Oil change HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 583 of 2189

MaintenanceBack-up Light Switch

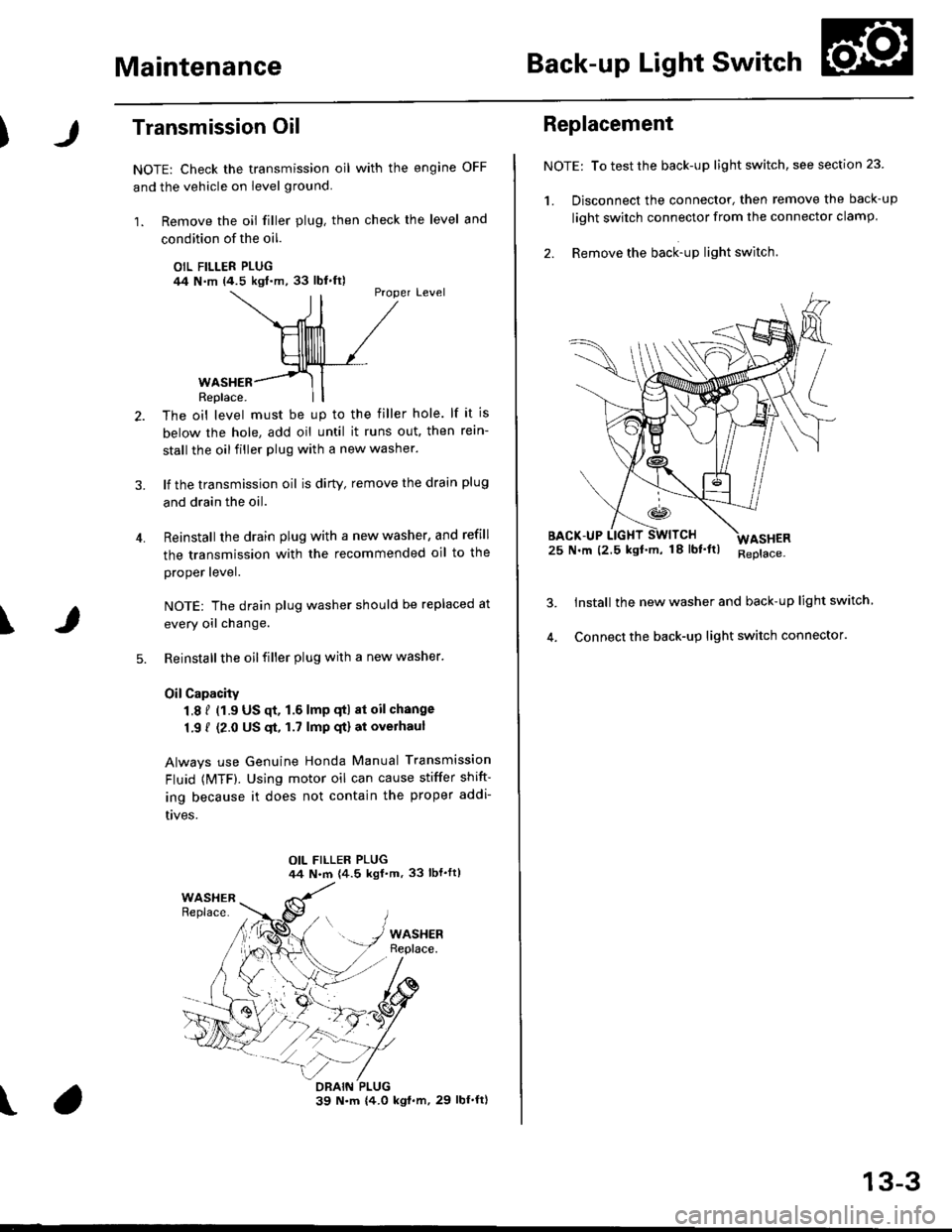

Transmission Oil

NOTE: Check the transmission oil with the engine OFF

and the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUG/14 N.m (4.5 kgl.m,33 lbl.ft)Proper Level

4.

WASHERReplace.

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out. then rein-

stall the oil filler plug with a new washer.

lf the transmission oil is dirty, remove the drain plug

and drain the oil.

Reinstall the drain plug with a new washer, and refill

the transmission with the recommended oil to the

proper lever.

NOTE: The drain plug washer should be replaced at

every oil change.

Reinstall the oil filler plug with a new washer.

OilCapacity

1.8 f (1.9 US qt. 1.6 lmp qtl at oil change

1.9 { (2.0 US $, 1.7 lmp qt) at overhaul

Always use Genuine Honda Manual Transmission

Fluid {MTF). Using motor oil can cause stiffer shift-

ing because it does not contain the proper addi-

t|ves.

\

\

Replacement

NOTE: To test the back-up light switch, see section 23

1. Disconnect the connector, then remove the back-up

light swirch connector from the connector clamp.

2. Remove the back-up light switch.

25 N.m (2.5 kgf'm, 18lbf'ltl

Install the new washer and back-up light switch

Connect the back-up light switch connector.

ASHER

13-3

Page 625 of 2189

S4C Model ('99 - 00 2-door Si, SiR)

Manual Transmission

Special Tools ............' 13-46

Maintenance

Transmission Oi1 ...................'.......... 13-47

Back-up Light Switch

Repfacement ...""" 13'47

Transmission Assembly

Removal ......'.......... 13-/tB

lnstallation ............. 13-52

lllustrated lndex ................................... 13-54

Transmission Housing

Removal ................. 13-55

Beverse Shift Holder, Reverse ldler Gear

Clearance lnspection ...................".. 13-57

Removal ................. 13-58

Change Holder Assembly

Clearance lnspection .................".... 13-59

Removal ....,,........... 13-61

Disassembly/Reassembly ............... 1 3-62

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-63

Shift Rod

Removal .........."'.... 13-64

Shift Fork Assembly

lndex ................ ...... 13-65

Clearance lnspection .............'......... 13'66

Mainshaft Assembly

lndex ............"" ...... 13-67

Clearance lnspection ....................... 13-68

Disassembly .......... 13-71

fnspection '."'.......', 13'72

Reassembly .......'... 13-73

Countershaft Assembly

fndex ................ "....13-71

Glearance Inspection'......'...........'... 1 3'75

Disassembly .......... 13-76

fnspection .'............13'77

Reassembly "......... 13'78

Synchro Sleeve, Synchro Hub

Inspection .............. 13'8C

Installation ............. 13-80

Synchro Ring, Gear

Inspection .'............ 13-81

Differential

lndex ................ ...... 13-82

Backlash Inspection ..."..........."'...... 1 3-82

Final Driven Gear Replacement ...... 13-83

Bearing Replacement ....."'.......""'.. 13-83

Thrust Shim Adiustment ......""'..... 13-84

Clutch Housing Bearing

Replacement ..'...... 13-86

Mainshaft Thrust Glearance

Adiustment '.........'. 13-88

Transmission

Reassembly ."'....... 13-91

Oil Seals

Replacement ..'...... 13-96

Gearshift Mechanism

Overhaul ................ 13-97

\

Page 627 of 2189

MaintenanceBack-up Light Switch

\

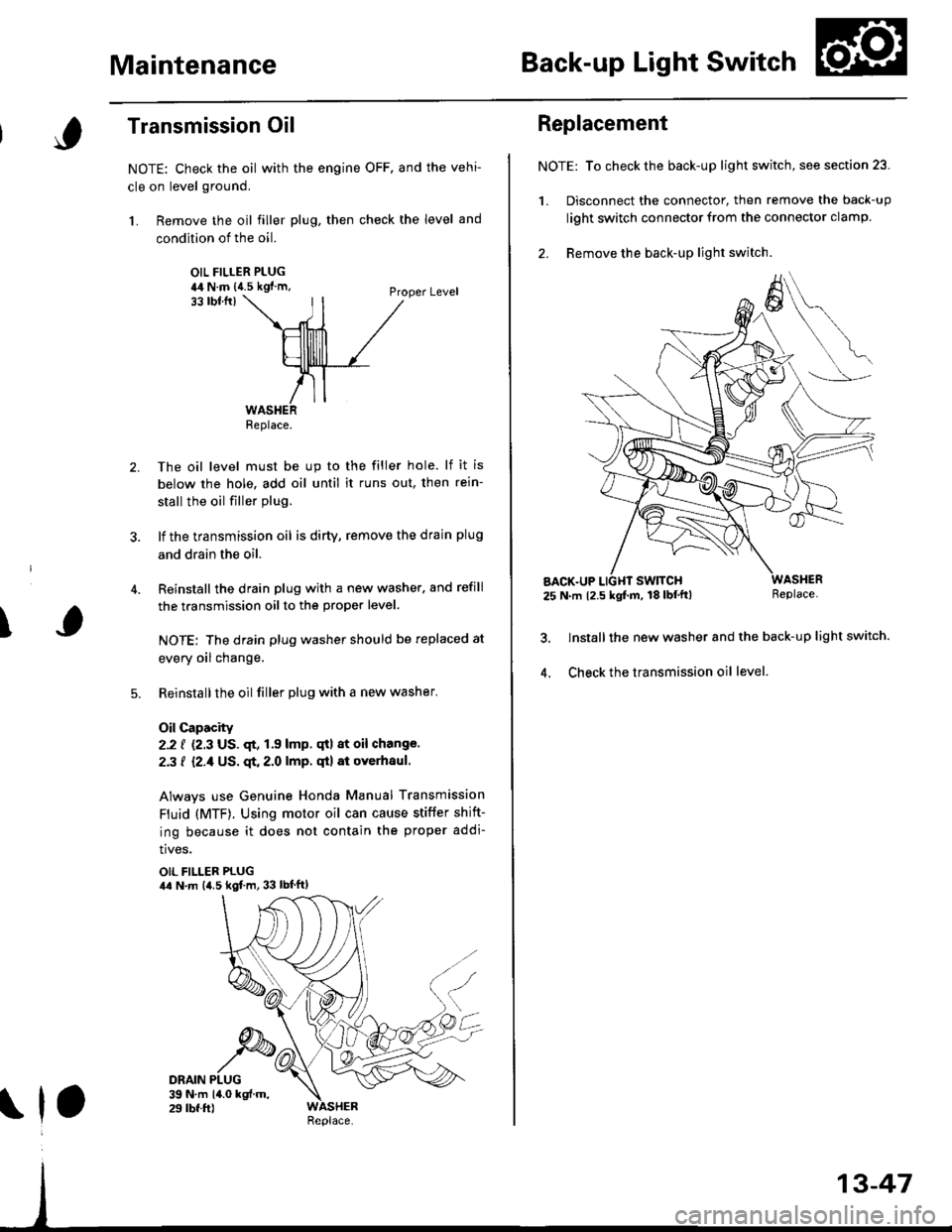

Transmission Oil

NOTE: Check the oil with the engine OFF. and the vehi-

cle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUGia4 N.m {{.5 kgf'm,Proper Level33 tbtfrl

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out, then rein-

stall the oil filler plug.

lf the transmission oil is dirty, remove the drain plug

and drain the oil.

Reinstall the drain plug with a new washer. and refill

the transmission oil to the proper level.

NOTE: The drain plug washer should be replaced at

every oil change.

Reinstallthe oilfiller plug with a new washer.

Oil Capacity

2.2 f {2.3 US. qt, 1.9 lmp. qtl at oil change.

2.3 f {2./f US. qt. 2.0 lmp. qt} at overhaul.

Always use Genuine Honda Manual Transmission

Fluid (MTF). Using motor oil can cause stiffer shift-

ing because it does not contain the proper addi-

tives.

OIL FILLER PLUGila N.m {4.5 kgf.m, 33 lbt'ftl

Replace.

\1,

Replacement

NOTE: To check the back-up light switch, see section 23.

1. Disconnect the connector, then remove the back-up

light switch connector from the connector clamp.

2. Remove the back-up lighr switch.

AACK.UP25 N.m 12.5 kgf.m, 18 lbf'tt)Replace.

lnstall the new washer and the back-up light switch.

Check the transmission oil level.4.

Page 630 of 2189

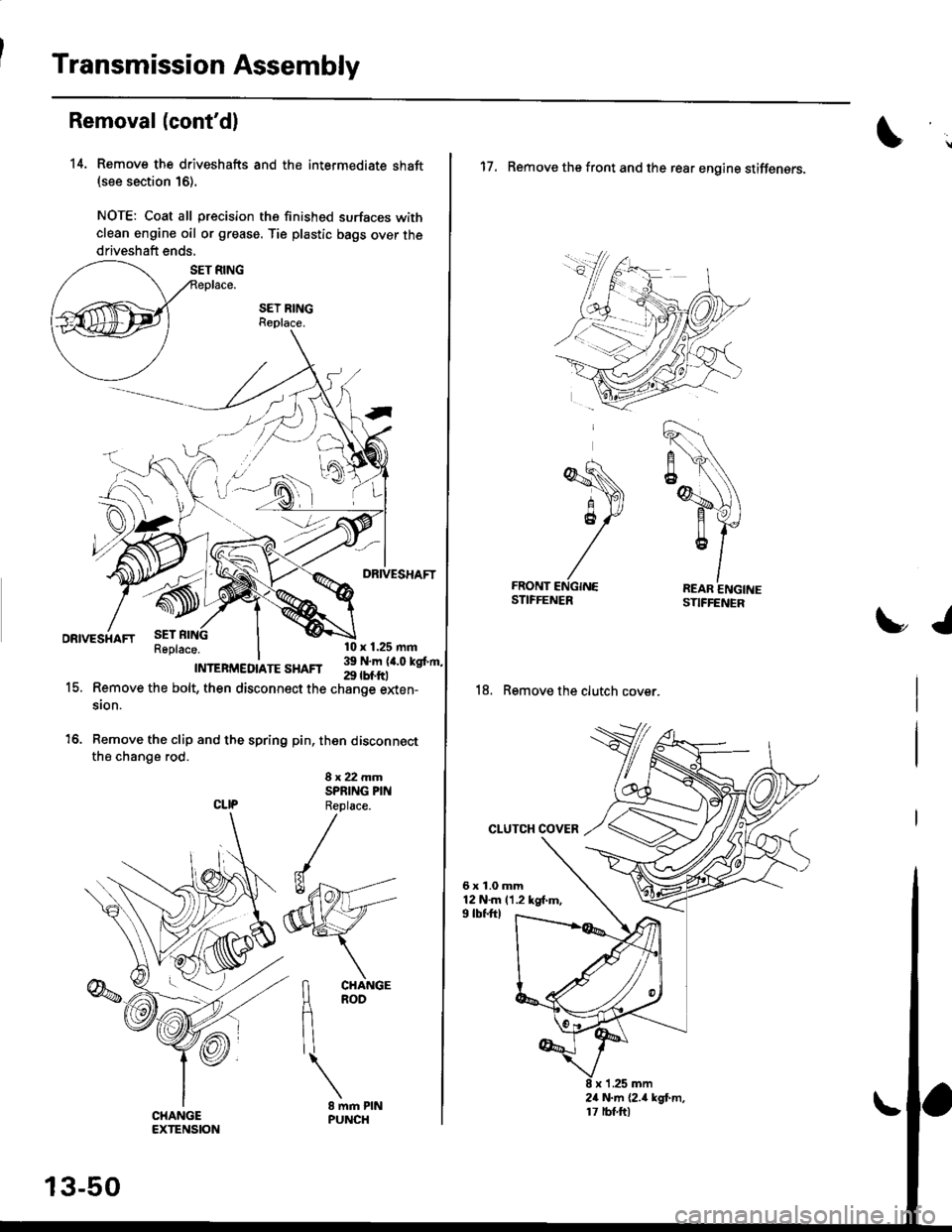

Transmission Assembly

Removal(cont'd)

14. Remove the driveshafts and the intermediate shaft(see section 16).

NOTE: Coat all precision the finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends,

Remove the bolt, then disconnect the change elden-

sion.

Remove the clip and the spring pin, then disconnectthe change rod.

8x22mmSPRING PINCLIP Replace.

15.

13-50

17. Remove the front and the rear engine stiffensrs.

18. Remove the clutch cover.

CLUTCH COVER

6x1.0mm12 N.m (1.2 kg{.m,9 tbf.ftl

x 'l .25 mm

tJ

24 N.m {2.4 kgt m,17 rbt ftl

Page 635 of 2189

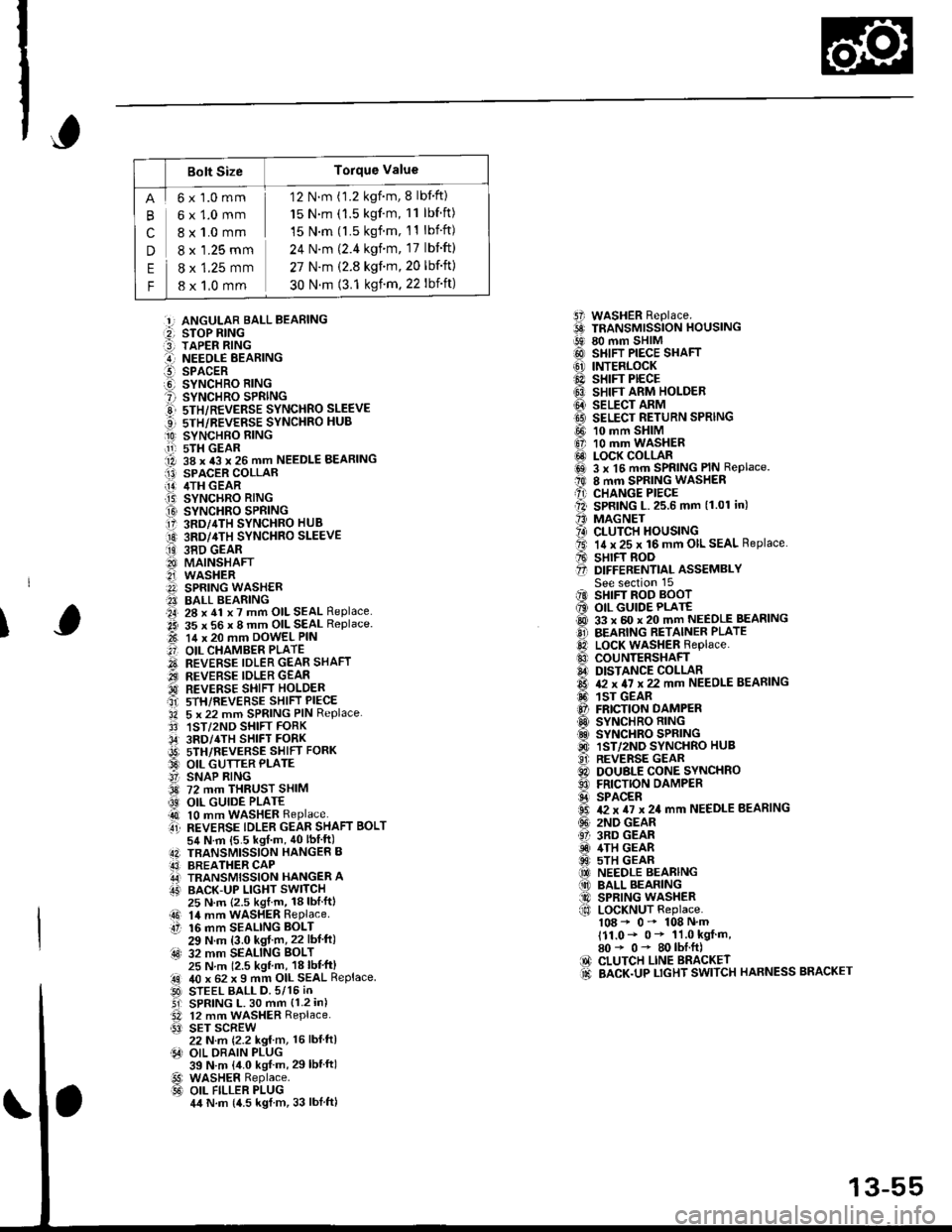

Bolt SizeTorque Value

cn

E

F

6x1.0mm

6x1.0mm

8 x 1.0 mm

8 x '1.25 mm

8 x 1.25 mm

8 x 1,0 mm

12 N.m (1.2 kgnm, 8 lbf'ft)

15 N.m (1.5 kgf'm, 11 lbf ft)

15 N.m (l.5 kgf.m, 11 lbift)

24 N'm (2.4 kgim, 17 lbift)

27 N.m (2.8 kgf.m,20 lbf'ft)

30 N.m (3.1 ksf m. 22 lbift)

5i WASHER Replace.6 TRANSMrssioN HouslNG!9 80 mm SHIM@ SHIFT PIECE SHAFT(6' INTERLOCK@ sHrFr PECE6} SHIFT ARM HOLDER@ seucr nnrvtI9 SELECT RETURN SPRING

@ 10 mm SHIM6, 10 mm WASHER@ LOCK COLLARi6sl 3 x l5 mm SPRING PIN Replace.t0 8 mm SPRING WASHERA) CHANGE PIECEll SPRING L.25.6 mm (1.01 in)'' MAGNET?4) CLUTCH HOUSINGta. 14 x 25 x 16 mm OIL SEAL Replace.A sHrFT BooO D|FFERENT|aL ASSEMBLYSee section 15iIO SHIFT ROD BOOT6 OIL GUIDE PLATE@ 33 x 60 x 20 mm NEEDLE BEASINGO BEARING RETAINER PLATElD LocK WASHER Replace..0 couNTERSHAFIA DISTANCE COLLAR6 & x 4I x 22 mm NEEDLE BEARING6. 1sr GEAR@ FRICTION DAMPERO SYNCHRO RING.d SYNCHRO SPRING@ 1ST/2ND SYNCHRO HUB..9i. REVERSE GEARC) DOUBLE CONE SYNCHROO FRICTION DAMPERS SPACER6 T2 x TI x 24 mm NEEDLE BEARING(!' 2ND GEAR61 3RD GEARiD 4TH GEAR@ 5TH GEAR(O NEEDLE BEARING(10 BALL BEARING@ SPRING WASHERf,o LoCKNUT Replace.108 - 0- 108 N'm111.0- 0* 11.0 kgf m,80* 0- 80lbI.ft)IO CLUTCH LINE BRACKET.d BACK.UP LTGHT SWITCH HARNESS BRACKET

:!, ANGULAR BALL BEABING:2, STOP RING:3] TAPER RING..-I NEEOLE BEARINGl!-- SPACERO SYNCHRO RING? SYNCHRO SPRINGE 5TH/REVERSE SYNCHRO SLEEVE...] sTH/REVERSE SYNCHRO HUB

O SYNCHBO EING.11-r sTH GEAR1A 38 x 43 x 26 mm NEEDLE BEARINGI13) SPACER COLLAR[!] /ITH GEAR.T5) SYNCHRO RING

O SYNCHRO SPRING17 3RD/4TH SYNCHRO HUB

O 3RD/4TH sYNcHRo SLEEVE

ii9 38D GEAR8I MAINSHAFT2i WASHERA SPRING WASH€R?I BALL BEARING.a4, 28 x 41 x 7 mm OIL SEAL Replace..2i 35 x 56 x 8 mm OIL SEAL Replace.t-t 14 x 20 mm DowEL PIN

.'] OIL CHAMBER PLATE

O REVERSE IDLER GEAR SHAFT.iI.., REVERSE IDLER GEAR'd REVERSE SHIFI HOLDERait srH/REVERSE sHIFT PIECE'34 5 x 22 mm SPRING PIN Replace.3' 1ST/2ND SHIFT FORK,34' 3RD/4TH SHIFT FORKi9t) srH/nevense sstrr ronx33 OIL GUTTER PLATE!' SNAP RING3d 72 mm THRUST SHIM

@ OIL GUIDE PLATE4t 10 mm WASHER Replaceti REVERSE TDLER GEAR SHAFT BoLT54 N.m {5.5 kgf m, 40lbIft)4N TBANSMISSION HANGER B43] BREATHER CAPA,J TRANSMISSION HANGER AIT' BACK-UP LIGHT SWITCH

I

25 N.m {2.5 kgl.m, 18lblftl14 mm WASHER RePlaceaO 14 mmtt 16 mm16 mm SEALING BOLT29 N.m (3.0 kgf m,22 lbf ft):4s) 32 mm SEALING BoLT25 N m 12.5 kgl m, 18 lbl'ft)40 x 62 x I mm OIL SEAL ReplaceSTEEL BALL D.5/15 iNSPRING L. 30 mm {1.2 in)12 mm WASHER Replace.SET SCREW22 N.m {2.2 kg{ m, 16 lbl ftlOIL DRAIN PLUG39 N.m {4.0 kgf m, 29lbtftlWASHER Replace.OIL FILLER PLUG4,t N.m {4.5 kgl m, 33 lblftl

.!rl00

@l

13-55

Page 644 of 2189

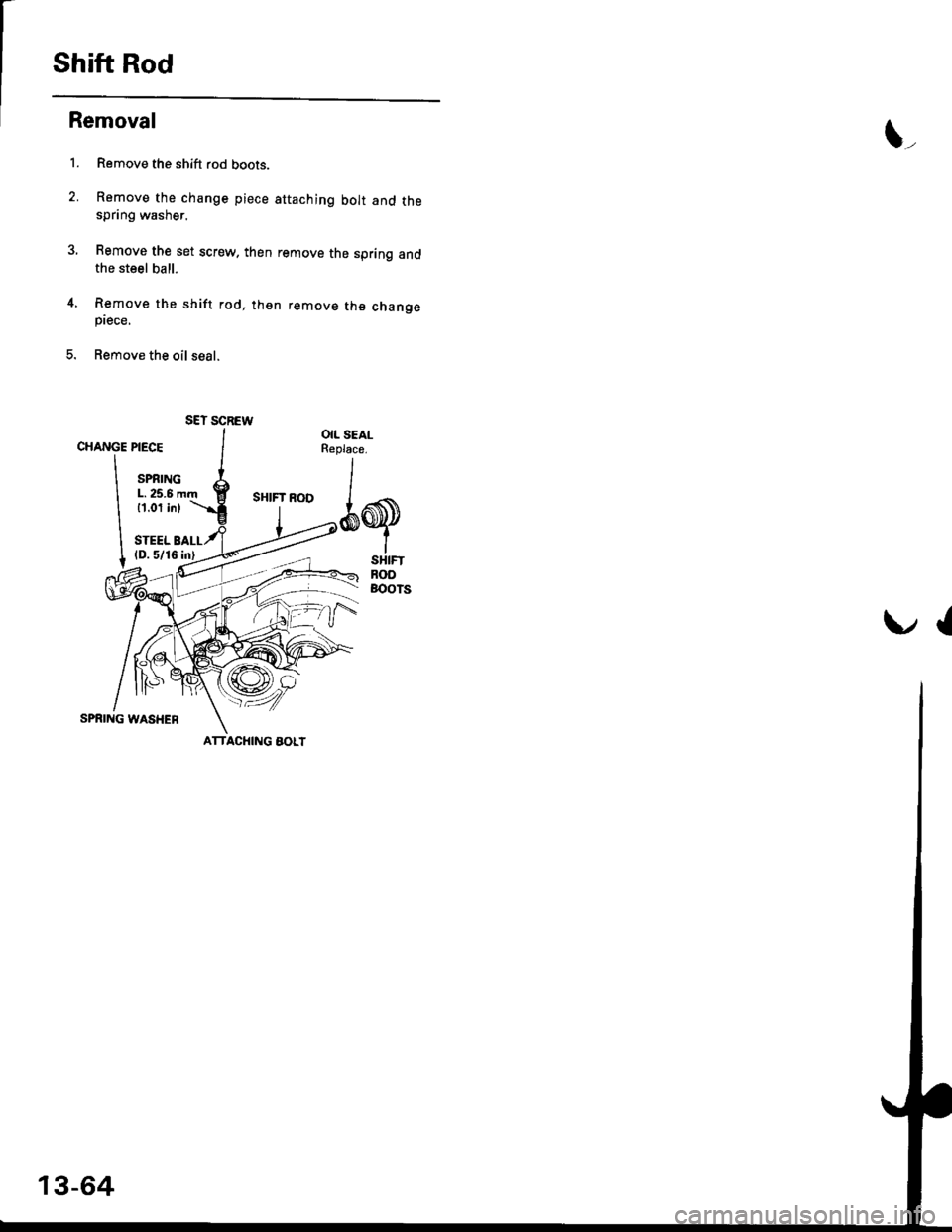

Shift Rod

Removal

1. Remove the shift rod boots.

2. Remove the change piece attaching bolt and thespring washer.

3, Bemove the set screw. then remove the spring andthe steel ball.

4, Remove the shift rod, then remove the changepiece,

5. Remove the oil seal.

l_

CHANGE PIECE

SPRINGL. 25.611.01 inl

STEEL(D. s/16

SPRING WASHEN

OIL SEALR€placs.

*ry

SHIFTnoDBOOTS

\,,rl

ATTACHING AOLI

SET SCREW

13-64

Page 671 of 2189

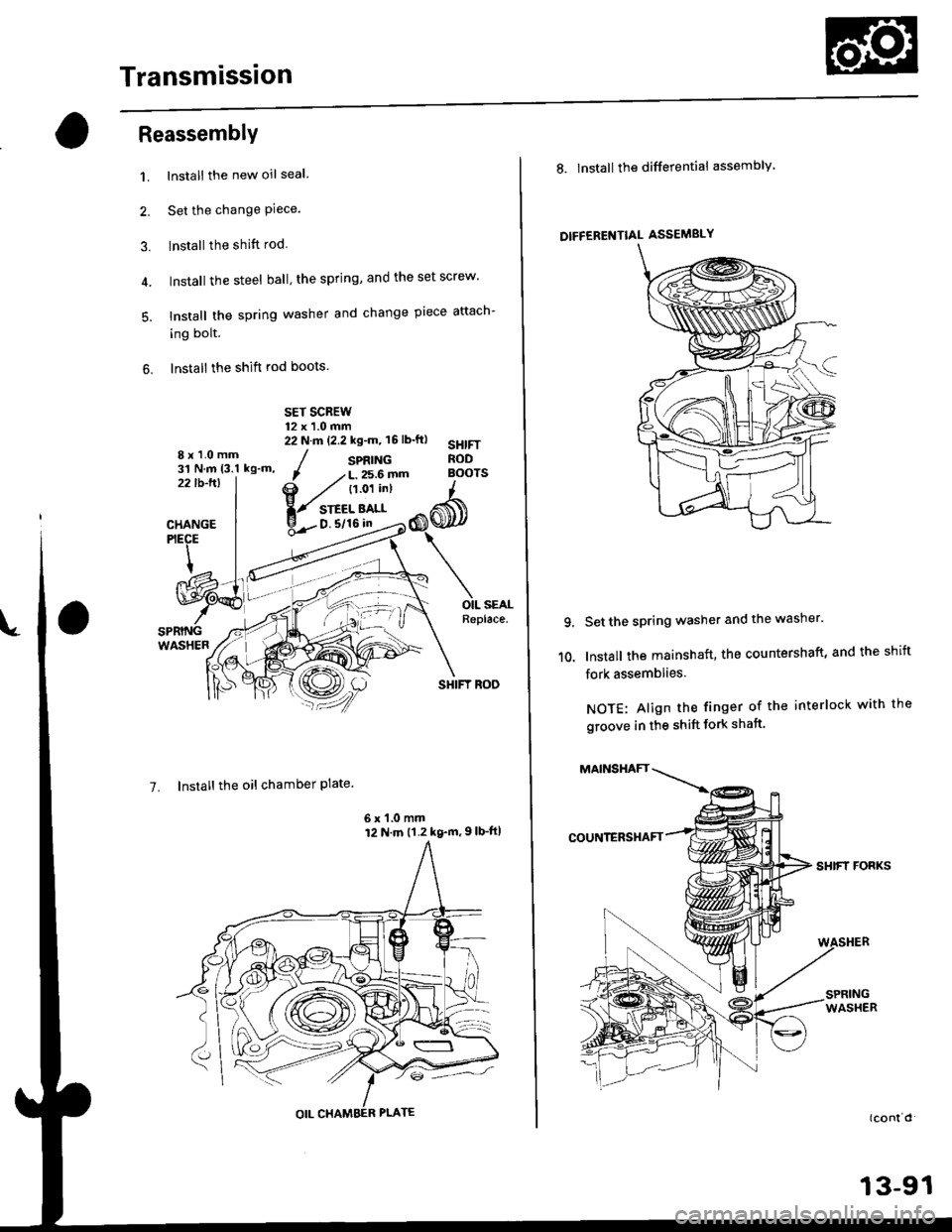

Transmission

ReassemblY

1. Install the new oil seal

2. Set the change Piece.

3. Install the shift rod

4. Install the steel ball' the spring, and the set screw'

5. Install the spring washer and change piece attach-

ing bolt.

6. Install the shift rod boots.

8x1.0mm31 N.m 13.1 kg-m,22lb-ltl

CHANGEPIECE

@:4OIL SEALReplace.SPRINGWASHER

7. Install the oil chamber Plate'

6 x '1.0 mm12 N.m (1.2 kg-m,9lb-ft|

SPRING

, /L.256fim B()(

@ / t't o'ti"l I

{zw"y-6@

q

10.

Set the spring washer and the washer'

lnstall the mainshaft, the countershaft, and the shift

fork assemblies.

NOTE: Align the finger of the interlock with the

groove in the shift fork shaft.

SHIFT FORKS

13-91

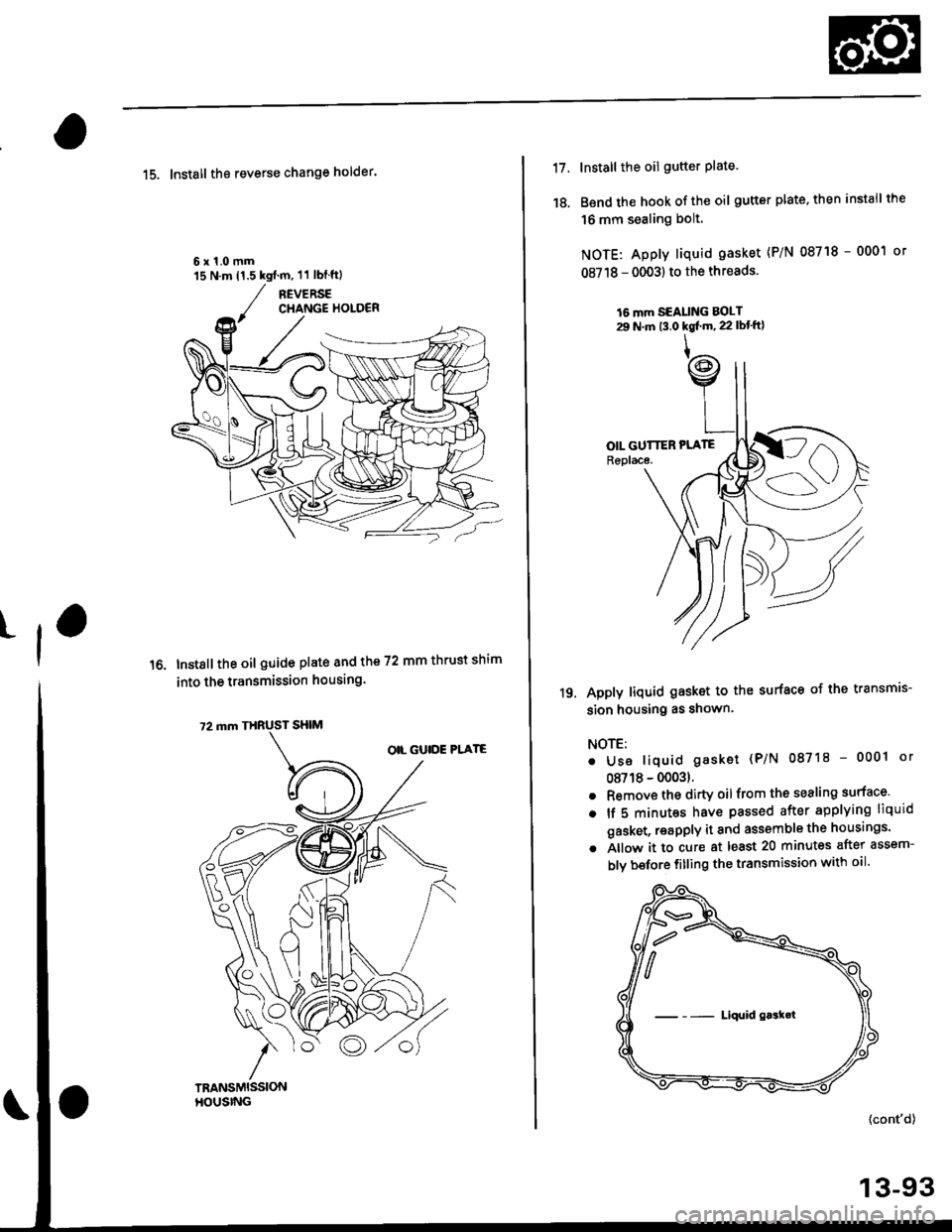

Page 673 of 2189

tl

15. Install the reverse change holder.

6x1.0mm'15 N.m 11.5 kgim, 11 lblftl

Instsll the oil guide plate and the 72 mm thrust shim

into the transmission housing.

17.

18.

Install the oil gutter plate.

Bend the hook of the oil gutter plate, then install the

16 mm sealing bolt.

NOTE: Apply liquid gasket {P/N 08718 - 0001 or

08718 - 0003) to the threads.

16 mm SEALING BOLT29 N.m t3.0 kgl'm, 22 lbt'ft}

Apply liquid gasket to the surface of the transmis-

sion housing as shown'

NOTE:

. Use liquid gasket (P/N 087'18 - 0001 or

08718 - 00031.

. Remove the dirty oilfrom the sealing surface'

. lf 5 minut€s have passed after applying liquid

gasket, reapply it and assemble the housings'

. Allow it to cure at least 20 minutes after assem-

blv bsfore fitling the transmission with oil'

19.

(cont'd)

13-93

--- Liqui.l gask€t

Page 677 of 2189

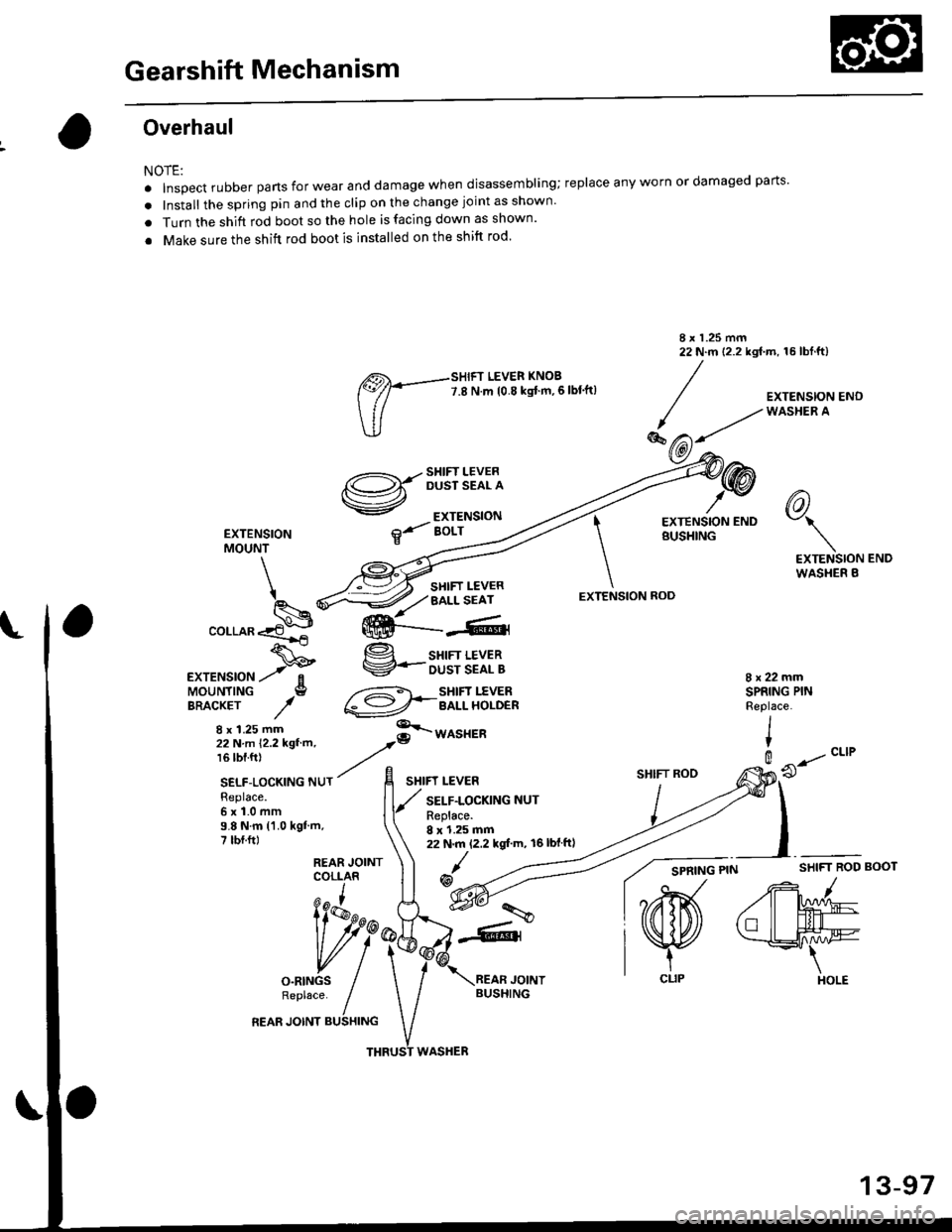

Gearshift Mechanism

Overhaul

NOTE:

. Inspect rubber parts for wear and damage when disassembling;

. Install the spring pin and the clip on the change joint as shown'

. Turn the shift rod boot so the hole is facing down as shown'

. Make sure the shift rod boot is installed on the shift rod'

reDlace any worn or damaged Parts.

I x 1.25 mm22 N.m 12.2 kgf.m, 16 lbf.ft)

ffi-:t't:il1ii51i?"'*,

TU

/g3i'51!Exii

V ExrENsroN

EXTENSfON ilr'eol.T

EXTENSION ENDBUSHING

hV\

EXTENSIONWASI{ER B

MOUNT -_.--_-_---

@2'

--1'>=2 -:liT.i'ff"

.o,-.o*&--ffi{---*,

v/,,/ BALL SEAT

8 x 1.25 mm22 N.m 12.2 kgf'm, 16lblftl

,@

EXTENSION ROD

SHIFT ROD

SPRING

END

BOOT

N: g sHrFr LEvER

.*rr"r,o"-tf V-oiliiSi[a

MOUNTING I --::=t SHIFT I"EVERBRAcxEr / €9-l--enr xoloen

8 x 1.2s mm :-,rro""a,ii-ri- ri.z rsr.-, -.Q u

16 tbf.ft) ,,,.

,rar-aoa*,"o "u, / E ,",t.ruaa

Replace.6x1.0mm9.8 N.m ('1.0 kgt'm,7 tbr.ftt

8x22mmSPRING PINReplace.

IIt

@CLIP

9.a-"t't

PIN SHIFT ROD/

ZW

€lt#-,\

HOLE

13-97

Page 1074 of 2189

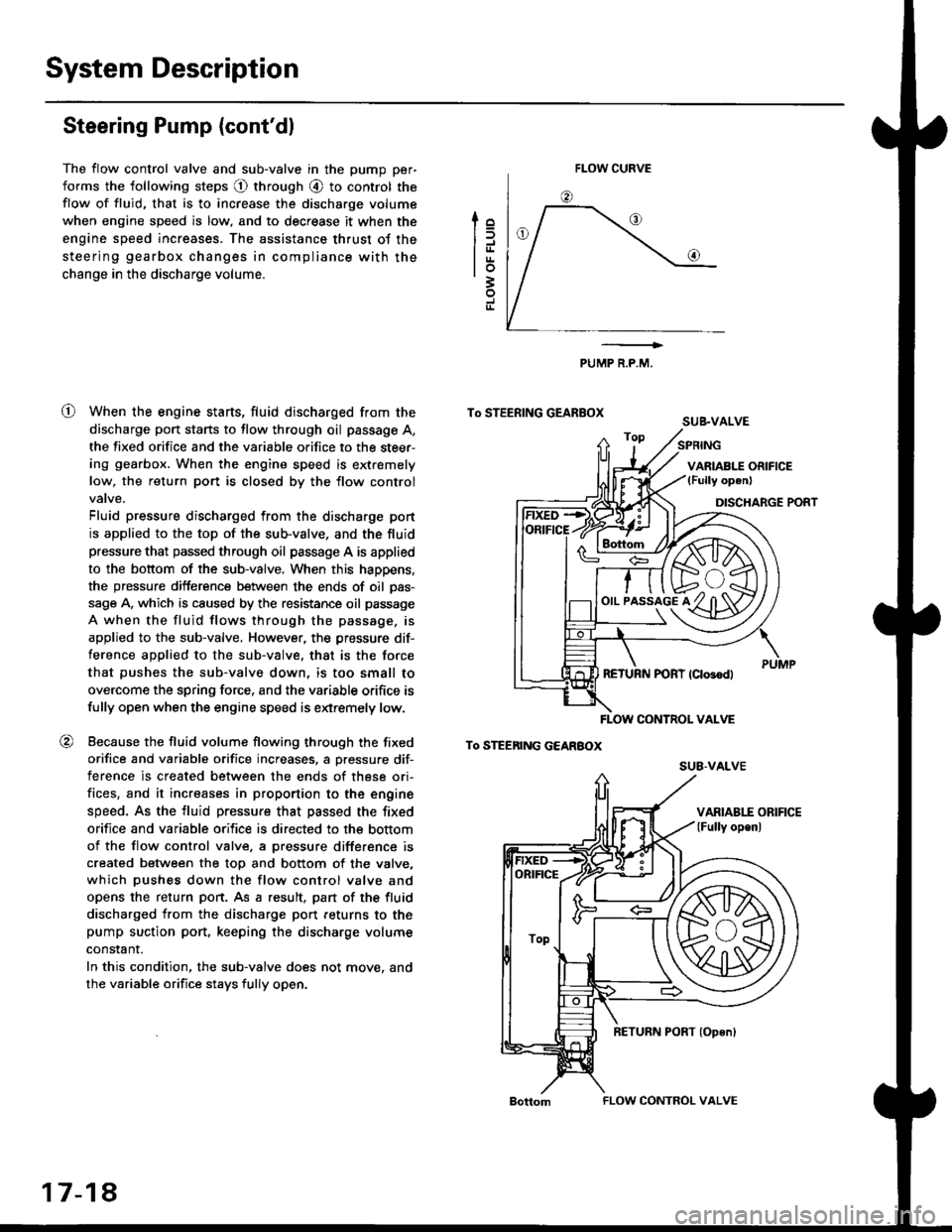

System Description

Steering Pump (cont'dl

The flow control valve and sub-valve in the pump per-

forms the following steps @ through @ to control the

flow of fluid, that is to increase the discharge volume

when engine speed is low, and to decrease it when the

engine speed increases. The assistance thrust of the

steering gearbox changes in compliance with the

change in the discharge volume.

When the engine starts, fluid discharged from the

discharge port starts to flow through oil passage A,

the fixed orifice and the variable orifice to the steer-

ing gearbox. When the engine speed is extremely

low, the return port is closed by the flow control

Fluid pressure discharged from the discharge port

is applied to the top of the sub-valve, and the fluid

pressure that passed through oil passage A is applied

to the bottom of the sub-valve. When this happens,

the pressure difference between the ends of oil pas-

sage A, which is caused by the resistance oil passage

A when the fluid flows through the passage. is

applied to the sub-valve, However, the pressure dif-

ference applied to the sub-valve. that is the force

that pushes the sub-valve down, is too small to

overcome the spring force, and the variable orifice is

fully open when the engine speed is extremely low.

Because the fluid volume flowing through the fixed

orifice and variable orifice increases, a pressure dif-

terence is created between the ends of these ori-

fices, and it increases in proportion to the engine

speed. As the fluid pressure that passed the fixed

orifice and variable orifice is directed to the bottom

of the flow control valve. a pressure difference is

created between the top and bottom of the valve,

which pushes down the flow control valve and

opens the return port. As a result, pan of the fluid

discharged from the discharge port feturns to the

pump suction port, keeping the discharge volume

constant.

In this condition, the sub-valve does not move. and

the variable orifice stays fully open.

lo

trrtrrlo3

J

o

PUMP R.P.M.

To STEERING GEARBOXSUB.VALVE

To STEEnING GEARBOX

FLOW CURVE

!rs+/f/ffih\

o,,-i^"l^tKzYt)91y ul3Yl

FLOW CONTNOL VALVE

su8-vALvE

ORIFICE

ToP

17-18

FLOW CONTROL VALVE