Rear wash HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 879 of 1139

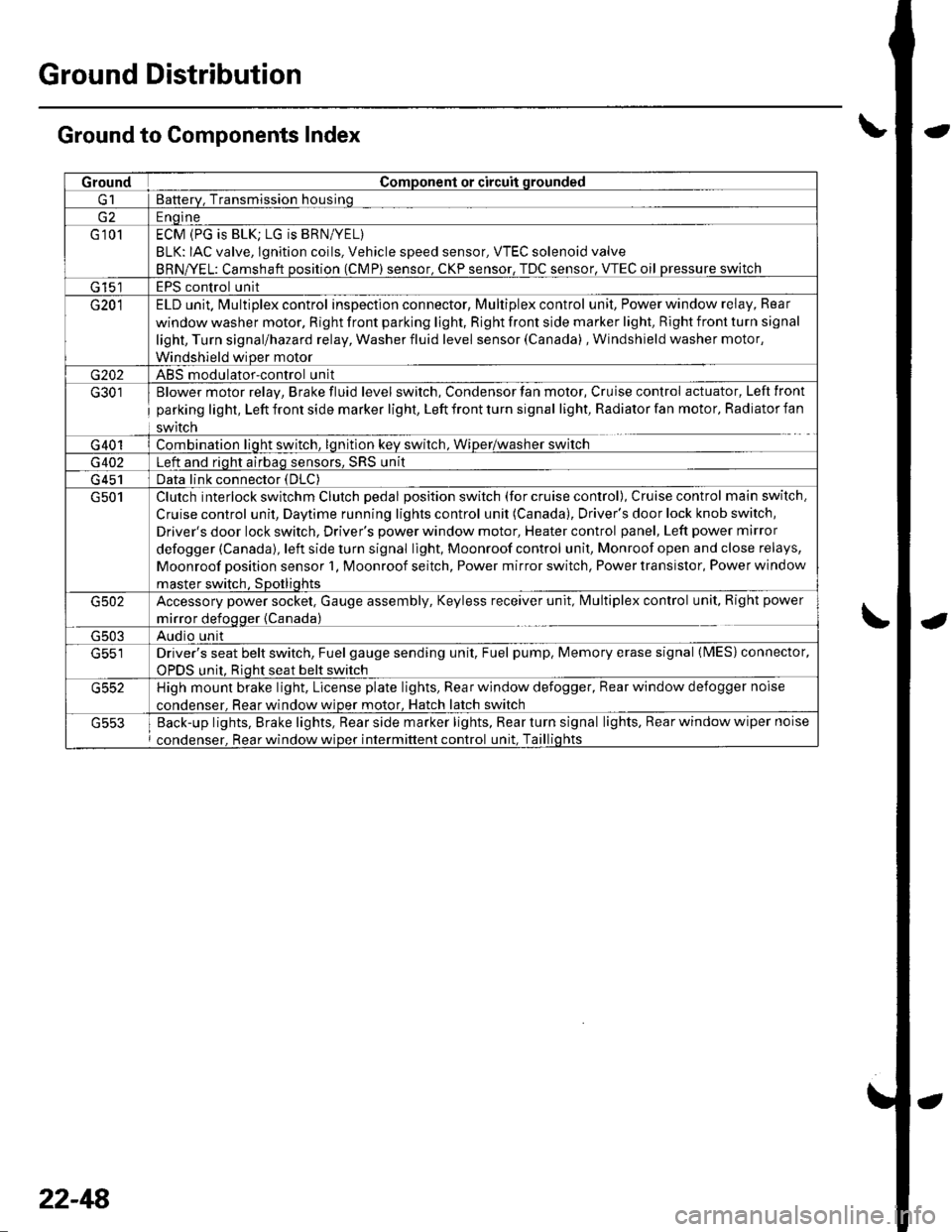

Ground Distribution

Ground to Components Index

GroundComponent or circuit qrounded

Batterv, Transmission housinq

E ngine

G 101ECM (PG is BLK; LG is BRN/YEL)

BLK: IAC valve, lgnition coils, Vehicle speed sensor, VTEC solenoid valve

BRNA/EL: Camshaft oosition (CMP) sensor. CKP sensor, TDC sensor. VTEC oil pressure switch

G 15'�]EPS control unit

G201ELD unit. Multiplex control inspection connector, Multiplex control unit, Power window relay, Rear

window washer motor, Right front parking light, Right front side marker light, Right front turn signal

light, Turn signal/hazard relay, Washer fluid level sensor (Canada) , Windshield washer motor,

Windshield wiDer motor

G202ABS modulator-control unit

G301

G401

Blower motor relay, Brake fluid level switch, Condensor fan motor, Cruise control actuator, Left front

parking light, Left front side marker light, Left front turn signal light, Radiator fan motor, Radiator fan

swrtcn

Combination liqht switch, lqnitlon kev srvitch, Wiper/wasfrer sr,virch

G402Left and riqht airbaq sensors, SRS unit

G 451Data link connector (DLC)

G501Clutch interlock switchm Clutch pedal position switch (for cruise control), Cruise control main switch,

Cruise control unit, Daytime running lights control unit (Canada), Driver's door lock knob switch,

Driver's door lock switch, Driver's power window motor, Heater control panel, Left power mirror

defogger (Canada), left side turn signal light, Moonroof control unit, Monroof open and close relays,

Moonroof position sensor '1, Moonroof seitch, Power mirror switch, Power transistor, Power window

master switch. SDotliqhts

G502Accessory power socket, Gauge assembly, Keyless receiver unit, lvlultiplex control unit, Right power

mirror defogger {Canada)

G503Audio unit

G551Driver's seat belt switch, Fuel gauge sending unit, Fuel pump, Memory erase signal (IMES) connector,

OPDS unit. Rioht seat belt switch

G552High mount brake light, License plate lights, Rear window defogger, Rear window defogger noise

condenser. Rear window wioer motor, Hatch latch switch

Back-up lights, Brake lights, Rear side marker lights, Rear turn signal lights, Rear window wiper noise

condenser, Rear window wiper intermittent control unit, Taillights

22-48

Page 966 of 1139

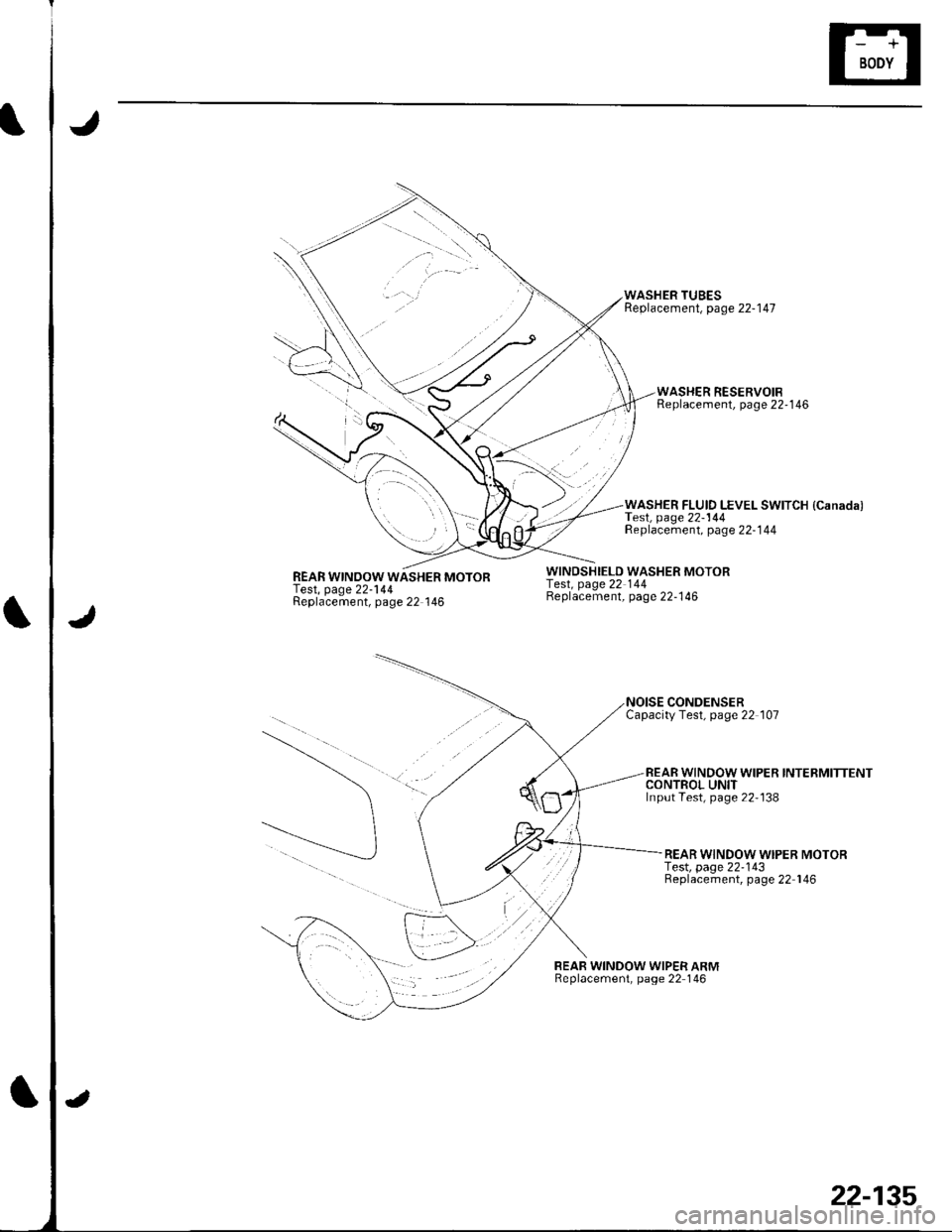

REAR WINOOW WASHER MOTORTest, page 22-144Replacement, page 22 146

WINDSHIELD WASHER MOTORfesl, page 22 144Beplacement, page 22-146

WASHER TUBESReplacement, page 22-147

CONDENSERCapacityTest, page 22 107

BEAR WINDOW WIPER ARMReplacement, page 22 146

WASHER RESERVOIBReplacement, page 22'146

WASHER FLUID LEVEL SWITCH {Canada)TesI, page22-144Replacement, page 22-144

REAR WINDOW WIPER INTERMITTENTCONTROL UNITInput Test, page 22'138

REAR WINDOW WIPER MOTORf e$, page 22-143Replacement, page 22 146

22-135

Page 969 of 1139

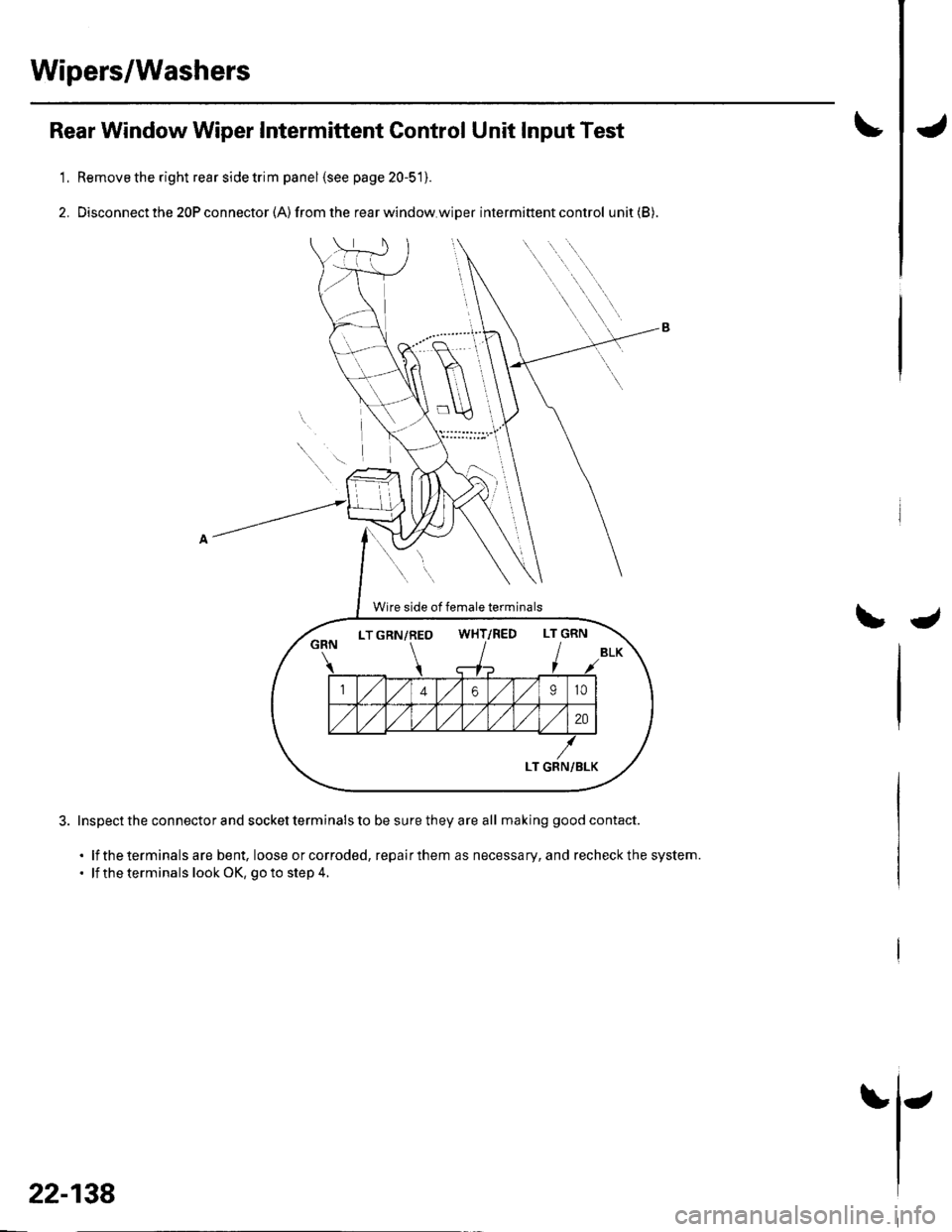

Wipers/Washers

1.

2.

Rear Window Wiper Intermittent Gontrol Unit Input Test

Remove the right rear side trim panel {see page 20-51).

Disconnect the 20P connector (A) from the rear window.wiDer intermittent control unit (B).

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose orcorroded, repairthem as necessary, and recheckthe system.. lf the terminals look OK, go to step 4.

Wire side of female terminals

LTGRN/REO WHT/RED LT GRNWHT/RED

LT GRN/BLK

22-138

Page 970 of 1139

\

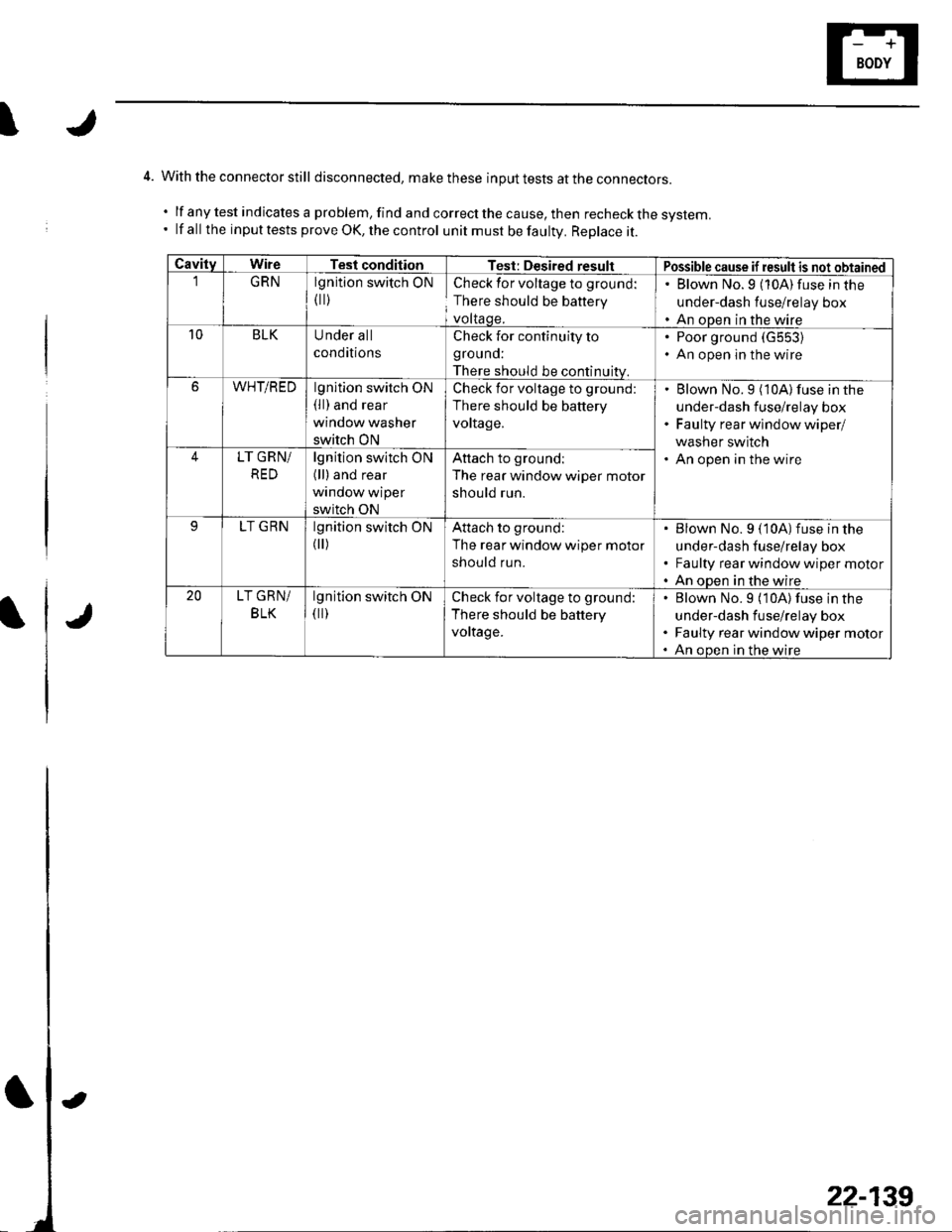

4. With the connector still disconnected, makethese input tests at the con necrors.

.lfanytestindicatesaproblem,findandcorrectthecause,thenrecheckthesystem.

' lf all the input tests prove OK, the control unit must be faultv. Replace it.

CavitvWireTesl conditionTest: Desired resultPossible cause if result is not obtainedGRNlgnition switch ON

flr)

Check for voltage to ground:

There should be battery

voltaqe.

. Blown No.9 (10A)fuse in the

under-dash fuse/relay box. An open in the wire10BLKUnder all

conditions

Check for continuity to

grouno:

There should be continuitv.

Poor ground (G553)

An open in the wire

6WHT/REDlgnition switch ON(ll) and rear

window washer

switch ON

Check for voltage to ground:

There should be battery

vortage.

Blown No.9 (10A) fuse in the

under-dash fuse/relay box

Faulty rear wlndow wiper/

washer switch

An open in the wire4LT GRN/

RED

lgnition switch ON(ll) and rear

window wiper

switch ON

Attach to groundl

The rear window wiper motor

should run.

LT GRNlgnition switch ON

flr)

Attach to ground:

The rear window wiper motor

should run.

Blown No. 9 (10A)fuse in the

under-dash fuse/relay box

Faulty rear window wiper motor

An open in the wire20LT GRN/

BLK

lgnition switch ON(ll)Check for voltage to ground:

There should be battery

voltage.

Blown No.9 (10A) fuse in the

under-dash fuse/relay box

Faulty rear window wiper motor

An oDen in the wire

22-139

Page 977 of 1139

Wipers/Washers

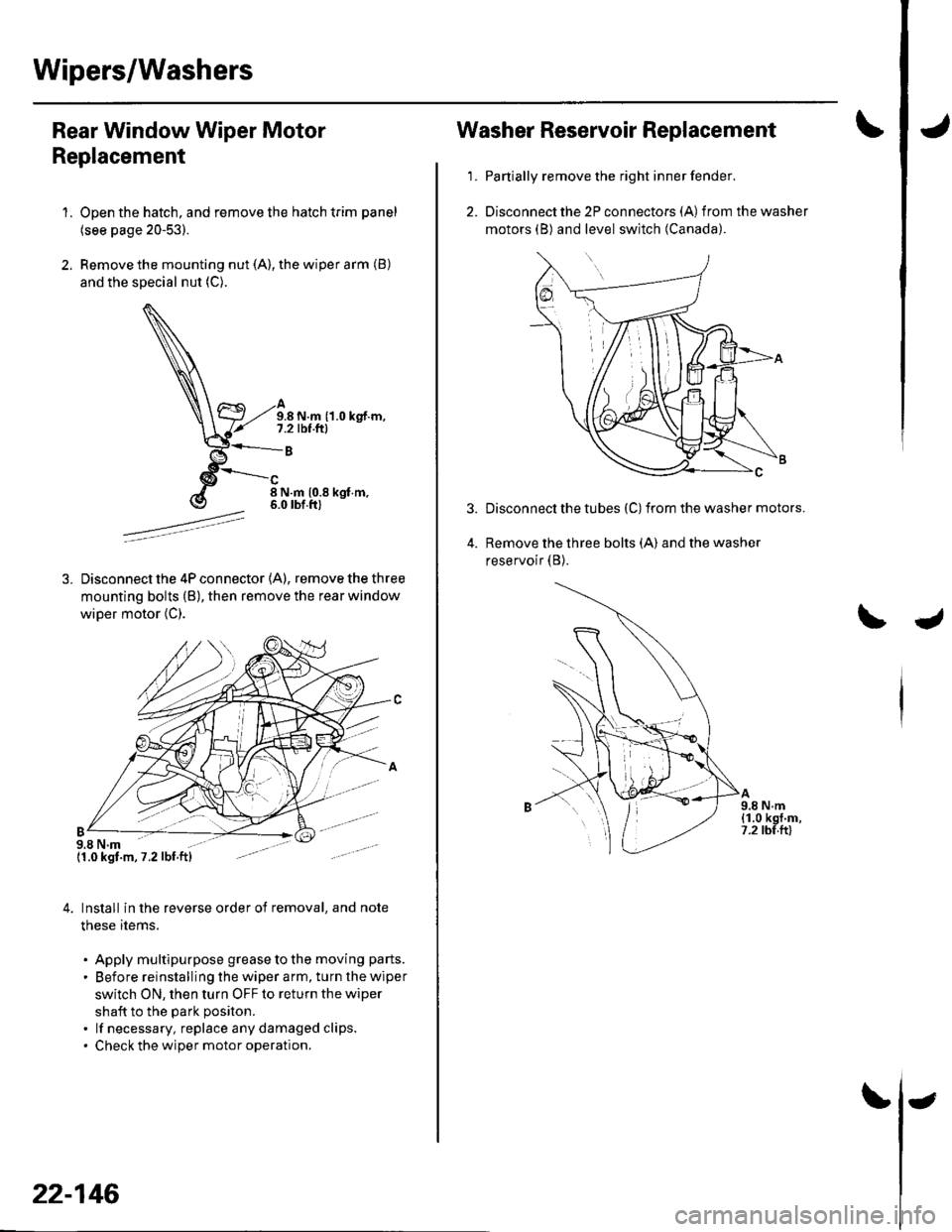

Rear Window Wiper Motor

Replacement

1.

B

Open the hatch, and remove the hatch trim panel

(see page 20-53).

Remove the mounting nut (A), the wiper arm (B)

and the special nut (C).

A9.8 N.m {1.0 kgf.m,7.2 rbf.ftl

B

8 N.m 10.8 kgt.m,6.0 rbf.ft)

Disconnect the 4P connector {A), remove the three

mounting bolts (B), then remove the rear window

wiDer motor (C).

9.8 N.m{1.0 kgt.m,7.2lbf ftl

4,Install in the reverse order oI removal, and note

these items.

Apply multipurpose grease to the moving parts.

Before reinstalling the wiper arm, turn the wiper

switch ON, then turn OFF to return the wiper

shaft to the Dark oositon.

lf necessary, replace any damaged clips.

Check the wiDer motor operation.

22-146

-

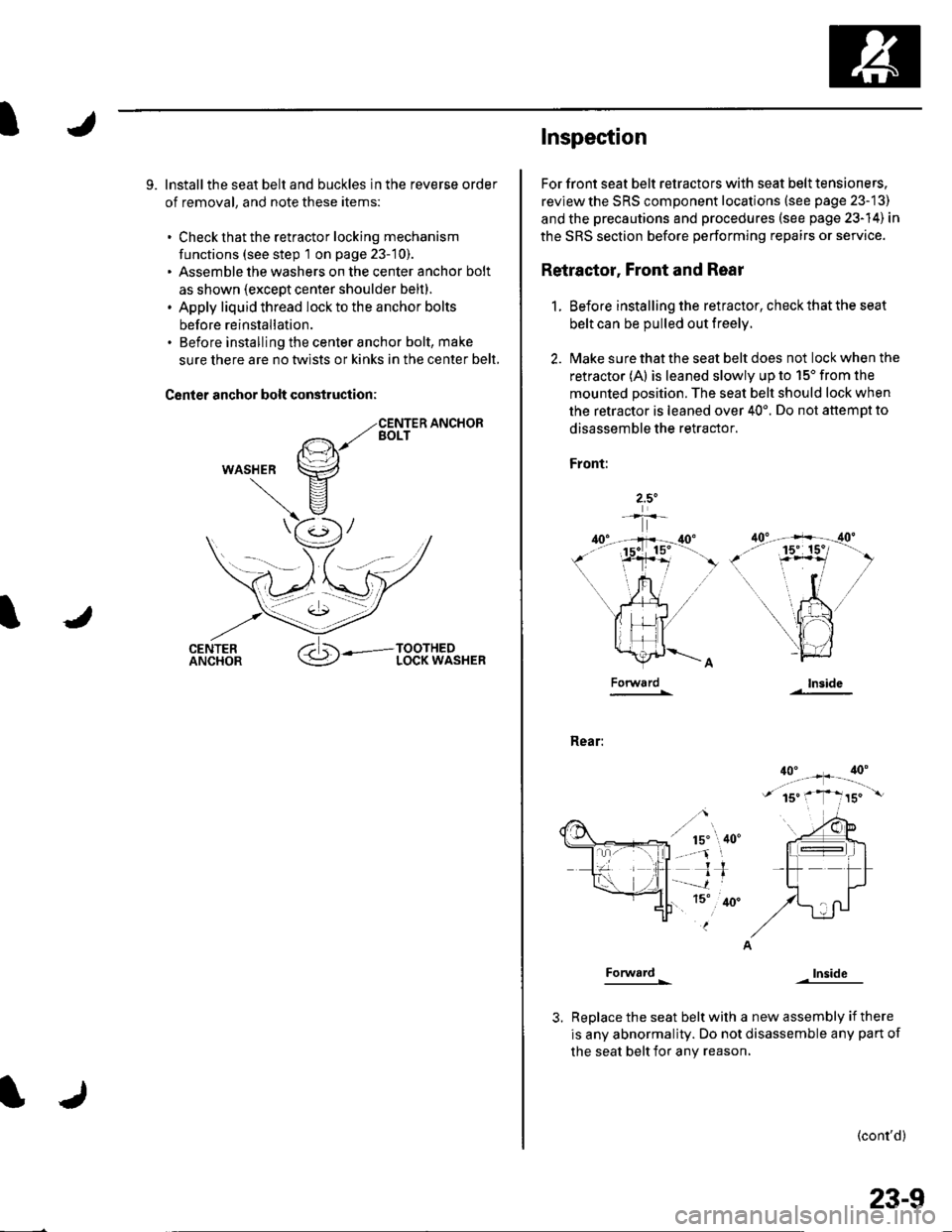

Washer Reservoir Replacement

1.Partially remove the right inner fender.

Disconnect the 2P connectors (A) irom the washer

motors (B) and level switch (Canada).

3.Disconnecl the tubes (C) from the washer motors.

Remove the three bolts (A) and the washer

reservoir (B).

A9.8 N.m(1.0 kgt.m,7.2 tbf.tt)

Page 1017 of 1139

I

9. lnstallthe seat belt and buckles in the reverse order

of removal, and note these items:

. Check that the retractor locking mechanism

functions (see step 1 on page 23-10).. Assemble the washers on the center anchor bolt

as shown (except center shoulder belt).. Apply liquid thread lock to the anchor bolts

before reinstallation.. Before installing the center anchor bolt, make

sure there are no twlsts or kinks in the center belt,

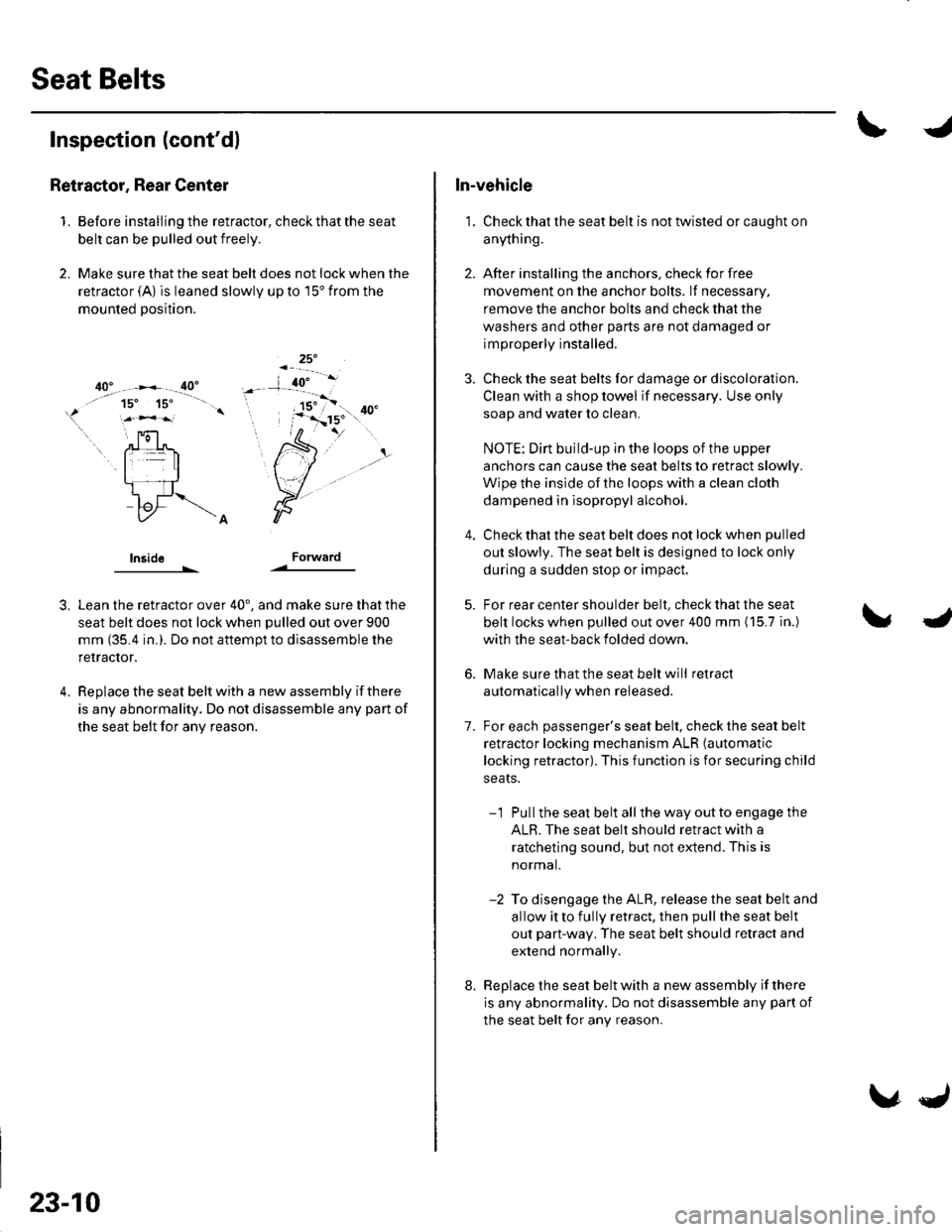

Canler anchor bolt construction:

WASHER

Inspec'tion

For front seat belt retractors with seat belt tensioners.

reviewthe SRS component locations (see page 23-13)

and the precautions and procedures (see psge 23-14) in

the SRS section before performing repairs or service.

Retractor, Front and Rear

1. Before installing the retractor, check that the seat

belt can be pulled out freely.

2. l\4ake sure that the seat belt does not lock when the

retractor (A) is leaned slowly up to 15'from the

mounted position. The seat belt should lock when

the retractor is leaned over 40'. Do not attemDt to

disassemble the retractor.

Front:

Rear:

Forward

Forward

lnside

Inside

Replace the seat belt with a new assembly if there

is any abnormality. Do not disassemble any pan of

the seat belt for any reason,

(cont'd)

23-9

Page 1018 of 1139

Seat Belts

Inspection (cont'd)

RetraEtor, Rear Center

1. Before installing the retractor, check that the seat

belt can be pulled out freely.

2, Make sure that the seat belt does not lock when the

retractor (A) is leaned slowly up to 15' from the

mounted position.

lnsideForward

3,

4.

Lean the retractor over 40', and make sure that the

seat belt does not lock when pulled out over 900

mm (35.4 in.). Do not aftempt to disassemble the

retractor.

Replace the seat belt with a new assembly if there

is any abnormality. Do not disassemble any part of

the seat belt for any reason.

23-10

\,J

In-vehicle

1. Check that the seat belt is not twisted or caught on

anything.

2. After installing the anchors. check for free

movement on the anchor bolts. lf necessary,

remove the anchor bolts and check that the

washers and other parts are not damaged or

improperly installed.

3. Check the seat belts for damage or discoloration.

Clean with a shop towel if necessary. Use only

soap and water to clean.

NOTE: Dirt build-up in the loops of the upper

anchors can cause the seat belts to retract slowly.

Wipe the inside of the loops with a clean cloth

dampened in lsopropyl alcohol.

Check that the seat belt does not lock when pulled

out slowly. The seat belt is designed to lock only

during a sudden stop or impact.

For rear center shoulder belt, check that the seat

belt locks when pulled out over 400 mm (15.7 in.)

with the seat-back folded down.

Make sure that the seat belt will retract

automatically when released.

For each passenger's seat belt, check the seat belt

retractor locking mechanism ALR (automatic

locking retractor). This function is for securing child

seats.

-1 Pullthe seat belt allthe way outto engage the

ALR. The seat belt should retract with a

ratcheting sound, but not extend. This is

normal.

-2 To disengage the ALR, release the seat belt and

allow itto fully retract, then pullthe seat belt

out part-way. The seat belt should retract and

extend normally.

Replace the seat belt with a new assembly if there

is any abnormality. Do not disassemble any part of

the seat belt for any reason.

7.

8.

Page 1019 of 1139

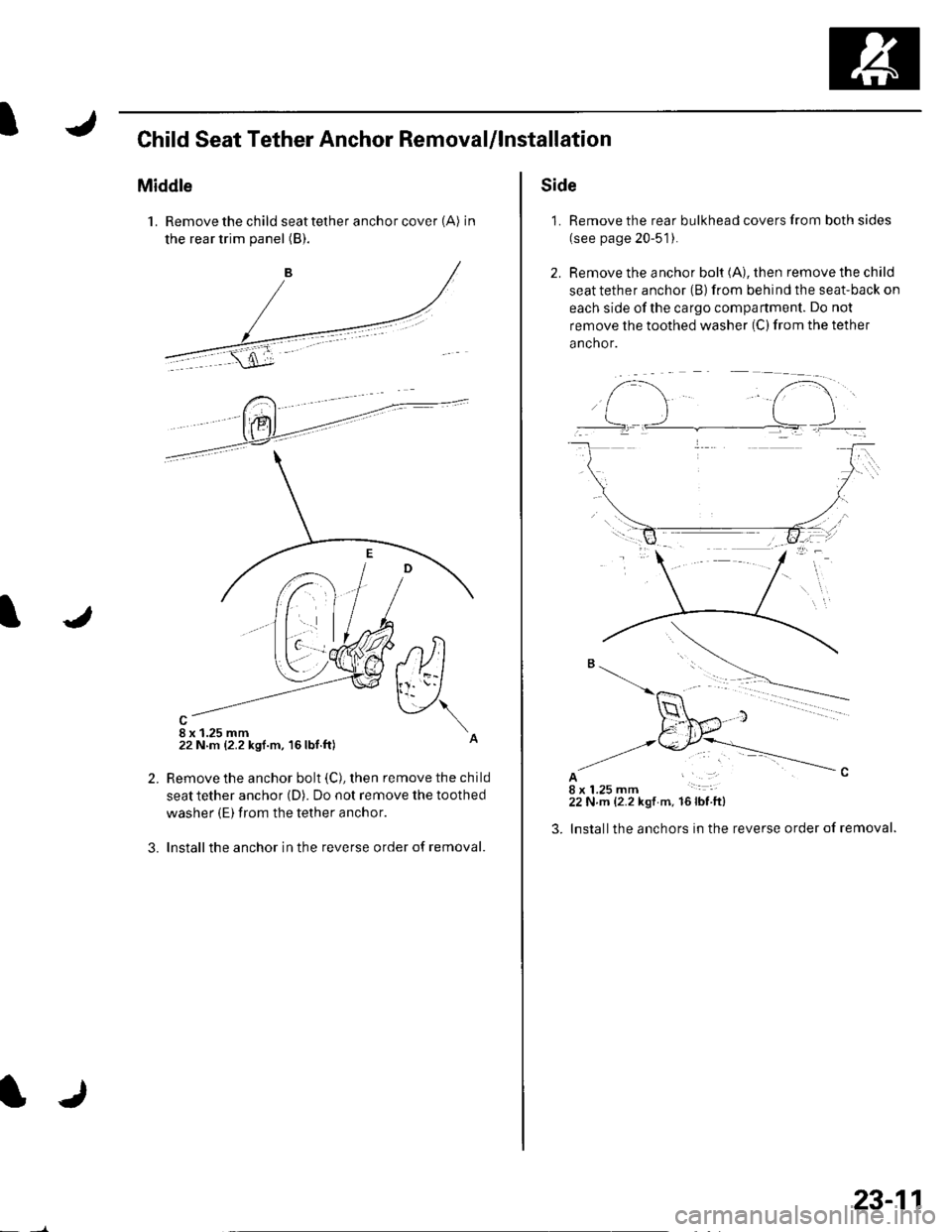

IChild Seat Tether Anchor RemovaUlnstallation

Middle

1. Remove the child seat tether anchor cover (A) in

the rear trim panel (B).

8 x 1.25 mm22 N m {2.2 ksf.m, 16lbf.ft)

,tltl

v\

2.

3.

Remove the anchor bolt (C), then remove the child

seat tether anchor (D). Do not remove the toothed

washer (E) from the tether anchor.

Installthe anchor in the reverse order of removal.

IJ

23-11

Side

1. Remove the rear bulkhead covers from both sides

(see page 20-51).

2. Remove the anchor bolt (A), then remove the child

seat tether anchor (B) from behind the seat-back on

each side ofthe cargo compartment. Do not

remove the toothed washer (C) from the tether

anchor.

AI18 x 1.25 mm22 N.m {2.2 kgt m. 16lbfft)

lnstallthe anchors in the reverse order of removal.

f-..- t".i..].-

Page 1139 of 1139

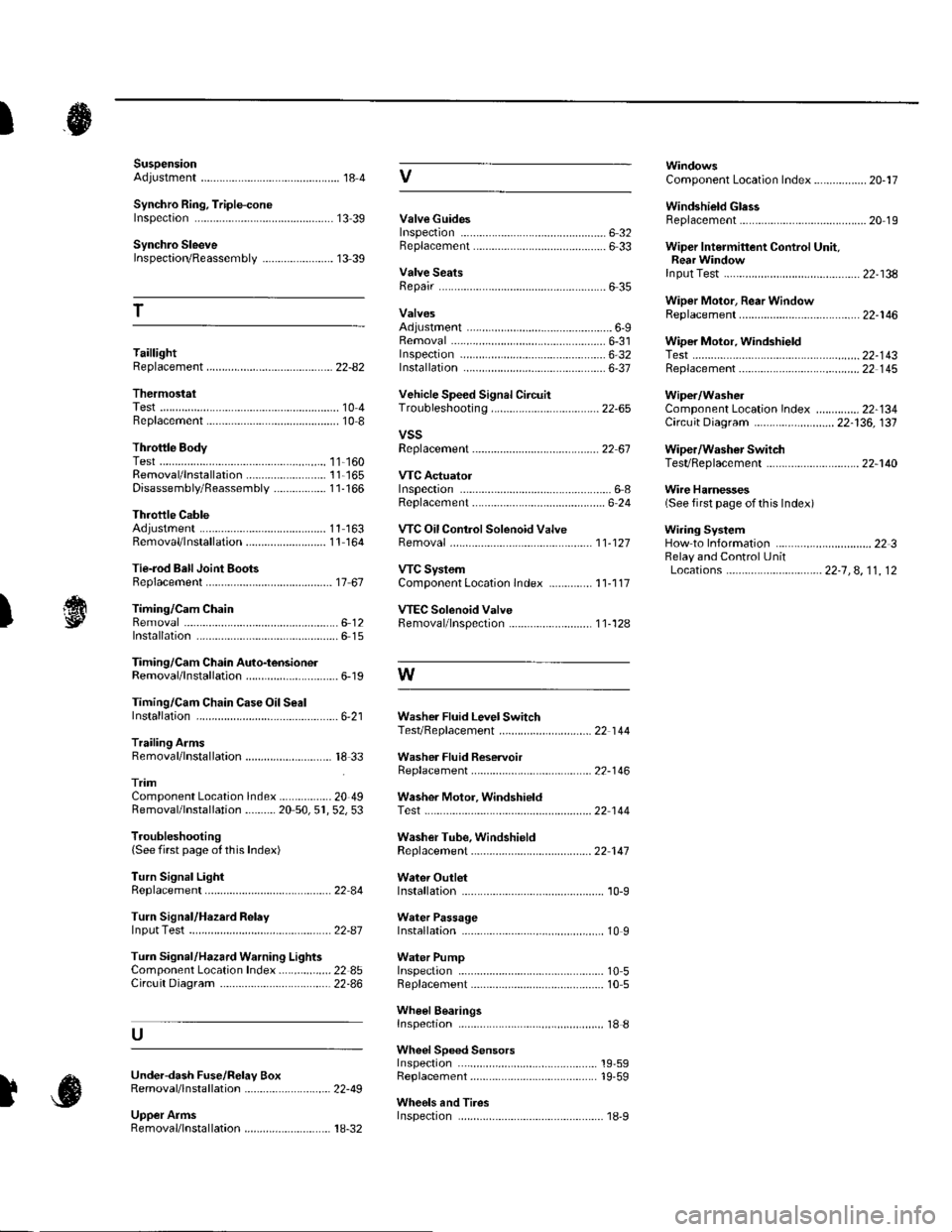

SuspensionAdjustment................-............................184 VComponent Location Index................. 20-17

Windshield GlessReplacement............-..............-............. 20 19

Synchro Ring, Triple-coneInspection...............-..........................1339 ValveGuides

Synchro SleeveInspectaon/Reassemb1y ....................... 13 39

Inspection ............-.-................................ 6 32Beplacement ..........-................................ 6 33 Wiper Intermittent Control Unit,Rear WindowInput Test

T

Valve SeatsRepair ...................................................... 6 35.....22-134

WiDer Motor, Rear WindowRep1acement....................................... 22-1 46Adjustment .-.-.......Removal ...-...-......................................-... 6-31 WiDer Motor, windshield6-9

.....6-32 Test.......-..........-.....-.............................22-143Taillight

ThermostaiTest ........................

Inspec!on

Vehicle Speed Signal Circuit

VTC System

Wiper/WasheI

Wi.ing System

10 4 Troubleshooting .....-... ..........................22-65 Component Location In dex ..............22-134Replacement.....-...-....... ...................... 10 IvssThrottle BodyTest ..................Removal/lnstallation .. . . . . . .. ... 11-'165 VTC ActuatorDisassembly/Feassemb|y................-11-166 Inspection

Circuit Diagram .......................... 22-136, 131

Replacement -.............. ............ .............22 61 Wiper/Washor SwitchTesVReplacement .............................. 22-1 40

.................68 WireHarnesses

11-160

Replacement ........................................... 6 24 (Seefirstpageofthislndex)Throttle CableAdjustment ...... ...-.................... 11163 VTC Oil ConlrolSolenoid ValveRemoval/1nsta11ation..........................11164 Removal....-...-... |1-127 HowtoIn{ormation ...............................223Belay and Control UnitLocations .-....-.............. -.-.-....- 22-7, 4, 1 1, 12Beplacement.........-............................... 1767 ComponentLocationlndex.............. 11-117Tie-rod Ball Joint Boots

lnstallation

Replacement

Turn Signal/Hazard Relay

tsTiming/Cam ChainVTEC Solenoid Valve...612 Femoval/lnspection....-......................11-128................ 6 15

Timing/Cam Chain Auto-tensionelRemoval/1nsta11ation..............................6-19 W

Troubleshooting{See first page ot this Index)

Turn Signal Light

Timing/Cam Chain CaseOil SealInstallation......................-......................6,21 Washer Fluid Level SwitchTesVReplacement .............................. 22 1 44Trailing ArmsRemoval/lnstallation .............. . . . . ..... 18 33 Washer Fluid ReservoirReplacement ....................................... 22-1 46tnmComponent Location lndex ................- 20 49 Washer Motor, WindshieldRemoval/lnstallation ..-.......20 50,51,52,53 Test -..............-.............. ........................22 144

Washer Tube, WindshieldReplacement......-...-............................ 22 1 47

W.ter Outlet.........22 A4 Installation ..................-........................... '10-9

InputTest........22-87 lnstallation................ 10IWeter Passage

Wheels andTires

Turn Signal/Hazard Warning Lights Water PumpComponent Location In dex .................22 85 Inspection ........................... .. . . . ....... 10 5Circu it Diagram ................-................... 22-86 Replacement .-......................................... 10 5

U

WheelBearingsInspec|ion ....................................... ....... 18 8

Wheel Speed SensorsInspection ..-..,.,.,,.,,,,,.,.,,,...................... 19-59Replac€ment ........-....... . . . . . . .. -.... 19-59UndeFdash Fuse/R€lay BoxRemoval/lnstaf lation ............................ 22-49

Upper ArmsRemoval/|nsta11ation................. ... 18-32

],sInspect|on