Lift HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1050 of 2189

I

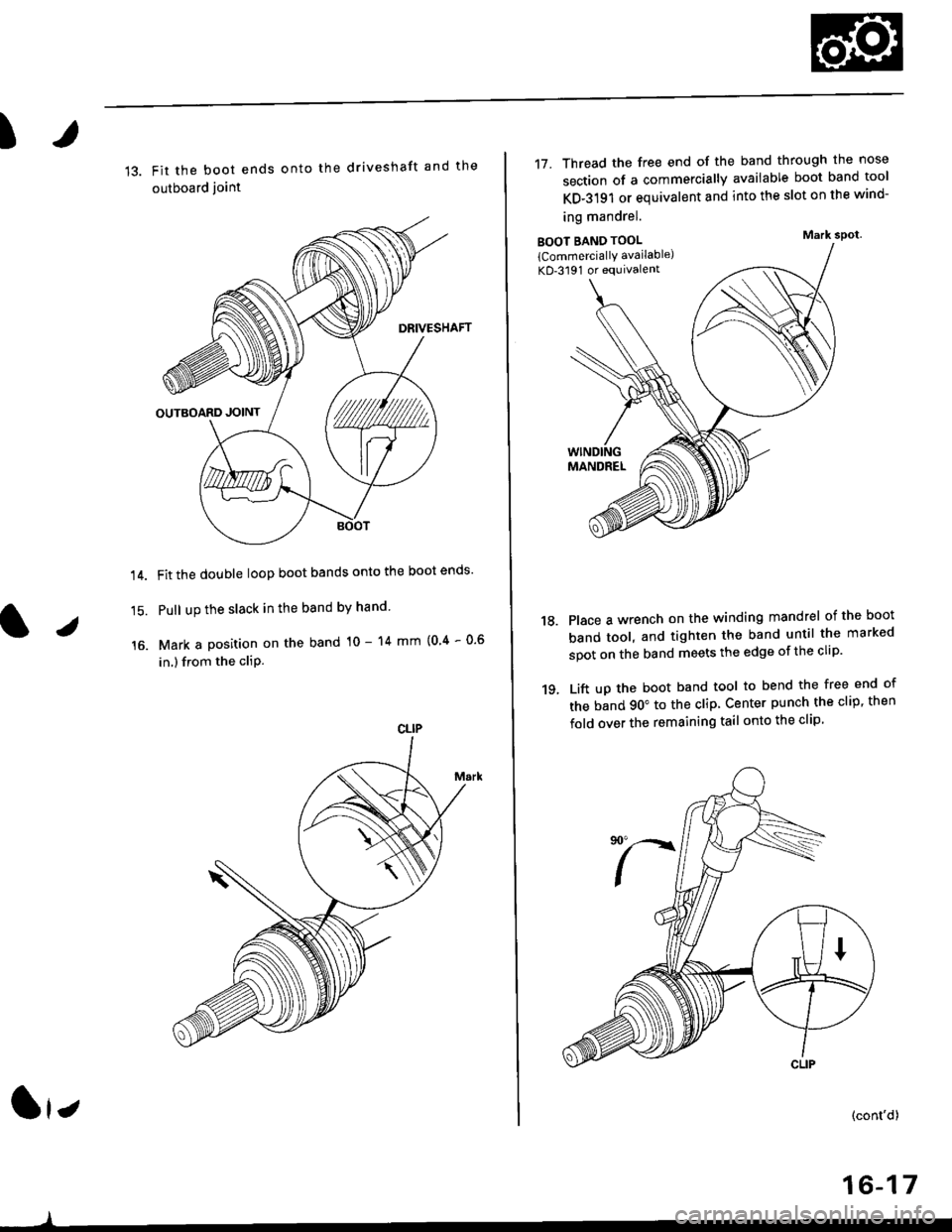

13. Fit the boot ends onto the driveshaft and the

outboard joint

Fit the double loop boot bands onto the boot ends'

Pull up the slack in the band by hand'

Mark a position on the band 10 - 14 mm {0 4 - 0 6

in,) from the cliP.

14.

16.

CLIP

lrz

17. Thread the free end of the band through the nose

section of a commercially avaiiable boot band tool

KD-3191 or equivalent and into the slot on the wind-

ing mandrel.

BOOT BAND TOOL

lCommerciallY available)

KD-3191 or equivalent

MANDREL

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot on the band meets the edge of the clip'

Lift uo the boot band tool to bend the free end of

the band 90" to the clip Center punch the clip, then

fold over the remaining tail onto the clip

Mark spot.

18.

1q

(cont'd)

16-17

Page 1144 of 2189

Front Damper

Installation (cont'd)

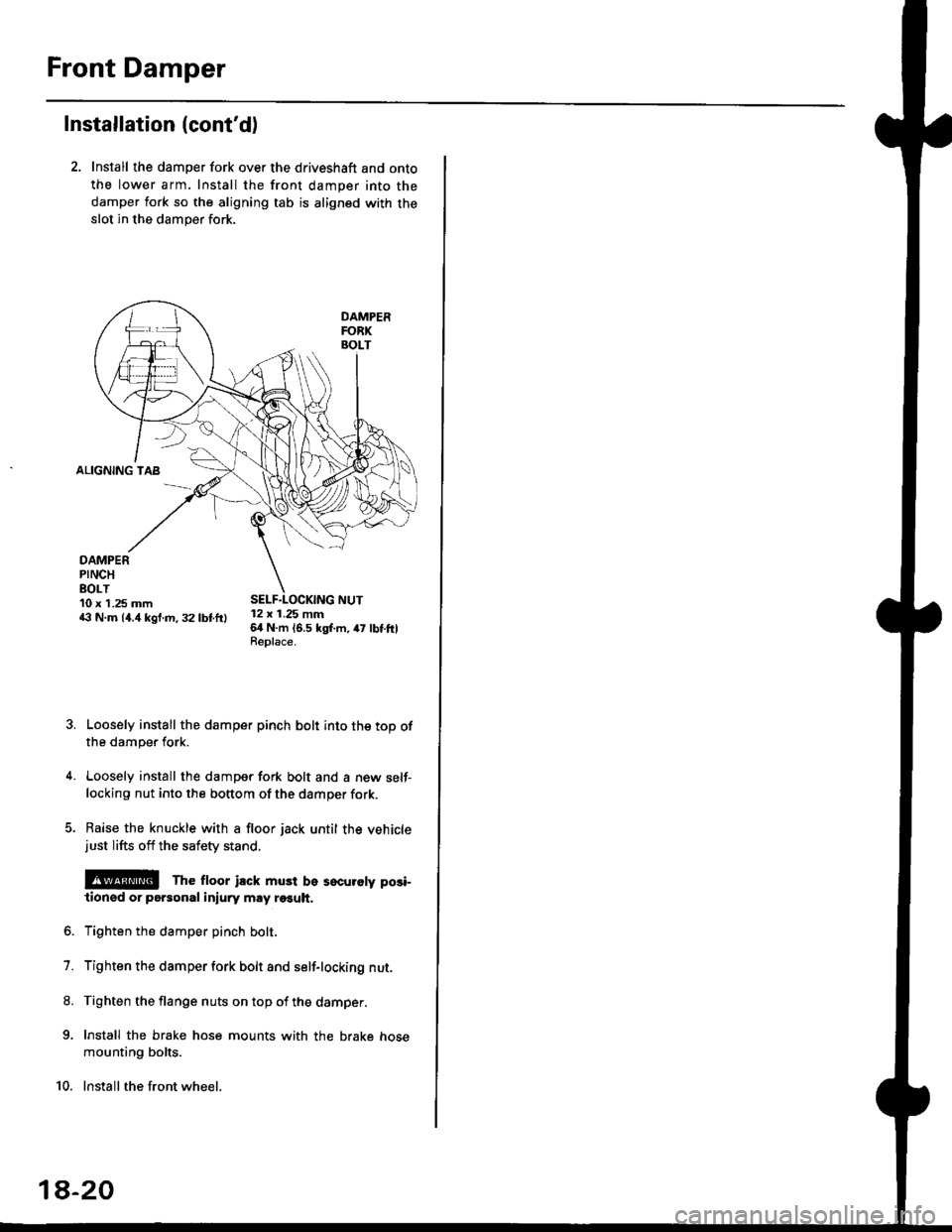

2. Install the damper fork over the driveshaft and onto

the lower arm. Install the front damper into the

damper fork so the aligning tab is aligned with the

slot in the damper fork.

ALIGNING TAB

DAMPERPINCHEOLT10 x 1.25 mm43 N.m 14.4 kgf.m, 32 lbtftl12 x 1.25 mm64 N.m 16.5 kgl.m, 47 lbtftlReplace.

Loosely install the damper pinch bolt into the top ofthe damper fork.

Loosely install the damper fork bolt and a new self-locking nut into the bottom of the damper fork.

Raise the knuckle with a floor jack until the vehiclejust lifts off the safety stand.

@E The ftoor ilck must be sscuroty posi-

lionsd or personal iniury may r€€uh.

Tighten the damper pinch bolt.

Tighten the damper fork bolt and self-locking nut.

Tighten the flange nuts on top of the damper.

Install the brake hose mounts with the brake hose

mounting bolts.

Install the front wheel.

7.

8.

9.

10.

1a-20

Page 1153 of 2189

Rear Damper

Ilnstallation

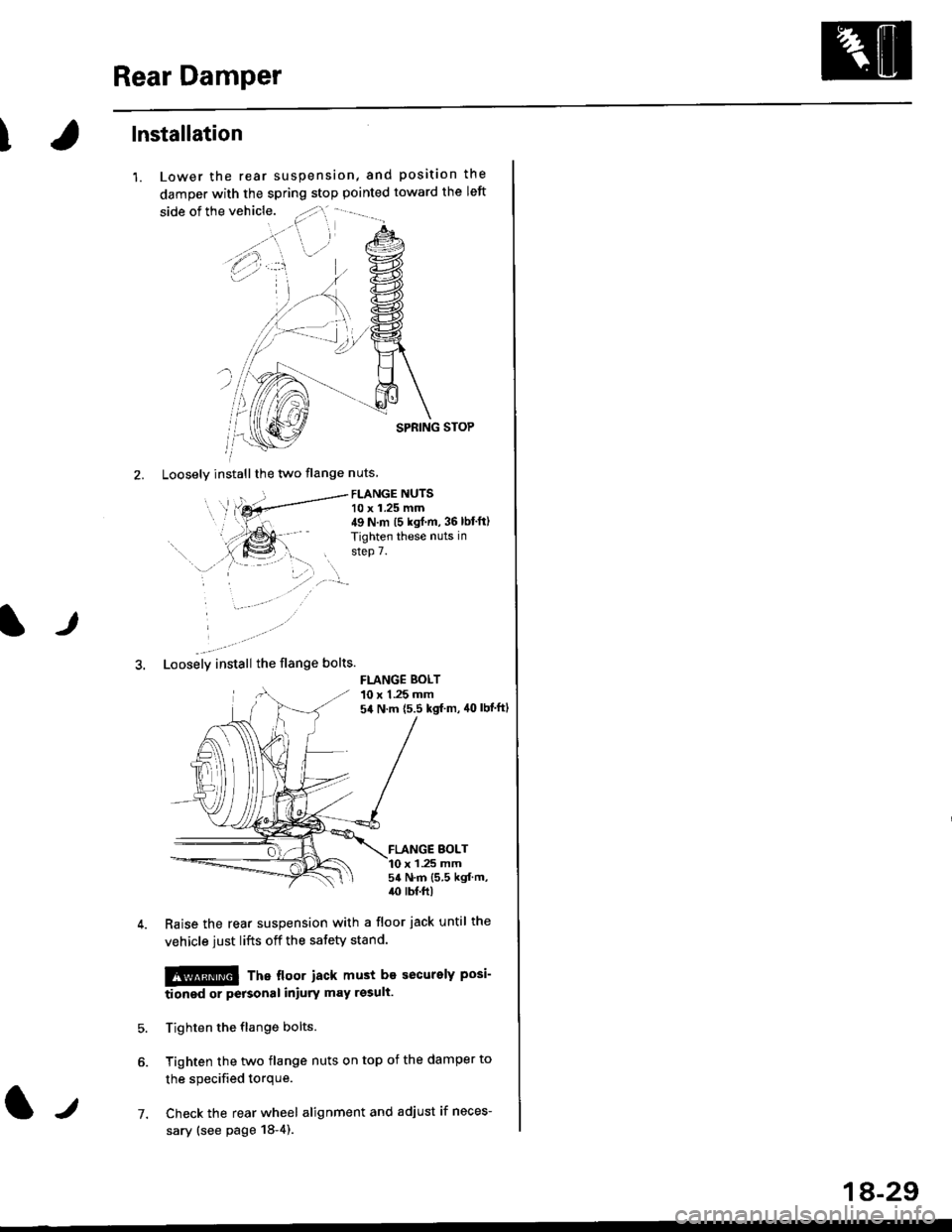

'1. Lower the rear suspension, and position the

damper with the spring stop pointed toward the left

SPRING STOP

2. Loosely installthe two flange nuts

FLANGE NUTS10 x 1.25 mm49 N.m (5 kgf.m, 36 lbt'ft)

Tighten these nuts in

step 7.

lr

3. Loosely install the flange bolts.

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgf m, 40 lbt'ft1

FLANGE BOLT10 x 1 .25 mm54 N.m {5.5 kgf.m,/r0 lb{.ft|

7.

Raise the rear suspension with a floor jack until the

vehicle just lifts off the safety stand.

!@@ Tne floor iacx must be securelY Posi-

tionod or peFonal iniury may rssull

Tighten the flange bolts.

Tighten the two flange nuts on top of the damper to

the specified torque.

Check the rear wheel alignment and adjust if neces-

sary (see page 18-4).

1A-29

Page 1282 of 2189

Moonroof

Glass, Glass Bracket and Sunshade Replacement

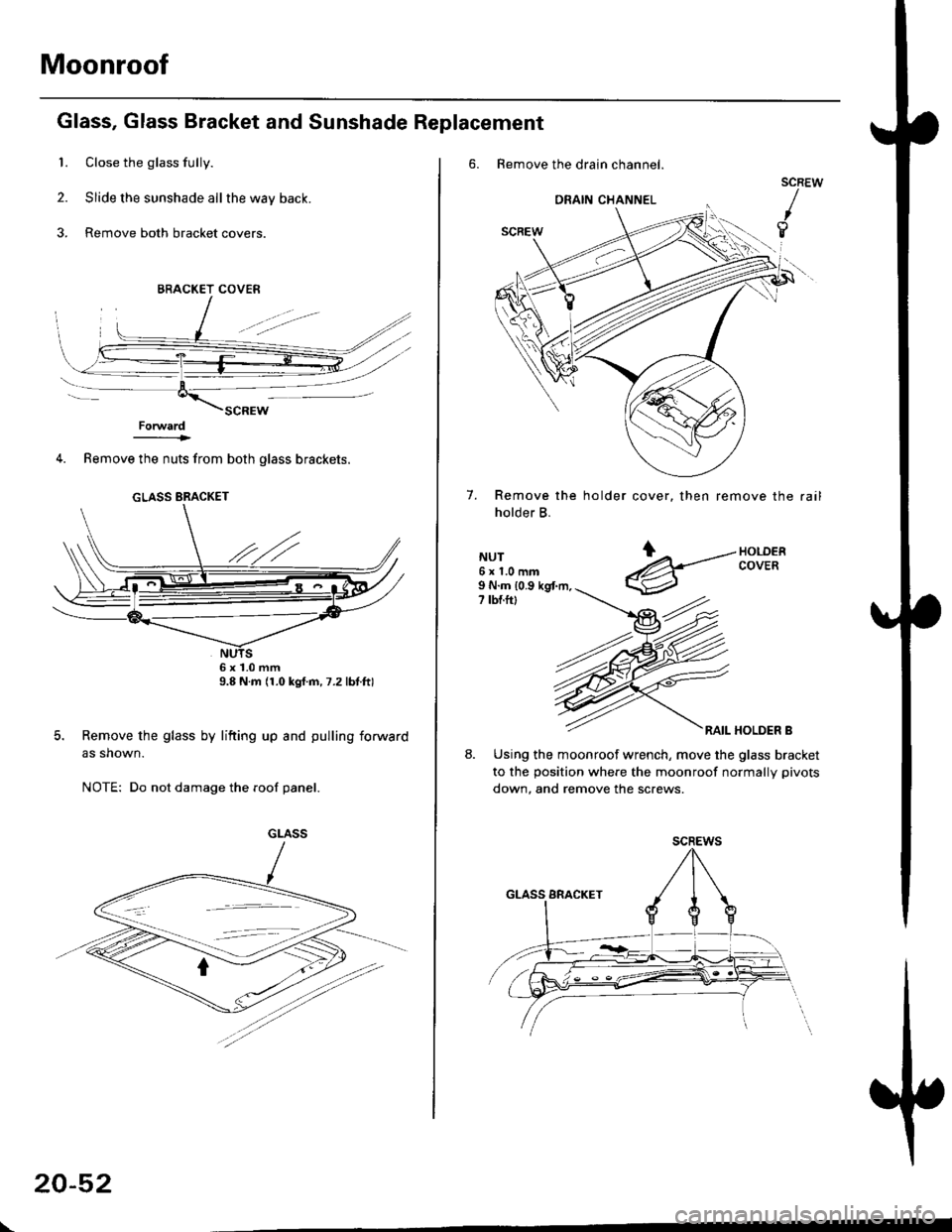

l. Close the glass fully.

2. Slide the sunshade all the way back.

3. Remove both bracket covers.

Forward_--____->

4. Remove the nuts from both glass brackets.

6x1.0mm9.8 N.m (1.0 kgf.m,7.2lbt.ftl

Remove the glass by lifting up and pulling forward

as shown.

NOTE: Do not damage the roof panet.

ERACKET COVER

GLASS EBACKET

GLASS

\

20-52

DRAIN CHANNEL

6. Remove the drain channel.

7. Remove the holder cover. then remove the

holder B.

NUT6x1.0mm9 N.m {0.9 kgf.m.? tbtftl{i;t'm

RAIL HOLDER B

Using the moonroof wrench, move the glass bracket

to the position where the moonroof normally pivots

down, and remove the screws.

scREws

Page 1285 of 2189

L

L

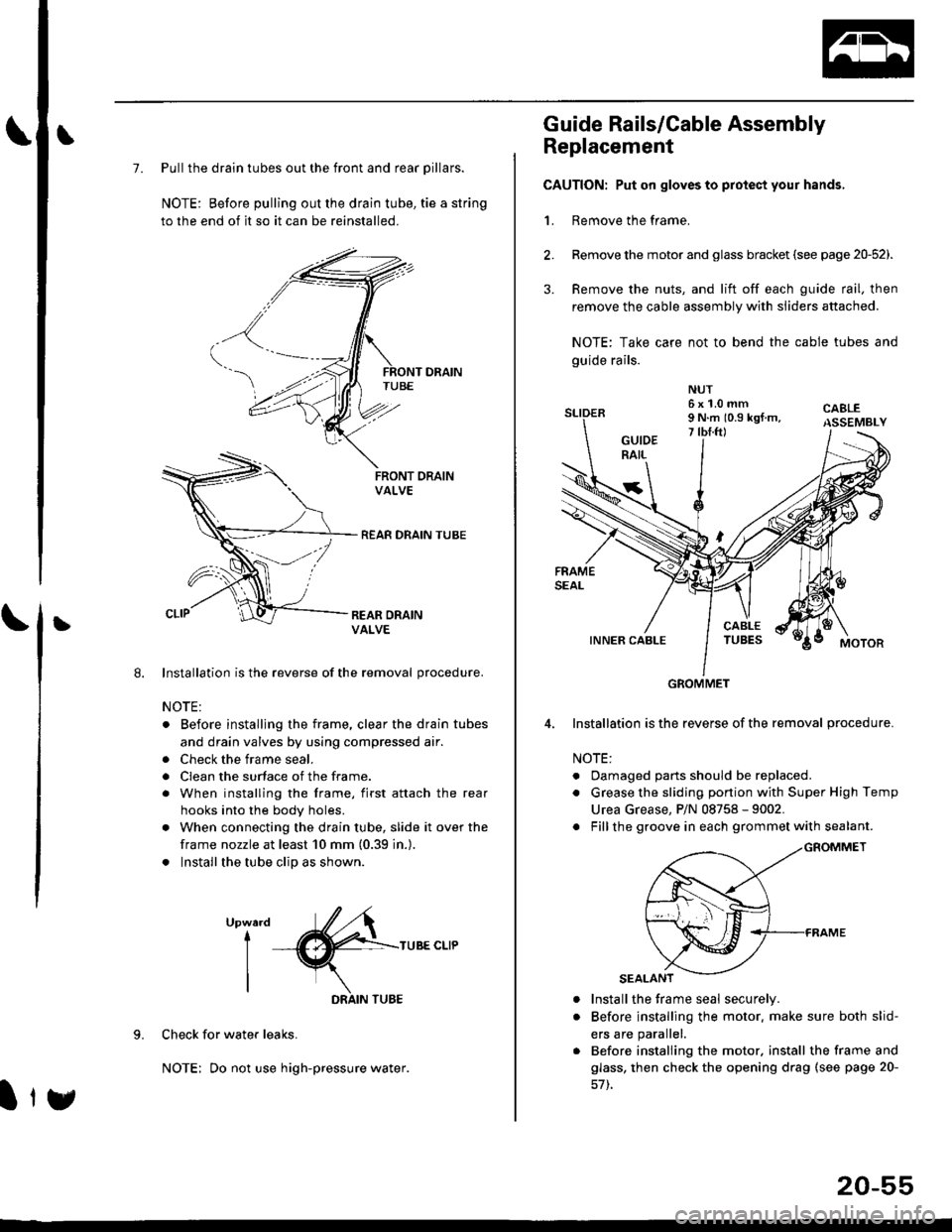

7. Pull the drain tubes out the front and rear pillars.

NOTE: Before pulling out the drain tube, tie a string

to the end of it so it can be reinstalled.

Installation is the reverse of the removal procedure.

NOTE:

. Before installjng the frame, clear the drain tubes

and drain valves by using compressed air.

. Check the frame seal.

. Clean the surface of the frame.

. When installing the frame, first attach the rear

hooks into the body holes.

. When connecting the drain tube, slide it over the

frame nozzle at least 10 mm (0.39 in.).

. Install the tube clip as shown.

UpwardI

I

I

TUBE CLIP

Check for water leaks.

NOTE: Do not use high-pressure water.

DRAIN TUBE

Ity

20-55

Guide Rails/Cable Assembly

Replacement

CAUTION: Put on gloves to protect your hands,

1. Remove the frame.

Remove the motor and glass bracket (see page 20-52).

Remove the nuts, and lift off each guide rail, then

remove the cable assembly with sliders attached.

NOTE: Take care not to bend the cable tubes and

guide rails.

Installation is the reverse of the removal procedure.

NOTE:

. Oamaged parts should be replaced.

. Grease the sliding portion with Super High Temp

Urea Grease, P/N 08758 - 9002.

. Fillthe groove in each grommet with sealant.

a

a

Install the frame seal securely.

Before installing the motor. make sure both slid-

ers are parallel.

Before installing the motor. install the frame and

glass, then check the opening drag (see page 20-

GROMMET

Page 1301 of 2189

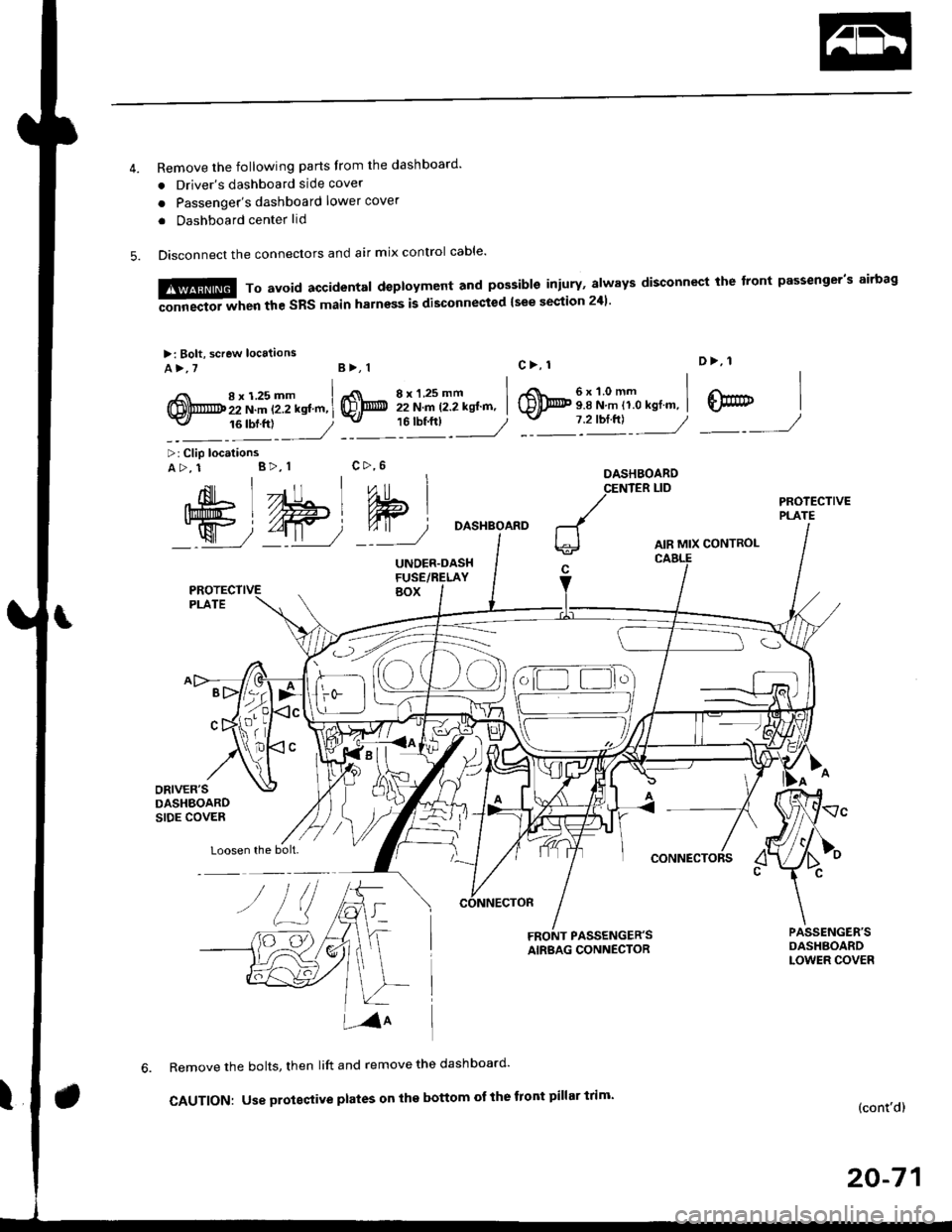

Remove the following parts Irom the dashboard'

. Driver's dashboard side cover

o Passenger's dashboard lower cover

. Dashboard center lid

Disconnect the connectors and air mix control cable'

6x1.0mm9.8 N.m 11.0 kgl.m,

D>, 1

@7 2'orftl - ---//_._J

,{nil Lll , ,"o

Ift#5 L //Hl Wlj%u|5 i//Wt qT

W72-t11 7'::--J

>: Clip locationsA>, 1 B>, 1

Loosen the bolt.

DASHBOARD

AIR MIX CONTROL

CONNECTORS

FRONT PASSENGER'SAIRBAG CONNECTOR

Remove the bolts, then lift and remove the dashboard'

CAUTION: Use proteqtive plates on the bottom ot the front pillar trim'(cont'd)

20-71

M,::;:"lx3T:iJnif:3lilH:fl"*:1::f"*'il;ili"'"

disconnect rhe front passeneer's airbas

>: Bolt, screw locaiions

A>,7B>, 1

,i( 8x125mm(!,@ 22 N.m t2.2 kstm,-v, 16 tbf.ftl

8xl.25mm I22 N.m 12.2 kgt'm, I'"tt:___J

c>, 1

@

c>,6

Page 1304 of 2189

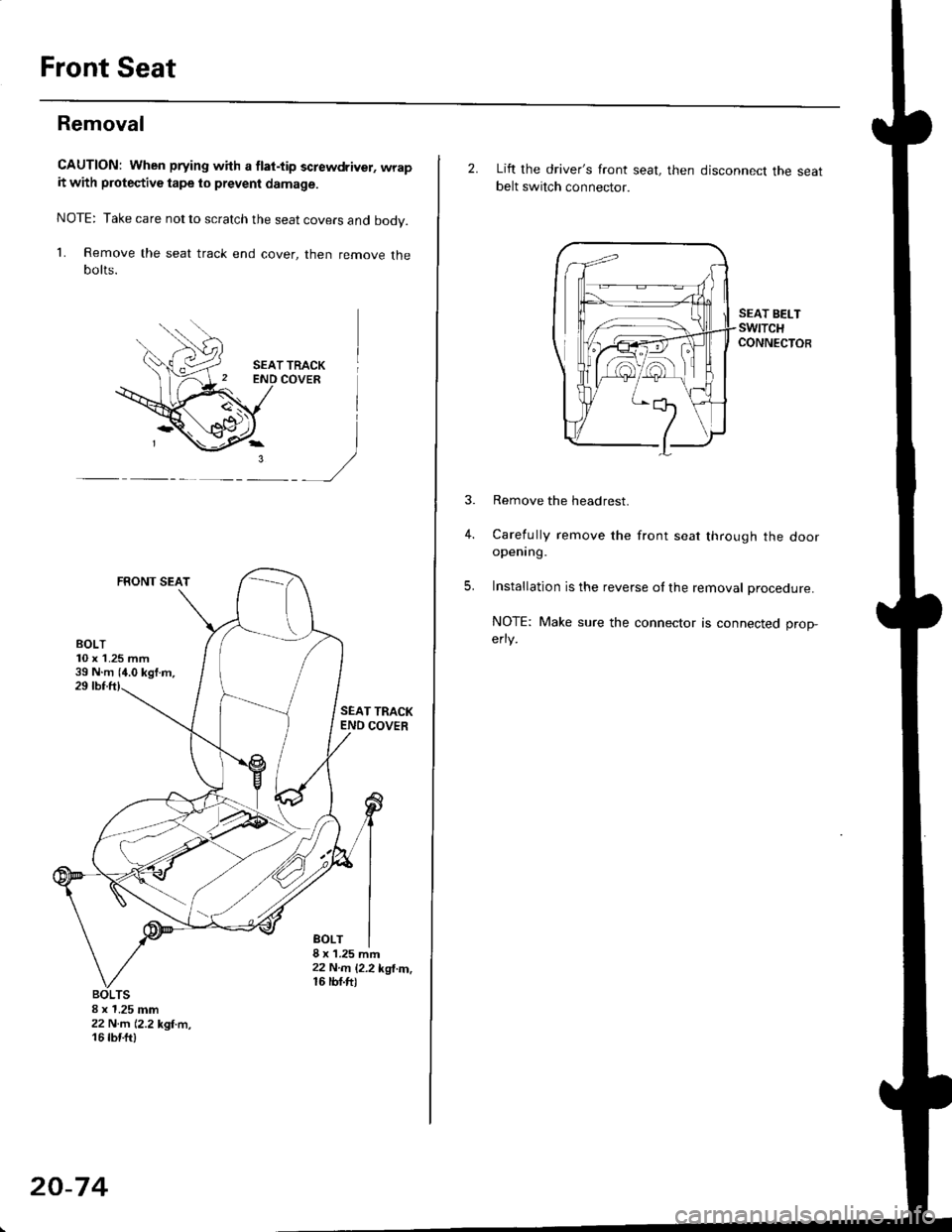

Front Seat

Removal

CAUTION: When prying with a flat-tip screwdriver, wrapit with protective tape lo prevent damage.

NOTE: Take care not to scratch the seat covers and body.

1. Remove the seat track end cover, then remove thebolts.

SEAT TRACKCOVER

FRONT SEAT

)

SEAT TRACKEND COVER

BOLT8 x'1.25 mft22 N..n 12.2 kgl.m,16 rbf.ft)

8 x 1.25 mm22 N.rn 12,2 kgl.m,16 tbtft)

20-74

2. Lift the driver's front seat, then disconnect the seatbelt switch connector.

SEAT BELTswtTcHCONNECTOR

4.

Remove the headrest.

Carefully remove the front seat through the dooropening.

Installation is the reverse ol the removal procedure.

NOTE: Make sure the connector is connected prop-

erry.

5.

Page 1331 of 2189

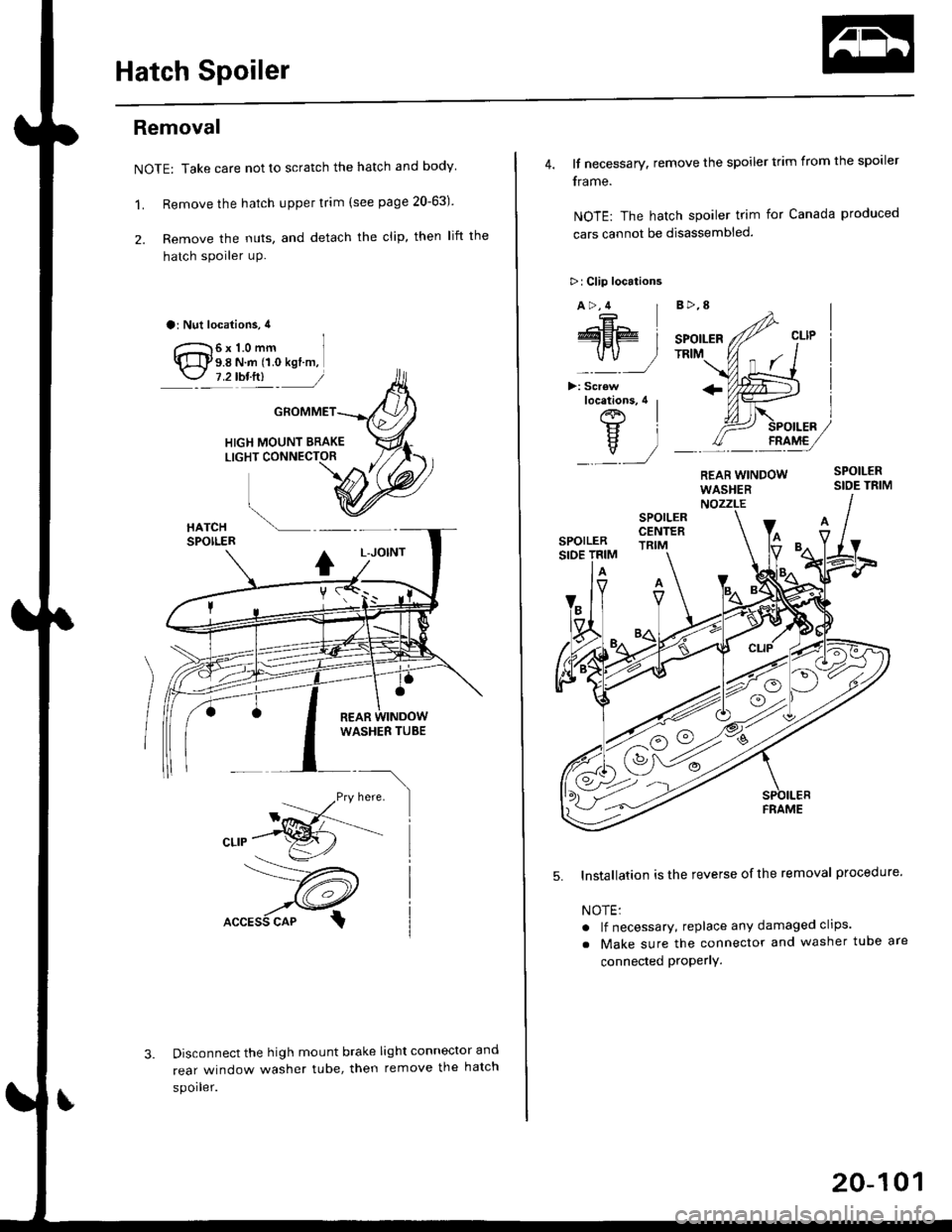

Hatch Spoiler

Removal

NOTE: Take care not to scratch the hatch and body

1. Remove the hatch upper trim (see page 20-63)

2. Remove the nuts, and detach the clip, then lift the

hatch spoiler uP.

a: Nut locations, 4

1 2lbt.ftl _ j/

GROMMET

HIGH MOUNT BRAKELIGHT CONNECTOR

Disconnect the high mount brake light connector and

rear window washer tube, then remove the hatch

spoiler.

------,*;)

4. lf necessary. remove the spoiler trim from the spoiler

frame.

NOTE: The hatch spoiler trim for Canada produced

cars cannot be disassembled.

>: Clip locations

A>,4

>: Scr€w

5. Installation is the reverse of the removal procedure'

NOTEi

. lf necessary, replace any damaged clips.

a Make sure the connector and washer tube are

connected ProPerlY.

20-101

Page 1468 of 2189

Condenser

Replacement

1.Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271.

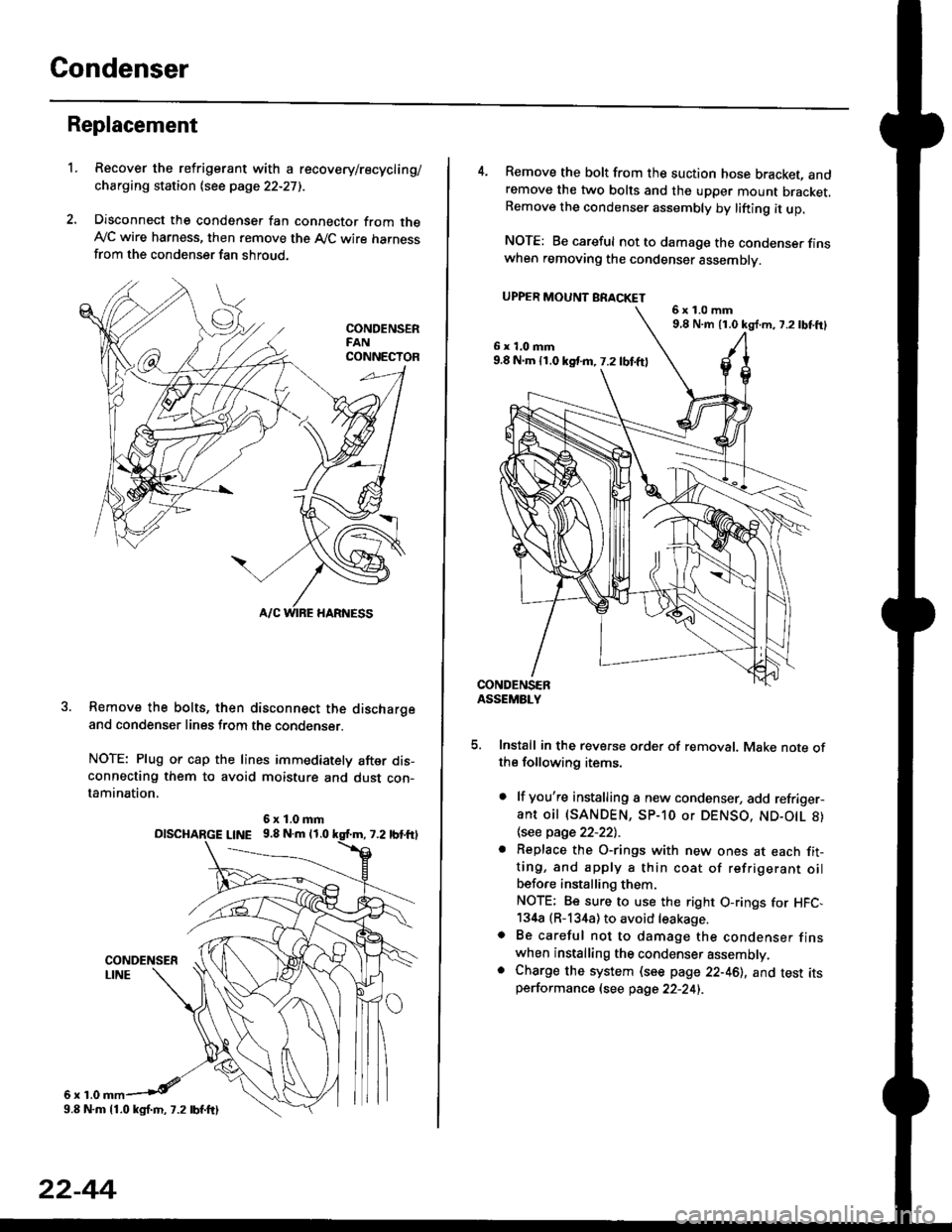

Disconnect the condenser fan connector from theAy'C wire harness, then remove the A,/C wire harnessfrom the condenser fan shroud.

Remove the bolts, then disconnect the dischargeand condenser lines from the condenser.

NOTE: Plug or cap the lines immediately after dis-connecting them to avoid moisture and dust con-tamination,

6r1.0

6x1.0mmolscHARGE L|NE 9.8 N.m 11.0

9.8 N.m 11.0 kgl.m, 7.2 lbf.ftl

22-44

4. Remove the bolt from the suction hose bracket, andremove the two bolts and the upper mount bracket.Remove the condenser assembly by lifting it up.

NOTE: Be careful not to damage the condenser finswhen removing the condenser assembly.

UPPER MOUNT BRACKET

5. Install in the reverse order of removal. Make note ofthe following items.

. lf you're installing a new condenser, add refriger-ant oil (SANDEN, SP-10 or DENSO, ND-O|L 8)

\see page 22-22l.-

. Replace the O-rings with new ones at each fit-ting, and apply a thin coat of refrigerant oilbefo.e installing them.

NOTE; Be sure to use the right O-rings for HFC,134a (R-134a) to avoid leakage.o Be careful not to damage the condenser finswhen installing the condenser assembly.. Charge the system (see page 22-46), and test itsperformance (see page 22-24i.

6x1.0mm9,8 N.m 11.0 kg{.m, 7.2lbtft}

6x1.0mm9.8 N.m 11.0 kst m, 7.2 lbf.ftl

Page 1569 of 2189

JBrush Holder Test

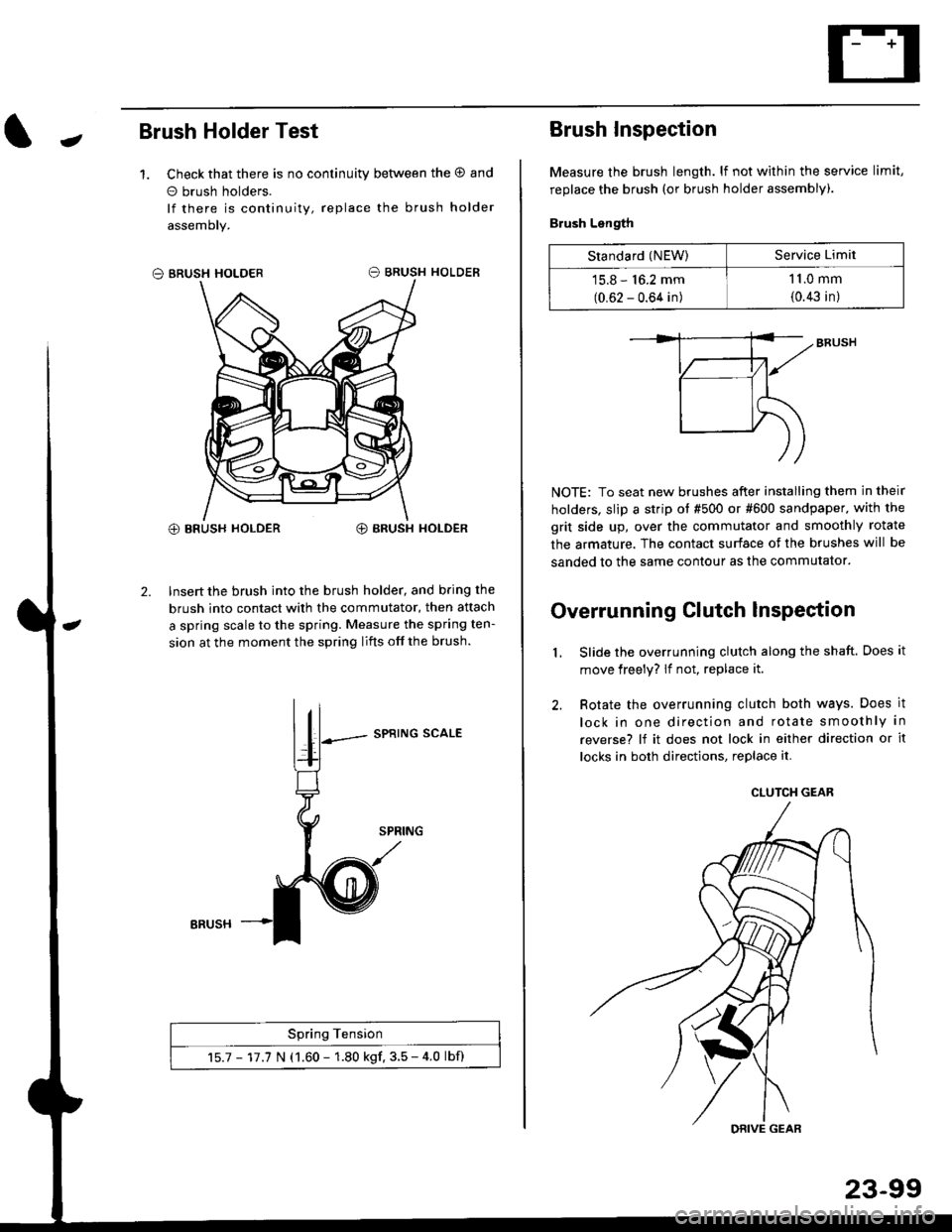

1. Check that there is no continuity between the O and

o brush holders.

lf there is continuity, replace the brush holder

assemoly.

O BRUSH HOLDER

@ BRUSH HOLDER€) BRUSH HOLDER

2. Insert the brush into the brush holder, and b.ing the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

sion at the moment the spring lifts off the brush.

SPRING SCALE

Spring Tension

15.7 - 17.7 N (1.60 - 1.80 kgf. 3.5 - 4.0 lbf)

ERUSH

Brush Inspection

Measure the brush length. lf not within the service limit,

replace the brush (or brush holder assembly).

Brush Length

NOTE: To seat new brushes after installing them in their

holders, slip a strip ot #500 or #600 sandpaper. with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

Overrunning Clutch lnspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

2.

L

Standard (NEW)Service Limit

15.8 - 16.2 mm

(0.62 - 0.64 in)

1 1.0 mm

{0.43 in)

CLUTCH GEAR

DRIVE GEAR