radiator HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 118 of 1139

Gylinder Head Removal

NOTE:. Use fender covers to avoid damaging painted

surfaces.

To avoid damage, unplug the wiring connectors

carefully whlle holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100'F (38"C)

betore loosening the cylinder head bolts.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

'1.

2.

3.

Drain the engine coolant (see page 10-6).

Remove the drive belt (see page 4-26).

Remove the intake manifold {see page 9-3).

Remove the air cleaner housing (see step 7 on page

5-2t.

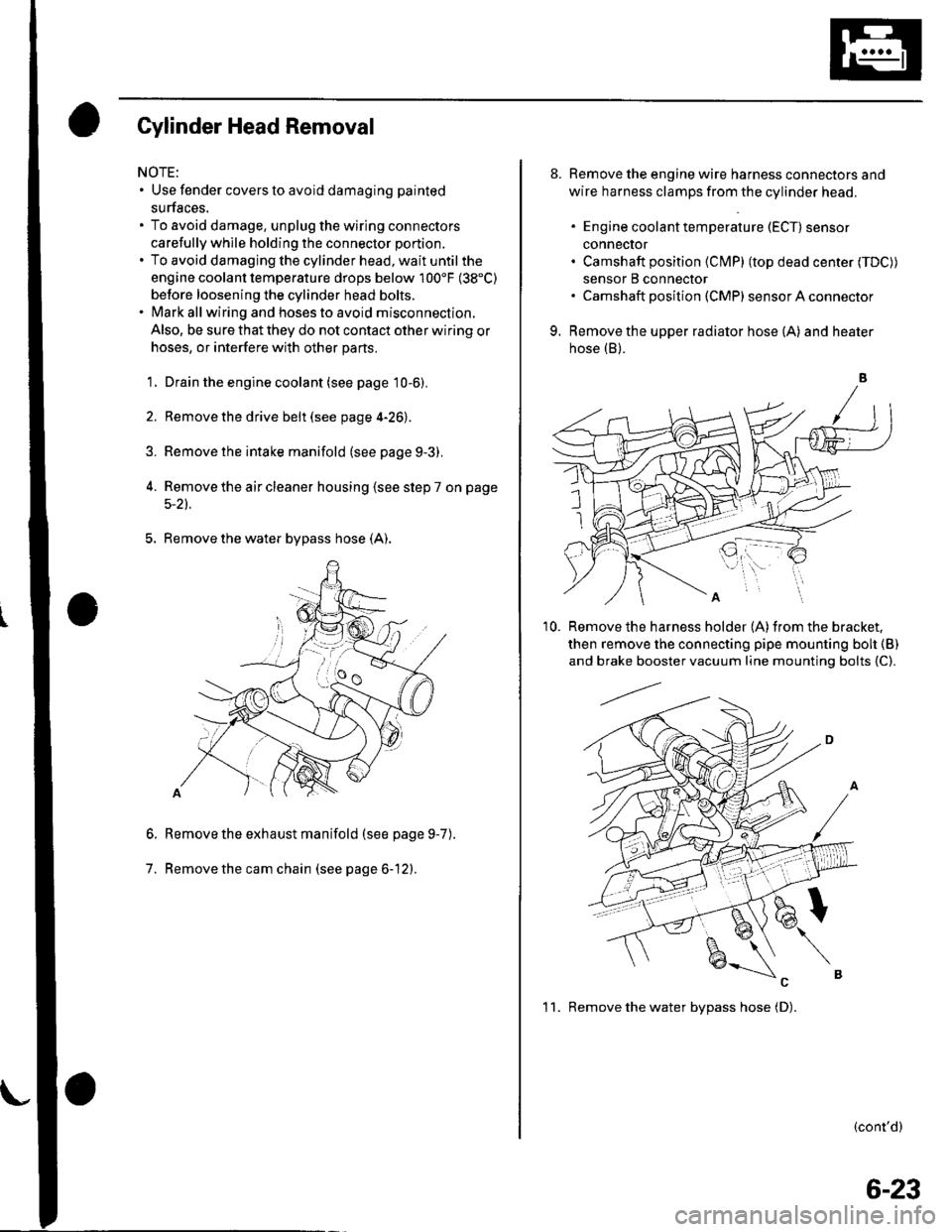

5. Remove the water bypass hose (A).

Remove the exhaust manifold (see page 9-7

Remove the cam chain (see page 6-12).

6.

7.

).

8. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head.

. Engine coolant temperature (ECT) sensor

conneclor. Camshaft position (Cl\4P) (top dead center (TDC))

sensor B connector. Camshaft posilion (CMP) sensor A connector

9. Remove the upper radiator hose (A) and heater

hose (B).

'10. Remove the harness holder (A)from the bracket,

then remove the connecting pipe mounting boh {B)

and brake booster vacuum line mounting bolts {C).

(cont'd)

1 1. Remove the water bvpass hose (D).

6-23

Page 135 of 1139

Cylinder Head

8.

Cylinder Head lnstallation (cont'd)

7.Apply engine oil to the bolt threads and under thebolt heads of all the cylinder head bolts.

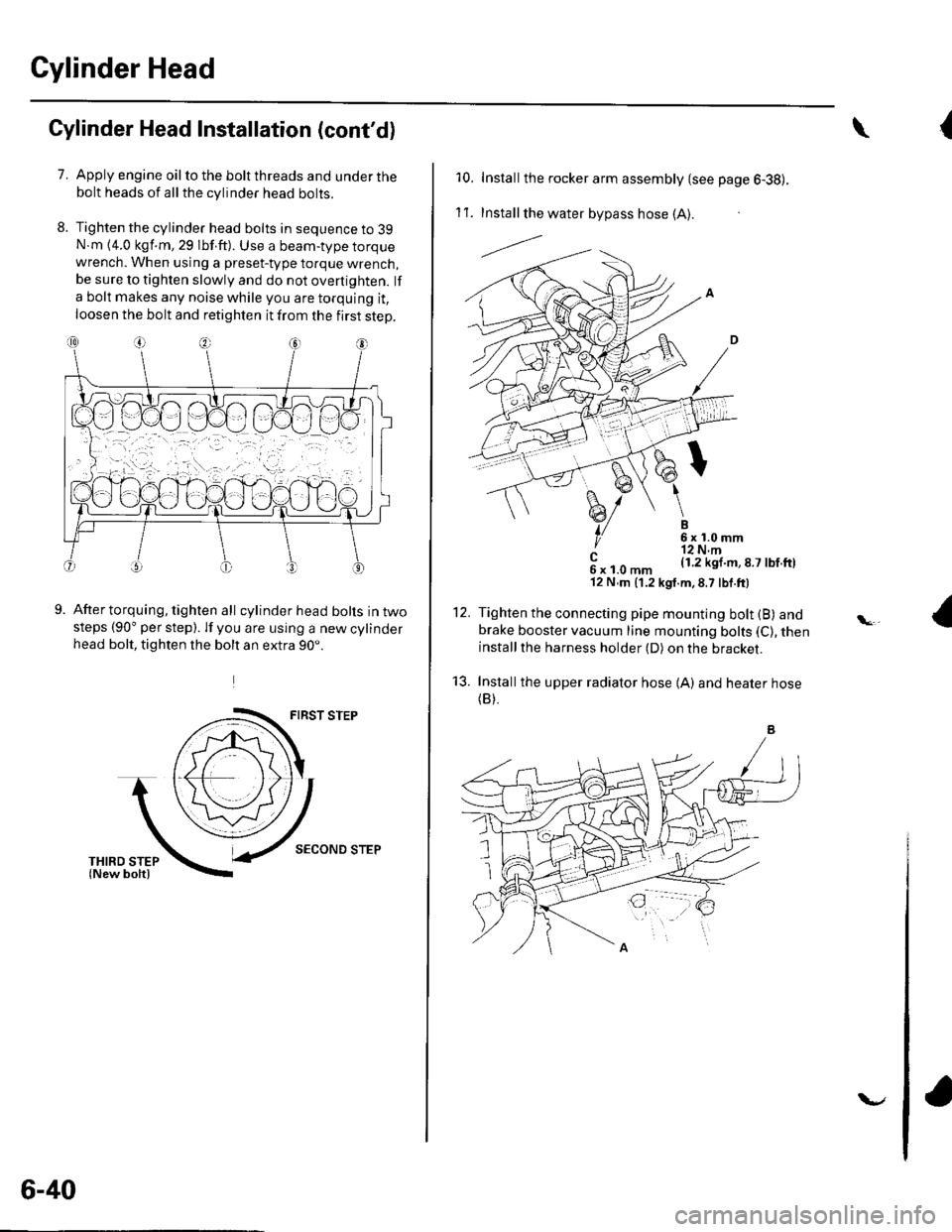

Tighten the cylinder head bolts in sequence to 39N.m {4.0 kgf.m, 29 lbf.ft). Use a beam-type torquewrench. When using a preset-type torque wrench,be sure to tighten slowly and do not overtighten. lf

a bolt makes any noise while you are torquing it,

loosen the bolt and retighten it from the first step.

9.After torquing, tighten all cylinder head bolts in twosteps (90" per step). lf you are using a new cylinderhead bolt, tighten the bolt an extra 90..

FIRST STEP

SECOND STEP

6-40

v

{\

10. Installthe rocker arm assembly {see page 6-38).

1't .Install the water bypass hose (A).

---l.-.

B6x1.0mm'r2 N.m(1.2 kgl.m,8.7 lbf.ftl

12.

't3.

c6xl.0mm'12 N,m (1.2 kgt.m,8.7 lbf.ft)

Tighten the connecting pipe mounting bolt (B) andbrake booster vacuum line mounting bolts (C), theninstallthe harness holder (D) on the bracket.

Installthe upper radiator hose {A) and heater hose(B).

Page 136 of 1139

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

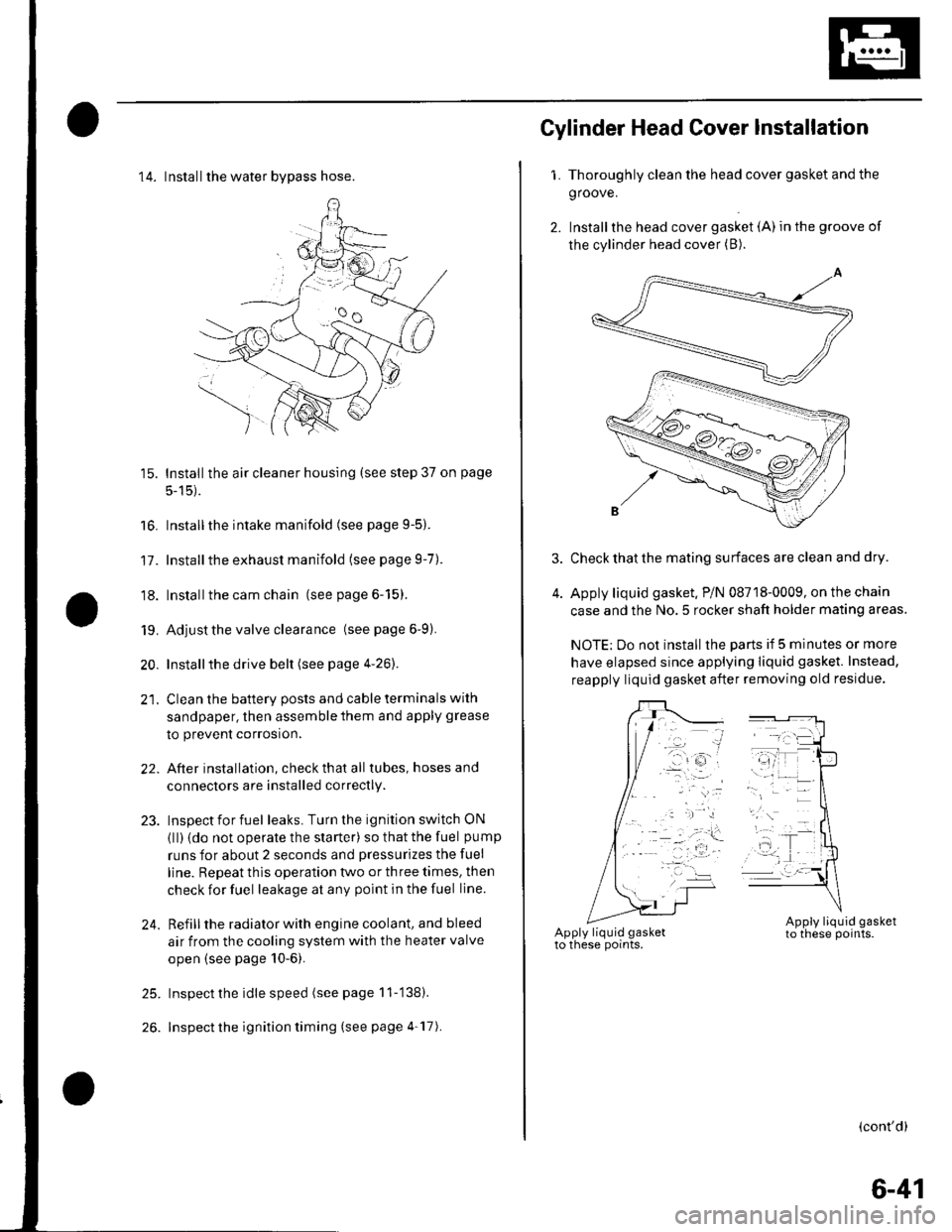

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 188 of 1139

lntake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'd)

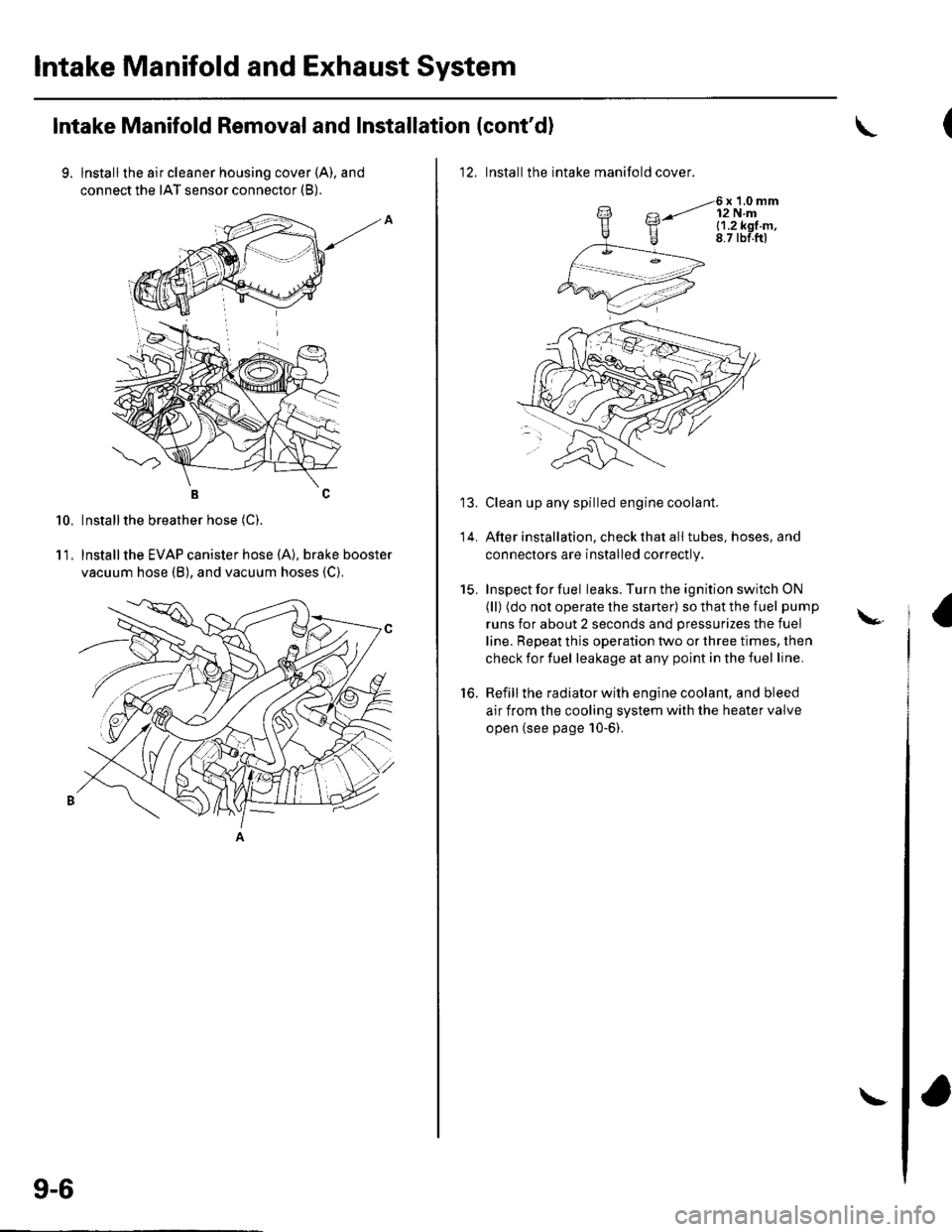

9. lnstallthe air cleaner housing cover (A), and

connect the IAT sensor connector (B).

BC

Installthe breather hose (C).

lnstallthe EVAP canister hose (A), brake booster

vacuum hose (B), and vacuum hoses {C).

10.

11.

9-6

\

12. Installthe intake manifold cover.

6x1.0mm12 N.ml.1.2k91.m,8.7 tbf.ftl

Clean up any spilled engine coolant.

After installation, check that all tubes, hoses, and

connectors are installed correctly.

Inspect for fuel leaks. Turn the ignition switch ON

(ll) (do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

to.

\-

Page 191 of 1139

Engine Cooling

Cooling System

Component Location Index ......................................... 10-2

Radiator Cap Test ..................... .......... 10-3

RadiatorTest ............. 10-3

Fan Motor Test .......... l0-4

Thermostat Test ...................... ........... 10-4

Water Pump Inspection ..................... 10-5

Water Pump Replacement ................. 10-5

Coolant Check .............. ....................... 10-6

Coolant Replacement ......................... 10-6

Thermostat Replacement .................. 10-8

Water Passage Installation ................ 10-9

Water Outlet Installation .................... 10-9

Radiator and Fan Replacement ................................... 10-10

Fan Controls

Component Location Index ......................................... 10-11

Symptom Troubleshooting Index ............................... 10-12

Circuit Diagram ......... 10-13

Radiator Fan CircuitTroubleshooting ........................ 10-14

Radiator Fan Switch Circuit Troubleshooting

(Open) ............ ........ 10-16

Radiator Fan Switch Circuit Troubleshooting

(Short) ............ ........ 10-16

Radiator Fan Switch Test ................... 10-17

Radiator Fan Switch Reolacement .............................. 10-17

Page 192 of 1139

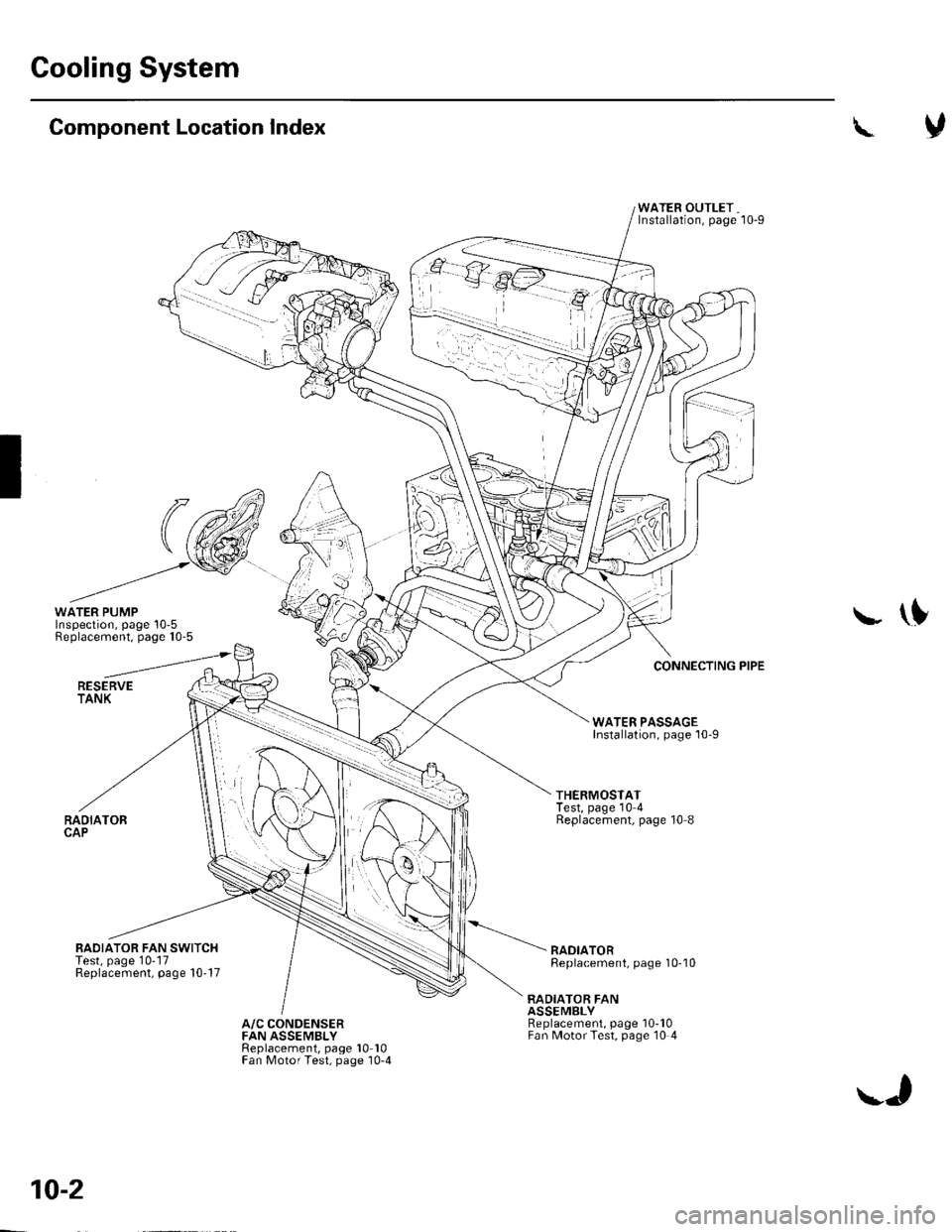

Cooling System

Component Location Index

WATER PUMPInspection, page 10-5Replacement. page 10-5

RESERVETANK

RADIATORCAP

RAOIATOR FAN SWITCHTest, page 10-17Replacement, page 10'17

\

WATER OUTLET,Installation, page'10-g

\f

CONNECTING PIPE

WATER PASSAGEInstallation, page 10-9

THERMOSTATTest, page 10 4Replacement, page 10 8

RADIATORReplacement, page 10-'l0

RADIATOR FANASSEMgLYReplacement, page 10-10Fan MotorTest, page 10 4A/C CONDENSERFAN ASSEMBLYReplacement, page 10 10Fan Motor Test, page '10-4

10-2

\J

Page 193 of 1139

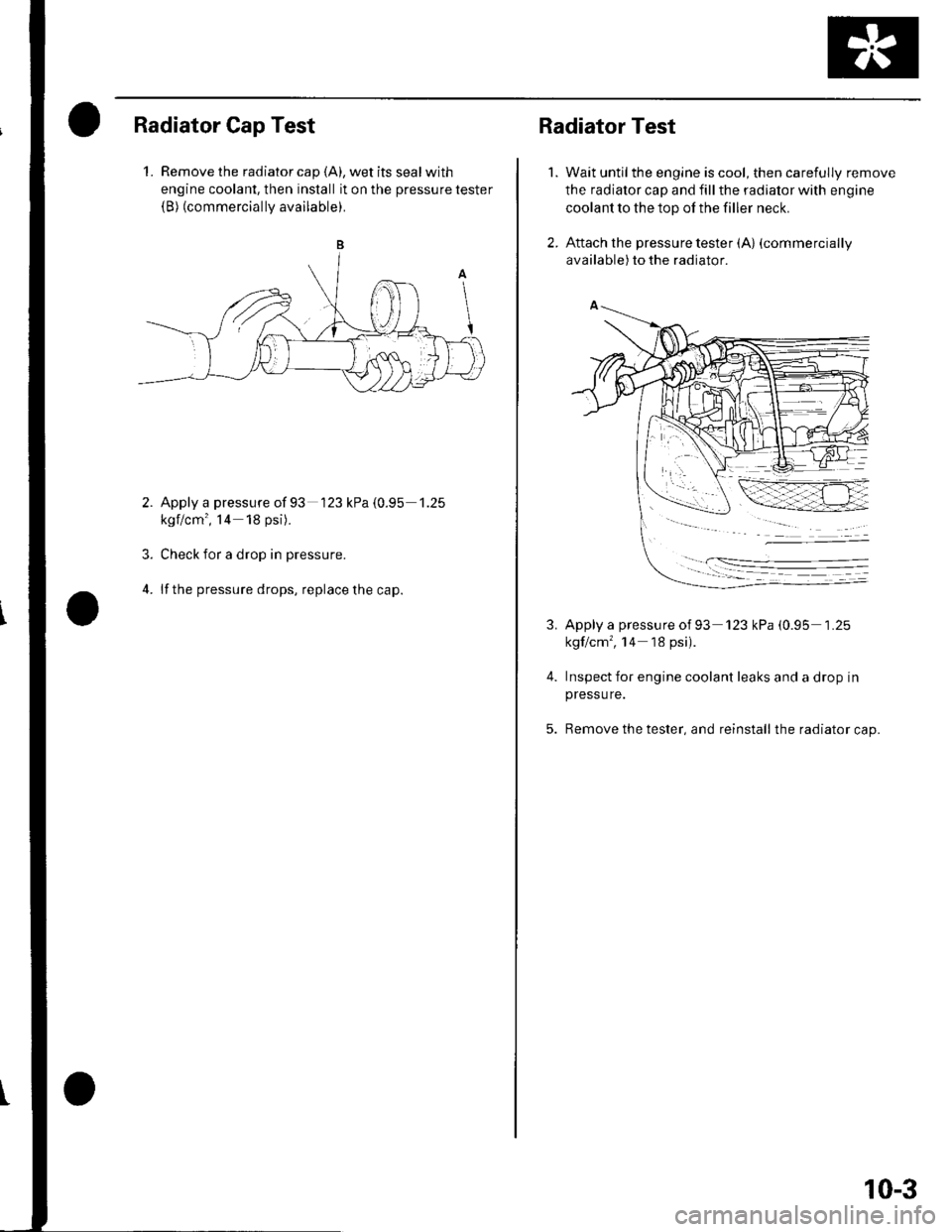

Radiator Cap Test

1. Remove the radiator cap {A), wet its seal with

engine coolant, then install it on the pressure tester(B) (commercially available).

Apply a pressure of 93 '123 kPa {0.95 1.25

kgf/cm', l4 18 psi).

Check for a drop in pressure.

lf the pressure drops, replace the cap.

3.

4.

Radiator Test

Wait untilthe engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the filler neck.

Attach the pressure tester (A) (commercially

available) to the radiator.

1.

3.

4.

Apply a pressure ot 93 '123 kPa (0.95 1 .25

kgf/cm', '14 18 psi).

Inspect for engine coolant leaks and a drop in

pressu re.

Remove the tester, and reinstall the radiator cap.

10-3

Page 194 of 1139

Cooling System

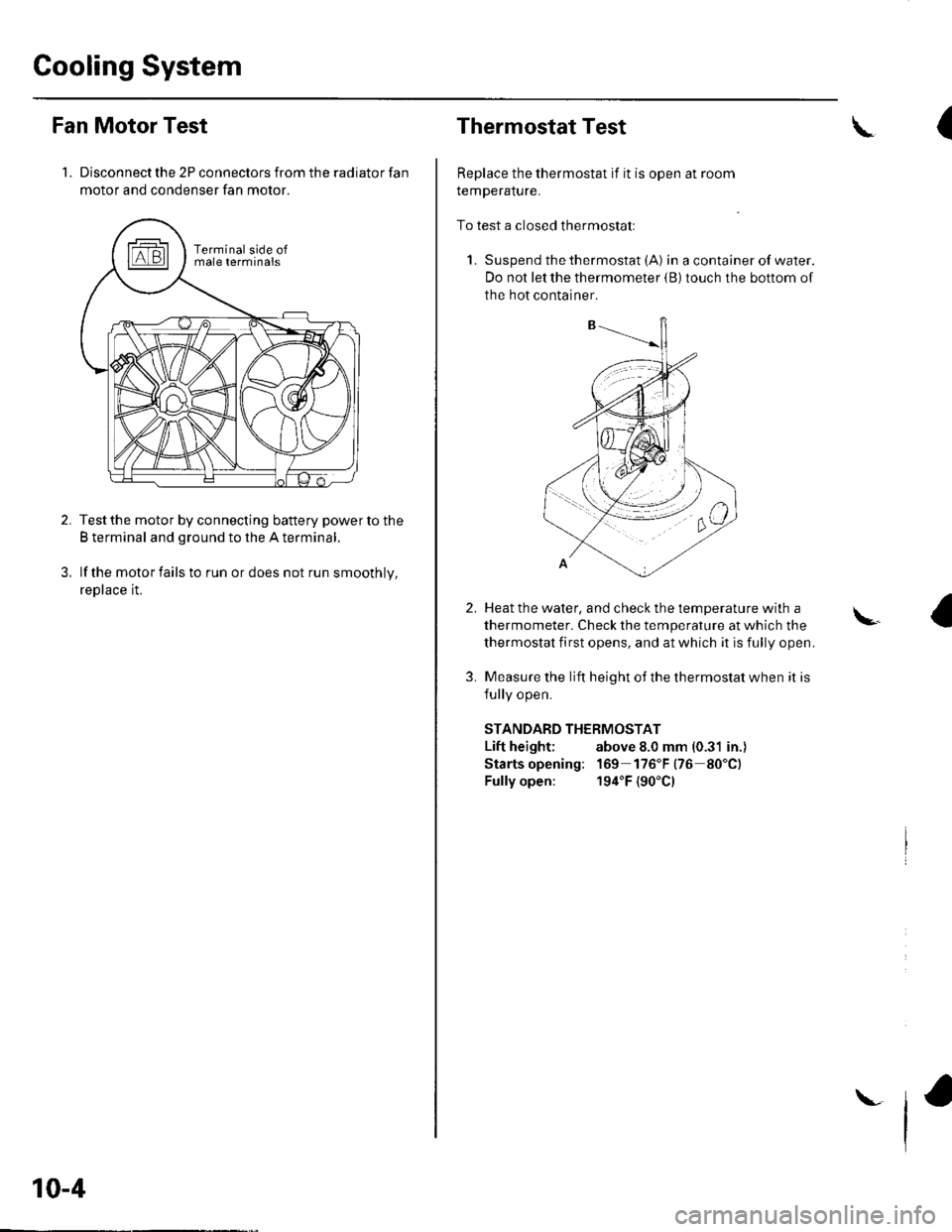

Fan Motor Test

1. Disconnect the 2P connectors from the radiator fan

motor and condenser fan motor.

Test the motor by connecting battery power to the

B terminal and ground to the A terminal.

lf the motor fails to run or does not run smoothly,

reptace rL

10-4

\

Thermostat Test

Replace the thermostat if it is open at room

remperalure.

To test a closed thermostatl

1. Suspend the thermostat (A) in a container of water.

Do not let the thermometer {B) touch the bottom of

the hot container.

(\

2.

3.

Heat the water, and check the temDerature with a

thermometer. Check the temperature at which the

thermostat first opens, and at which it is fully open.

Measure the lift height of the thermostat when it is

fullv ooen.

STANDARD THERMOSTAT

Lift height; above 8.0 mm (0.31 in.)

Starts opening: 169 176"F(76 80"C)

Fully open: 194"F {90'Cl

\.

Page 195 of 1139

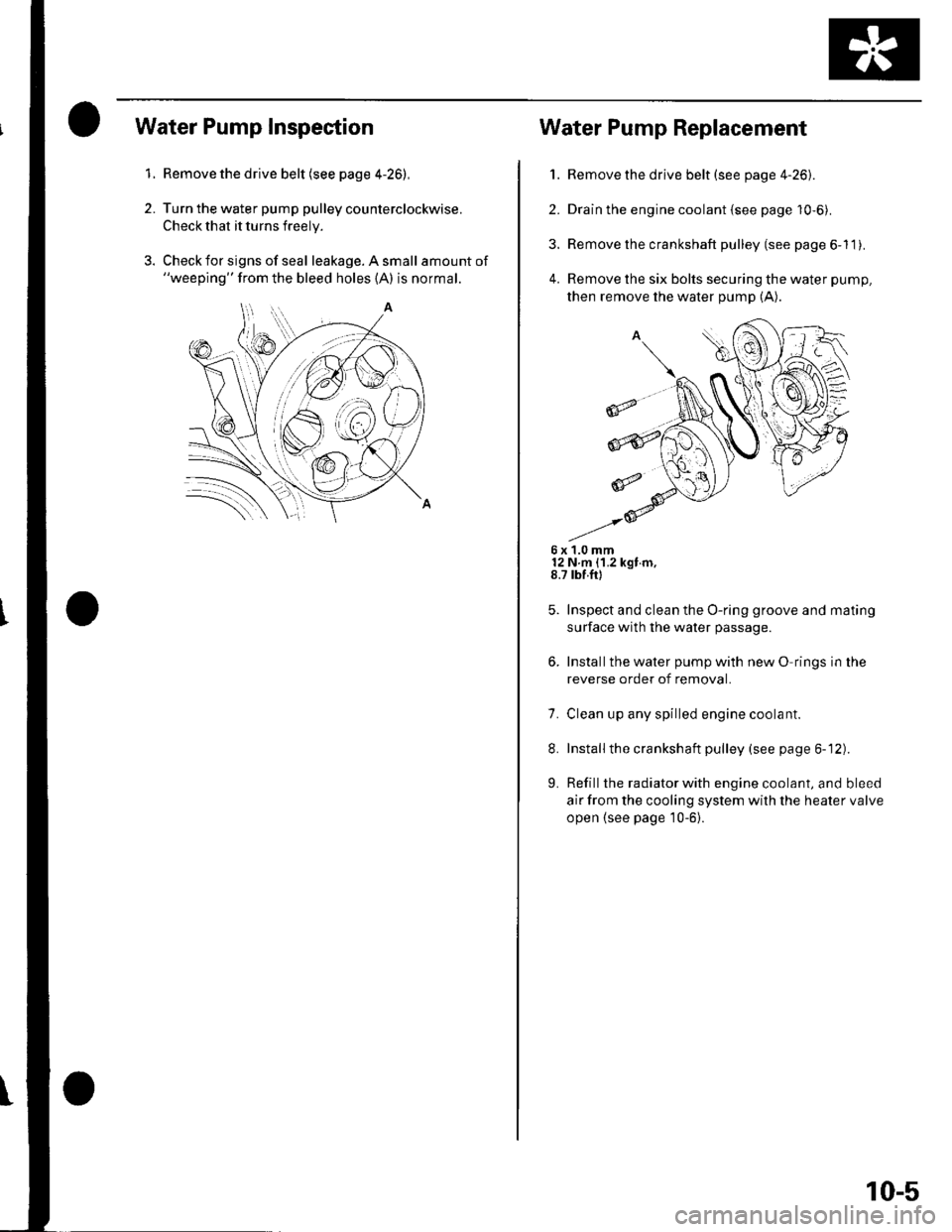

1.

2.

Water Pump Inspection

Remove the drive belt (see page 4-26),

Turn the water pump pulley counterclockwise.

Check that it turns freely.

Check for signs of seal leakage. A small amount of"weeping" from the bleed holes (A) is normal.

Water Pump Replacement

1. Remove the drive belt (see page 4-26).

2. Drain the engine coolant {see page 10-6).

3. Remove the crankshaft pulley (see page 6-11).

4. Remove the six bolts securing the water pump,

then remove the water pump (A).

6x1.0mm12 N m {1.2 kgt m,8.7 rbf.ft)

Inspect and clean the O-ring groove and mating

surface with the water passage.

Installthe water pump with new O rings in the

reverse order of removal.

7. Clean up any spilled engine coolant.

8. Installthe crankshaft pulley (see page 6-12).

L Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open {see page 10-6}.

10-5

Page 196 of 1139

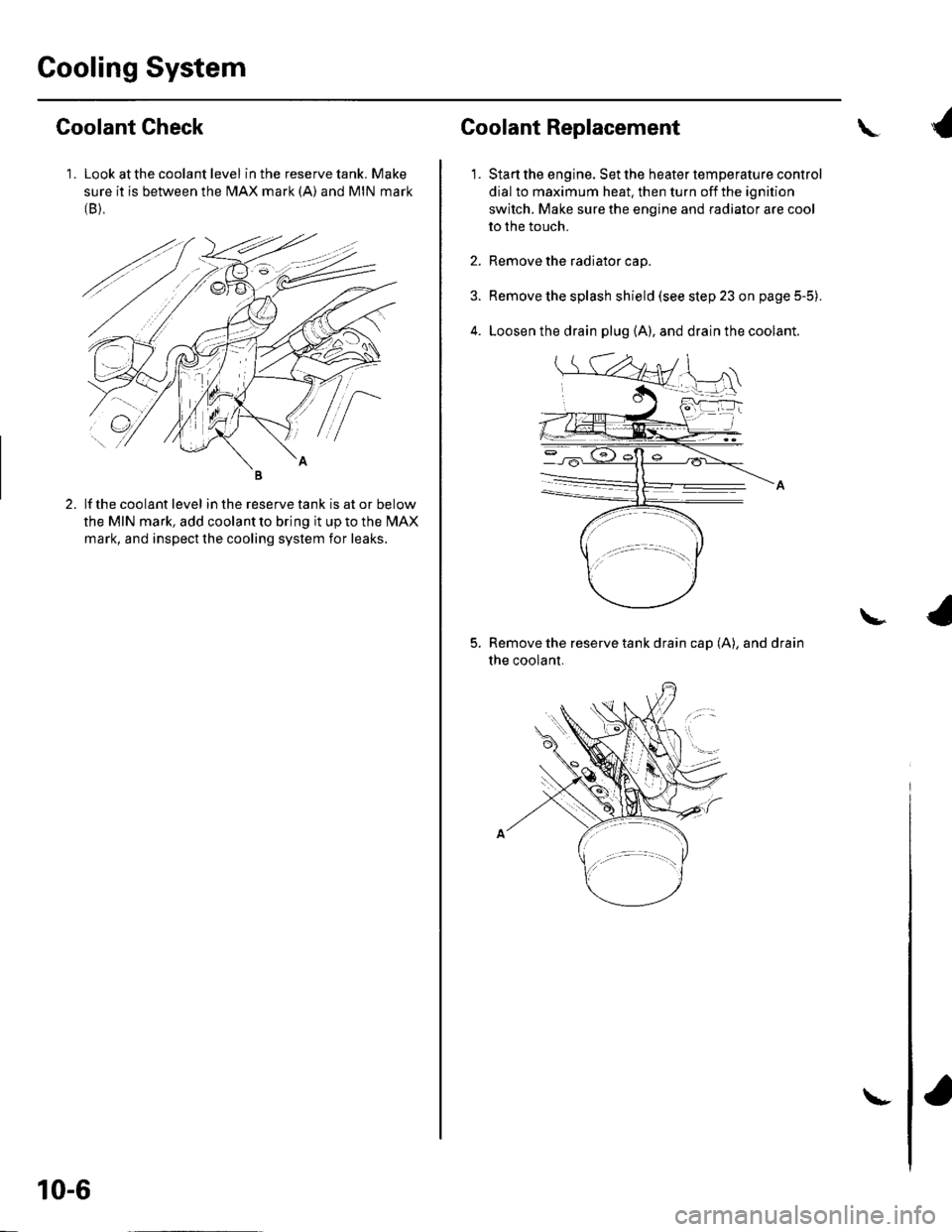

Cooling System

1 . Look at the coolant level in the reserve tank. Make

sure it is between the MAX mark (A) and MIN mark(B),

Goolant Check

lf the coolant level in the reserve tank is at or below

the MIN mark, add coolant to bring it up to the l\4AX

mark, and inspect the cooling system for leaks.

10-6

\-

Coolant Replacement

1.

\

Start the engine. Set the heater temperature control

dial to maximum heat. then turn off the ignition

switch. Make sure the engine and radiator are cool

to the touch.

Remove the radiator cap.

Remove the splash shield (see step 23 on page 5-5).

Loosen the drain plug (A), and drain the coolant.

Remove the reserve tank drain cap (A), and drain

the coolant.

\