engine coolant HONDA CIVIC 2002 7.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 256 of 1139

![HONDA CIVIC 2002 7.G Owners Guide PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting, HONDA CIVIC 2002 7.G Owners Guide PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,](/img/13/5744/w960_5744-255.png)

PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,page 1'l -92

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting,page 'l'l-55

Replacement, page 11-'l 15

f- \

rl

KNOCK SENSORTroubleshooting, page 1 1-77Beplacement, page 11 115

ENGINE COOLANT TEMPERATURE(ECTI SENSORTroubleshooting, page 1 1-57Replacement, page 11 114

MANIFOLD ABSOLUTE PRESSURE(MAP) SENSORTroubleshooting, page 1 1-52

THROTTLE POSITIONITP} SENSORTroubleshooting, page 11-60CRANKSHAFT POSITIONICKPISENSORTroubleshooting, page'l 1-78Beplacement, page 1 1-'l 16

AIR FUEL RATIO {A/F)SENSOR ISENSOR 1}Trorrbleshooting, page 1 1-84Replacement, page 11- 1 13

{cont'd)

ii'- r'1

.I11 ---:,I''.!,i(..,.?:fir-J-

.....,..:--.

11-49

Page 271 of 1139

PGM-FI System

aDTG Troubleshootang (cont'dl

DTC P0128: Cooling System Malfunction

NOTE; lf the DTCS listed below are stored at the same

time as DTC P0128. troubleshoot those DTCS first, thenrecheck for P0128.

P0107, P0108, P1128, P1129: N4anifold absolutepressure (MAP) sensor

P] I06, P1 107, P1 108: Barometric pressure (BARO)

sensor

P1259: VTEC system

P01 16, P01 17, P01 18: Engine coolant temperature (ECT)

sensor

P01 12, P01 13: Intake air temperature (lAT) sensor

P0500: Vehicle speed sensor {VSS)P0335, P0336: Crankshaft position (CKP) sensor

P0300: Random misfire

P0301, P0302, P0303, P0304: No. 1, No. 2, No.3 or No.4

cylinder misfire

P0505: ldle control system malfunction

P1519: ldle air control (lAC)valve

DTC P0128 can occasionally set when the hood is

opened while the engine is running.

1. Check the engine coolant level

Is the engine coolant level low?

VES Refill the engine coolant. lf necessary, repair

the coolant leakage.l

NO Go to step 2.

2. Turn the ignition switch ON (ll), and make sure the

A,/C is off.

11-64

\

3. Check the radiator fan.

Does the tadiator fan keep running?

YES Checkthe rad iato r fan circuit (see page 10-

14), the radiator fan switch circuit (Short) (see page

10-'16), and the radiator fan switch (see page 10-17).

Also, inspect the ECT and IAT circuits and terminal

connections. lf the circuits, the switch, and the

connections are OK, update the ECI\4 if it does not

have the latest software. or substitute a known-good ECM, then recheck (see page 1 1-6). lf the

symptom/indication goes away with a known-good

ECM, replace the original ECM.I

NO Replace the thermostat (see page 10-8).1

Page 346 of 1139

ECM ldle Learn Procedure

The idle learn procedure must be done so the ECM can

learn the engine idle characteristics.

Do the idle learn procedure whenever you do any of

these actions:. Disconnect the battery.

Replace the ECM or disconnect its connector.

Reset the ECM.

NOTE: Erasing DTCS with the Honda PGM Tester

does not require you to do the idle learn procedure.

Remove the No.6 ECU {ECM) ( 15A) fuse from the

under-hood fuse/relay box.

Remove the No.19 baftery (80A) fuse from the under-

hood fuse/relay box.

Remove PGM-FI main relay 1.

Remove any of the wires from the under-hood fuse/

retay Dox.

Disconnect any of the connectors from the under

hood fuse/relay box.

Disconnect the connector between the engine

compartment wire harness and ECM wire harness.

Disconnect the G2 terminal from the transmission

ho u srng.

Disconnectthe G'l terminal from the body.

Disconnectthe G101 terminal from the cylinder head

cover.

Procedure:

To complete the idle learn procedure, do this:

1. Make sure all electrical items (Ay'C, audio, rear

defogger, l:ghts, etc.,) are off.

2. Start the engine, and hold it at 3,000 rpm with no

load {in neutral) until the radiator fan comes on, or

until the engine coolanttemperature reaches 194"F(90'c).

3. Let the engine idle for about 5 minutes with the

throttle fully closed.

NOTE: lf the radiator fan comes on, do not include its

running time in the 5 minutes.

11-139

Page 368 of 1139

Intake Air Bypass GontrolThermalValve Test

Special Tools Required

Vacuum Pump/Gauge,0 30 in. Hg A973X-041-XXXXX

1. Stan the engine. Then let it idl€.

NOTE: The engine coolant temperature must be

below 149'F (65'C).

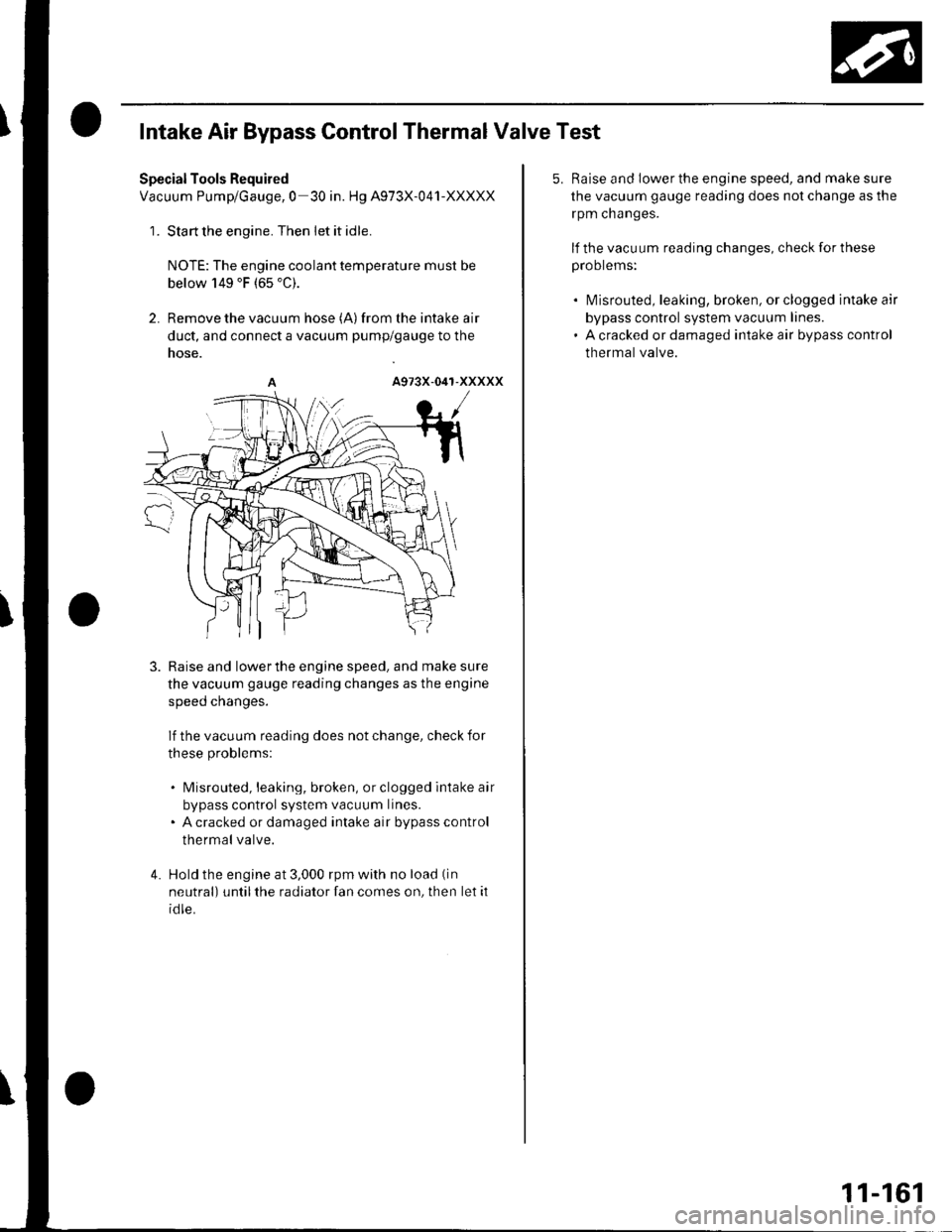

2. Remove the vacuum hose (A)from the intake air

duct, and connect a vacuum pump/gauge to the

nose.

3. Raise and lowerthe engine speed. and make sure

the vacuum gauge reading changes as the engine

speeo cnanges.

lf the vacuum reading does not change, check for

these problems:

. Misrouted, leaking, broken, or clogged intake air

bypass control system vacuum lines.. A cracked or damaged intake air bypass control

thermal valve.

4. Hold the engine at 3,000 rpm with no load (in

neutral) until the radiator fan comes on, then let it

id le.

5. Raise and lower the engine speed, and make sure

the vacuum gauge reading does not change as the

rpm cnanges.

lf the vacuum reading changes, check for these

proorems:

. l\4isrouted, leaking, broken, or clogged intake air

bypass control system vacuum lines.. A cracked or damaged intake air bypass control

thermal valve.

11-161

Page 391 of 1139

EVAP System

DTC Troubleshooting (cont'dl

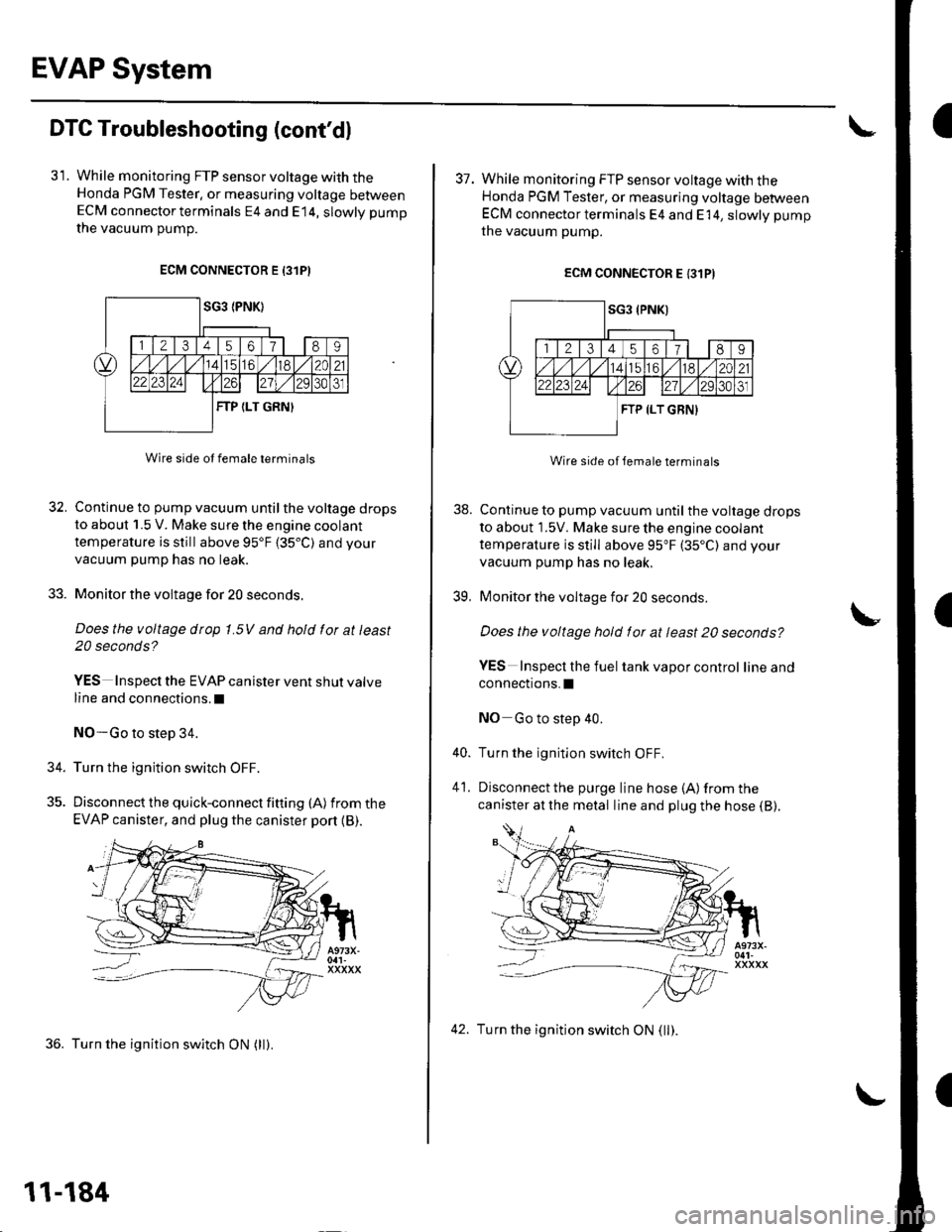

31. While monitoring FTP sensor voltage with theHonda PGM Tester, or measuring voltage betweenECM connector terminals E4 and E14, slowly pump

the vacuum oumD.

ECM CONNECTOR E 13lPI

Wire side ot female terminals

32. Continue to pump vacuum until the voltage drops

to about 1.5 V. Make sure the engine coolant

temperature is still above 95'F 135.C) and your

vacuum pump has no leak.

33. Monitor the voltage for 20 seconds.

Does the voltage drop 1.5V and hold for at least

20 seconds?

YES Inspect the EVAP canister vent shut valve

line and connections.l

NO-Go to step 34.

34. Turn the ignition switch OFF.

35. Discon nect the quick-con nect fitting (A) fromthe

EVAP canister, and plug the canister port {B).

36. Turn the ignition switch ON (ll).

11-184

42. Turn the ignition switch ON (ll).

I

38.

39.

37. While monitoring FTP sensor voltage with theHonda PGM Tester, or measuring voltage betweenECM connector terminals E4 and E 14, slowly pump

the vacuum pump.

ECM CONNECTOR E {31PI

Wire side of lemale terminals

Continue to pump vacuum until the voltage drops

to about 1.5V. Make sure the engine coolant

temperature is still above 95"F (35"C) and your

vacuum pump has no leak.

Monitor the voltage for 20 seconds

Does the voltage hold for at least 20 seconds?

YES Inspecl the fuel tank vapor control lineand

connections.I

NO Go to step 40.

Turn the ignition switch OFF.

Disconnect the purge line hose {A) from the

canister at the metal line and plug the hose (B).

40.

41.

Page 392 of 1139

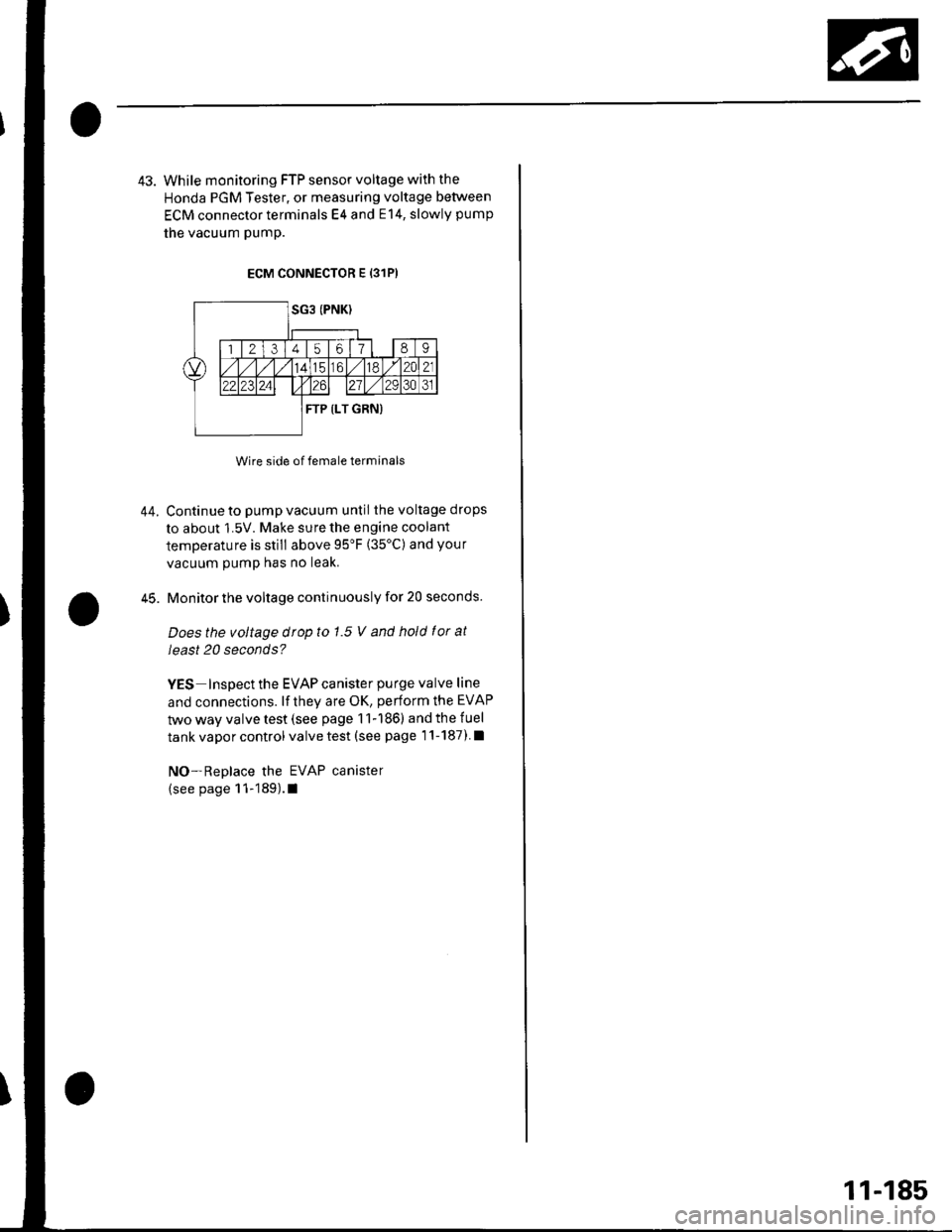

43. While monitoring FTP sensor voltage with the

Honda PGM Tester, or measuring voltage between

ECM connector terminals E4 and E14, slowly pump

the vacuum pump.

ECM CONNECTOR E {31P)

Wire side of female terminals

Continue to pump vacuum until the voltage drops

to about 1.5V. Make sure the engine coolant

temperature is still above 95'F (35'C) and your

vacuum pump has no leak.

Monitor the voltage continuously for 20 seconds.

Does the voltage drop to 1.5 V and hold f or at

least 20 seconds?

YES Inspect the EVAP canister purge valve line

and connections. lf they are OK, perform the EVAP

two way valve test (see page 11-186) and the fuel

tank vapor control valve test (see page 1'l-187) l

NO-Replace the EVAP canister

(see page 11-189).1

44.

45.

11-185

Page 801 of 1139

Heating and Air Conditioning

Radiator and Condenser Fans

Common

(cont'dl

Circuit Troubleshooting

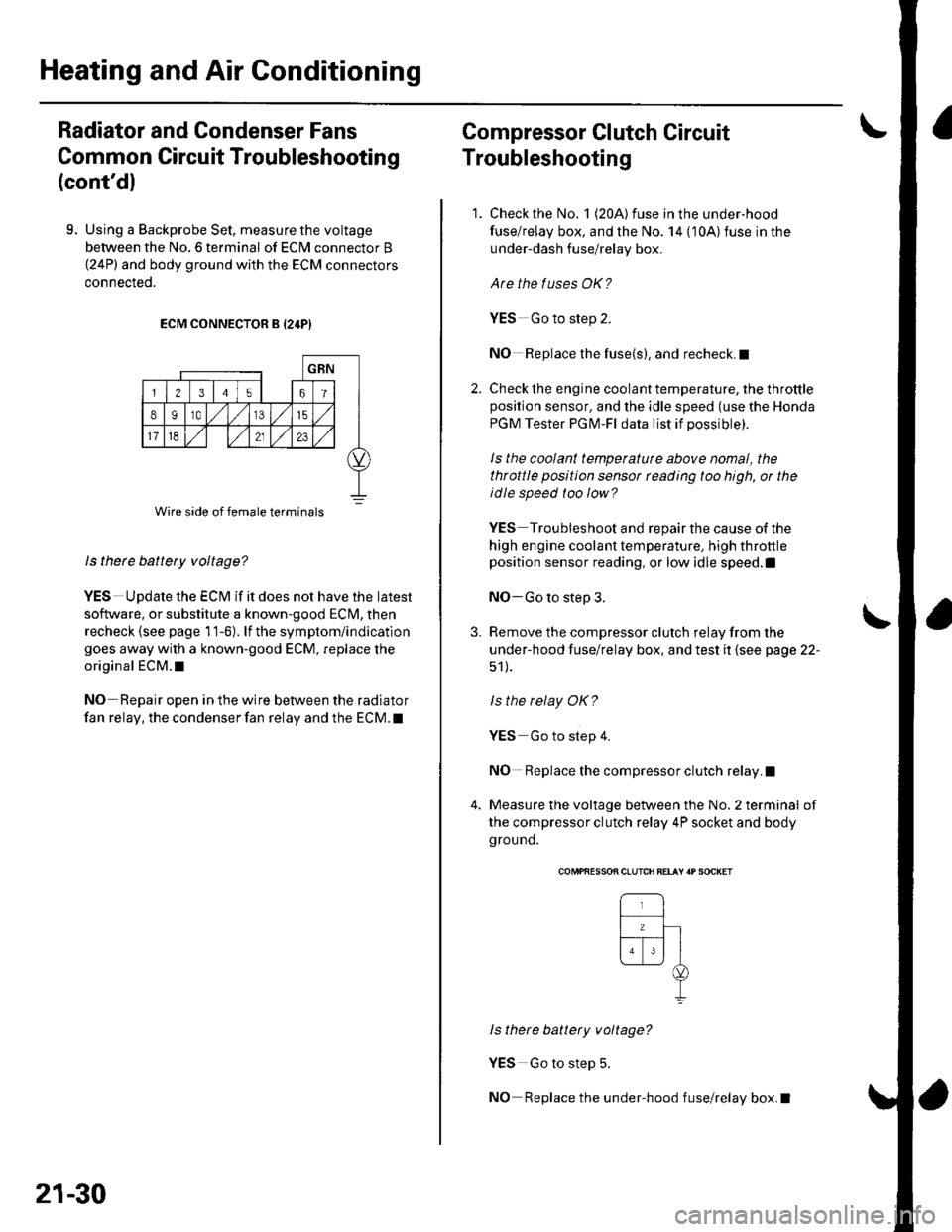

9. Using a Backprobe Set, measure the voltage

between the No. 6 terminal of ECN4 connector B

{24P) and body ground with the ECM connectors

connecteo.

ECM CONNECTOR B {24P}

ls there battery voltage?

YES UDdate the ECM if it does not have the latest

so{tware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Repair open in the wire between the radiator

fan relay, the condenser fan relay and the ECM. t

Wire side of female terminals

21-30

Compressor Clutch Circuit

Troubleshooting

1. Check the No. 1 (20A) fuse in the under-hood

fuse/relay box, and the No. 14 {10A)fuse in the

under-dash fuse/relay box.

Are the tuses OK?

YES Go to step 2.

NO Replace the fuse(s), and recheck.I

2. Check the engine coolant temperature, the throttleposition sensor, and the idle speed (use the Honda

PGM Tester PGM-Fl data list if possible).

ls the coolant temperaturc above nomal, the

throttle position sensor rcading too high, or the

idle speed too low?

YES Troubleshoot and repair the cause of the

high engine coolant temperature, high throttle

position sensor reading, or low idle speed.l

NO-Go to step 3.

3. Remove the compressor clutch relay from the

under-hood fuse/relay box, and test it (see page 22-

51 ).

ls the relay OK?

YES Go to step 4.

NO Replace the compressor clutch relay.I

4. Measure the voltage between the No. 2 terminal of

the compressor clutch relay 4P socket and body

ground.

\

COMPfiESSON CLUTCH BELAY 'P SOCKET

ls there battery voltage?

YES Go to step 5.

NO Replace the under-hood fuse/relay box.I

Page 814 of 1139

Heater Unit/Core Replacement

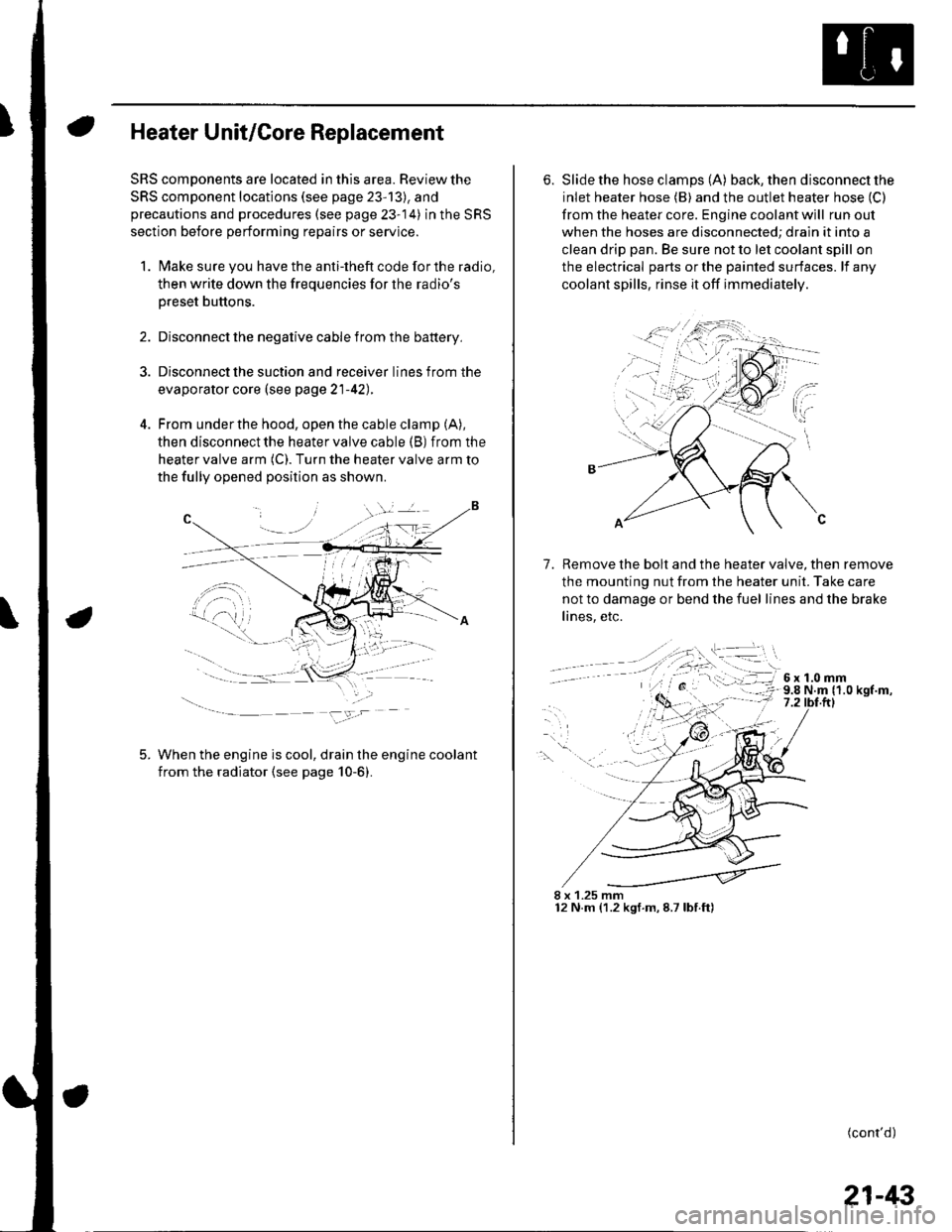

SRS components are located in this area. Review the

SRS component locations (see page 23'13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Make sure you have the anti-theft code forthe radio,

then write down the freouencies for the radio's

Dreset buttons.

4.

Disconnect the negative cable from the battery,

Disconnect the suction and receiver lines from the

evaporator core (see page 21-42).

From under the hood, open the cable clamp (A),

then disconnect the heater valve cable (B) from the

heater valve arm (C). Turn the heater valve arm to

the fully opened position as shown

When the engine is cool, drain the engine coolant

from the radiator (see page 10-6).

6. Slide the hose clamps (A) back, the n d isconnect the

inlet heater hose (B) and the outlet heater hose (C)

from the heater core. Engine coolant will run out

when the hoses are disconnected; drain it into a

clean drip pan. Be sure not to let coolant spill on

the electrical parts or the painted surfaces. lf any

coolant spills, rinse it off immediately.

Remove the bolt and the heater valve, then remove

the mounting nut from the heater unit. Take care

not to damage or bend the fuel lines and the brake

lines, etc.

7.

8 x 1.25 mm12 N.m (1.2 kgf.m,8.7lbf.ft)

(cont'd)

21-43

Page 816 of 1139

13. Installthe heater core and the evaporator core in

the reverse order of removal.

14. Installthe heater unit in the reverse order of

removal, and note these items:

. Do not interchange the inlet and outlet heater

hoses, and installthe hose clamps securely.. Refillthe cooling system with engine coolant (see

page 10-6).. Adjust the heater valve cable (see page 2'l-461.. Make sure that there is no coolant leakage.. Make sure that there is no air leakage.. Refer to evaporator core replacement {see step 6

on page 21-42).. Do the engine control module (ECl\4) idle learn

procedure (see page 11-139).. Enter the anti-theft code for the radio, then enter

the customer's radio station Dresets.

21-45

Page 847 of 1139

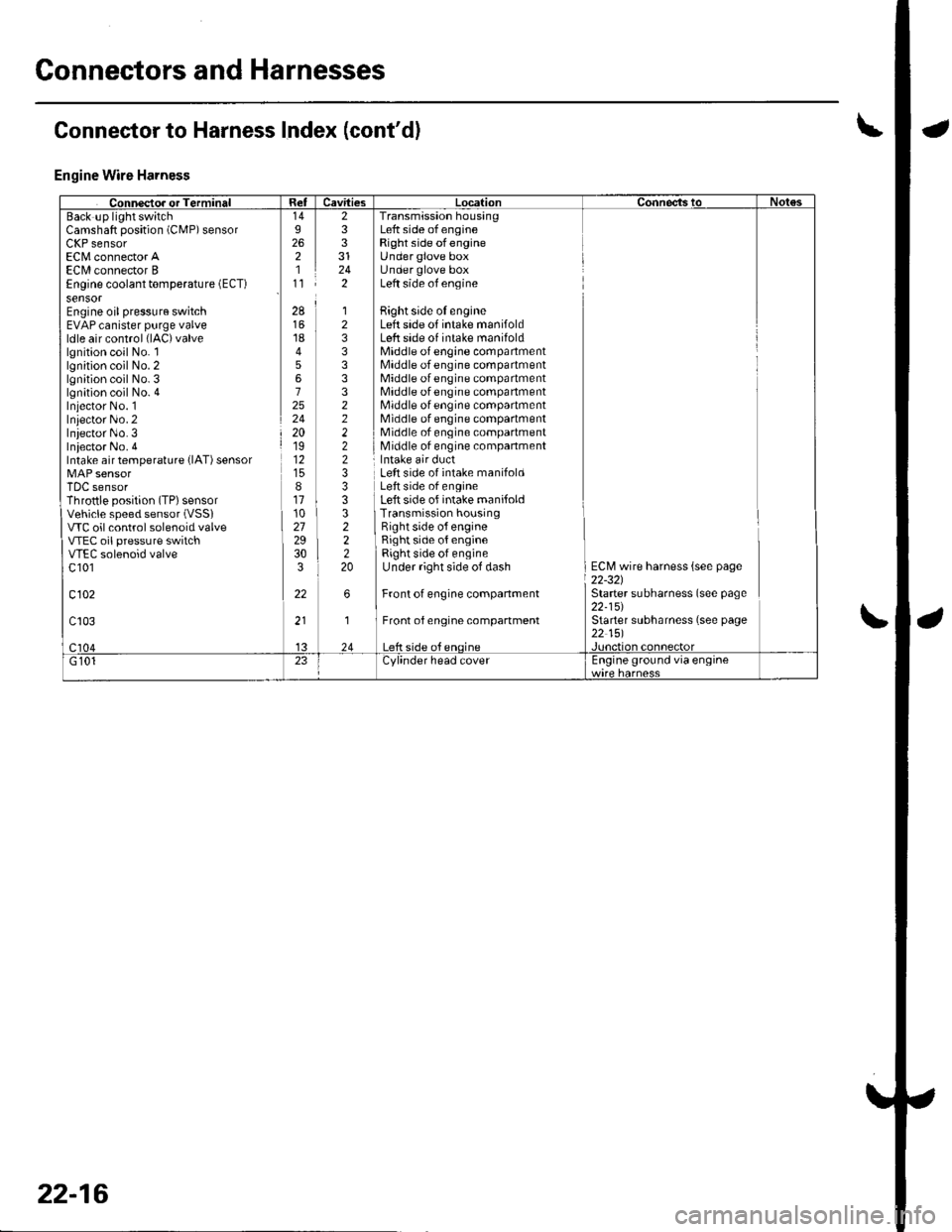

Connectors and Harnesses

Engine Wire Harness

Camshaft position (CMP) sensorLllr sensorEC[,4 connector AECI/l connector BEngine coolant temperature (ECT)

sensorEngine oil pressure switchEVAP canister purge valveldle air control (lAC)valve

lgnition coil No. llgnition coil No. 2lgnition coil No. 3lgnition coil No. 4Iniector No. 1Inlector No.2Iniector No.3Iniector No. 4Intake air temperature {lAT) sensor

TDC sensorThrottle position (TP) sensorVehicle speed sensor (VSSI

VTC oil control solenoid valveVTEC oil pressure switchVTEC solenoid valvec 101

c102

233

242

Transmission housingLeft side of engineRight side ofengineUnder glove boxUnder glove boxLeft side of engine

Bight side oI engineLeft side of intake manifoldLeft side of intake manifoldMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine companment

28

1845672524201912

811102729303

22

12333332222233

322220

Left side of intake manifoldLeft side of engineLeft side of intake manifoldTransmission housingRight side o{ engineRight side of engineRight side of engineUnder right side of dash

Front of engine companment

Front of engine compartment

ECM wire harness {see page22-321Starter subharness (see page22-15)Starter subharness (see page22 151

Connector to Harness Index (cont'dl

22-16