EVAP canister HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 373 of 1139

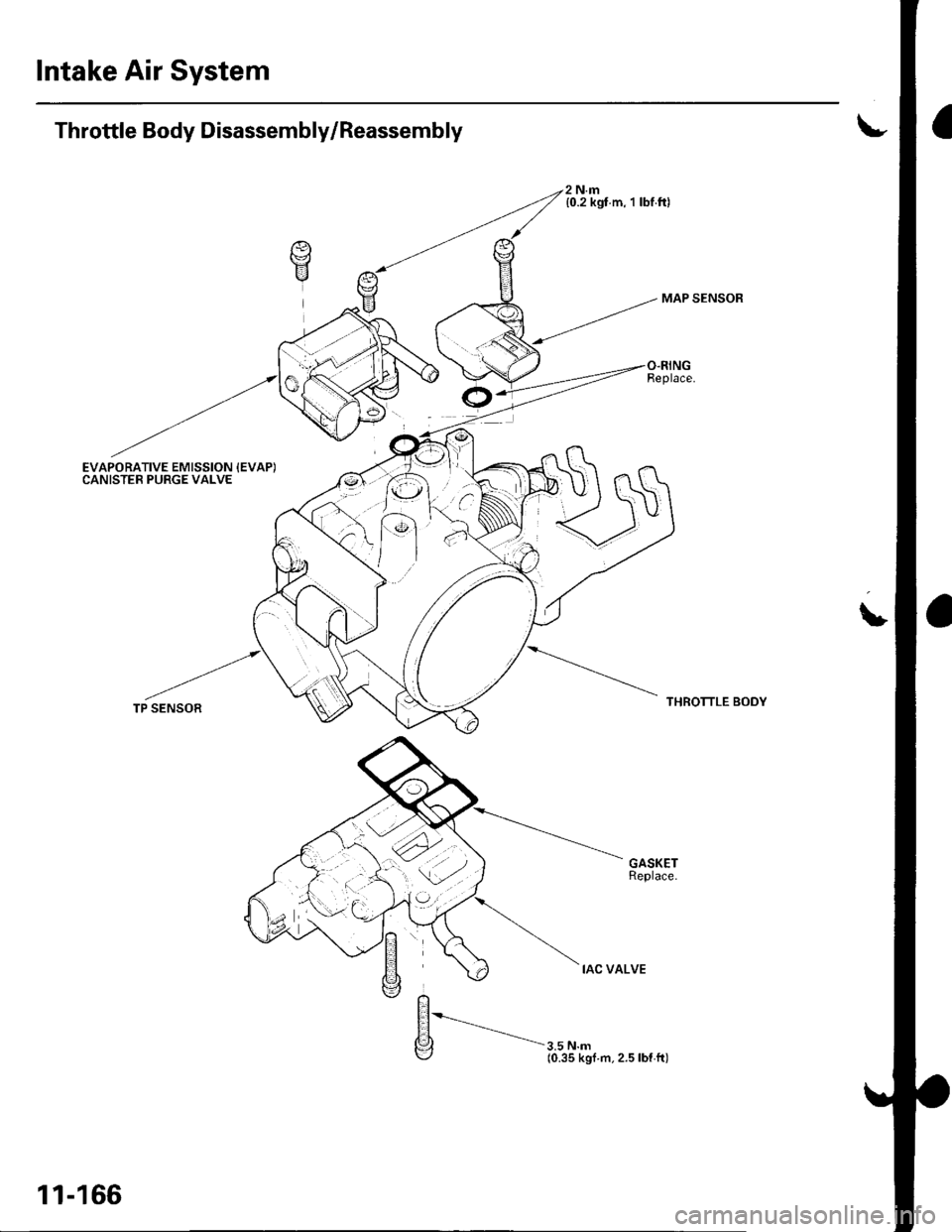

Intake Air System

Throttle Body Disassembly/Reassembly

EVAPORATIVE EMISSION {EVAP)CANISTER PURGE VALVE

A

V

2 N.m{0.2 kgt m, 1 lbf.ft)

3.5 N.m(0.35 kgf m.2.5lbf ft)

MAP SENSOR

THROTTLE BODY

L

TP SENSOR

11-166

Page 375 of 1139

PCV System

DTC Troubleshooting

DTC P1505: PCV Air Leakage

1. Reset the ECM (see page 11-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on

3. Let the engine idle tor al least 40 seconds with the

throttle fully closed.

4. Check for a DTC P1505 with the scan tool

ls DTC P1505 indicated?

YES-Check these parts for vacuum leaks l

. PCV valve. PCV hose. EVAP canister purge valve

. Throttle body. Brake booster hose

NO - Intermittent failure, system is OK at this

time.l

11-168

Page 377 of 1139

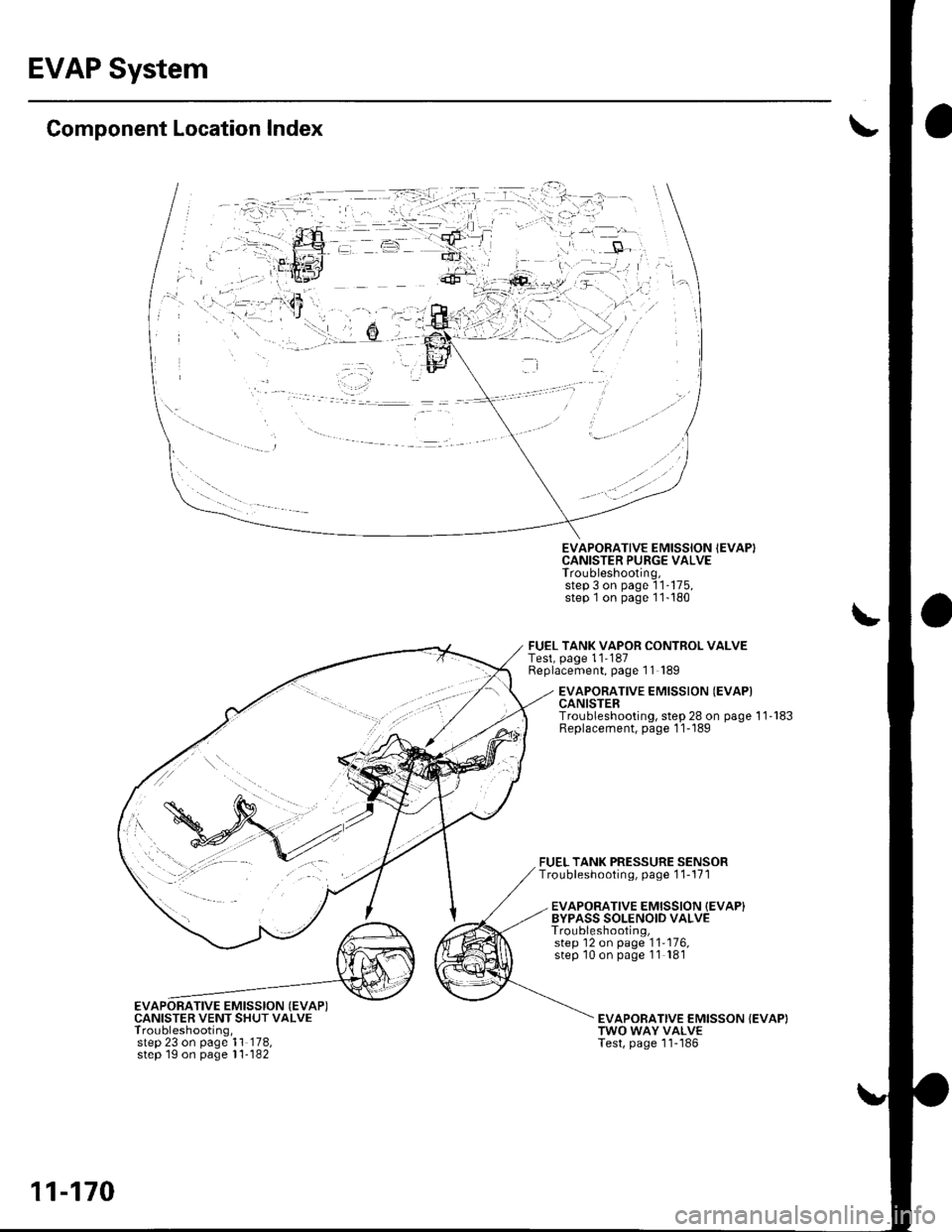

EVAP System

Component Location Index

EVAPORATIVE EMISSION {EVAP)CANISTER VENT SHUT VALVETroubleshooting,step 23 on page 1'l 178,step 1g on page l1- 182

EVAPORATIVE EMISSION IEVAPICANISTER PURGE VALVETroubleshooting,step 3 on page 'l1-175,

step 1on page 11-180

FUEL TANK VAPOR CONTROL VALVETest, page 11'187Replacement, page 11 189

FUEL TANK PRESSURE SENSORTroubleshooting, page 1 1-171

EVAPORATIVE EMISSION {EVAPICANISTERTroubleshooting, step 28 on page 11'183Replacement, page 1 1-189

EVAPORATIVE EMISSION {EVAP}BYPASS SOLENOID VALVETroubleshooting,step 12 on page '11'176,

step '10 on page 11 181

EVAPOBATIVE EMISSON {EVAP)TWO WAY VALVETest, page 'l1-'186

11-170

Page 382 of 1139

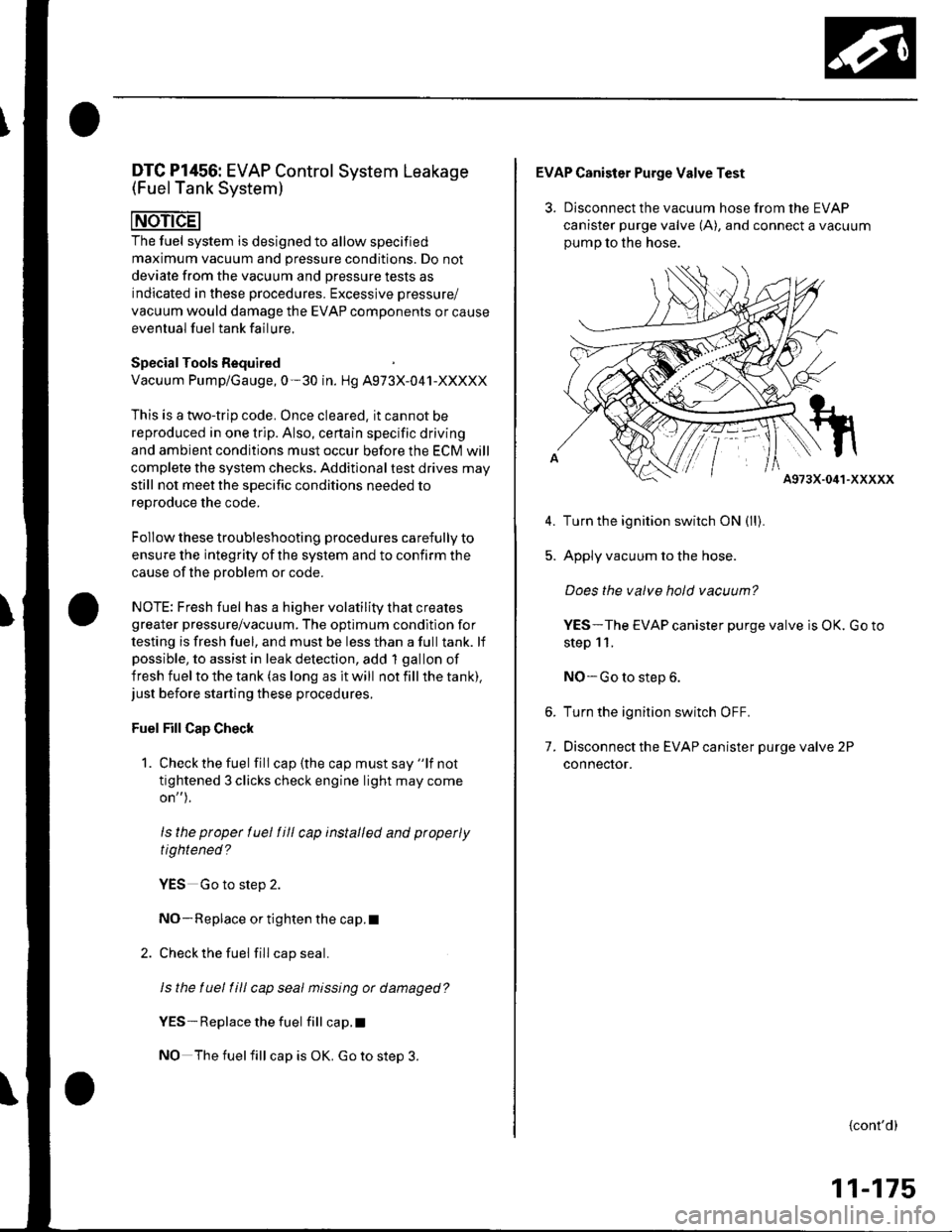

DTC Pl456: EVAP Control(Fuel Tank Svstem)

System Leakage

The fuel system is designed to allow specified

maximum vacuum and pressure conditions. Do not

deviate from the vacuum and pressure tests as

indicated in these procedures. Excessive pressure/

vacuum would damage the EVAP components or cause

eventual fuel tank failure.

Special Tools Required

Vacuum Pump/Gauge, 0-30 in. Hg A973X-041-XXXXX

This is a two-trip code. Once cleared, it cannot be

reproduced in one trip. Also, cenain specific driving

and ambient conditions must occur before the ECM will

complete the system checks. Additional test drives may

still not meet the specific conditions needed to

reproduce the code.

Follow these troubleshooting procedures carefully to

ensure the integrity of the system and to confirm the

cause of the problem or code.

NOTE: Fresh fuel has a higher volatility that createsgreater pressure/vacuum. The optimum condltlon for

testing is fresh fuel, and must be less than a full tank. lf

possible, to assist in leak detection, add 1 gallon of

fresh fuel to the tank (as long as it will not fill the tank).just before starting these procedures.

Fuel Fill Cap Check

1. Check the fuel fill cap (the cap must say "lf not

tightened 3 clicks check engine light may come

on" ).

ls the proper luel till cap installed and properly

tightened?

YES Go to step 2.

NO- Replace or tighten the cap.I

2. Check the fuel fill cap seal.

ls the tuel fill cap seal missing or damaged?

YES- Replace the fuel fill cap.I

NO The fuelfill cap is OK. Go to step 3.

EVAP Canister Purge Valve Test

3. Disconnect the vacuum hose from the EVAP

canister purge valve (A), and connect a vacuum

oumo to the hose.

A973X-041-XXXXX

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-The EVAP canister purge valve is OK. Go to

step 11.

NO-Go to step 6.

Turn the ignition switch OFF.

Disconnect the EVAP canister purge valve 2P

connecror.

5.

7.

{cont'd)

11-175

Page 383 of 1139

EVAP System

DTC Troubleshooting (cont'd)

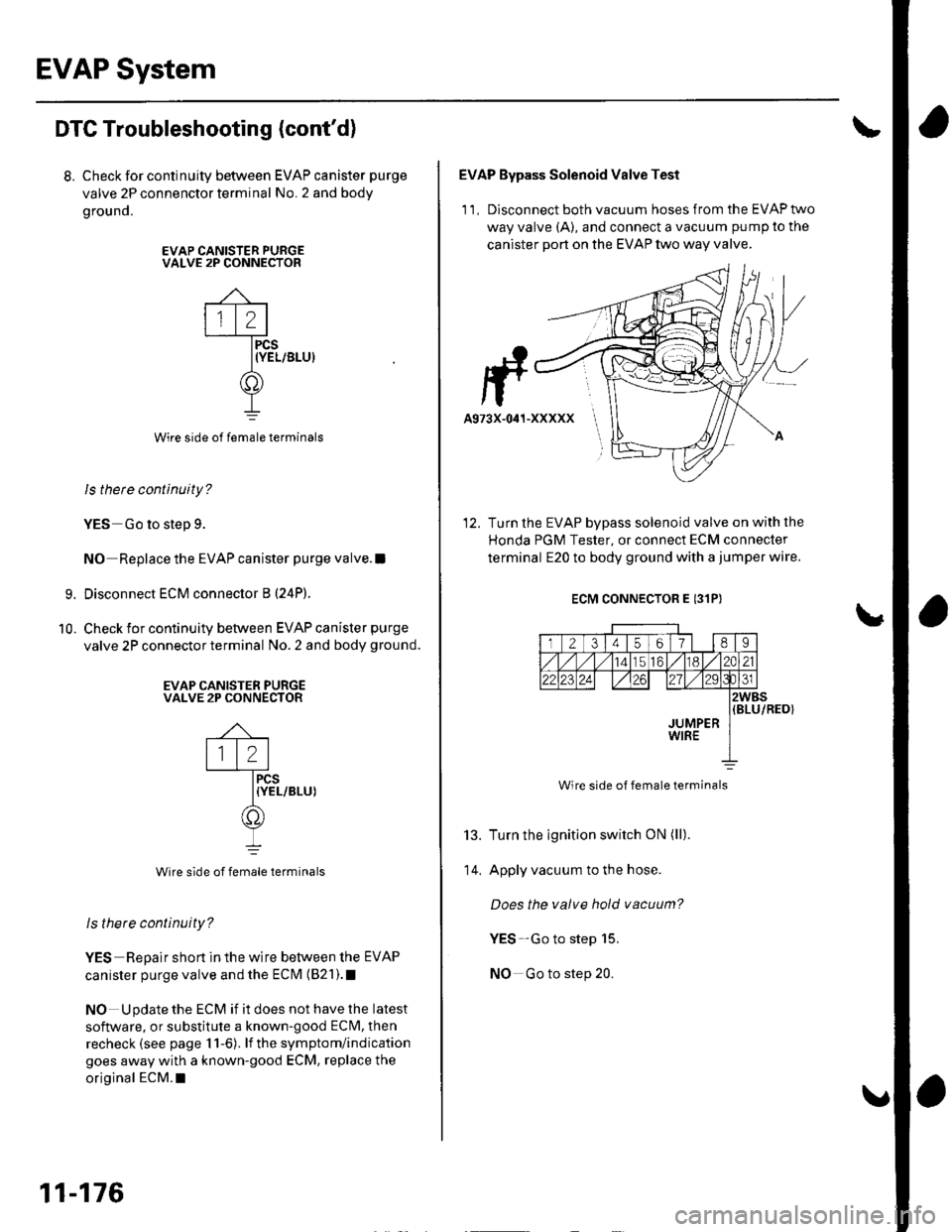

8. Check for continuity between EVAP canister purge

valve 2P connenctor terminal No. 2 and body

grou no.

EVAP CANISTER PURGEVALVE 2P CONNECTOR

Wire side of female terminals

ls there continuity?

YES Go to step 9.

NO Replace the EVAP canister purge valve.l

Disconnect ECM connector B (24P).

Check for continuity between EVAP canister purge

valve 2P connector terminal No. 2 and body ground.

EVAP CANISTER PURGEVALVE 2P CONNECTOR

PCS{YEL/BLU)

Wire side of female terminals

ls there continuity?

YES Repair short in the wire between the EVAP

canister purge valve and the ECI\4 {821).1

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

9.

10.

12

'.\'

11-176

v

F-

A973X-041-XXXXX

EVAP Bypass Solenoid Valve Test

1 1 , Disconnect both vacuum hoses from the EVAP two

way valve (A), and connect a vacuum pump to the

canister port on the EVAP two way valve.

Turn the EVAP bypass solenoid valve on with the

Honda PGM Tester, or connect ECM connecter

terminal E20 to body ground with a jumper wire.

ECM CONNECTOR E 131P)

12345617l 189

456/ 1182C21

22t2?24z7l./29

JUMPERWIRE

2WBS(BLU/RED}

13.

14.

Wire side of female terminals

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-Go to step 15,

NO Go to step 20.

Page 385 of 1139

EVAP System

DTC Troubleshooting (cont'dl

20. Plug the fueltank port (A) oftheEVAPtwoway

valve,

While monitoring FTP sensor voltage with the

Honda PGM Tester, or measuring the voltage

between ECM connector terminals E4 and E 14,

slowly pump the vacuum pump until the voitage

droDS to about 1.5 volts.

ECM CONNECTOR E {31PI

Wire side of female terminals

Does the voltage dtop to 1.5 V and hold fot at

Ieast 20 seconds?

YES-The EVAP bypass solenoid valve/EVAP two

way valve is OK. Go to step 22.

NO Repair the leak from the EVAP bypass

solenoid valve, EVAP two way valve. or

FTP sensor.l

11-178

Wire side of female terminals

EVAP Canister Vent Shut Valve Test

22. Disconnect the vacuum hose from the EVAP

canister vent filter (A), and connect a vacuum pump

to the hose.

Turn the ignitlon switch ON (ll).

Apply vacuum to the hose with five strokes of the

pump.

Does the valve hold vacuum?

YES Go to step 25.

NO The EVAP canister vent shut valve is OK. Go

to step 30.

Turn the ignition switch OFF.

Disconnect the EVAP canister vent shut valve 2P

conneclor.

Check for continuity between EVAP canister vent

shut valve 2P connector terminal No. 2 and body

ground.

EVAP CANISTEB VENT SHUTVALVE 2P CONNECTOR

{LT GRN/REOI

\

25.

26.

21.

Page 386 of 1139

28.

29.

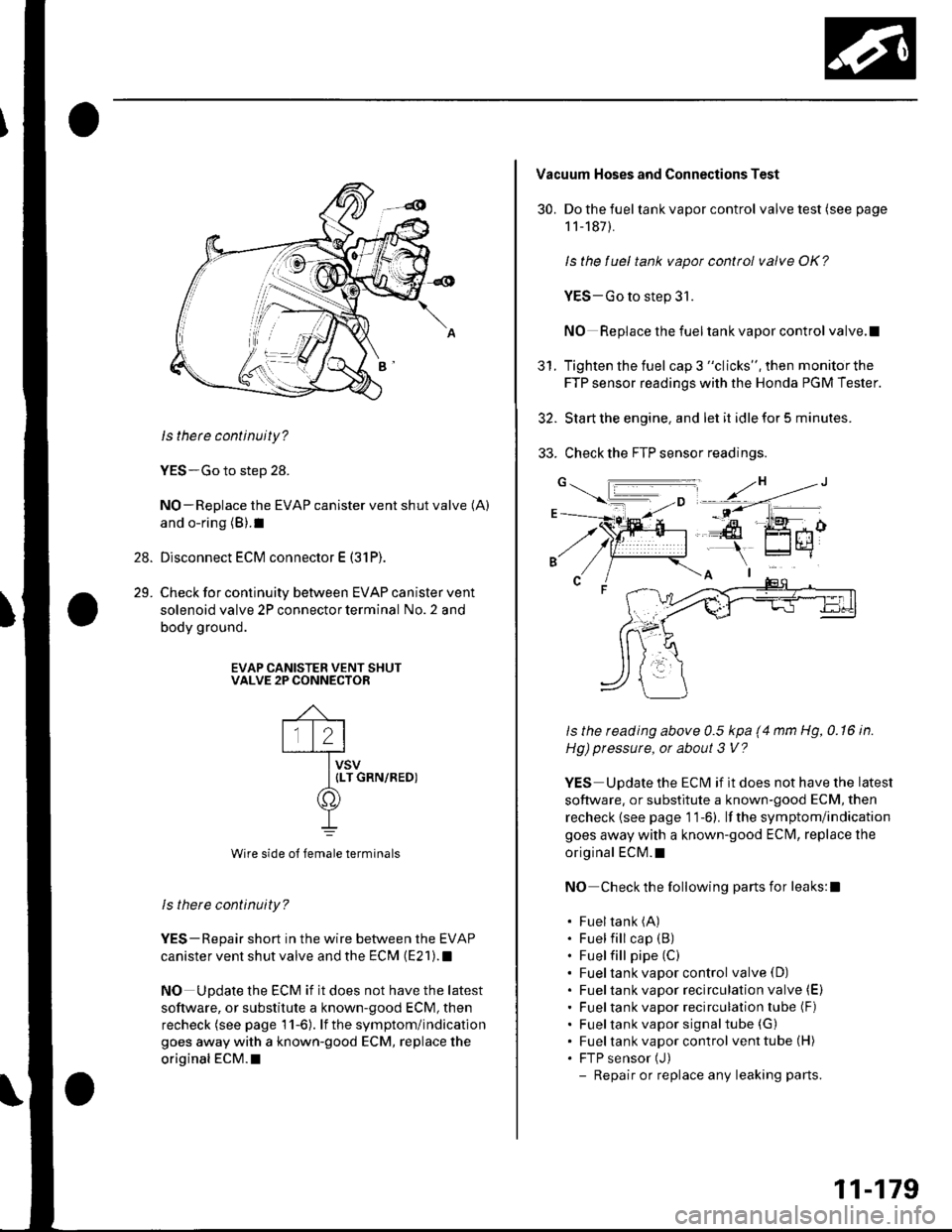

ls thete continuity?

YES-Go to step 28.

NO-Replace the EVAP canister vent shut valve (A)

and o-ring (B).1

Disconnect ECM connector E (31P).

Check for continuity between EVAP canister vent

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP CANISTER VENT SHUTVALVE 2P CONNECTOR

Wire side o{ female terminals

ls there continuity?

YES-Repair short in the wire between the EVAP

canister vent shut valve and the ECM (E21).1

NO Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

30.

Vacuum Hoses and Connections Test

Do the fuel tank vapor control valve test (see page

1 1-187).

ls the fuel tank vapot control valve OK?

YES-Go to step 31.

NO Replace the fueltank vapor control valve.l

Tighten the fuel cap 3 "clicks", then monitorthe

FTP sensor readings with the Honda PGM Tester.

Start the engine. and let it idle for 5 minutes.

Check the FTP sensor readings.

ls the reading above 0.5 kpa (4 mm Hg, 0.16 in.

Hg) pressure, or about 3 V?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck {see page 1 1-6). lf the symptom/indication

goes away with a known-good ECfvl, replace the

original ECM.t

NO Check the following parts for leaks:l

. Fueltank (A)

. Fuel fill cap (B)

. Fuel fill pipe (C)

. Fueltank vapor control valve(D). Fueltank vapor recirculation valve (E)

. Fueltank vapor recirculation tube (F)

. Fueltank vapor signaltube (G)

. Fueltank vapor control venttube(H). FTP sensor (J)

- Repair or replace any leaking parts.

5t.

11-179

Page 387 of 1139

EVAP System

DTC Troubleshooting (cont'd)

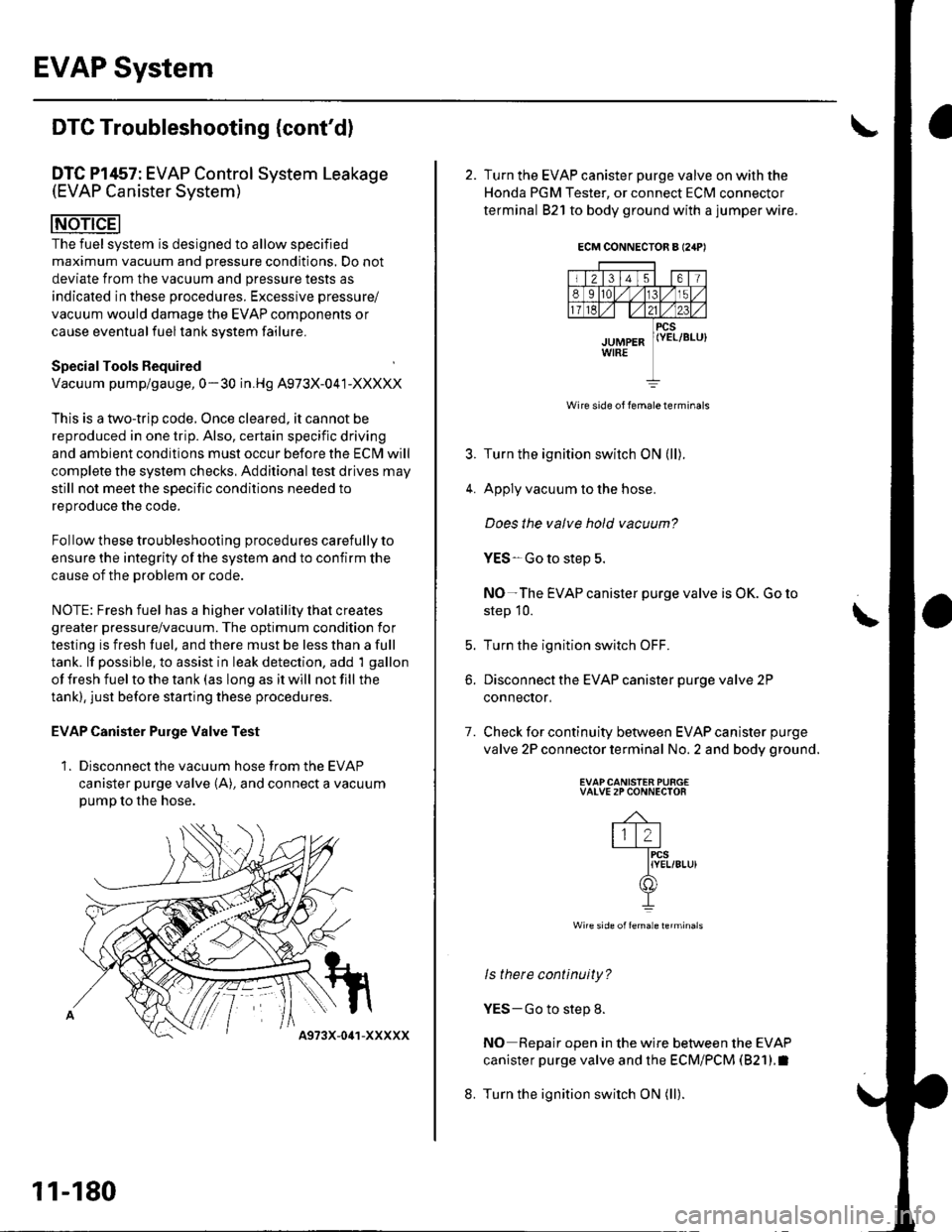

DTC Pl457: EVAP Control System(EVAP Canister System)

Leakage

The fuel system is designed to allow specified

maximum vacuum and pressure conditions. Do not

deviate from the vacuum and pressure tests as

indicated in these procedures. Excessive pressure/

vacuum would damage the EVAP components or

cause eventual fuel tank system failure.

SpecialTools Required

Vacuum pump/gauge, 0-30 in.Hg A973X-041-XXXXX

This is a two-trip code. Once cleared, it cannot be

reproduced in one trip. Also, certain specific driving

and ambient conditions must occur before the ECfM will

complete the system checks, Additional test drives may

still not meet the specific conditions needed to16^r^.1' '^6 rh6 ^^.16

Follow these troubleshooting procedures carefully to

ensure the integrity of the system and to confirm the

cause of the problem or code.

NOTE: Fresh fuel has a higher volatility lhat creates

greater pressure/vacuum. The optimum condition for

testing is fresh fuel, and there must be less than a full

tank. lf possible, to assist in leak detection, add I gallon

of fresh fuel to the tank (as long as it will not fill the

tank), just before starting these procedures.

EVAP Canister Purge Valve Test

1. Disconnect the vacuum hose from the EVAP

canister purge valve (A), and connect a vacuumpump to the hose.

11-180

4973X-041-XXXXX

ECM CONNECTOR A I24P'

Wire side of lemale terminals

4.

7.

2. Turn the EVAP canister purge valve on with the

Honda PGM Tester, or connect ECM connector

terminal 821 to body ground with a jumper wire.

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-Go to step 5.

NO-The EVAP canister purge valve is OK. Go to

step 10.

Turn the ignition switch OFF.

Disconnect the EVAP canister purge valve 2P

conneclor,

Check for continuity between EVAP canister purge

valve 2P connector terminal No. 2 and body ground.

EVAPCANISTEN PURG€VALVE 2P CONNECTOR

-4-

lll2l-fircs

IYEL/8Lu)(f])

I

Wire side offemale lerminals

ls there continuity?

YES-Go to step 8.

NO Repair open in the wire between the EVAP

canister purge valve and the ECM/PCM (821).I

Turn the ignition switch ON (ll).

t

b.

8.

Page 388 of 1139

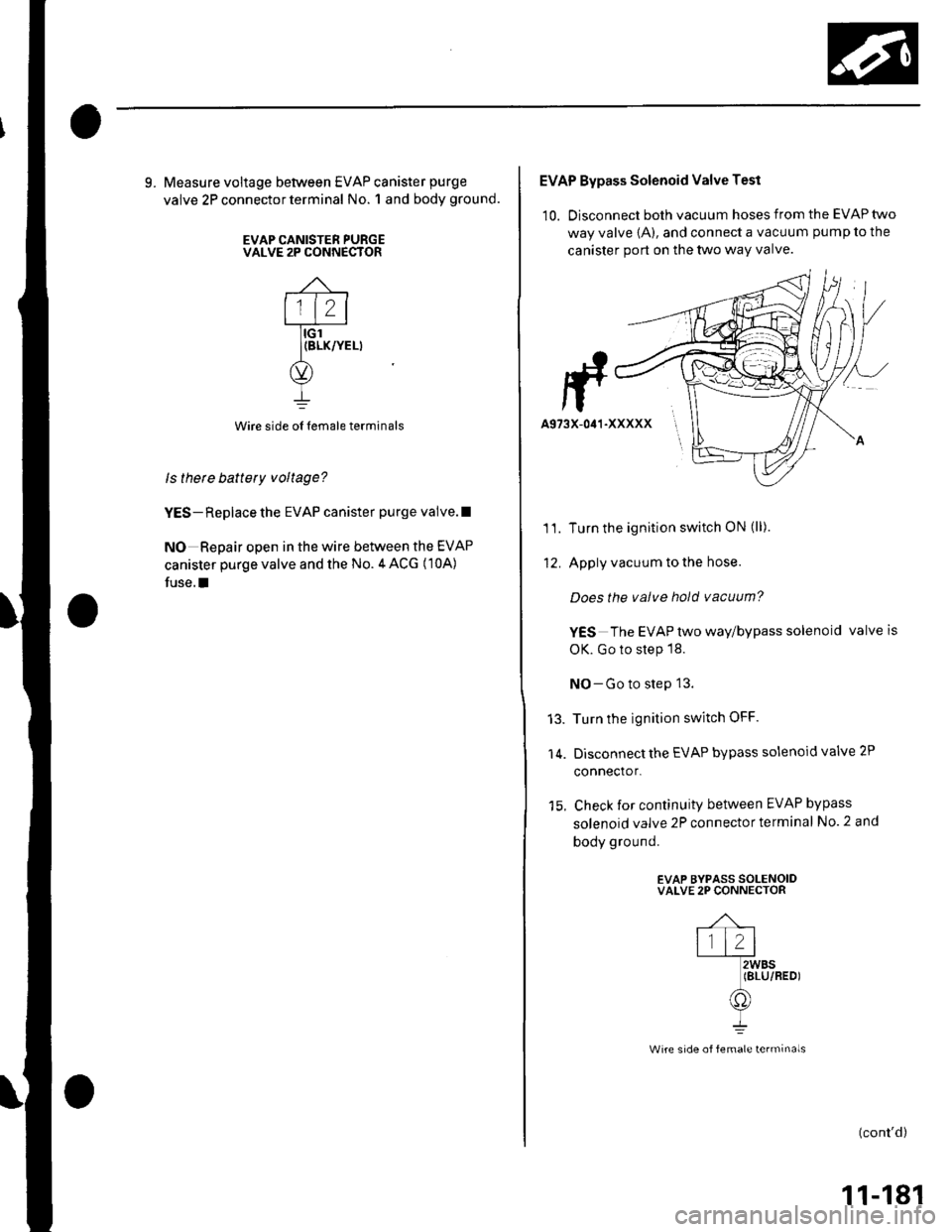

9. Measure voltage between EVAP canister purge

valve 2P connector terminal No. 1 and body ground.

EVAP CANISTER PURGEVALVE 2P CONNECTOR

Wire side oI lemale terminals

ls thete battery voltage?

YES- Replace the EVAP canister purge valve.l

NO Repair open in the wire between the EVAP

canister purge valve and the No.4 ACG (10A)

fuse.I

EVAP Bypass Solenoid Valve Test

10. Disconnect both vacuum hoses from the EVAP two

way valve {A), and connect a vacuum pump to the

canister port on the two way valve.

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES The EVAP two way/bypass solenoid valveis

OK. Go to step 18.

NO-Go to step 13.

Turn the ignition switch OFF.

Disconnect the EVAP bypass solenoid valve 2P

connector.

Check for continuity between EVAP bypass

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

11.

'It

14.

(cont'd)

11-181

Wire side of female terminals

Page 389 of 1139

EVAP System

to.

't7.

DTC Troubleshooting (cont'd)

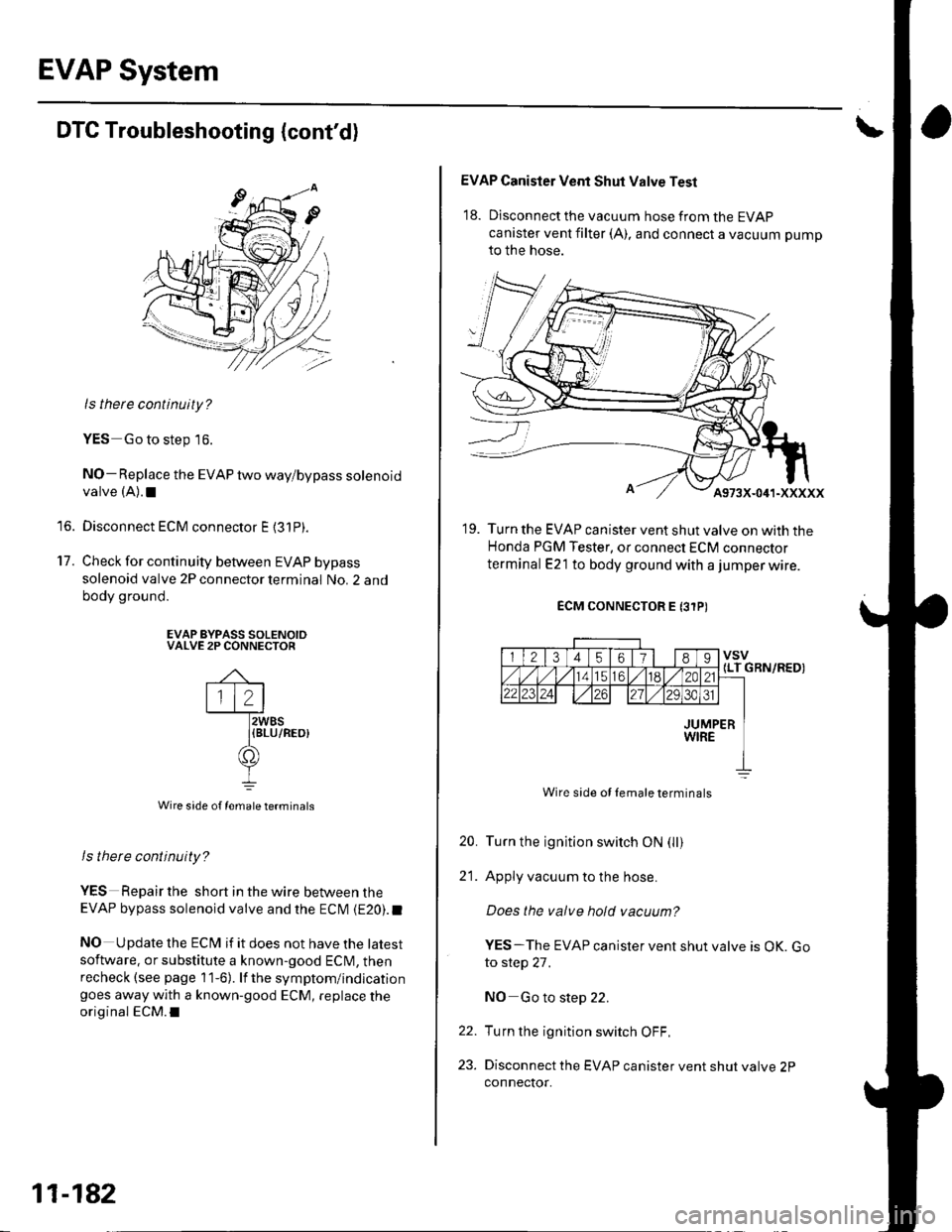

ls there continuity?

YES Go to step 16.

NO- Replace the EVAP two waylbypass solenoidvalve (A).1

Disconnect ECM connector E {31P).

Check for continuity between EVAP bypass

solenoid valve 2P connector terminal No. 2 and

body ground.

ls there continuity?

YES Repair the short in the wire between theEVAP bypass solenoid valve and the ECM {E20). f

NO Update the ECI\4 if it does not have the latest

software. or substitute a known-good EClvl, thenrecheck (see page 11-6). lf the symptom/indlcationgoes away with a known-good ECM, replace theoriginal ECM.I

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

\,

lll2lI t-l2WBS

-[BLU/REo)())

I

Wire side of female terminals

11-182

EVAP Canisler Vent Shut Valve Test

18. Disconnect the vacuum hose from the EVAP

canister vent filter (A), and connect a vacuum pump

to the hose.

19. Turn the EVAP canister vent shut valve on with theHonda PGM Tester, or connect ECM connector

terminal E21 to body ground with a jumper wire.

ECM CONNECTOR E (3TP)

112134589vsv{LT (1/15tal/la2A21

z3lz4zil./m31

JUMPERWIRE

Wire side ol lemale terminals

Turn the ignition switch ON (ll)

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-The EVAP canister vent shut valve is OK. Goto step 27.

NO Go to step 22.

Turn the ignition switch OFF.

Disconnect the EVAP canister vent shut valve 2Pconnector.

GBN/RED)

20.

21.

22.

23.