check engine HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1589 of 2189

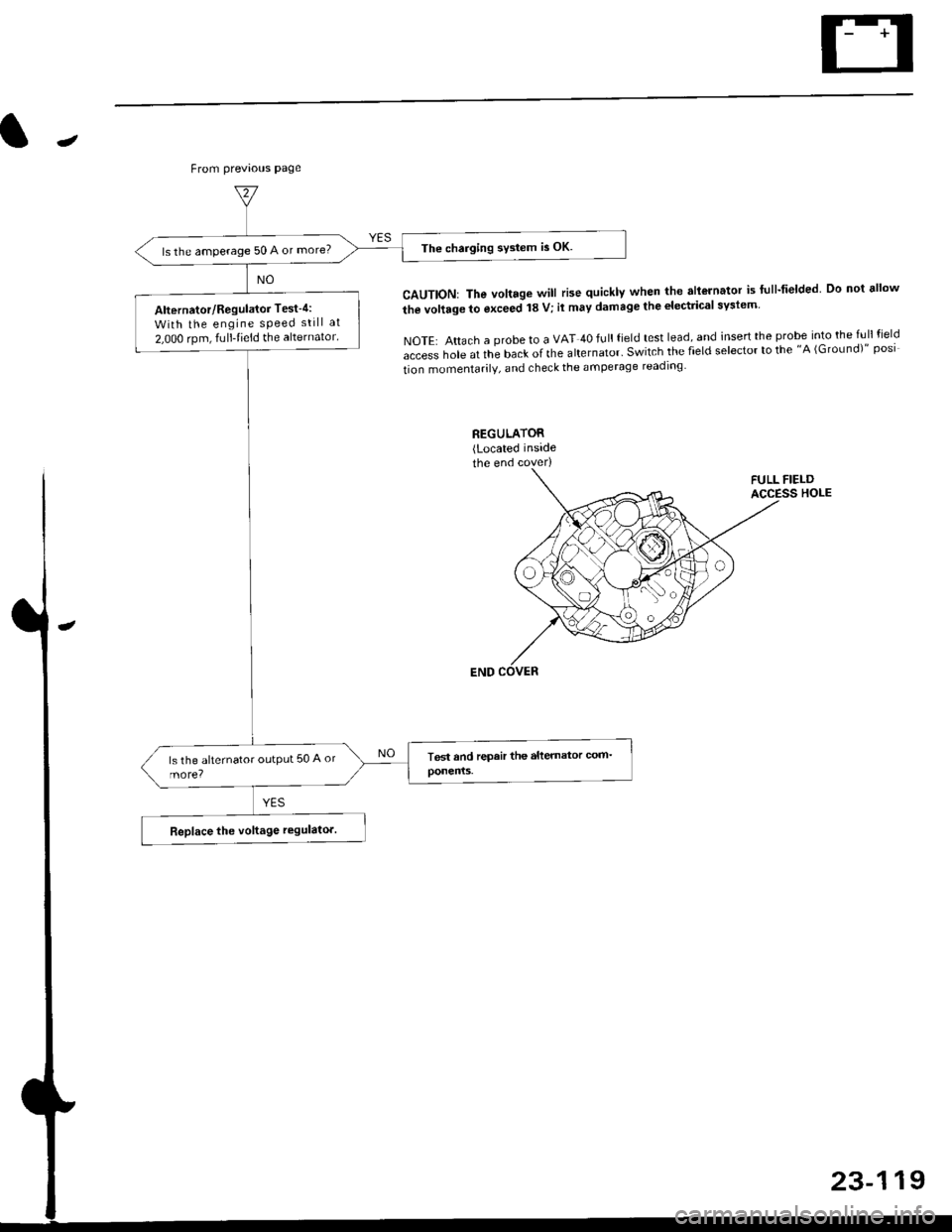

The charging system is OK.ls the amperage 50 A or more?

Alternator/Regulator Test-4:

With the engine sPeed still at

2,000 rpm, fulltieid the alternator.

J

From previous page

CAUTION: The voltage will rise quickly when the allGrnator is flll-fielded Do not ellow

the vollage to exceed 18 V; il may damage the electrical syslem

NOTE: Attach a probe to a VAT 40 full field test lead, and insert the probe into the full field

access hole at the back of the alternator' Switch the field selector to the "A (GroLrnd)" posi

tion momentarilV, and check the amperage readlng

23-119

Page 1610 of 2189

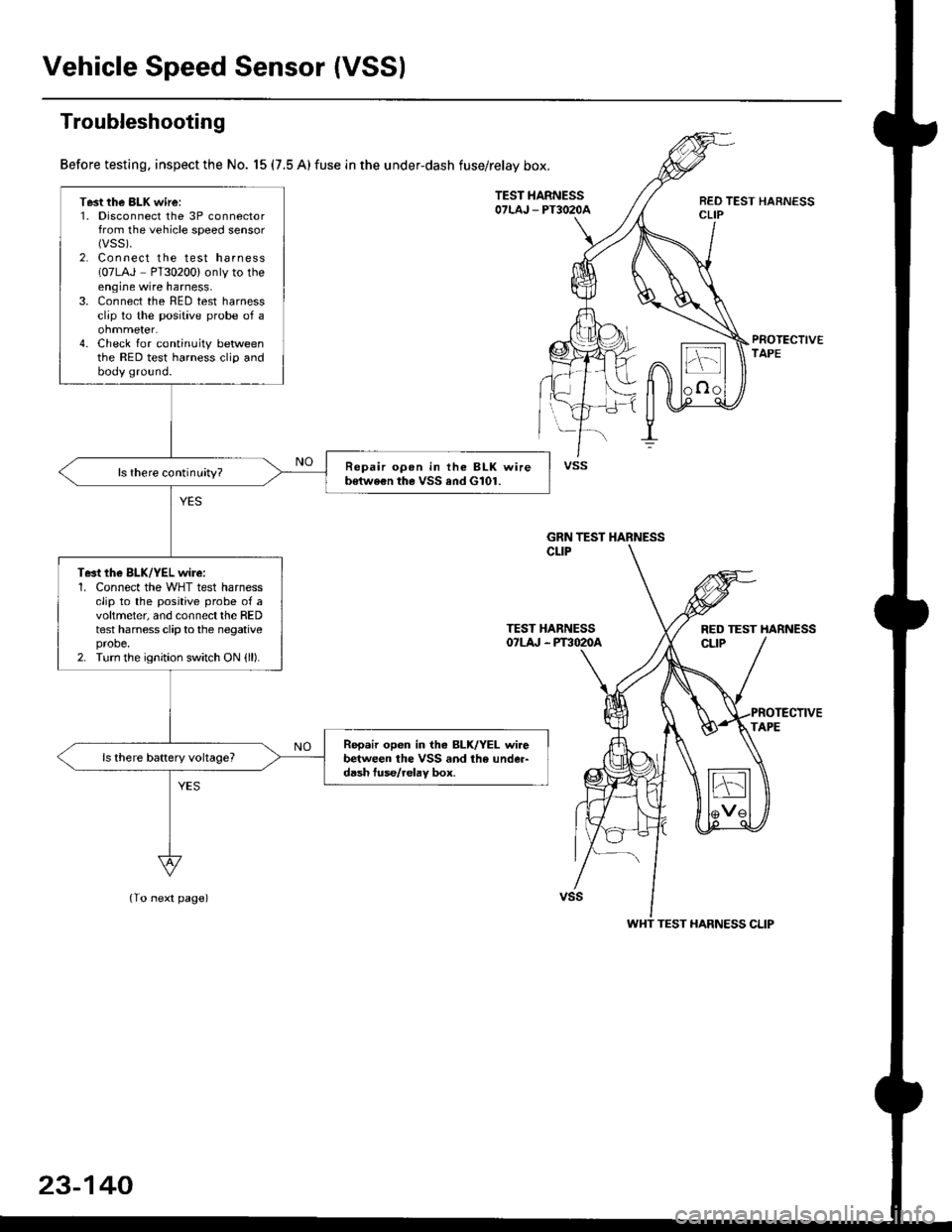

Vehicle Speed Sensor (VSSI

Troubleshooting

Before testing, inspect the No. 15 (7.5 A) fuse in the under-dash fuse/relay box.

TEST HARNESSOTLAJ _ PT3O2OAREO TEST HARNESSCLIP

PROTECTIVETAPE

TEST HARNESSOTLA' . PT3O2OA

(To next page)

Test the BLK wire:1. Disconnect the 3P connectorfrom the vehicle speed sensor(vss).

2. Connect the test harness(07LAJ PT30200) only to theengine wire harness,3. Connect the RED test harnessclip to the positive probe of a

4. Check for continuity betweenthe RED test harness clip andbody ground.

Repair opon in the BLK wireb€twe€n the VSS and G101.ls there continuity?

Te3t the BLK/YEL wire:1. Connect the WHT test harnessclip to the positive probe of avoltmeter, and connectthe REDtest harness clip to the negativeprobe.2. Turn the ignition switch ON {ll).

Repair open in iho BLK/YEL wirebetween the VSS and the under-d6sh tuse/relav box.

vss

GRN TEST HARNESS

RED TEST HARNESS

WHT TEST HARNESS CLIP

23-140

Page 1625 of 2189

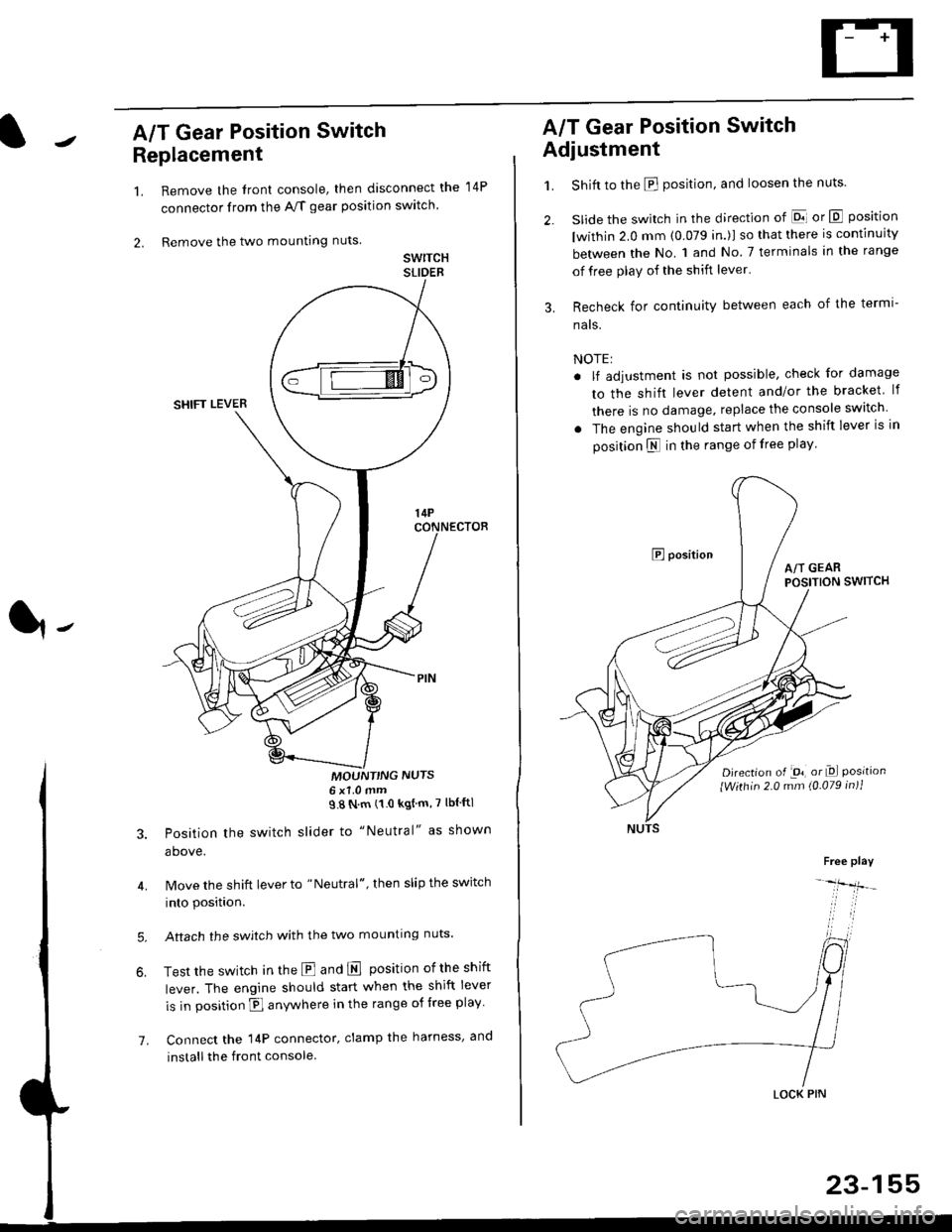

A/T Gear Position Switch

Replacement

1.

2.

7.

Remove the front console, then disconnect the

connector from the A/f gear position swltch

Remove the two mounting nuts

swrTcHSLIDEB

MOUNT'NG NUTS6x1 0mm98Nm(10kgtm'7lblftl

Position the switch slider to "Neutral" as shown

above.

Move the shift lever to "Neutral", then slip the switch

into position.

Aftach the swjtch with the two mounting nuts.

Test the switch in the E and E position ofthe shift

lever. The engine should start when the shift lever

is in position fl anywhere in the range of free play

Connect the 14P connector, clamp the harness, and

install the front console

14P

A/T Gear Position Switch

Adjustment

1.

3.

Shift to the E position, and loosen the nuts.

slide the switch in the direction of El or E position

lwithin 2.0 mm (0.079 in.)l so that there is continuity

between the No. 1 and No 7 terminals in the range

of free play of the shift lever'

Recheck for continuity between each of the termi-

nats.

NOTE:

. lf adjustment is not possible, check for damage

to the shift lever detent and/or the bracket lf

there is no damage. replace the console switch

. The engine should start when the shift lever is in

position N in the range of free play

E positionA/T GEARPOSITION SWITCH

Djrection of -on, or Dl Positionlwithin 2.0 mm (0.079 in)1

Free play

-lfr-

LOCK PIN

23-155

Page 1718 of 2189

Cruise Control

t

D=

t

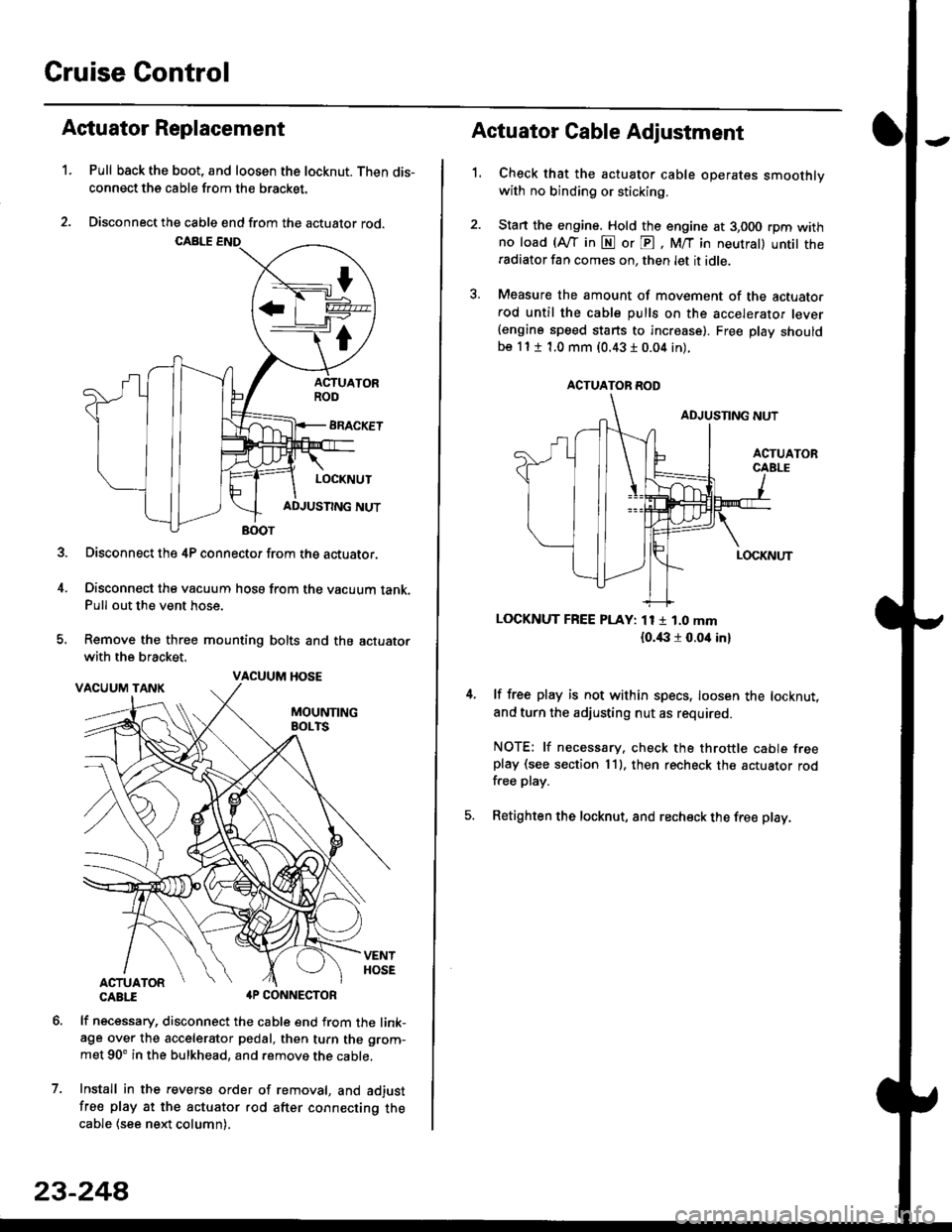

Astuator Replacement

1.Pull back the boot, and loosen the locknut. Then dis-

connect the cable from the bracket.

Disconnect the cable end from the actuator rod.

Disconnect the 4P connector from the actuator.

Disconnect the vacuum hosa from the vacuum tank.Pull out the vent hose.

Remove the three mounting bolts and the actuator

with the bracket.

CABTI aP CONNECTOR

lf necessary, disconnect the cable end from the link-age over the accelerator pedal, then turn the grom-

met 90' in the bulkhead, and remove the cable,

Install in the revers€ order of removal, and adjust

free play at the actuator rod after connecting thecable (see ne)d column).

7.

VACUUM HOSE

23-244

1.

Actuator Cable Adjustment

Check that the actuator cable operates smoothlywith no binding or sticking.

Stan the engine. Hold the engine at 3,000 rpm withno load (Afl'in N or E, M/T in neutral) untit theradiator fan comes on, then let it idle.

Measure the amount of movement of the actuato.rod until the cable pulls on the accelerator lever(engine speed starts to increase). Free Dlay shouldbe 11 t 1.0 mm (0.43 I 0.04 in).

LOCKNUT FREE PLAY: 11 1 1.0 mm

{o.i|:l r 0.oit in}

lf free play is not within specs, loosen the locknut,

and turn the adjusting nut as required.

NOTE: lf necessary. check the throttle cable freeplay (see section 11). then recheck the actuator rodfree play.

Retighten the locknut, and recheck the free play.

ACTUATOR ROD

Page 1753 of 2189

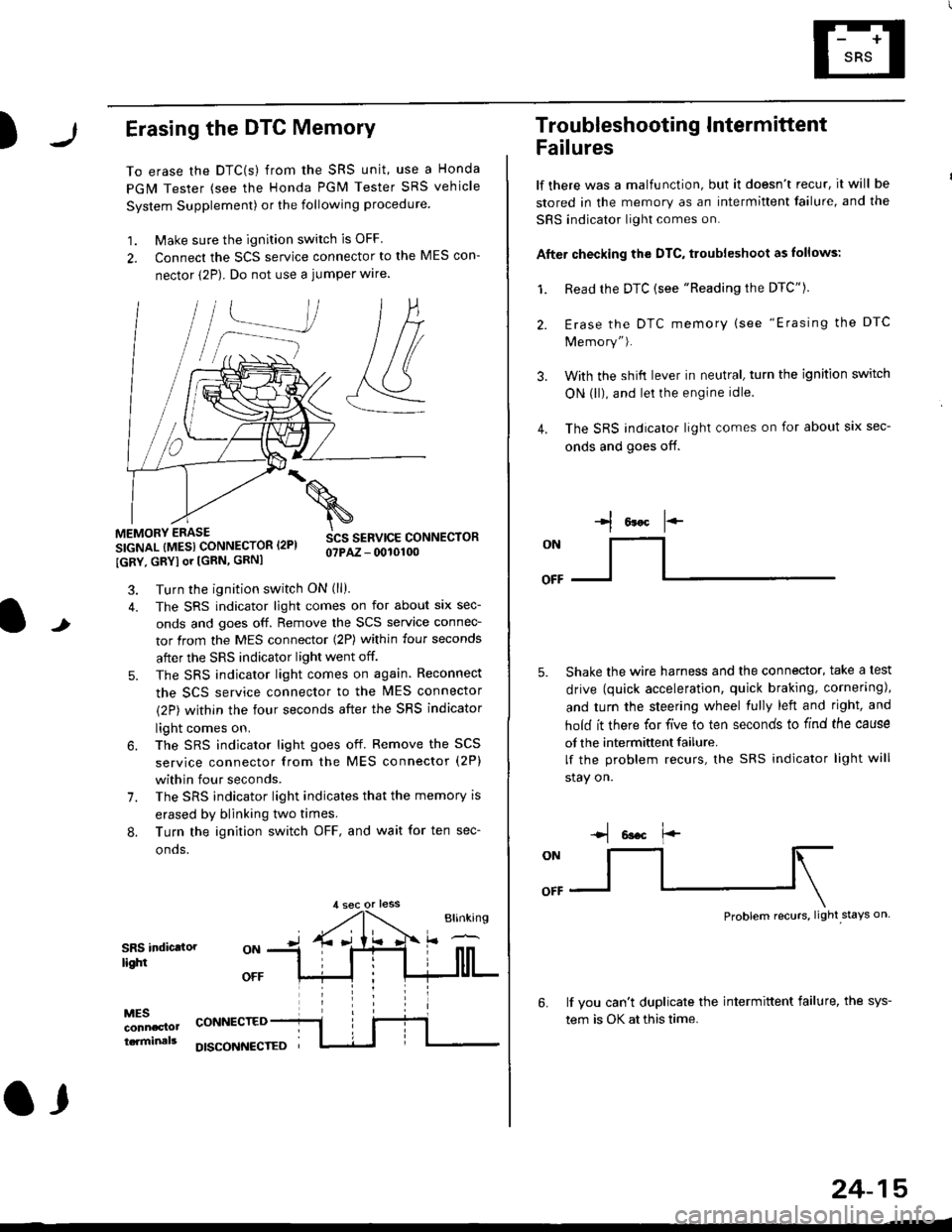

)Erasing the DTC Memory

To erase the DTC(s) from the SRS unit, use a Honda

PGM Tester (see the Honda PGM Tester SRS vehicle

System Supplement) or the following procedure

1. Make sure the ignition switch is OFF

2. Connect the SCS service connector to the MES con-

nector (2P). Do not use a jumper wlre.

]P,

&

.!--J

MEMORY ERASE

SIGNAL (MESI CONNECTOR I2PI

IGRY, GRYI or [GRN, GRNI

SCS SERVICE CONNECTORo?PAZ - 0010100

t

7.

Turn the ignition switch ON (ll).

The SRS indicator light comes on for about six sec-

onds and goes off. Remove the SCS service connec-

tor from the MES connector (2P) within four seconds

after the SRS indicator light went off.

The SRS indicator light comes on again. Reconnect

the SCS service connector to the lvlES connector

(2P) within the four seconds after the SRS indicator

light comes on.

The SRS indicator light goes off. Remove the SCS

service connector from the MES connector (2P)

within four seconds.

The SRS indicator light indicates that the memory is

erased by blinking two times.

Turn the ignition switch OFF, and wait for ten sec-

onos.

8.

SRS indictlorlighi

MESconncclottcaminals

CONNECTED

O,

DISCONI{ECTED

24-15

Troubleshooting Intermittent

Failures

lf there was a malfunction, but it doesn't recur, it will be

stored in the memory as an intermittent failure, and the

SRS indicator light comes on.

Afte. checking the DTC, troubleshoot as lollows:

1. Read rhe DTC {see "Reading the DTC"}.

Erase the DTC memory (see "Erasing the DTC

Memory").

With the shifi lever in neutral, turn the ignition switch

ON (ll), and lei the engine idle.

The SRS indicator light comes on for about six sec-

onds and goes off.

l*F

ON

tl-- -l

Shake the wire harness and the connector, take a test

drive (quick acceleration, quick braking, cornering),

and turn the steering wheel fully left and right, and

hold it there for five lo ten seconds to find the cause

of the intermittent failure.

lf the problem recurs, the SRS indicator light will

stay on.

-q 6a.c f'-

:q

Problem recurs, light stays on

3.

4.

6.lf vou can't duplicate the intermittent failure, the sys-

tem is OK at this time.

Page 1824 of 2189

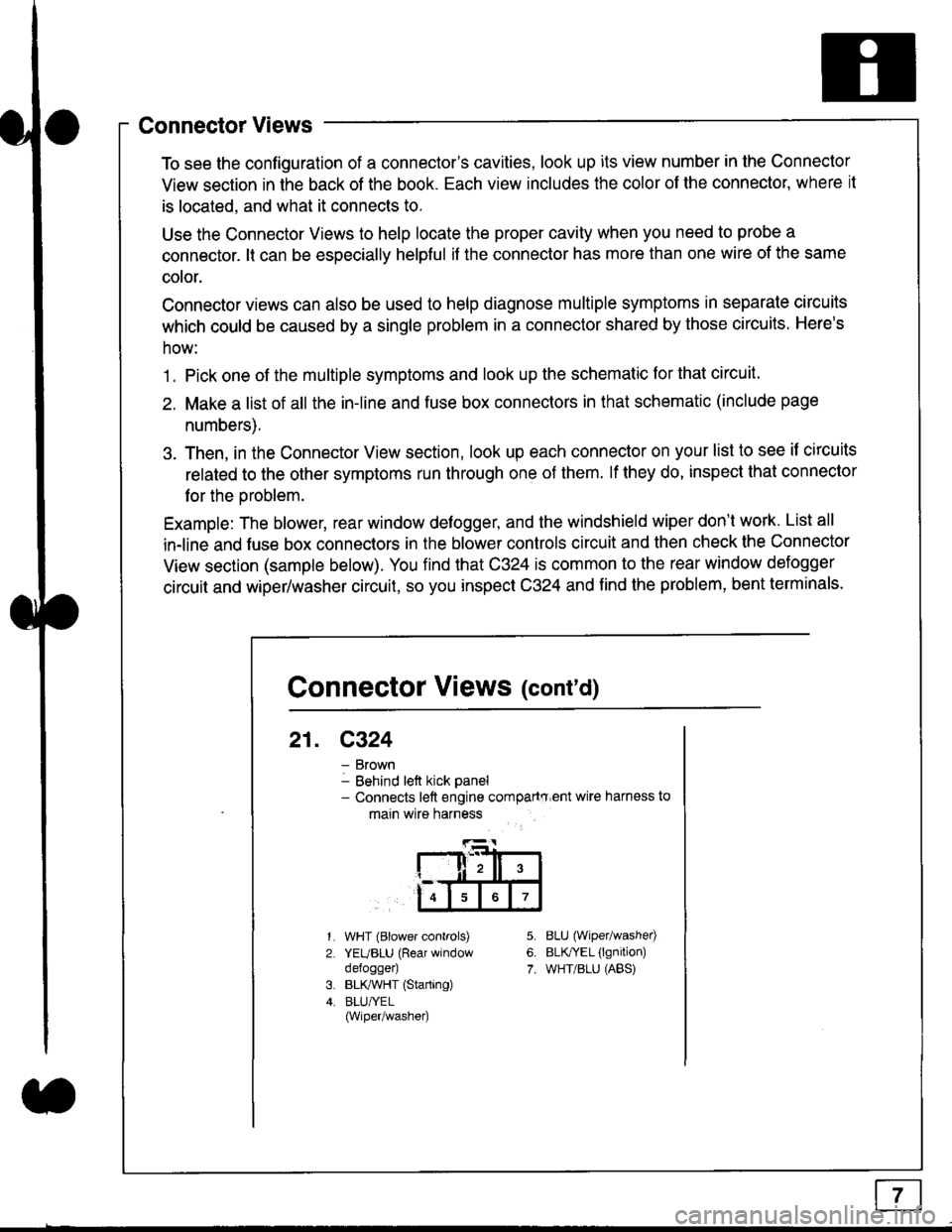

Connector Views

To see the configuration of a connector's cavities, look up its view number in the Connector

View section in the back of the book. Each view includes the color of the connector, where it

is located, and what it connects to.

Use the Connector Views to help locate the proper cavity when you need to probe a

connector. lt can be especially helpful if the connector has more than one wire of the same

cotor.

Connector views can also be used to help diagnose multiple symptoms in separate circuits

which could be caused by a single problem in a connector shared by those circuits. Here's

how:

1. Pick one of the multiple symptoms and look up the schematic for that circuit.

2. Make a list of all the in-line and fuse box connectors in that schematic (include page

numbers).

3. Then, in the Connector View section, look up each connector on your list to see il circuits

related to the other symptoms run through one of them. lf they do, inspect that connector

for the oroblem.

Example: The blower, rear window defogger, and the windshield wiper don't work. List all

in-line and fuse box connectors in the blower controls circuit and then check the Connector

View section (sample below). You find that C324 is common to the rear window defogger

circuit and wiper/washer circuit, so you inspect C324 and find the problem, bent terminals.

5.

6.

7.

1.

2.

WHT (Blower controls)

YEUBLU (Rear window

defogger)

BLK,ryVHT (Starting)

BLU/YEL(Wiper/washe0

8LU (Wiper/washed

BLfiEL (lgnition)

WHT/BLU (ABS)

Connector Views (cont'd)

21. C324

Brown

Behind left kick panel- Connects left engine compartry'ent wire harness to

main wire harness

ll,ll,

567

Page 1829 of 2189

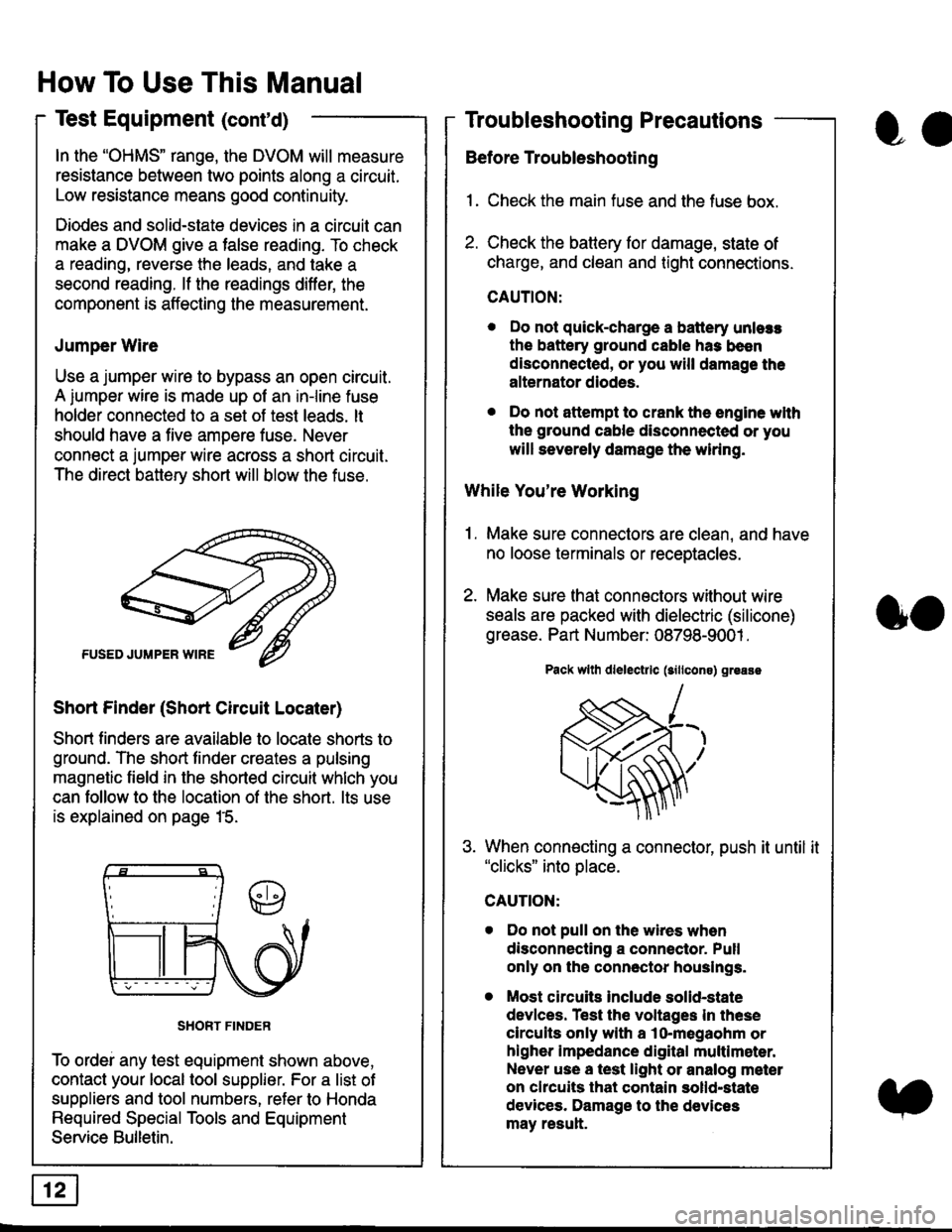

In the "OHMS" range, the DVOM will measure

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting lhe measurement.

Jumper Wire

Use a jumper wire to bypass an open circuit.

A iumper wire is made up ot an in-line fuse

holder connected to a set of test leads. lt

should have a five amoere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Short finders are available to locale shorts to

ground. The short tinder creates a pulsing

magnetic field in the shorted circuit whlch you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To ordei any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Honda

Required Special Tools and Equipment

Service Bulletin.

How To Use This Manual

Test Equipment (cont'd)

oa

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage, state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unlers

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine wlth

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receptacles.

2. Make sure lhat connectors without wire

seals are packed with dielectric (silicone)

grease. Part Number: 08798-9001 .

Pack wllh dlelectrlc (sillcons) greass

When connecting a connector, push it until it"clicks" into place.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector houslngs.

Most circuits Include solid-state

devlces. Test the voltages In these

circuits only with a lo-megaohm or

higher impedance digital multlm6ter.

Never use a test light or analog meter

on chcuits that contain solld-state

devices. Damage to the devices

may result.

oo

Page 1871 of 2189

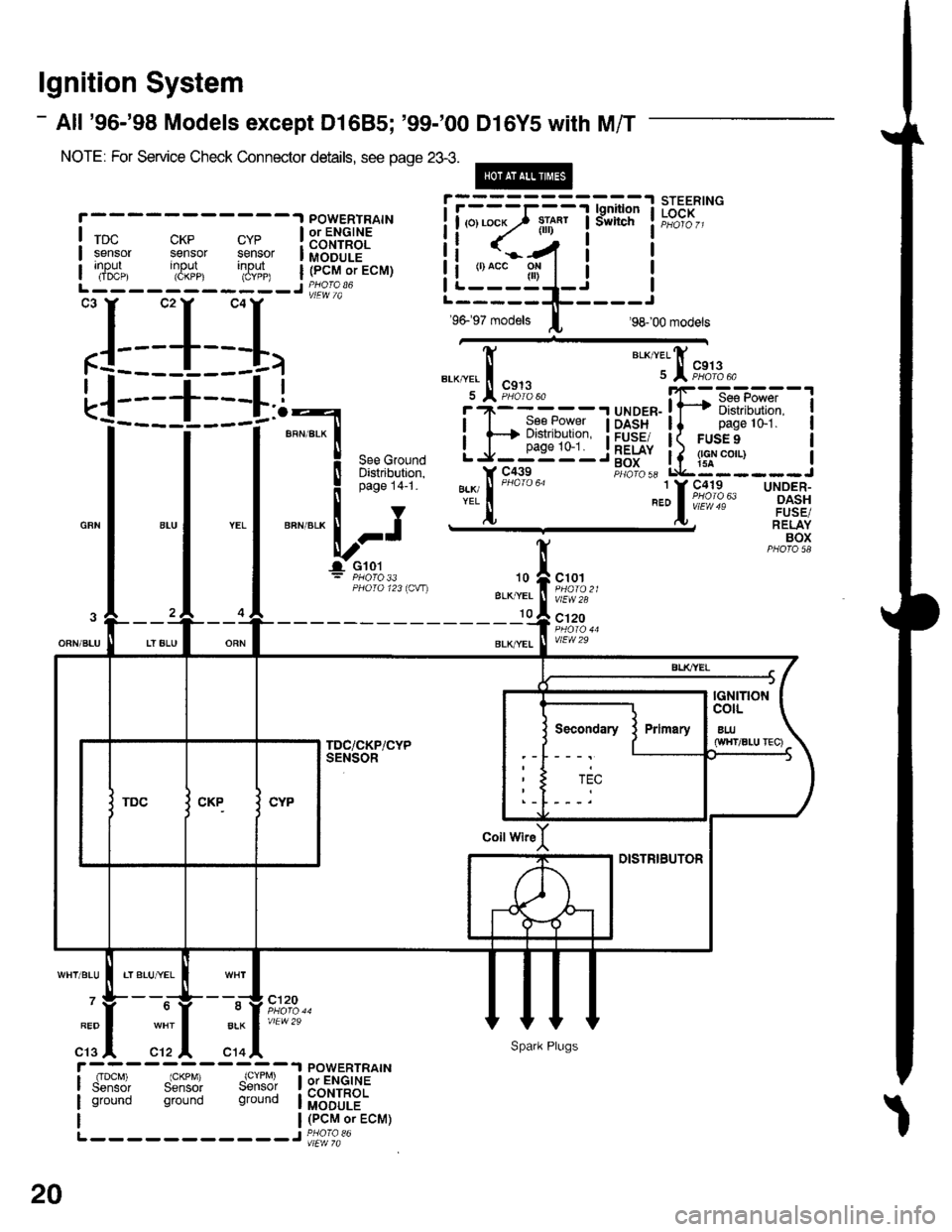

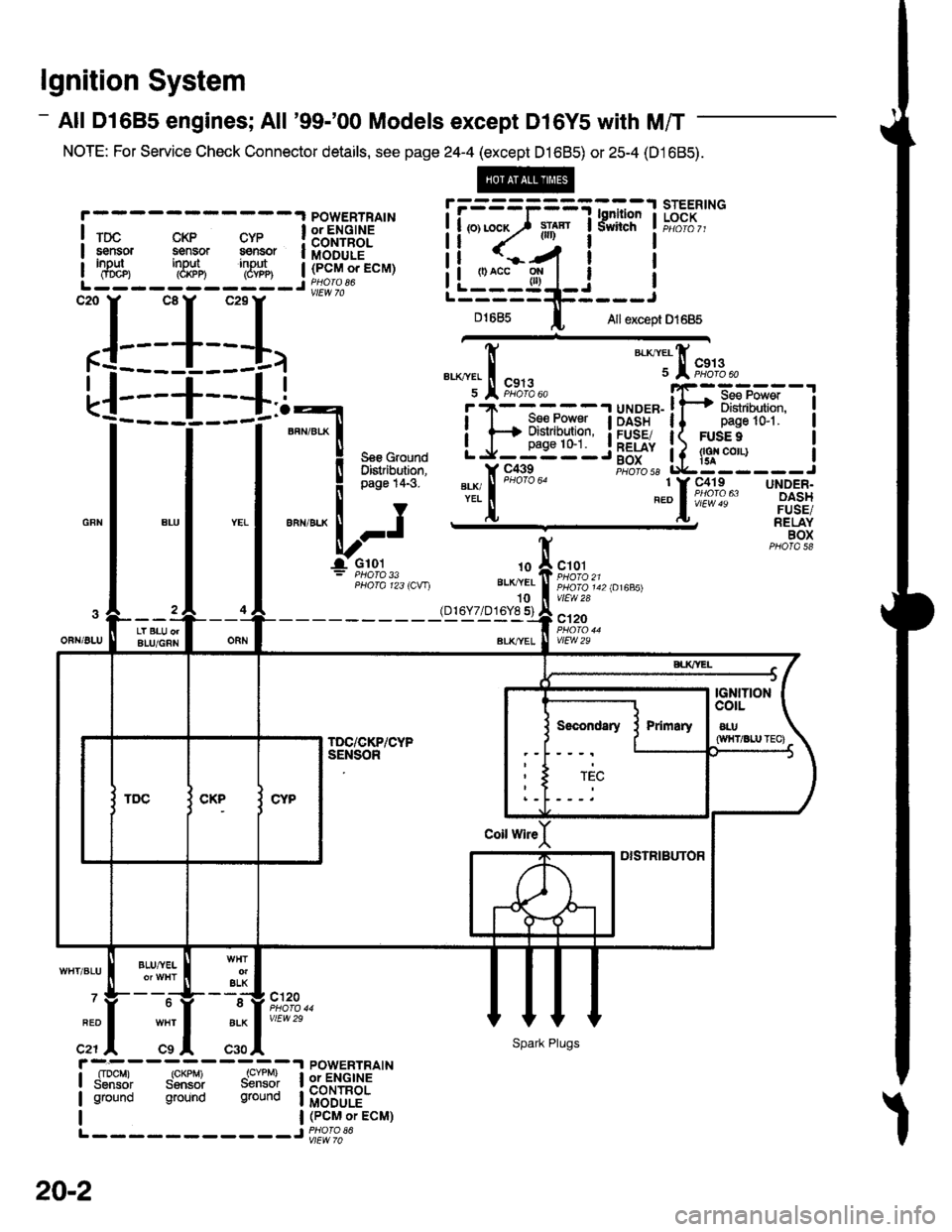

lgnition System

- All '96-'98 Models except Dl685; '99-'00 Dl6Y5 with M/T

NOTE: For Service Check Connector details, see page 23-3.

@

CKP CYPsensor sensorinput input(CKPP) (CYPP)

X,*.,

rDcsensorInpur(IDCP)

POWERTRAINor ENGINECONTROLMODULE(PCM or ECM)

POWERTRAINor ENGINECONTROLMODULE(PCM or ECM)

xr*"

BLKI/EL

I

I

BLK/YEL

I See Power

H Distribution,

J__99'�"'_

I

I

I

I

I

I

UNOER-OASHFUSE/RELAYBOX

"a*,telfi

u I """%t'3.

,rrrr.iFiFx".-,''ril'fi :T-DASH ll pagelo-1.FUSE/ I( FUSE 9

F.itl, Lq::---

".:lo63

10

BLK,YEL

10

c101

vlEW28

c'120

vlEW29

BLK

c14

c120

vlEW29

rIDcM) IGKPM) (CYPM)Sensor Sensor Sensolground ground ground

L-- - - -- -----J PHora 36

L-----------J

:L_1__I,

! iii:?ifq"l

I

**:'

*-"*,t";'

= PHO|O 33PHOTO 123ICW)

Secondary

ti <..-/4 i t

iLi:"_gl_i iL-----1!-----r

96- 97 models I 98- 00 modets

20

Spark Plugs

Page 1873 of 2189

lgnition System

- All Dl685 engines; All '99-'00 Models except Dl6Y5 with M/T

NOTE: For Service Check Connector details, see page 24-4 (except D1685) or 25-4 (D1685).

STEERINGLOCKPOWERTRAIN

lm- sii.- s*- iffffiEgr

I '8f", '3#n '3#n | (Pcn' or EcM)

L------ -----J Wro 86

',L_I__J,

!l---+--l !

'i---

j----i'

fl '","?siii,xl

I I I

i*n"'."

-"1 "-l '-l *"-^lr";J

I I I ='i.{i31i",,-

All except D1685D1685

gLK.Yer t

u l9f#'

fi

"*1,[

F,*';.,

!'T-f*-'i"i! {F+ Distdbution,

LJ_gg'n'_

i.x,r

9'x*"

-.t

iF--Hs-,mT-l

ll pase lGi. I

l( FUsEe I

!Lig::___J

.I UNDER-I DASH

a FUSE/

! RELAY- BOX

1 Y C419 UNDER-^,ol',lill,l?"u' rlir?IA) RELAYBOX

.t0

BLKI/EL

10(D16Y7/D16Y8 s)

c101

PHO|O 142 lA1685)vlEw 2a

c120

vtEw 29OFN/ALULT BLU orALU/GRN

BLU,^VEL

c120

vtEw 29

ELKWHT/BLU

7

FED

c21c9

ALK

c30

;;--;;---o;;;lSensor Sonsor Sensor I

POWERTRAINor ENGINECONTROLMODULE(PCM or ECM)

ground ground gtound

L ------ -----J PHoro 36

Sec!l|dary

Sparh Plugs

20-2

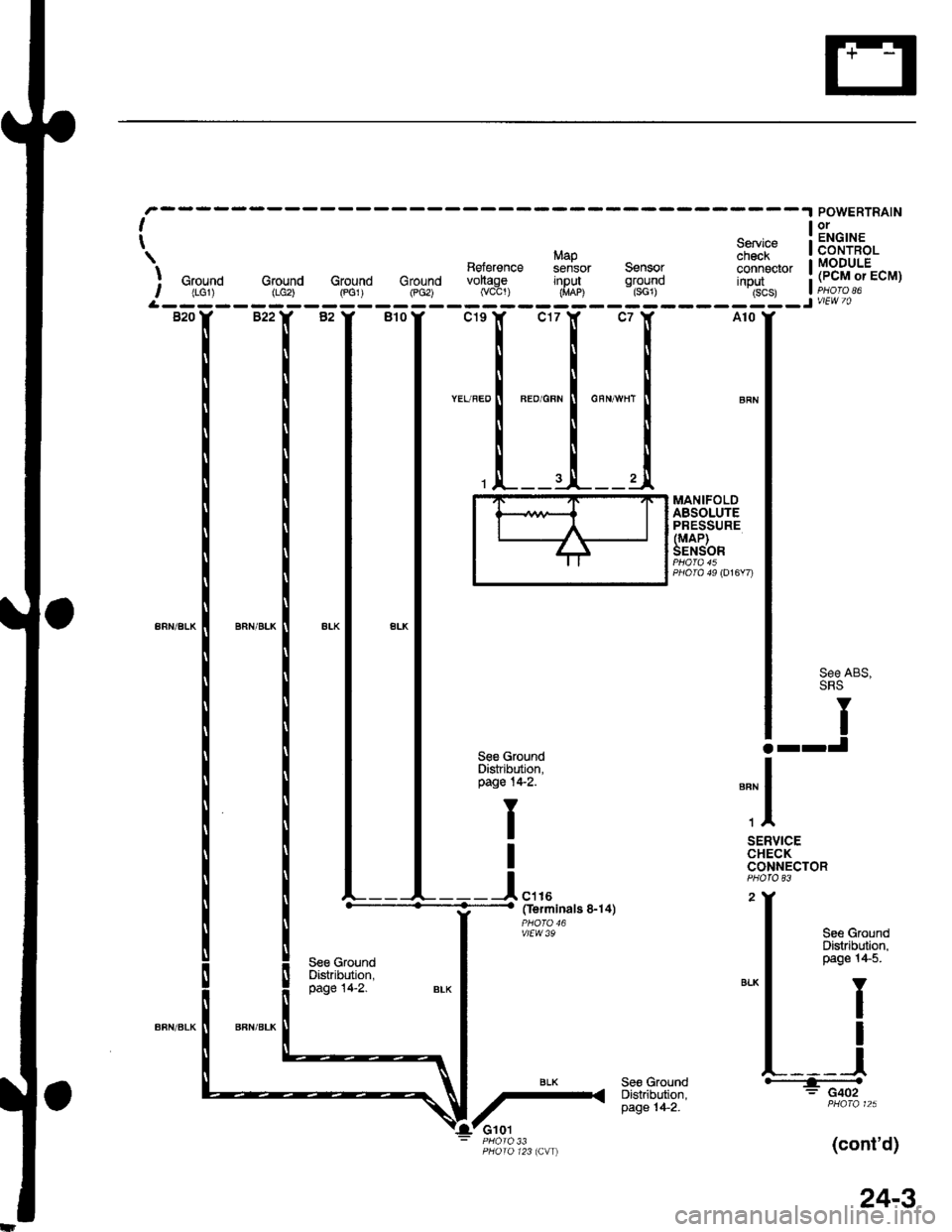

Page 1898 of 2189

I

t

! c,orna, (LG1)

Referencevoltage(vcc1)

ServicecnecKconn€ctorInput(scs)

POWERTRAINolENGINECONTROLMODULE(PCM or ECM)PHOfO 86

MapsensorinputSensorground(sGl)

A10

Ground Ground Ground1LG2) (PG1) (PG2)

See GroundDistribution,page 14-2.

MANIFOLDABSOLUTEPRESSURE(MAP}SENSOR

PHO|A 49 p16v7l

See ABS,SRS

Y

I

--J

SERVICECHECKCONNECTOR

vtEw39See GroundDistribution,page 14-5.

I

I

___JSe€ Ground: c402

(cont'd)

24-3