sensor HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 777 of 1139

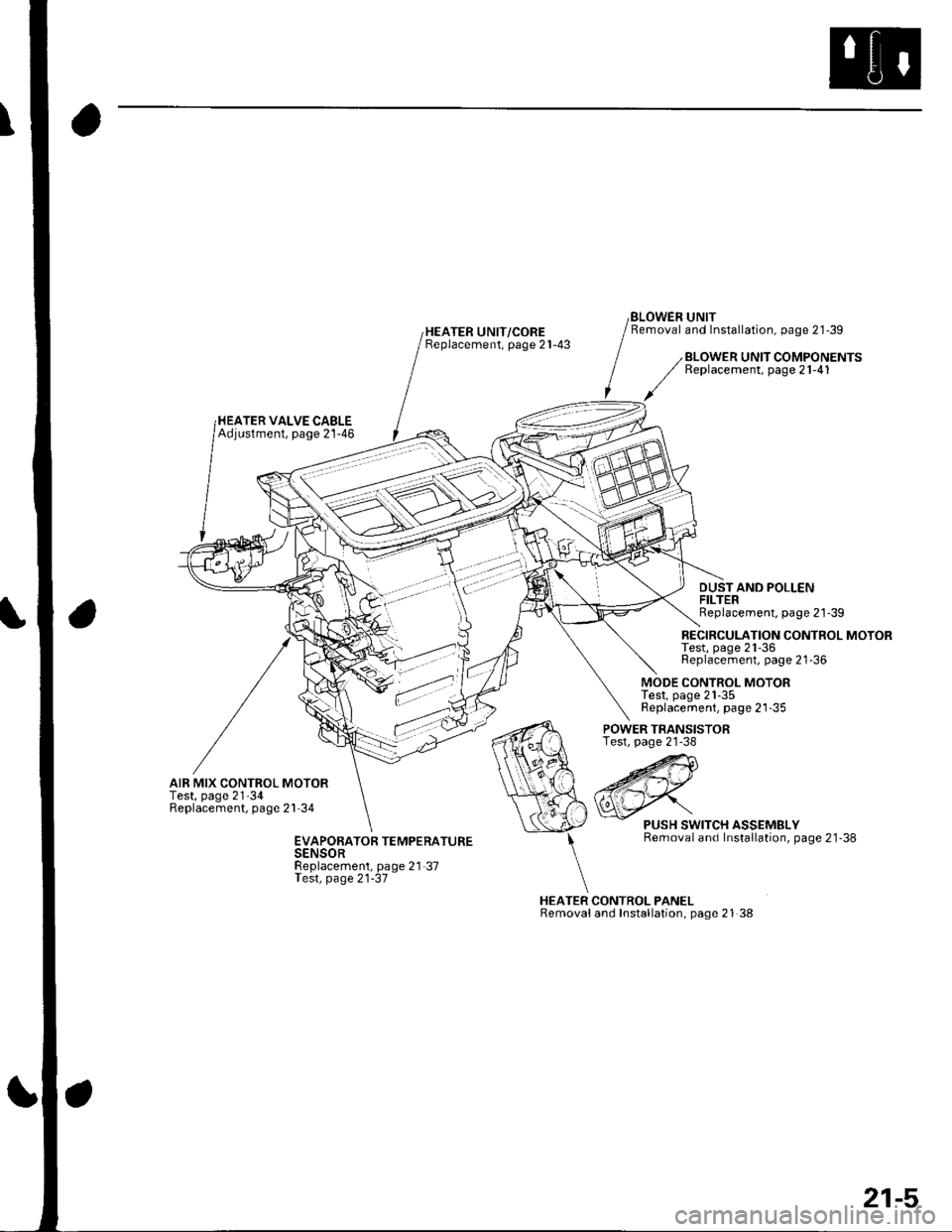

HEATER UNIT/COREBeplacement, page 21-43

BLOWEN UNITRemoval and Installation, page 21-39

HEATER VALVE CABLEAdjustment, page 21-46

BLOWER UNIT COMPONENTSReplacement, page 21-41

DUSTAND POLLENFILTERReplacement, page 21'39

RECIRCULATION CONTROL MOTORTest, page 21-36Replacement, page 21-36

MODE CONTROL MOTORTest, page 21-35Replacement, page 21-35

AIR MIX CONTROL MOTORTest, page 21'34Replacement, page 21'34

POWER TRANSISTORTest, page 21-38

HEATER CONTROL PANELRemovaland Installation, page 21 38

PUSH SWITCH ASSEMBLYRemoval and Installation, page 21'38EVAPORATOR TEMPERATURESENSORReplacement, page 21-37Test, page 21-37

21-5

Page 781 of 1139

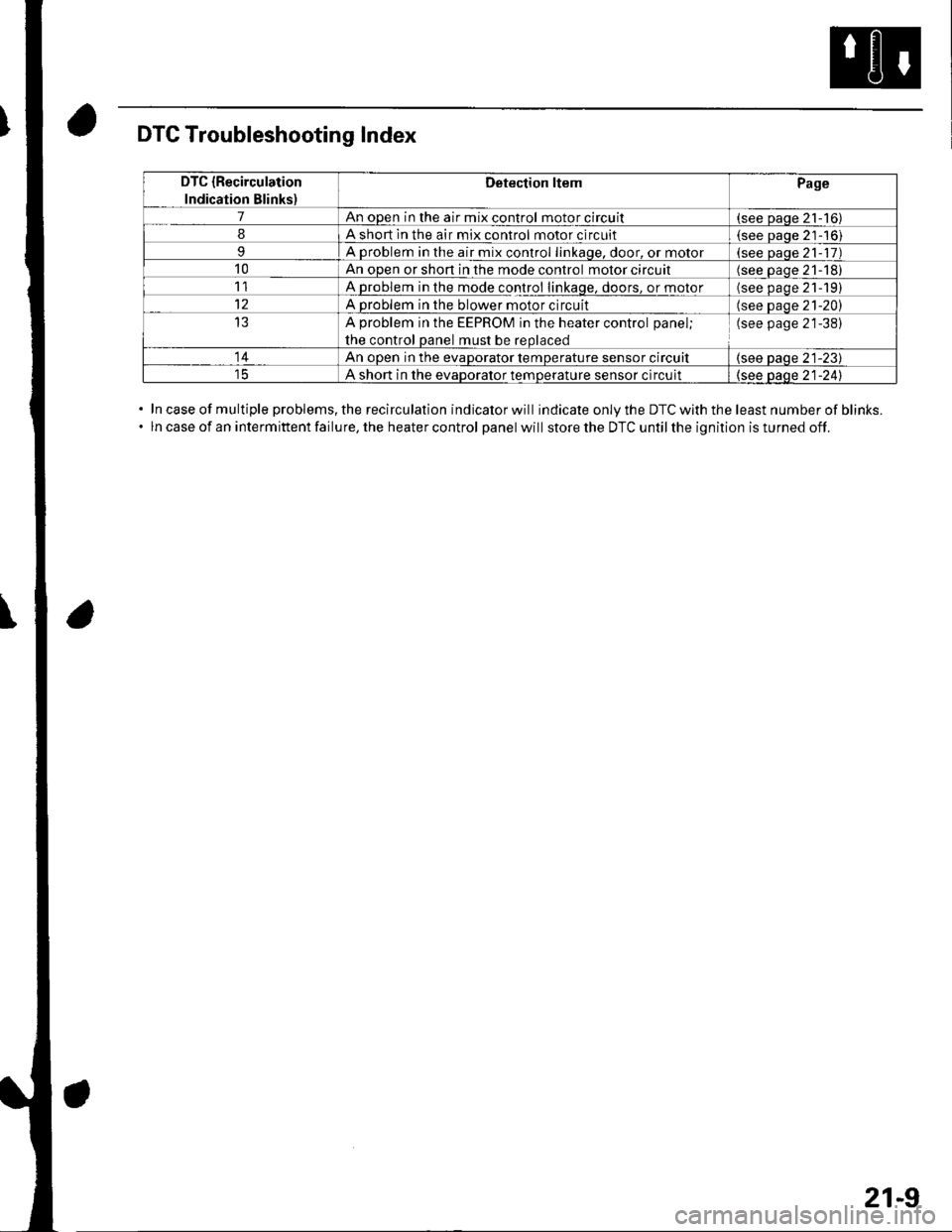

DTC Troubleshooting Index

In case of multiple problems, the recirculation indicator will indicate only the DTC with the least number of blinks.

ln case of an intermittent failure, the heater control panel will store the DTC until the ignition is turned off.

DTC {Recirculation

Indication Blinks)

Detection ltemPage

7An open in the air mix control motor circuit(see paqe 21-16)

8A short ln the air mix control motor circuit(see Daoe 21-'16)

9A problem in the air mix control linkaqe, door, or motor(see paqe 21- 17)

10An open or shon in the mode control motor circuit(see oaqe 21-18)

11A problem in the mode control linkage, doors, or motor(see paqe 21191

12A problem in the blower motor circuit(see paqe 21-20)

13A problem in the EEPROM in the heater control panel;

the control oanel must be reolaced

(see page 21-38)

14An ooen in the evaDorator temDerature sensor circuit(see paqe 21-23)

A short in the evaDoralor temoerature sensor circuit(see oaqe 21-241

21-9

Page 783 of 1139

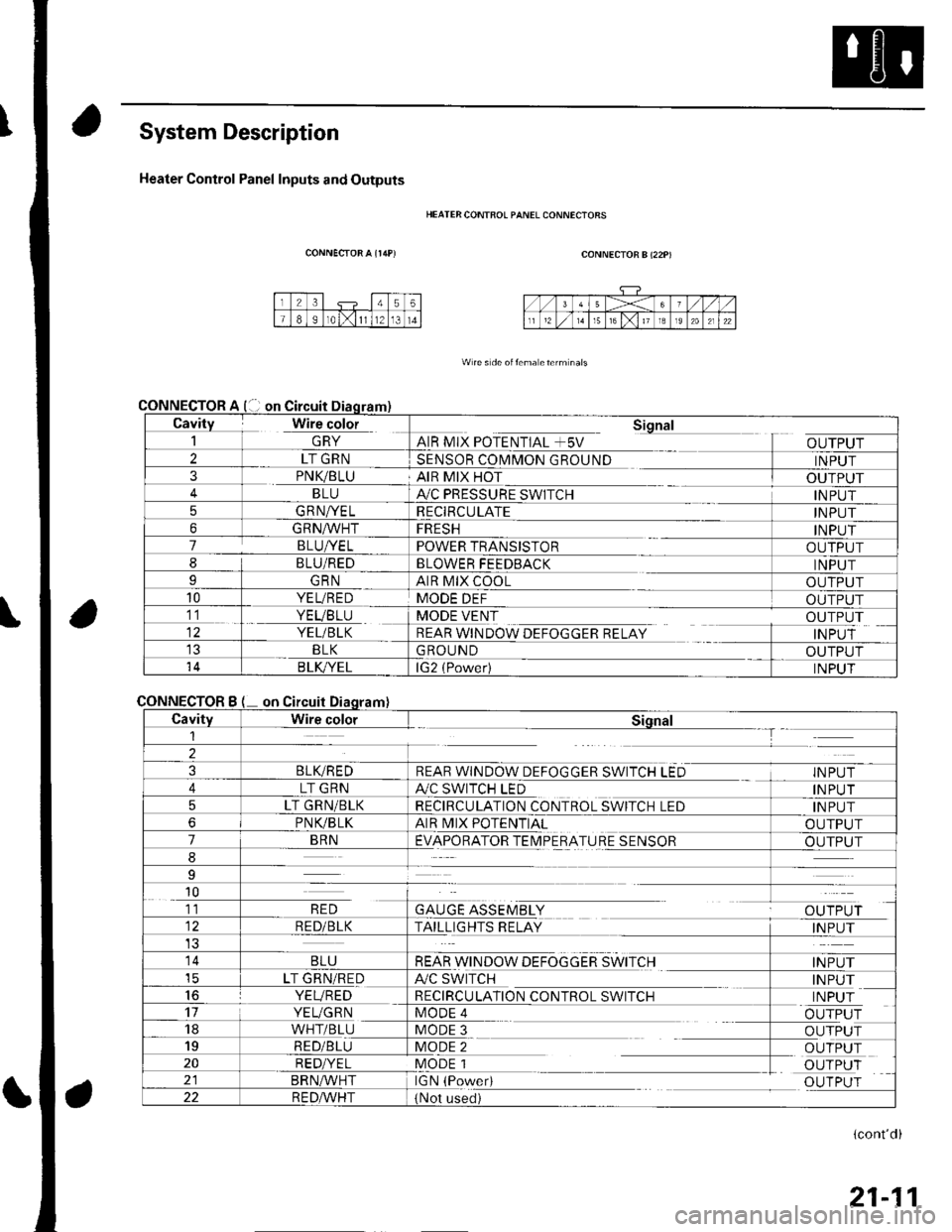

System Description

Heater Control Panel Inputs and Outputs

CONNECTOR A {r/rP)

CONNECTOR

CONNECTOR

HEATER CONTFOL PANEL CONNECIORS

CONNECTOR B (22P)

W re s de oitema eterm nals

Cavity Wire color_| \ln YAIR MIX POTENTIAL +5V

Sional

OUTPUT2LT GRNSENSOR COMMON GROUNDINPUT3PNK/BLUAIR MIX HOTOUTPUTBLUA,/C PRESSURE SWITCHINPUT5GRNA/ELRECIRCULATEINPUT6GRNA/VHTFRESHINPUT7BLUI/ELPOWER TRANSISTOROUTPUT8BLU/REDBLOWER FEEDBACKINPUTIGRNAIR MIX COOLOUTPUT10YEL/REDMODE DEFOUTPUT11. YEVBTU

YEL/BLK

MODE VENT

REAR WINDOW DEFOGGER RELAY

OUTPUT

INPUTBLKGROUNDOUTPUT14B LK/YELlG2 (Power)INPUT

Bon

CavityWire colorSiqnal1--T

2

3BLIVREDREAR WINDOW DEFOGGER SWITCH LEDINPUT

4LT GRNA./C SWITCH LEDINPUT

5LT GRN/BLKRECIRCULATION CONTROL SWITCH LEDINPUT

6PNVBLKAIR MIX POTENTIALOUTPUT

7BRNEVAPORATOR TEIMPERATURE SENSOROUTPUT

8

9

10

GAUGE ASSEMBLYal' 'TDr ri11RED

RED/BLKTAILLIGHTS RELAYINPUT

14BLUREAR WINDOW DEFOGGER SWITCHINPUTicLT GRN/REDA/C SWITCHINPUT16YEVREDRECIRCULATION CONTROL SWITCHINPUT17YEUGRNMODE 4OUTPUT18WHT/BLUMODE 3OUTPUT19RED/BLUMODE 2OUTPUT20RED/YELMODE 1OUTPUTBRN^,^/HTIGN (PowedOUTPUT22R E DA/r'HT(Not used)

(cont'd)

21-11

Page 784 of 1139

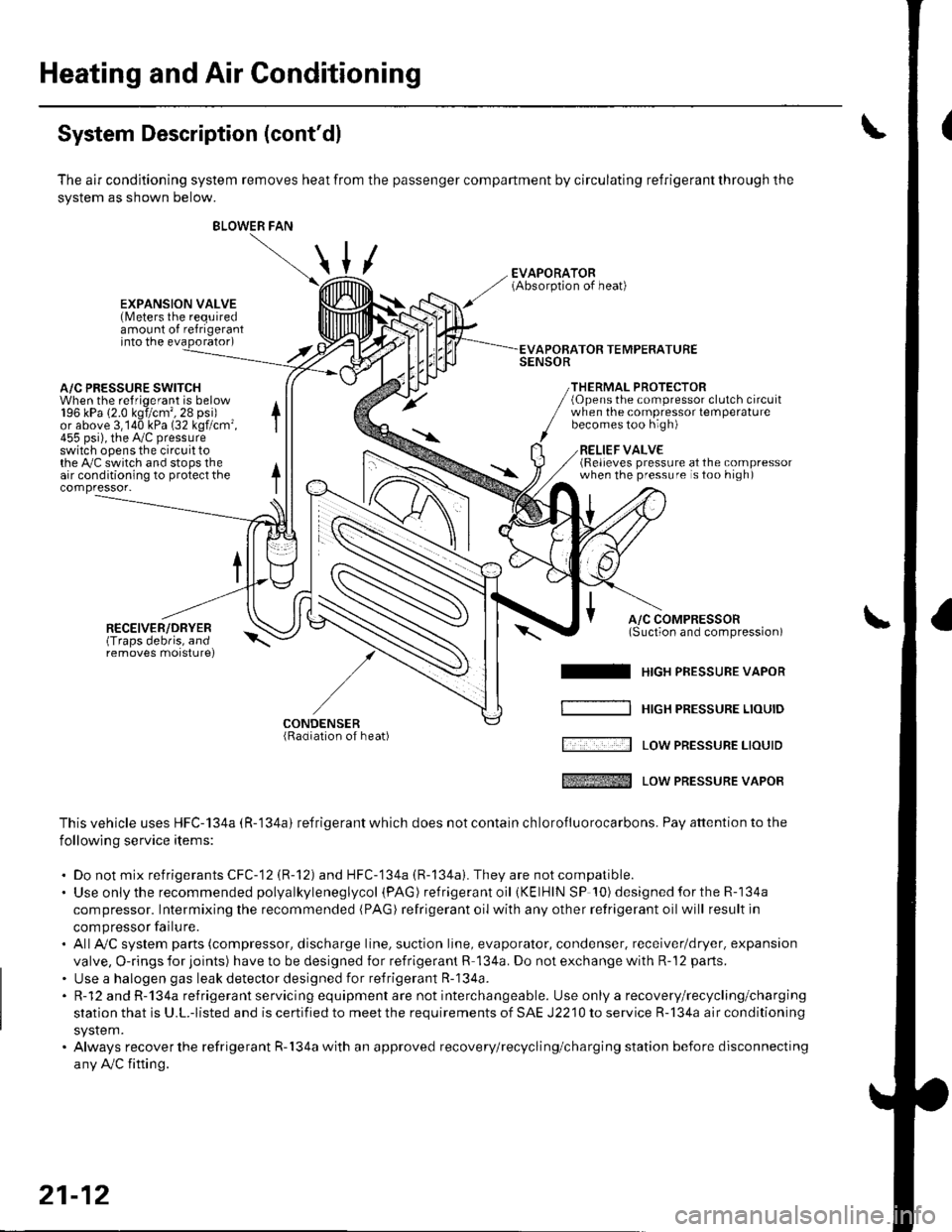

Heating and Air Gonditioning

System Description (cont'dl

The air conditioning system removes heat from the passenger compartment by circulating refrigerant through the

system as shown below.

/

BLOWER FAN

\

\,u

EXPANSION VALVE(Meters the requiredamount of refrigerantinto the evaporator)

A/C PRESSURE SWITCHWhen the refriqerant is below196 kPa (2.0 kgi/cm',28 psi)or above 3,140 kPa (32 kgf/cm'455 psi), the Py'c pressureswitch opens the circuit tothe Py'C switch and stops theair conditioning to protect thecompressor-

RECEIVER/DRYER(Traps debris, andremoves morsturel

APOBATOR TEMPERATURESENSOR

THERMAL PROTECTOR(Opens the compressor clutch circuitwhen the compressot temperaturebecomes too high)

RELIEF VALVE(Relieves pressure at the compressorwhen the pressure is too high)

A/C COMPRESSOR(Suction and comoression)\-^

I HrcH PRESSURE vAPoR

[ '.... -:--l Low PREsSUBE LrourD

tffi Low PREssURE vAPoR

This vehicle uses HFC-134a (R-'134a) refrigerant which does not contain ch lorofluorocarbons. Pay attention to the

following service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are notcompatible.. Use onlythe recommended polyalkyleneglycol (PAG ) refrigera nt oil (KElHlN SP '!0) designedfortheR-134a

compressor. Intermixing the recommended (PAG) refrigerant oil with any other retrigerant oil will result in

compressor failu re.. AllAy'C system parts (compressor, discharge line, suction line, evaporator, condenser, receiver/dryer. expansion

valve, O-rings for joints) have to be designed for refrigerant R 134a. Do not exchange with R-'12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging

station that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning

system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting

any Ay'C fifting.

/-

CONDENSER(Radiation of heat)

21-12

Page 786 of 1139

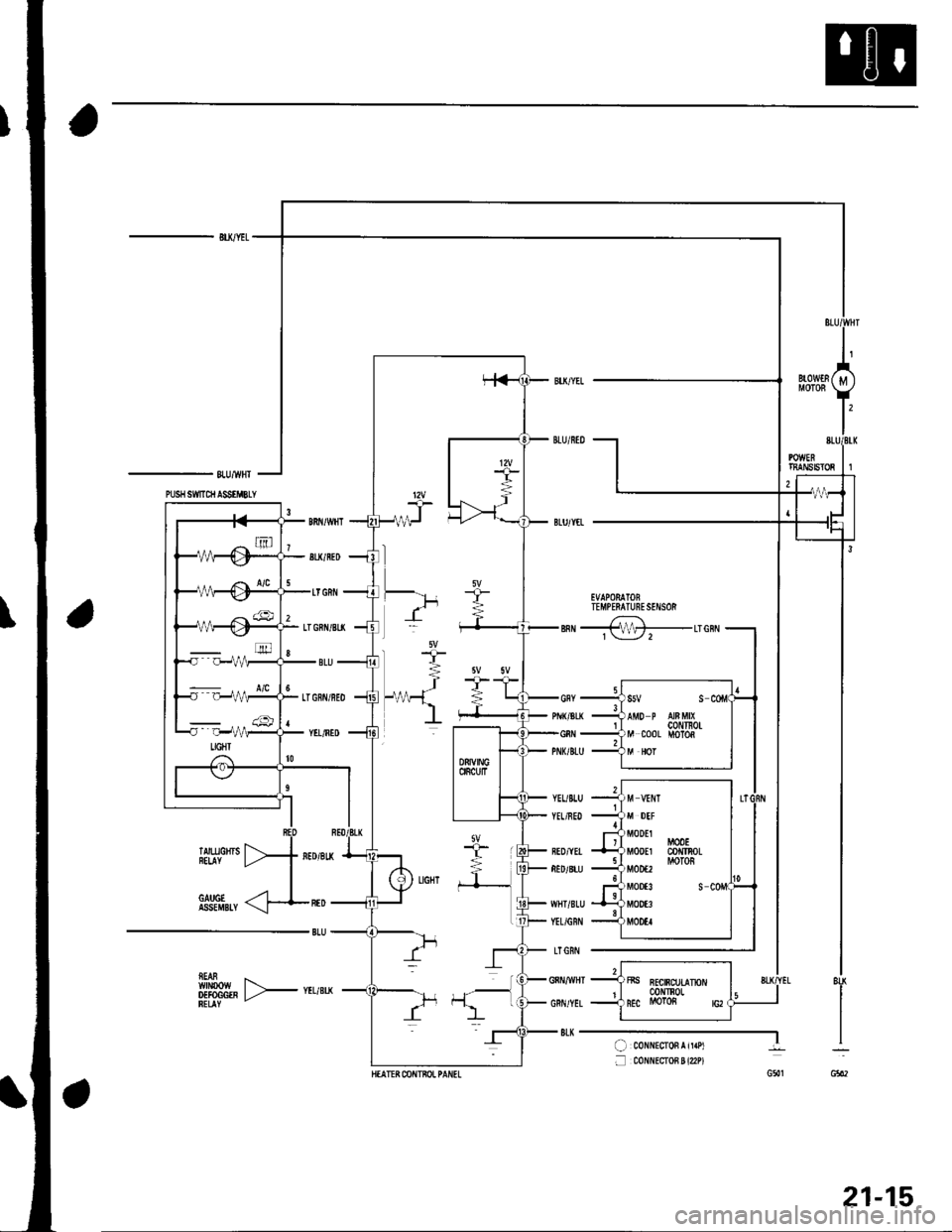

- BU/YEL

-8lU/wH'I

EVAPORATOBTEMPERATUNESENSOR

sn 4-Lrenil

ffftH,, F*u,*

YEUBLU

YEL/NED

BED/YEI

RED/8LU

WHT/8LU

YEL/GRN

LTGRI'l

GNNMHT

GRN/YEL

8LK--..-...-l( coNNEcroFrir.Pt

f mxr{EcroB ! {2P)G5'1

8U

I

G602

m

::-:::: ., . a/c

M DEF

MODEl

Mq)EI

M00€2

M00t3

MOOE3

MOOEI

M00lco TnoLMOTOS

s

21-15

Page 794 of 1139

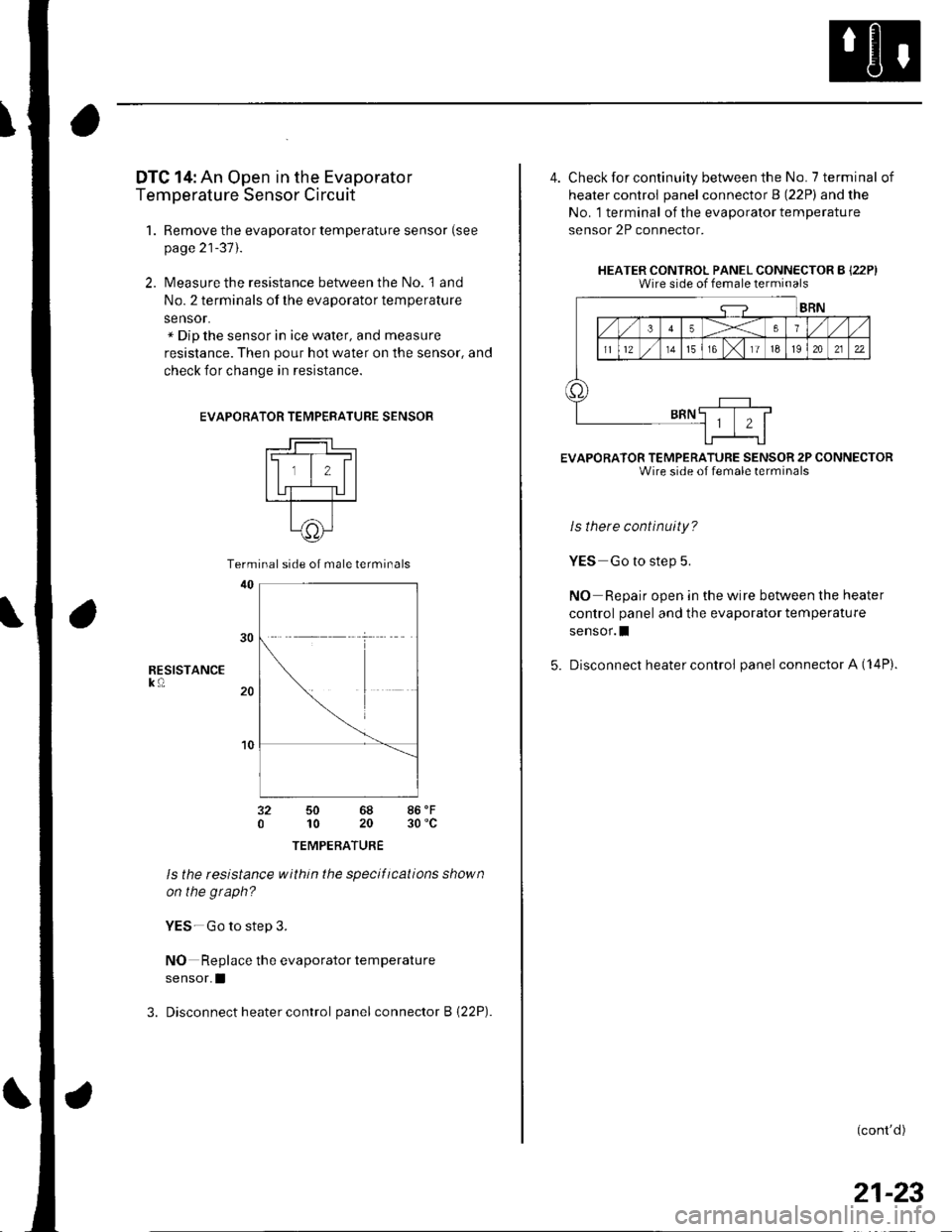

DTC 14: An Open in the Evaporator

Temperature Sensor Circuit

1. Remove the evaporator temperature sensor (see

page 21-37).

2. Measure the resistance between the No. l and

No. 2 terminals of the evaporator temperature

sensor.x Dip the sensor in ice water, and measure

resistance. Then pour hot water on the sensor, and

check for change in resistance.

EVAPORA

RESISTANCEk0

TOR TEMPERATURE SENSOR

t-lll#l

ll,l,llI UT-TU I---r---T--

t^11c))-l\9/

50 6810 20

TEMPERATURE

ls the tesistance within the specifications shown

on the graph?

YES-Go to step 3.

NO Replace the evaporator temperature

sensor.I

3. Disconnect heater control panel connector B {22P).

86'F30 'c

Terminal side of male terminals

4. Check for continuity between the No. 7 terminal of

heater control panel connector B (22P) and the

No. 1 terminal of the evaporalor temperature

sensor 2P connector.

HEATER CONTROL PANEL CONNECTOR B {22P)Wire side of female terminals

EVAPORATOR TEMPERATURE SENSOR 2P CONNECTORWire side of female terminals

ls there continuity?

YES Go to step 5.

NO Repair open in the wire between the heater

control panel and the evaporator temperature

sensor.I

5. Disconnect heater control panel connector A (14P).

(cont'd)

21-23

Page 795 of 1139

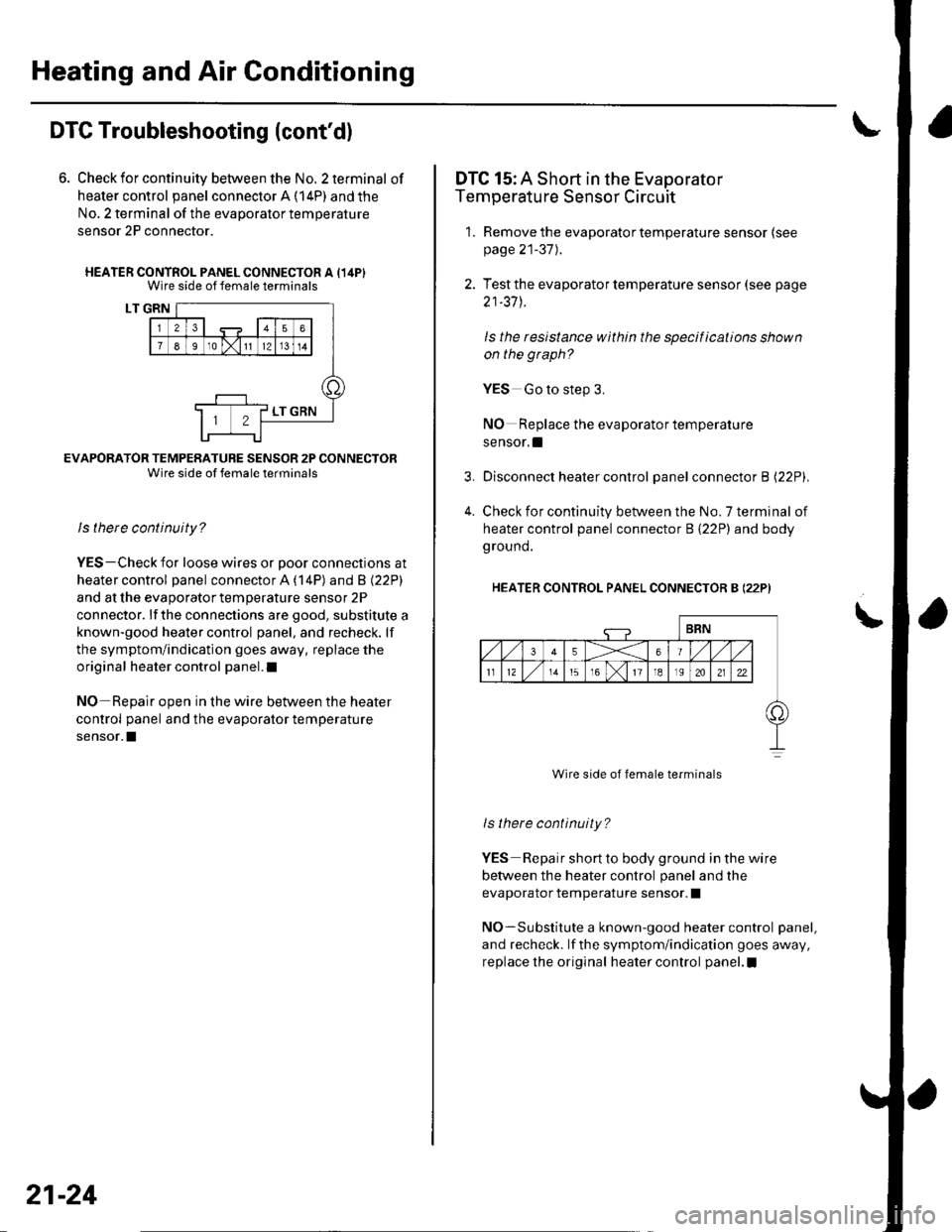

Heating and Air Gonditioning

\

DTC Troubleshooting {cont'd)

6. Check for continuity between the No. 2 terminal of

heater control panel connector A (14P) and the

No, 2 terminal of the evaporalor temperature

sensor 2P connector.

HEATER CONTROL PANEL CONNECTOR A {14PIWire side of female terminals

LT GRN

EVAFORATOR TEMPERATURE SENSOR 2P CONNECTORWire side of female terminals

ls there continuity?

YES-Check for loose wires or Door connections at

heater control panel connector A ('l4P) and B l22Pl

and at the evaporator temperature sensor 2P

connector. lf the connections are good, substitute a

known-good heater control panel, and recheck. lf

the symptom/indication goes away, replace the

original heater control panel.l

NO Reoair ooen in the wire between the heater

control panel and the evaporator temperature

sensor.I

21-24

4.

DTC 15: A Short in the Evaporator

Temperature Sensor Circuit

1. Remove the evaporator temperature sensor (see

page 21-37).

2. Test the evaporator temperature sensor (see page

21-37 J.

ls the resistance within the specifications shown

on the graph?

YES Go to step 3.

NO Replace the evaporator temperature

sensor. !

Disconnect heater control panel connector B l22Pl.

Check for continuity between the No. 7 terminal of

heater control panel connector B {22P) and body

ground.

HEATER CONTROL PANEL CONNECTOR B (22P)

Wire side of female terminals

ls there continuity?

YES Repair short to body ground in the wire

betvveen the heater control panel and the

evaporator temperature sensor. I

NO-Substitute a known-good heater control panel,

and recheck. lf the symptom/indication goes away,

replace the original heater control panel.I

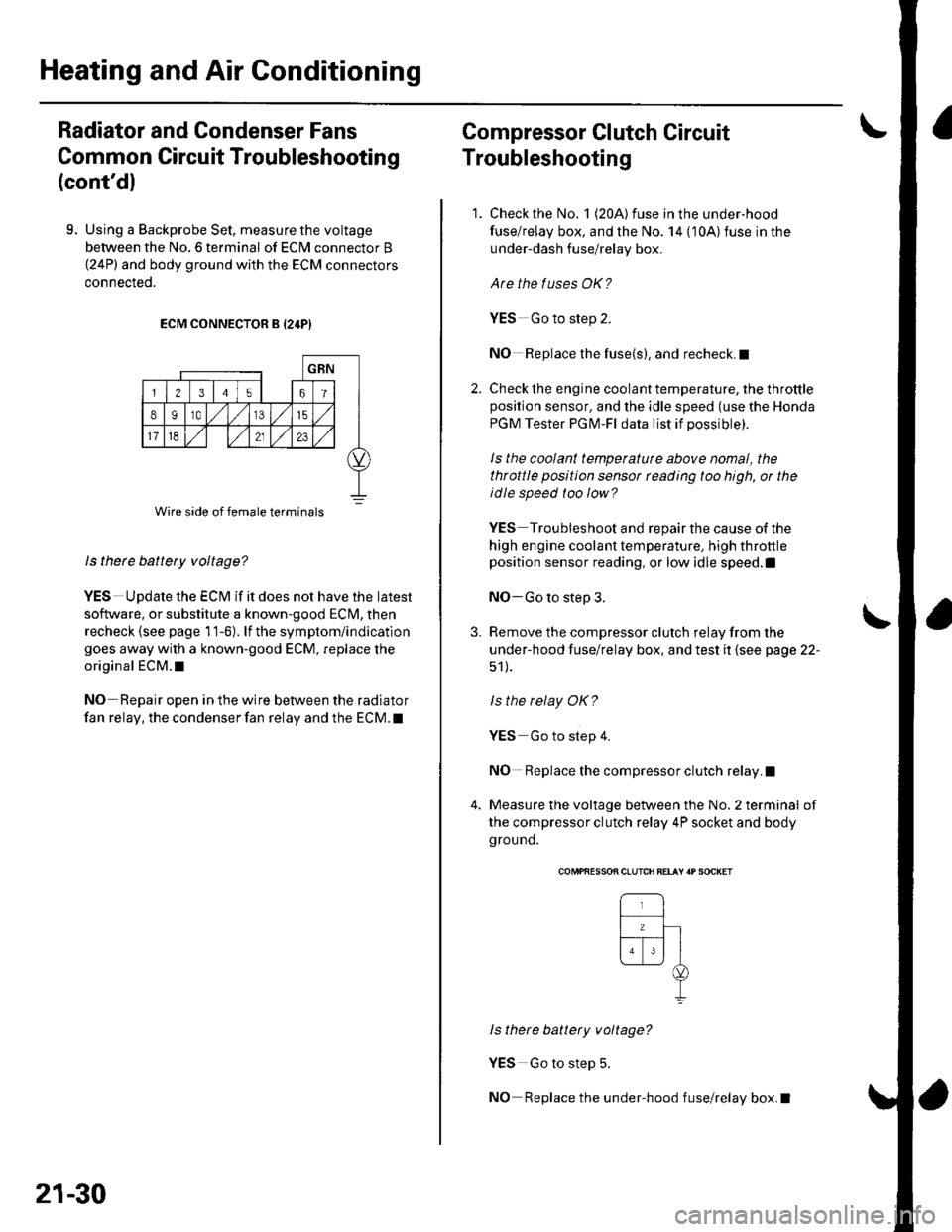

Page 801 of 1139

Heating and Air Conditioning

Radiator and Condenser Fans

Common

(cont'dl

Circuit Troubleshooting

9. Using a Backprobe Set, measure the voltage

between the No. 6 terminal of ECN4 connector B

{24P) and body ground with the ECM connectors

connecteo.

ECM CONNECTOR B {24P}

ls there battery voltage?

YES UDdate the ECM if it does not have the latest

so{tware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Repair open in the wire between the radiator

fan relay, the condenser fan relay and the ECM. t

Wire side of female terminals

21-30

Compressor Clutch Circuit

Troubleshooting

1. Check the No. 1 (20A) fuse in the under-hood

fuse/relay box, and the No. 14 {10A)fuse in the

under-dash fuse/relay box.

Are the tuses OK?

YES Go to step 2.

NO Replace the fuse(s), and recheck.I

2. Check the engine coolant temperature, the throttleposition sensor, and the idle speed (use the Honda

PGM Tester PGM-Fl data list if possible).

ls the coolant temperaturc above nomal, the

throttle position sensor rcading too high, or the

idle speed too low?

YES Troubleshoot and repair the cause of the

high engine coolant temperature, high throttle

position sensor reading, or low idle speed.l

NO-Go to step 3.

3. Remove the compressor clutch relay from the

under-hood fuse/relay box, and test it (see page 22-

51 ).

ls the relay OK?

YES Go to step 4.

NO Replace the compressor clutch relay.I

4. Measure the voltage between the No. 2 terminal of

the compressor clutch relay 4P socket and body

ground.

\

COMPfiESSON CLUTCH BELAY 'P SOCKET

ls there battery voltage?

YES Go to step 5.

NO Replace the under-hood fuse/relay box.I

Page 808 of 1139

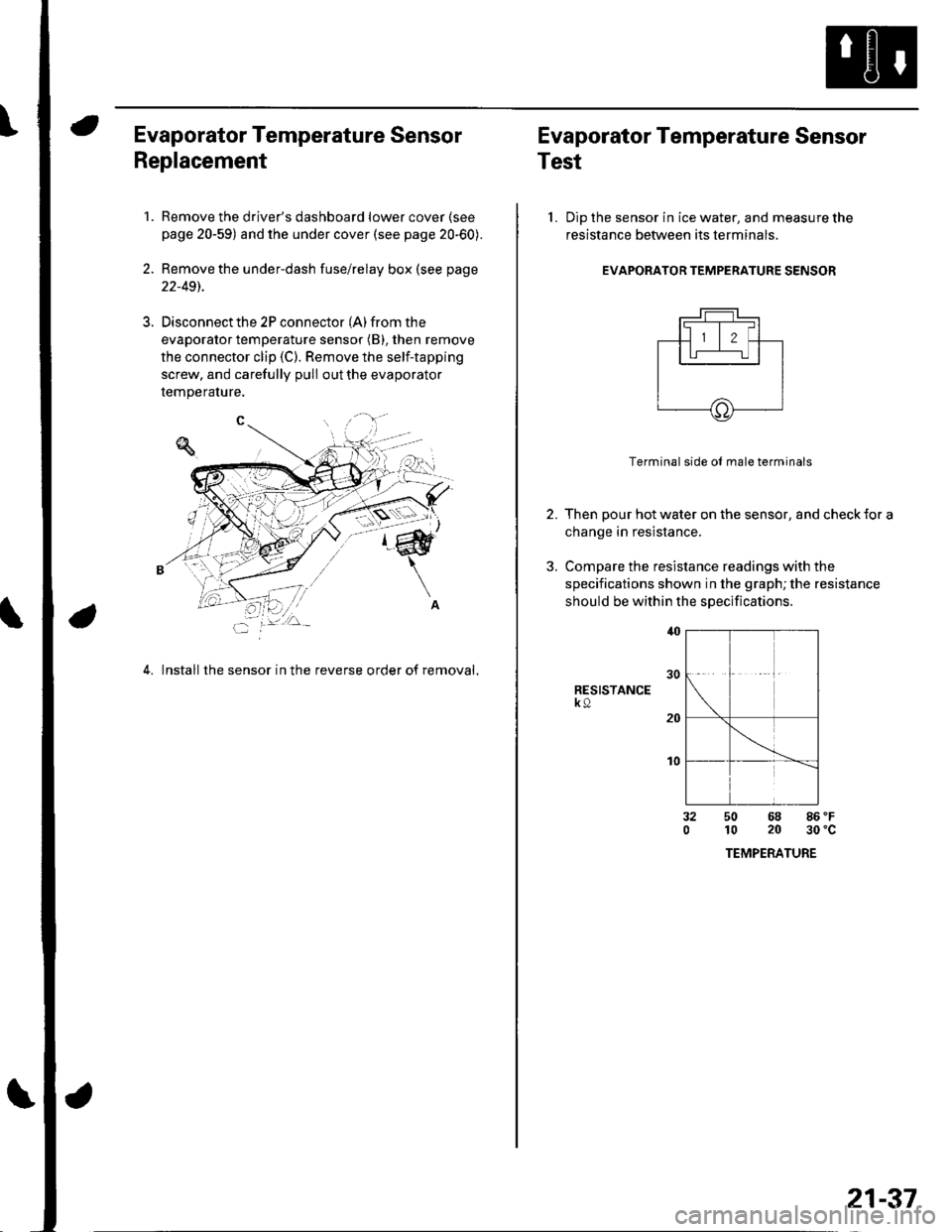

Evaporator Temperature Sensor

Replacement

1.Remove the driver's dashboard lower cover (see

page 20-59) and the under cover (see page 20-60).

Remove the under-dash fuse/relay box (see page

22-491.

Disconnect the 2P connector (A) from the

evaporator temperature sensor (B), then remove

the connector clip (C). Remove the self-tapping

screw, and carefully pull out the evaporator

temperature.

4. Install the sensor in the reverse order of removal,

Evaporator Temperature Sensor

Test

l. Dip the sensor in ice water, and measure the

resistance between its terminals

EVAPORATOR TEMPERATURE SENSOR

2.

3.

Terminal side ol male terminals

Then pour hot water on the sensor, and check {or a

change in resistance.

Compare the resistance readings with the

specifications shown in the graph; the resistance

should be within the specifications

RESISTANCEk9

t0

32050 68 86 'F

10 20 30'c

TEMPERATURE

21-37

Page 815 of 1139

Heating and Air Conditioning

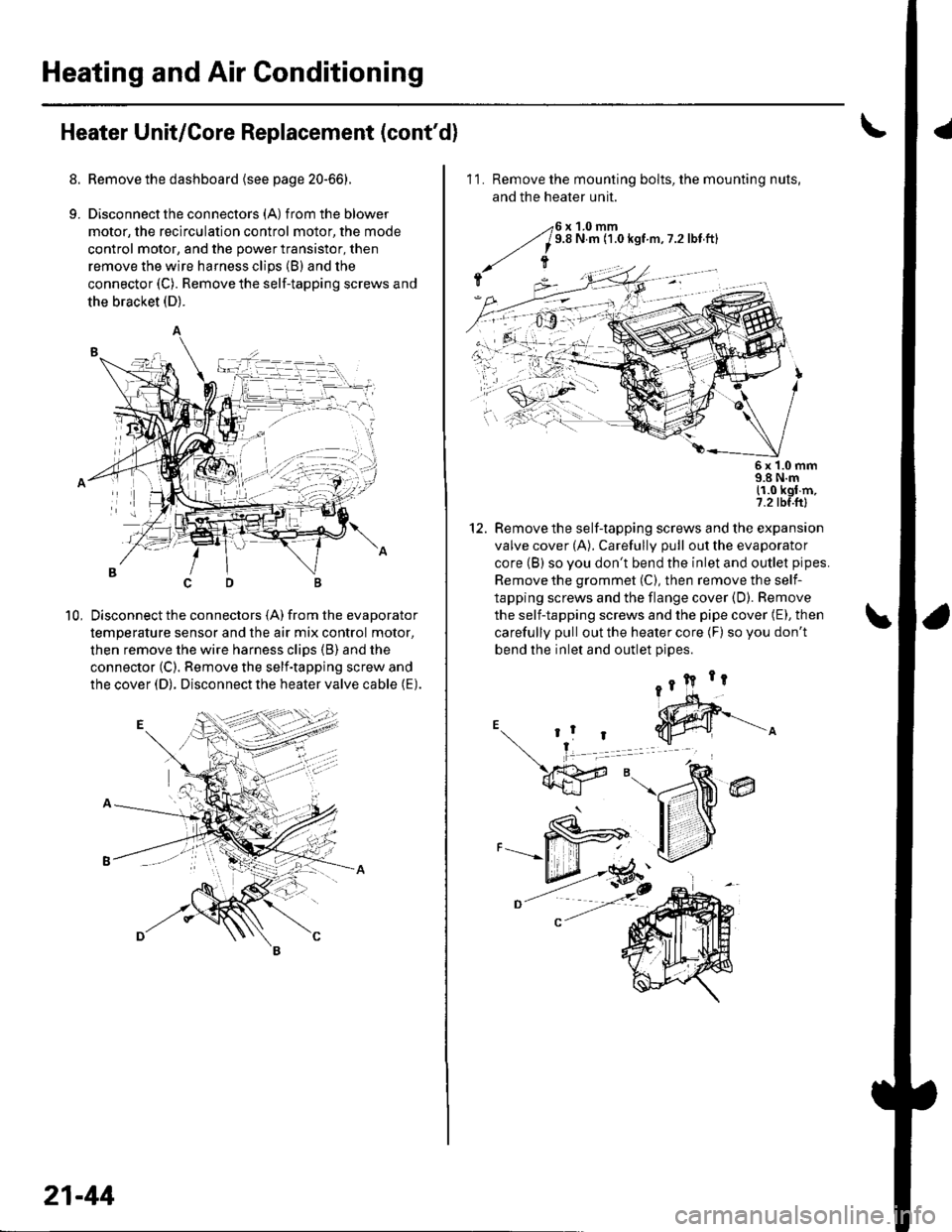

Heater Unit/Core Replacement (cont'd)

8. Remove the dashboard {see page 20-66).

9. Disconnectthe connectors (A) from the blower

motor, the recirculation control motor, the mode

control motor, and the power transistor, then

remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screws and

the bracket (D).

Disconnect the connectors (A) from the evaporator

temperature sensor and the air mix control motor,

then remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screw and

the cover (D). Disconnect the heater valve cable (E).

10,

7t,

21-44

11. Remove the mounting bolts, the mounting nuts,

and the heater unit.

Remove the self-tapping screws and the expansion

valve cover (A). Carefully pull out the evaporator

core (B) so you don't bend the inlet and outlet pipes.

Remove the grommet (C), then remove the self-

tapping screws and the flange cover (D). Bemove

the self-tapping screws and the pipe cover (E), then

carefully pull out the heater core (F) so you don't

bend the inlet and outlet oioes.

@

5x 1.0 mm9.8 N.m11.0 kgl m,7.2 tbf.ftl

12.