v tec HONDA CIVIC 1999 6.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 441 of 2189

PGM-FI System

tFos3sl

tFffi6l

tPr361 I

fPfi62l

fFr38il

tF13s2-l

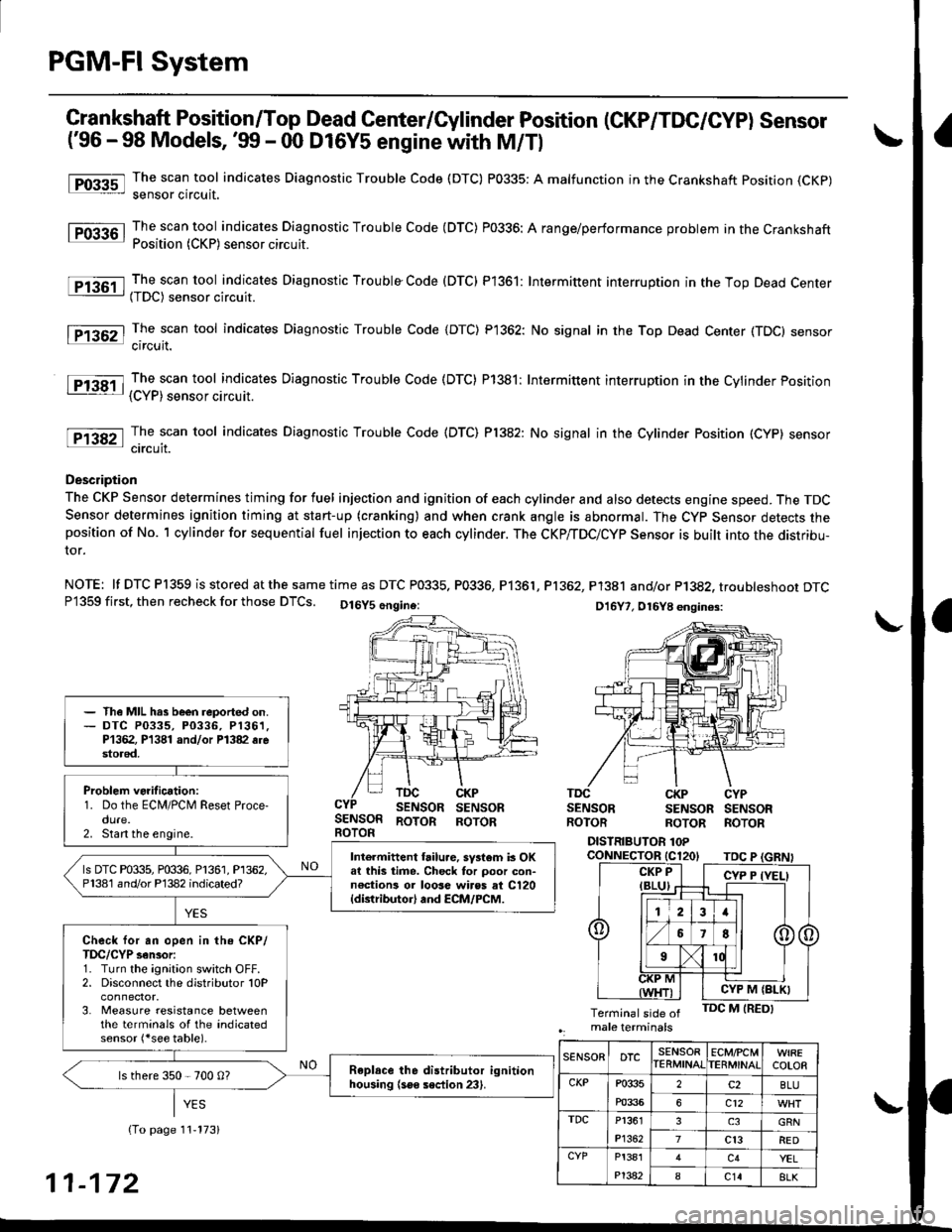

Crankshaft Position/Top Dead Genter/Gylinder Position (CKP/TDC/CYP) Sensor

('96 - 98 Models, '!n - 00 D16Y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P0335: A malfunction in the Crankshaft position (CKp)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the CrankshaftPosition (CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1361: Intermittent interruotion in the Too Dead Center(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1362: No signal in the Top Dead Center (TDC} sensorcircuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cvlinder Position{CYP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) Pl382: No signal in the Cylinder Position (CYP} sensorcircuit.

Description

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDCSensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The Cyp Sensor detects theposition of No. 1 cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-ror.

NOTE: lf DTC P1359 is stored atthesametime as DTC P0335. P0336, P1361, Pl362, P1381 and/or P1382, troubteshoor DTCP1359 first, then recheck for those DTCS. Ot6y5 6ngine: Dt6y7, ot6y8 enqin6s:

SENSORBOTOR

TDCSENSORCKPSENSORSENSORROTORSENSORROTORSENSORROTORROTORROTOR

DISTRIBUTOR 1OPcoNNECTOR tC120tTDC P

- The MIL hrs been reported on.- DTC P0335, P0336, P1361,P1362, P1381 and/or Pl382 6restored,

Problem verification:1. Do the ECM/PCM Reset Proce-dure.2. Stan the engine.

Intermittent hilu.e, system b OKat this time. Check tor poor con-n€ctions or 10036 wiros at C120{distributor} and ECM/PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or P'l382 indicated?

Check for an open in the CKP/TDC/CYP sensor:1. Turn the ignition switch OFF.2. Disconnect the distributor 10P

3. Measure resistance betweenthe terminals of the indicatedsensor (*see table).

Replace the distributor ignitionhousing (soe section 23).ls there 350 - 700 0?

CYP M {BLK}

SENSORDTCSENSORIERMINATECMfCMTERMINATCOLOR

CKPP033s

m336

2c2BLU

6c12

TDCP1361

P1362

3GRN

7cl3RED

CYPP!381

P't382

c4YEL

8c148LK11-172

Page 443 of 2189

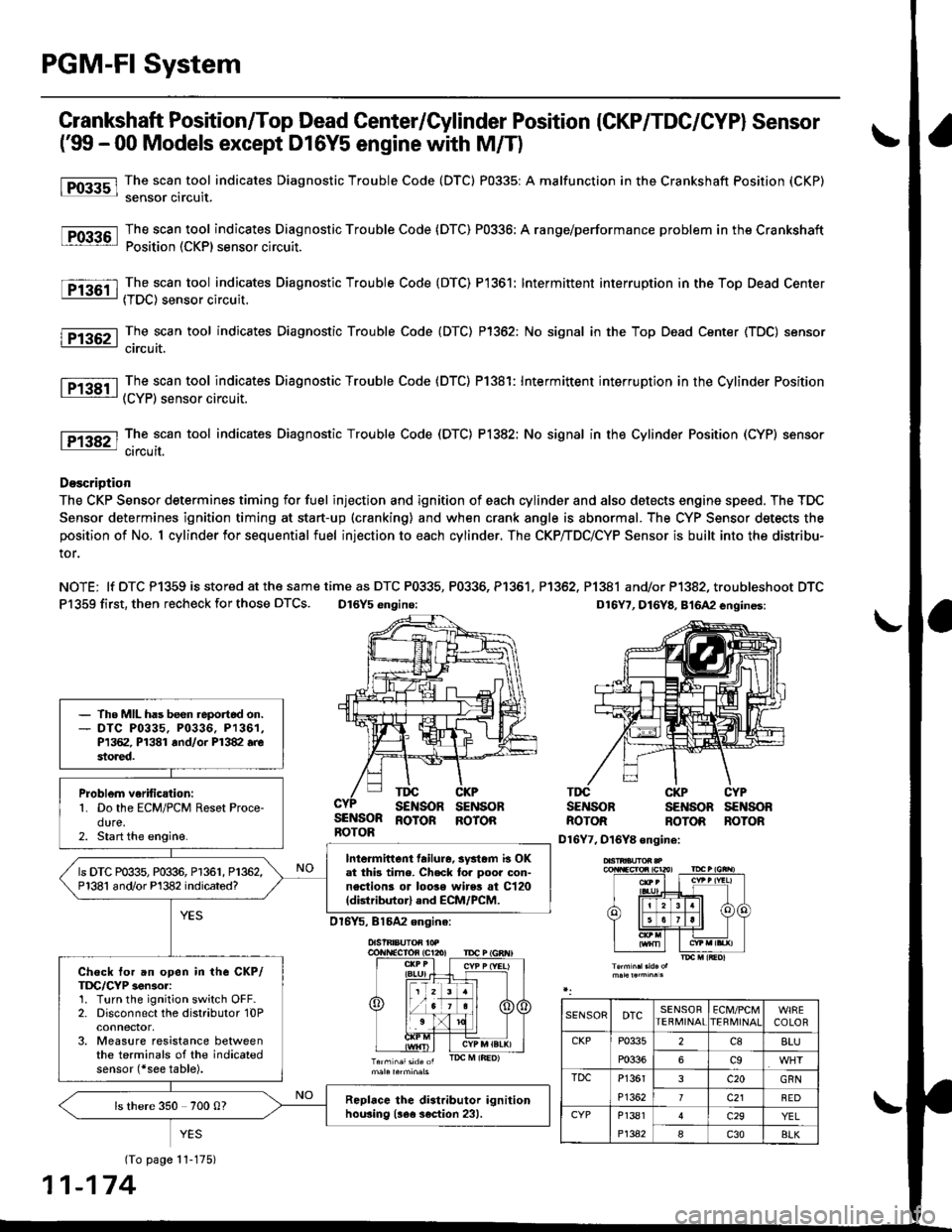

PGM-FI System

l-Fos3sl

tFos36l

tF1361 l

Fr362-1

tF13sil

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

f99 - 00 Models except D16Y5 engine with M/T)

The scan tool indicates Diagnostic Trouble Code (DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position (CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1361: Intermittent interruption in the Top Dead Center

{TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1362: No signal in the Top Dead Center (TDC) sensor

circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

lTiaSt The scan tool indicates Diagnostic Trouble Code (DTC) P1382; No signal in the Cylinder Position (CYP) sensor: circuil.

DoscriDtion

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 1 cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

tor.

NOTE; lf DTC P1359 is stored at the same time as DTC P0335, P0336, P1361. P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then recheck for those DTCS. D16Y5 engino:

SENSORROTOR

TDGSENSORCKPSENSOBTDCSENSOBCKPSENSOBCYPs€NsonBOTORROTORBOTONROTOR ROTOR

D16Y7, D16Y8 ongine:

(To page 11-175)

1-174

- The MIL has been reportod on.- DTC P0335, P0336. P1361,P1362, P1381 rnd/or P1382.restored.

Problem verific{tion:1. Do the ECM/PCM Reset Proce-dure.2. Start the engine.

Intormittcnt failure, systom b OKat thb time. Check to. poor con-nections or loose wires at C120(dktributorl and ECM/PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or Pl382 indicated?

Check tor an open in the CKP/TDC/CYP 3enior:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector,3. Measure resistance betweenthe terminals of the indicatedsensor (*see table).

Replrce the distributor ignitionhou3ing (!ee section 231.ls there 350 700 0?

SENSORDTCSENSORTEBMINAIECM/PCMTERI\,4INAICOLOR

CKPP0335

P0336

2c88LU

6c9

TDCP1361

P1362

3c20GRN

7c21BED

CYPP1381

P1342

c29YEL

Ic30BLK

Page 448 of 2189

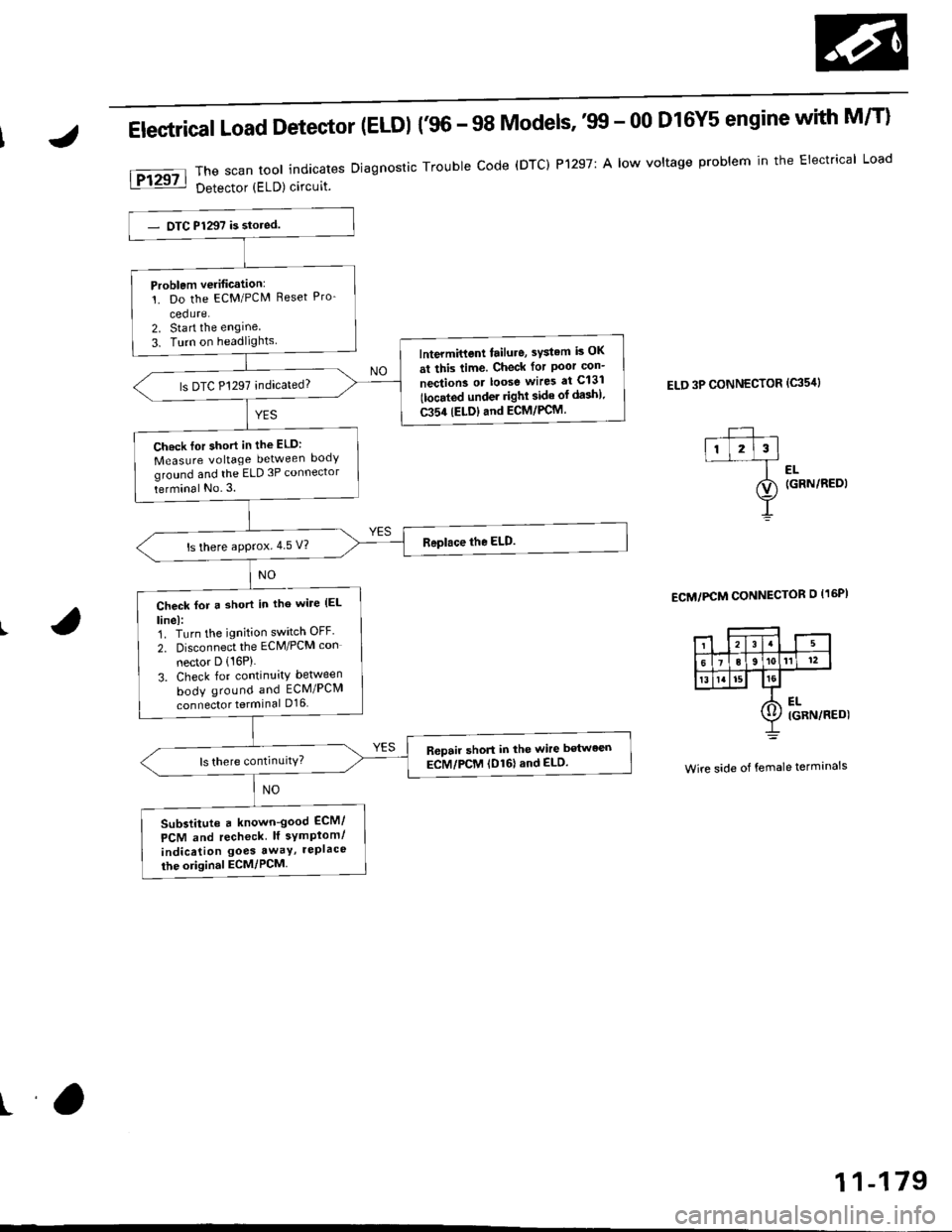

Electrical Load Detector (ELDI {'96 - 98 Models,'tn - 00 D16Y5 engine with M/T}

The scan tool indicates Diagnostic Trouble code (DTC) P1297: A low voltage problem in the Electrical Load

Detector (ELD) circuit.

ELD 3P CONNECTOR (c35'rl

l-- ,ll l2l3l--f ..

ao (GRN/REDI

Y

ECM/PCM CONNECTOR O I16PI

Wire side of female terminals

Problem verification:'!. Do the ECM/PCM Reset Pro-

cedure.2. Sta rt the engine

3. Turn on headlightslntermittent tailure, sYstem is OK

at this time. Check for Poor con-

nection3 or loose wires at C131

tlocated under righl side of da3h).

C354 (ELDIand ECM/PCM.

ls DTC P1297 indicated?

Ch.ck lor short in the ELD:

Measure voltage between body

ground and the ELD 3P connector

terminal No.3.

ls there approx.4 5 V?

Check for a short in tho wile (EL

linel:1. Turn the ignition switch OFF'

2. Disconnect the ECM/PCM con

nector D (16P)

3. Check for continuity between

body ground and ECM/PCM

connector terminal D16

R6pair short in the wire between

ECM/PCM (D161and ELD.

Substitute a known-good ECM/

PCM and recheck lf symplom/

indication goes awaY, rePlace

the original ECM/PCM

ra

11-179

Page 449 of 2189

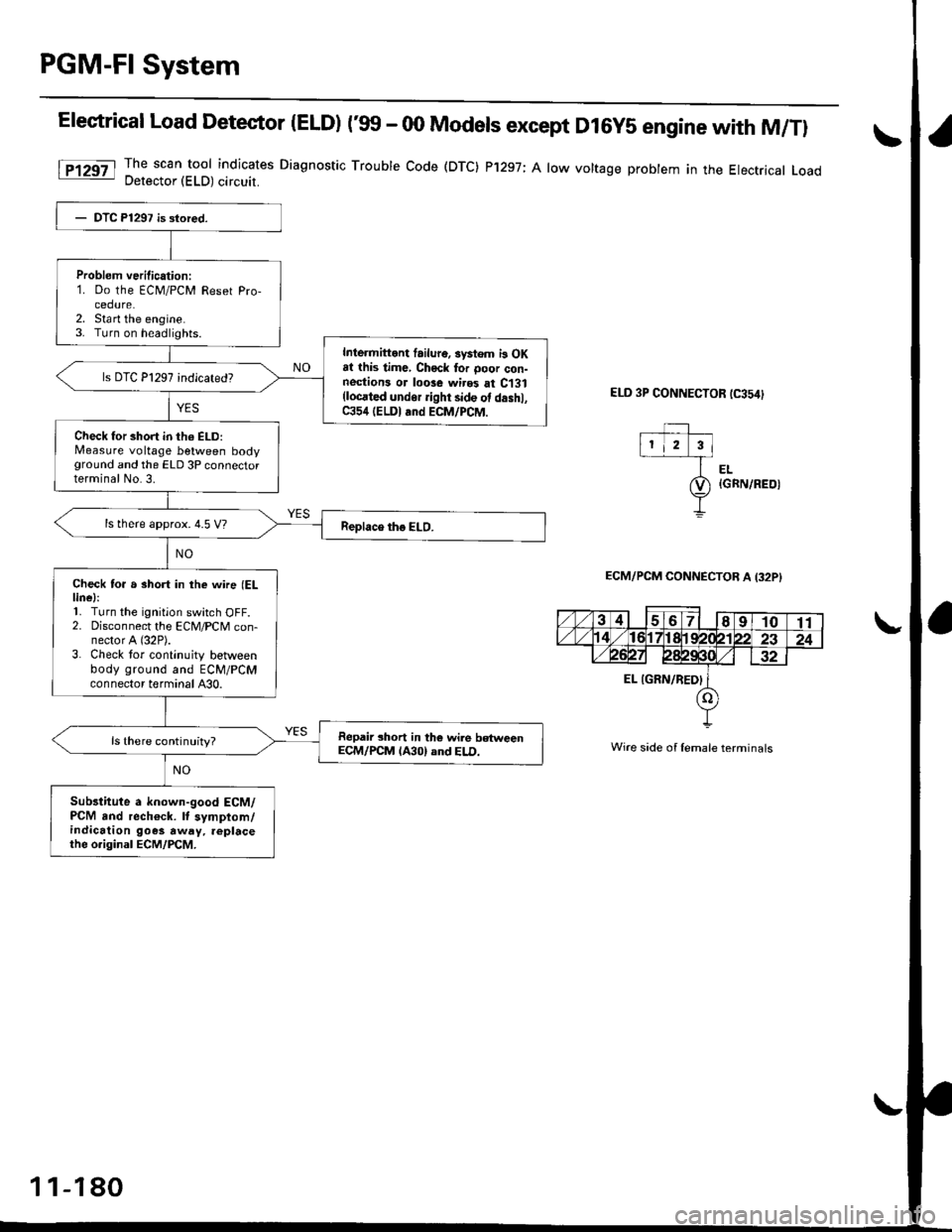

PGM-Fl System

Elestrical Load Detector |ELD) t'glf - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P'1297; A low voltage probtem in the Electrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR tC354)

EL{GRN/REOI

ECM/PCM CONNECTOB A I32PI

Wire side of lemale terminals

Problem verilication:1. Do the ECM/PCM Reset Pro-cedure.2. Sta rt the engine.3. Turn on headlights.

Inlermittont failur6. systom i3 OKat this time, Chock tor ooor con-nestions or loose wires at C131(locrted undor ight side ot d.shl,C354 (ELDI and ECM/PCM.

Check for short in th6 ELD:Measure voltage between bodyground and the ELD 3P connectorterminal No.3.

ls there approx. 4.5 V?

Check to. a short in the wne (ELlinel:'L Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector A (32P).

3. Check tor continuity betlveenbody ground and ECM/PCMconnector terminal A30.

Repair short in the wile betweenECM/PCM lA30) and ELD.ls there continuity?

Sub3titute a known-good ECM/PCM and rech€ck. It symptom/indication goes away. replacethe o.iginal ECM/PCM.

1 1-180

Page 450 of 2189

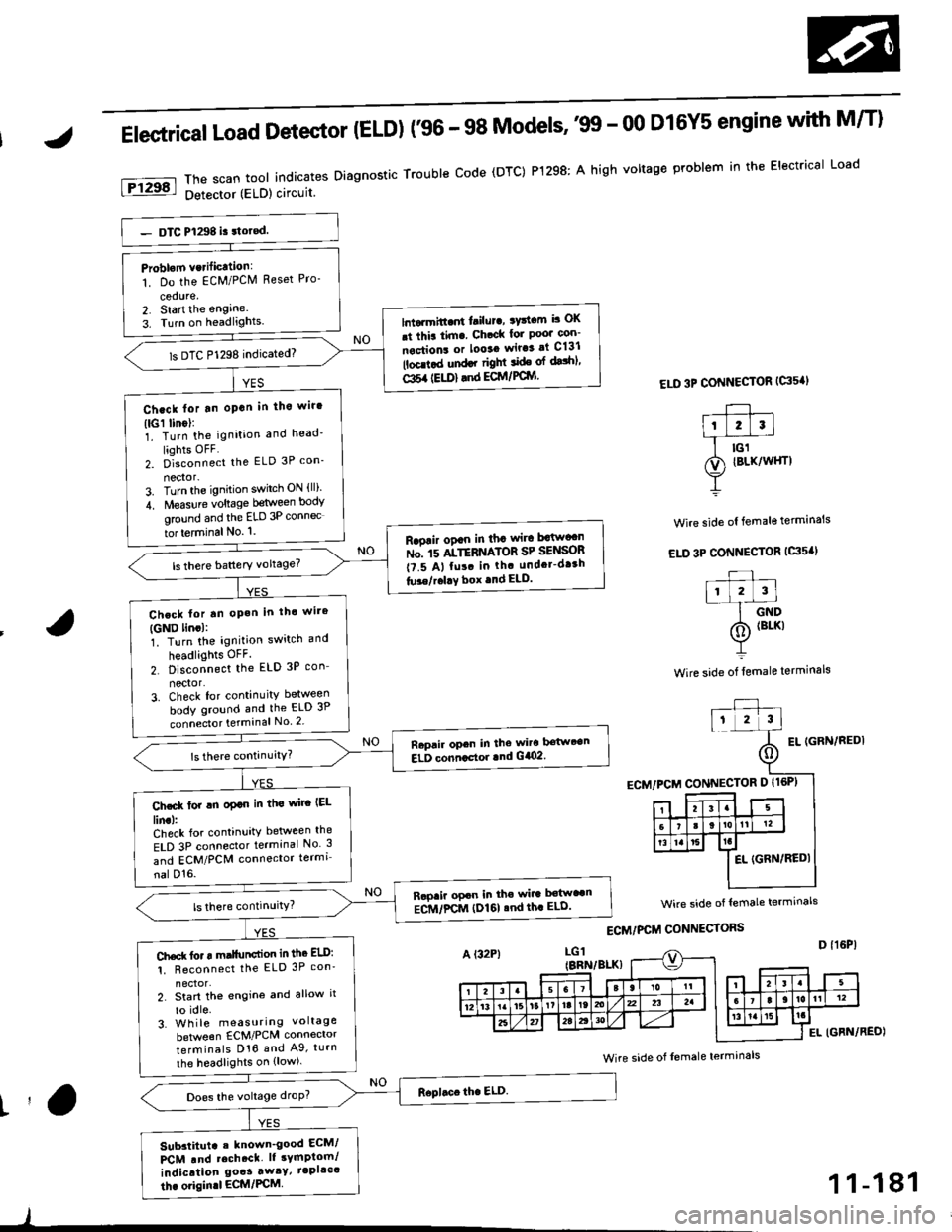

Elestrical Load Detector (ELD) f96 - 98 Models''99 - 00 D16Y5 engine with M/T)

ThescantoolindicatesDiagnosticTroubleCode(DTC)P1298:AhighvoltageproblemintheElectricalLoad

Detector (ELD) circuit

ELD 3P CONNECTOR {G's'I

Wire side ol female terminals

EL IGFN/REDI

Problom vcrificttion:

1. Do the EcM/PClVl Reset Pro-

cedure,2. Start the engine.

3. Turn on headlights.lntarmitt..rt l.ilur., ryttcm b OK

.t thia tim. Ch.ck lor Poo' con-

nections or looaa wir.3 at C131

lbcd.d und.r right ide ol dalhl'

Gl5a {EU)} .nd ECM/PCIYI

ls DTC P1298 indicated)

Ch.ck lor tn oPan in tho wir'

(lGl linol:1. Turn the ignition and head'

liohts OFF2. D]""onn""t the ELD 3P con_

nector-3. Turn the ignition switch ON {ll)'

4. Measure voltage between body

ground and the ELD 3P connec

tor terminal No. '1.

R.oair ogan in tha wira Mw"n

ru". rs ltTEnrlton SP SelSOn

t?.5 A, fu!. in th. undcr-dr3h

tu3e/r.l!Y box .nd ELD.

Chcck lor tn oP.h in thc wire

{GND lincl:1. Turn the ignition switch and

headlights OFF.

2. Disconnect the ELD 3P con_

nector'3. Check for continuity between

body ground and the ELD 3P

connecto. terminal No 2

Raprir opcn in the wira bstwt€n

ELD conncctor lnd G/O2.

Ch.ck lor !n oplo in tha wirc IEL

lin.l:Check for continuity between the

ELD 3P connector terminal No 3

and ECM/PCM connector termi

nal D'16.

Rapaii opcn in the wira b€tw"n

ECM/FCM (I)161 .nd th. ELD'

Ch.d( fo. r m.llunction in thc ELD:

1. Reconnect the ELD 3P con'

2. Start th€ engine and allow it

to idle.3. Wh ile measuring voltage

beNveen ECM/PCM connector

terminals D16 and A9, turn

the headlights on {low).

Does the voltage droP?

Sub3titut. . known_good ECM/

PCM .nd rcch.ct. lt sYmptom/

indication goas away/ iapllc'

thc origin.l ECM/PCM

wire side of lemale termrnals

Wire side of Iemale terminals

t'a

)

1 1-181

Page 451 of 2189

PGM-FI System

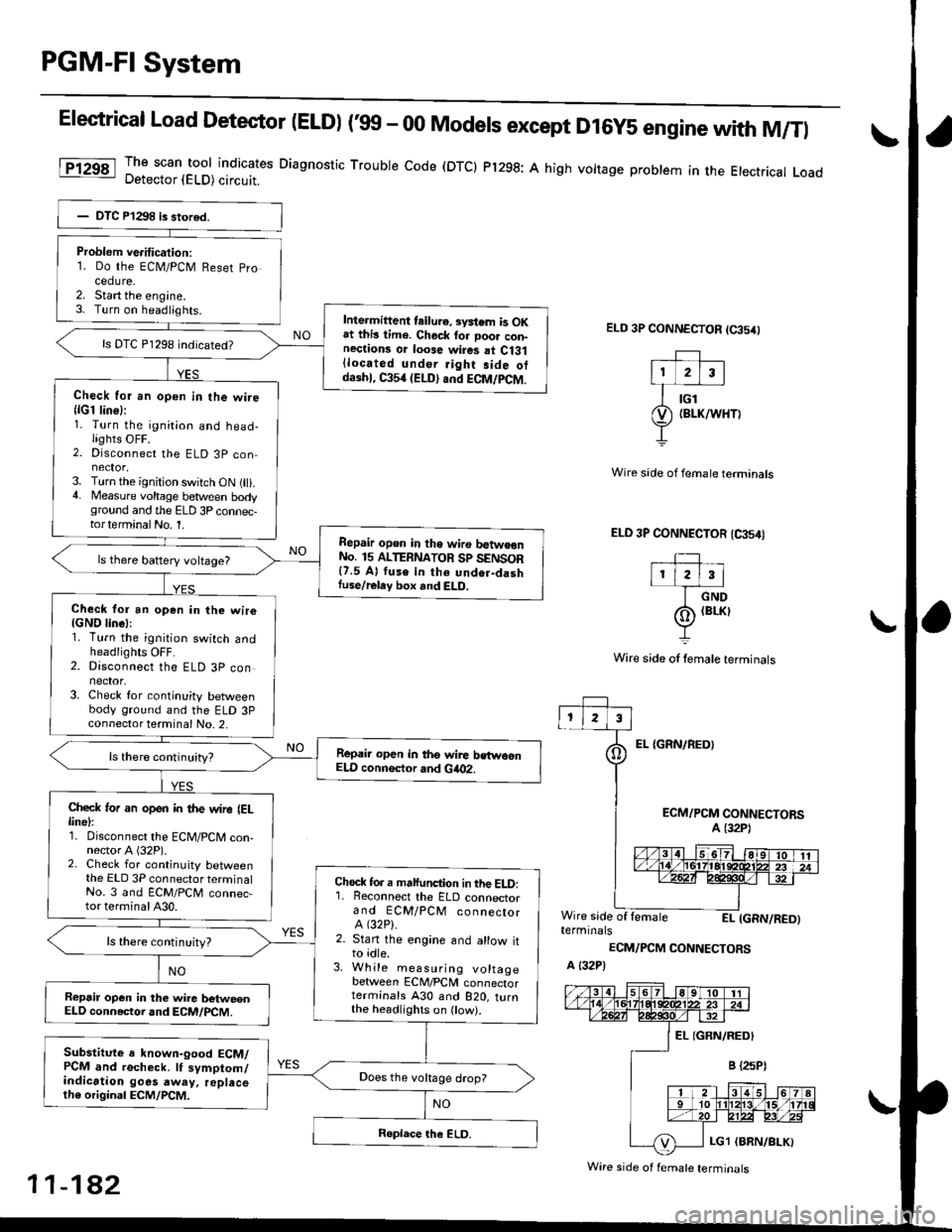

Elestrical Load Detector (ELDI ('99 - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble code (DTCI Pl298: A high vottage problem in the Etectrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR (65/0

EL {GRN/REOI

Wire side of fernale terminals

ELD 3P CONNECTOR (CA54I

TIr l2l3l

I crvo

(o) (BrKr

Y

Wire side of lemale terminals

ECM/PCM CONNECTORSA (32P1

Wire side of lemaleEI- IGRN/RED)terminals

ECM/PCM CONNECTORS

A {32P)

Problem ve.itication:1. Do the ECN4/PCM Reset pro

cedure.2. Start the engine.3- Turn on headiights.Inte.mittent teilu.e, svstem is OKat this lime. Chock for Door con-nections or loose wires at Ci31{located under Jight side otdaihl, C354 (ELD) and ECM/PCM.

ls DTC P1298 indicated?

Check for an open in the wire{lG1 line}:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con

3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the ELD 3P connec-torterminalNo. 1.

Repair opon in tho wiro batwe€nNo. 15 ALTERNATOR Sp SENSOR{7.5 A} fuse in th6 undor-dashIuse/reley box and ELD.

ls there battery voltage?

Check for an open in the wiro{GND linel:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P connector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2,

Repair open in the wire bstwoenELD connsctor and Gia02.

Check ,or an open in the wire IELlinel:1. Disconnect the ECM/PCM con-nector A (32P).2. Check for continuity betweenthe ELD 3P connector terminalNo. 3 and ECM/PCM connec-tor terminal A30.

Chock fo. a malfunction in the ELD:'1. Reconnect the ELD connectorand ECM/PCM connectorA (32P).

2. Stan the engine and allow itto idle.3. While measuring voltagebetween ECM/PCM connectorterminals A30 and B2O, turnthe headlighrs on ow).

ls there continuity?

Repsir op€n in the wire betweenELD connector and ECM/PCM.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away. replacelh6 original ECM/PCM.

Does the vokage drop?

Wire side of f€male terminals

11-182

Page 510 of 2189

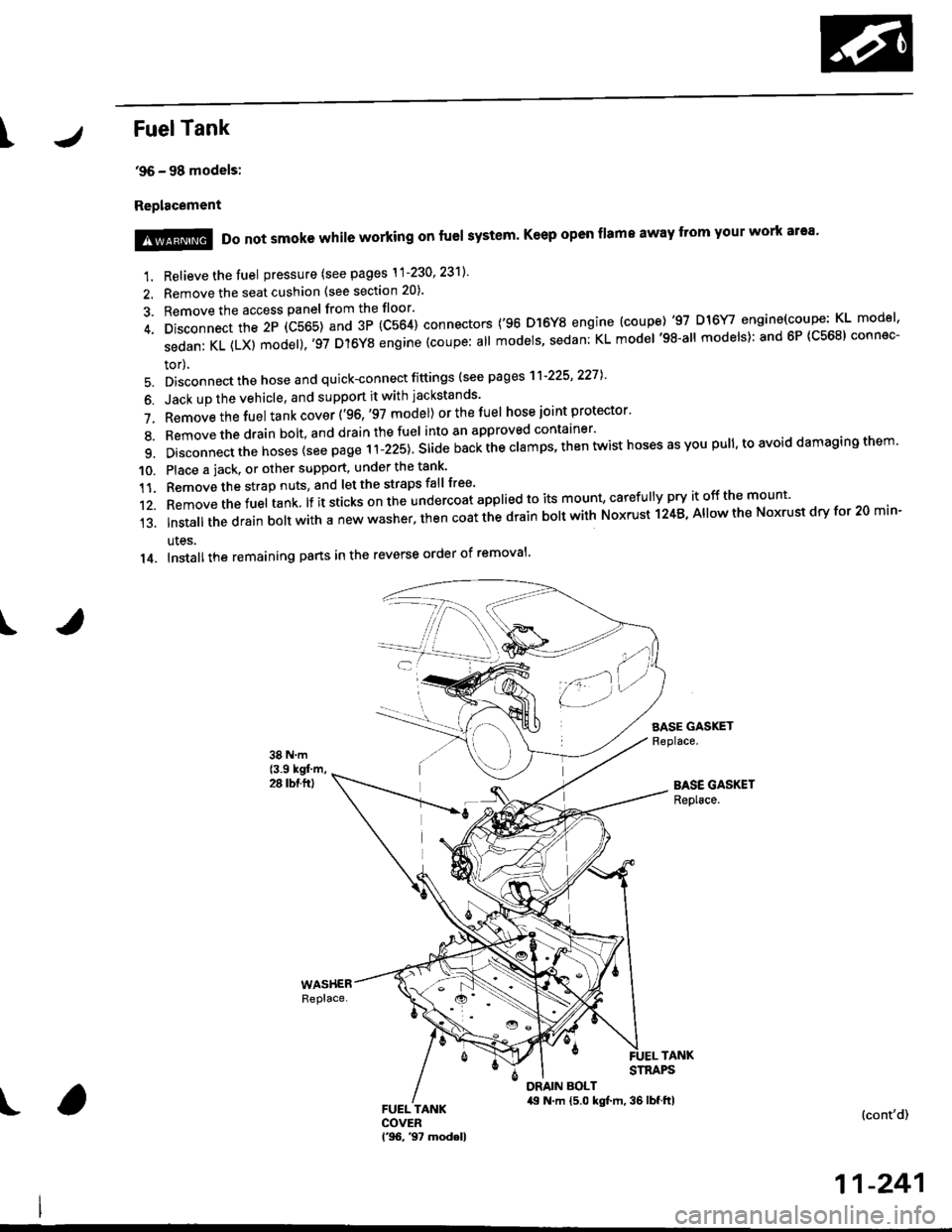

IFuelTank

'96 - 98 models:

Replacement

I

1. Relieve the fuel pressure (see pages \1-230' 23'll'

2. Remove the seat cushion (see section 20).

3. Remove the access panel from the floor'

4. Disconnect the 2P (C565) and 3P (C564) connectors ('96 D]6Y8 engine (coupe) '97 D16Y/ engine(coupe: KL model'

sedanKL(LX)model).'97D'l6YSengine(coupe:allmodels'sedan:KLmodel'98-allmodels):and6P(C568)connec-

tor),

5. Disconnect the hose and quick-connect fittings (see pag es'l'l-225' 2271

6. Jack up the vehicle, and support it with jackstands'

7. Removethefuel tank cover ('96,'97 model) orthefuel hose joint protector'

8. Bemovethedrain bolt,and drainthefuel into an approved container'

9. Disconnect the hoses {see page r i-izst. Sria" nu"i ihe clamps, then twist hoses as you pull, to avoid damaging them'

10. Place a jack. or other support, under the tank'

11. Remove the strap nuts, and let the straps fall free'

12. Removethefuel tank lf it sticks on the undercoat applied to its mount' caref u lly pry it off the mount'

13.|nsta||thedrainbo|twithanewwasher.thencoatthedrainbo|twithNoxrustl24B,A||owtheNoxrustdryfor20min-

ules.

14. Installthe remaining pans in the reverse order of removal'

SASE GASKETReplace.

BASE GASKETReplace.

!@@ Do not smoke while working on fuel system' Keep open flame away from your work ar'a'

TANKSTRAPS

DRAIN BOLT,19 N.m {5.0 kgt m, 36 lbf.ftl(cont'd)

11-241

Page 511 of 2189

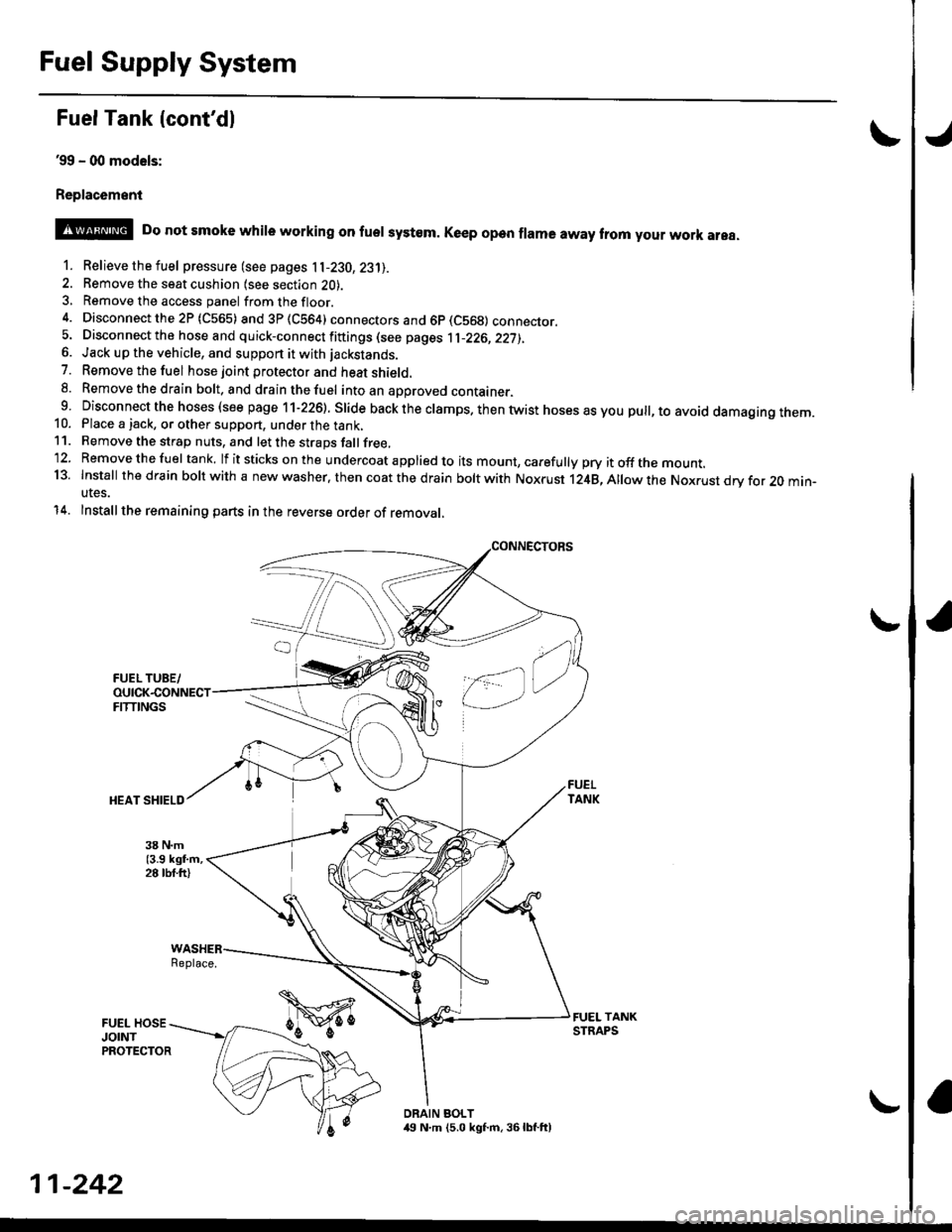

Fuel Supply System

Fuel Tank {cont'dl

39 - (xt models:

Replac6ment

o

@ Do not smoke whire working on fuer system. Ke€p open frama away trom your work area.

1. Relievethefuel pressure (see pages 11-230,23'll.

2. Remove the seat cushion lsee section 2O).3, Remove the access panel fromthefloor.

4. Disconnectthe2P (C565) and3P(CS64) connectors and 6p (C569) connecror.5. Disconnect the hose and quick-connect fiftings (see pages 1l-226,22j),6. Jack up the vehicle, and support it with jackstands.

7. Removethefuel hose joint protector and heat shield.8. Removethedrain bolt. and drainthefuel intoan aporoved container.9 Disconnect the hoses (see page 11-226). Slide back the clamps. then twist hoses as you pull, to avoid damagtng rnem.10. Place a jack, or other support, under the tank,11. Remove the strap nuts, and let the straps fallfree,'12. Removethefuel tank. lf itsticks onthe undercoat applied to its mount, carefully pry itoffthe mount.13. Install thedfain boltwith a new washer. then coat the d rain bolt with Noxrust 124B,Allowthe Nox.ust drv for 20 min-utes.

14. Installthe remaining parts in the reverse order of removal,

Replace.

DRAIN BOLT,19 N.m (5.0 kgf.m, 36lbf.ft)

11-242

Page 522 of 2189

\

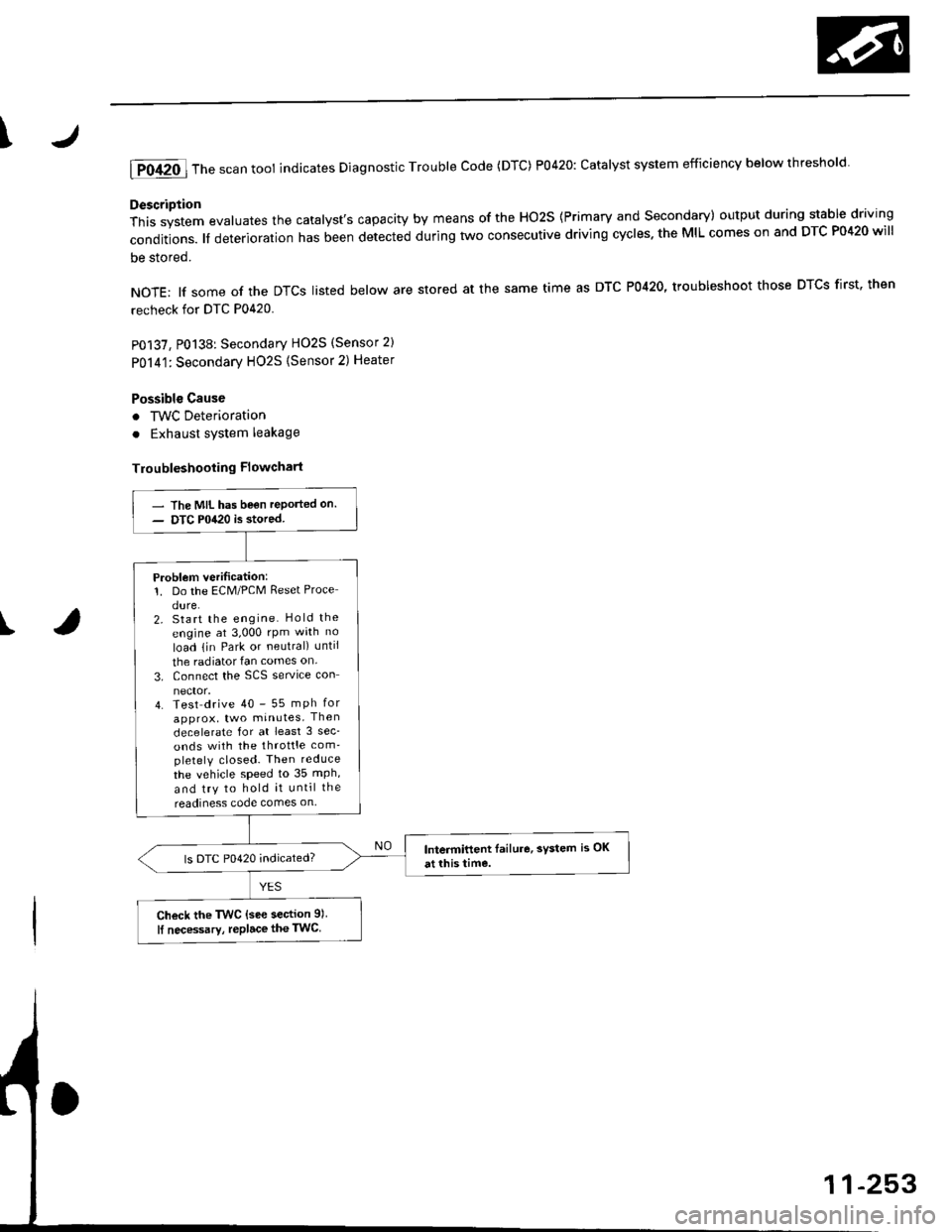

lTo420l Th" """n toot indicates Diagnostic Troubte code (DTc) p0420: catatyst sysrem efficiency below threshold.

Description

This system evaluates the catalyst's capacity by means of the Ho2s {Primary and secondary) output during stable driving

conditions. ll deterioration has been detected during two consecutive driving cycles. the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS tisted below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

recheck for DTC P0420

P0137, P0138: Secondary HO2S (Sensor 2)

Po14'1:Secondary H02S {Sensor 2) Heater

Possibl€ Cause

. TWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

I

The MIL has been reported on.

DTC P0420 is stored

Problem verilication:1. Do the ECM/PCM Reset Proce

dure.2. Start the engine Hold the

engine at 3,000 rpm wath no

load {in Park or neutral) until

the radiator fan comes on.

3. Connect the SCS service con

4. Test drive 40 - 55 mph for

approx, two minutes Then

decelerate for at least 3 sec_

onds with the throttle com'pletely closed- Then reduce

the vehicle speed to 35 mph,

and try to hold it until the

readiness code comes on

Intermittent Iailure, system is OK

at this time.ls DTC P0420 indicated?

Check the TWC {see section 9l

lf necessary, replace the TwC

Page 523 of 2189

Emission Control System

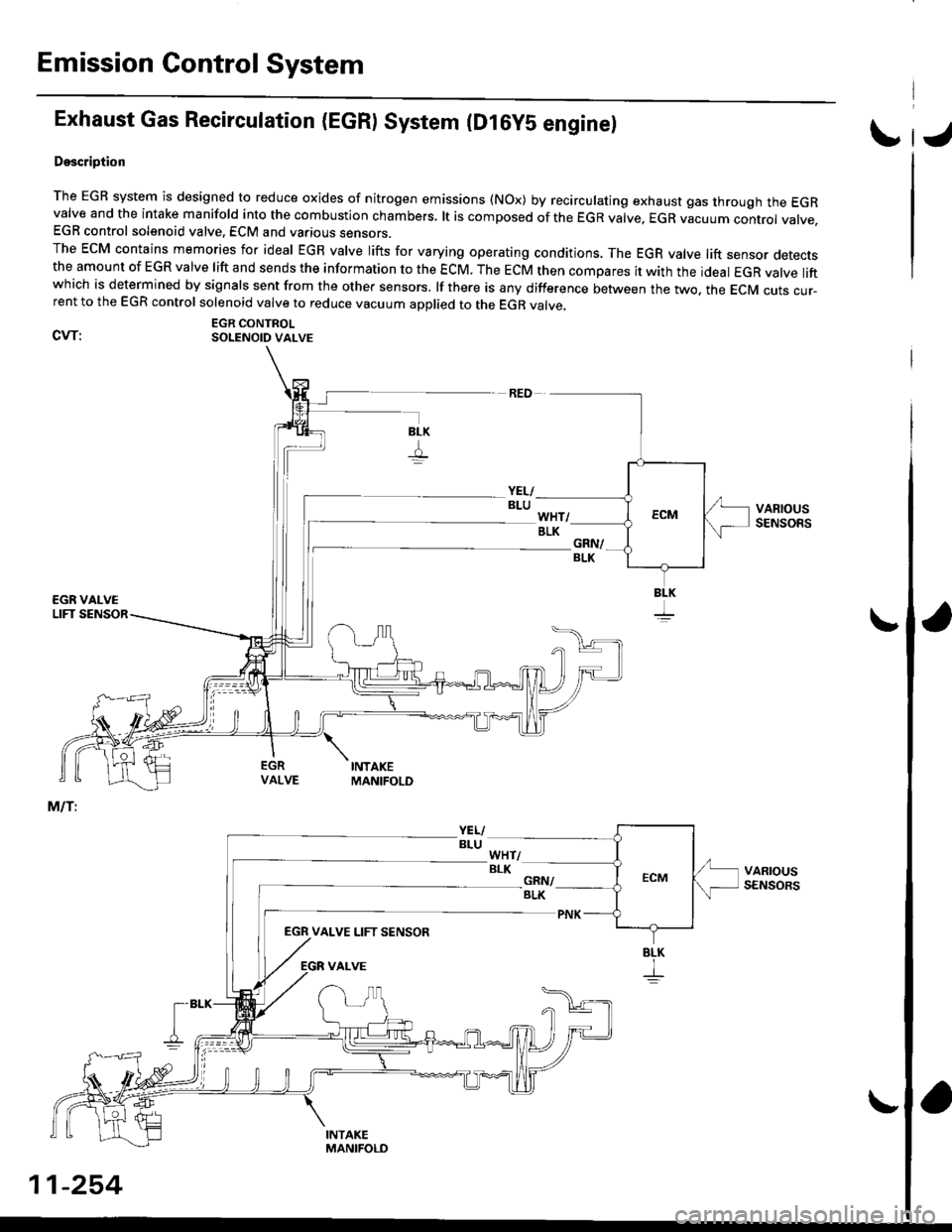

Exhaust Gas Recirculation (EGR) System (D16yS engine)

Doscription

The EGR system is designed to reduce oxides of nitrogen emissions (NOx) by recirculating exhaust gas through the EGRvalve and the intake manifold into the combustion chambers. lt is composed of the EGR valve. EGR vacuum conrrot vatve.EGR control solenoid valve. ECM and various sensors.The EcM contains memories for ideal EGR valve lifts for varying operating conditions, The EGR valve lift sensor detectsthe amount of EGR valve lift and sends the information to the ECM. The ECM then compares it with the ideat EGR valve liftwhich is determined by signals sent from the other sensors. lf there is any difference between the two. the EcM cuts cur-rent to the EGR control solenoid valve to reduce vacuum applied to the EGR valve.

EGR CONTROLCVT: SOLENoID vALvE

EGN VALVE LIFT SENSOR

BLK

I

I

11-254