Top HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 1210 of 2189

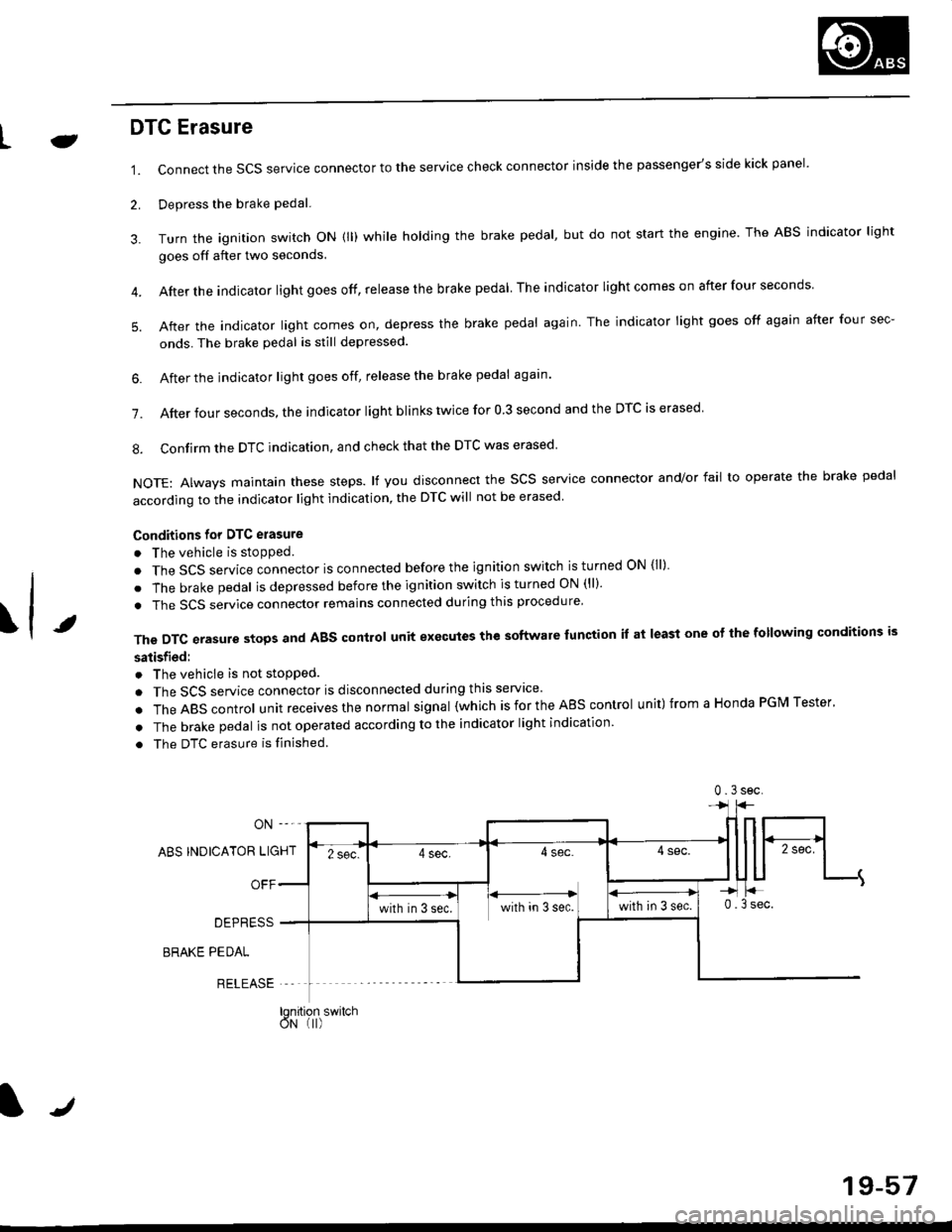

LJDTG Erasure

1.

2.

Connect the SCS service connector to the service check connector inside the passenger's side kick panel.

Depress the brake pedal.

Turn the ignition switch oN (ll) while holding the brake pedal, but do not start the engine. The ABS indicator light

goes off after two seconds.

After the indicator light goes off, release the brake pedal The indicator lightcomeson after four seconds

After the indicator light comes on, depress the brake pedal again. The indicator light goes off again after four sec-

onds. The brake pedal is still depressed.

4.

5.

\t

6. After the jndicator light goes off, release the brake pedal again'

7. After four seconds, the indicator light blinks twice for 0 3 second and the DTC is erased

8. Confirm the DTC indication, and check that the DTC was erased

NOTE: Always maintain these steps. lf you disconnect the scs service connector and/or fail to operate the brake pedal

according to the indicator light indication, the DTC will not be erased

Conditions for DTC erasure

o The vehicle is stopped.

. The SCS service connector is connected before the ignition switch is turned ON {ll)

. The brake pedal is depressed before the ignition switch is turned ON (ll)'

. The SCS service connector remains connected during this procedure

The DTC erasure stops and ABS control unit executes the software lunction it at least one ot the following conditions is

satisfied:

o The vehicle is not stopped.

. The SCS service connector is disconnected during this servace'

.TheABscontro|unitreceivesthenormaIsigna|(whichisfortheAEscontro|unit)fromaHondaPGMTester'

. The brake pedal is not operated according to the indicator light indication

. The DTC erasure is finished

ABS INDICATOR LIGHT

OFF

DEPRESS

BRAKE PEDAL

RELEASE

0.3sec

lqnition switchoN (I)

J

19-57

Page 1211 of 2189

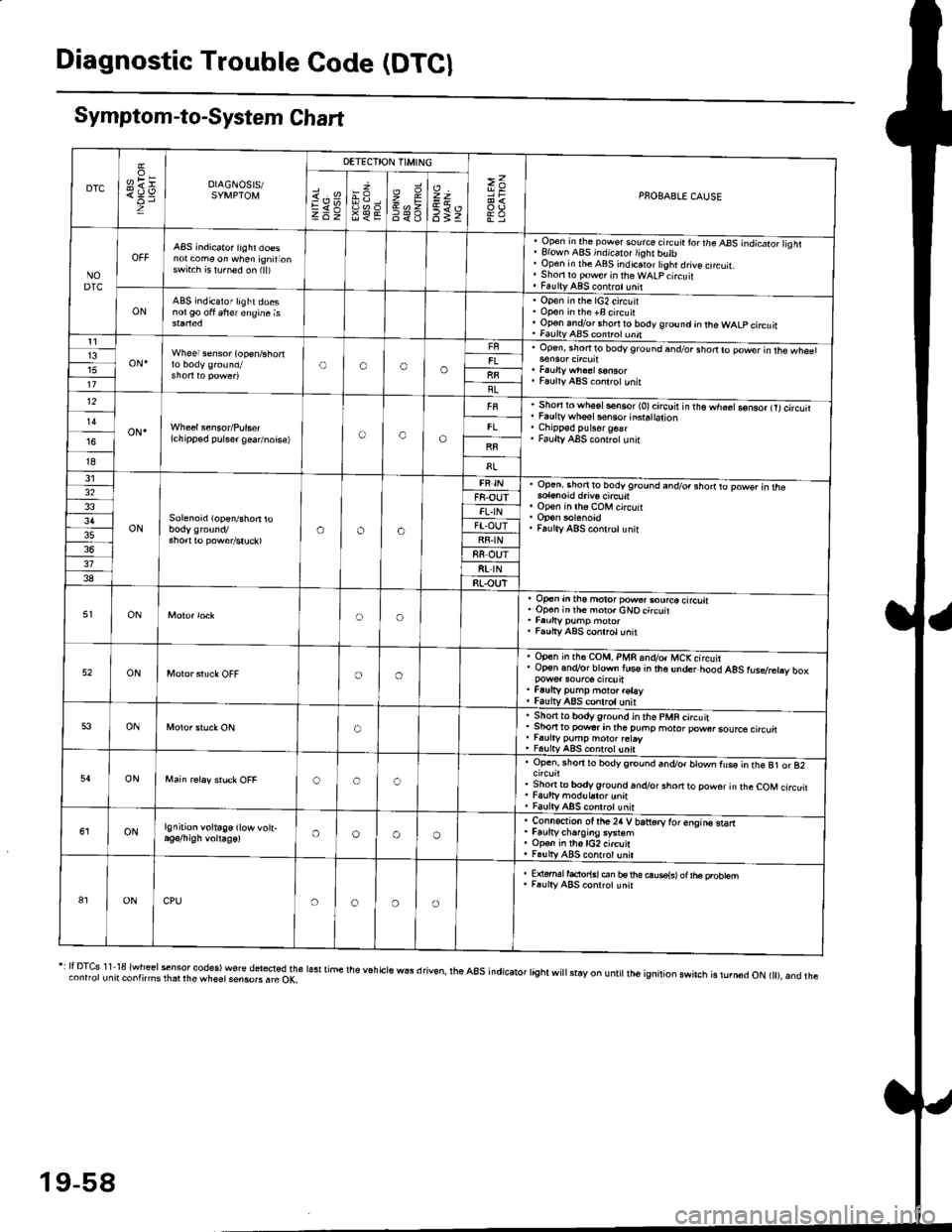

Diagnostic Trouble Code (DTCI

Symptom-to-System Chart

DTC

oH1=DIAGNOSIS/SYMPTOM

DETECTION TIMING

>=PNOBABLE CAUSEi.'sEV98€E

zr\9=6<_6

=t

6tz

NODTC

ABS indicator iighr doesnot com€ on when ignirionswrt.h is lu.ned on (ll)

, Open in the pow€. source circ!ir ror the ABS -.ndicato;l isht. Elown ABS indicalo.lighr butb' Open in rhe ABS indicaror tight drive cncuit.. Shori ro pow€r in theWALpcircuit. FaultyABS contrct!nit

ONABS indicator light doesnol90 oft 6frer engine isOpen in the lG2 circuitOpon in the +B circuirOp€n andlor short ro body ground jn the WALP circuitFaultv AAS coni.ol unnt1

oN.Wheel sensor (op€n/shortOooo13upen, snofiro bodyground and/or shodro power in rhe wh€61

Faulty ABS co.lrctunitllBL12

oN.(chipp€d pulser gea/noise)oao

Short to wh6sls€n6or (O)circuir in t'e.h;;Go-nso, trtcircutiFaulty whsel s€nsor insra|ation

Faulty ABS cont.olunir

I8

31

ONSolenoid (open/shon roaoa

Op.ni shon to bodyground and/o. shorrto powsr in rhe

op€n in lh6 coM circuit

Faulty ABS conlrclunit

32F8-OUTFL.IN3'lFT.OUTRF.IN88 OUT318t rN38RLOUT

ONoo

op€n in tho motor pow€..ourco circliaOp€n inih€ moro.cNOcircuit

Faulty ABS conrrol unit

52ONoo

Open in rh€ COM, PMR 6nd/o. MCKcircuirOp€n.n.Vor blown lus€ in the under hood AgS rusdretry box

Faufty pump moto. rotayfaulv ABS conlrolunit

53ONo

. Sho.tto bodygrou.d in the pMR circuit. Shon to powsr in tha puhp moror pow6rsource circu. r.urty pump motor.etay, FalltyABS contolunit

54ONooc

Open, rhorr ro bodygrcund and/or blown fus€ in the B1 or 82

Shonto body ground.n.Vor short to powor in rhe COM circuitFaulty modul.tor unnFaulty ABS controt unit

ONlgnition voltage (low vott-oooo

. Connection ot the24 V bariorv tor enqins starr. Faurtycharoins system. Op€n in th6lG2 circuit. Fa!lly ABS contrcl unil

81ONCPUoooo

E {€rml facior{sl en bs rhe ouse{sl ot |he probtemF.ulty ABS conrrot unit

r: It DTcs 1 1 18 {wheel sensor codes) wore del*ted the lasr time the v6h cls wEs d riv€n, rhe a8s indicator tight wi

stay on u ntit lh6 ignition swirch is rurn6d oN t), and theconnorunit contnms rhat rhe wheet sensoB . rc OK,

19-58

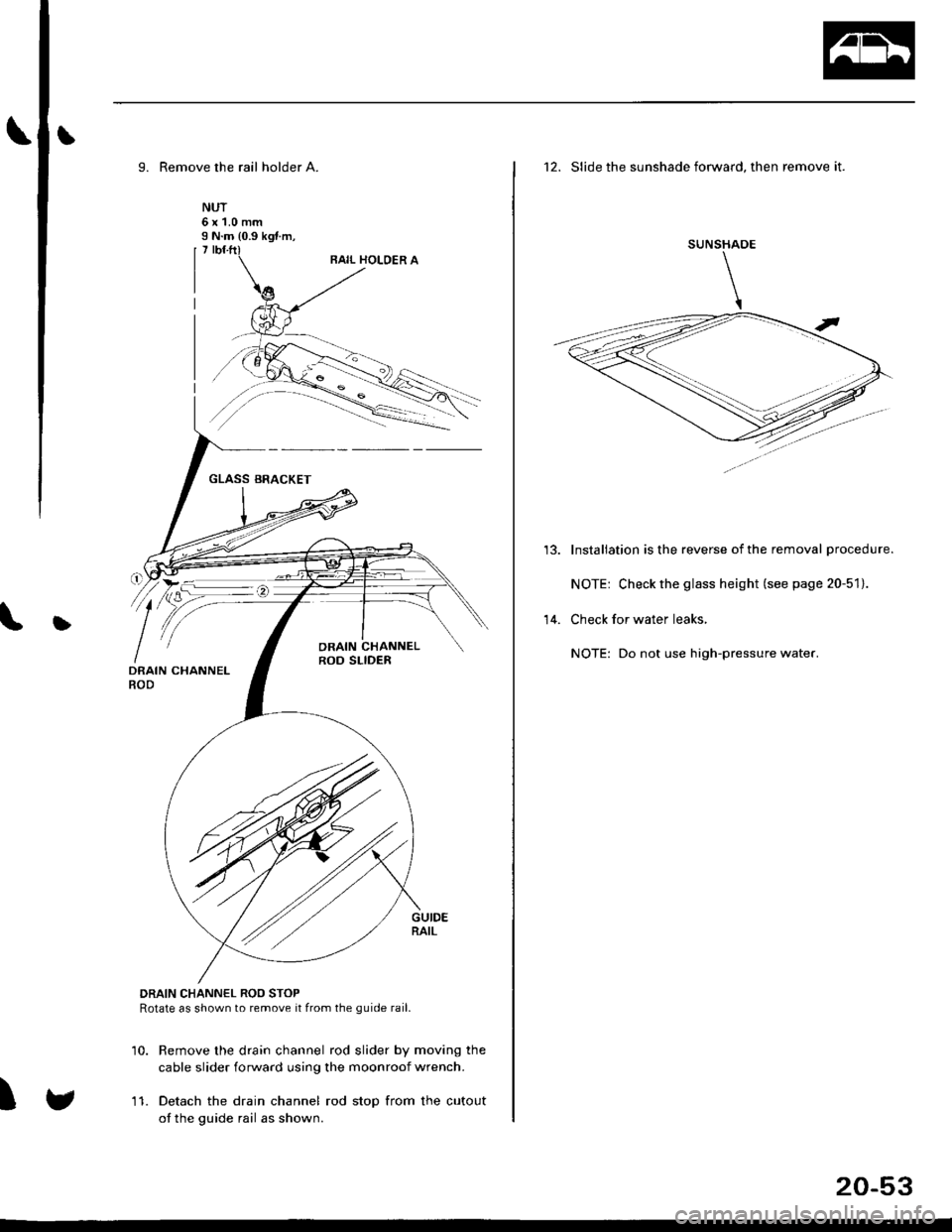

Page 1212 of 2189

Le

\.t

CONDITION FOR DETECTION

MANAGEI\,4ENT

FEFERTOPAGEDUNINGABS CONTFOLEXCEPTABS CONTAOL

19-60

19-62

The ABS indicator lighl cones on when vehicle is stopp€d and wheel sensor a given vohaqe does nol

19 64

The ABS indicaror comes on under th€lollowing conditions.When morethan one otwheels are a standstiland thelelocirv otthe fastest wheel reaches a

' fohen th. velocity of the faslesl wheel reaches or exceds a given sped, and it there ar€ somewh@lswhose velocity is slowe.lhan a cenain percenlage oi lh€ fast6t wheelsped for 3 given period. when rhere are lemporary open or short ctcuits ol rhe wheel sonsor' chipp€d pulser gear, orsrgnalorslJrbaaLe

19 64

The main relay repeats ON/OFF switching atalltimes.WhenthemainrelayisON,ashortt$tpulseissentloeachvalve lfthere s some dis'repa ncv, lheABS indicalor lightcomes on.. When rhe main relay is OFF, a shonl€sl pulse is s€nlto each valve lfth6 solenoid drive voltage rsout ol a qiven range, the ABS ndicalor lighl comes on19-66

'The pump nolot s activaled orc€ o' Mrce sfier every gn't'on sw'lch ON (ll) operarion whrle lte -^vchicle acLelerales lrenthemolorotivevo'taSersrhecled When lhevolla96 rs abnormar,lre Absindicaror llghl comes on.. Afte. ABS ;onl rol com pletion, the moror isswitched ofi 6nd the main CPU checks the molor dnvevoltase. when rhe vortase is abnormsl, the ABS indicato49!!!99!:l!:_-

19-68

D!rino an active motor lesl or AAS control,lhe main CPU checks ihe supplv voltage to the motor'whe;lhe vohage s abnofmal, the ABS indicator lightcomes on19,68

lirhe moror drvevoltage indicates molot operalion when the main cPU does notswilch the motoroN, rhe ABs indicaro. comes on19-64

. Wh"" " ".1"".1d ""1r. f"llure is detecred, the CPU checksth€ voltage ofthe main rel6v output lllhevohaqe is lowerthan 6 given vohage, theABS indicator light comes on. The ;ain r€lay repeats ON/OFF switching ar a!ltimss when the main rel.v is ofi, a shorl l6st pulse

is sent ro €ach valve. The CPU mon tors the reJer€nce vohage ll the vohage is out ot a g iven range'

the ABS indic.tor lightcomes on

19 71

wt'",, rt'e lgnitlon rottag" is ower or higherthan a given voltage,lhe CPU inhibils ABSlonlrolandswirches oli the ma in relaY, 6nd the ABS indicaror lig ht com€s on When the ig n ilion vohage recove'sto normal f6ng6, ABS inhibition is canceled.19.73

rimln CpU anO suU CeU ch€ck each other undercertain condnions. Whon rhe CPUS dstectthe fol'lowing discrepanaies, rhe ABS indicator light comss on. whe; rh€re is discGpancv n lhacarculated wheelspeed velocirv thar continuosJor more than a given

.i^/hen rhere is discrcoancv in the ehase informalion lhat continuesfor morerhan a given period' When rhere is discrepancY in thecalculared conlfol pa.amerer'. When thewatch dog conrrolp!lsetailslof a given penod. When th6 checkotth€ ROM tai1s.. when there is disrepancy inrhe data roading.nd wriung prcledurc ot RAM

19 7'l

tr

19-59

Page 1283 of 2189

b

D

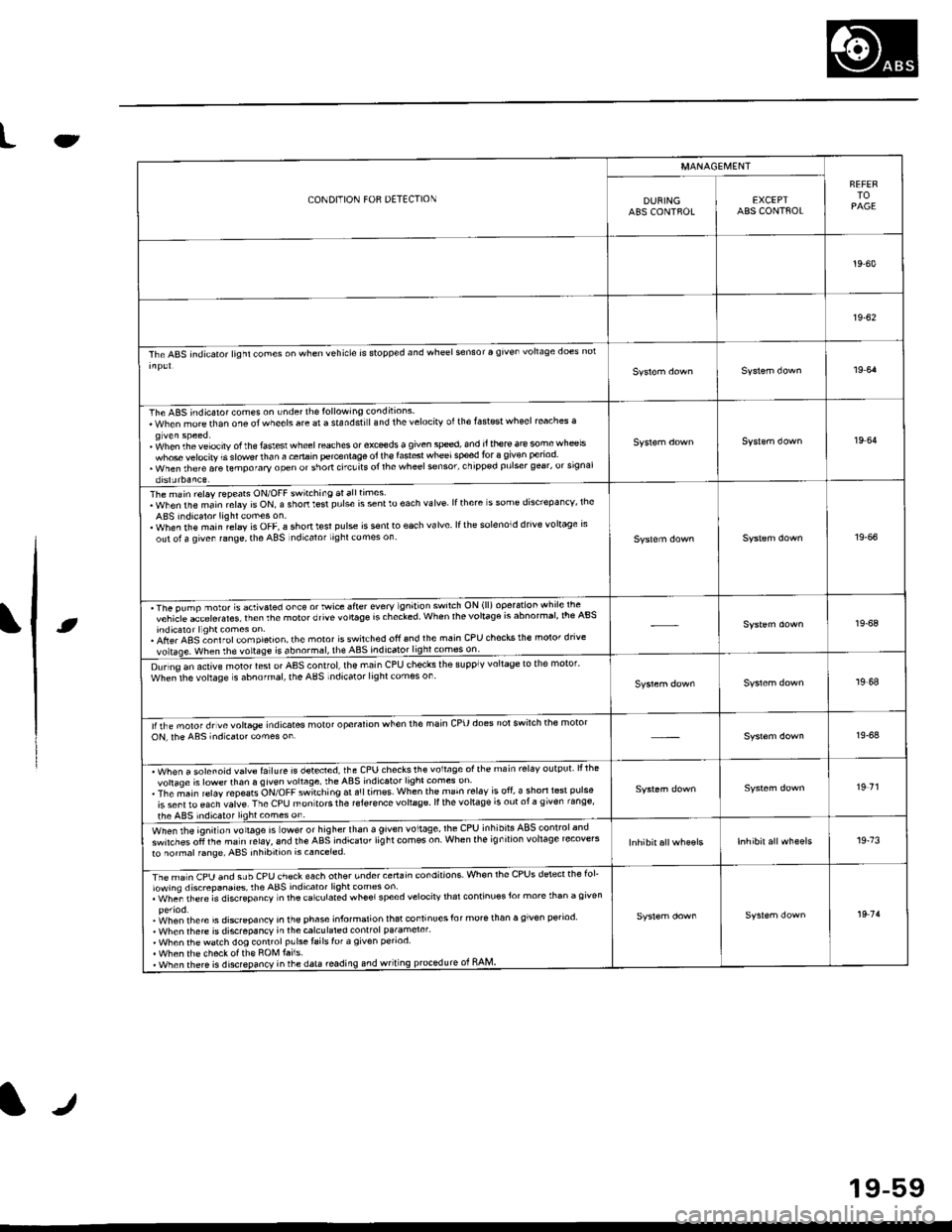

9. Remove the rail holder A.

GLASS BRACKET

DRAIN CHANNEL ROO STOPRotate as shown to remove it from the guide rail.

10. Remove the drain channel rod slider by moving the

cable slider forward using the moonroof wrench.

'11. Detach the drain channel rod stop from the cutout

of the guide rail as shown.

DRAIN CHANNELROD

I

NUT6x1.0mmI N.m (0.9 kgf.m,SUNSHAOE

\

'14.

12. Slide the sunshade forward, then remove it.

Installation is the reverse of the removal procedure.

NOTE: Check the glass height (see page 20-51).

Check for water leaks,

NOTE: Do not use high-pressure water.

20-53

Page 1287 of 2189

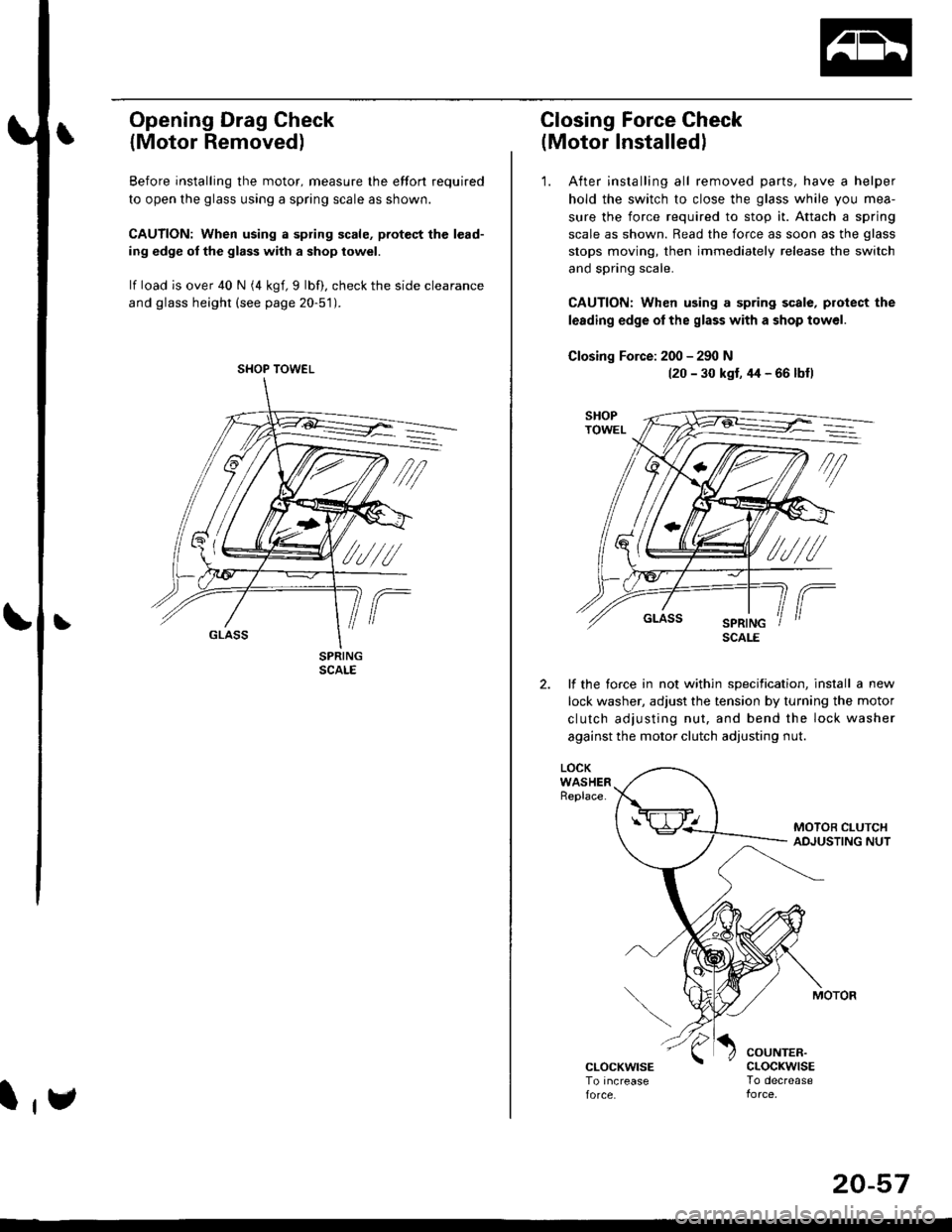

Opening Drag Check

{Motor Removed)

Before installing the motor, measure lhe effort required

to open the glass using a spring scale as shown.

CAUTION: When using a spring scale, pfotest the lead-

ing edge ol the glass with a shop towel.

lf load is over 40 N (4 kgf,9 lbf), check the side clearance

and glass height (see page 20-51).

SHOP TOWEL

l,e

20-57

Closing Force Check

(Motor Installedl

'1. After installing all removed parts, have a helper

hold the switch to close the glass while you mea-

sure the force required to stop it. Attach a spring

scale as shown. Read the force as soon as the glass

stops moving, then immediately release the switch

and spring scale.

CAUTION: When using a spring scale, protect the

lerding edge ol the glass with a shop towel.

Closing Force: 200 - 290 N(20 - 30 kst, 44 - 66 lbfl

lf the torce in not within specification, install a new

lock washer, adjust the tension by turnang the motor

clutch adjusting nut, and bend the lock washer

against the motor clutch adjusting nut.

LOCKWASHERReplace.

COUNTER.cLocKwrsETo decrease

SCALE

Page 1321 of 2189

Seat Belts

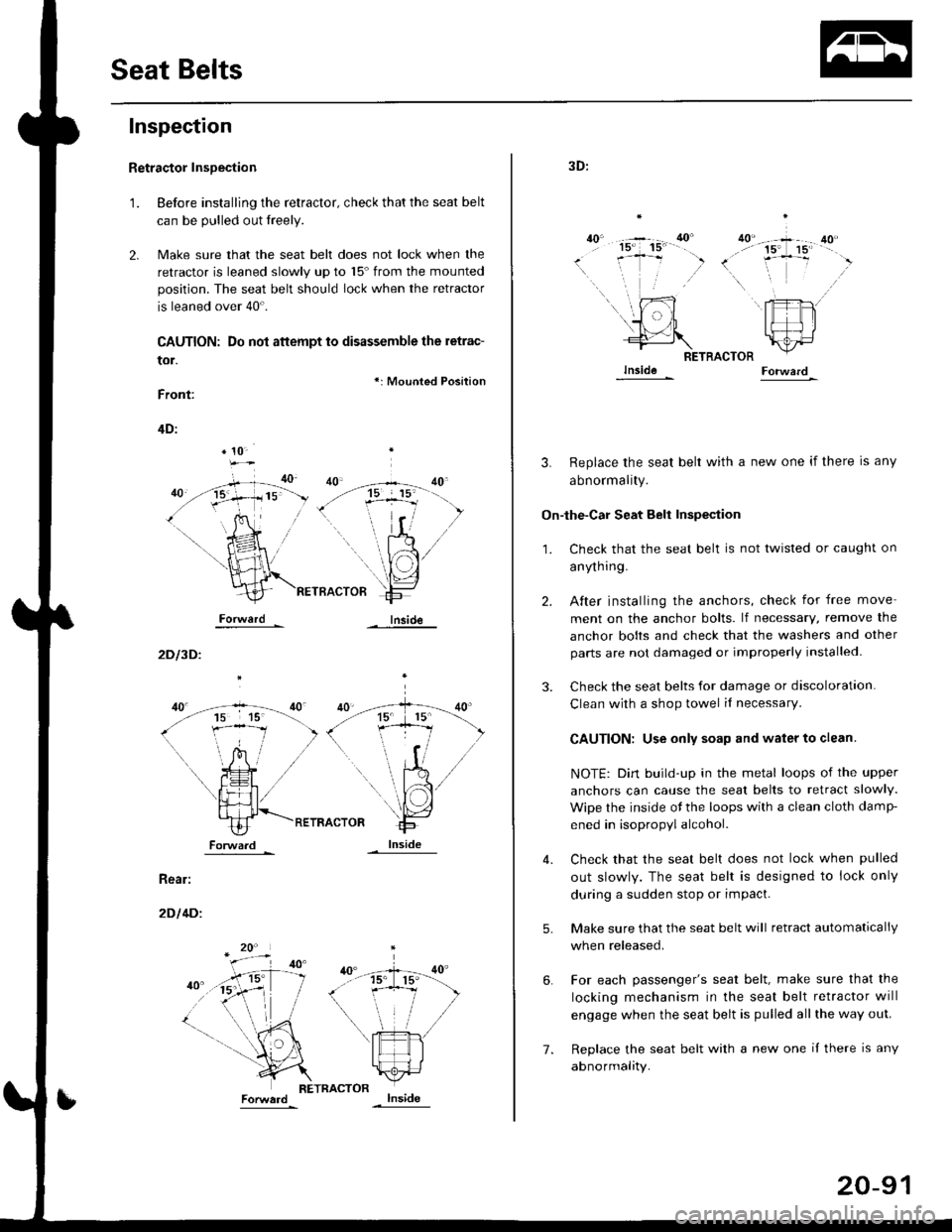

Inspection

t.

Retractor InsDection

Before installing the retractor, check that the seat belt

can be pulled out freely.

Make sure that the seat belt does not lock when the

retractor is leaned slowly up to 15'from the mounted

position. The seat belt should lock when the retractor

is leaned over 40'.

CAUTION: Do not attempt to disassemble the retrac-

tor.

Front:

*: Mounted Position

Inside

4D:

Forward

2D l3D.

Rear:

2D l4Di

* 10-

15 15'

i-Tl

I ],f

ForwaJdlnside

7.

20-91

3D:

ao"40'- -+ 40...'' 15' 15' --

(. .-j- ,)\,

RETRACTOR

3. Replace the seat belt with a new one if there is any

abnormality.

On-lhe-Car Seat Belt Inspeqtion

2.

3.

1.

5.

6.

4.

Check that the seat belt is not twisted or caught on

anyrn I ng.

After installing the anchors, check for free move

ment on the anchor bolts. lf necessary, remove the

anchor bolts and check that the washers and other

parts are not damaged or improperly installed

Check the seat belts for damage or discoloration.

Clean with a shop towel il necessary

CAUTION: Use only soap and water to clean.

NOTE: Dirt build-up in the metal loops of the upper

anchors can cause the seat belts to retract slowly.

Wipe the inside ot the loops with a clean cloth damF

ened in isopropyl alcohol.

Check that the seat belt does not lock when pulled

out slowly. The seat belt is designed to lock only

during a sudden stop or impact.

Make sure that the seat belt will retract automatically

when released.

For each passenger's seat belt, make sure that the

locking mechanism in the seat belt retractor will

engage when the seat belt is pulled all the way out.

Replace the seat belt with a new one il there is any

abnormality.

Page 1322 of 2189

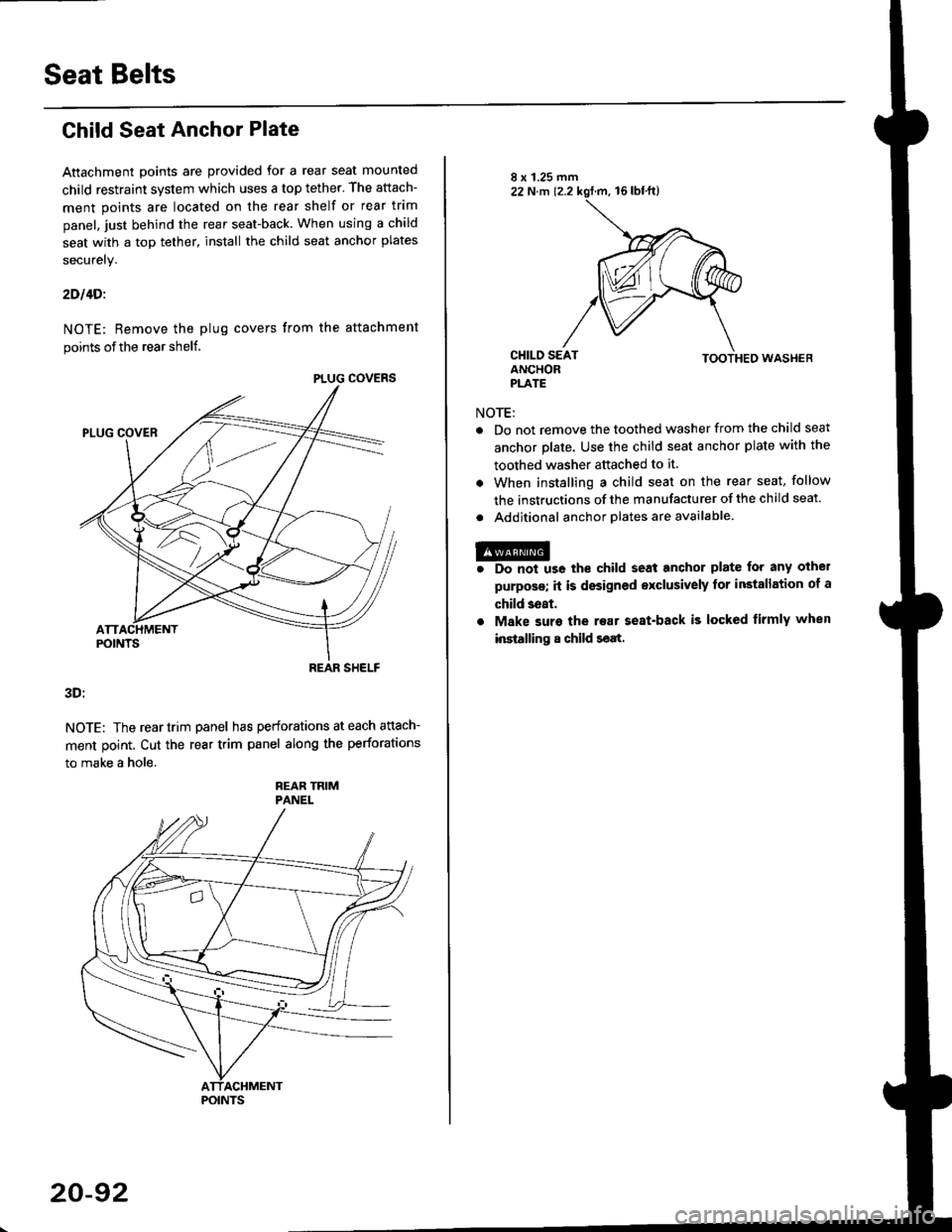

Seat Belts

Child Seat Anchor Plate

Attachment points are provided for a rear seat mounted

child restraint system which uses a top tether. The attach-

ment points are located on the rear shelf or rear trim

panel, just behind the rear seat-back. When using a child

seat with a top tether, install the child seat anchor plates

securely.

2Dl4Di

NOTE; Remove the plug covers from the attachment

points of the rear shelf.

3D:

NOTE: The reartrim panel has perforations at each attach-

ment point. Cut the rear trim panel along the perforations

to make a hole.

REAR TRIMPANEL

PLUG COVERS

REAR SHELF

POINTS

20-92

NOTE:

TOOTHED WASHEB

Do not remove the toothed washer from the child seat

anchor plate. Use the child seat anchor plate with the

toothed washer attached to it.

When installing a child seat on the rear seat, follow

the instructions of the manufacturer of the child seat

Additional anchor olates are available.

@r Do not us6 the child seat anchor plate for any othel

purposs; it is designed exclusively tor installation of a

child 3eat.

. Make suro the rear seat-back is locked firmly when

installing 8 child seat.

Page 1371 of 2189

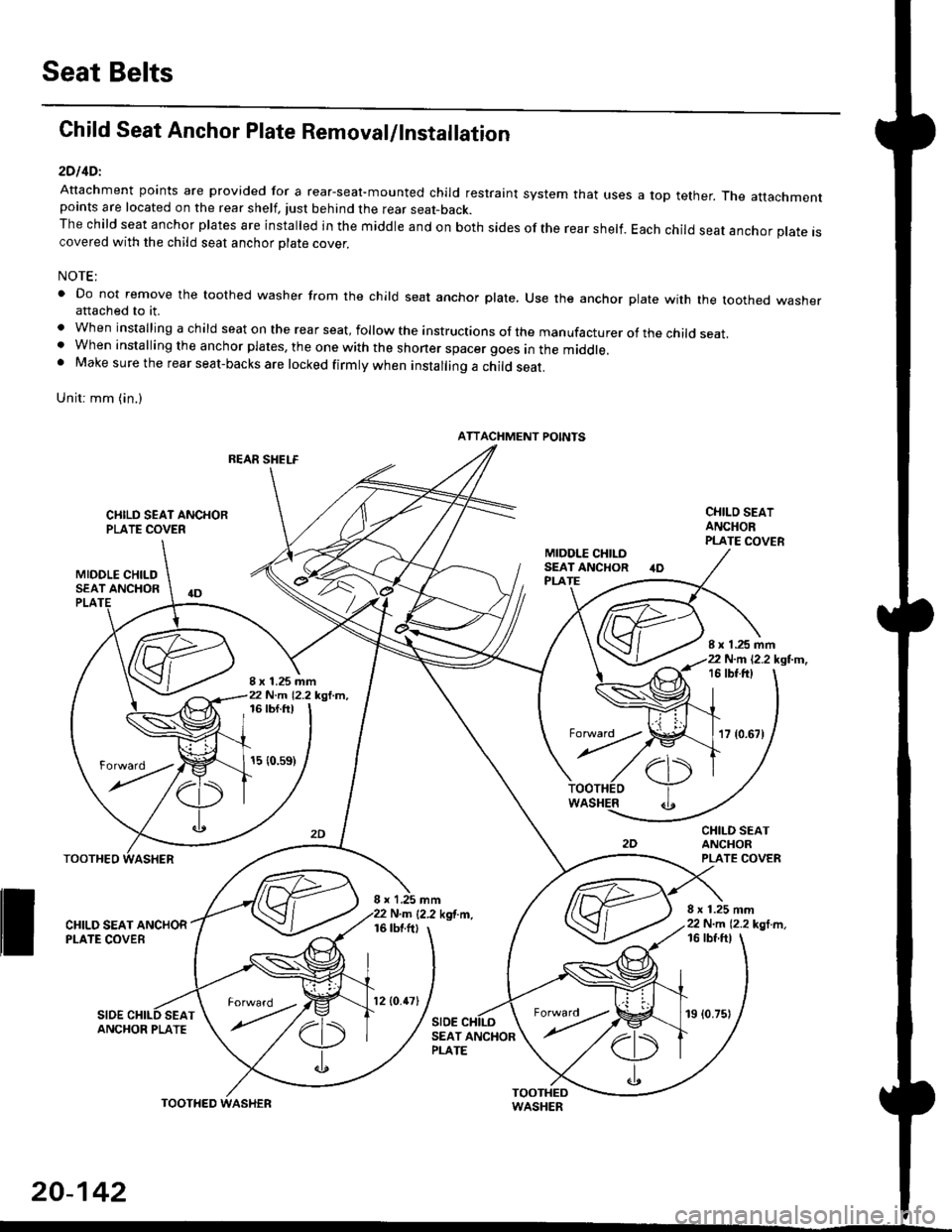

Seat Belts

Child Seat Anchor Plate Removal/lnstallation

2DllDl

Attachment points are provided for a rear-seal-mounted child restraint system that usespoints are located on the rear shelf, tust behind the rear seat-back.The child seat anchor plates are installed in the middle and on both sides of the rear shelf.covered with the child seat anchor olate cover.

a top tether. The attachment

Each child seat anchor plate is

NOTE:

' Do not remove the toothed washer from the child seat anchor plate, Use the anchor plate with the toothed washerattached to it.

. When installing a child seat on the rear seat, follow the instructions of the manufacturer of the child seat.. When installing the anchor plates, the one with the shoner spacer goes in the middle.. Make sure the rear seat-backs are locked firmly when installing a child seat.

Unit: mm (in.)

REAR SHELF

CIIILD SEAT ANCHORPLATE COVER

MIDOLE CHILDSEAT ANCHOR

CHILO SEATANCHORPLATE COVER

CHILD SEATANCHORPLATE COVER

8 x 1.25 mm22 N.m 12.2 kgl m,

PLA

8 x 1.25 mm22 N.m 12.2 kgl.m,

I x 1.25 mm22 N.m 12.2 kgl.m,16 tbt.ftt

17 {0.67)

16 tbf.ft)

15 {0.s9)

WASHER

rl)

.t

TOOTHEO

ll ff*,".rd,',i"'"o*

SIDESEAT

I x 1,25 mmN.m {2.2 kgf.m.16 tbtftl

SIDE

16 tbf ftl

ANCHOR PLATESEAT ANCHORPLATE

ATTACHMENT POINTS

torward .

20-142

TOOTHED

12lO.47l19 (0.75)

Page 1372 of 2189

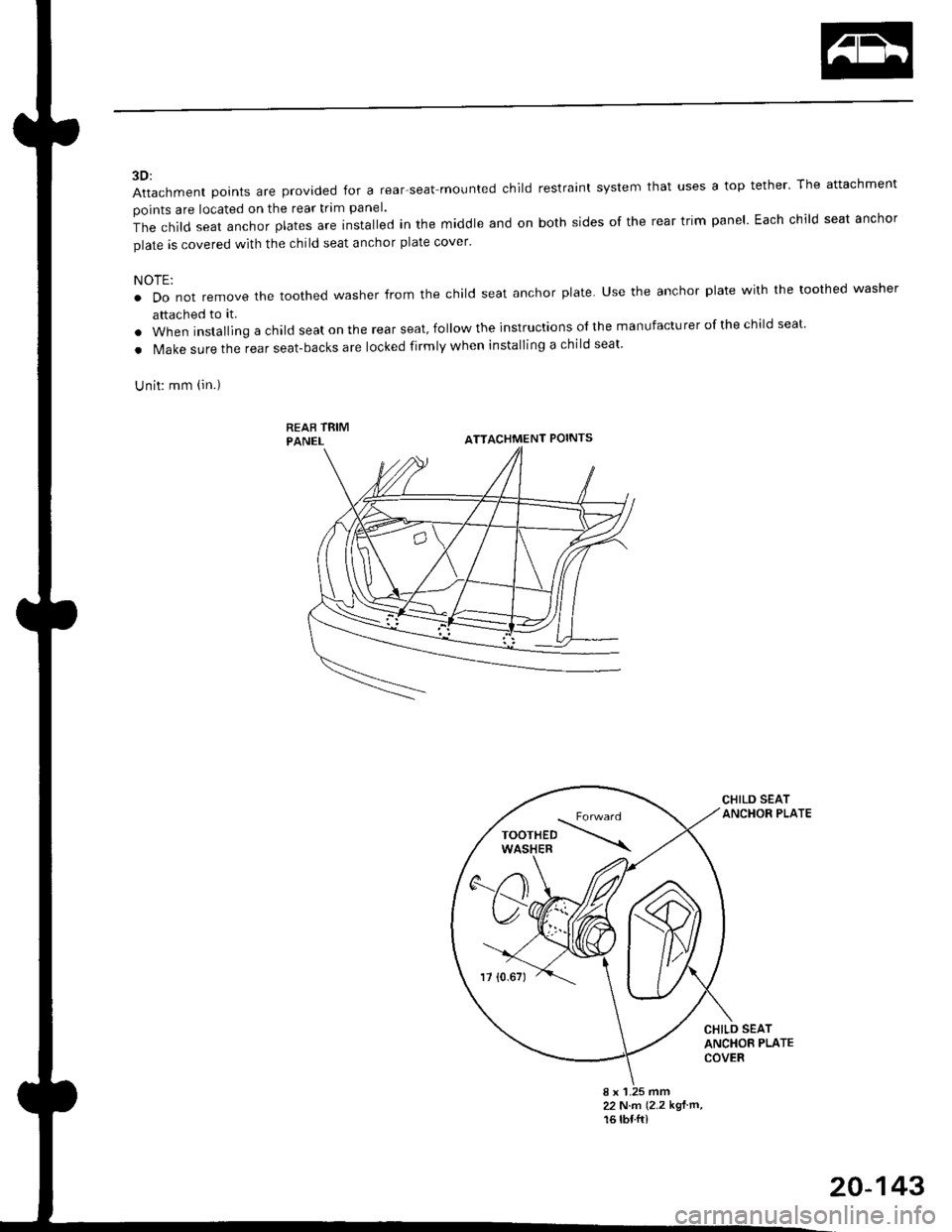

3D:

Attachment points are provided for a rear-seat mounted child restraint system that uses a top tether' The attachment

points are located on the rear trim panel.

The child seat anchor plates are rnstalled in the middle and on both sides of the rear trim panel Each child seat anchor

plale is covered with the child seat anchor plate cover'

NOTE:

. Do not remove the toothed washer from the child seat anchor plate. use the anchor plate with the toothed washer

attached to it.

. when installing a child seat on the rear seat, follow the instructions ol the manufacturer of the child seat'

. Make sure the rear seat-backs are locked firmly when installing a child seat'

gn;1 6rn (in.)

ATTACHMENT POINTS

CHILO SEATANCHOR PLATE

CHILD SEATANCHOB PLATECOVER

8 x 1.25 mm22 N..n (2.2 kgl'm.16 tbfft)

;x?',rff{-*.

20-143

Page 1417 of 2189

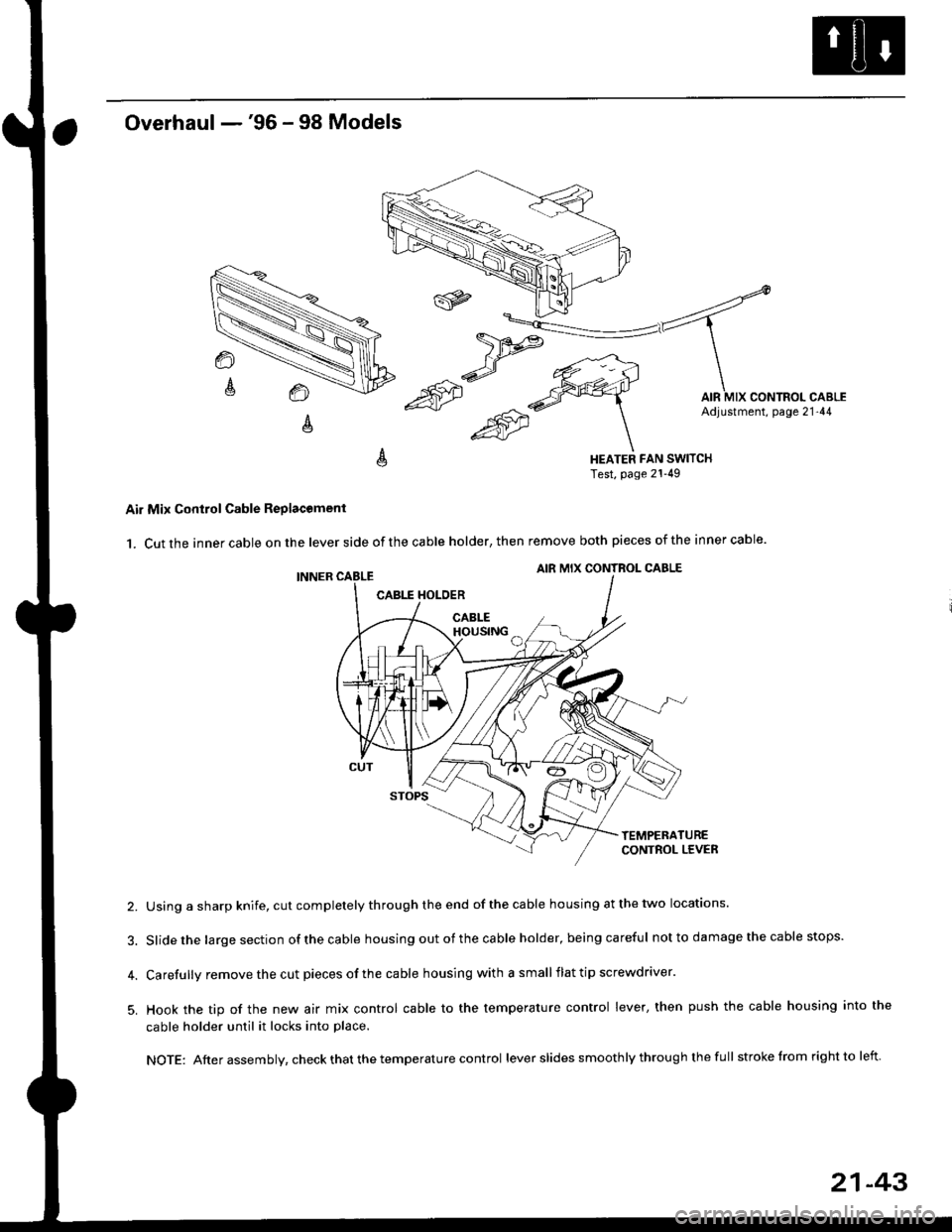

Overhaul -'96 - 98 Models

HEATER FAN SWITCHTest, page 21-49

Air Mix Control Cable Replacomenl

1. Cut the inner cable on the lever side of the cable holder, then remove both pieces of the inner cable.

2. Using a sharp knife, cut completely through the end of the cable housing at the two locations.

3. Slidethe largesection ofthecable housing outofthe cable holder, being careful not to da mage the cable stops.

4. Carefully remove the cut pieces of the cable housing with a small flat tip screwdriver.

5. Hook the tip of the new air mix control cable to the temperature control lever, then push the cable housing into the

cable holder until it locks into place.

NOTE: After assembly, check that the temperature control lever slides smoothly through the full stroke lrom right to left.

21-43