Switch ac HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 1564 of 2189

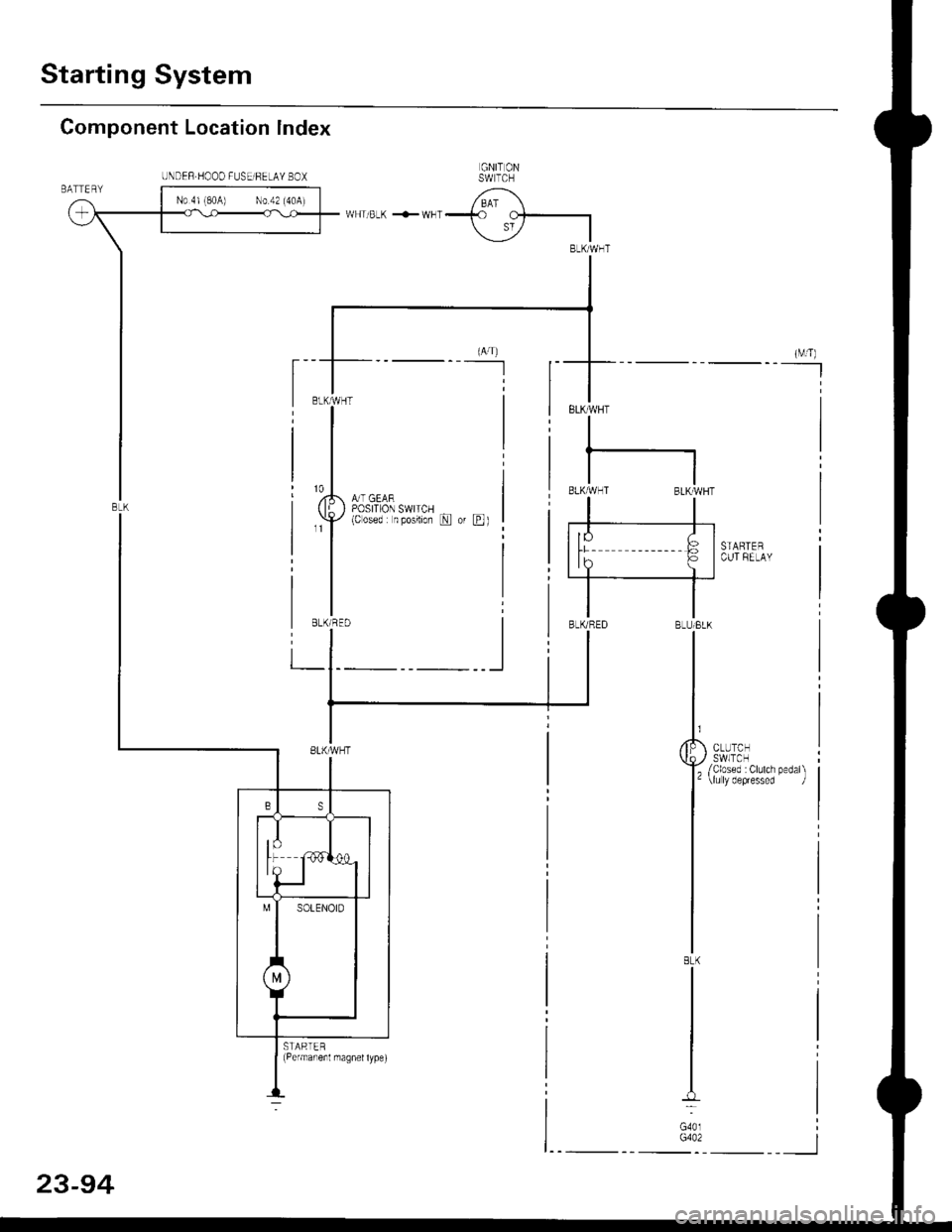

Starting System

Component Location lndex

GNIT ONSW TCH

t,U,-*€,-l

&T GEARPOSITION SWITCH(Cosed n posilion N or E)

ELKMHT

I

tl81X,4{HT BLKIWHT

STARTERCUT FELAY

STAPTER(Permaneit nragnel type)

N0 4l (80A) N0 42 (40A)

UNDEF.HOOO FUSEiFELAY BOX

-

__l

23-94

Page 1565 of 2189

-Starter Test

NOTE; The air temoerature must be between 59 and

100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described,

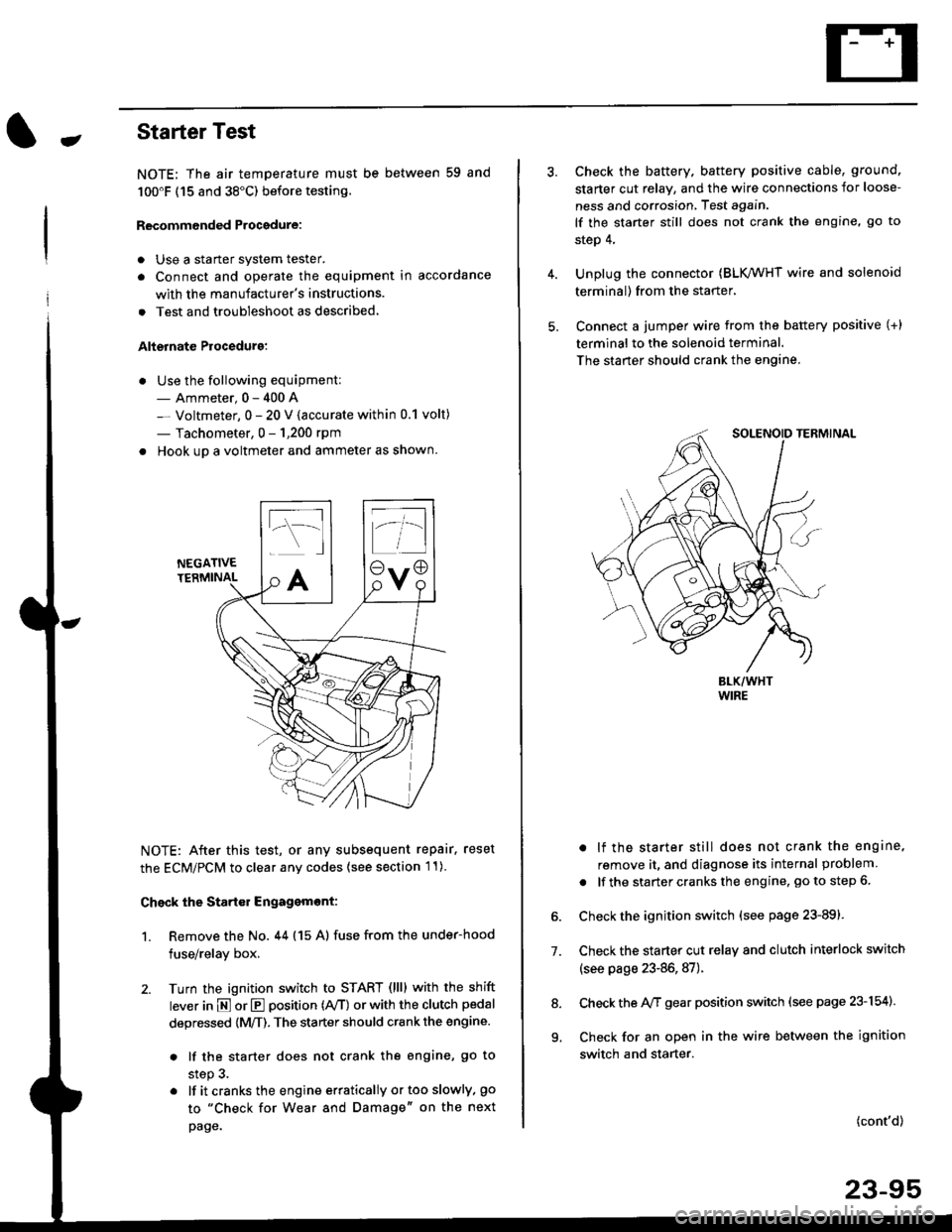

Alternate Procedurg:

. Use the following equipment:- Ammeter, 0 - 400 A

- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

- Tachometer, 0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NEGATIVETERMINAL

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section l1)

Check the Start€r Engagemont:

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

2. Turn the ignition switch to START (llll with the shift

lever in E or E position (rVT) or with the clutch pedal

depressed {M/T). The starter should crank the engine.

. lf the starter does not crank the engine, go to

step 3.

. lf itcranksthe engineerraticallyortooslowly, go

to "Check for Wear and Damage" on the next

page.

Check the battery. battery positive cable, ground,

starter cut relay, and the wire connections for loose-

ness and corrosion, Test again.

lf the starter still does not crank the engine, go to

step 4,

Unplug the connector (BLK,/WHT wire and solenoid

terminal) from the starter,

Connect a jumper wire from the battery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem

. lf the startercranksthe engine, goto step 6.

Check the ignition switch (see page 23-891.

Check the starter cut relay and clutch interlock switch

(see page 23-86,87).

Check the A/f gear position switch (see page 23-154).

Check for an open in the wire between the ignition

switch and starter.

7.

(cont'd)

23-95

9.

Page 1566 of 2189

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

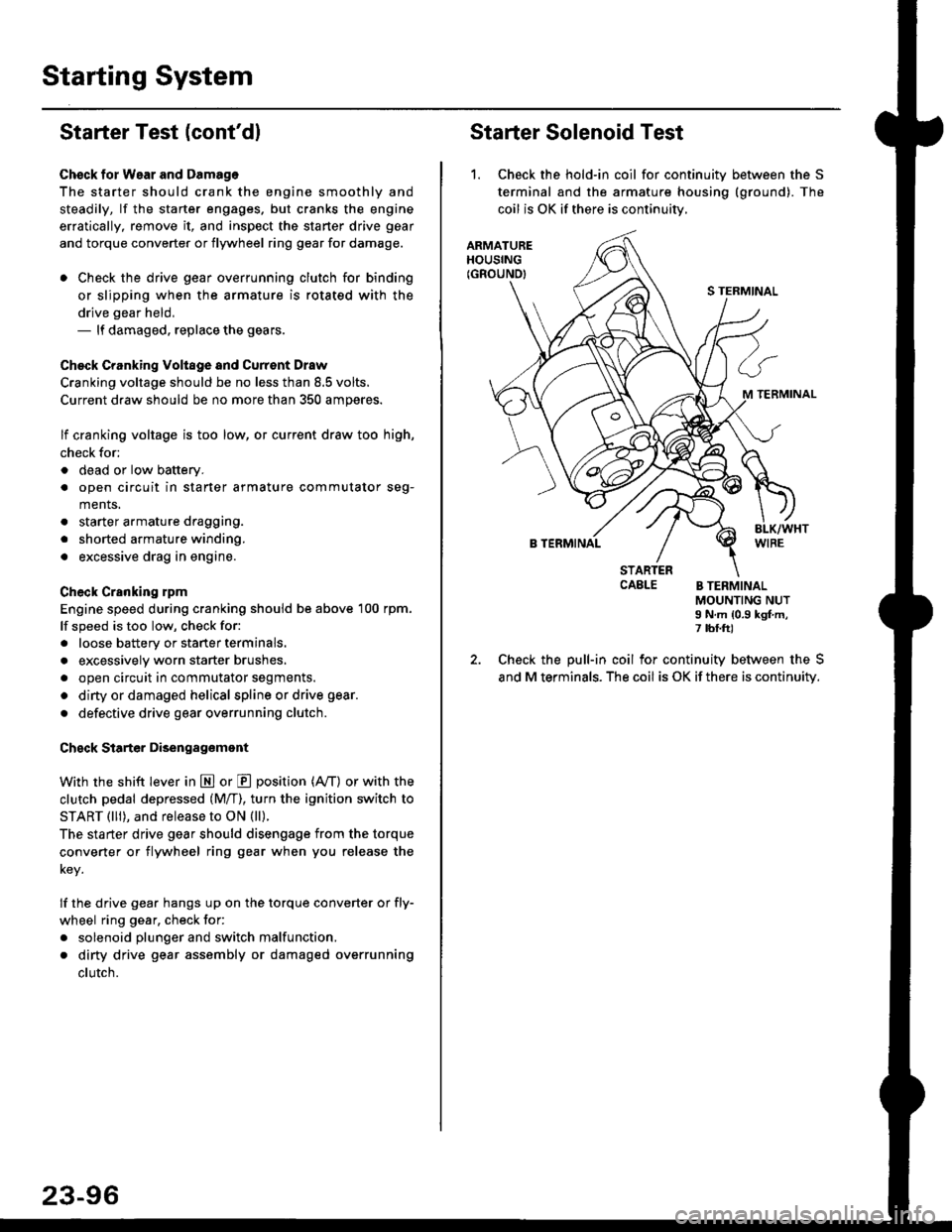

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1579 of 2189

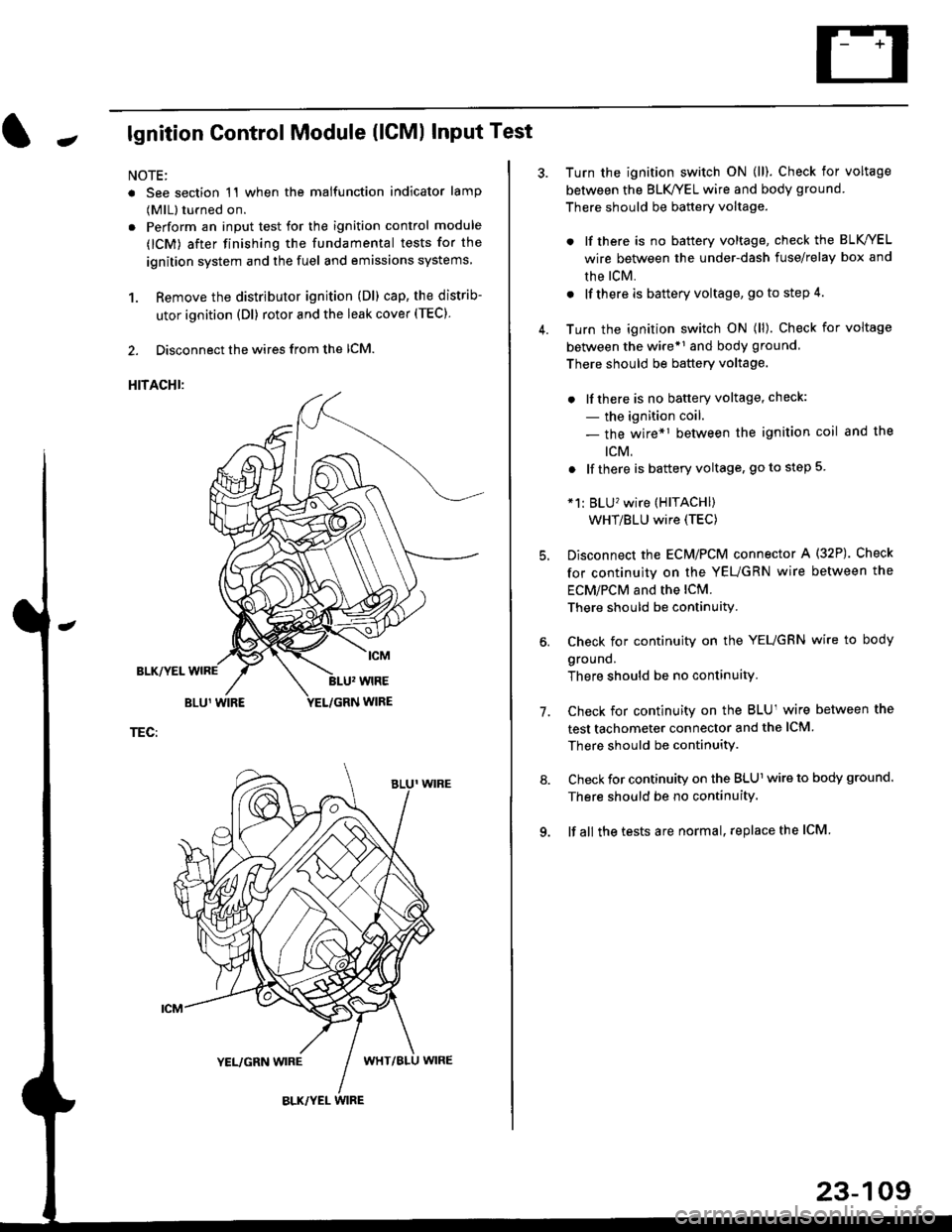

Jlgnition Control Module (lCMl Input Test

NOTE:

. See section 1'l when the malfunction indicator lamp

(MlL) turned on.

. Perform an input test for the ignition control module

(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems

1. Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor and the leak cover (TEC).

2. Disconnect the wires from the lCM.

HITACHI:

BLK/YEL

TEC:

Turn the ignition switch ON (ll). Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

. lf there is no battery voltage, check the BLK/YEL

wire between the under-dash fuse/relay box and

rhe lcM.

. lf there is battery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the wire*r and body ground

There should be battery voltage.

. lfthere is no battery voltage, check:

- the ignition coil.

- the wire*1 between the ignition coil and the

tcM.

. lf there is battery voltage, go to step 5

*1: BLU'�wire (HITACHI)

WHT/BLU wire (TEC)

Disconnect the EcM/PCM connector A (32P). Check

for continuity on the YEUGRN wire between the

ECM/PCM and the lCM.

There should be continuity.

Check for continuity on the YEUGRN wire to body

ground.

There should be no continuity.

Check for continuity on the BLUl wire between the

test tachometer connector and the ICM

There should be continuitY.

Check for continuity on the BLUl wire to body ground.

There should be no continuity.

lf all the tests are normal, replace the ICM

7.

23-109

Page 1583 of 2189

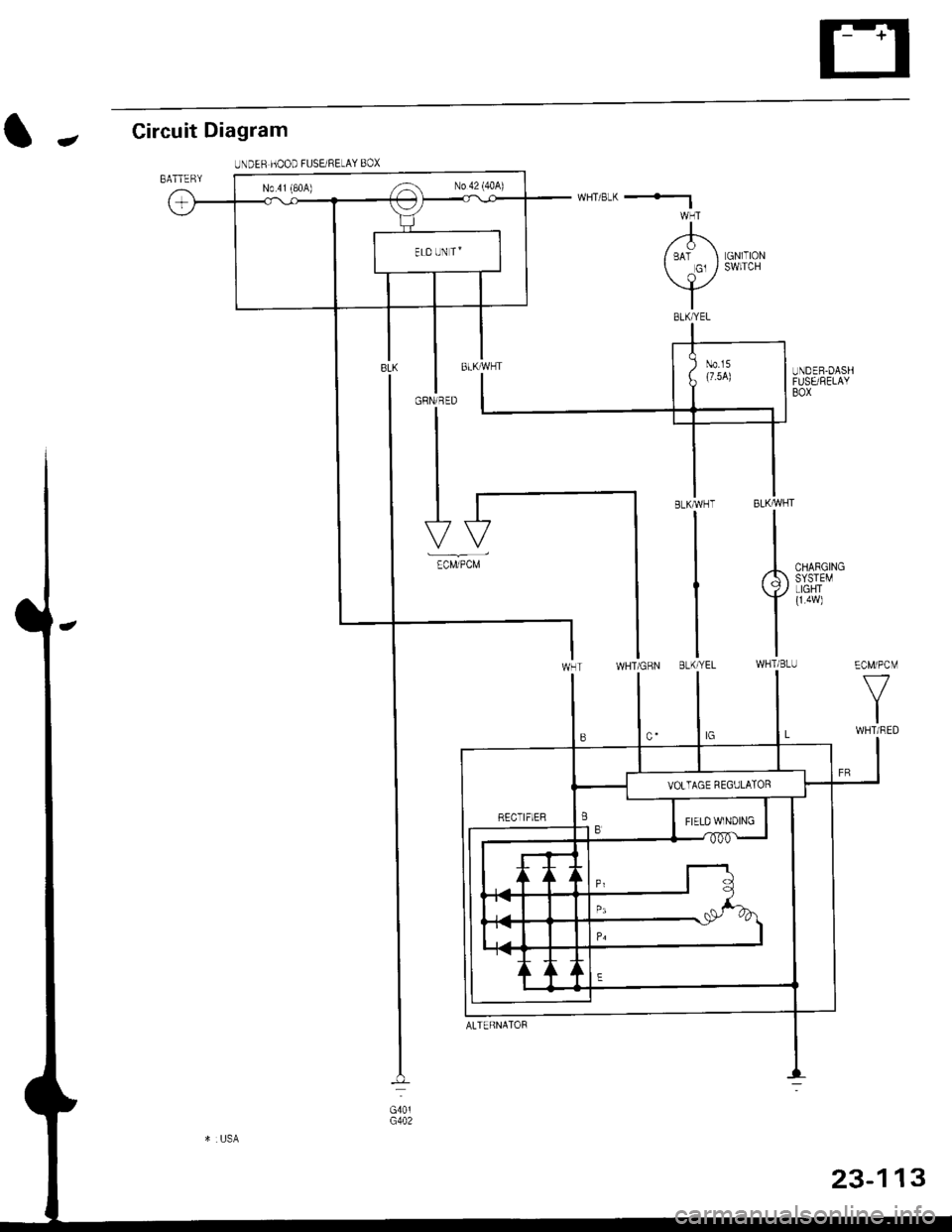

Circuit Diagram

IJNDER HOOD FUSEi RELAY BOX

-

BATTERY

LGNlTIONSWITCH

I

,'-F\I BAT I Gl /

\l_/

I

GRN/RED

I

N0.41 (80A) ,-a No 42 (40A)

ECM/PCM

f7

IWHT/RED

CHARGINGSYSTEMLIGHTI

TWHTi BLU

1323-1

ALTERNATOF

Page 1584 of 2189

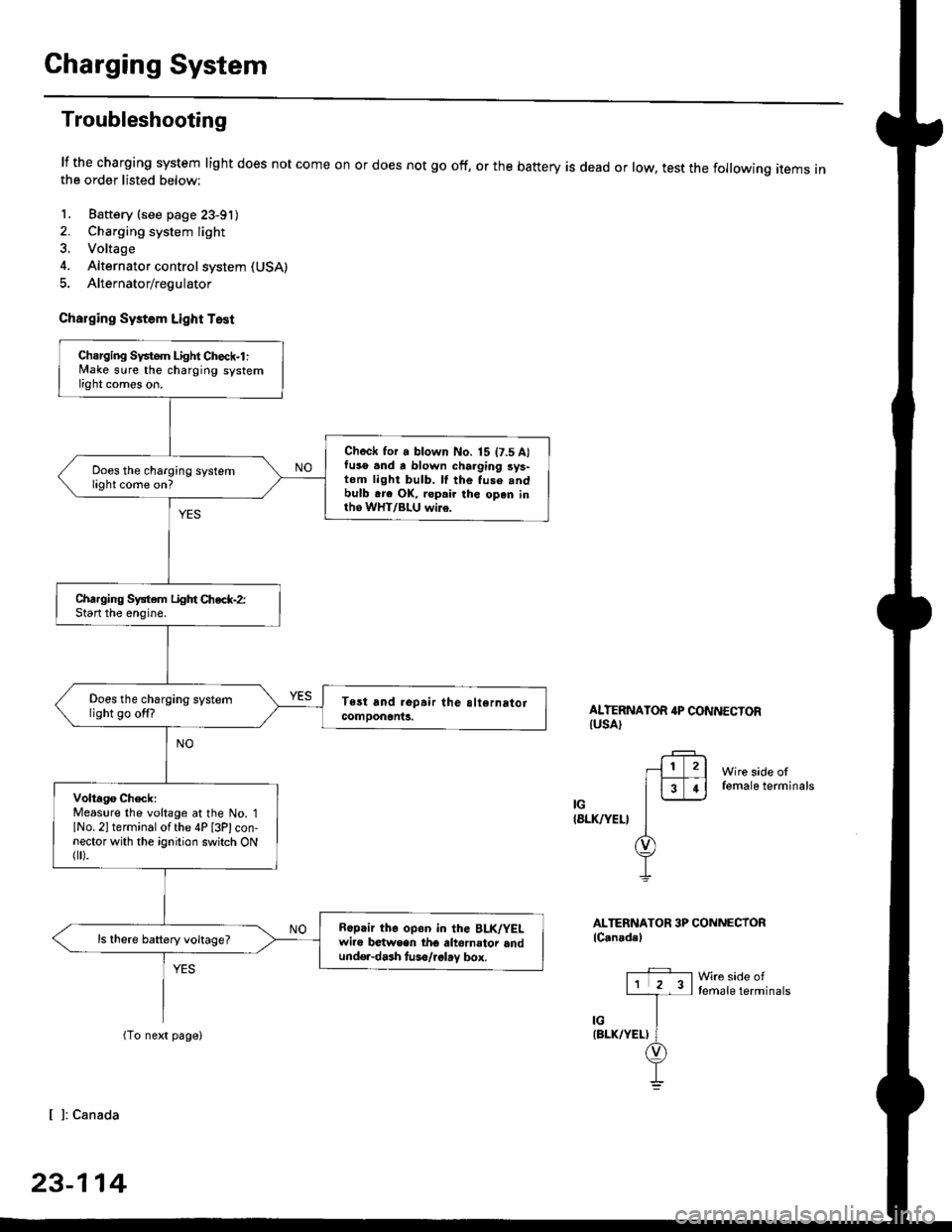

Charging System

Troubleshooting

lf the charging system light does not come onthe order listed below:

1. Baftery (see page 23-91)

2. Charging system light

3. Voltage

4. Alternator control system (USA)

5. Alternator/regulator

Charging Systom Light Test

or does not go off, or the battery is dead or low, test the following items in

ALTERNATOR 4P CONNECTORIUSA)

Wire side offemale terminals

IG(8LK/YEL}

ALTERNATOR 3P CONNECTORlC.nadal

Wre side oftemale terminals

[ ]: Canada

23-114

Charging Svstem Light Check-l :lvlake sure the charging systemlight comes on.

Check for a blown No. 15 t7.5 A)fuso .nd a blown charging sys-tom light bulb. ll the fuse .ndbulb .re OK, ropair the open inth6 WHT/BLU wi16.

Does the charging systemlight come on?

Charging System Light Chec*-2:Start the enoine.

Does the charging systemlight go off?

Volta96 ChecklMeaslre the voltage at the No. 1lNo. 2l terminal of the 4P [3Plcon-nector with the ignition switch ONflr).

R6p.ir the op6n in the BLK/YELwire b€twsen tho altornator andund€r-dash tuso/.glay box.

ls there battery voltage?

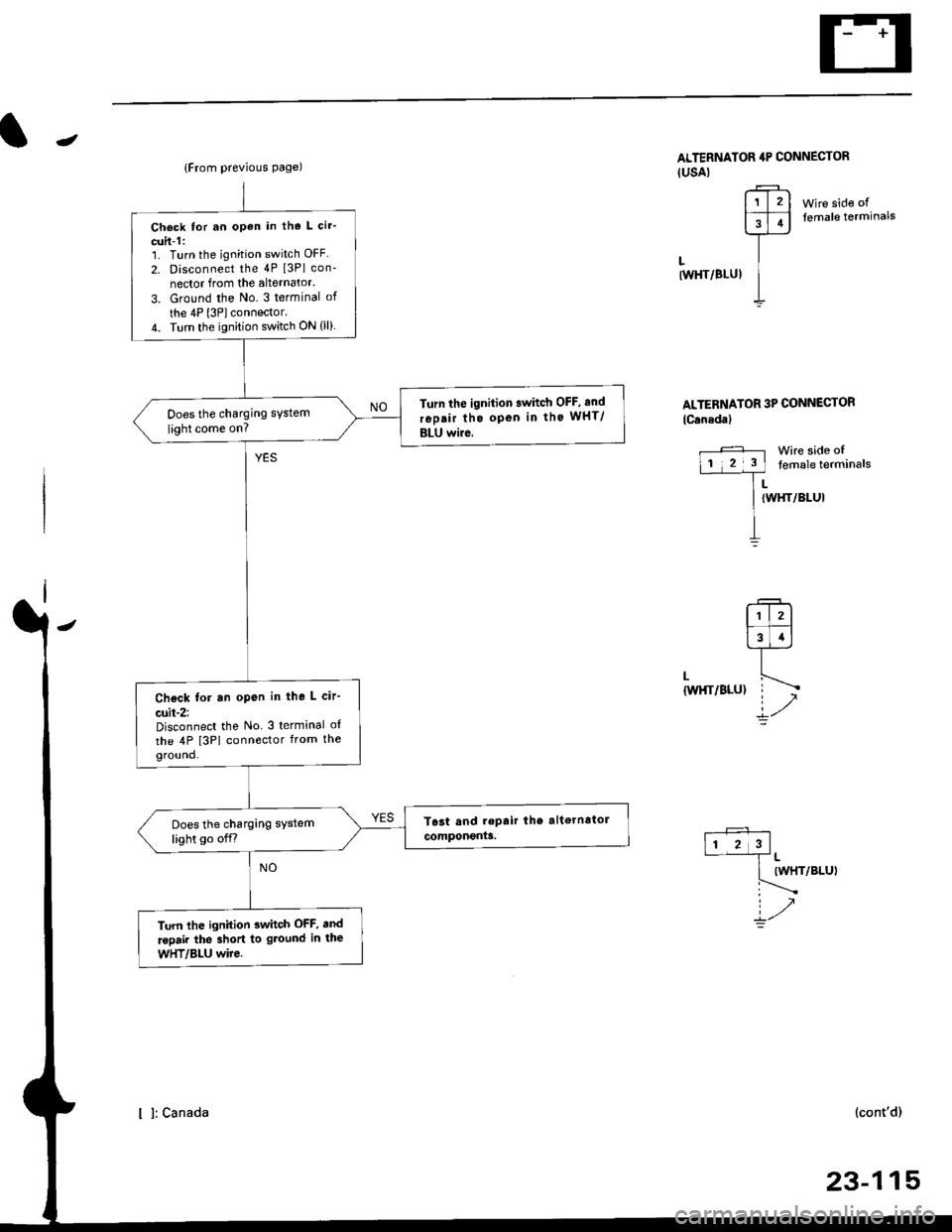

Page 1585 of 2189

-

Wire side offemale terminals

LtwHT/8LUl

ALTERNATOR 3P CONNECTOR

lCanada)

Wire side oftemale terminals

LIWHT/BLUI

L

{W}IT/BLU)

.+1lr l2l

l3T.l-l-

ir/

(WHT/BLUI

(cont'd)

23-115

{From previous page)

Check tor an open in tho L cir'

cuit-1:1. Turn the ignition switch OFF

2. Disconnect the 4P [3Pl con-

nector from the alternator.

3. Ground the No. 3 terminal of

the 4P l3Plconnector.4. Turn the ignition switch ON (ll)

Turn the ignition swhch OFF, and

rep.ir tho open in tho wHT/

BLU wire.

Does the charging system

light come on?

Check for an open in the L cir-

cuit-2:Disconnect the No 3 terminal o{

the 4P [3PI connector from theground.

Does the charging system

light go off.r

Turn lhe ignition 3whch OFF, and

.epair the 3hort to gtound in the

wHT/Bl-U wire.

ALTERNATOR 4P CONNECTOR(USAI

r?-rl1l2l

FFI

]--

I

I l: canada

Page 1586 of 2189

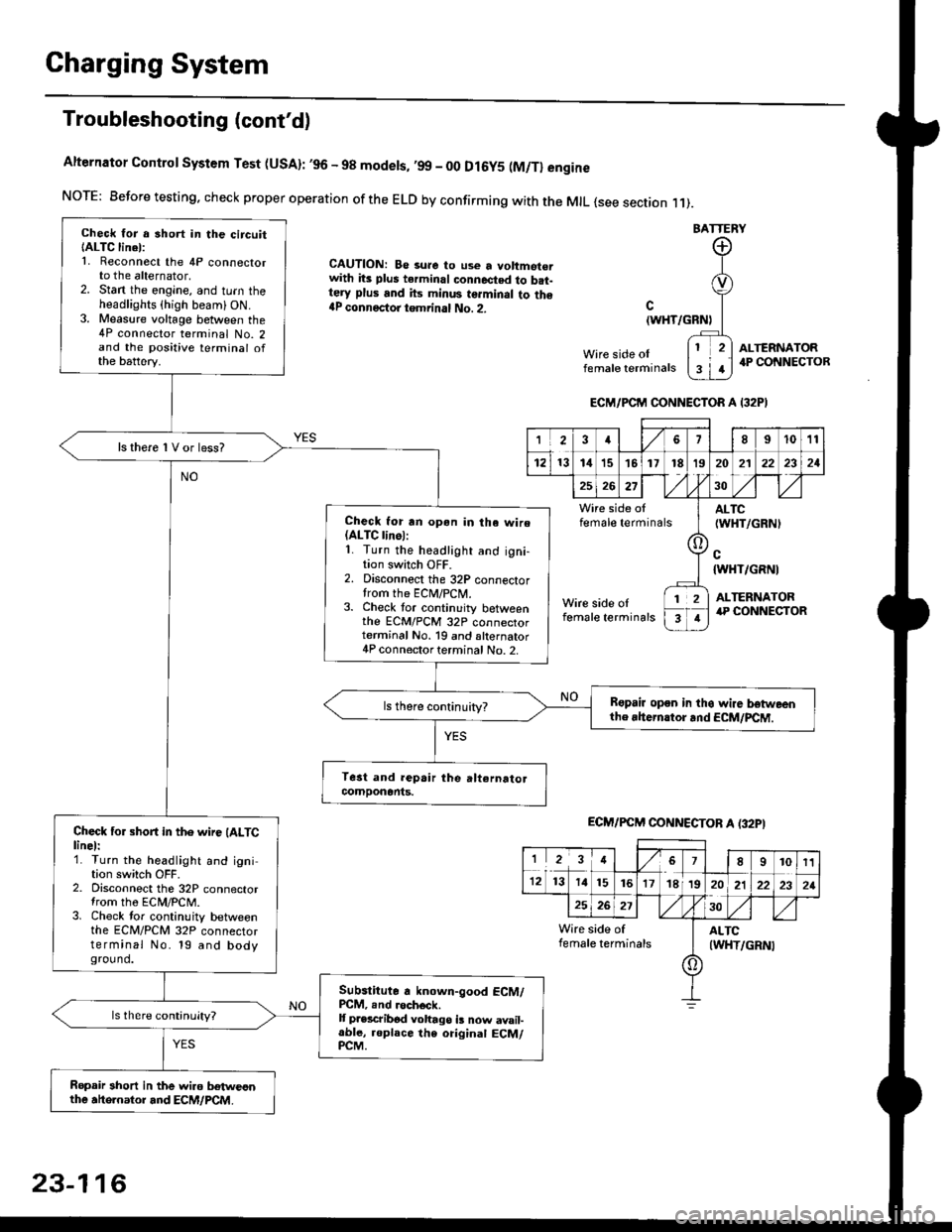

Charging System

Troubleshooting (cont'd)

Alternator Control System Test (USA): ,96 - 98 modets, ,99 _ 00 Dl6y5 (M/Tl engine

NorE: Before testing. check proper operation of the ELD by confirming with the MrL {see section r 1).

BATTERY

CAUTION: Be 3ure to use a voltmot€.with its plus terminal connected to b.t-tery plus and its minus terminal to the{P connectoi tgmrinal No. 2.c

{WHT/GRNt

Wire side oIfemale terminals

ALTERNATOR.P CONNECTOB

Check for a 3hort in the circuitIALTC linel:1. Reconnect the 4P connectorto the alternator,2. Stan the engine, and turn theheadlights {high beam) ON.3. Measure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

ls there 1V or less?

Check for rn opon in tha wire(ALTC linol:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectortrom the ECM/PCN4.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and alternator4P connector terminal No. 2.

Bspair open in thg wire lrstweenthe rhern.tor .nd ECM/PCM.

Check for short in the wire (ALTClinel:1. Turn the headlight and ignition switch OFF.2. Disconnect the 32P connectortrom the ECM/PCM.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and bodyground.

Subslitute a known-good ECM/PCM, .nd .och6ck.It p.escribod vohago i! now avail-able, replace the original ECM/PCM.

Ropair 3hort in the wiro betweonthe ahe.nator and ECM/PCM.

ECM/PCM CONNECTOR A I32PI

'Ia18I1011

121314151718t9

7

202'l2221

262730

Wire side offemale terminalsALTC(WHT/GRNI

c{WHT/GRNI

ALTERNATORWire side oIfemale terminals

([l

T

12

1

ECM/PCM CONNECTOB A (32PI

I23478910t1

1213 14151617182021222321

262730

Wire side of I AITCfemate terminats

A

(WHT/GRN|

23-116

Page 1587 of 2189

-

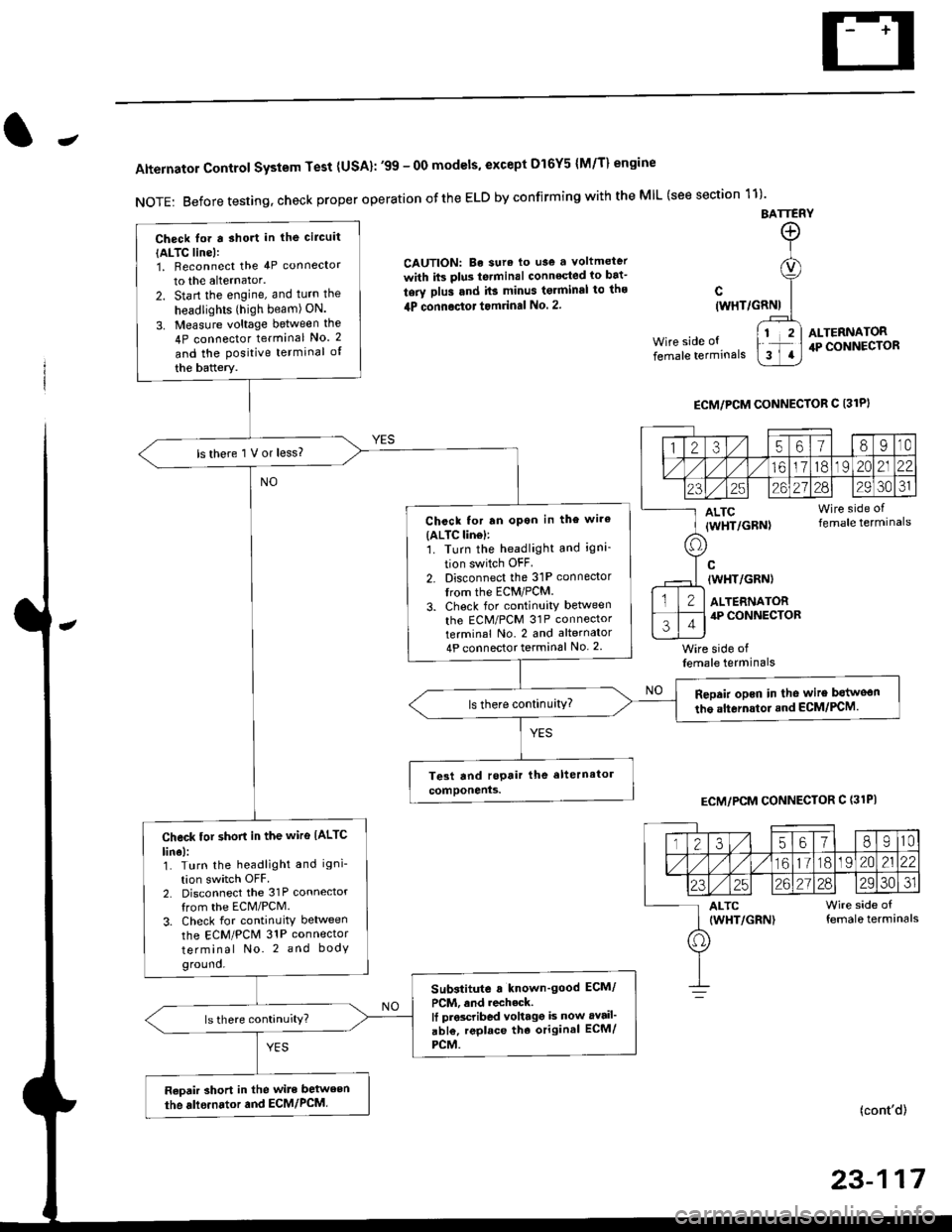

Alternator Control System Test {USA}: '99 - 0O models, except Dl6Y5 {M/T} engine

NOTE: Before testing, check proper operation ofthe ELD by confirming with the MIL (see section 11)'

BATTERY

CAUTION: Be sura lo use a voltmeter

with its plus te.minal conneqted io bat-

tery plus and it3 minus tgrminal to ths

4P connoctot tomrinal No. 2.

Wire side of

female terminals

c(WHT/GRNI

wire side offemale terminals

ALTERNATOR.P CONNECTOR

ECM/PCM CONNECTOR C 13lPI

ECM/PCM CONNECTOR C (31PI

(cont'd)

23-117

Check lor a sho.t in the circuit

{ALTC line):1, Beconnect the 4P connector

to the alternator.

2. Start the engine, and turn the

headlights (high beam) ON.

3. Measure voltage between the

4P connector terminal No. 2

and the Positive terminal of

the battery.

ls there 1 V or less?

Chcck for rn opon in the wire(ALTC lin6l:1. Turn the headlight and igni-

tion switch OFF

2. Disconnect the 31P connector

trom the ECM/PCM.

3. Check for continuity betlveen

the ECM/PCM 31P connectorterminal No. 2 and alternator

4P connector terminal No. 2

Repair opcn in the wire botweon

the alternstoi.nd ECM/PCM.ls there continuity?

Check tor short in the wire IALTC

line):1. Turn the headlight and igni-

tion switch OFF2. Disconnect the 31P connector

from the ECM/PCM.

3. Check for continuity between

the ECM/PCM 31P connector

terminal No. 2 and body

ground.

Substitute a known'good ECM/

PCM, and recheck.It prscribed voltagg is now avail'

abl€, replace tho original ECM/

PCM.

Raoair short in the wite between

the alle.nator and ECM/PCM,

1235618I10

/11611lo191 zo2122

23252621?82930JI

ALTC Wire side of(WHT/GRN) female terminals

o

Page 1588 of 2189

Charging System

Troubleshooting (cont'd)

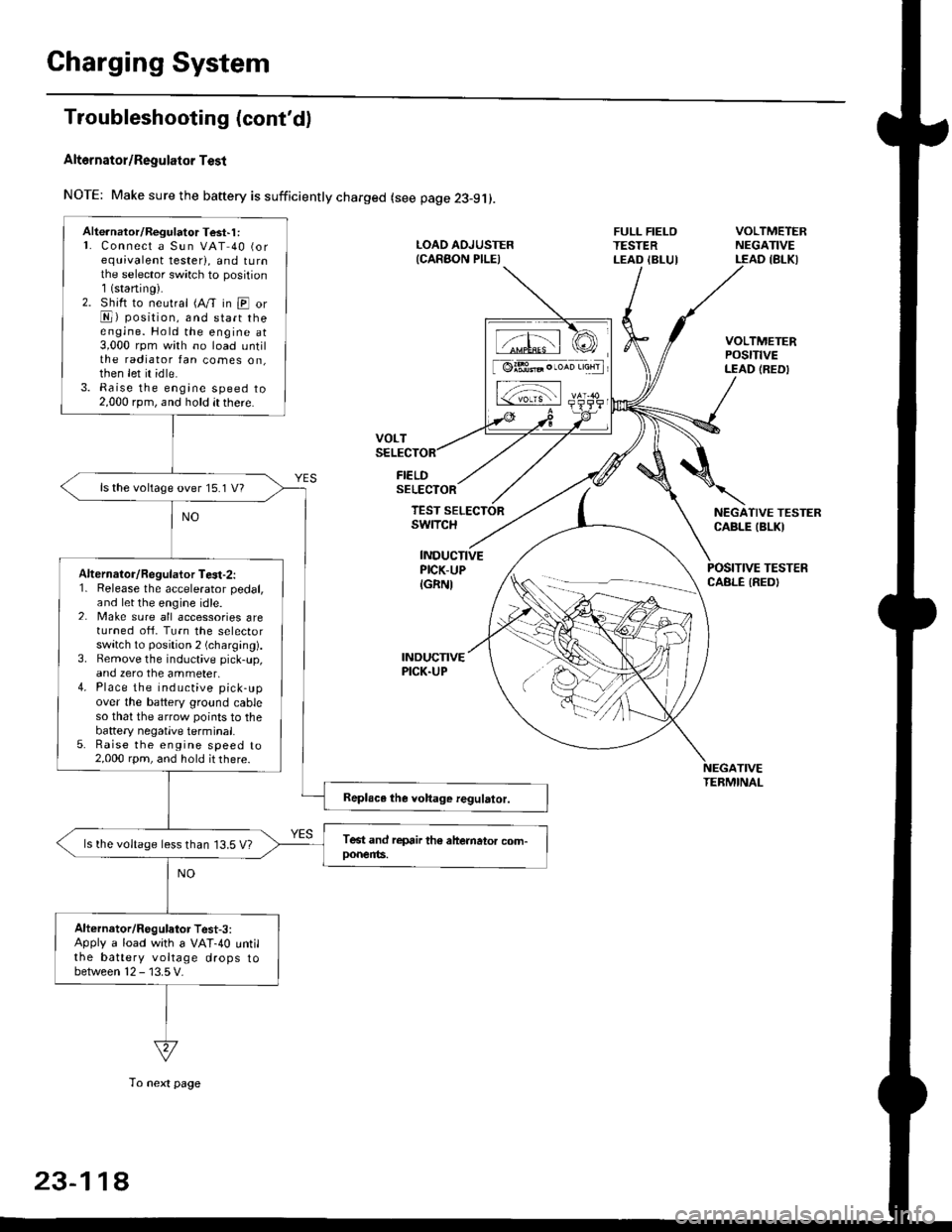

Alt6rnator/Regulator Test

NOTE: Make sure the baftery is sufficiently charged (see page 23-9j).

FIELDSELECTOR

LOAD AOJUSTER{CARAON PILEI

FULL FIELOTESTERLEAD IBLUI

VOLTMETERNEGATIVELEAD IBLKI

VOLTMETERPOStTtVELEAD (REDI

NEGATIVE TESTERCABLE IBLKI

POSITIVE TESTERCABLE IREDI

TEST SELECTORswrTcH

INDUCTIVEPICK-UP

IGRNI

INDUCNVEPICK.UP

TIVETEBMINAL

Alte.nator/Regulator Test'1 :L Connect a Sun VAT 40 (orequivalent tester), and tu rnthe selector sw;tch to position1(staning).2. Shift to neutral (A/T in E orE) position, and start theengine. Hold the engine at3,000 rpm with no load untilthe radiator fan comes on,then let it idle.3. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

Alternalor/Regulator Te3t-2:1. Release the accelerator pedal,and let the engine idle.2. Make sure all accessories areturned ofi. Turn the selectorswitch to position 2 (charging).3. Bemove the inductive pick-up,and zero the ammeter,4. Place the inductive pick-upover the battery ground cableso that the arrow points to thebattery negatlve terminal.5. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage less than 13.5 V?

Alternator/Regulator Test-3:Apply a load with a VAT-40 untilthe battery voltage drops tobetween 12 - 13.5 V.

tffil rCI

[ @lBt* . ,*n 'aHrl

L-;-;l rs-

23-11A

To next page