light HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 996 of 1139

)

I

Troubleshooting

Before troubleshooting the immobilizer system,

troubleshoot any EClvl Diagnostic Trouble Codes (DTCS)

(see page 11-3), and make sure the ECM has no

malfunction.

Note these items before trou bleshooting:

. Due to the action of the immobilizer system, the

engine takes slightly more time to start than on a

vehicle without an immobilizer system.. When the system is normal, and the proper key is

inserted, the indicator light comes on for 2 seconds,

then it will go off.. If the indicatorstartsto blink after 2 seconds, or if the

engine does not start. remove any other immobilizer

keys or large key fobs on the key ring, then repeat the

starting procedure.

lf the engine still does not start, continue with thisprocedure.

1. Turn the ignition switch ON {ll) with proper key.

2. Check to see if the immobilizer indicator light

comes on.

Does the indicator light blink?

YES Disconnect the 7P connector from the

immobilizer control unit-receiver, then go to step 9.

NO Check for these problems, then go to step 3.

. Blown No. 9 (10A)fuse in the under-hood

fuse/relay box.I. An open in the wire between the gauge assembly

and the immobilizer control unit-receiver.l. A faulty immobilizer indicator light,I. An open in the wire between the gauge assembly

and the under-hood fuse/relay box.l

Remove the driver's dashboard lower cover (see

page 20-59).

Remove the steering column lower cover (see page

11-9).

l

-_--t

22-165

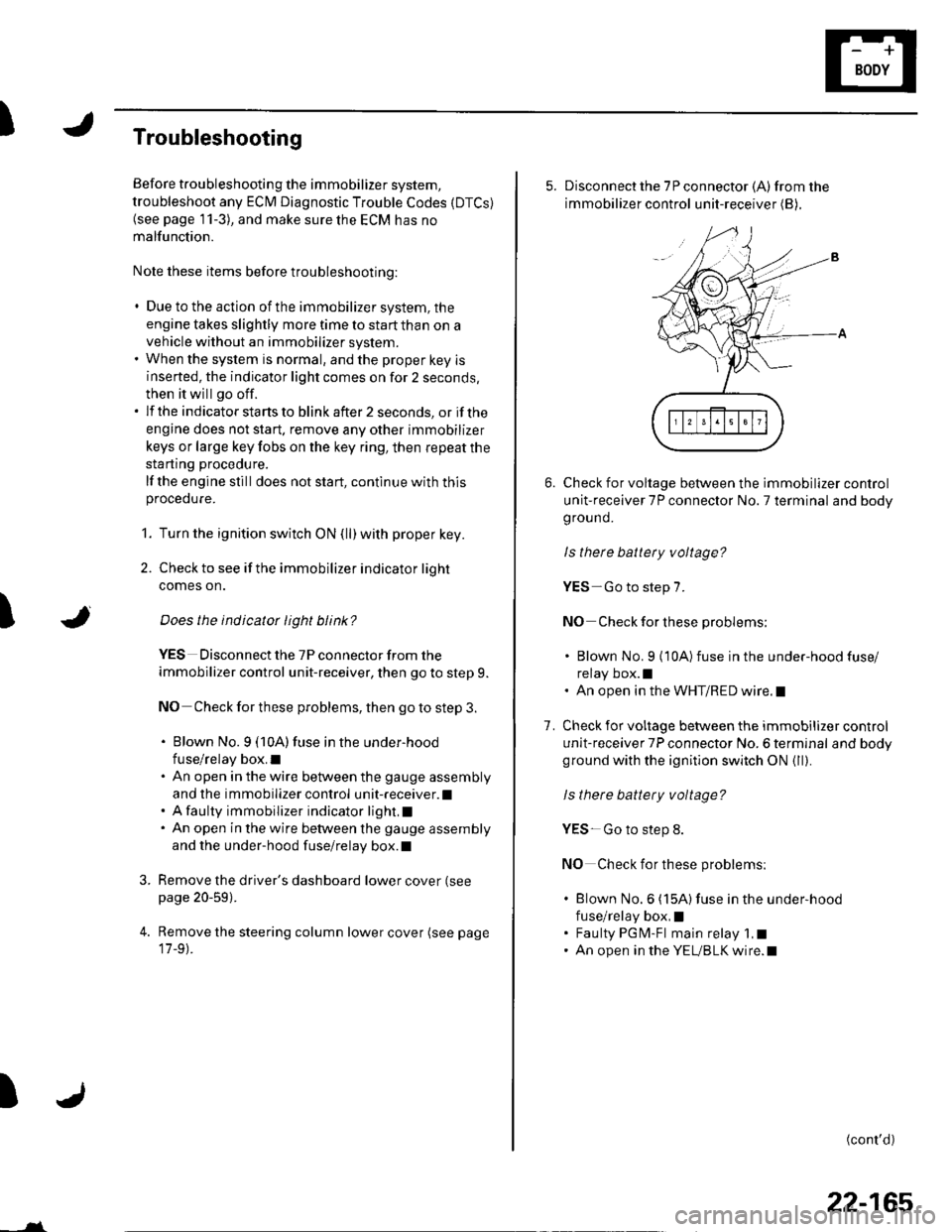

5. Disconnect the 7P connector (A)from the

immobilizer control unit-receiver (B),

Check for voltage between the immobilizer control

unit-receiver 7P connector No. 7 terminal and body

ground.

ls there battery voltage?

YES-Go to step 7.

NO Check for these problems;

. Blown No. 9 {10A)fuse in the under-hood fuse/

relay box.l. An open in the WHT/RED wire.l

Check for voltage between the immobilizer control

unit-receiver 7P connector No. 6 terminal and bodyground with the ignition switch ON {ll).

ls there battery voltage?

YES- Go to step 8.

NO Check for these problems:

. Blown No.6 (15A)fuse in the under-hood

fuse/relay box,I. Faulty PGM-Fl main relay 1,t. An open in the YEUBLK wire.l

1.

(cont'd)

Page 999 of 1139

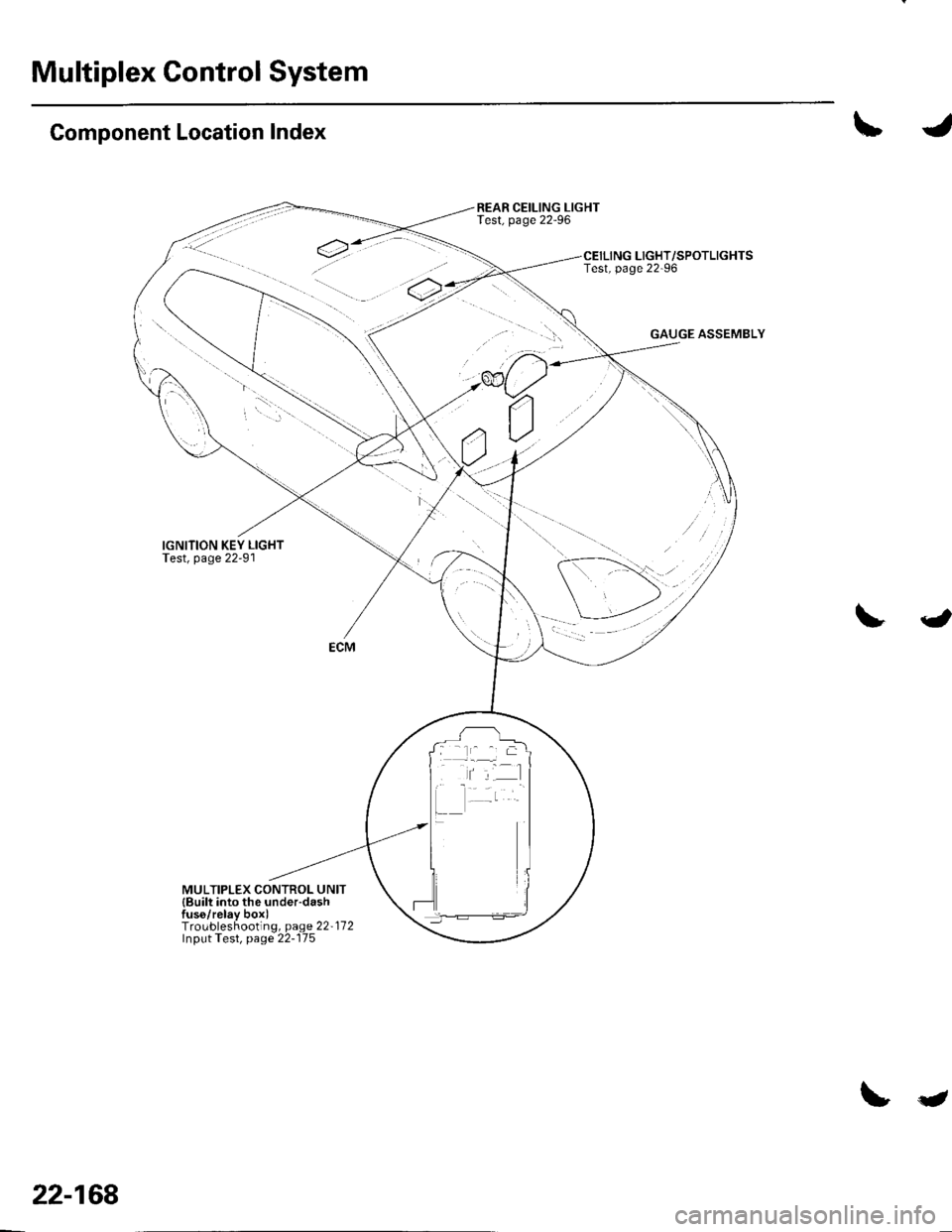

Multiplex Control System

Component Location Index

IGNITION KEY LIGHTTest, page 22'91

lr, J

REAR CEILING LIGHTTest, page 22'96

LIGHT/SPOTLIGHTSTest, page 22-96

GAUGE ASSEMBLY

ECM

MULTIPLEX CONTROL UNIT{Built into the under-dashfus6/relav boxlTroubleshooting, page 22'172Input Test, page 22-175

22-168

t

Page 1001 of 1139

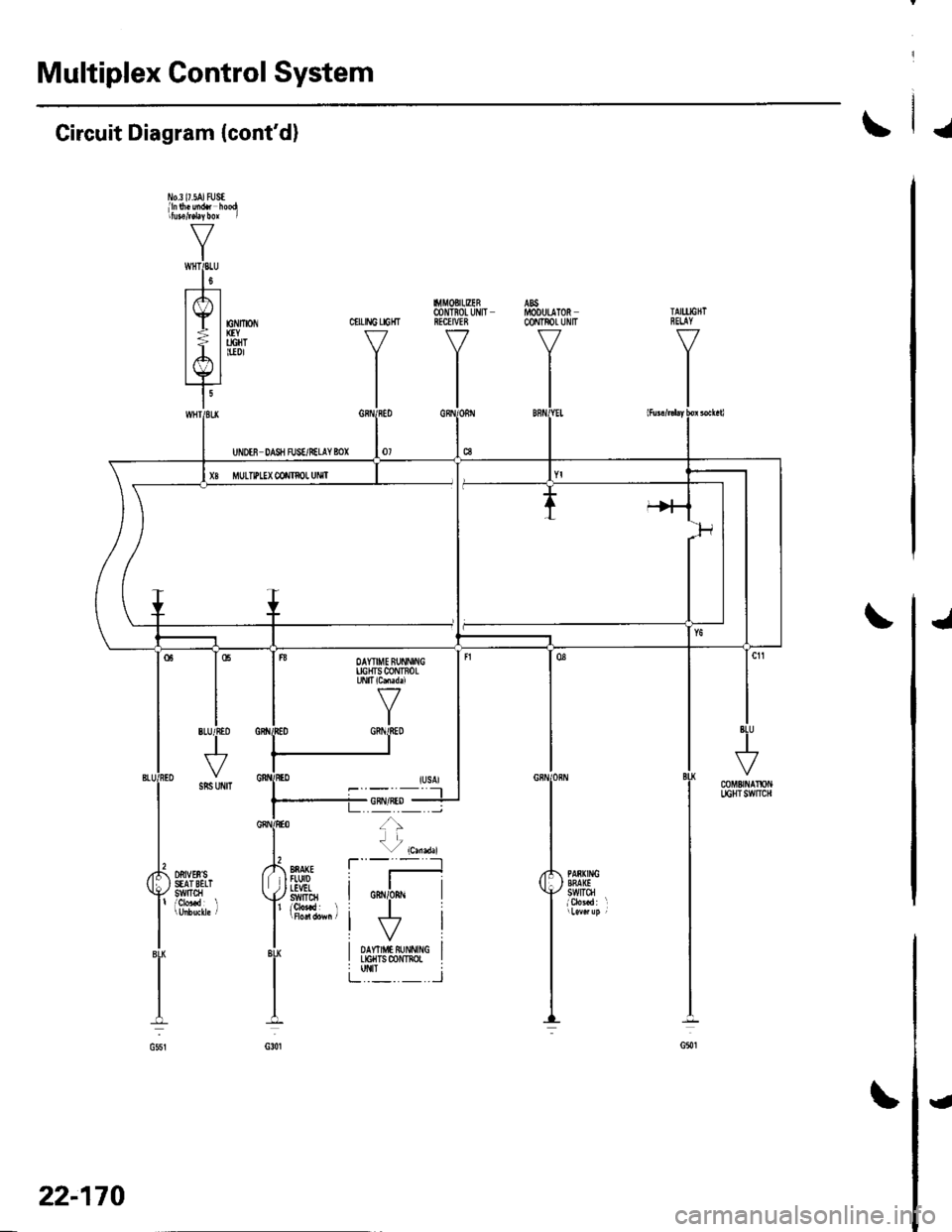

Multiplex Control System

J

J

Circuit Diagram (cont'd)

l'1o.3 l7.5AJ tUStlln$.uidt hoodritutefd4bor I

V

IwHTPLU

l0t--t---

lrfl |

lE lnv*-| > | ucHT

lA l'*'tYl

I'

CIILING LIGHT

I.l|MOBItEER@NTIOL UIIITRECEIVEE

VI

I

22-170

{

Page 1002 of 1139

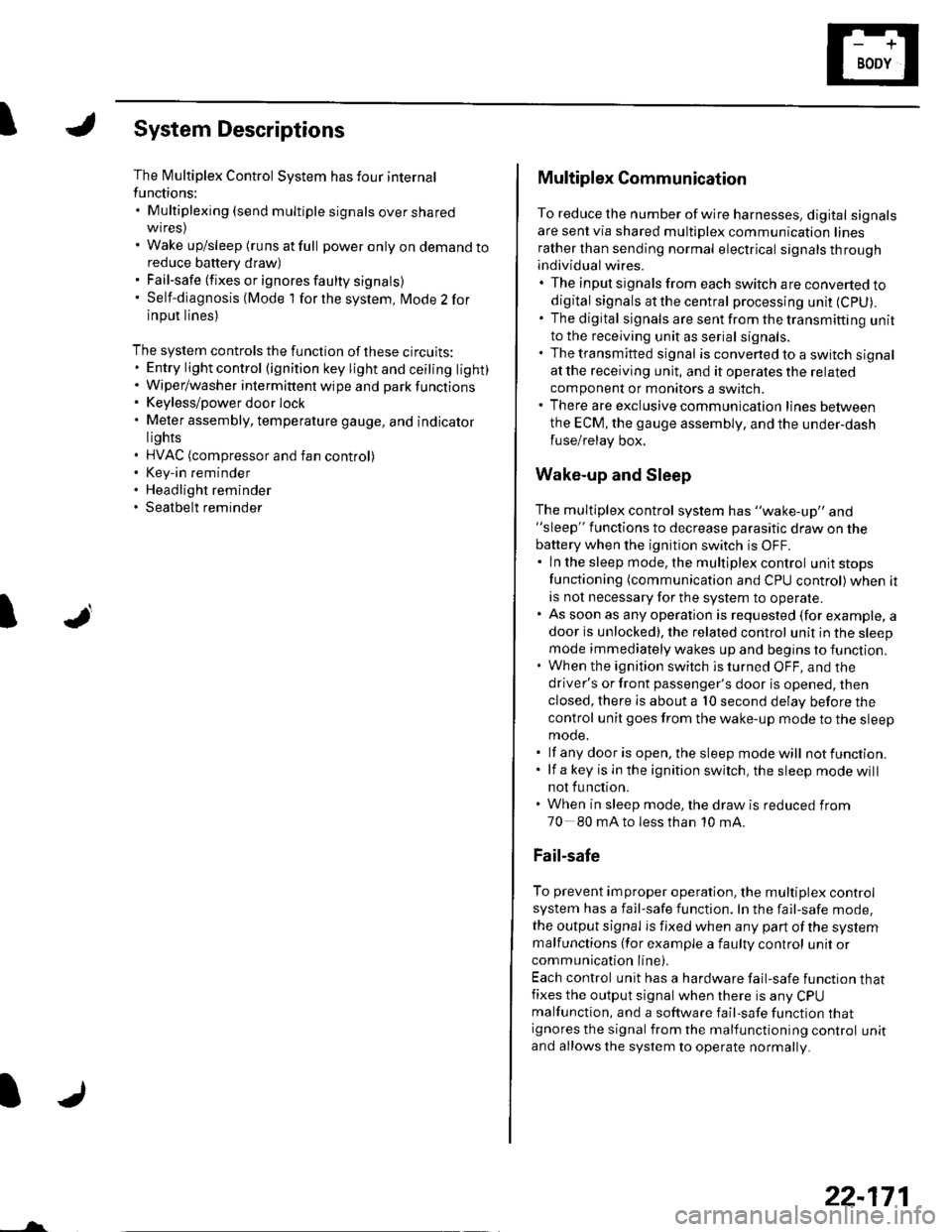

ISystem Descriptions

The Multiplex Control System has four internal

functions:. Multiplexing (send multiple signals over sharedwtres). Wake up/sleep (runs at full power only on demand toreduce battery draw). Fail-safe (fixes or ignores faulty signals). Self-diagnosis (Mode 1 for the system, Mode 2 for

input lines)

The system controls the function of these circuits:. Entry lightcontrol (ignition key lightandceiting light). Wiper/washer intermittent wipe and park functions. Keyless/power door lock. Meter assembly, temperature gauge, and indicator

lights. HVAC (compressor and fan control). Key-in reminder. Headlight reminder. Seatbelt reminder

JI

/ar

22-171

Multiplex Communication

To reduce the number of wire harnesses, digital signals

are sent via shared multiplex communication linesrather than sending normal electrical signals throughindividual wires.. The input signals from each switch are converted todigital signals at the central processing unit (CpU).. The digital signalsaresentfromthetransmitting unitto the receiving unit as serial signals.. The transmitted signal is converted to a switch signalat the receiving unit, and it operates the related

component or monitors a swltch.. There are exclusive communicalion lines between

the ECM, the gauge assembly, and the under,dash

fuse/relay box.

Wake-up and Sleep

The multiplex control system has "wake-up" and"sleep" functions to decrease parasitic draw on the

battery when the ignition switch is OFF.. ln the sleep mode, the multiplex control unit stops

functioning (communication and CPU control) when it

is not necessary for the system to operate.. As soon as any operation is requested (for example, adoor is unlocked), the related control unit in the sleep

mode immediately wakes up and begins to function.. When the ignition switch is turned OFF, and the

driver's or front passenger's door is opened, then

closed, there is about a 10 second delay before the

control unit goes from the wake-up mode to the sleepmode.. lf any door is open, the sleep mode will not function.. lf a key is in the ignition switch, the sleep mode will

not function.. When in sleep mode, the draw is reduced from

70 80 mA to less than 10 mA.

Fail-safe

To prevent improper operation, the multiplex controlsystem has a fail-safe function. In the fail-safe mode,

the output signal js fixed when any part of the systemmalfunctions (for example a faulty control unit orcommunication line).

Each control unit has a hardware fail-safe function thatfixes the output signal when there is any CPUmalfunction, and a software fail-safe function thatignores the signal from the malfunctioning control unitand allows the system to operate normally.

Page 1003 of 1139

Multiplex Control System

Troubleshooting

Mode 1 Tset

1. Remove the driver's dashboard lower cover {see

page 20-59).

2. Check the No. 9 ( 10A) fuse in the under-hood fuse/

relay box and the No. 10 (7.5A) fuse in the under-

dash fuse/relay box.

Are the fuses OK?

YES-Go to step 2.

NO-Find and repairthe cause ofthe blown fuse.!

3. Turn the ignition switch ON (ll).lf the driver's

seatbelt is unbuckled the seat belt reminder will

chime 6 times.

4. Set the ceiling light to the center position and close

allthe doors.

5. Connect the specialtoolto the multiplex inspection

conneclor.

6. After about 5 seconds the spotlight and ceiling light

should come on for 2 seconds, go out, then blink on

for 0.2 second to show the system is now in mode

1.

Did the spotlight and ceiling light indicate mode

1?

YES-Go to step 8.

NO Go to step 7.

22-172

-

7. Check for continuity between terminal 4ofthe

under-dash fuse/relay box connector J and body

ground.

ls there continuity?

YES Replace the under-dash fuse/relay box.l

NO - Repair the open in the wire.lf the wire is ok,

repair G301.1

8. lf ther are any DTCS present, the spotlight and

ceiling light will blink to indicate the DTC(S). lf more

than one DTC is present, the DTCS will be displayed

in ascending order, lf there are no DTCS the

spotlight and ceiling light will not blink again after

the mode 1 indication.

Are there any DTCg?

YES Go to step 9.

NO Go to the Mode 2 test.

9. Troubleshoot the DTC(S) in the order indicated

using the following charts.

lf a faulty control unit is suspected, substitute it

with a known food part and recheck for DTCS,

. lf the DTC(s) isstill present. go to the next step

listed for the DTC.. lf the DTC(S) is no longer present replace the

original part.

Page 1008 of 1139

IJ

IJ

IJ

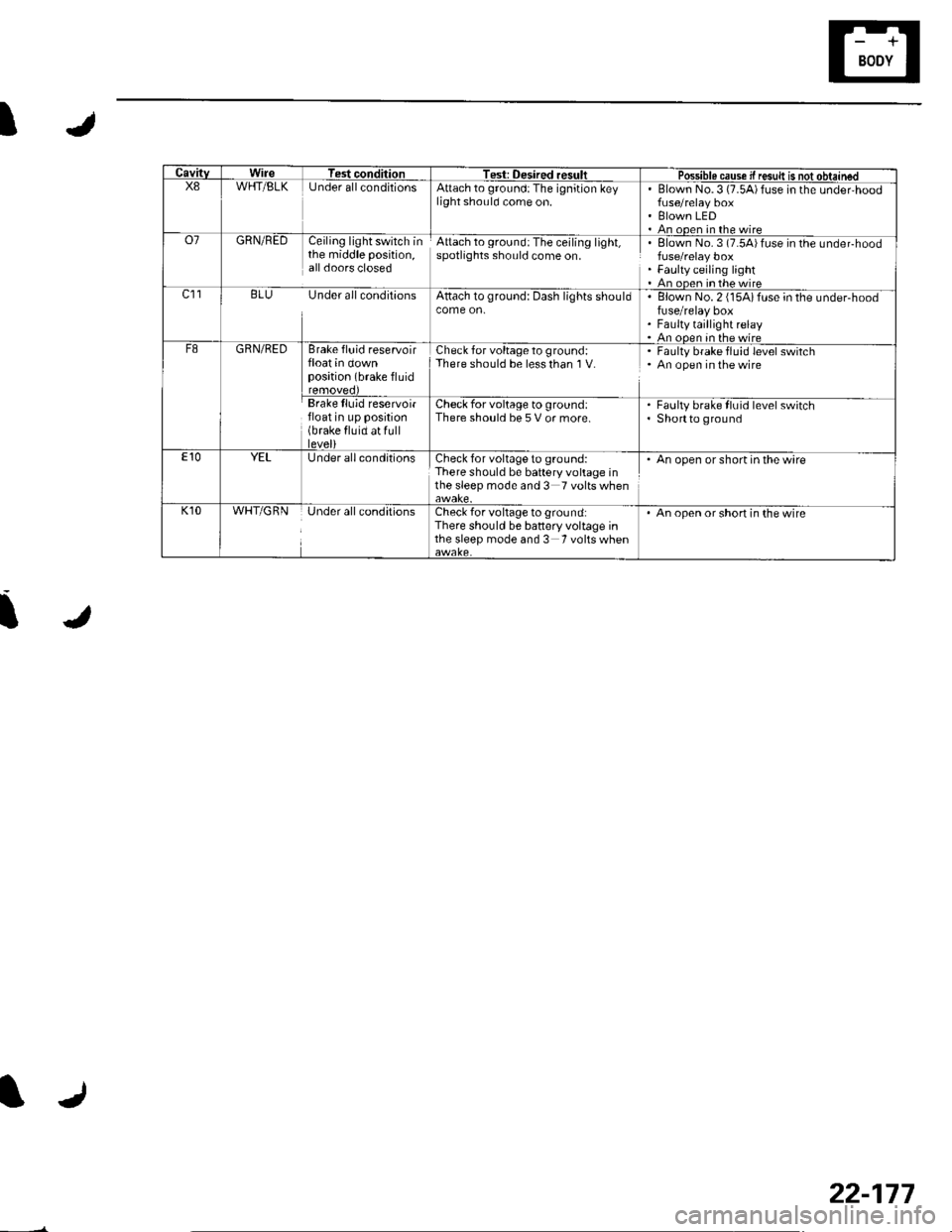

CavitvWireTest conditionTest: Desired resultPossible cause if resuk is not obtainedX8WHT/BLKUnder allconditionsAttach to ground:The ignition keylight should come on.Blown No.3 (7.5A)fuse in the under,hood

Blown LEDAn ooen in the wireo7GRN/REDCeiling light switch inthe middle position,all doors closed

Attach to ground:The ceiling light,spotlights should come on.Elown No. 3 (7.54)fuse in the undeFhood

Faulty ceiling lightAn oDen in the wirec]1BLU Under all conditionsAttach to ground: Dash lights shouldBlown No. 2 (15Aifuse in the under-hoodfuse/relay boxFaulty taillight relayAn ooen in the wireF8GRN/REDBrake fluid reservoirfloat in downposition (brake fluid

Check for voltage to ground:There should be less than I V.Faulty brake fluid level switchAn open in the wire

Brake lluid reservoirfloat in up position(brake fluid at fulllevel)

Check for voltage to ground:There should be 5 V or more.Faulty brake fluid level switchShortto ground

E10YELUnder all conditionsCheck for voltage to ground:There should be battery voltage inthe sleep mode and 3 Tvoltswhen

. An open or short in the wire

K10WHT/GRNUnder all conditionsCheck for voltage to ground:There should be battery voltage inthe sleep mode and 3 Tvoltswhen

An open or short in the wire

22-177

Page 1026 of 1139

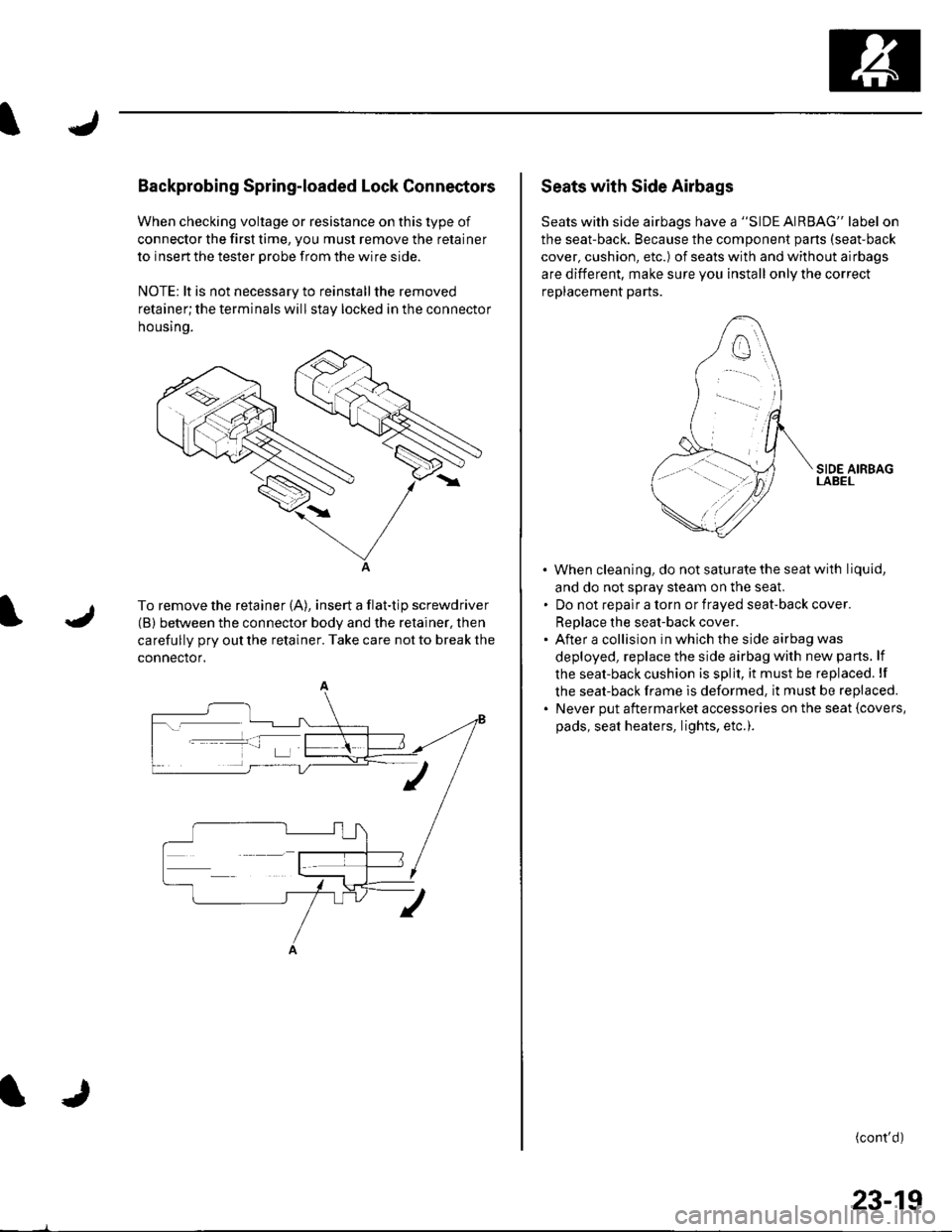

Backprobing Spring-loaded Lock Connectors

When checking voltage or resistance on this type of

connector the first time, you must remove the retainer

to insert the tester orobe from the wire side.

NOTE: lt is not necessary to reinstall the removed

retainer;the terminals will stay locked in the connector

housrno.

A

To remove the retainer (A), insert a flat-tip screwdriver

(B) between the connector body and the retainer, then

carefully pry out the retainer. Take care not to break the

connector.

Seats with Side Airbags

Seats with side airbags have a "SIDE AIRBAG" label on

the seat-back. Because the component pans (seat-back

cover, cushion, etc.) of seats with and without airbags

are different, make sure you install only the correct

replacement parts.

When cleaning, do notsaturatethe seatwith liquid,

and do not sDrav steam on the seal

Do not reoalr a torn or fraved seat-back cover.

ReDlace the seat-back cover.

After a collision in which the side airbag was

deployed, replace the side airbag with new parts. lf

the seat-back cushion is split, it must be replaced. lf

the seat-back frame is deformed, it must be replaced.

Never put aftermarket accessories on the seat {covers,

pads, seat heaters, lights, etc.).

(cont'd)

23-19

Page 1111 of 1139

sRs

DTG Troubleshooting (cont'dl

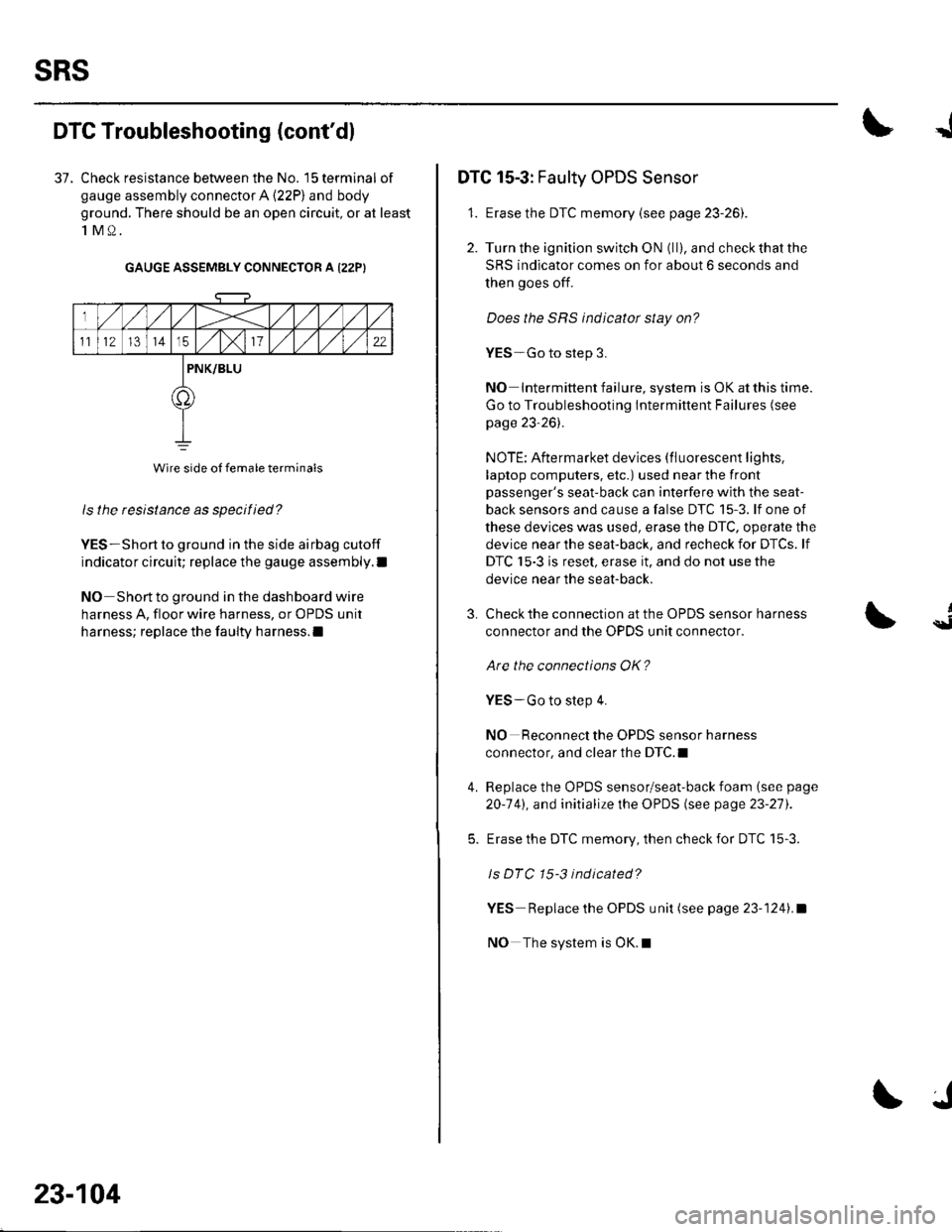

37. Check resistance between the No. 15 terminal of

gauge assembly connector A (22P) and body

ground. There should be an open circuit, or at least

1M0.

GAUGE ASSEMBLY CONNECTOR A I22PI

ls the resistance as specified?

YES-Short to ground in the side airbag cutoff

indicator circuit; replace the gauge assembly.l

NO Short to ground in the dashboard wire

harness A, floor wire harness, or OPDS unit

harness; replace the faulty harness.l

Wire side of female terminals

23-104

J

DTC 15-3: Faulty OPDS Sensor

1. Erase the DTC memory {see page 23-261.

2. Turn the ignition switch ON (ll), and check that the

SRS indicator comes on for about 6 seconds and

then goes off.

Does the SRS indicator stay on?

YES-Go to step 3.

NO Intermittent failure, system is OK at this time.

Go to Troubleshooting Intermittent Failures (see

page 23-26).

NOTE: Aftermarket devices (fluorescent lights,

laptop computers, etc.) used near the front

passenger's seat-back can interfere with the seat-

back sensors and cause a false DTC 15-3. lf one of

these devices was used, erase the DTC, operate the

device near the seat-back, and recheck for DTCs. lf

DTC 15-3 is reset, erase it, and do not use the

device near the seat-back.

3.

4.

Check the connection at the OPDS sensor harness

connector and the OPDS unit connector.

Are the connections OK?

YES-Go to step 4.

NO Reconnect the OPDS sensor harness

connector, and clear the DTC.I

Replace the OPDS sensor/seat-back foam (see page

20-141, and initialize the OPDS (see page 23-27).

Erase the DTC memory, then check for DTC 15-3.

ls DTC 15-3 indicated?

YES Replace the OPDS unit (see page 23-1241.a

NO The system is OK.l

{

Page 1124 of 1139

)

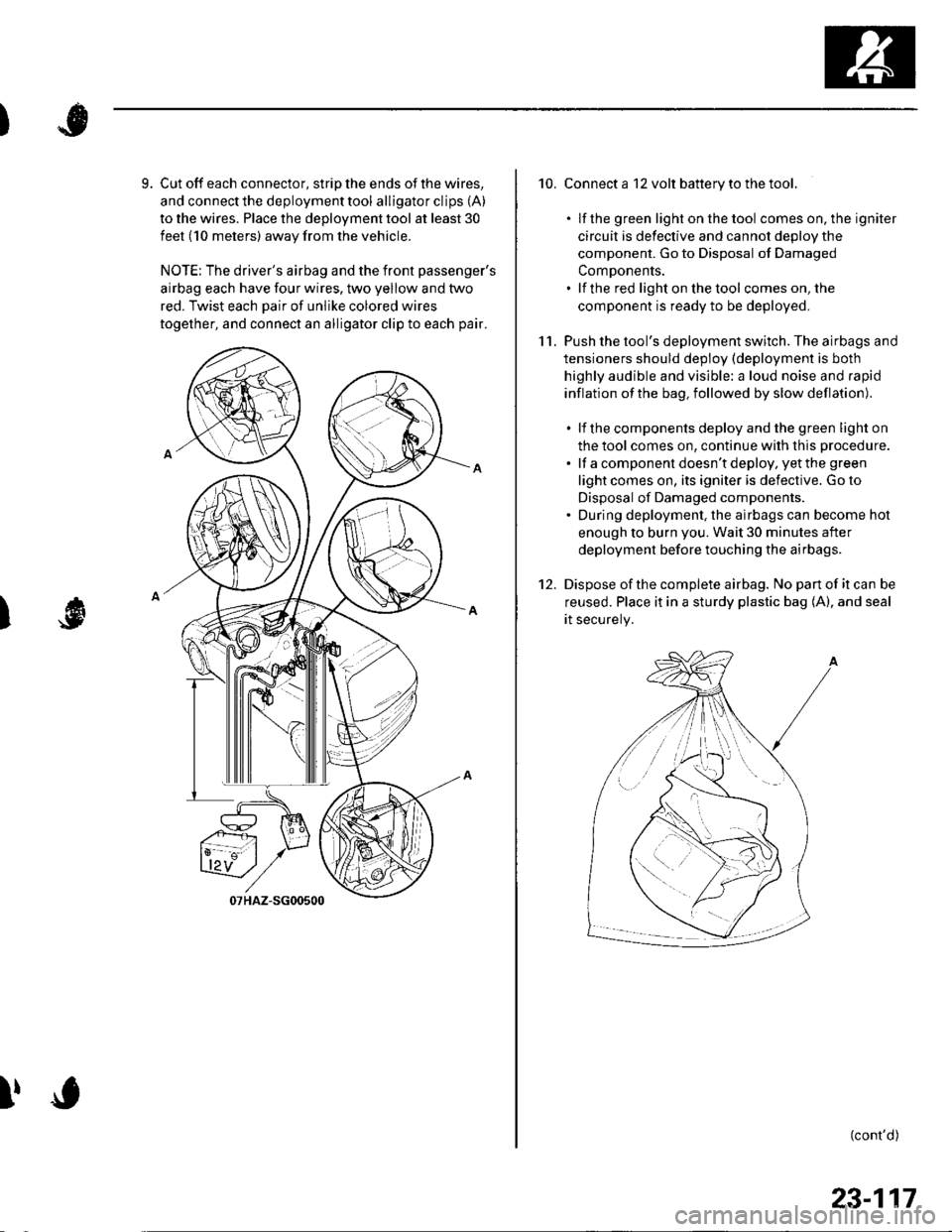

9. Cut off each connector, strip the ends of the wires,

and connect the deployment tool alligator clips (A)

to the wires. Place the deployment tool at least 30

feet (10 meters) away from the vehicle.

NOTE: The driver's airbag and the front passenger's

airbag each have four wires, two yellow and two

red. Twist each Dair of unlike colored wires

together, and connect an alligator clip to each pair.

I

!

10. Connect a 12 volt battery to the tool.

. lf the green light on the tool comes on, the igniter

circuit is defective and cannot deDlov the

component. Go to Disposal of Damaged

ComDonents.. lf the red light on the tool comes on, the

component is ready to be deployed.

11. Push the tool's deployment switch. The airbags and

tensioners should deploy (deployment is both

highly audible and visible: a loud noise and rapid

inflation of the bag, followed by slow deflation).

. lf the components deploy and the green light on

the tool comes on, continue with this procedure.

. lf a component doesn't deploy, yet the green

light comes on, its igniter is defective. Go to

Disposal of Damaged components.. During deployment, the airbags can become hot

enough to burn you. Wait 30 minutes after

deployment before touching the airbags.

12. Dispose ofthe complete airbag. No pan of it can be

reused. Place it in a sturdy plastic bag (A), and seal

rt securery.

(cont'd)

/:

i'..-':

23-117

Page 1133 of 1139

Service Manual lndex

)s

NOTE: Referto the lollowing listto look up A/C Pressure Switch CircuitDTCS, symptoms, fuses, connectors, wire Troubleshooting ......... ...-.-....-...-.-.-....-..21-32 Bharnesses, specifications, maintenanceschedules, and general serviceinlormation:

DTC Troubleshooting Indexes

A/C Signal CircuitTroubleshooting.........................-...... 11-'133 Back-up Light SwitchTest .......................................................... 13'3A/F lAir Fuel Ratiol SensorABS/TCS Components ........................ 19-34 Replacement ....................................... 1 1-113 Back-up Li9ht3EPS Components ................................. '17-22 Circuit DiagramFueland Emissions11-i A-Dillar Corner Trim

ABS Indicator Circuit

Heating/Ventilation ................................ 21-9 Replacement ...............-.....-..............-.... 20,96 Ball Joint BootssRS ........................................................ 23-28Replacement ......

... 19-52 Ball Joints

22-75

18 16

Remova1.............-.......... . ...........18-10Symptom Troubleshooting Indexes TroubleshootingABS/TCSComponents........................ 19 35Cruise Control System ..........................4 38 ABS Modulator-contml UnitEPS Components ................................. 17-23 Bemoval/lnstallation ............................ 19-57 BettervFan Controls10,12

Accessory Powor Socket Front

Blowor Pow€r Transistor

.......22 50

Blower UnitRemoval/lnstallation ............................ 21-39

Fuel and Em issions .............................. 11-10 ABS/TCS ComoonentsHeating/Ventilation..............................21 10 Component Location Index ................. 19-30 Beverage Holder

SRS ........................................................ 23'30 CircuitDiaqram.......................... 19'42Blower MotorReplacement .....21 41

21-38

Power 0istribution ...............................22-46 TesVReplacement .............................. 22'149Under-dash Fuse/Relay Box ............... 22 45Under-hood Fuse/Belay Box ...............22 44 Accessory Power Sockets

Fuse/Relay lndexes

(to harness)

Connector and Wire Harness lndexesComponent Connectors

Circuit Oiagram .................................. 22-149

Air Cleaner......2214 Rep1acemen1.....................................11-162

Air MixControl MotorMeintenence section .................... Section 3 Replacement ......................................... 21'34 Brake CelipersTest......................21-34 Overhaul19-14,23Gene.al lnlormation section........ Section 1

21.57

Airbag. Driver's

Ahernator FR Signal CircuitTroubleshooting .... .........-..........11 134

AntennaReplacement

Inspection ............................................. 19-24Rep|acement................. .................... 19-25

Bieke Meder Cylinder

Irake Discs

A

Replacement ....................................... 23 1 'l3 Inspection .................... ................... 19-13,22Repair ...........-...................................... 23 1 16Brake Fluid Level SwitchAirbag. Front Passenger's TestBeplacement....................................... 23-1 14AIC Brake LightsComponent Location fndex ...................21-3 Altemator CircuitDiagram....................................22-74Description.....................................-....21'1'l Beplacement ................ ........................... 4 29CircuitDiagram....................................21-14 Overhaul .................................................4-30 Brake Lines and Hoses

19.10

A/C CompressolReplacement .......-...-............................. 21 -41

A/C Compr€ssor ClulchRep1acement......................................... 19-15.........22-103 Inspection ............................................. 19-16Inspecton........Overhaul ..........

A/C CondenserReplacement,.,

21-442l-49 Audio Unit

Replacement

Brake PadsRemoval/lnstallation .. ........................22-100 Inspection/Rep1acement................ 19-11,20A/C Compressor Clutch CircuitTroubleshooting ................................... 21-30 Audio Unit Connector Brake Pedal22101 Adjustment..............19,6ArfC Comoressor Relief ValvcReplacement ..........-...-.......................... 21-51 Audio/Entertainment

A/C Compr$sor Thermal Protector Circuit DiagramReplacement............-............................ 21-51

Component Location In dex .................22-9A Test .......-.............. 22-84Breke Pedal Posilion Switch

Brake Pedal Position Switch Signal Clrcuit11-137

.....21 52

A/C Condenser Fan CircuitTroubleshooting ................... . . . . . .....21-28

)s

Troubleshooting

(cont'd)