FUSE/RELAY BOX

PUMP MOTOR {'O A} FUSE

PUMP MOTOR BELAY

E

o

METEB I7.5 AI FUSE

0

0

0

00000 n

00000 u

BR DEF RLY 17,5 A) FUSE

t

MTR CHECK (7.5 AI FUSE

19-45

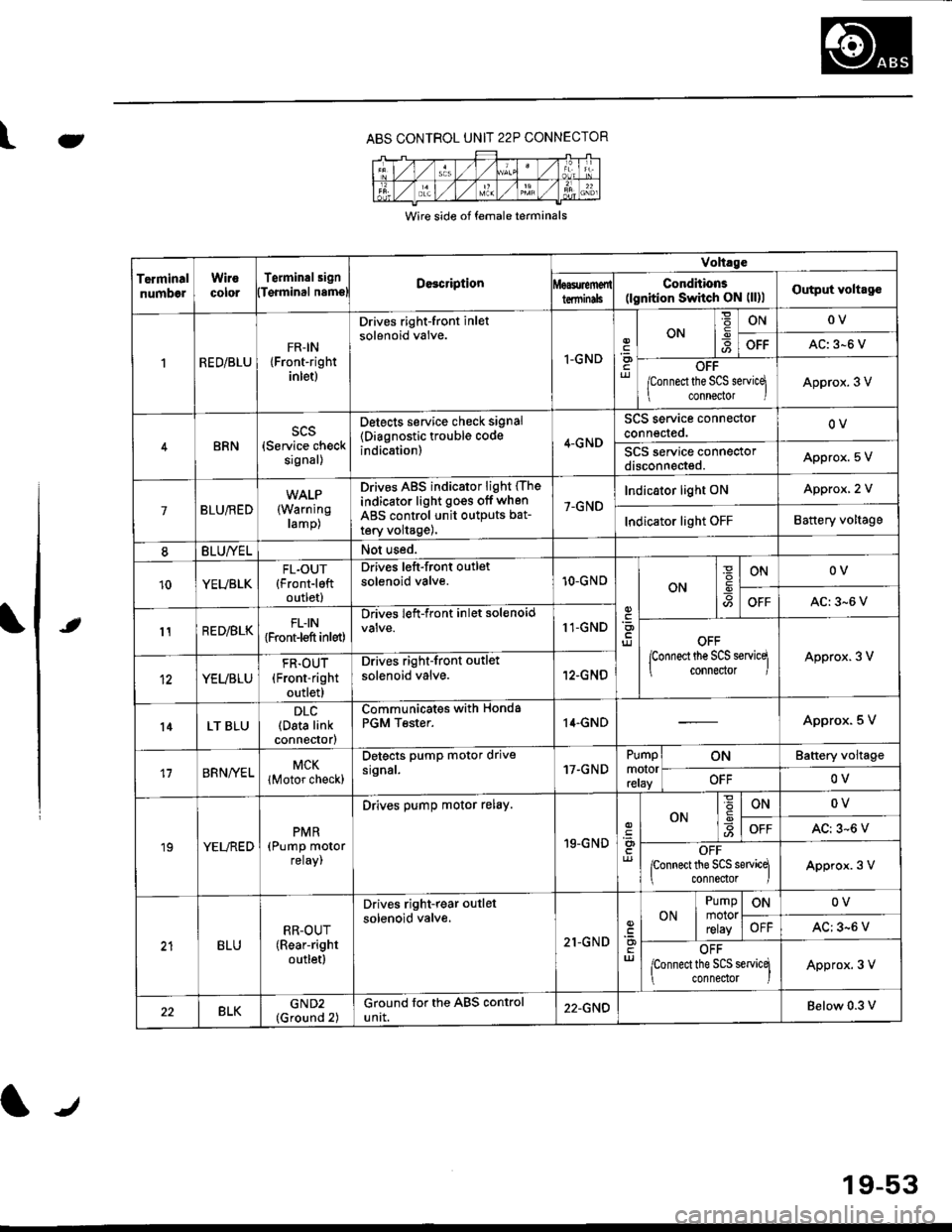

Page 1206 of 2189

e\

t

ABS CONTROL UNIT 22P CONNECTOR

Wire side of female terminals

TerminalnumbelWirocororTerminalsignDe3cription

Volt.ge

ConditionE(lgnition Switch ON (ll)lOutput voltagolTqrminal namslterminils

RED/BLUFR-IN{Front-rightinlet)

Drives right-front inletsolenoid valve.

I-GNDriJ

ON-9ONOV

OFFAC: 3-6 V

OFF

/Connect the SCS servicq

connector IApprox. 3 V

BRNscs(Service checksignal)

Detects service check signal

{Diagnostic trouble codeindication)4-GND

SCS service connectorconnected.OV

SCS service connectordisconneded.Appro)(. 5 V

7BLU/RED(Warning

ramp)

Drives ABS indicator light (The

indicator light go€s off when

ABS control unit outputs bat-

tery volta9e),

7-GND

Indicator light ONApprox, 2 V

Indicator light OFFBattery voltage

8BLU/YELNot used.

10YEUBLKFL.OUT{Front-leftoutlet)

Drives left-front outletsolenoid valve.10-GNOON

ONOV

OFFAC:3-6 V

11RED/BLKFLIN{Front-l€ft inlet)

Drives left-front inlet solenoid11-GNDOFF

lconnect the SCS servicq

connector IApprox. 3 V

YEUBLU

FR.OUT(Front-right

outlet)

Drives right-front outlet

solenoid valve.12-GNO

l4LT BLUDLC(Data linkconnector)

Communicates withPGM Tester.Honda14.GNDApprox. 5 V

17BRNA/ELMCK

lMotor check)

Detects pump motor drivesrgnal.17.GNDPumpmotorreray

ONBattery voltage

OFFOV

19YELREDPMR(Pump motorreray,

Drives pump motor relay.

19-GND

ONONOV

OFFAC: 3-6 V

OFFponnect the SCS sewicq

connedor lApprox. 3 V

BLURR-OUT(Rear-right

outletl

Drives right-rear outlel

solenoid valve.

21-GNDuJ

ON

Pumpmotorrelay

ONOV

OFFAC: 3-6 V

OFF

lconnect the SCS servicq

connedor )Approx. 3 V

22BLKGND2(Ground 2)Ground for the ABS controluntt.22-GNDBelow 0.3 v

19-53

Page 1209 of 2189

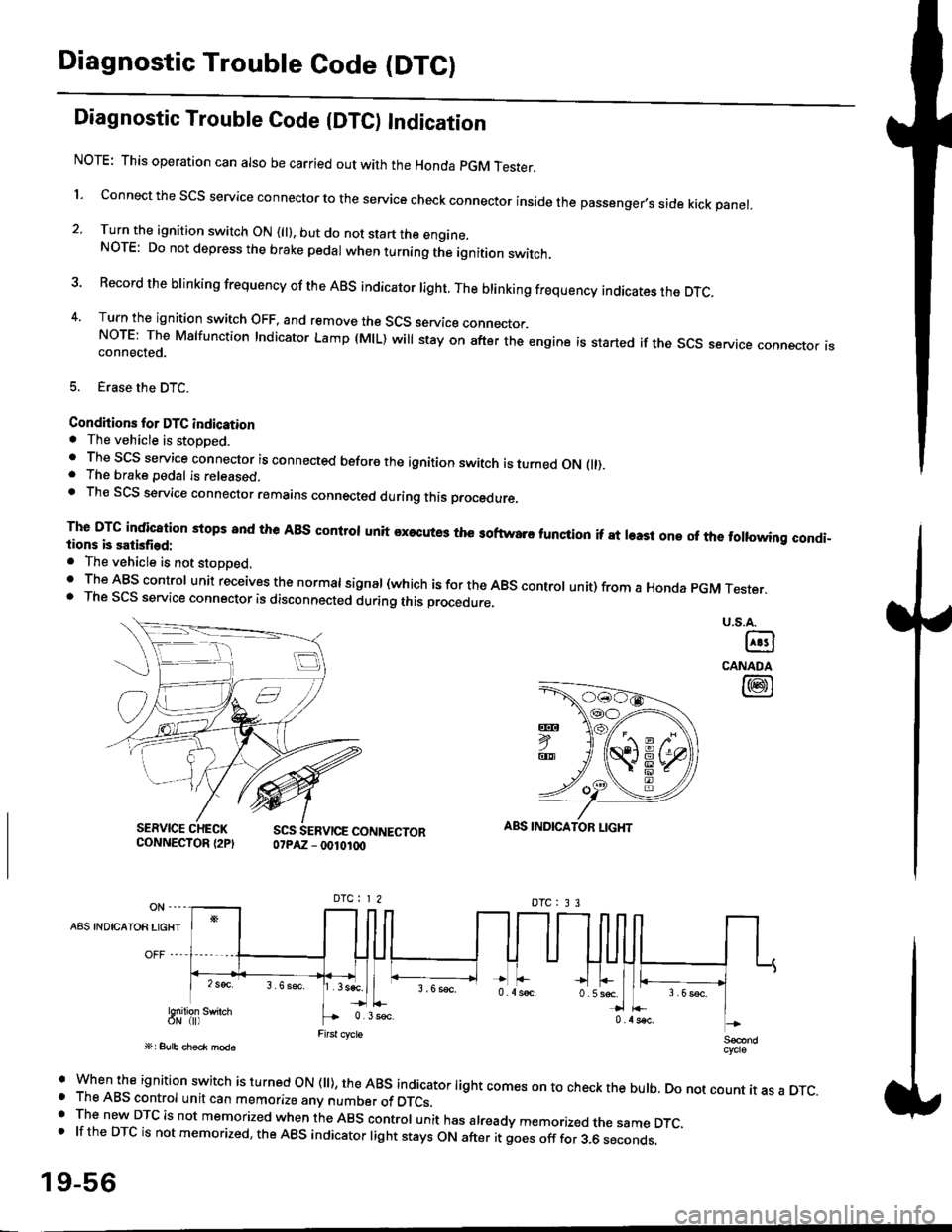

Diagnostic Trouble Code (DTCI

Diagnostic Trouble Code {DTC) Indication

NOTE: This operation can also be carried out with the Honda pGM Tesrer.

l connect the scs service connector to the service check connector inside the passenger,s side kick panel.

2. Turn the ignition switch ON (||). but do not start the engine.NOTE: Do not depress the brake pedal when turning the ignition switch.

3 Record the brinking frequency of the ABS indicator right. The brinking frequency indicates the DTc.

4, Turn the ignition switch OFF, and remove the SCS service connector.NorE: The Mslfunction Indicator Lamp (MlL) will stay on after the engine is started if the scs service connector isconnected.

5. Erase the DTC.

Condhions for DTC indication. The vehicle is stoDDed.. The SCS service connector is connected before the ignition switch is turned ON fll).. The brake pedal is released.. Th€ SCS service connector remains connected during this procedure

The DTG indication stops 8nd the ABs conltol unit executes the softwaro tunqtion if at least one of the following condi-tions b satisfied:

o The vehicle is not stoDoed.' The ABS control unit receives the normat signal (which is for the ABS controt unit) from a Honda pGM Tester.. The SCS service connector is disconnected during this procedu.e,

u.s.A.

@

CANADA

@

SERVICE CHECKCONNECTOR {2PISCS SERVICE CONNECTOR07PAZ - 0010100

ABS INDICATOR LIGHT

DTC : 3 3

A8S INDICAIOR LIGHT

Snilion swirch

' when the ignition switch is turned oN (ll), the ABs indicator light comes on to check the bulb. Do not count it as a DTc.o The ABS control unit can memorize any number of DTCs.. The new DTC is not memorized when the ABS control unit has already memorized the same DTC,.lftheDTCisnotmemorized,theABSindicatorlightstaysONafteritgoesofffor3.6seconds.

19-56

Page 1210 of 2189

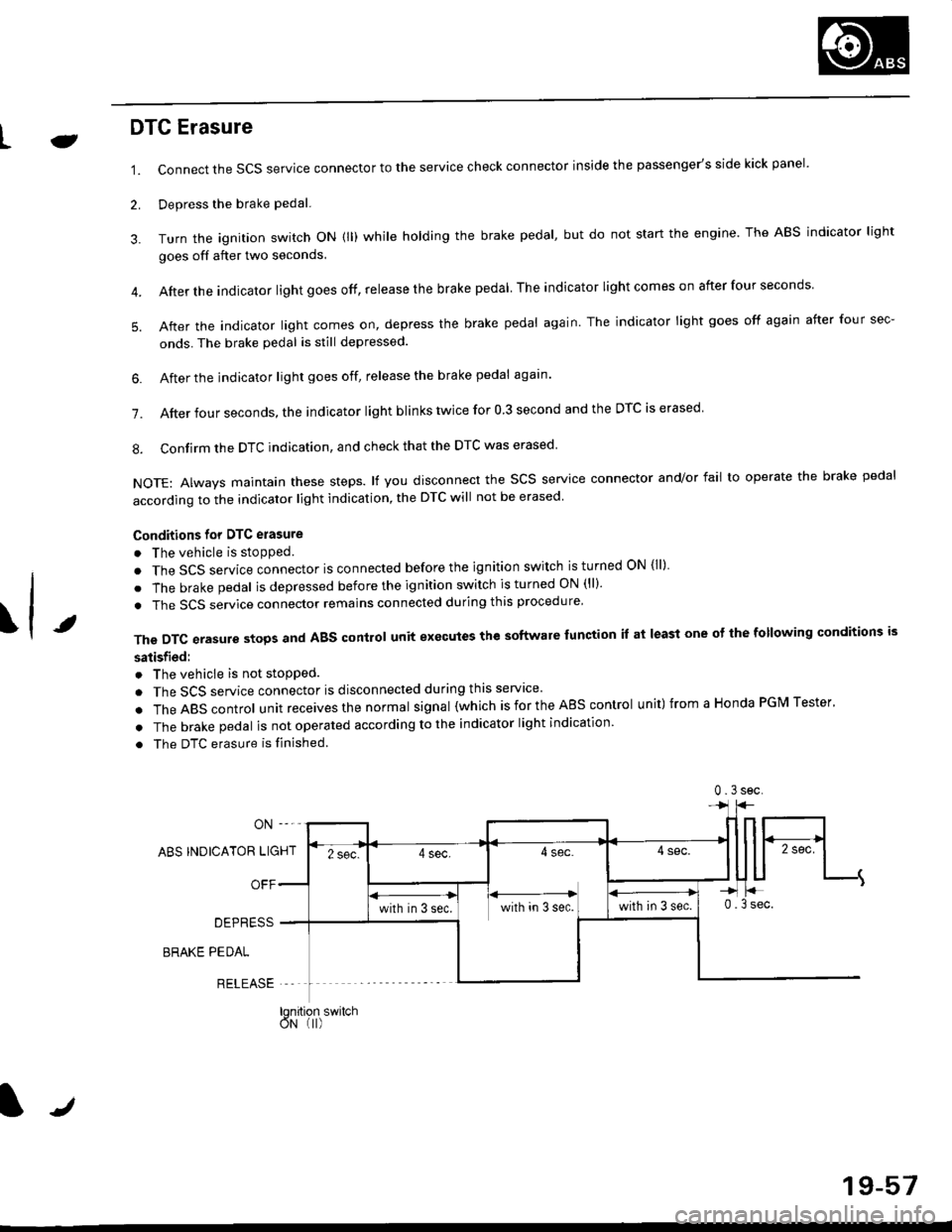

LJDTG Erasure

1.

2.

Connect the SCS service connector to the service check connector inside the passenger's side kick panel.

Depress the brake pedal.

Turn the ignition switch oN (ll) while holding the brake pedal, but do not start the engine. The ABS indicator light

goes off after two seconds.

After the indicator light goes off, release the brake pedal The indicator lightcomeson after four seconds

After the indicator light comes on, depress the brake pedal again. The indicator light goes off again after four sec-

onds. The brake pedal is still depressed.

4.

5.

\t

6. After the jndicator light goes off, release the brake pedal again'

7. After four seconds, the indicator light blinks twice for 0 3 second and the DTC is erased

8. Confirm the DTC indication, and check that the DTC was erased

NOTE: Always maintain these steps. lf you disconnect the scs service connector and/or fail to operate the brake pedal

according to the indicator light indication, the DTC will not be erased

Conditions for DTC erasure

o The vehicle is stopped.

. The SCS service connector is connected before the ignition switch is turned ON {ll)

. The brake pedal is depressed before the ignition switch is turned ON (ll)'

. The SCS service connector remains connected during this procedure

The DTC erasure stops and ABS control unit executes the software lunction it at least one ot the following conditions is

satisfied:

o The vehicle is not stopped.

. The SCS service connector is disconnected during this servace'

.TheABscontro|unitreceivesthenormaIsigna|(whichisfortheAEscontro|unit)fromaHondaPGMTester'

. The brake pedal is not operated according to the indicator light indication

. The DTC erasure is finished

ABS INDICATOR LIGHT

OFF

DEPRESS

BRAKE PEDAL

RELEASE

0.3sec

lqnition switchoN (I)

J

19-57

Page 1219 of 2189

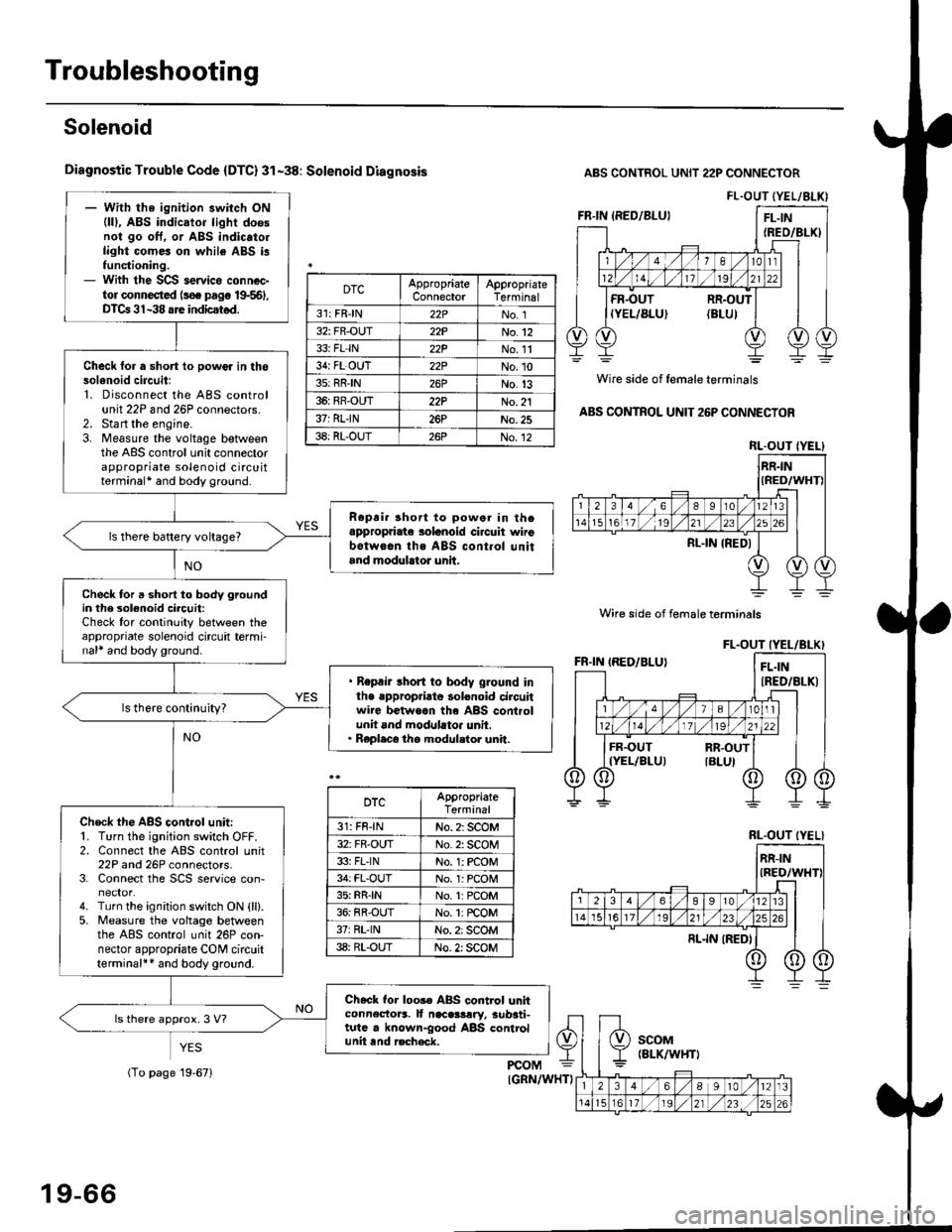

Troubleshooting

Solenoid

Diagnostic Trouble Code {DTC} 31-38: Solenoid Diagnosis

YES

ABS CONTROL UNIT 22P CONNECTOR

Wire side of female terminals

ABS CONTROL UNIT 26P CONNECTOR

FL.OUT (YEL/ALK)- With the ignition switch ON(lll, ABS indicator light doesnol go oft. or ABS indic.to.light comes on while ABS i3functioning.- With the SCS servico connec-tor connected ls€. pag€ 19-561,DTCa 31-38 are indicstod.

Check for a short lo powor in thosol6noid circuitl1. Disconnect the ABS controlunit 22P and 26P connectors.2. Sta rt the engine.3. Measure the voltage betweenthe ABS control unit connectorappropriate solenoid circuitterminal* and body ground.

Ropri. short to powor in thcappropriate solanoid ci.cuit wirobotw6.n ths ABS cont.ol unitand modulrtor unit.

ls there battery voltage?

Check for a short to body groundin the 3olenoid circuit:Check tor continuity between theappropriate solenoid circuit termi-nal* and body ground.

. Repair short to body ground inlhe .ppropriato solonoid circuitwire betwoan th6 ABS controlunit and modllato. unit.. Replaco the modul.tor unit.

Check th€ ABS control unit:'1. Turn the ignition switch OFF.2. Connect the ABS control unit22P and 26P connectors.3. Connect the SCS service con-

4. Turn the ignition switch ON {ll}.5. Measure the voltage betweenthe ABS control unit 26P con-nector appropriate CONI circuitterminal++ and body ground.

Check for loos€ ABS control unhconnectora. It naceslrry, aub3ti-tutc . known-good ABS controlunit tnd recheck.

ls there approx. 3 V?

DTCAppropriateConnectorAppropriateTerminal

31: FRJN22PNo. 1

32: FR-OUT22PNo.12

33i FL'IN22PNo. 11

34: FL OUT22PNo.10

3s: RRIN26PNo.13

36: RR-OUT22PNo. 21

37: RLIN26PNo.25

38: RL-OUT26PNo.12RL.OUT IYEL}

Wire side of female terminals

DTCAppropriateTerminal

31: FR-lNNo. 2: SCOM

32: FR-OUTNo. 2: SCOM

33i FLINNo. 1: rcOM

34: FL-OUTNo. l: PCOM

35: RR{NNo.1:PCOM

36: RR-OUTNo. 1: rcOM

37rRL'lNNo. 2: SCOM

38: RL-OUTNo. 2: SCOM

RL.OUT (YEL}

19-66

(To page 19-671