fuel pump HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 237 of 1139

Fuel and Emissions Systems

(System Descriptions (cont'dl

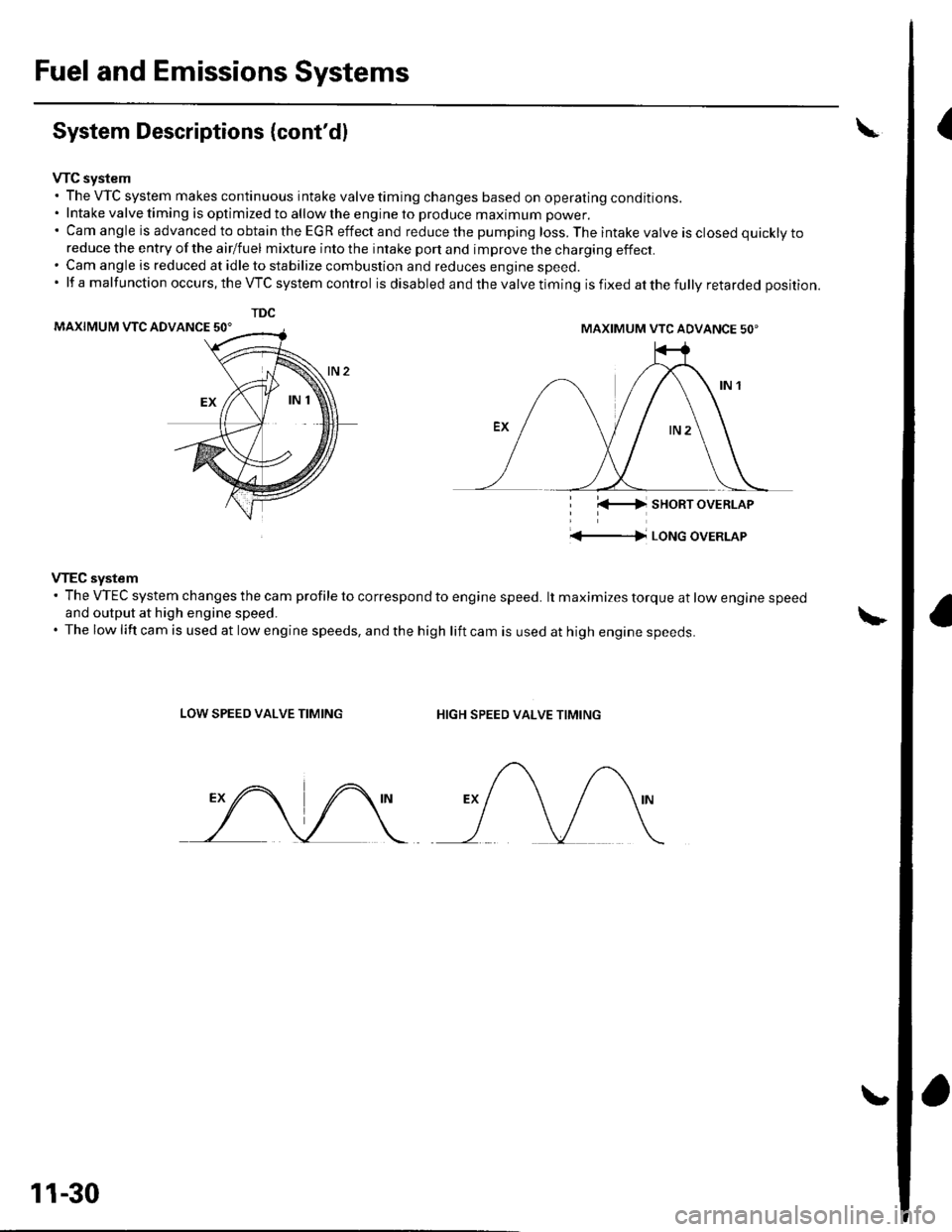

VTC system. The VTC system makes continuous intake valve timing changes based on operating conditions.. Intake valve timing is optimized to allow the engine to produce maximum power.'CamangleisadvancedtoobtaintheEGReffectandreducethepumpingloss.Theintakevalveisclosedquicklyto

reduce the entry of the airlfuel mixture into the intake port and improve the charging effect.. Cam angle is reduced at idle to stabilize combustion and reduces engine speed.'lfamalfunctionoccurs,theVTCsystemcontrol is disabled and the valve timing is fixed at the fully retarded position.

MAXIMUM VTC ADVANCE 50'

i l(-4 sHoRT oVERLAP

'+-|l LoNG oVERLAP

VTEC system' The VTEC system changes the cam profile to correspond to engine speed. lt maximizes torque at low engine speedand output at high engine speed.. The low lift cam is used at low engine speeds, and the high lift cam is used at high engine speeds.

LOW SPEED VALVE TIMINGHIGH SPEED VALVE TIMING

TDC

MAXIMUM VTC ADVANCE 50'

11-30

Page 239 of 1139

Fuel and Emissions Systems

(

{

System Descriptions (cont'd)

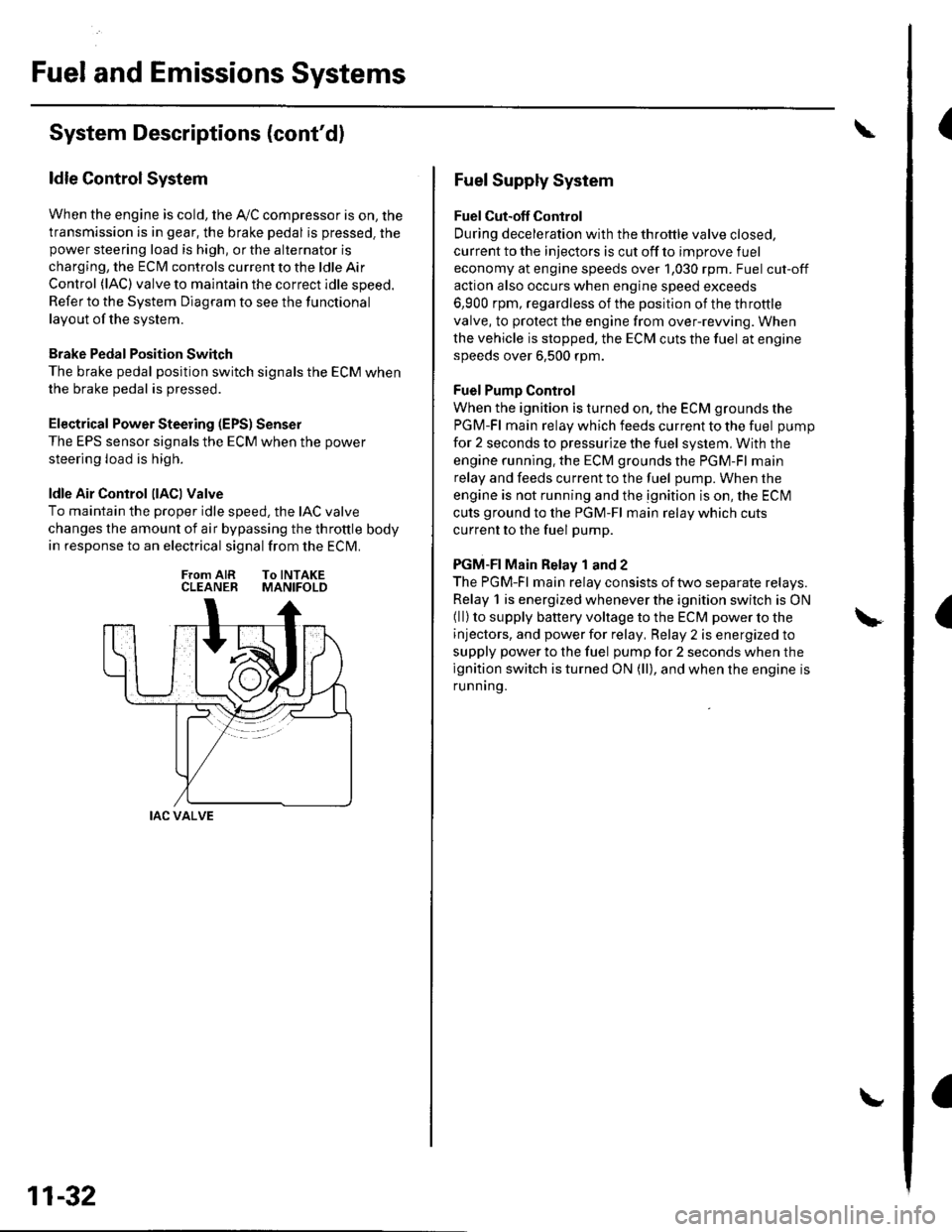

ldle Control System

When the engine is cold, the Ay'C compressor is on, the

transmission is in gear, the brake pedal is pressed. thepower steering load is high, or the alternator is

charging, the ECIM controls current to the ldle Air

Control (lAC) valve to maintain the correct idle speed.

Refer to the System Diagram to see the functional

layout of the system.

Brake Pedal Position Switch

The brake pedal position switch signals the ECM when

the brake pedal is oressed.

Electrical Power Steering (EPS) Senser

The EPS sensor signals the ECM when the power

steering load is high.

ldle Air Control llACl Valve

To maintain the proper idle speed, the IAC valve

changes the amount of air bypassing the throttle body

in response to an electrical signal from the ECM.

From AIR To INTAKECLEANER MANIFOLD

IAC VALVE

11-32

Fuel Supply System

Fuel Cut-off Control

During deceleration with the throttle valve closed,

current to the injectors is cut off to improve fuel

economy at engine speeds over 1,030 rpm. Fuel cut-off

action also occurs when engine speed exceeds

6,900 rpm, regardless of the position of the throttle

valve, to protect the engine from over-rewing. When

the vehicle is stopped. the ECM cuts the fuel at engine

speeds over 6,500 rpm.

Fuel Pump Control

When the ignition is turned on, the ECM grounds the

PGM-Fl main relay which feeds current to the fuel pump

for 2 seconds to pressurize the fuel system, With the

engine running. the ECM grounds the PGM-Fl main

relay and feeds current to the fuel pump. When the

engine is not running and the ignition is on, the ECI\4

cuts ground to the PGM-Fl main relay which cuts

current to the fuel pump.

PGM-FI Main Relay 1 and 2

The PGM-Fl main relay consists of two separate relays.

Relay 1 is energized whenever the ignition switch is ON(ll) to supply battery voltage to the ECM power to the

injectors, and power for relay, Relay 2 is energized to

supply power to the fuel pump for 2 seconds when the

ignition switch is turned ON (ll), and when the engine is

runnrng.

Page 252 of 1139

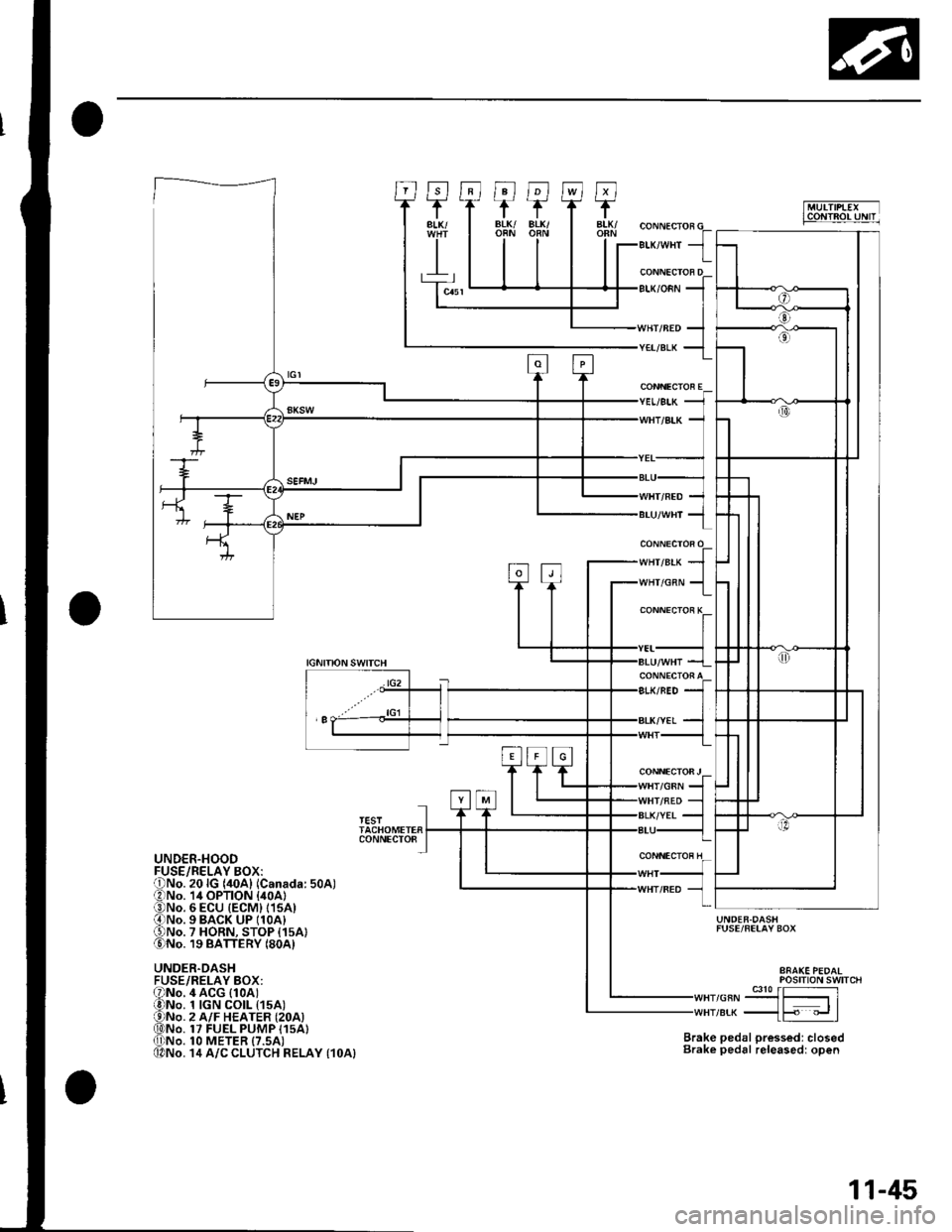

""rr"a* JIr''lHr/cnN 1

CONNECTOR E

CONNECTOi K

CONNECTOFJ/GRN

IGNITIONSWITCH

lG2

'I

TESTTACHOMETERCONNECTO8

UNDER.HOOD

UNDER.DASHFUSE/RELAY BOX:

UNDER.DASHFUSE/FELAY BOX

Brake pedal pressed: closedBrake pedal releasedr open

POStTtON SWTTCH

,or"-9J3{51re* _{F "_.rl

4 ACG (1oAt1 tGN CO|L t15A)2 A/F HEATER {2OA)17 FUEL PUMP I15A}1O METER {7.5AI14 A/C CLUTCH RELAY {1OA}

11-45

Page 277 of 1139

PGM-FI System

DTC Troubleshooting (cont'dl

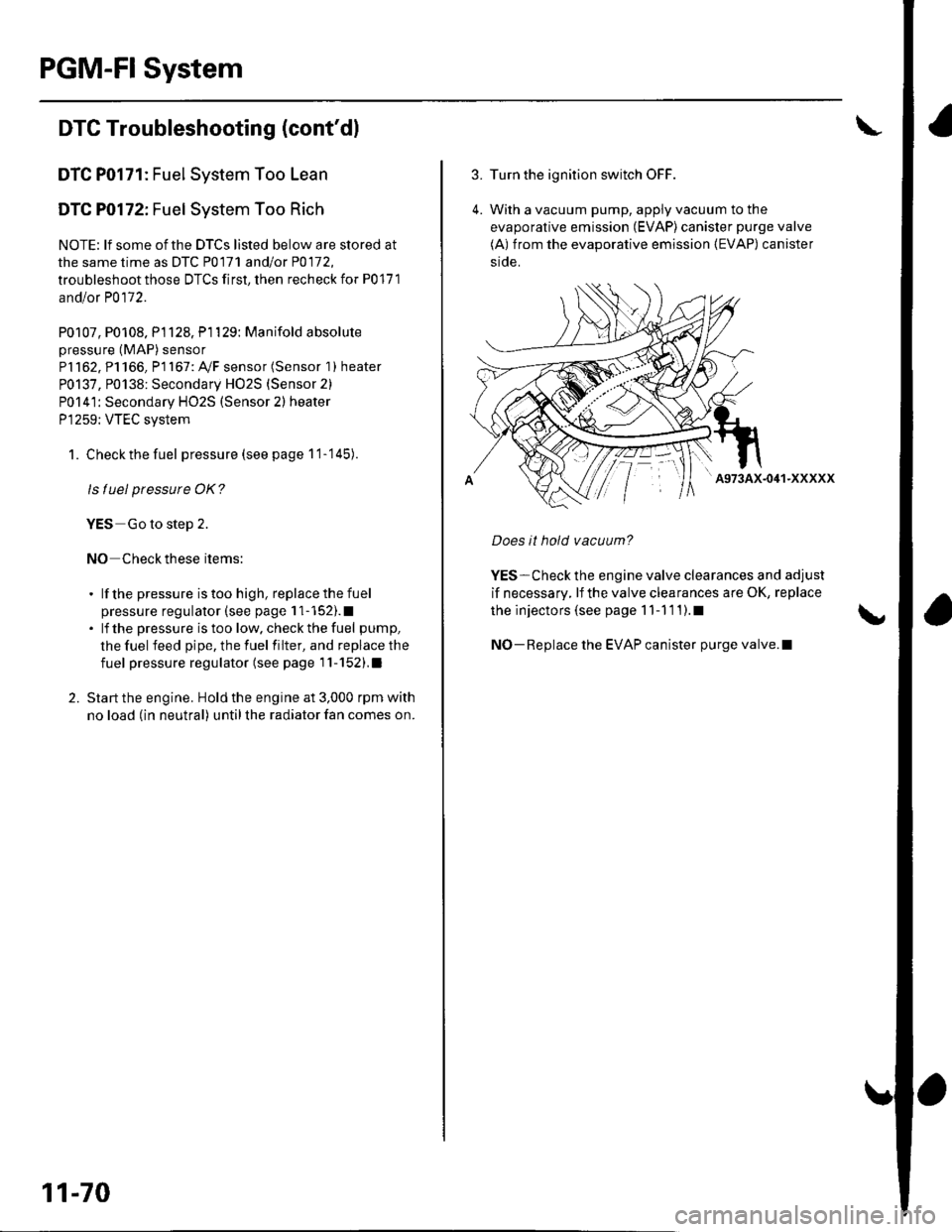

DTC P0171: Fuel System Too Lean

DTC P0172: Fuel System Too Rich

NOTE: lf some of the DTCS listed below are stored at

the same time as DfC PO17'l and/ot PO172,

troubleshoot those DTCS first, then recheck for P0171

andlot P0112.

P0107, P0108. P1 128. P1 129: Manifold absolute

pressure (MAP) sensor

P1 162. P1 166, P 1 167: 4,,/F sensor (Sensor 1 ) heater

P0137, P0138: Secondary HO2S (Sensor 2)

P014'l: Secondary HO2S (Sensor 2) heater

P1259: VTEC system

1. Check the fuel pressure (see page 11-'145).

ls luel pressure OK?

YES Go to step 2.

NO Check these items:

. lf the pressure is too high, replace the fuel

pressure regulator (see page 11-152).1. lf the pressure istoo low.checkthefuel pump,

the fuel feed pipe, the fuel filter, and replace the

fuel pressure regulator (see page 11-152).I

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

11-70

3. Turn the ignition switch OFF.

4. With a vacuum pump, apply vacuum to the

evaporative emission (EVAP) canister purge valve

(A) from the evaporative emission (EVAP) canister

side.

' A973AX-041-XXXXX

Does it hold vacuum?

YES-Check the engine valve clearances and adjust

if necessary, lf the valve clearances are OK, replace

the injectors (see page 1 1-1 1 1).1

NO-Replace the EVAP canister purge valve.l

Page 304 of 1139

MIL Circuit Troubleshooting

1. Connect an OBD ll scan tool/Honda PGM Tester

(see page 11-3).

2. Turn the ignition switch ON (ll) and read the OBD ll

scan tool/Honda PGM Tester.

Does the OBD ll scan tool/Honda PGM Tester

communicate with the ECM?

YES Go to step 3.

NO Go to troubleshooting " DLC Circuit

Troubleshooting" (see page 11-109).

3. Check the OBD ll scan tool/Honda PGM Testerfor

DTCs.

Are any DTCs ind icated?

YES Go to the DTC Troubleshooting Index.

NO-Go to step 4.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON (ll)and watch the

lMalfunction Indicator Lamp (MlL).

Does the MIL come on and stay on for more than

20 seconds aftet turning the ignition switch

oN (tr)?

YES lf the MIL always comes on and stays on, go

to step 76. But if the lMlL sometimes works

normally, first check for these problems.

. An intermittent short in the wire between the

ECIM (E29) and the data link connector (DLC).

. An intermittent short in the wire between the

ECM (E31) and the gauge assembly.

NO lf the MIL is always off, go to step 6. But if the

lvllL sometimes works normally, first check for

these problems.

. A loose No. 10 METER (7.5A) fuse in the under

dash fuse/relay box.. A loose No. 20 lG (40A) (Canada: 50A)Iuse in the

under-hood fuse/relay box.. A ioose No. 6 ECU (ECM) (15A) fuse in the under-

hood fuse/relay box.

. A loose No. 17 FUEL PUMP (15A)fuse in the

under-dash fuse/relay box.. A poor connection at ECM terminal E31.. An intermittent open in the GRN/ORN wire

between the ECM (E31) and the gauge assembly.. An intermittent short in the wire between the

ECM (A21) and the manifold absolute pressure

(MAP) sensor.. An intermittent short in the wire between the

ECI\4 (A20) and the throttle posilion (TPi sensor.. An intermittent short in the wire between the

ECM (E5) and the fuel tank pressure (FTP) sensor.

6. Turn the ignition switch OFF.

7. Turn the ignition switch ON (ll).

ls the low oil pressure light on?

YES Go to step 10.

NO-Go to step 8.

8. Inspectthe No. 10 l\4ETER (7.5A)fuse inthe under-

dash fuse/relay box.

ls the luse OK?

YES Go to step L

NO Repair shon in the wire between No. 10

METER (7.5A)fuse and the gauge assembly. Also

replacethe No. 10 METER {7.5A) fuse.l

9. Inspect the No. 20 lG1 (40A) (Canada: 50A) fuse in

the under-hood fuse/relay box.

ls the f use OK?

YES Repair open in the wire between the No. 20

lG (40A) {Canadar 50A)fuse and the gauge

assembly. lf the wire is OK, test the ignition switch

{see page 22 53).

NO Repair short in the wire between No. 20 lG

(40A) lCanada: 50A)fuse and the under'dash fusel

relay box. Also replace the No.20 lG (40Ai

(Canada: 50A) fuse.I

(conr'd)

11-97

Page 306 of 1139

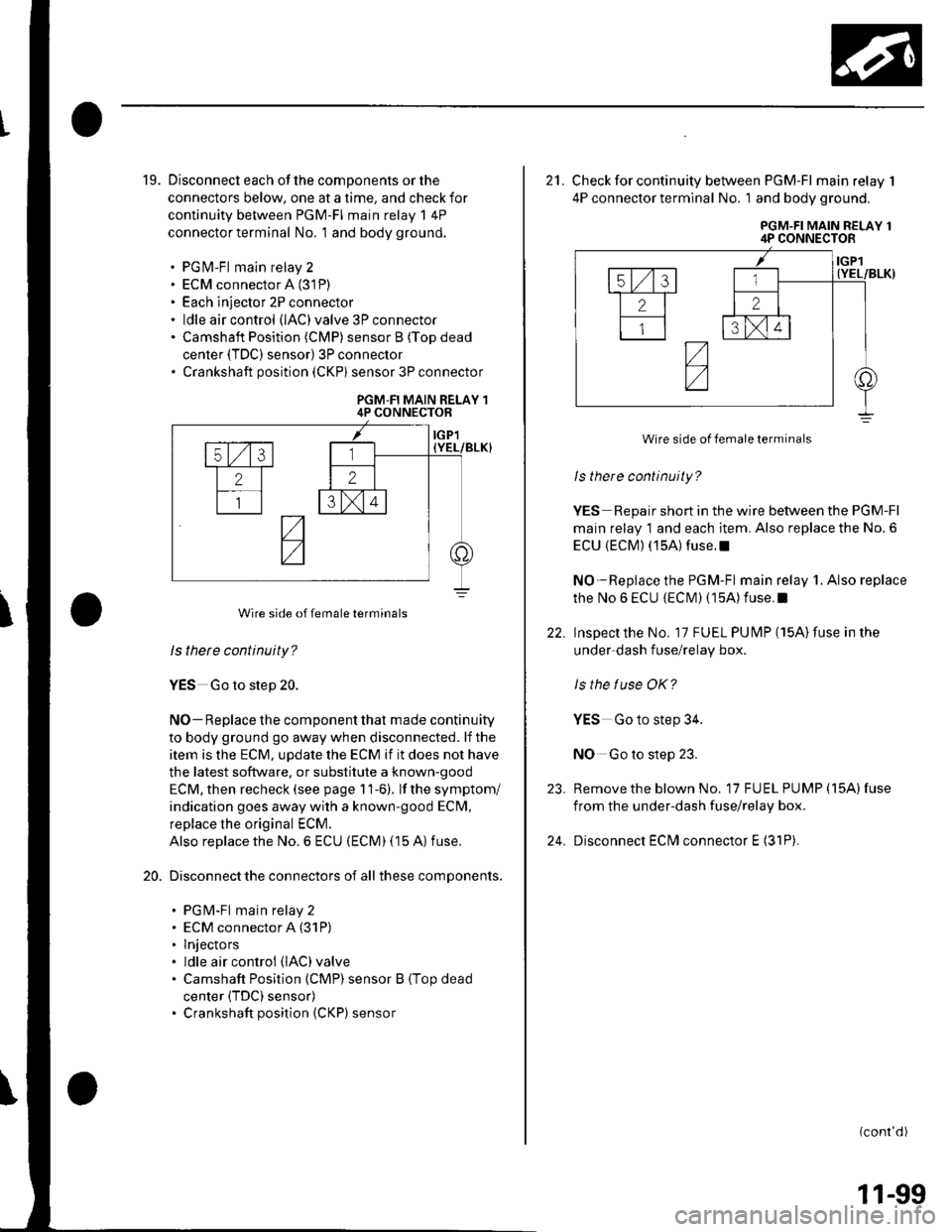

19. Disconnect each of the components or the

connectors below, one at a time, and check for

continuity between PGM-FI main relay 1 4P

connector terminal No. 1 and body ground.

. PGfvl-Fl main relay 2. ECM connector A (31P)

. Each injector 2P connector. ldle air control (lAC)valve 3P connector. Camshaft Position (CMP) sensor B (Top dead

center (TDC) sensor) 3P connector. Crankshaft position (CKP) sensor 3P connector

PGM-FI MAIN RELAY 14P CONNECTOR

ls thete continuity?

YES Go to step 20.

NO- Replace the component that made continuity

to body ground go away when disconnected. lf the

item is the ECM, update the ECM if it does not have

the latest software. or substitute a known-good

ECM, then recheck (see page 11-6). lf the symptom/

indication goes away with a known'good ECM,

replace the original ECM.

Also replace the No. 6 ECU (ECM) (15 A) fuse,

Disconnect the connectors of all these components.

. PGM-Fl main relay 2. ECM connector A (31P)

. lnjectors. ldle air control (lAC)valve

. Camshaft Position {CMP) sensor B (Top dead

center (TDC) sensor). Crankshaft position (CKP) sensor

20.

Wire side of female terminals

22.

21. Check for continuity between PGM-FI main relay 1

4P connector termlnal No. 1 and body ground.

PGM-FI MAIN RELAY 14P CONNECTOR

ls there continuity?

YES Repair short in the wire between the PGM-Fl

main relay 1 and each item. Also replace the No. 6

ECU {ECM) (15A) fuse.l

NO-Replace the PGM-Fl main relay 1. Also replace

the No 6 ECU {ECIM) (15A) f use. I

Inspectthe No. 17 FUEL PUI\4P (15A)fuse in the

under-dash f use/relay box.

ls the tuse OK?

YES Go to step 34.

NO Go to step 23.

Remove the blown No, 17 FU EL PUMP (15A) fuse

from the under-dash fuse/relay box.

Disconnect ECfvl connector E (31P).

(conr'd)

23.

24.

Wire side of female terminals

11-99

Page 307 of 1139

PGM-FI System

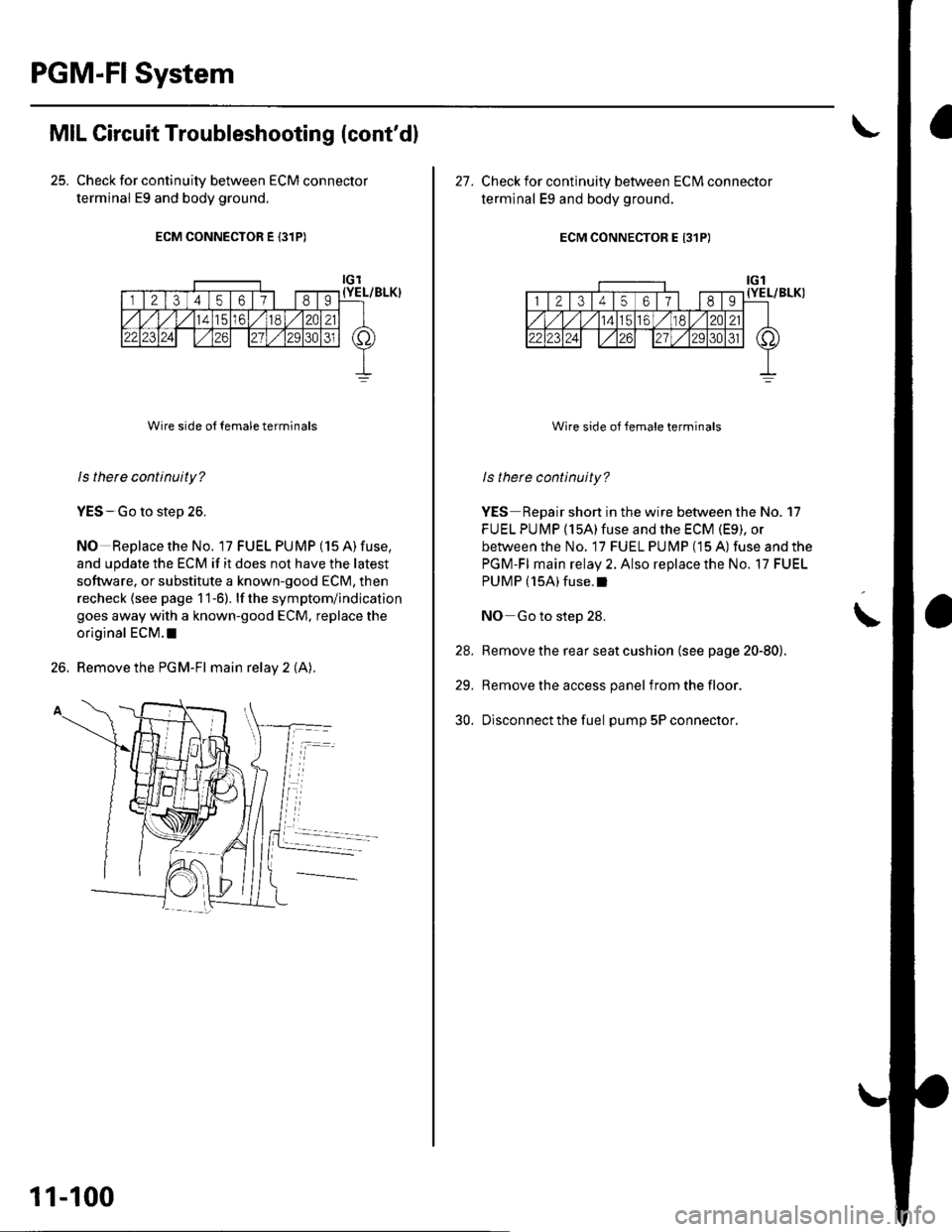

25.

MIL Circuit Troubleshooting (cont'dl

Check for continuity between ECM connector

terminal E9 and body ground.

ECM CONNECTOR E (31P)

Wire side o{ {emale terminals

ls therc continuity?

YES-Go to step 26.

NO Replace the No. lTFUELPUMP(15A)fuse,

and update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM. replace the

original ECM.I

26. Remove the PGM-Fl main relay 2 (A).

11-100

27. Check for continuity between ECIVI connector

terminal Eg and body ground.

ECM CONNECTOR E 131P)

Wire side oI Jemale terminals

ls there continuity?

YES Repair short in the wire between the No. 17

FU EL PUMP (15A)fuse and the ECM (E9), or

between the No. 17 FUEL PU MP (15 A) fuse and the

PGM-FI main relay 2. Also replace the No. 17 FUEL

PUMP (15A)fuse.l

NO Go to step 28.

Remove the rear seat cushion (see page 20-80).

Remove the access panel from the floor.

Disconnect the fuel pump 5P connector.

\

28.

29.

30.

Page 308 of 1139

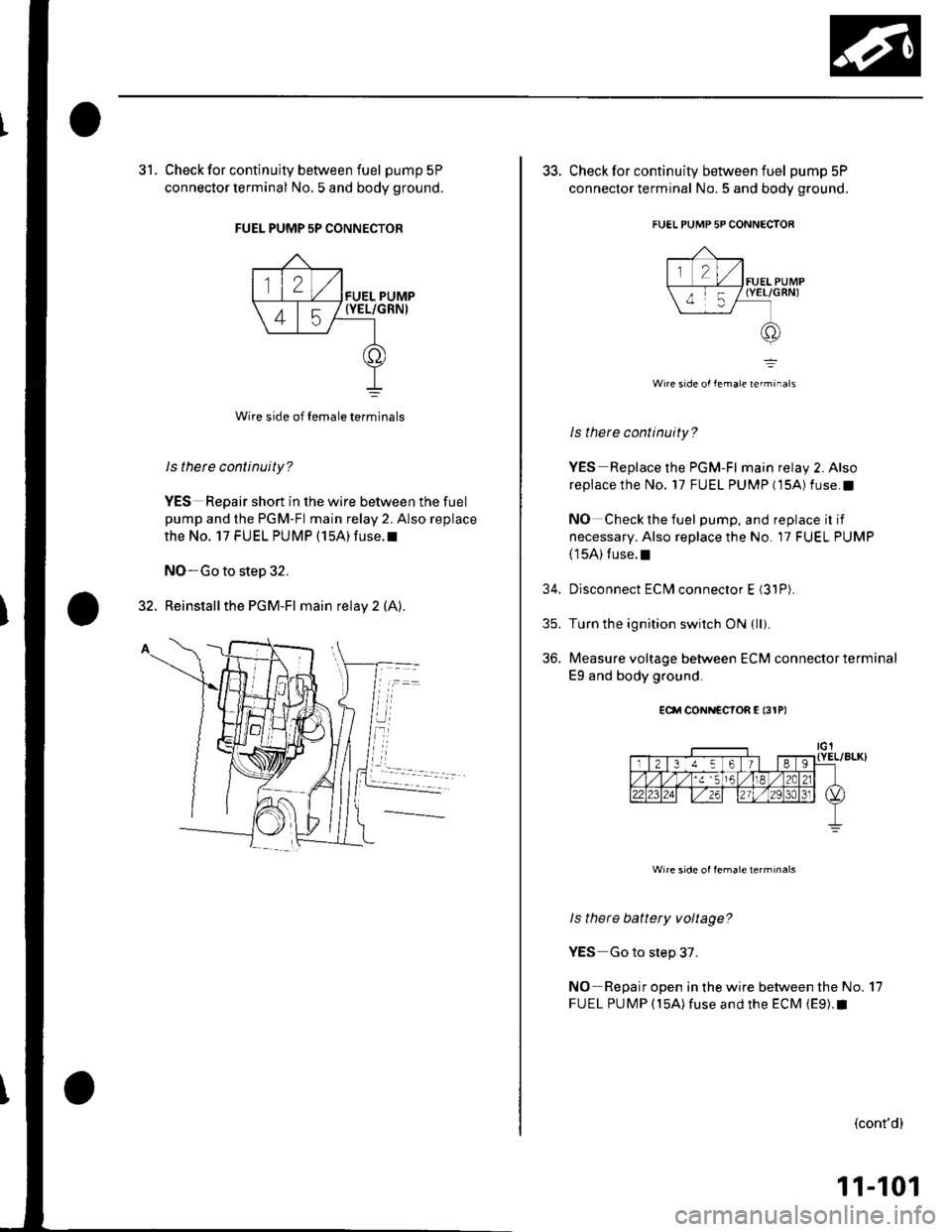

31. Check for continuity between fuel pump 5P

connector terminal No. 5 and body ground.

FUEL PUMP 5P CONNECTOR

Wire side of temale terminals

ls therc continuity?

YES Repair short in the wire between the fuel

pump and the PGM-Fl main relay 2. Also replace

thE NO. 17 FUEL PUMP (15A) fUSE.T

NO-Go to step 32.

32. Reinstallthe PGM-Fl main relay 2 (A).

33. Check for continuity between fuel pump5P

connector terminal No. 5 and body ground.

FUEL PUMP 5P CONNECTOR

=

Wire side ol lemal€ rerminals

ls there continuity?

YES Replace the PGM-Fl main relay 2. Also

replace the No. 17 FUEL PUMP (15A) fuse.l

NO Check the iuel pump, and replace il if

necessary. Also replace the No. 17 FUEL PUMP(15A) fuse.!

34. Disconnect ECM connector E (31P).

35. Turn the ignition swirch ON {111.

36. Measure voltage between ECM connectorterminal

E9 and body ground.

ECfl CON|{CCIOR E (3rPt

Wire side ol female lerminals

ls there battery voltage?

YES Go to step 37.

NO Repair open in the wire between the No. 17

FUEL PUMP (15A)fuse and the ECM (E9).1

(cont'd)

11-101

Page 319 of 1139

PGM-FI System

Injector Replacement (cont'd)

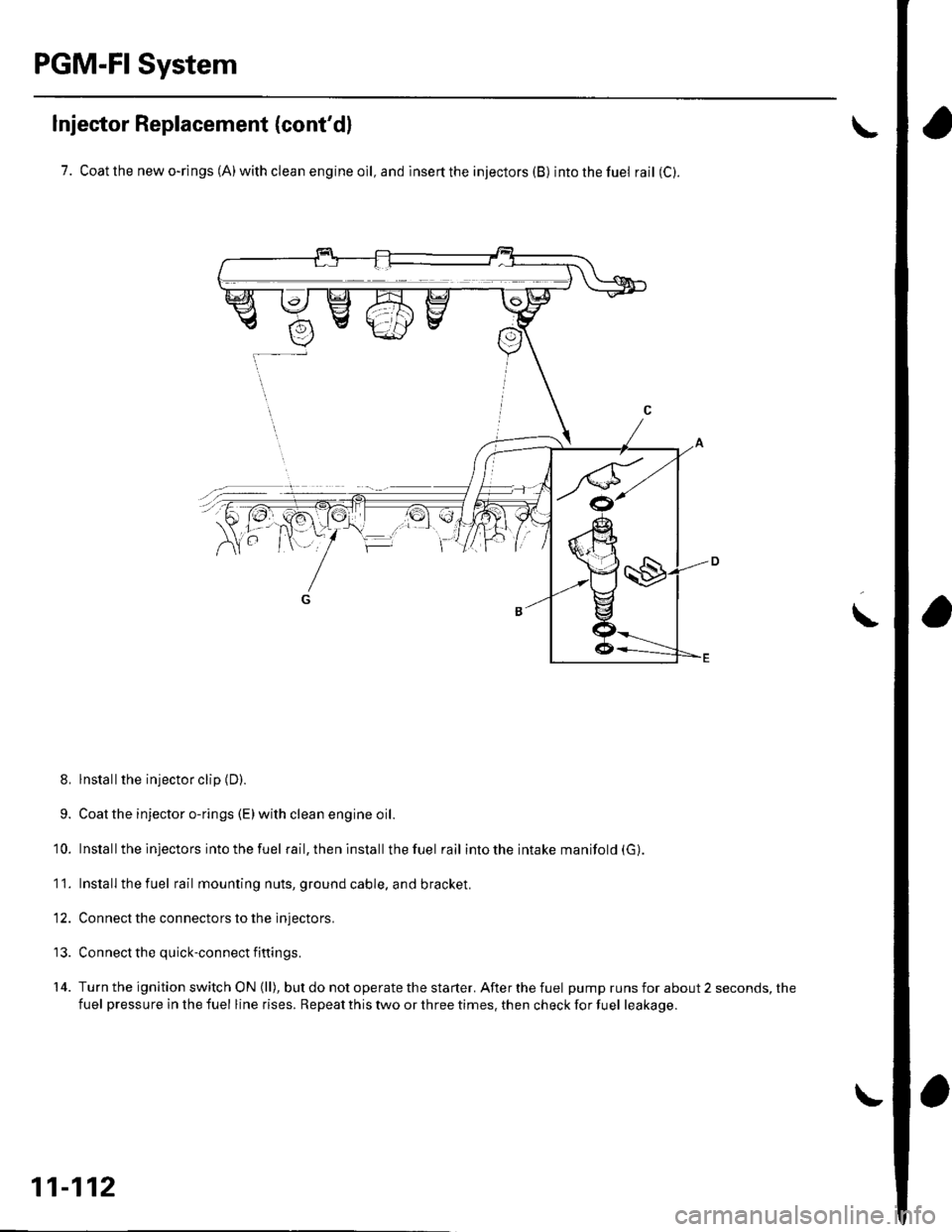

7. Coatthenewo-rings(A)withcleanengineoll,andinserttheinjectors(B) intothefuel rail (C).

8, lnstall the injector clip {D).

9. Coat the injector o-rings (E)with clean engine oil.

10. Installthe injectors intothefuel rail, then install the fuel rail intotheintakemanifold(G).

1 '1. Install the fuel rail mounting nuts, ground cable. and bracket.

12. Connect the connectors to the injectors.

13. Connect the quick-connect fittings.

14. Turnthe ignition switch ON (ll), butdo notoperatethe starter. Afterthefuel pump runs for about 2 seconds, the

fuel pressure in the fuel line rises. Repeat this two or three times. then check for fuel leakage.

\

11-112

Page 347 of 1139

Fuel Supply System

{

a

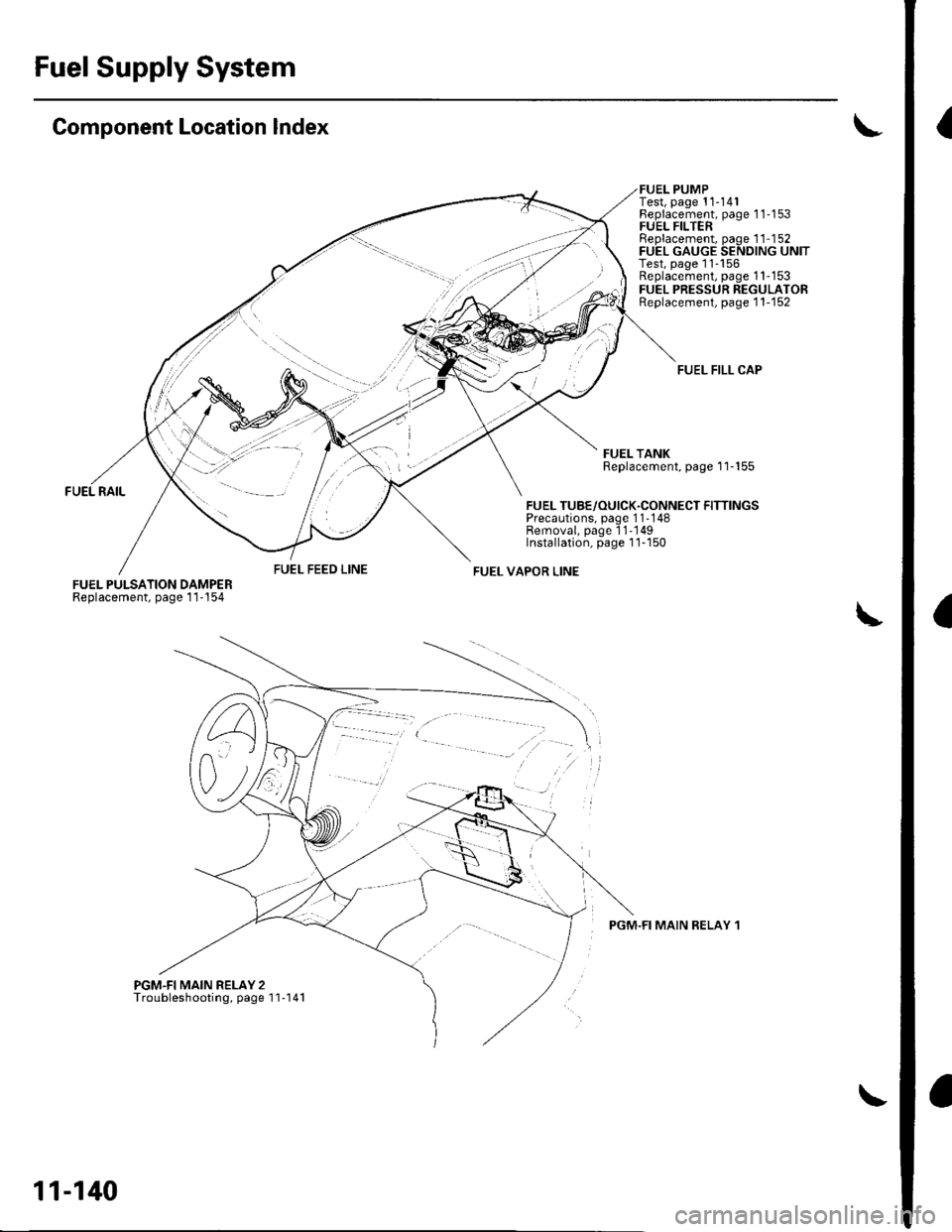

Component Location Index

FUEL FEED LINEFUEL PULSATION DAMPERReplacement, page 1 1'154

PGM.FI MAIN RELAY 2Troubleshooting, page'l'l-141

FUEL TUBE/OUICK.CONNECT FITTINGSPrecautions, page 1 1-148Removal, page 11-'149Installation, page 1 1-'l50

FUEL VAPOR LINE

i../

PUMPTest, page 11-141

FUEL FILL CAP

FUEL TANKReplacement, page'l 1-155

PGM.FI MAIN RELAY 1

Fleplacement, page 1 1'1 53FUEL FILTERReplacement, page 1 1-1 52FUEL GAUGE SENDING UNITTest, page 11-156Replacement, page 1 1-153FUEL PRESSUN REGULATORReplacement, page'1 1-'152

11-140