HONDA CIVIC 2002 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 201 of 1139

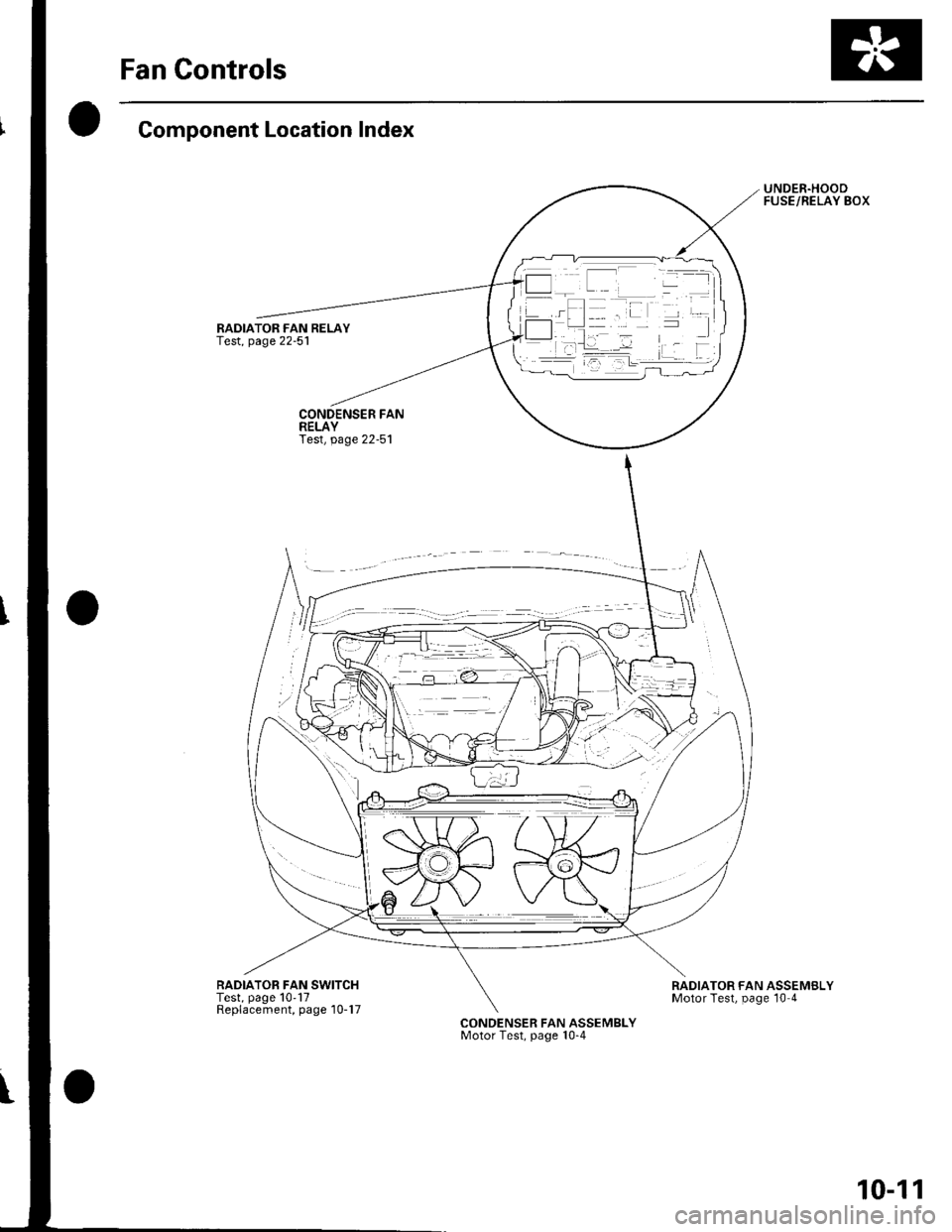

Fan Controls

Component Location Index

RADIATOR FAN RELAY

RADIATOB FAN SWITCHTest, page 10'17Replacement, page'10-17

UNDER.HOODFUSE/RELAY BOX

RADIATOR FAN ASSEMBLYMotor Test, page 10 4

CONDENSER FAN ASSEMBLYMotor Test, page 10-4

10-11

Page 202 of 1139

Fan Controls

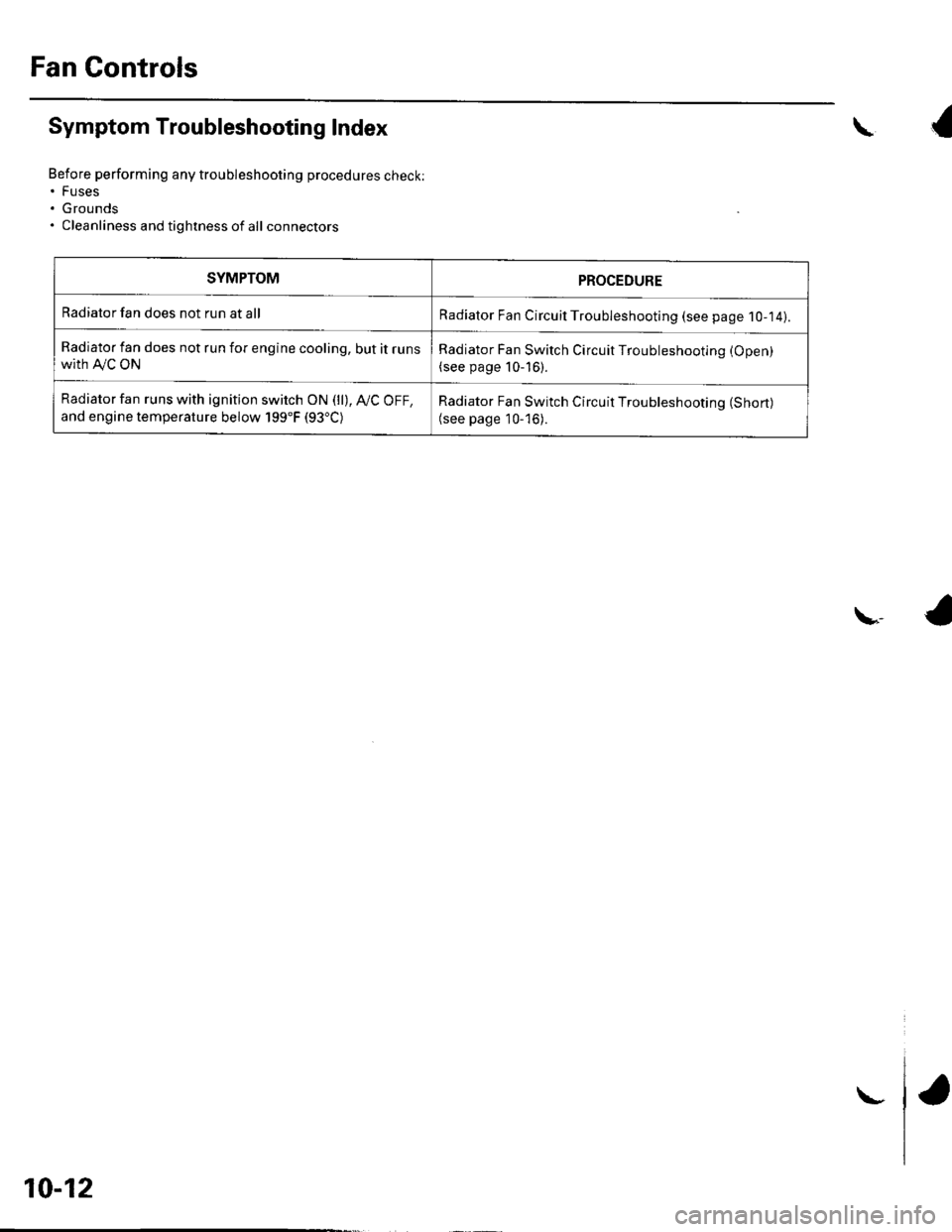

Symptom Troubleshooting Index

Before performing any troubleshooting procedures check:. Fuses. Grounds. Cleanliness and tightness of all connectors

\{

\,4

SYMPTOMPROCEDURE

Radiator fan does not run at allRadiator Fan Circuil Troubleshooting (see page 1O-14).

Radiator fan does not run for engine cooling, but it runswith A,/C ON

Radiator Fan Switch Circuit Troubleshooting (Open)

(see page 10-16).

Radiator fan runs with ignition switch ON (ll), Ay'C OFF,

and engine temperature below 199"F (93"C)Radiator Fan Switch Circuit Troubleshooting (Short)

(see page 10-'16).

10-12

\-

Page 203 of 1139

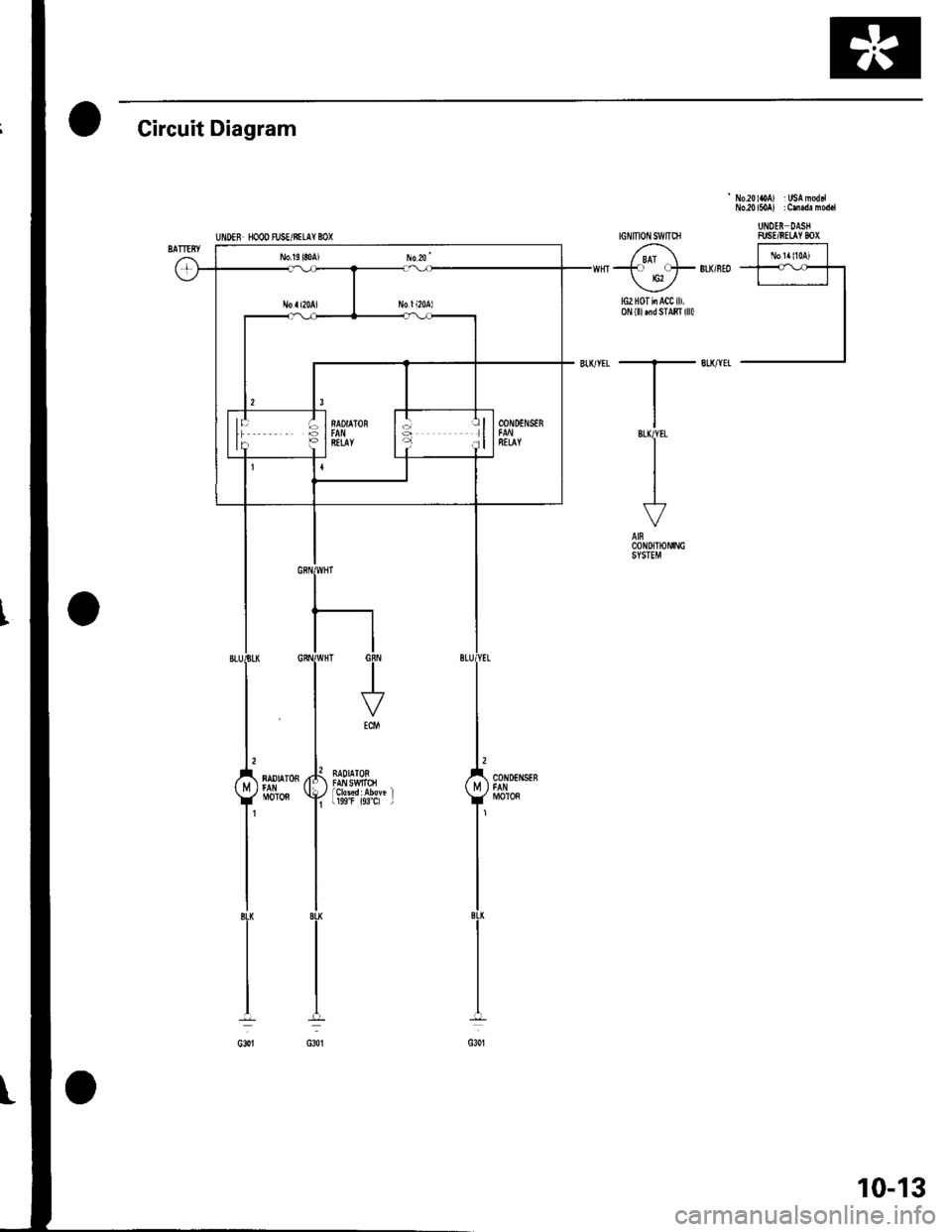

oCircuit Diagram

UIIDEF HOOD FJSE/NILAY BOX

' No.20loA) : USA moddNo.20l50A) : Cm.de mod.l

UNDEN DASXFUSE/RELAY BOX

lG2H0TiiAClill,0N{lllrndSTABI llll)

10-13

Page 204 of 1139

Fan Gontrols

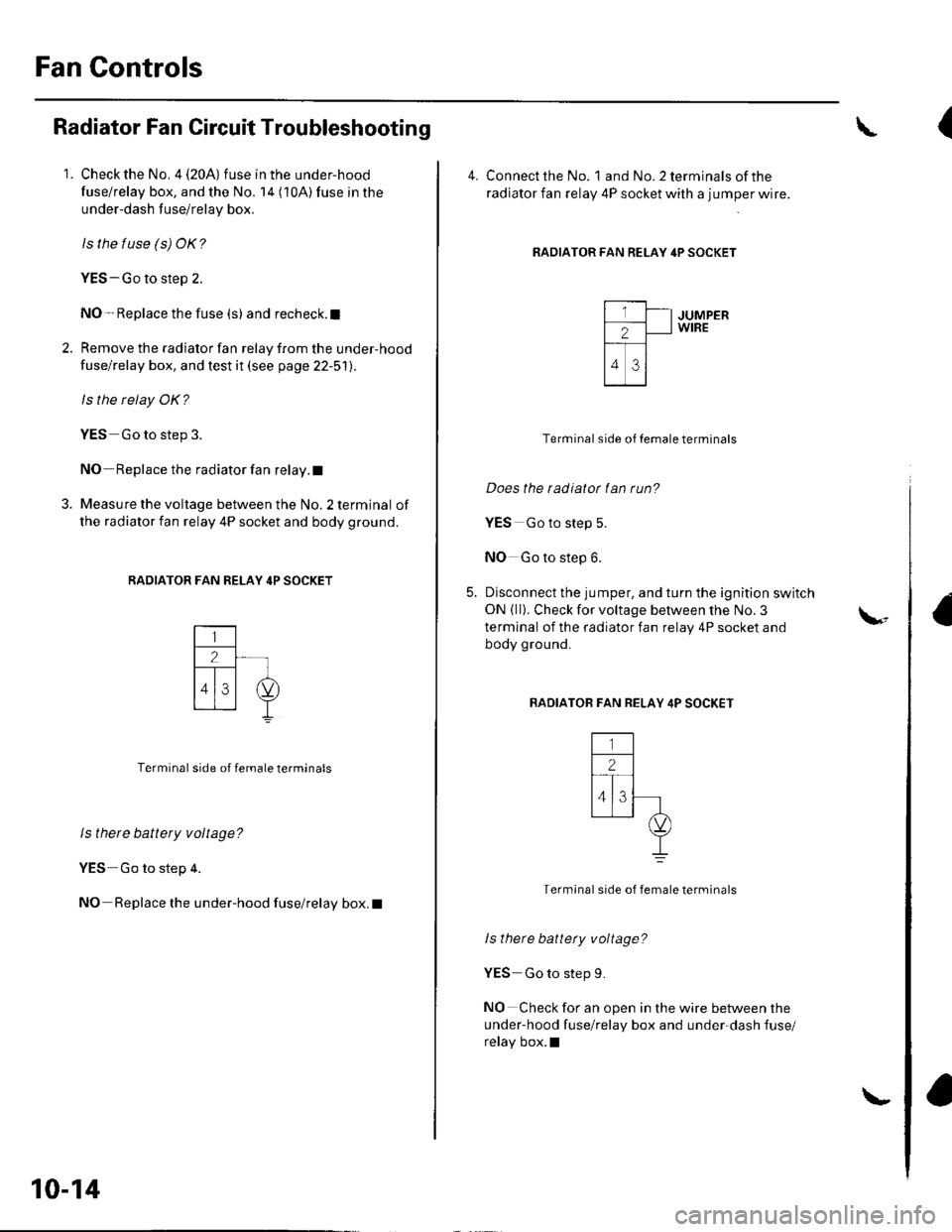

Radiator Fan Circuit Troubleshooting

1. Check the No. 4 (20A) fuse in the under-hood

fuse/relay box, and the No. 14 (10A) fuse in the

under-dash fuse/relay box.

ls the tuse (s) OK?

YES-Go to step 2.

NO- Replace the fuse (s) and recheck.l

2. Remove the radiator fan relay from the under-hood

fuse/relay box, and test it (see page 22-51).

ls the relay OK?

YES Go to step 3.

NO Replace the radiator fan relay. t

3. Measure the voltage between the No. 2 terminal of

the radiator fan relay 4P socket and body ground.

RADIATOR FAN RELAY 4P SOCKET

Terminal side of female terminals

ls there battery voltage?

YES Go to step 4.

NO Replace the under-hood fuse/relay box. I

10-14

\-

(

4. Connect the No. landNo.2terminalsofthe

radiator fan relay 4P socket with a jumper wire.

RADIATOR FAN RELAY 4P SOCKET

JUMPERWIRE

Terminal side of Iemale terminals

Does the radiatot fan run?

YES Go to step 5.

NO Go to step 6.

Disconnect the jumper, and turn the ignition switch

ON { ll}. Check for voltage between the No. 3

terminal of the radiator fan relay 4P socket and

body ground.

BADIATOB FAN RELAY 4P SOCKET

Termlnal side of female terminals

ls there battety voltage?

YES-Go to step 9.

NO Check for an open in the wire between the

under-hood fuse/relay box and under-dash fuse/

relay box.l

\-

Page 205 of 1139

7.

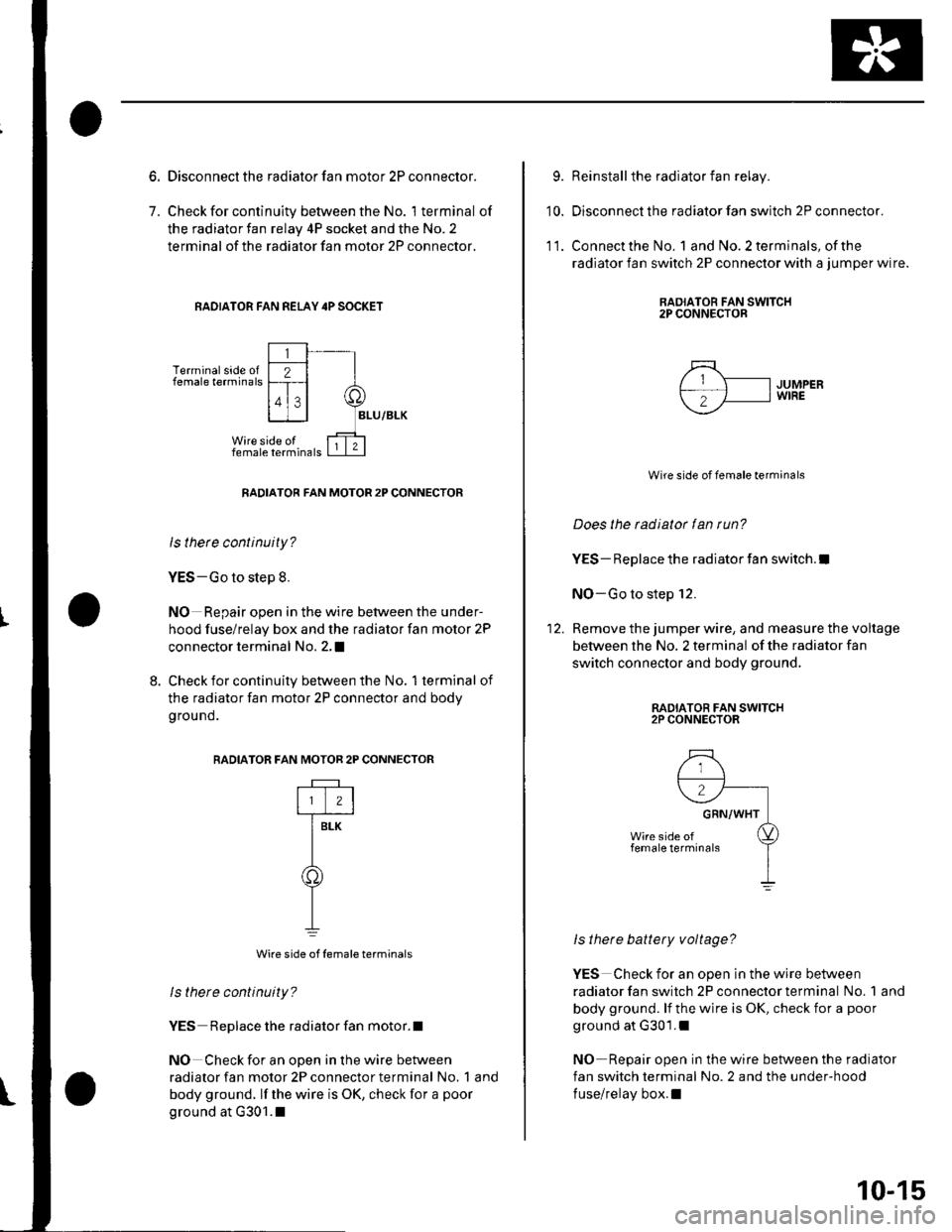

Disconnect the radiator fan motor 2P connector.

Check for continuity between the No. 1 terminal of

the radiator fan relay 4P socket and the No. 2

terminal of the radiator fan motor 2P connector.

RAOIATOR FAN REI-AY 4P SOCKET

Terminal side offemale terminals

RADIATOR FAN MOTOR 2P CONNECTOR

ls thete continuity?

YES-Go to step 8.

NO Repair open in the wire between the under-

hood fuse/relay box and the radiator fan motor 2P

connector terminal No. 2,I

8. Check for continuity between the No, 1terminal of

the radiator fan motor 2P connector and bodv

g rou nd.

RADIATOR F

Wire side of female terminals

ls there continuity?

YES Replace the radiator fan motor.l

NO Check for an open in the wire between

radiator fan motor 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

AN MOTOR 2P CONNECTOR

rftr

T-

Y

9.

10.

Reinstall the radiator fan relay.

Disconnect the radiator fan switch 2P connector.

Connect the No. 1 and No. 2 terminals, of the

radiator fan switch 2P connector with a jumper wire.

RAOIATOR FAN SWITCH2P CONNECTOR

11.

5\- IJUMPERf-; 'fl I wrRE

--

Wire side of female terminals

Does the radiator fan run?

YES- Replace the radiator fan switch.l

NO-Go to step 12.

Remove the jumper wire, and measure the voltage

between the No, 2 terminal of the radiator fan

switch connector and body ground,

RADIATOR FAN SWITCH2P CONNECTOR

ls there battery voltage?

YES Check for an open in the wire between

radiator fan switch 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

NO Repair open in the wire between the radiator

fan switch terminal No. 2 and the under-hood

fuse/relay box.l

10-15

Page 206 of 1139

Fan Controls

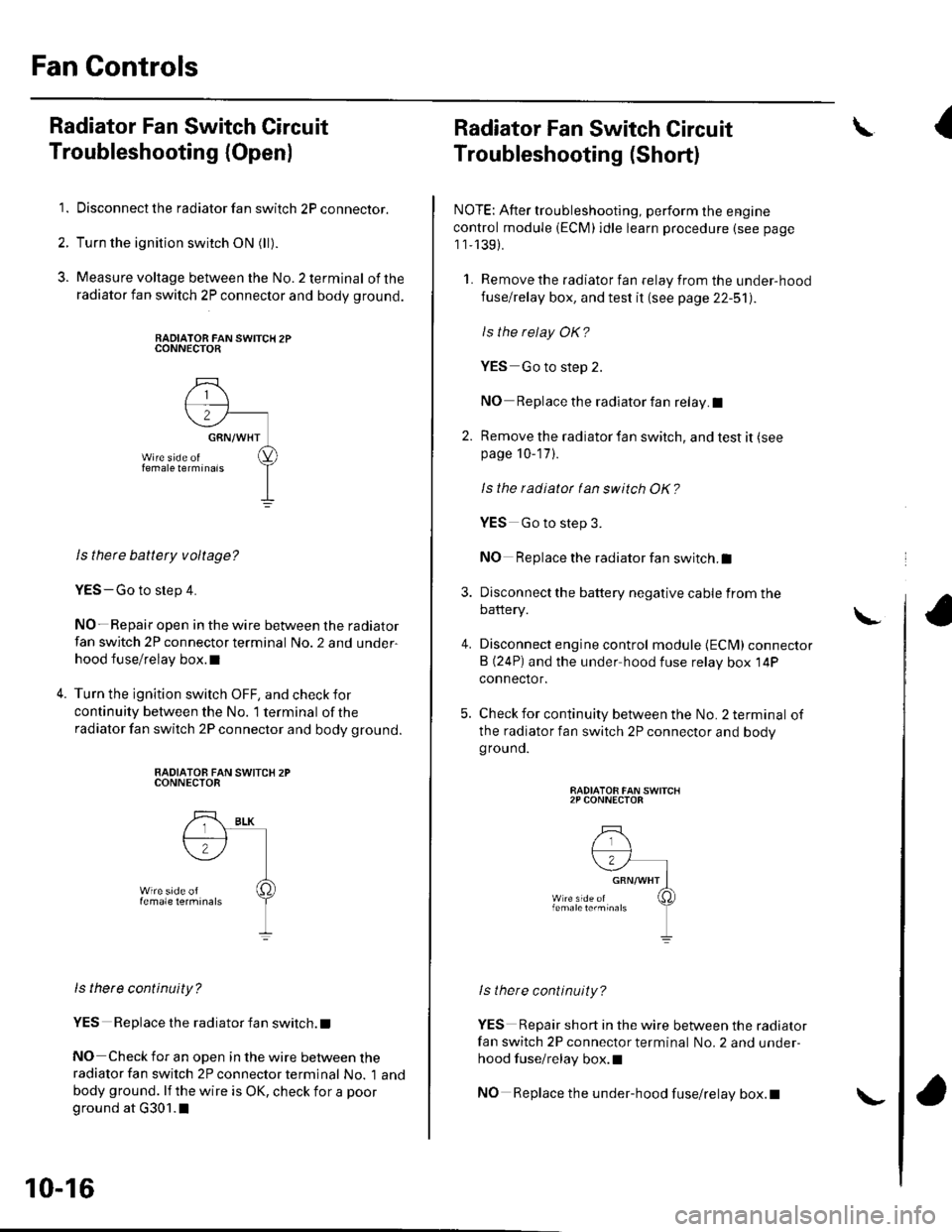

Radiator Fan Switch Circuit

Troubleshooting (Openl

1. Disconnect the radiator fan switch 2P connector.

2. Turn the ignition switch ON (ll).

3. Measure voltage between the No.2 terminal ofthe

radiator fan switch 2P connector and body ground.

RADIATOR FAN SWITCH 2PCONNECTOR

ls there battety voltage?

YES-Go to step 4.

NO- Repair open in the wire between the radiator

fan switch 2P connector terminal No. 2 and under-

hood fuse/relay box.l

Turn the ignition switch OFF, and check for

continuity between the No. '1 terminal of the

radiator fan switch 2P connector and body ground.

RADIATOB FAN SWITCX 2PCONNECTOR

ls there continuity?

YES Replace the radiator fan switch. t

NO Check for an open in the wire between theradiator fan switch 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

10-16

\-

Radiator Fan Switch Circuit

Troubleshooting (Short)

NOTE: After troubleshooting, perform the engine

control module (ECM)idle learn procedure (see page

1 1,139).

1. Remove the radiator fan relay from the under-hood

fuse/relay box, and test it (see page 22-51).

ls the relay OK?

YES Go to step 2.

NO Replace the radiator fan relay.I

2. Remove the radiator fan switch, and test it (see

page 10-17 ).

Is the radiatot tan switch OK?

4.

YES Go to step 3.

NO Replace the radiator fan switch.I

Disconnect the battery negative cable from the

battery.

Disconnect engine control module {ECM) connector

B (24P) and the under hood fuse relay box 14P

connector.

Check for continuity between the No. 2 terminal of

the radiator fan switch 2P connector and bodygrouno.

RADIATOR FAN SWITCH2P CONNECTOR

lstnere continuity?

YES Repair short in the wire between the radiator

fan switch 2P connector terminal No. 2 and under-

hood fuse/relay box.l

NO Replace the under-hood fuse/relay box.t

\I

\

Page 207 of 1139

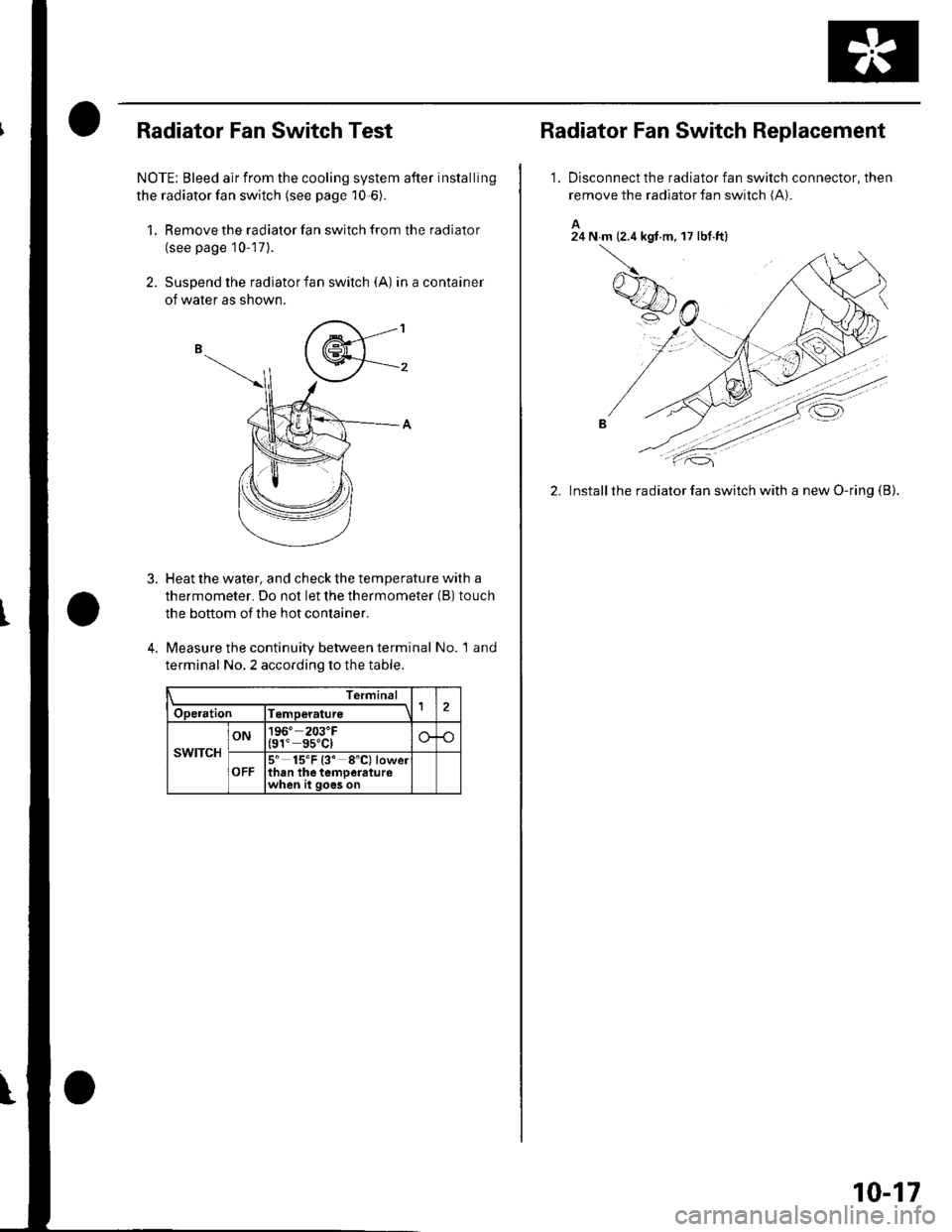

Radiator Fan Switch Test

NOTE: Bleed air from the cooling system after installing

the radiator fan switch (see page 10-6).

1, Remove the radiator fan switch from the radiator

(see page 10-17).

2. Suspend the radiator fan switch (A) inacontainer

of water as shown.

3. Heat the water, and check the temperature with a

thermometer. Do not let the thermometer (B) touch

the bottom of the hot conlainer.

4. Measure the continuity between terminal No. 1 and

terminal No. 2 according to the table.

Termina

Operation lTemperature1

swtTcH

ON196" 203'F(91" gs"C)

OFF5' 15'F {3' 8'C) lowelthan the temoeraturewhen it goes on

Radiator Fan Switch Replacement

1.Disconnect the radiator fan switch connector, then

remove the radiator fan switch (A).

A24 N m (2.4 kgt.m, 17 lbt.ftl

2. Installthe radiator fan switch with a new O-ring (B).

10-17

Page 208 of 1139

Fuel and Emissions

Fuel and Emissions Systems

SpecialTools

General Troubleshooting

Information

DTC Troubleshooting lndex ....

Symptom Troubleshooting

1ndex...............

System Descriptions ................

Howto Set Readiness Codes ..

PGM-FlSystem

Component Location Index ....

DTC Troubleshooting ..............

MIL Circuit Troubleshooting ...

DLC Circuit Troubleshooting ..

Injector Replacement ...............

A,/F Sensor Replacement .........

Secondary HO2S

Replacement

ECT Sensor Reolacement .......

CMP Sensor B {TDC Sensor)

Replacement

IAT Sensor Replacement .........

Knock Sensor Replacement ....

CKP Sensor Reolacement .......

VTEC/VTC

Comoonent Location Index ....

DTC Troubleshooting ..............

VTC Oil Control Solenoid

Valve Removal/Test .............

CMP Sensor A Replacement ...

VTEC Solenoid Valve

Removal/lnsoection .............

ldle Control System

Component Location Index

DTC Troubleshooting ..............

A,/C Signal Circuit

TroubleshootinS ...................

Alternator FR Signal Circu it

TroubleshootinS ...................

EPS Signal Circuit

TroubleshootinS ...................

Brake Pedal Position Switch Signal

Circuit Troubleshooting .............

ldle Speed Inspection

ECM ldle learn Procedure .......

Fuel Supply System

Component Location Index

Fuel Pump Circuit Troubleshooting

1't-2

I I-J

11-7

1 1-10

11-12

11-46

11-49

11-52

11-97

11-109

11-111

11-113

11-113

11-114

11-114

11-115

11-115

11-116

11-117

1 1-1 18

11-127

11-128

11-128

11-129

1I-130

I t- t55

11-134

1 1- 135

1 1-137

1 1-138

1 1-139

1 1-140

11-141

11-144

Fuel PressureTest ................... 11-145

Fuel Lines Inspection ............... 11-146

Fuel Line/Ouick-Connect

Fittings Precautions ............. 1 1-148

Fuel Line/Ou ick-Con nect

Fittings Removal .................. 1 1-149

Fuel Line/Ou ick-Con nect

Fittings lnstallation ............... 11-150

Fuel Pressure Regu lator

Replacement ......................... 11-152

Fuel Fifter Replacement ........... 11-152

Fuel Pump/Fuel Gauge Sending

UnitReDlacement ................. 11-153

Fuel Pulsation Damoer

Rep1acement ......................... 11-154

Fuel Tank Reolacement ........... 11-155

Fuel GaugeSending UnitTest ....... 11-156

Low Fuel lndicatorTest ................. 1 1-158

Intake Air System

Comoonent Location Index .... 11-159

Throttle BodyTest ................... 11-160

Intake Air Bypass Control

Thermal Valve Test .............. 11-161

Air Cleaner Reolacement ........ 11-162

Air Cleaner Element

Reolacement ......................... 11-162

Throttle Cable Adjustment ...... 11-163

Th rottle Cable

Removal/lnstallation ............ 1 1-164

Th rottle Body Removal/

Installation .. 11-165

Th rottle Body Disassembly/

Reassemblv .......................... 11-166

Catalytic Converter System

DTC Troubleshooting .............. 1 1-167

PCV System

DTC Troubleshooting .............. 1 1-168

PCV Valve InsDection

and Test ...... 1 1- 169

PCV Valve Reolacement .......... 11-169

EVAP System

Component Location Index .... 11-170

DTCTroubleshooting .............. 11-171

EVAP Two Way Valve Test ...... 11-186

Fuel Tank Vaoor Control

Valve Test ... 11-187

EVAP Canister Replacement ... 11-189

Fuel Tank Vaoor Control

Valve Reolacement .............. 1 1-189Fuel Pressu re Relieving ...........

Page 209 of 1139

Fuel and Emissions Systems

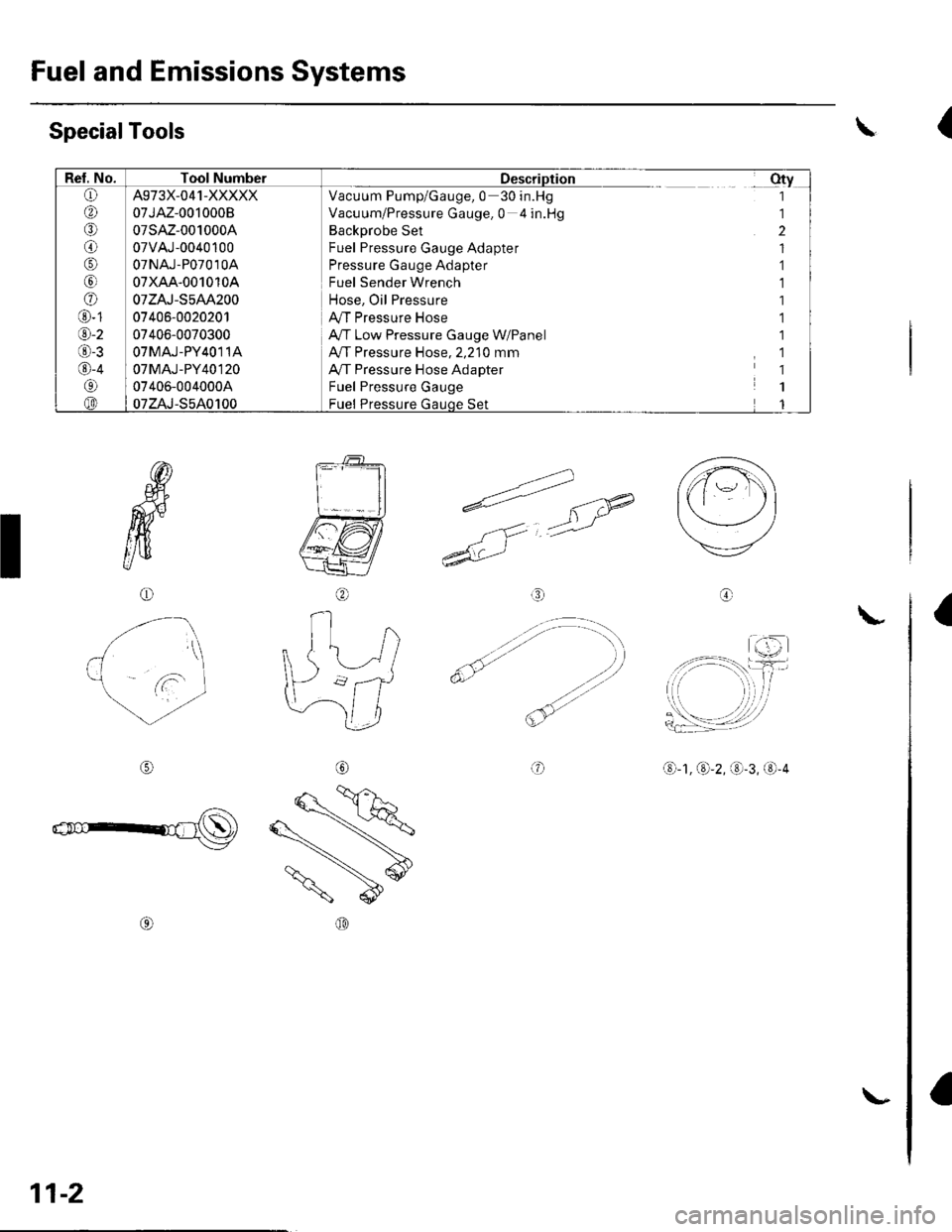

Rel. No.Tool NumberDescriptionotv(L)

@

o

@

@

@

o

@-t

@-2

O-3

@-4

@(iD

A973X-041-XXXXX

07JAZ-0010008

07sAz-001000A

07vAJ-0040100

07NAJ-P07010A

07xAA-001010A

07zAJ-S5AA200

07406-0020201

07406-0070300

OTMAJ-PY4O11A

07MAJ-PY40120

07406-004000A

07zAJ-S5A0100

Vacuum Pump/Gauge, 0 30 in.Hg

Vacuum/Pressure Gauge. 0 4 in.Hg

Backprobe Set

Fuel Pressure Gauge Adapter

Pressure Gauge Adapter

Fuel Sender Wrench

Hose, Oil Pressure

A,/T Pressure Hose

A,/T Low Pressure Gauge W/Panel

A,/T Pressure Hose ,2,210 mm

A,/T Pressure Hose Adapter

Fuel Pressure Gauge

Fuel Pressure Gauoe Set

1

1

2

1

1

1

SpecialTools

ffi

W

UtB

o

o

*.'l€)

(\,

I

/6\

l

)l

\-,/

\7

@

--1

a=:t=' (F

/'r';-:'-;--'

At-''

o

\-I-'-,---=---1,-'.

ut/t

) i-==.€

'jt' *==-.2'l

(i) -1,40-2, -3, @-4@

\h

\:

\d

@o

a

11-2

\-

Page 210 of 1139

General Troubleshooting Information

Intermittent Failures

The term "intermittent failure" means a svstem mav

have had a failure. but it checks OK now. lf the

Malfunction Indicator Lamp (MlL) on the dash does not

come on, check for Door connections or loose terminals

at all connectors related to the circuit that Vou are

troubleshooting.

Opens and Shorts

"Ooen" and "Short" are common electrical terms. An

open is a break in a wire or at a connection. A short is

an accidental connection of a wire to ground or to

another wire. In simple electronics, this usually means

something won't work at all. With complex electronics(such as ECMs)this can sometimes mean something

works, but not the way it's supposed to.

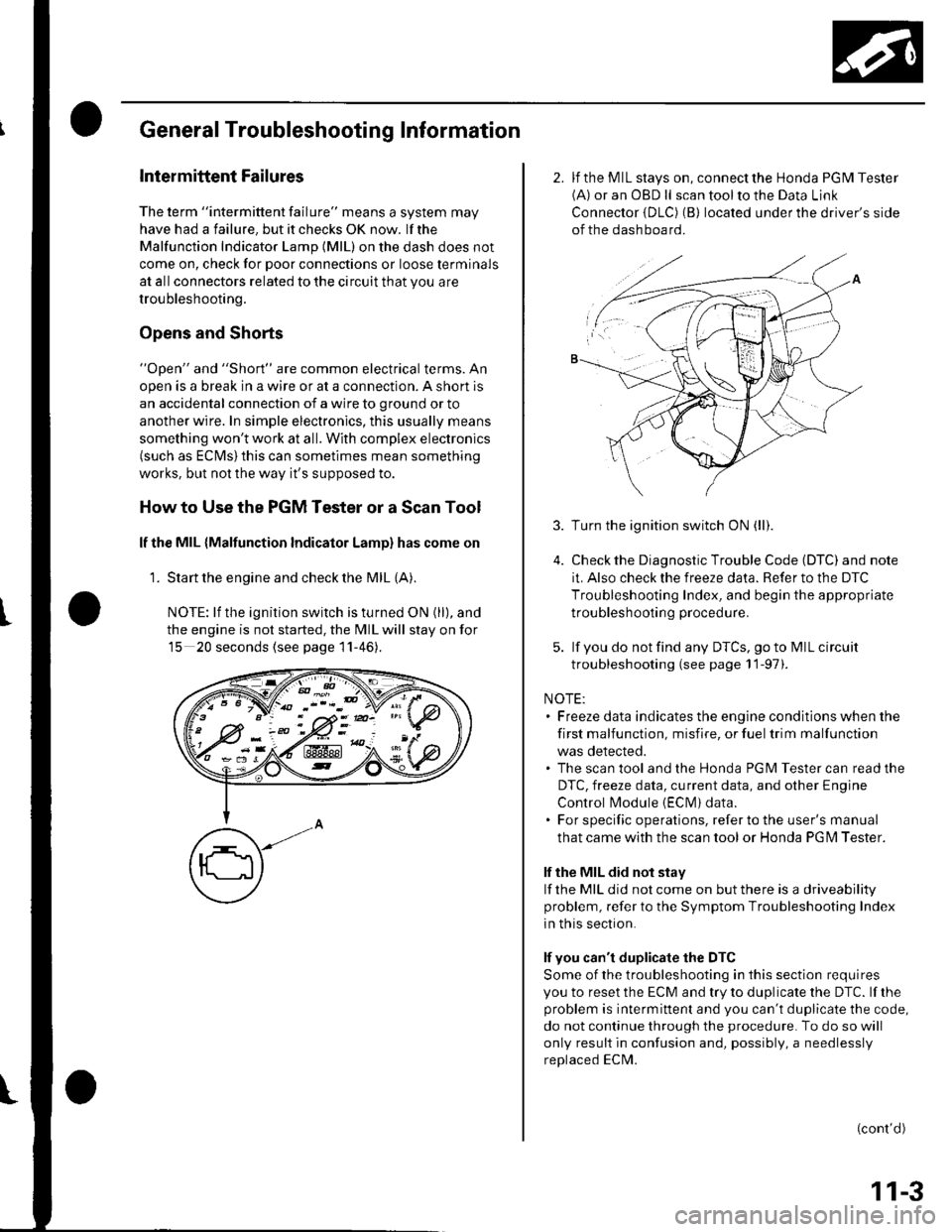

How to Use the PGM Tester or a Scan Tool

lf the MIL {Malfunction Indicator Lamp} has come on

'1. Start the engine and check the MIL {A).

NOTE: lf the ignition switch is turned ON (ll), and

the engine is not started, the MIL will stay on for

15 20 seconds (see page 11-46).

K-> ;"PN/.- -::: - -d V-: !

w:ix&K#

2. lf the MIL stays on, connect the Honda PGM Tester(A) or an OBD ll scan tool to the Data Link

Connector {DLC) (B) located under the driver's side

of the dashboard.

3.

5.

Turn the ignition switch ON (ll).

Check the Diagnostic Trouble Code (DTC) and note

it. Also check the freeze data. Refer to the DTC

Troubleshooting Index, and begin the appropriate

troubleshooting procedure.

lf you do not find any DTCS, go to MIL circuit

troubleshooting (see page 11-97).

NOTE:. Freeze data indicates the engine conditions when the

first malfunction, misfire, or fuel trim malfunction

was detected.. The scan tool and the Honda PGM Tester can read the

DTC, freeze data, current data, and other Engine

Control l\4odule {EClvl) data.. For specific operations, refer to the user's manual

that came with the scan tool or Honda PG l\4 Tester.

lf the MIL did not stay

lf the MIL did not come on but there is a driveability

problem, refer to the Symptom Troubleshooting Index

in this section.

lf you can't duplicate the DTC

Some of the troubleshooting in this section requires

you to reset the ECM and try to duplicate the DTC. lf rhe

problem is intermittent and you can't duplicate the code,

do not continue through the procedure. To do so will

only result in confusion and, possibly, a needlessly

replaced ECM.

(cont'd)

11-3