throttle HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 682 of 2189

Description

(cont'dl

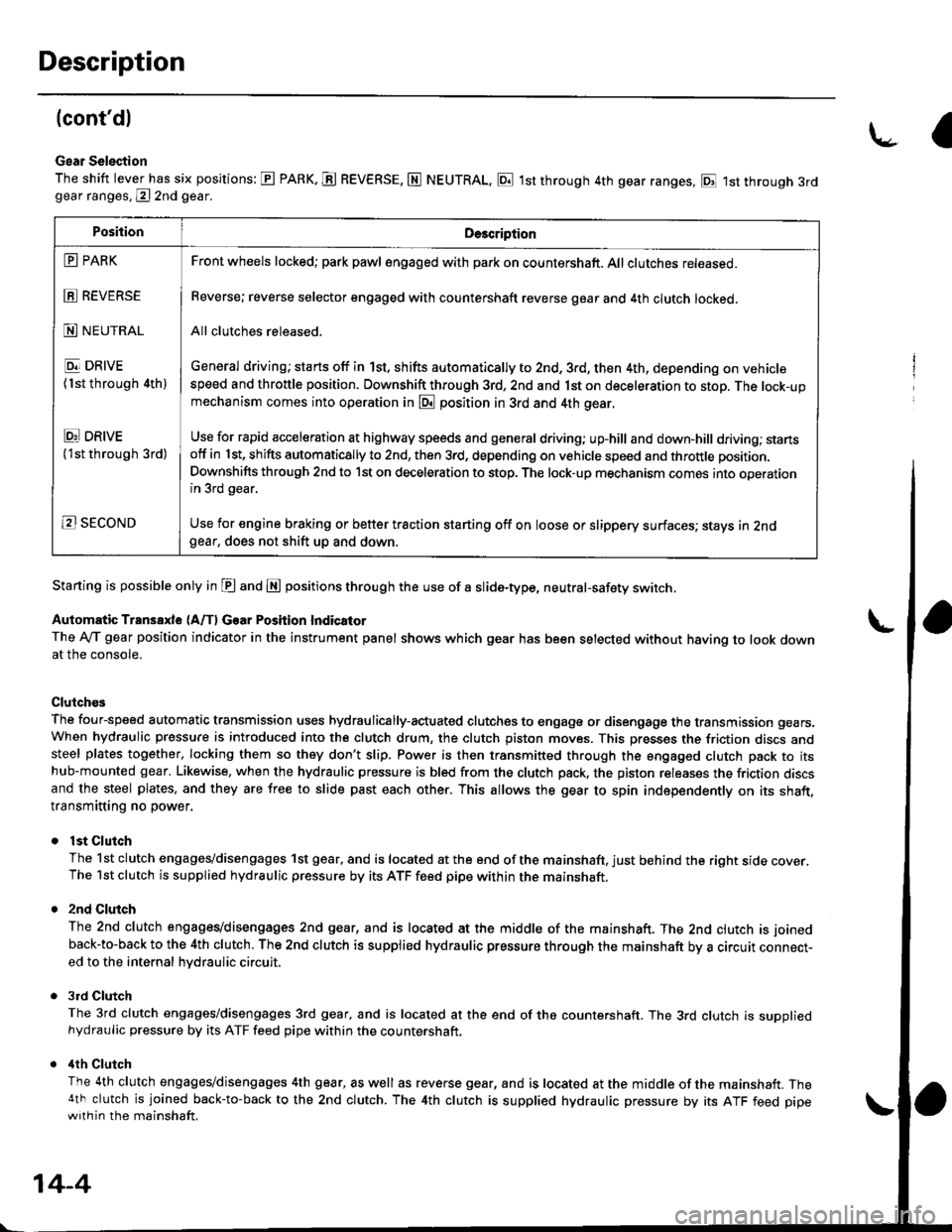

Gear Selection

The shift lever has six positions: E PARK. E REVERSE, N NEUTRAL, E 1st through 4th gear ranges, E 1st through 3rdgear ranges, @ 2nd gear.

Starting is possible only in E and E positions through the use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/f, Gear Position Indicator

The Ay'T gear position indicator in the instrument panel shows which gear has been selected without having to look downat the console.

Clutch€s

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.When hydraulic pressure is introduced into the clutch drum, the clutch piston moves. This presses the friction discs andsteel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack to itshub-mounted gear. Likewise, when the hydraulic pressure is bled from the clutch pack, the piston releases the friction discsand the steel plates, and they are free to slide past each other. This allows the gear to spin independently on its shaft,transmitting no power.

lst Clutch

The 1st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the right sroe cover.The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

2nd Clulch

The 2nd clutch engagegdisengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined

back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circutr connect-ed to the internal hvdraulic circuit,

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft. The 3rd clutch is suooliedhydraulic pressure by its ATF feed pipe within the countershaft.

ilth Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the middle of the mainshaft. The4th clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied hydraulic pressure by its ATF feed pipewith in the mainshaft.

\-a

PositionDe3cription

E PARK

E REVERSE

N NEUTRAL

E DRIVE

{1st through 4th)

Ei DRtvE('lst through 3rd)

B SECOND

Front wheels locked; park pawl engaged with pa* on countershaft. All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on vehiclespeed and throttle position. Downshift through 3rd, 2nd and 1st on deceleration to stop. The lock-upmechanism comes into operation in @ position in 3rd and 4th gear.

Use for rapid acceleration at highway speeds and general driving; up-hill and down,hill dfiving; stansotf in 1st, shifts automatically to 2nd, then 3rd, depending on vehicle speed and throttle position.

Downshifts through 2nd to lst on deceleration to stop. The lock-up mechanism comes into operationin 3rd gear,

Use for engine braking or better traction starting off on loose or slippery surfaces; stays in 2ndgear, does not shift up and down.

14-4

Page 686 of 2189

Description

Power Flow (cont'dl

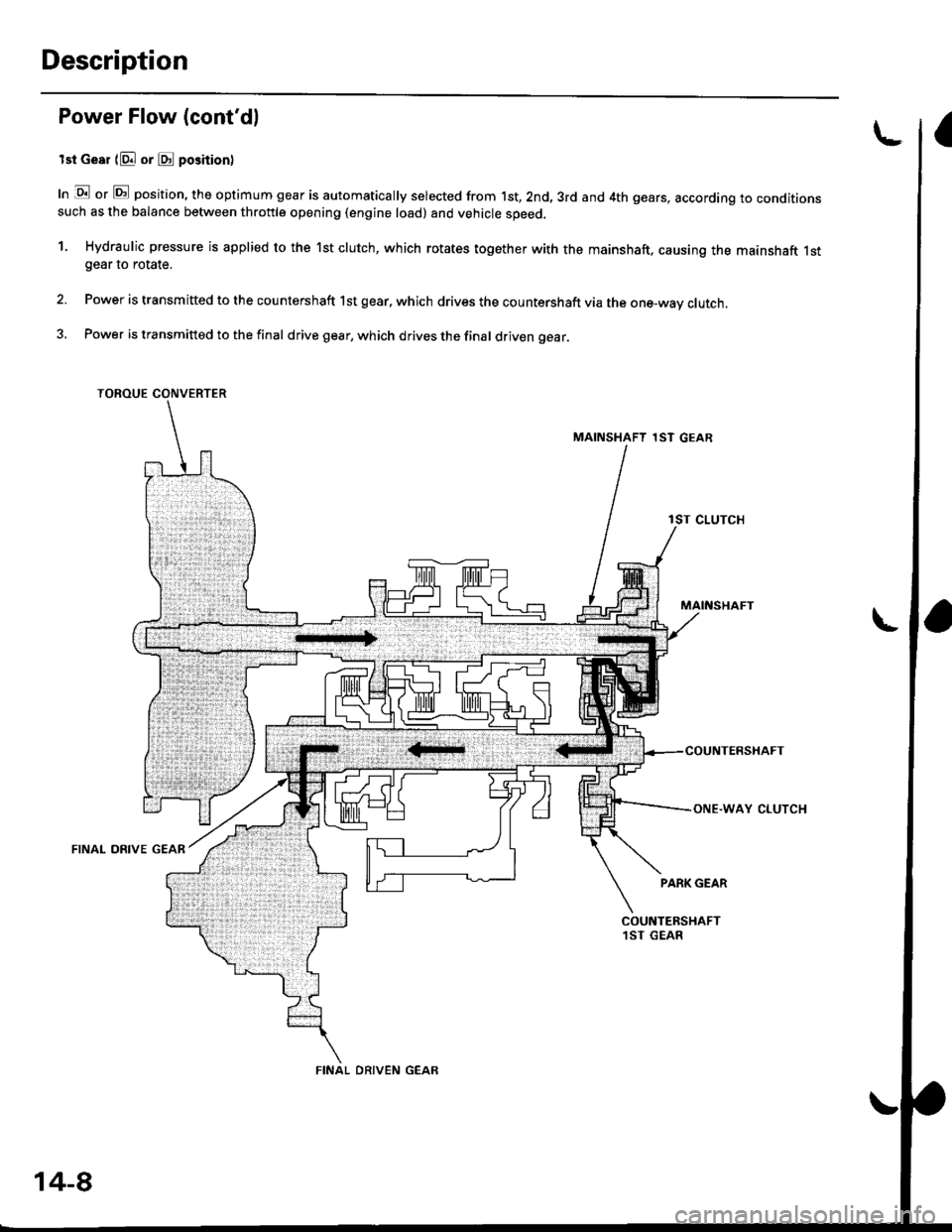

lst Gesr (E or @ position)

In lE or E position, the optimum gear is automatically selected from 1st,2nd,3rd and 4th gears, according to conditionssuch as the balance between throttle opening (engine load) and vehicle speed.

1. Hydraulic pressure is applied to the 1st clutch, which rotates together with the mainshaft, causing the mainshaft 1stgear to rotate.

Power is transmitted to the countershaft 1st gear, which drives the countershaft via the one-way clutch.

Power is transmitted to the final drive gear, which drives the final driven gear.

TOROUE CONVERTER

MAINSHAFT 1ST GEAR

lST CLUTCH

MAINSHAFT

AY CLUTCH

FINAL DRIVE GEAR

PARK GEAR

L

COUNTERSHAFT1ST GEAR

14-8

Page 693 of 2189

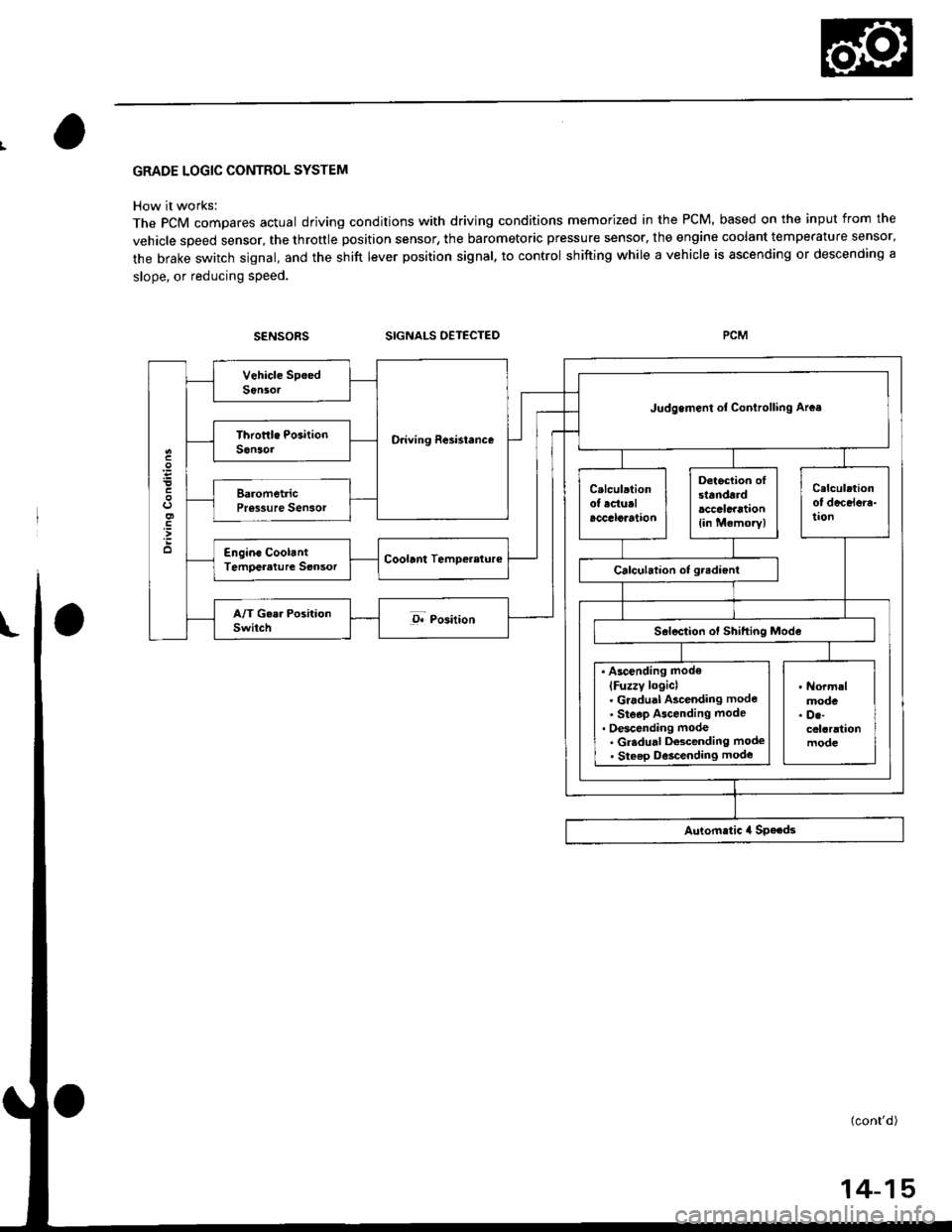

GRADE LOGIC CONTROL SYSTEM

How it works:

The pCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, the throttle position sensor, the barometoric pressure sensor, the engine coolant temperature sensor,

the brake switch signal, and the shift lever position signal, to control shifting while a vehicle is ascending or descending a

slope, or reducing speed.

SIGNALS OETECTED

O.iving Resi3lence

Judgemenl ot Conirolling Arca

. Ascending mod€

lFuzzy loqicl. Gradual Ascending mode' Ste€p Ascending mode. Oescending mode. Gr.du.l Descending mode. Steep D6cending mode

14-15

Page 791 of 2189

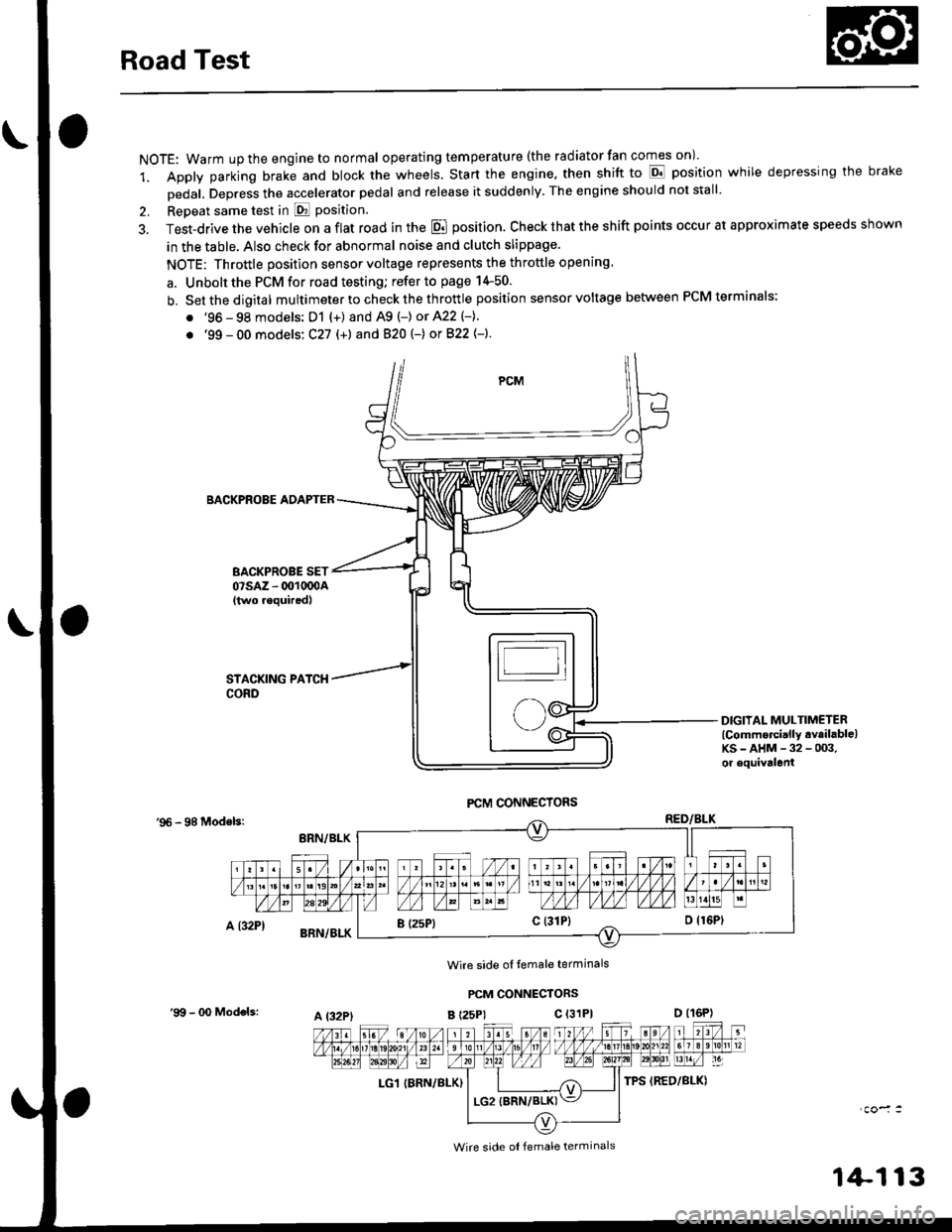

Road Test

NOTE: Warm up the engine to normal operating tem peratu re (the rad iator fan comes on )'

1. Apply parking brake and block the wheels. Start the engine, then shift to E position while depressing the brake

Dedal, Depress the accelerator pedal and release it suddenly. The engine should not stall'

2. Repeat same test in E Position.

3. Test-drive the vehicle on a flat road in the E position. Check that the shift points occur at approximate speeds shown

in the table. Also check for abnormal noise and clutch slippage.

NOTE: Throttle position sensor voltage represents the throttle opening

a. Unbolt the PCM for road testing; refer to page 14-50.

b. Setthedigital multimeter to check the th rottle position sensor voltage between PCM terminals;

. '96 - 98 models: D1 {+) and A9 (-) or 422 (-}.

. '99 - 00 models: C27 (+) andB20t-) orB22{-}.

BACKPROBE ADAPTER

BACKPROBE SET07sAz - 001oq)A{two requiredl

DIGIIAL MULTIMETERlCommercially available)KS-AHM-32-003,or equivalenl

'96 - 98 Modelsr

Wire side ol temale terminals

PCM CONNECTORS

B t25Pl c (31P)

LG1 IBRN/BLK)

I (25P1c (31P}

A t32PtD (16P)

Wire side ol female terminals

'9!t - 00 Models:

1+113

Page 792 of 2189

Road Test

(cont'dl

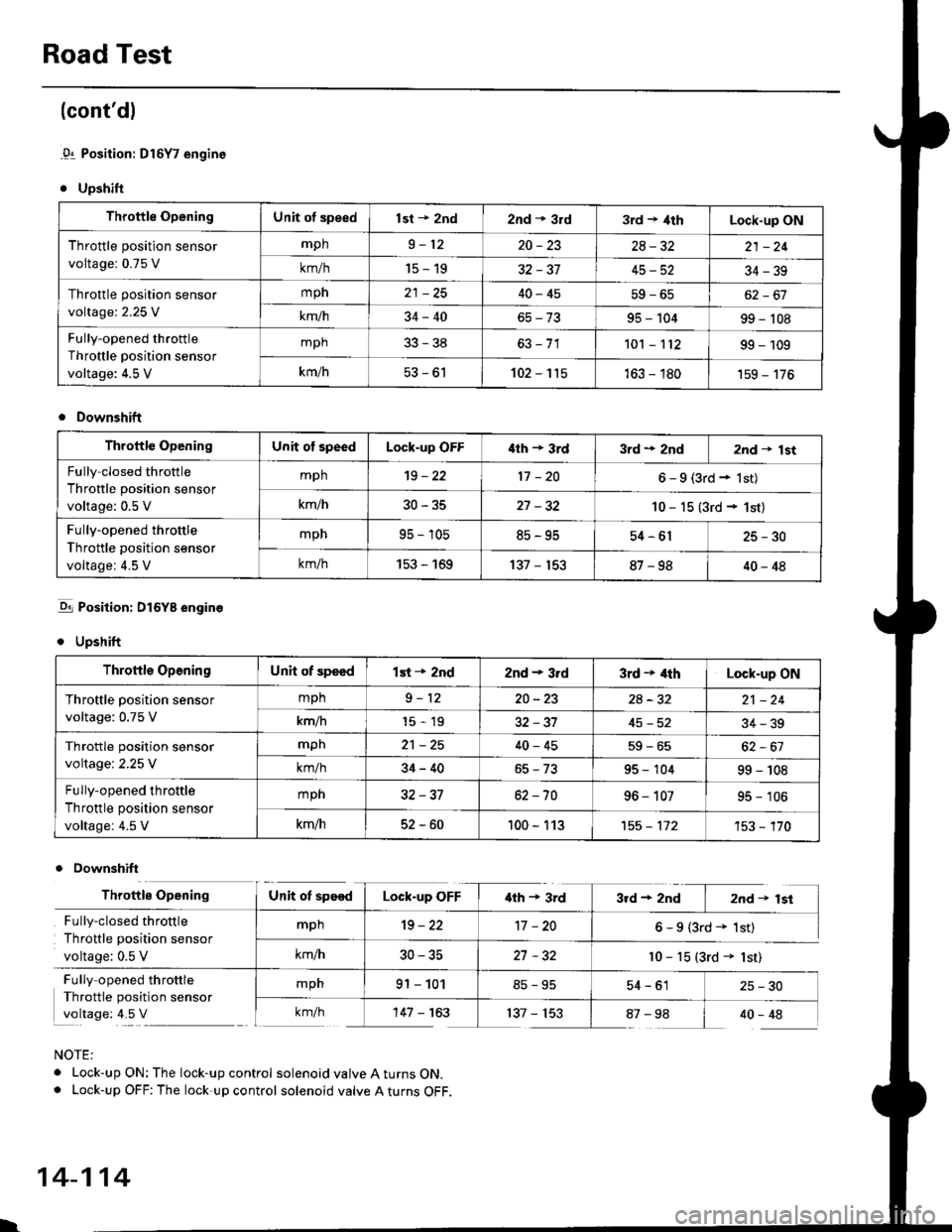

.91 Position: Dl6Y7 engine

. Upshift

Throttle OpeningUnit of speedlst + znd2nd * 3rd3rd t 4thLock-up ON

Throttle position sensor

voltage: 0.75 V

mph9-1220-2328-3221 -24

km/h15-1932-3745-5234-39

Throttle position sensor

voltage:2.25 V

mph40-4562-67

km/h34-4095 - 10499 - 't08

Fully-opened throttle

Throttle position sensor

voltage: 4.5 V

mph33-38101 - 't1299 - 109

km/h53-61102-115163 - 180'159 - 176

Downshift

Throftle OpeningUnit of speedLock-up OFF'lth + 3rd3rd + 2nd2nd t lst

Fully closed throttle

Throttle position sensor

voltage: 0.5 V

mph't9 - 2217 -206-9(3rd+lst)

km/h30-3527 -3210 - 15 (3rd + 1st)

Fully-opened throttle

Throttle position sensor

voltage: 4.5 V

mpn95 - 10585-9554-6125-30

km/h153 - 169137 - 15387-9840-48

-q1 Position: DI6YB engine

. Upshift

Downshift

NOTE:

. Lock-up ON: The lock-up control solenoid valve A turns ON.. Lock-up OFF: The lock-up control solenoid valve A turns OFF.

Throttle OpeningUnit of speedlst + 2nd2nd - 3rd3rd + 4thLock-up ON

Throftle position sensor

voltage: 0.75 V

mph9-1220-232A-3221 -24

km/h15-1932-3745-5234-39

Throttle position sensor

voltage:2.25 V

mpn21 -2540-4559-65

km/h34-4095 - 10499 - 108

Fully-opened throttle

Throttle position sensor

voltage: 4.5 V

mph32-3762 -7096 - 10795 - 106

km/h52-60100 - 113't55 - 112't53 - '�170

Throttle OpeningUnit ot speedLock-up OFF'lth + 3rd3rd+2nd I 2nd+lst

Fully-closed throttle

Throttle position sensor

voltage: 0.5 V

mph19-2217 -206-9(3rd+ 1st)

km/h30-3527 -32l0 - 15 (3rd + lst)

Fully opened throttle

Throttle position sensor

voltage: 4.5 V

mpn91 - 10154-61 25-30

km/h'147 - 163137 - 15387-98 I 40-48

l.

14-114

Page 793 of 2189

Accelerate to about 35 mph (57 km/h) so the transmlssion is in 4th, then shift from Dl position to Z position The

vehicle should immediately begin slowing down from engine braking'

CAUTION: Do not shift from -91 or -Dd position to E position at speeds ov6r 63 mph {100 km/hl; You mav damage

the transmission.

Check for abnormal noise and clutch slippage in the following positions'

E (2nd Gear) Position

ll Accelerate from a stop at full throttle. check that there is no abnormal noise or clutch slippage.

b. Upshifts and downshifts should not occur with the selector in this posirion'

E (Reverse) Position

i"ccelerate from a stop at fullthrottle, and check for abnormal noise and clutch slippage'

Test in B (Park) Position

Park the vehicle on slope (approx. l6'), apply the parking brake' and shift into E position Belease the brake; the veh'

cle shou,d nol move

1+115

Page 879 of 2189

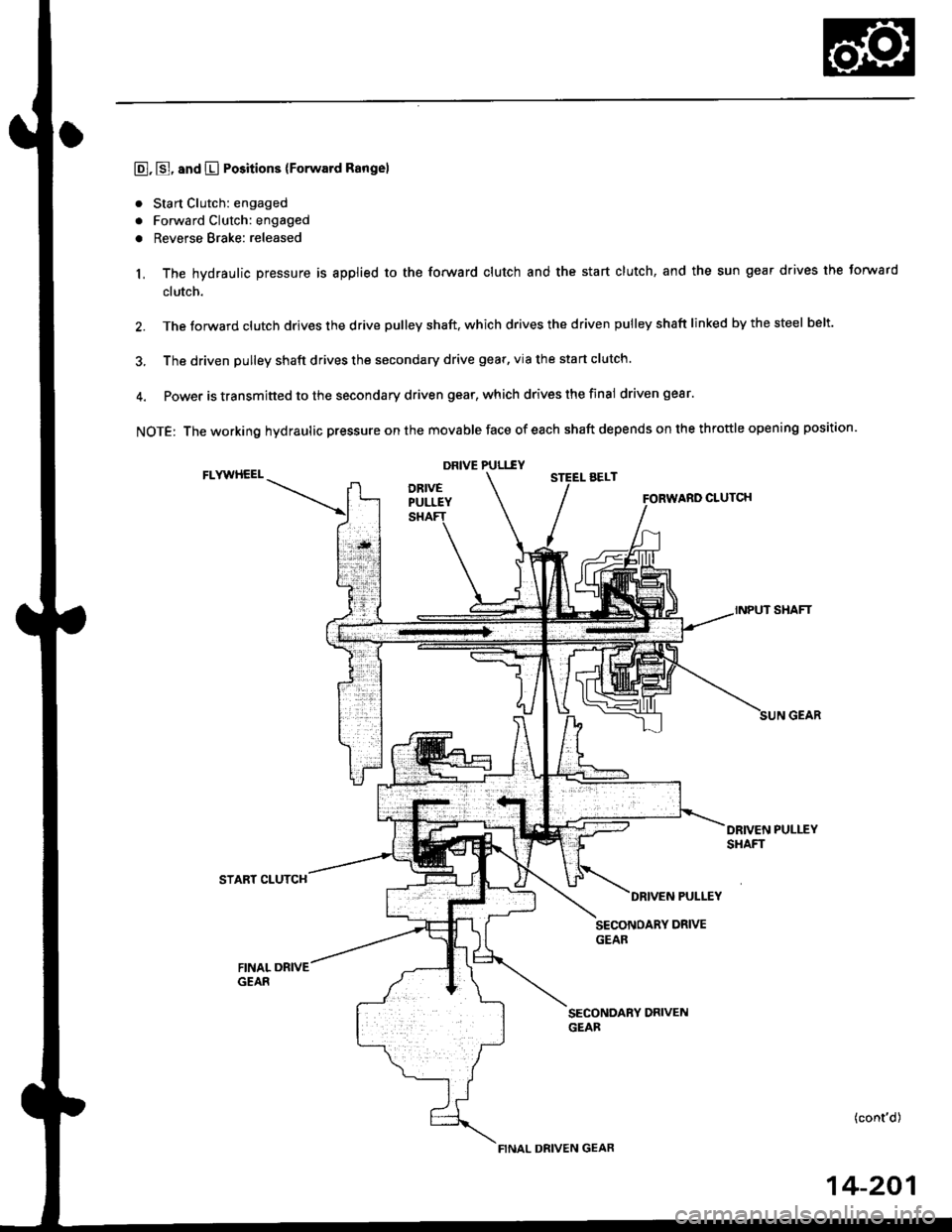

E, E, and E Positions {Forward Rangel

. Sta rt Clutch: engaged

. Forward Clutch: engaged

o Reverse Brake: released

1, The hydraulic pressure is applied to the forward clutch and the start clutch, and the sun gear drives the torward

clutch.

2. The torward clutch drives the drive pulleV shaft. which drives the driven pulley shaft linked by the steel belt.

3, The driven pulley shaft drives the secondary drive gear, via the start clutch.

4. Power is transmitted to the secondary driven gear, which drives the final driven gear.

NOTE: The working hydraulic pressure on the movable face of each shaft depends on the throttle opening position.

DRIVE PULI.f YFLYWHEELSTEEL AELT

CLUTCH

INPUT SHAFT

START CLUTCH

SECONDARY DRIVENGEAR

(cont'd)

FINAL DRIVEN GEAR

14-201

Page 881 of 2189

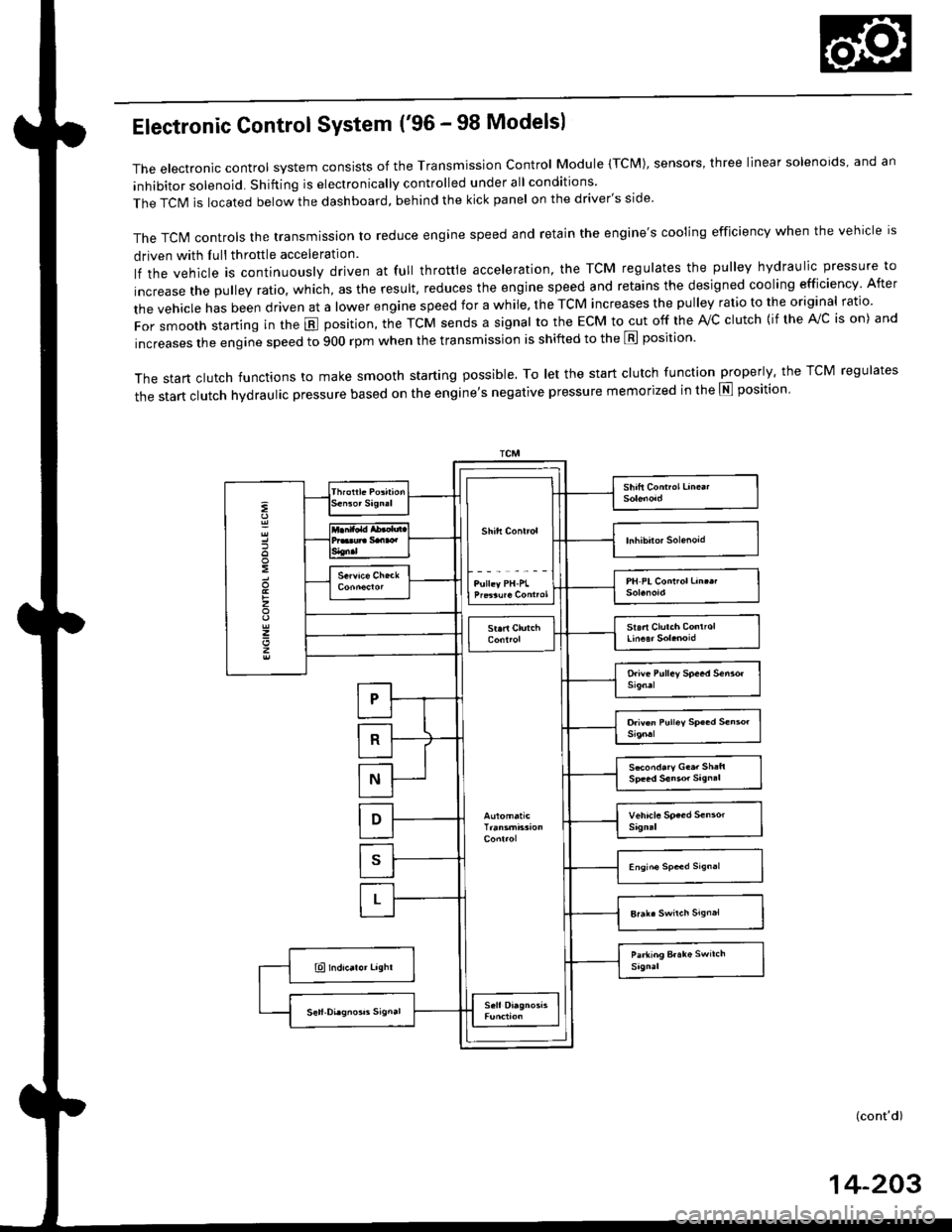

Electronic Control System ('96 - 98 Modelsl

The electronic control system consists of the Transmission control Module (TcM), sensors, three linear solenoids, and an

inhibitor solenoid. Shifting is electronically controlled under all conditions

The TCIM is located below the dashboard, behind the kick panel on the driver's side'

The TcN4 controls the transmission to reduce engine speed and retain the engine's cooling efficiency when the vehicle is

driven with Iull throttle acceleration

lf the vehicle is continuously driven at full throttle acceleration, the TCM regulates the pulley hydraulic pressure to

increase the pulley ratio, which, as the result. reduces the engine speed and retains the designed cooling efficiency After

the vehicle has been driven at a lower engine speed for a while, the TCM increases the pulley ratio to the original ratio.

For smooth starting in the E position, the TcM sends a signal to the EcM to cut off the rvc clutch {if the A!/c is on) and

increases the engine speed to 900 rpm when the transmission is shifted to the E position'

The start clutch functions to make smooth starting possible. To let the start clutch function properly. the TCM regulates

the start clutch hydraulic pressure based on the entine's negative pressure memorized in the E position'

:

:

z

z

z

S*ond.ry G..r Sh:ft

(cont'd)

14-203

Page 883 of 2189

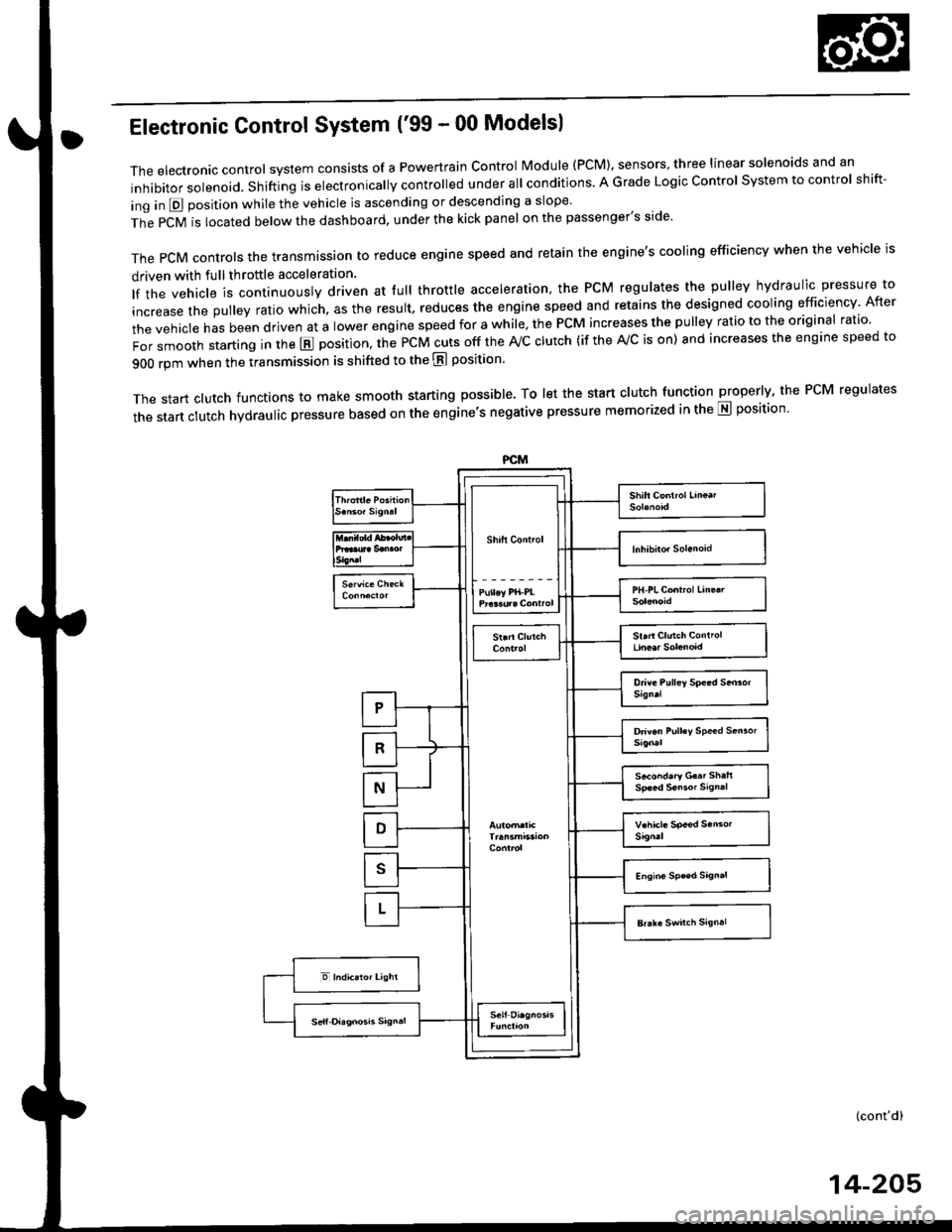

Electronic Gontrol System ('99 - 00 Modelsl

The electronic controt system conststs of a Powertrain control Module (PCM). sensors, three linear solenoids and an

inhibitor solenoid. shifting is electronically controlled under all conditions A Grade Logic control system to control shift-

ing in E position while the vehicle is ascending or descending a slope'

fn"pCVirlocatedbelowthedashboard,underthekickpanelonthepassenger'sside'

The pCM controls the transmassion to reduce engine speed and retain the engine's cooling efficiency when the vehicle is

driven with full throftle acceleration

lf the vehicle is continuously driven at lull throttle acceleration, the PCM regulates the pulley hydraulic pressure to

increase the pulley ratio which. as the result, reduces the engine speed and retains the designed cooling efficiency After

the vehicle has been driven at a lower engine speed for a while, the PCM increases the pulley ratio to the original ratio'

i"i ".nl",rr starting in the E position, the PcM cuts off the ,Vc clutch (if the A/c is on) and increases the engine speed to

900 rpm when the transmission is shifted to the E position'

The start clutch functions to make smooth starting possible. To let the start clutch function properly, the PcM regulates

the start clutch hydraulic pressure based on the engine's negative pressure memorized in the E position'

FCM

s*o.d.ry G..t Sh.h

(cont'd)

14-205

Page 884 of 2189

Description

Electronic Control System ('99 - 00 Modelsl (cont'dl

Grade Logic Control System

How it works:

The PcM compares actual driving conditions with memorized driving conditions. based on the input from the vehiclespeed sensor, the throttle position sensor, the manifold absolute pressure sensor, the engine coolant temperature sensor,the brake switch signal, and the shift lever position signal, to control shifting while the vehicle is ascending or descendinga slope.

Ascending Control

When the PCM determines that the vehicle is climbing a hill in E position, the system selects the most suitable shiftschedule (pulley ratio) according to the magnitude of a gradient. so the vehicle can run smooth and have more powerwhen needed. There are three ascending modes with different shift schedules according to the magnitude ot a gradient inthe PCM.

Descending Control

when the PCM determines that the vehicle is going down a hill in E position. the system selects the most suitable shiftschedule (pulley ratio) according to the magnitude of a gradient. This, in combinstion with engine braking, achievessmooth driving when the vehicle is descending, There are three descending modes with different shift schedules accord-ing to the magnitude of a gradient in the PCM.

L

14-206