no spark HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 58 of 2189

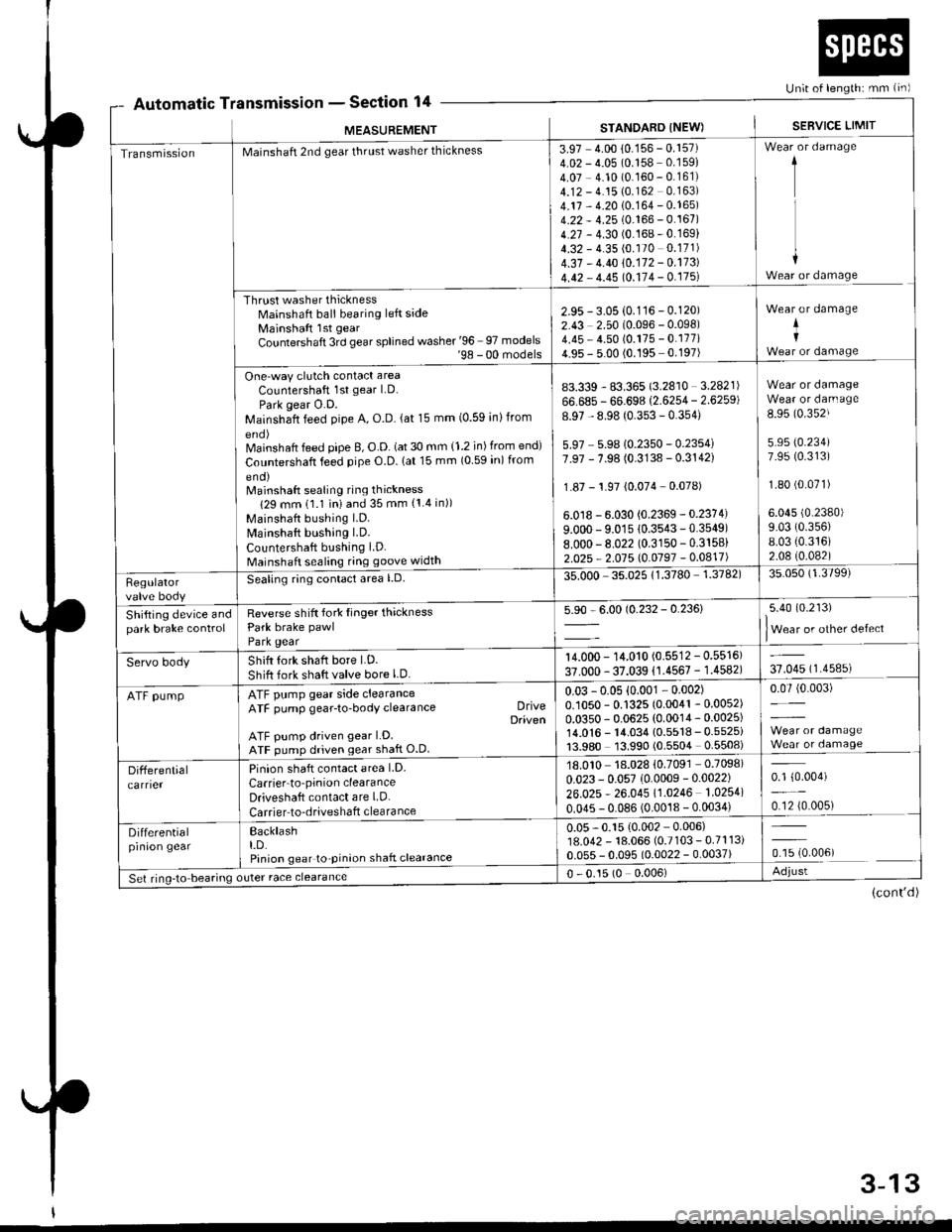

Automatic TnsmtsstonSection 14Un;t of length: mm {in)

r

MEASUREMENT

a

STANDARD INEW)SEBVICE LIMIT

TransmissionMainshaft 2nd gear thrust washer thickness

Thrust washer thicknessMainshaft ball bearing left sideMainshaft lst gear

Countershaft 3rd gear splined washer '96 97 models'98 - 00 models

One-way clutch contact area

Countershaft 1st gear LD.

Park gear O.D.Mainshaft feed pipe A, O.D. (at 15 mm (0.59 inlfrom

Mainshaft feed pipe B, O.D. (at 30 mm {1.2 in) from end)

Countershaft feed pipe O.D. lat 15 mm (0 59 in) from

eno)Mainshaft sealing ring thickness

129 mm 11.1 iniand 35 mm {1.4 in))

Mainshaft bushing l.D.

Mainshaft bushing LD.

Countershaft bushing LD.Mainshaft sealing ring goove width

3.97 4.00 10.156 - 0.157)4.02 - 4.05 (0.158 0.159)

4.07 - 4.10 (0.160 - 0.161)4.12 - 4.15 (0.162 0.163)

4.17 - 4.20 10.164 - 0.165)4.22 - 4.25 (0.166 - 0.167)4.27 - 4.30 (0.168-0.169)

4.32 - 4.35 (0.170 0.171)

4.37 - 4.40 10.172 - 0.173)

4.42 - 4.45 10.114 - 0.175l

1

I

+Wear or damage

2.95 - 3.05 {0.116 - 0.120)2.43 2.50 (0.096 - 0.098)4.45 - 4.50 (0.175 - 0.177i4.95 - 5.00 (0.195 0.197)

Wear or damage

+I

83.339 - 83.365 (3.2810 3.2821)

66.685 - 66.698 (2.6254 - 2.6259)

8.97 - 8.98 (0.353 - 0.354)

5.97 5.9810.2350 - 0.2354i7.97 - 7.98 (0.3138 - 0.3142)

1.87 - 1.97 {0.074 0.078)

6.0 r8 - 6.030 {0.2369 - 0.2374)

9.000 - 9.01s 10.3543-0.3549)8.000-8.022 (0.3150 - 0.3158)

2.025 - 2.015 l0.0197 -0.0417)

Wear or damageWear or darn age

8.95 (0.352J

5.95 (0.234)

7.95 (0.313)

1.80 (0.071)

6.045 (0.2380)

9.03 (0.356)

8.03 {0.316)2.08 (0.082)

Regulatorvalve body

Seating ring conlact area l.D.35.000 35.02511.3780 1.3782)35.050 (1.3799)

Shifting device andpark brake controlReverse shift fork Iinger thicknessPark brake pawl

Park gear

5.90 - 6.00 (0.232 - 0.236)5.40 (0.213)

lWear or other defect

Servo bodyShift fork shaft bore LD.

Shift fork shaft valve bore l.D.

14.000 - 14.010 (0.5512 - 0.5516)

37.000 - 37.039 (1.4567 - 1.4582)37.045 (1.4585)

ATF pumpATF pump gear side clearanceATF pump gear-to-body clearance DriveDaiven

ATF pump driven gear LD.ATF pump driven gear shaft O.D

0.03 -0.05 {0.001 - 0.002)0.1050 - 0.1325 (0.0041 - 0.0052)

0.0350 - 0.0625 (0.0014 - 0.0025)14.0'�|6 - 14.034 {0.5518 - 0.5525i13.980 13.990 (0.5504 0.5508)

0.07 (0.003)

Differentialcarrier

Pinion shaft contact area LD.

Carrier to'pinion clearanceDriveshaft contact are LD.

Carrier to-driveshaft clearance

18.010 18.028 {0.7091 0.7098)

0.023 - 0.057 (0.0009 -0.0022)

26.025 * 26.045 11.0246 1.0254)

0.045 - 0.086 (0.0018 - 0.0034)

0.1 {0.004)

0.12 {0.005)

Differentialprnron gearBacklasht.D.Pinion gear to-pinion shaft clearance

0.05 - 0.15 {0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.7113i0.055 - 0.095 (0.0022 - 0.0037)ffi.oour

Set ring-to bearing outer race clearance0 - 0.15 (0 0.006)Adjust

(cont'd)

3-13

Page 64 of 2189

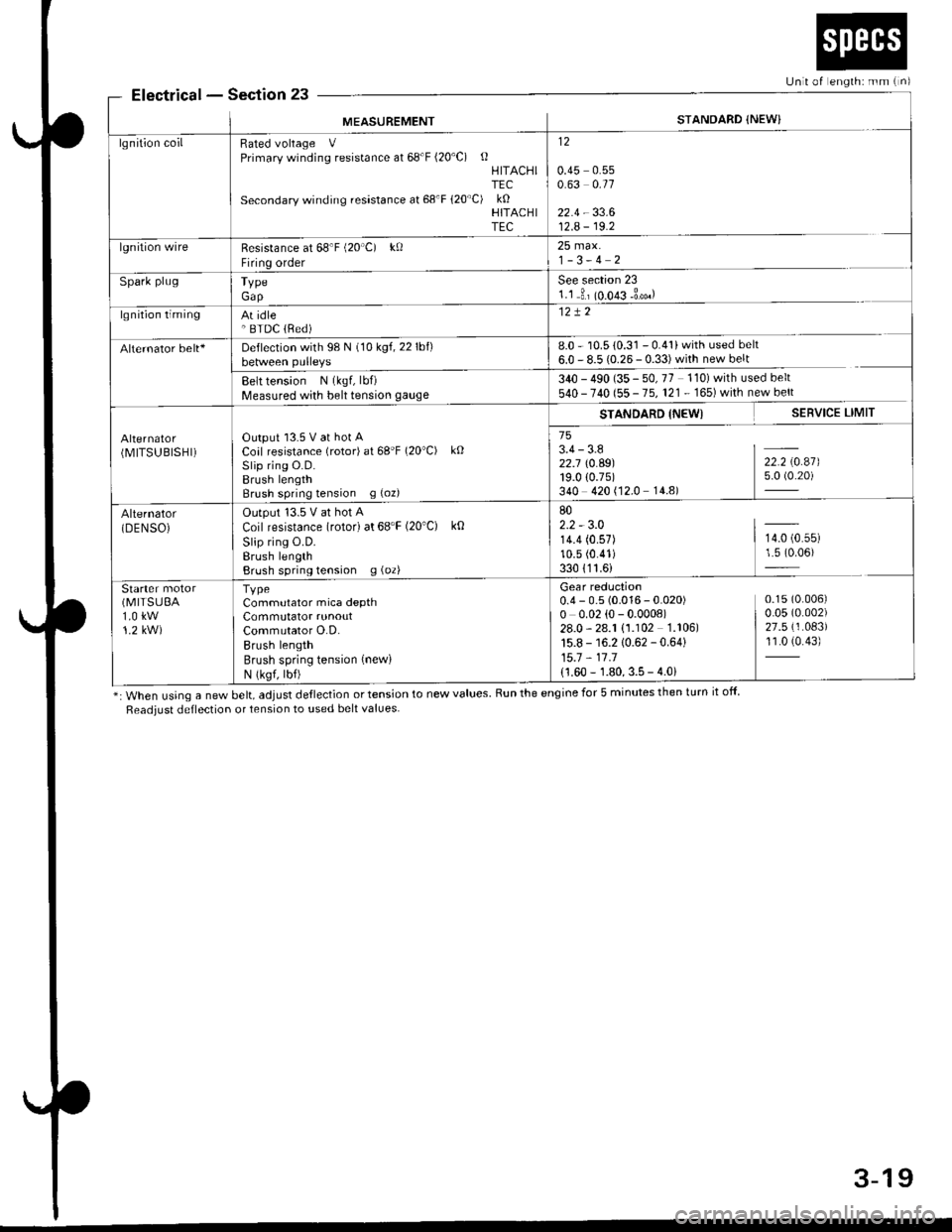

ElectricalSection 23

*: When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off

Readiust deflection or tension to used belt values

Unit of englh: mm {n)

MEASUREMENTSTANDARD {NEW}

lgnition coilRated voltage VPrimary winding resistance at 68'F (20'C) oHITACHITEC

Secondary winding resastance at 68'F 120"C) kOHITACHITEC

12

0.45 0.550.63 0.11

22.4 - 33.612.A - 19.2

lgnition wireResistance at 68'F (20'C) kf)

Firing order

25 max.1-3-4 2

Spark plugTypeGap

See section 231.1 3, (o.o€ -3*.)

lgnition timingAt idle' BTDC lRed)

Alternator belt+Deflection with 98 N (10 kgf,22lbf)between pulleys8.0 - 10.5 {0.31 - 0.41} with used belt

6.0 - 8.5 {0.26- 0.33)with new belt

Belt tension N (kgf, lbf)

Measured with belt tension gauge340 - 490 (35 - 50, 77 110) with used belt

540 - 740 (55 - 75, 121. 165)whh newbert

(MITSUBISHI)Output l3.5 V at hot ACoal resistance (rotor) at 68'F (20"C) kO

Slip rins O.D.Brush lengthBrush spring tension g (oz)

STANDARD INEWI SERVICE LIMIT

753.4-3.8 I -

Z2.j \0.A9) 22.2 \0.47)19.0 (0.75) 5.0 (0.20)

340 420 (12.0 14.8)

Alternator(DENSOiOutput '13.5 V at hot A

Coil resistance (rotor) at 68'F (20'C) k0

Slip ring O.D.Erush lengthBrush spring tension g (oz)

802.2 - 3.014.4 (0.57) | 14.0 (0.55)

10.5 (0.41) 1.5 (0.06)

330 {11.6)

Starter(MITSUEA

1.0 kw1.2 kW)

TvpeCommutator mica depthCommutator runoutCommutator O.D.Brush lengthBrush spring tension (new)

N (ksf, lbf)

Gear reduction0.4 - 0.5 (0.016 - 0.020) 0.15(0.006)

o o.o2 (o - 0.000e) | o.o5 (o.oo2)

28.0-28.1 (1.102 1.106) | 27.5(1.083)

15.8 - 16.2 10.62 - 0.64) 11.0 (0.43)

15.7 - 11 .1

{1.60 - 1.80, 3.5 - 4.0i

3-19

Page 98 of 2189

Engine Removal/lnstallation

Removal (cont'dl

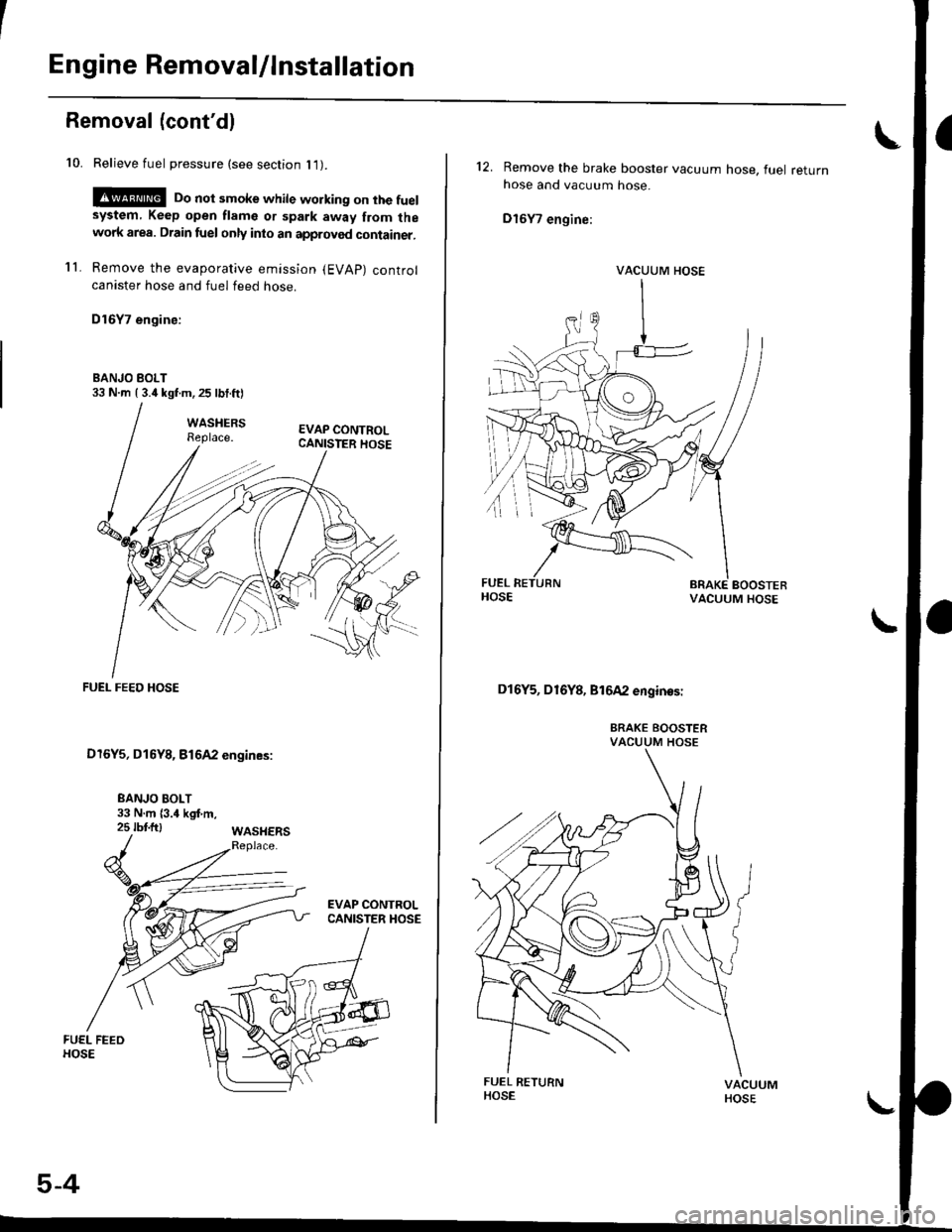

10. Relieve fuel pressure (see section l1).

!@ Do not smoke while working on the fuelsystem, Keep open flame or spark away from thewolk area. Drain fuel only inlo an approved container.

11. Remove the evaporative emission (EVAP) controlcanister hose and fuel feed hose.

D16Y7 engine:

BANJO BOLT33 N m ( 3.it lgt m, 25 lbt.ft)

FUEI- FEED HOSE

D16Y5, D16Y8, Bt642 engines:

5-4

I

12. Remove the brake

hose and vacuum

D16Y7 engine:

booster vacuum hose, fuel returnhose.

VACUUM HOSE

Dl6Y5, D16Y8, Bl642 enginos:

BRAKE BOOSTERVACUUM HOSE

Page 125 of 2189

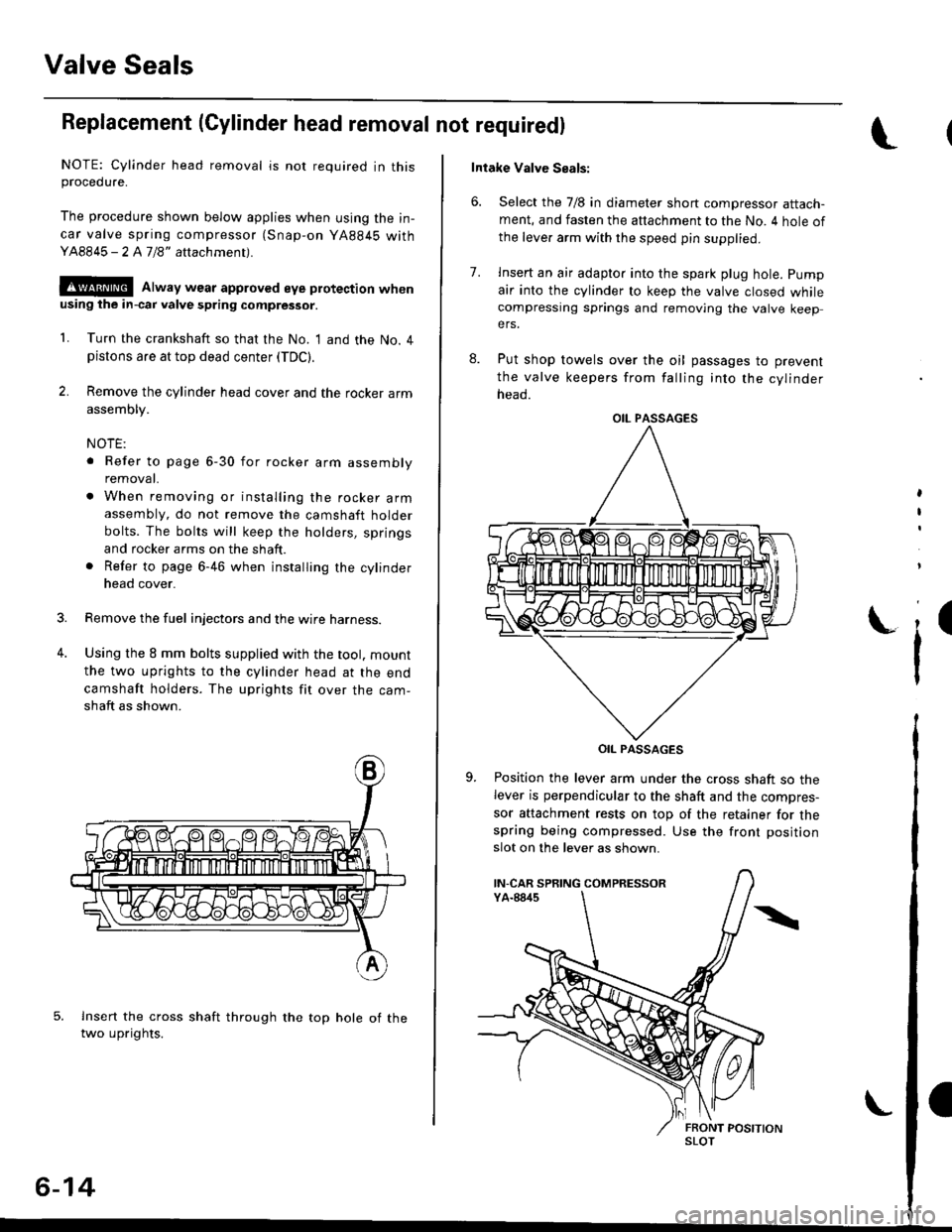

Valve Seals

Replacement (Cylinder head removal not requiredl

NOTE: Cylinder head removal is not required in thisprocedure.

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA884S withY48845 - 2 A7/8" attachment).

!@@ Alway wear approved eye protection whenusing ihe in-cai valve spring compressor.

1. Turn the crankshaft so that the No. I and the No. 4pistons are at top dead center (TDC).

2. Remove the cylinder head cover and the rocker arm

assembly.

NOTE:

. Refer to page 6-30 for rocker arm assembly

removat.

. When removing or installing the rocker armassembly, do not remove the camshaft holder

bolts. The bolts will keep the holders, springs

and rocker arms on the shaft.

. Refer to page 6-46 when installing the cylinder

head cover.

Remove the fuel injectors and the wire harness.

Using the 8 mm bolts supplied with the tool. mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit over the cam-

shaft as shown.

lnsert the cross shaft through the top hole of thetwo uprights.

3.

4.

6-14

Intake Valve Seals:

6. Select the 7/8 in diameter short compressor attach-ment, and fasten the attachment to the No. 4 hole of

the leve. arm with the speed pin supplied.

8.

7.lnsert an air adapto. into the spark plug hole. pump

air into the cylinder to keep the valve closed whilecompressing springs and removing the valve keepers.

Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

neao.

OIL PASSAGES

Position the lever arm under the cross shaft so thelever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for thespring being compressed. Use the front position

slot on the lever as shown.

,

I

i'

OIL PASSAGES

IN-CAR SPRING COMPRESSOR

SLOT

Page 140 of 2189

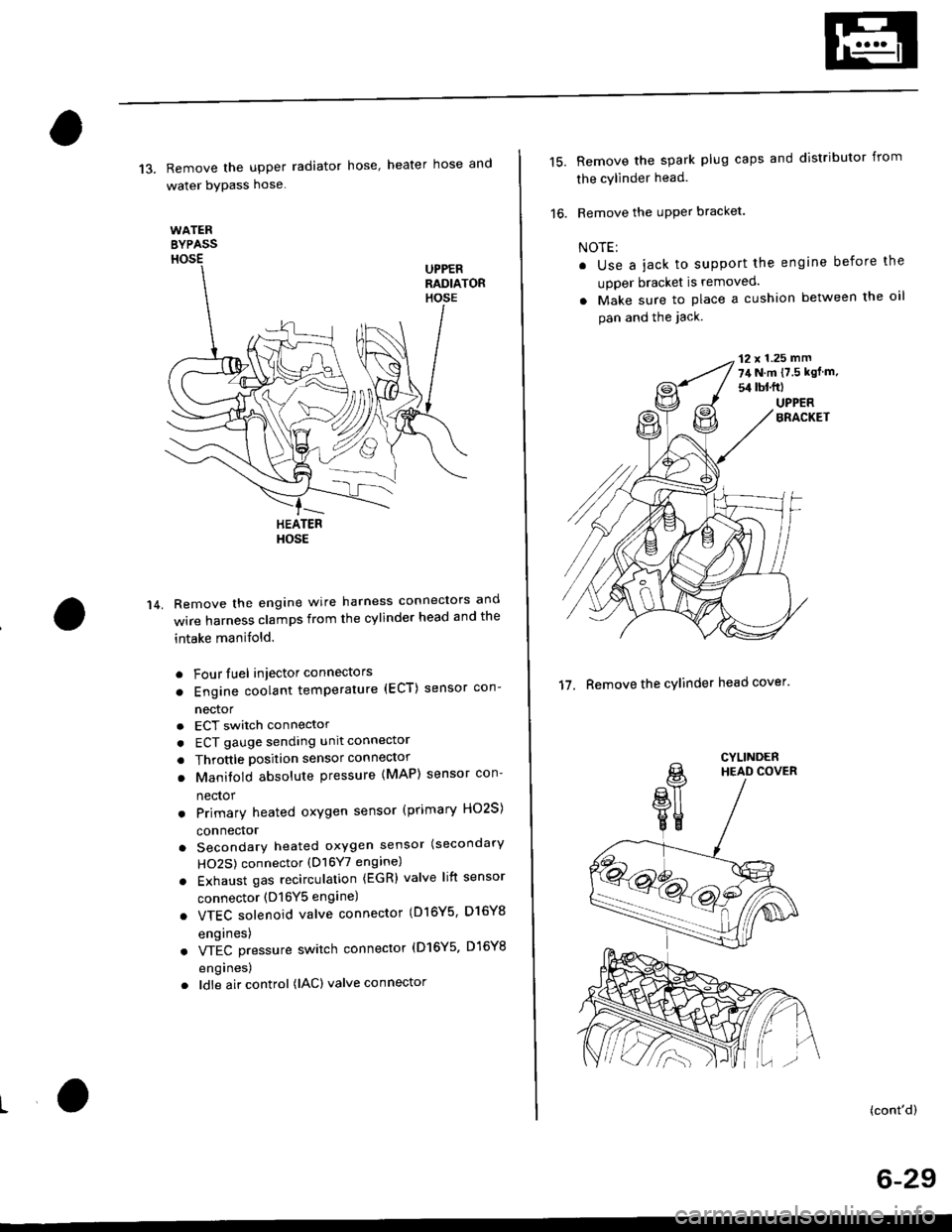

13. Remove the upper radiator hose' heater hose and

water bYPass hose

WATEREYPASSHOSEUPPERRADIATORHOSE

14.

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

nector

a

a

a

ECT switch connector

ECT gauge sending unit connector

Throttle position sensor connector

Manitold absolute pressure (MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

Secondary heated oxygen sensor (secondary

HO2S) connector (D16Y7 engine)

Exhaust gas recirculation (EGR) valve lift sensor

connector (D16Y5 engine)

. VTEC solenoid valve connector (Dl6Y5, D16Y8

engrnes)

. VTEC pressure switch connector (D16Y5. D16Y8

engrnes,

. ldle air control (lAC) valve connector

15.Remove the spark plug caps and distributor from

the cylinder head.

Remove the uPPer bracket.

NOTE:

. Use a jack to support the engine before the

upper bracket is removed.

. Make sure to place a cushion between the oil

pan and the jack.

12 x 1.25 mm

74 N.m {7.5 kgf m.

sil lbl.ftl

UPPERBRACKET

'17. Remove the cylinder head cover'

CYLINDERHEAD COVER

(cont'd)

6-29

Page 158 of 2189

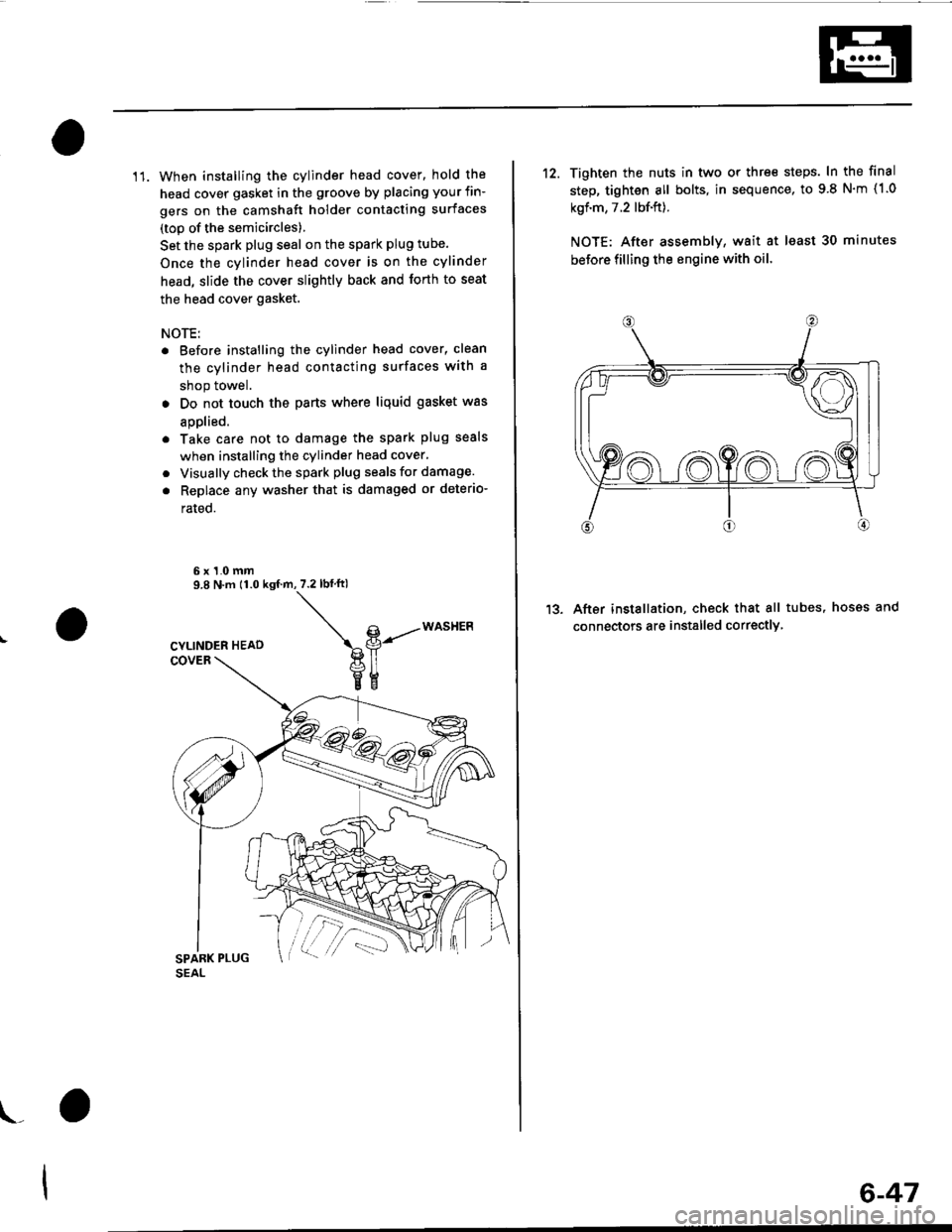

11. When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft holder contacting surfaces

(top of the semicircles)

Set the spark plug seal on the spark plug tube.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

. Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

. Do not touch the parts where liquid gasket was

aDolied.

. Take care not to damage the spark plug seals

when installing the cylinder head cover,

. Visually check the spark plug seals for damage.

. Replace any washer that is damaged or deterio-

rated.

6x1.0mm9.8 N.m 11.0 ksf.m,7.2lbf ftl

\g-----*o""t'Ptl

veEE

\_

6-47

12. Tighten the nuts in two or thre€ steps. In the final

step, tighten all bolts, in sequence, to 9 8 N'm (1.0

kgf.m, 7.2 lbf.ft).

NOTE: After assemblv, wait at least 30 minutes

before filling the engine with oil

After installation, check that all tubes, hosss and

connectors are installed correctlY

1?

Page 178 of 2189

Cylinder Head

Removal (cont'd)

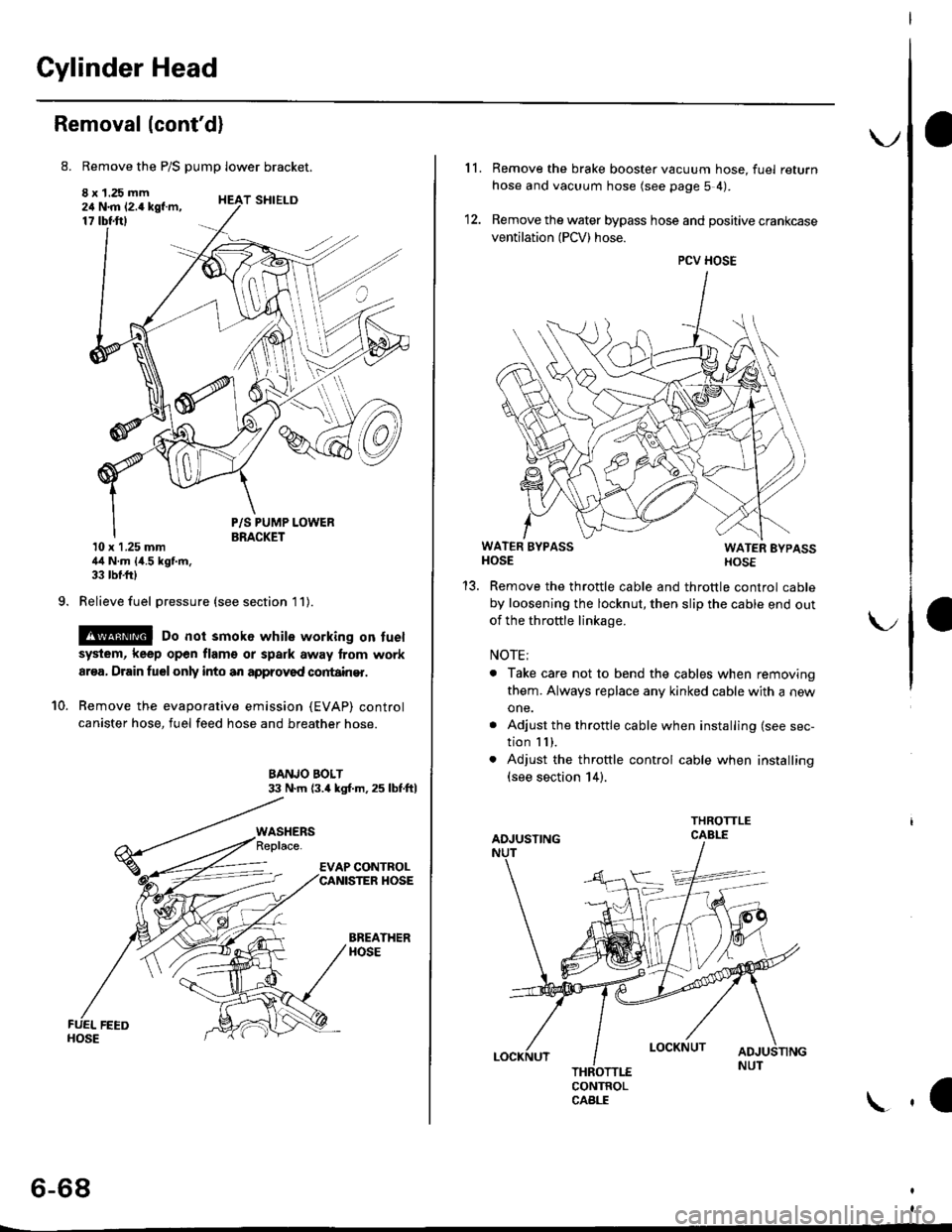

8. Remove the P/S pump lower bracket.

8 x 1.25 mm24 N.m 12.4 kgf.m,17 tbtftl

9.

T SHIELD

10.

P/S PUMP LOWERBRACKET10 x 1.25 mm44 N.m {4.5 kgf.m,33 tbf.frl

Relieve fuel pressure (see section l1).

@ Do not smok6 while working on fuel

system, keep open flam€ or spark away lrom work

ar€a, Drain fuelonly into an approved cortain€r.

Remove the evaporative emission (EVAP) control

canister hose, fuel feed hose and breather hose.

BANJO BOLT33 N.m (3.4 kgl.m.25 lbf.ftl

BREATHERHOSE

WASHERS

6-68

\.

11. Remove the brake booster vacuum hose, fuel return

hose and vacuum hose (see page 5 4).

12. Remove the water bypass hose and positive crankcase

ventilation (PCV) hose.

WATER BYPASSHOSEWATER EYPASSHOSE

Remove the throttle cable and throttle control cable

by loosening the locknut, then slip the cable end out

of the throftle linkage.

NOTE;

. Take care not to bend the cables when removing

them. Always replace any kinked cable with a new

one.

. Adjust the throttle cable when installing (see sec-

tion I I ),. Adjust the throttle control cable when installing(see section 14).

CONTROLCABLE

1a

PCV HOSE

Page 179 of 2189

WATER BYPASS

HOSE

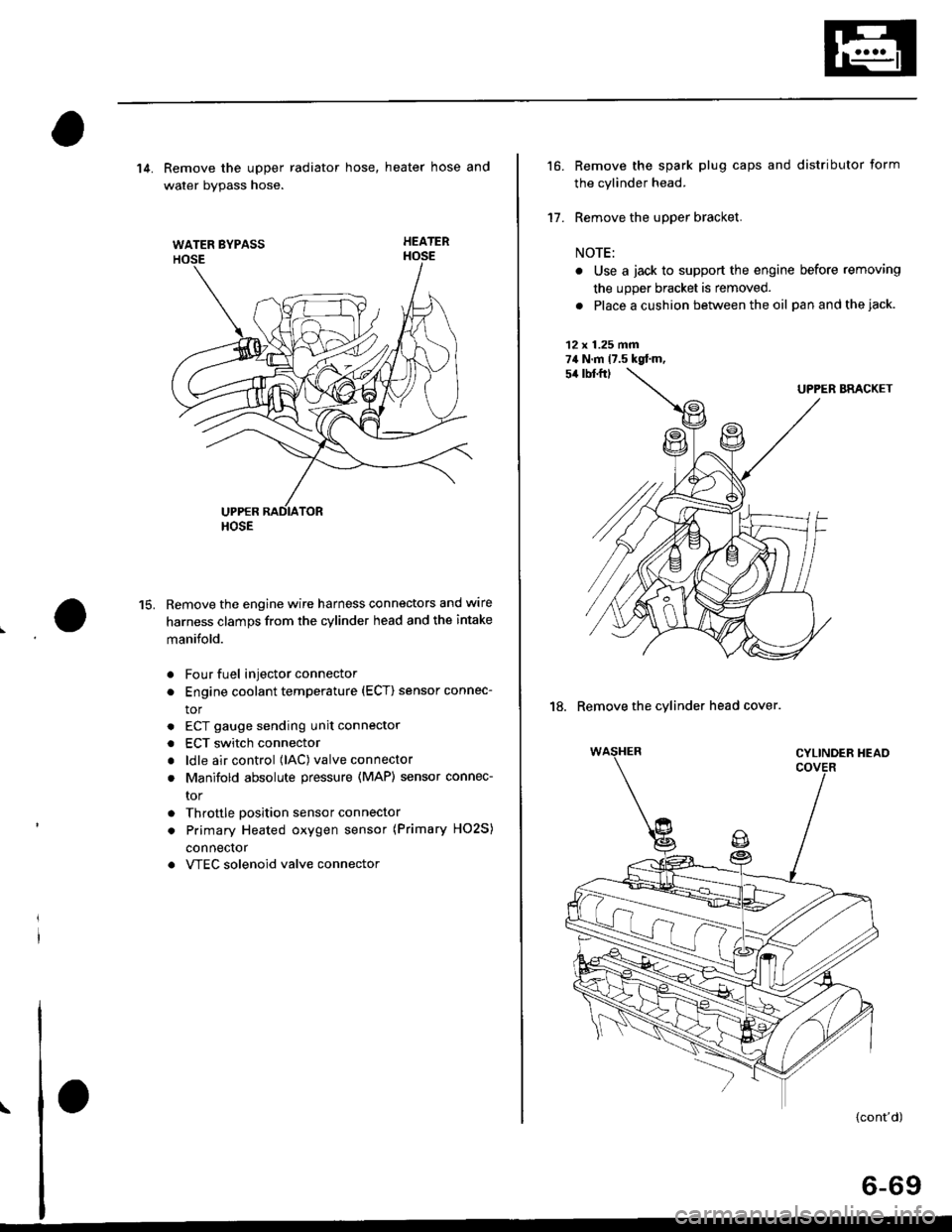

14. Remove the upper radiator hose, heater hose and

water bvpass hose.

HEATER

Remove the engine wire harness connectors and wlre

harness clamps from the cylinder head and the intake

manifold.

Four fuel injector connector

Engine coolant temperature (ECT) sensor connec-

tor

ECT gauge sending unit connector

ECT switch connector

ldle air control (lAC) valve connector

Manifold absolute pressure (MAP) sensor connec-

tor

Throttle position sensor connector

Primary Heated oxygen sensor (Primary HO2S)

connecror

VTEC solenoid valve connector

15.

a

a

a

a

a

\

16.

17.

Remove the spark plug caps and distributor form

the cylinder head.

Remove the upper bracket.

NOTE:

. Use a jack to support the engine before removing

the upp€r bracket is removed.

. Place a cushion between the oil panandthejack.

12 x 1.25 fin74 N.m 17.5 kgtm,

UPPER BRACKET

18. Remove the cylinder head cover.

{cont'd)

6-69

Page 435 of 2189

PGM-FI System

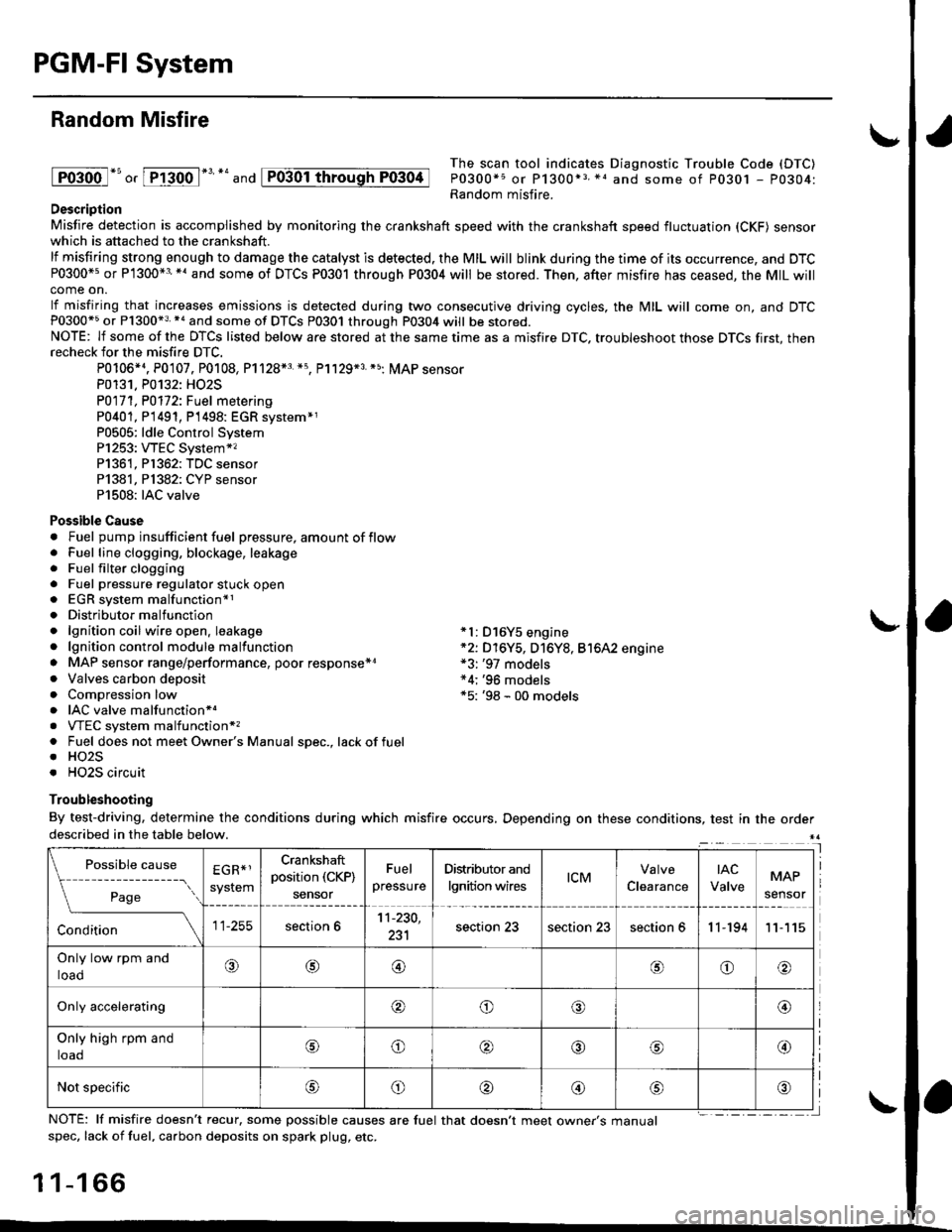

Random Misfire

lFoioo l*u o, [FTioo l*' *' and

The scan tool indicates Diagnostic Trouble Code (DTC)

P0300*5 or P1300*3 *1 and some of P0301 - P0304:Random misfire.Description

Misfire detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluctuation (CKF) sensorwhich is attached to the crankshaft.

lf misfiring strong enough to damage the catalyst is detected. the MIL will blink during the time of its occurrence, and DTCP0300*5 or P1300*3'*' and some of DTCs P0301 through P0304 will be stored. Then, after misfire has ceased, the MIL willcome on.

lf misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and DTCP0300*5 or P1300*3 *a and some of DTCS P0301 through P0304 will be stored.NOTE: lf some of the DTCS listed below are stored at the same time as a misfire DTC. troubleshoot those DTCS first, thenrecheck for the misfire DTC.

P0106*4. P0107. P0108, P1128*3 *5, Pl129*3 *5; MAP sensorP0131. P0132: HO2S

P0171, P0112i Fuel metering

P0401, P 1491, P1498: EGR svstem*1P0505: ldle Control SystemP1253: VTEC System*,P1361, P1362: TDC sensorP1381, Pl382: CYP sensorP1508: IAC valve

Possible Cause. Fuel pump insufficient fuel pressure, amount of flow. Fuel line clogging, blockage, leakage. Fuel filter clogging. Fuel pressure regulator stuck open. EGR system malfunction*1. Distributormalfunction. lgnition coil wire open. leakage *l: D16Y5 engine. lgnition control module malfunction *2: D16Y5, D16Y8, Bt6A2 engine. MAP sensor range/performance, poor response*r *3: '97 models. Valves carbon deposit *4;'96 models. Compression low *5: '98 - 00 models. IAC valve malfunctionr.. VTEC system malfunction*,. Fuel does not meet Owner's Manual spec., lackoffuel. HO2S. HO2S circuit

Troubleshooting

By test-driving, determine the conditions during which misfire occurs, Depending on these conditions, test in the orderdescribed in the table below.

Possible

- --^ ---

rage

causeEGR*1

system

Crankshaft

position (CKP)

sensor

Fuel

pressure

Distributor and

lgnition wirestcMClearance

tAc

ValveMAP

sensor

section 611-230,

231section 23section 23section 611-19411

Only low rpm and

loado@@oo

Only accelerating@o@@

Only high rpm and

toaooo@

Not specificoo@

NOTE: lf misfire doesn't recur, some possible causes are fuel that doesn't meet owne/s manualspec, lack of fuel, carbon deposits on spark plug, etc.

1 1-1 66

I

P0304

Page 436 of 2189

I

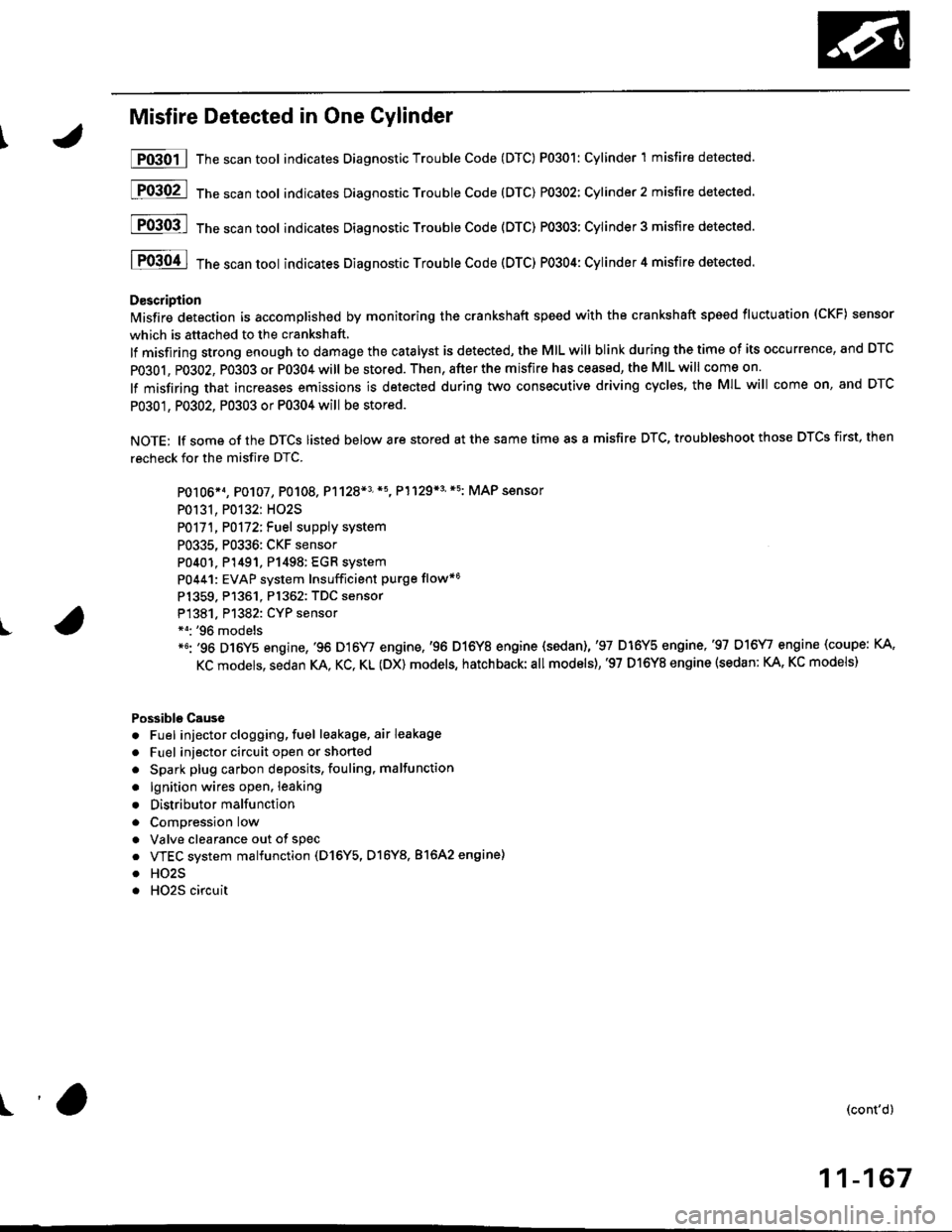

Misfire Detected in One Cylinder

P0301 | The scan tool indicates Diagnostic Trouble Code (DTC) P0301: Cylinder 1 misfire detected.

[F03O2l 16"""untool indicates Diagnostic Trouble code (DTc) P0302: Cylinder2 misfire detected.

[FO3Ofl 16" ".un toot indicates Diagnostic Troubte Code (DTC) P0303; Cylinder 3 misfire detected.

I P0304 I ths..rr tool indicates Diagnostic Trouble Code (DTC) PO3O4: Cylinder 4 misfire detected.

D€scription

lMisfire detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluctuation (CKF) sensor

which is attached to the crankshaft,

lf misfiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence, and DTC

PO3O1, P0302, PO3O3 or P0304 will be stored. Then, after the misfire has ceased, the MIL will come on.

lf misfiring that increases emissions is detected during two consecutive driving cyclss, the MIL will come on, and DTC

P0301, P0302, P0303 or P0304 will be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as a misfire DTC, troubleshoot those DTCS first, then

recheck for the misfire DTC.

PO106*1, P0107, P0108. P1128*3'*5, P1129*3'*5: MAP sensor

P0131, P0132: HO2S

P0171, P0172iFuel suppiy system

P0335, P0336: CKF sensor

P0401. P1491, P1498: EGR system

P0441: EVAP system Insufficient purge flow*6

Pl359. P1361. Pl362: TDC sensor

P1381. Pl382: CYP sensor*o: '96 models*6: '96 D16Y5 engine,'96 D16Y/ engine,'96 D16Y8 engine {sedan),'97 D16Y5 engine,'97 D16\4, engine (coupe: KA,

KC models, sedan KA. KC, KL (DX) models, hatchback:all models),'97 D16Y8 engine (sedan: KA, KC models)

Possible Cause

. Fuel injector clogging, fuel leakage, air leakage

. Fuel injector circuit open or shorted

. Spark plug carbon deposits, fouling, malfunction

. lgnition wires open. leaking

. Distributor malfunction

. ComDression low

. Valve clearance out of spec

. VTEC system malfunction (D16Y5, D16Y8. 81642 engine)

. HO2S

. HO2S circuit

(cont'd)

11-167

r'a