sensor HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 931 of 2189

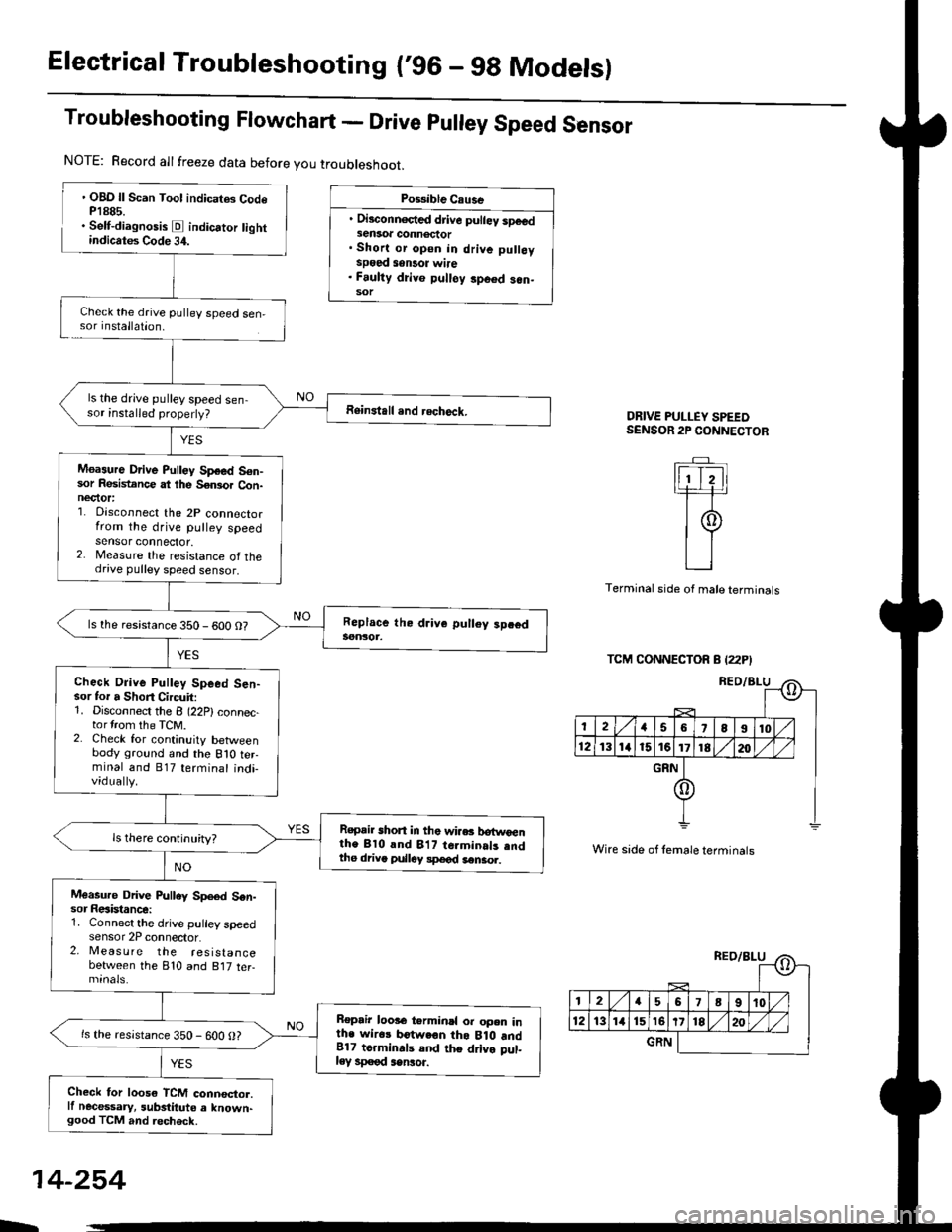

Electrical Troubleshooting {'96 - 9g Models)

Troubleshooting Flowchart - Drive pulley Speed Sensor

' OBD ll Scan Tool indicates CodeP1885.. Self-diagnosis E indicator tightindicates Code 34.

NOTE: Record all freeze data before you troubleshoot,

Check the drive pulley speed sen,sor installation.

ls the drive pulley speed sen-sor installed properly?

M6a3ure Drive Pulley Sp€ed S€n-sor Resistance ai the Seosor Con-nectot:1. Disconnect the 2P connectorfrom the drive pulley speedsensor connector.2. Measure the resistance of thedrive pulley speed sensor.

ls the resistance 350 - 600 O?

Check Orive Pulley Speed Sen-sor tor a Short Circuit:1. Disconnect the B (22P)connec-tortrom the TCM.2. Check for continuity betveenbody ground and the 810 ter-minal and 817 terminal individually.

Rspair shon in the wi.es botwoenthe Bl0 and 817 te.minals andthe driva pulloy 3peod 3eniol.

Measure Drive Pulley Sp€€d Sen-sor Re3istance:1. Connect the drive pulley speedsensor 2P connector.2, Meas u re the resistancebetween the 810 and 817 ter-mtnals.

Repair loos6 t.rmin.l or open inth. wiros botweon tho Bl0 and817 torminals and thg driva pul-ley sp€gd sensor.

ls the resistance 350 - 600 O?

Check tor looso TCM connoctor.ll necessary, substituto a known-good TCM and recheck.

Po$ible Cause

. Oisconn€cted drive pulley speedsensor connector. Shon or op€n in drive pulleyspged sonsor wire. Faulty drive pulley spoed s.n-sot

ORIVE PULLEY SPEEDSENSOR 2P CONNECTOR

lT_ T---_l

1 | 2 tlt|�]--+i-rr

l9tl

L_t

side oI male terminals

TCM CONNECTOR 8 I22PI

REO/BLU

Terminal

Wire side of female terminals

REO/8LU

J(l

24568910v1213t41516171820

GRN

o

1215iliI;W1M

1213111516tdil)lil/l

GRN

14-254

b

Page 932 of 2189

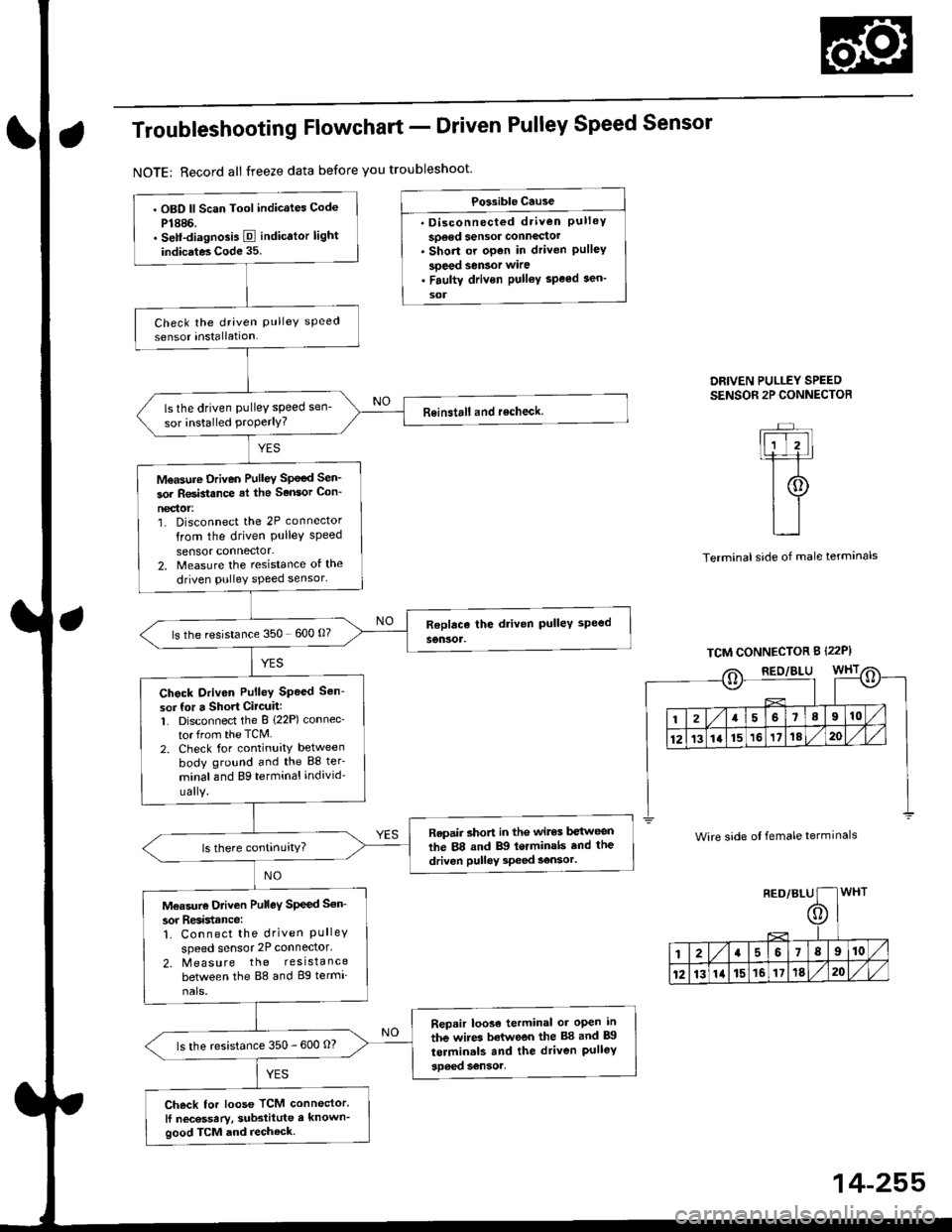

Troubleshooting Flowchart - Driven Pulley Speed Sensor

NOTE: Record all freeze data before you troubleshoot'

Po3sible Cause

. Disconnected dtiven PulleYso6ed sensor connector. Short or open in driven PulleYapeed sen3or wire. Faulty driven PulloY sPeod 3en-

DRIVEN PULLEY SPEEOSENSOR 2P CONNECTOR

l-_r-|1 2l

:-

t9tt

L_.1

Terminal side of male

TCM CONNECTOR I l22p)

WHT

termrnals

. OBD ll Scan Tool indicates Code

P1886.. Sell-diagnosis E indicator light

indicates Code 35.

ls the driven Pulley speed sen-

sor installed proPerlY?

M€asure Driven Pulley SP€ed Sen_

sor Resbt nce at the Sensor Con-

neclof:1. Disconnect the 2P connector

from the driven PUlley speed

sensor connectol.2. Measure the resistance ot the

driven pulley speed sensor.

ls the resistance 350 600 0?

Check Driven Pulley Speed Sen-

sor {or a Short Circuit:1. Disconnect the B (22P) connec_

tor from the TCM.2. Check for continuity between

body ground and the BB ter

minal and 89 terminal individ'

Repair sho.t in the wiles between

lhe 88 and Bg lerminals tnd the

driven pulleY 3Peed 3€nsor.

Measure Driven Pulley SPeed S€n-

sor Reistance:1. Connect the driven PulleYspeed sensor 2P connector'

2. M easu re the resistance

between the 88 and Bg terml_

nals.

Repair loos€ terminal or oPen in

the wires between the Bg and Bg

torminals and the dtiven Pulley3D6eO S6n50a,

ls the resistance 350 - 600 O?

Check lor loose TCM connector.

lf necessary, substitute a known_good TCM and rechack.

^\, REO/BLUo

12a68910

12131a15'16'171820

Wire side oI female terminals

RED/BLU]

o

WHT

1216810

12131a1516171820

14-255

Page 933 of 2189

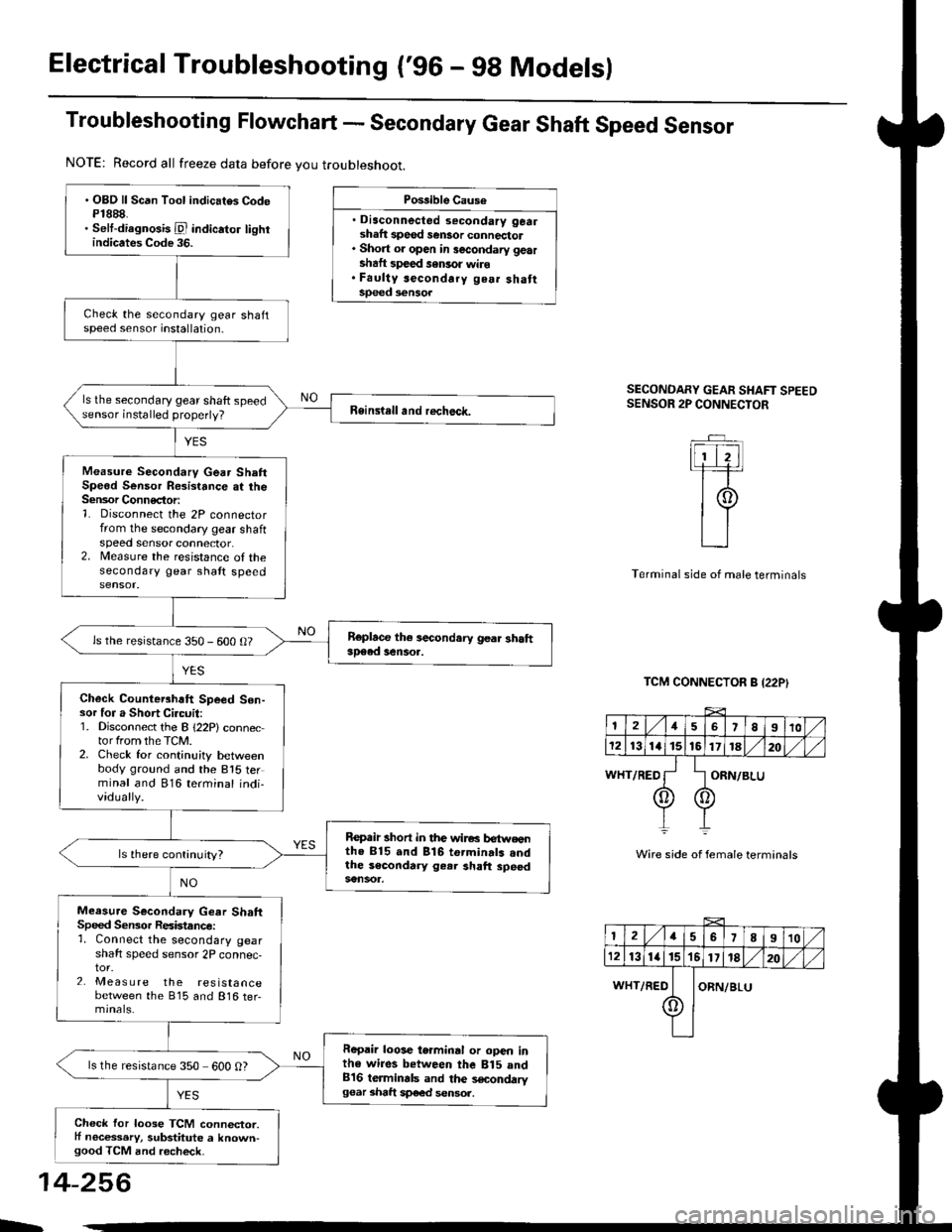

Electrical Troubleshooting ('96 - 98 Modelsl

Troubleshooting Flowchart - Secondary Gear Shaft Speed Sensor

Po$ible Cause

. Disconnected secondary gealshaft speod sen3or connectol. Short ol open in s€condary gearshaft spe€d sen3or wiro. Faulty secondary gear shattspeed s€nsor

SECONDARY GEAR SHAFT SPEEDSENSOR 2P CONNECIOR

llll;ll

T_T

l@

tl

LJ

side of male terminalsTerminal

TCM CONNECTOR B {22P}

Wire side of female termanals

14-256

NOTE: Record all freeze data before you troubleshoot.

. OBD ll Scan Tool indicates CodeP1888.. Selt-diagnosis Iq indicator lightindicates Code 36.

Check the secondary gear shaftspeed sensor installation.

ls the secondary gear shaft speedsensor installed properly?

Measure Secondary Gear SheftSpeod Sensor R8istance at theSensor Connector:1. Disconnect the 2P connectorfrom the secondary gear shaftspeed sensor connector.2. Measure the resistance ol thesecondary gear shalt speed

ls the resistance 350 - 600 0?

Check Counterchaft Speed Son-sor for a Short Circuit:1. Disconnect the B 122P) connectorfrom the TCM.2. Check for continuity betweenbody ground and the 815 terminal and 816 terminal individually.

Repair short in the wir€6 bctuveenth. 815 and 816 torminrls.ndthe s€condary ge.r shaft speodls there continuity?

Measu.e Secondary Gear ShattSpeed Sensor Resistance:1. Connect the secondary gearshaft speed sensor 2P connec-

2. Meas u re the resistancebetween the 815 and 816 te.mrnals.

Reprir loose terminal or opcn inthe wires between the 815 and8'16 terminals and the secondaryg€ar shaft sp€ed s€nsor,

ls the resistance 350 600 O?

Check lor loose TCM connector.lf n€cessary, substitute a known-good TCM and recheck.

I2156910

12131a1516171820

WHT/RED T - ORN/BLU

D (o.

1a5678I10

1213141515171820

WHT/REI

A

I

ORN/BLU

L

Page 956 of 2189

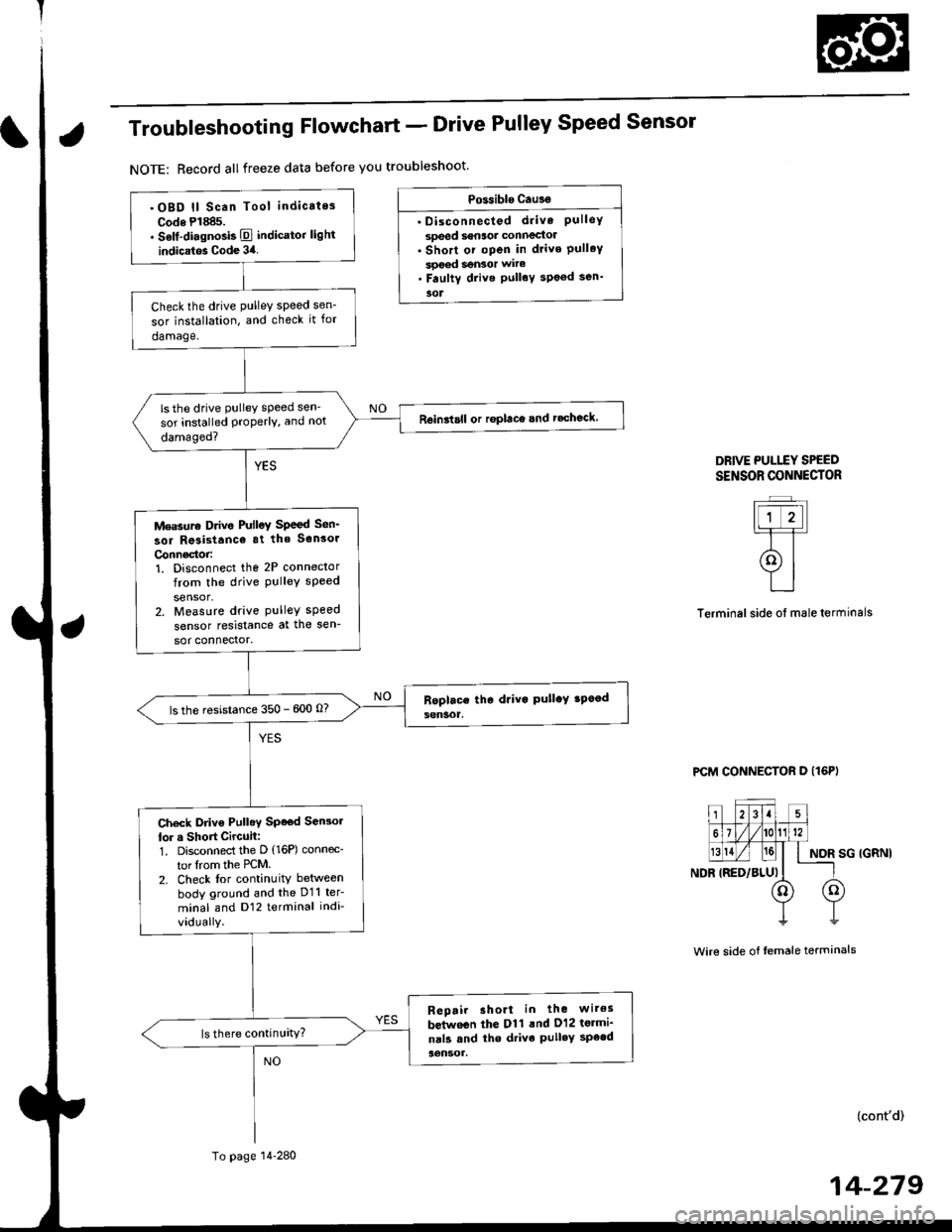

Troubleshooting Flowchart - Drive Pulley Speed Sensor

NOTE: Record allfreeze data before you troubleshoot'

Possible Cau3€

. Disconnected diive PulleYsoeed s6n3or connectol. Short or open in drive Pull.Ysooed sonsor wire. FaultY drive PulleY spo€d sen'

301

DRIVE PULEY SPEED

SENSOR @NNEfiOR

Terminal side of male terminals

PCM CONNECTOR D (16PI

NDR SG IGRNI

Wire side o{ Iemale terminals

(cont'd)

14-279

.OBD ll Scan Tool indicates

Code Pl885.. Selt-diagnosb E indicator light

indicatos Code 34

check the drive pulleY sPeed sen-

sor installation, and check it for

damage.

ls the drive PulleY speed sen-

sor installed properly, and not

damaged?

Rein3tall or roplace and techeck

Measuro Drive PulleY Speed Sen_

sor Ro3istanco at the Sonsol

Connector:1. Disconnect the 2P conneclor

from the drive Pulley speed

sensor,2. Measure drive Pulley speed

sensor resislance at the sen-

sor connecror.

ls the resistance 350 - 600 O?

Check Drivo PulleY SP6€d Sen3o.

lor . Short Circuit:1. Disconnect the D {16P) connec-

torlrom the PCM.

2. Check lor continuity between

body ground and the D11 ter

minal and D'l2 terminal indi

vidually.

Repai. short in the wiles

between the Dll lnd D12 termi-

nals and iho drive Pull.Y speed

To page 14-280

Page 957 of 2189

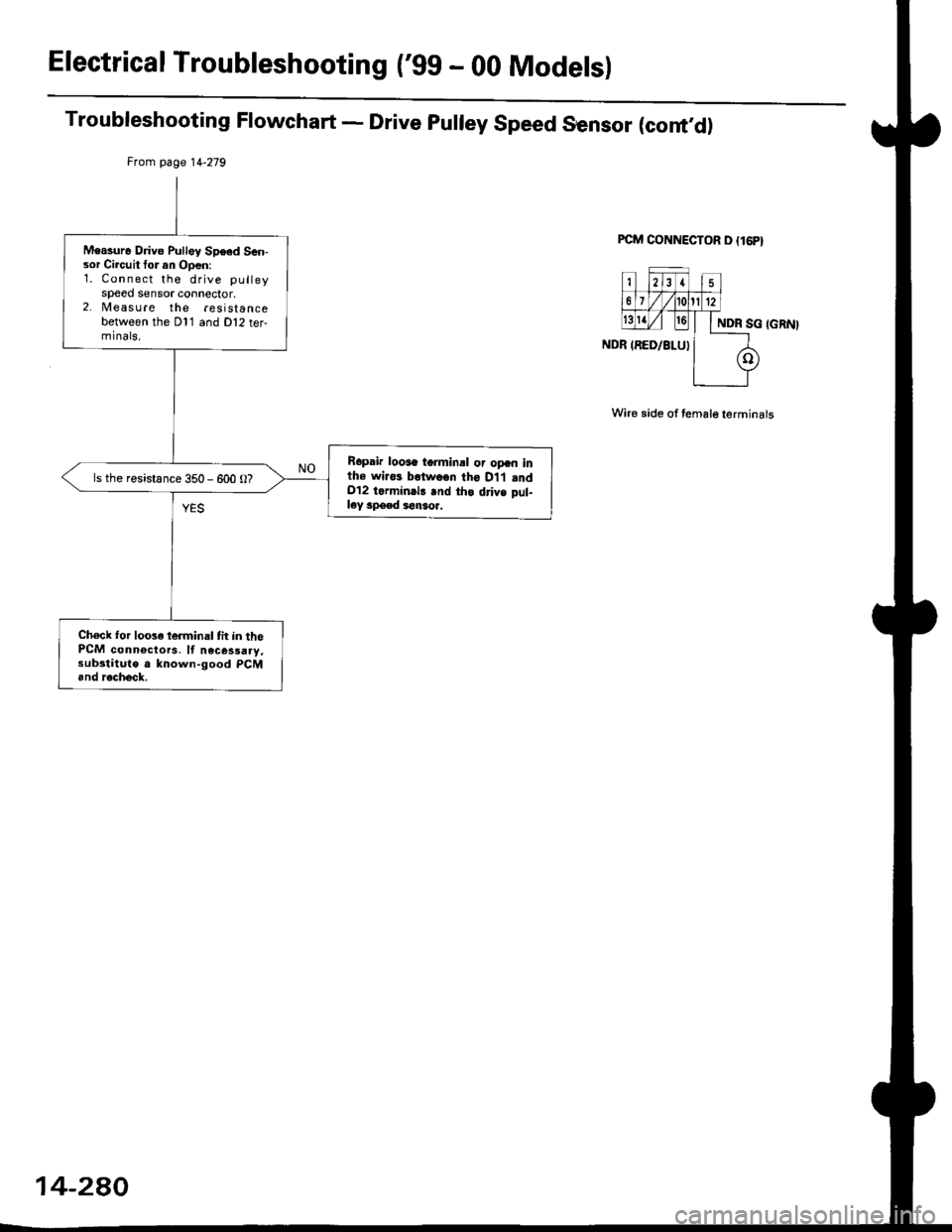

Electrical Troubleshooting ('gg - 00 Models)

Troubleshooting Flowchart - Drive pulley Speed Sensor (cont,d)

PCM CONNECTOR D {16P}

Wire side of temale terminals

From page 14-279

Measure Drivo Pulley Speed Sen-sor Circuit tor an Open:1. Connect the drive pulleyspeed sensor connector,2. lvleasu re the resistancebetween the Dl1 and Dl2 ter-minals.

R6pair loose tgrminal or opan inthe wiros betwo€n tho D1,l .ndOl2 tarminrl! .nd th. drivs pul-ley speed *n3or.

ls the resistance 350 - 600 O?

Ch6ck for loose lerminal tit in thePCM connectors, ll nece3saay,substituto a known-good PCM6nd r€check.

14-280

Page 958 of 2189

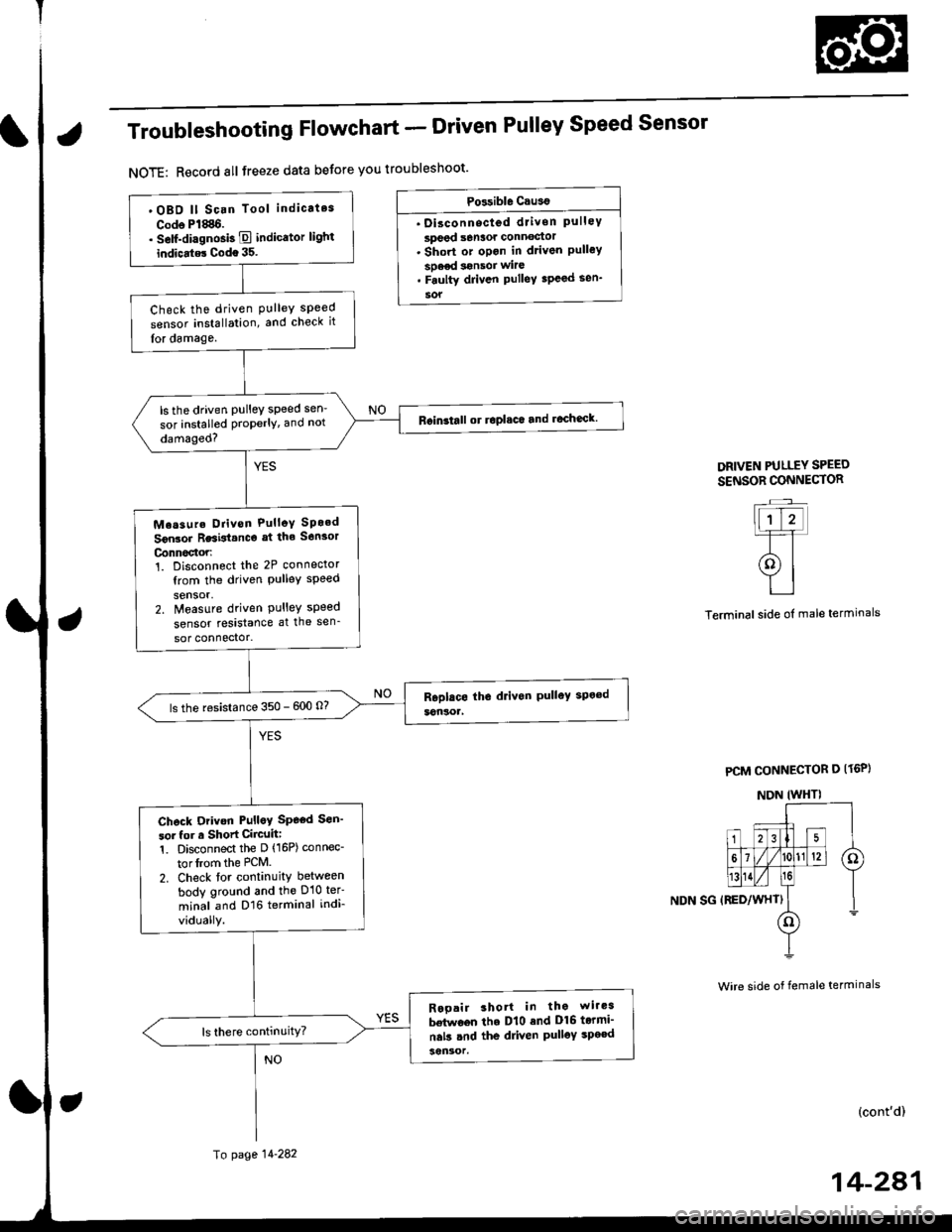

Troubleshooting Flowchart - Driven Pulley Speed Sensor

NOTE: Record all freeze data betore you troubleshoot'

Po3sible Caus€

' Oisconnected driven PulleYspeed s6nlor connoctor. Short or opon in d.iven Pulleysoeed sonsol wirc. Faulty driven Pulley speed sen_

sor

DRIVEN PULLEY SPEED

SENSOR CONNECTOR

Terminal side ol male terminals

FCM CONNECTOR D If6P)

NDN IWHTI

Wire side of female terminals

(cont'd)

'OBD lt Sc.n Tool indicates

Code Pl886.. Self-diagnosb E indicator light

indicrt€. Codo 35.

Check the driven Pulley speed

sensor installation, and check it

Ior damage.

lsthe driven pulleY speed sen'

sor installed ProPerly, and not

damaged?

Boin3tall or ropl.ca and recheck.

M..sure Drivon PulloY SPoed

Sonsor Rosblanco at the S6n3or

Conn6ctori1. Disconnect the 2P connector

trom the driven PUlley sPeed

sensor,2. lveasure driven Pulley speed

sensor resistance at the sen_

sor connector.

ls the resistance 350 - 600 0?

Check Dtivon Pulloy SP€ed Sen'

sor for a Short Circuit:

1. Disconnect the D (16P) connec-

torfrom the PCM.

2. Check tor continuity between

body ground and the D10 ter'

minal and Dl6 terminal indi-

vidually.

Raoair shott in tho wi.6s

betwoon th. Dlo end D16 tormi'

nak .nd the ddven Pulley spo€d

Fo page 14'282

14-2A1

Page 959 of 2189

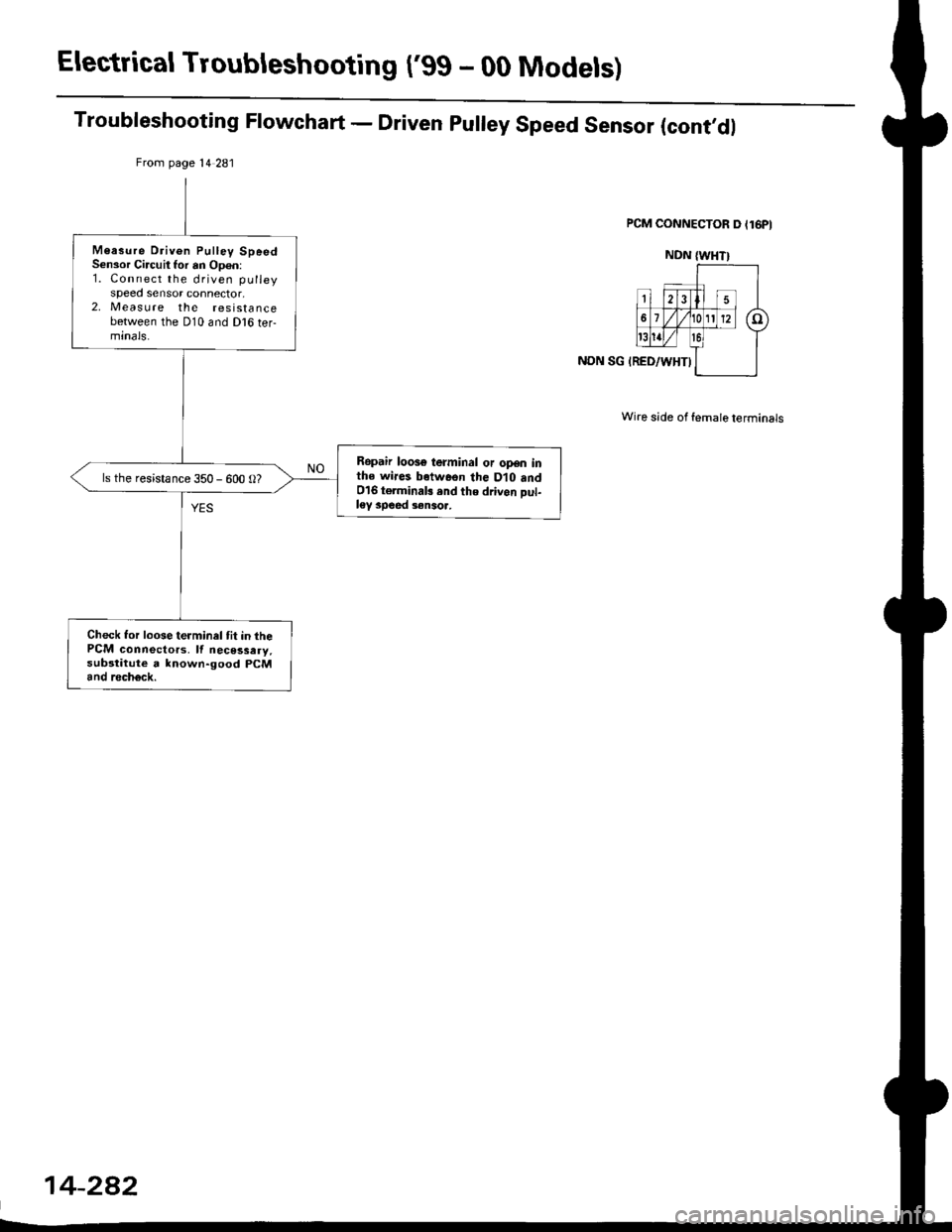

Electrical Troubleshooting ['gg - 00 Models)

Troubleshooting Flowchart - Driven pulley Speed Sensor (cont,dl

NON SG IRED/WHTI

Wire side of female terminals

From page l4 281

M6asure Driven Pulley SpeedSensor Circuit Ior an Op€n:1. Connect the driven pulleyspeed sensor connector,2, Measure the resistancebetween the D10 and Dl6 ter-minals.

Rgpair loose terminal or open inthe wires botwosn the Dlo and016 torminab rnd the drivon Dul-ley speed 3ensoa,

ls the resistance 350 - 600 O?

Check tor loose terminal tit in thePCM connectors, lf necessary,sub3titute a lnown-good PCMand rech6ck.

14-282

Page 960 of 2189

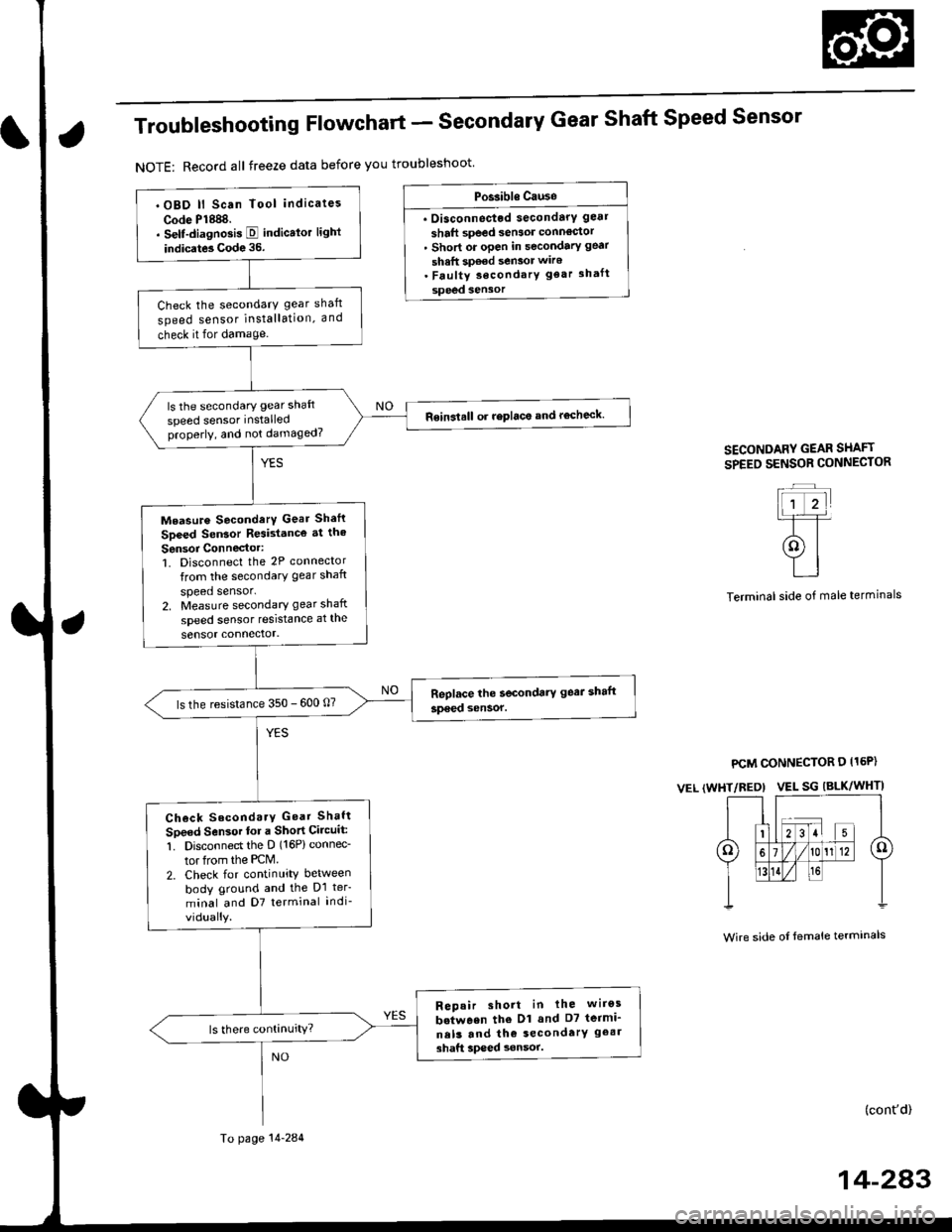

Troubleshooting Flowchart - Secondary Gear Shaft Speed Sensor

NOTE: Record all freeze data before you troubleshoot

Po$ible Causo

. Oisconnectod secondarY gear

shaft speed sensor conn66or' short or open in secondary gear

shaft spe€d sensor wiro. Faulty secondarY gear 3haft

sPeed sensor

SECONDARY GEAR SHAFT

SPEEO SENSOR CONNECTOR

Terminal side of male terminals

PCM CONNECTOR D I15P)

VEL (WHT/REO) VEL SG IALK/WHTI

Wire side oI female terminals

(cont'd)

14-243

' OBD ll Scan Tool indicates

Code P1888.. Self-diagnosis E indicalor light

indicats Code 35.

Check the secondarY gear shaft

speed sensor installation, and

check it for damage.

ls the secondary gear shaft

speed sensor installedproperly, and not damaged?

Reinatall or replace and rocheck.

Measure SocondarY Gear Sh.ft

Speed Sen3or Resistance at the

Sensor Connector:1. Disconnect the 2P connector

trom the secondary gear shaft

speed sensor.2. Measure secondary gear shaft

speed sensor resistance at the

sensor connector.

ls the resistance 350 - 600 0?

Check SecondarY Gear Shaft

Speed Sensor lor a Short Circuit:

1. Disconned the D (16P) connec-

tor from the PCM.

2. Check for continuity between

body ground and the D1 ter-

minal and D7 terminal indi-

vidually.

Repair short in the wiros

b.tween the Dl and D7 termi_

ne13 and th€ secondarY geal

3haft lpeed sonsor.

To page 14-284

Page 961 of 2189

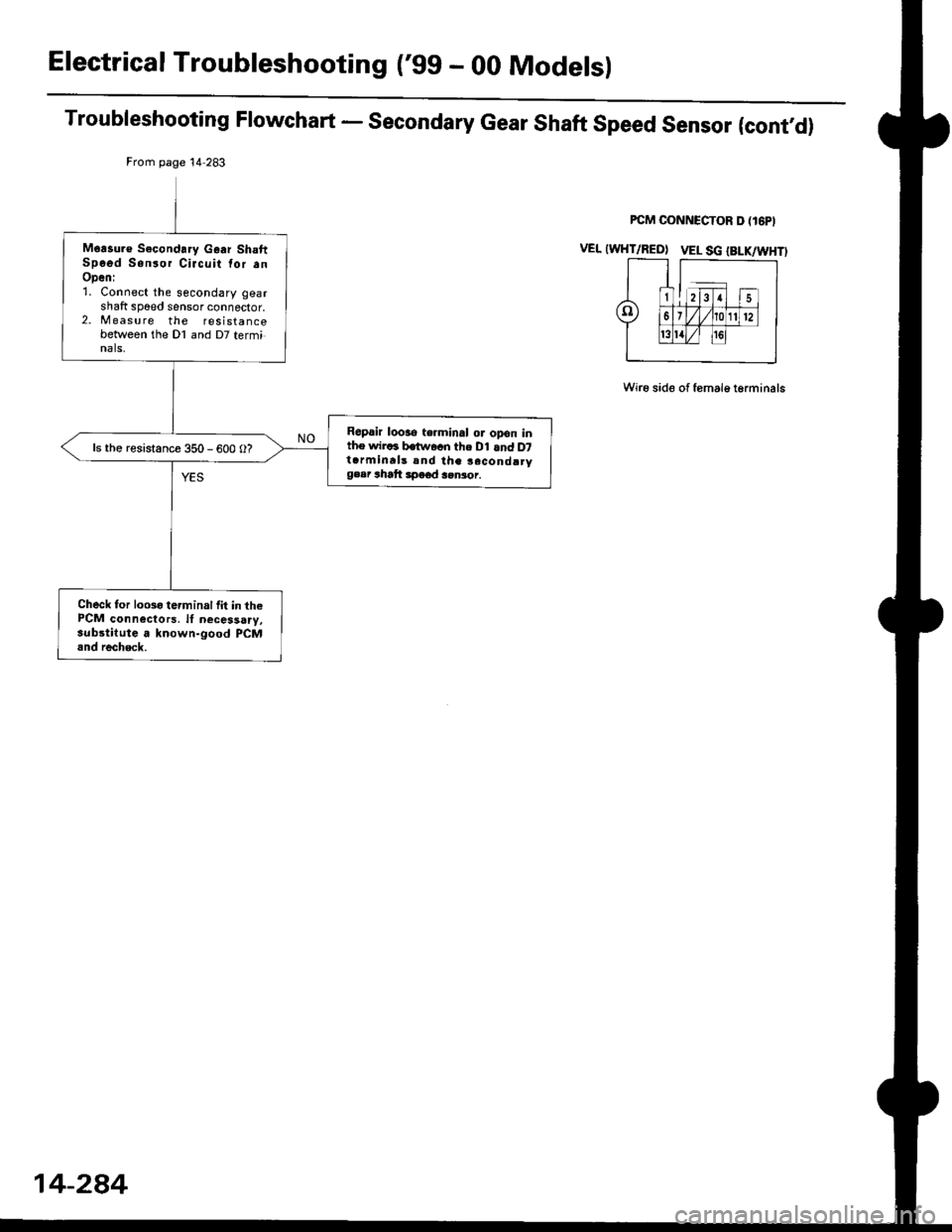

Electrical Troubleshooting ('gg - 00 Modelsl

Troubleshooting Flowchart - Secondary Gear Shaft Speed Sensor (cont'd)

Wi16 side of female t6rminals

From page 14 283

Moasu.€ Secondary Gaar ShaftSpo6d Sonsor Circuit tor anOpeni1. Connect the secondary gearshaft sp6ed sensor connector,2. M easu re the resistancebetween the Dl and D7 terminals,

Repair looao terminal or opon inthe wiraa batuvacn the Dl and D7t.rminrls snd the second!rygeer rhatt 3peod 3.nior.

ls the resistance 350 - 600 O?

Check for looso terminal lit in thePCM connectors. lf necessary,substilute a known-good PCM.nd recheck.

14-284

Page 969 of 2189

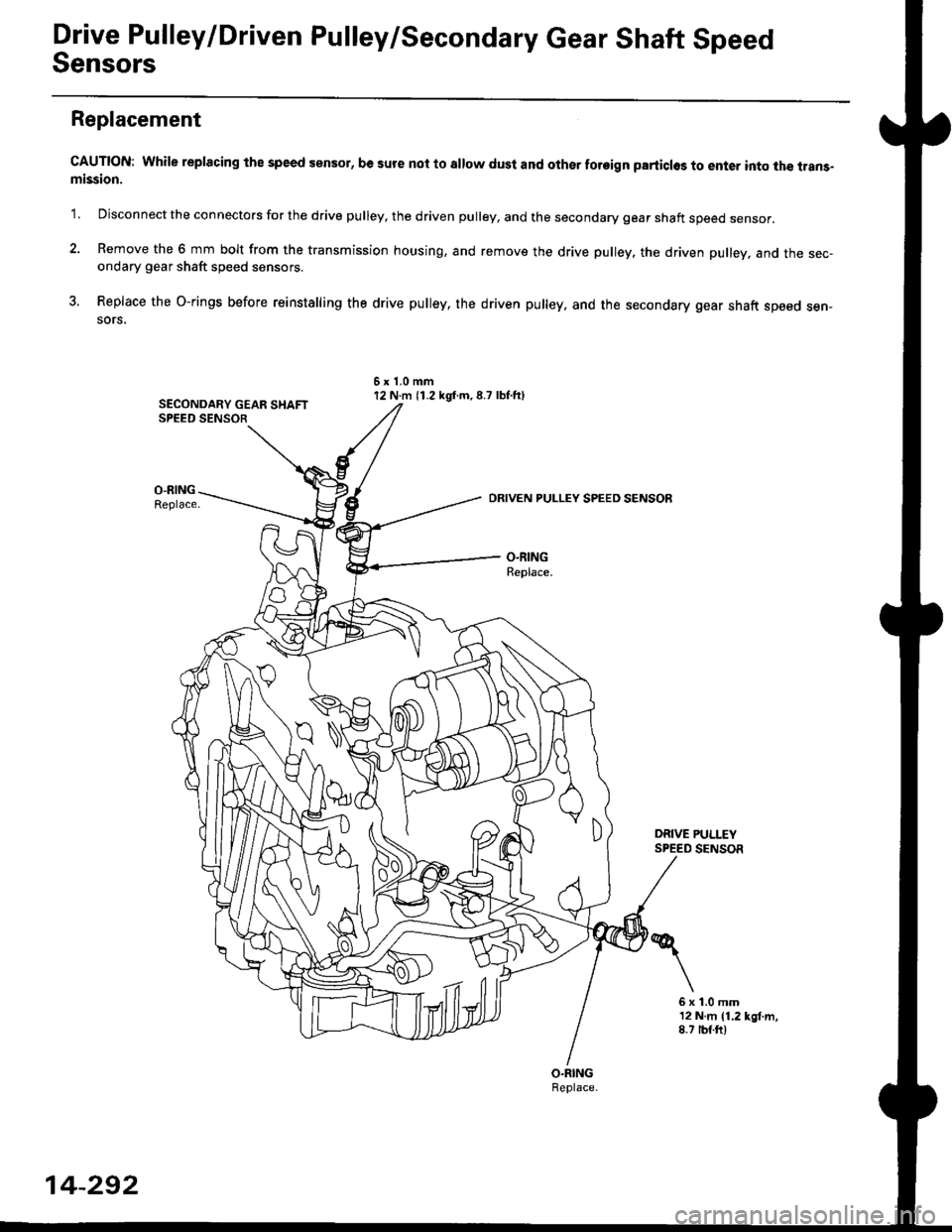

Drive Pulley/Driven Pulley/Secondary Gear Shaft Speed

Sensors

Replacement

CAUTION: While replacing the speed sensor, be sure not to allow dust and other foreign parliclos to enter into the trans-mission.

'1. Disconnect the connectors for the drive pulley, the driven pulley, and the secondary gear shaft speed sensor.

2. Remove the 6 mm bolt from the transmission housing, and remove the drive pulley. the driven pulley, and the sec-ondary gear shaft speed sensors.

3. Replace the O-rings before reinstalling the drive pulley, the driven pulley, and the secondary gear shaft sp€ed sen-sors.

6x1.0mm12 N.m (1.2 kgf.m,8.7 lbf.ft)

6x1.0mm12 N.m (1.2 kgt.m,8.7 tbf.ft)

DRIVEN PULLEY SPEED SENSOB

14-292