ESP HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 2 of 1139

INTRODUCTION

Safety

Your safety, and the satety of others, is very important. To helpyou make informed decisions, we have provided safetymessages, and other safety information throughout this manual.Of course, it is not practical or possible to warn you about all thehazards associated with servicing this vehicle. You must useyour own good judgment.

You will find impoftant safety information in a variety of formsincluding:. Satety Labels - on the vehicle.. Satetv Messages preceded by a salety alert symbol A andone of three signal words, DANGEF, WARNING, or CAUTION.These signal words mean:

tmEnEEril y;,: H,ll i": 5* i5"?;r s E R I o u s LY H u Br ir

E$EEEE ys,: f#,ff ,:hl:3,:JjERrousLY HURT ir

tlGtltT]llilll You cAN b€ HUBT if vou don't follow

. lnstructions - how to service this vehicle correctlv and safelv.

All information contained in this manual is based on the latestproduct information available at the time of printing. We reservethe right to make changes at any time without notice. No part ofthis Oublication maV be reDrodLrced, or stored in a retrievalsystem, or transmitted, in any form by any means, electronic,mechanical, photocopying, recording, or otherwise, without theprior written permission o{ the publisher. This includes text,figures, and tables-

As vou read this manual, vou will tind information that ispreceded by a @ symbol. The purpose of this message isto help prevent damage to your vehicle, other property, or theenvironment,

*Bodyz-tl!^t l

First Edition 8/2002 1,168 pages HONDA MOTOR CO.. LTD.All Rights Reserved Service Publication OfficeSpecifications apply to U.S.A. and Canada

As seclion3 with *inclode SRS comoonentsispecial precautionsare required when servicing.

How to Use This Manual -

This manual is divided into 23 sections. The first page of eachseclion is marked with a black tab that lines up with itscorresponding thumb index tab on this page and the back cover.You can quickly find the first page of each section withoutlooking through a full table of contents. The symbols printed atthe top corner of each page can also be used as a quickre{erence system.

Each section includes:1. A table of contents, or an exploded view index showingl. Parts disassembly sequence.. Bolt torques and thread sizes.. Page references to descriptions in text.Disassembly/assembly procedures and tools.Inspefiron.Testing/troubleshootin g.Repair.Adjustments.

2.3.4.5.6.

Specifications1)ll:{l+'

Maintenance

Emissions

*Restraints

Page 22 of 1139

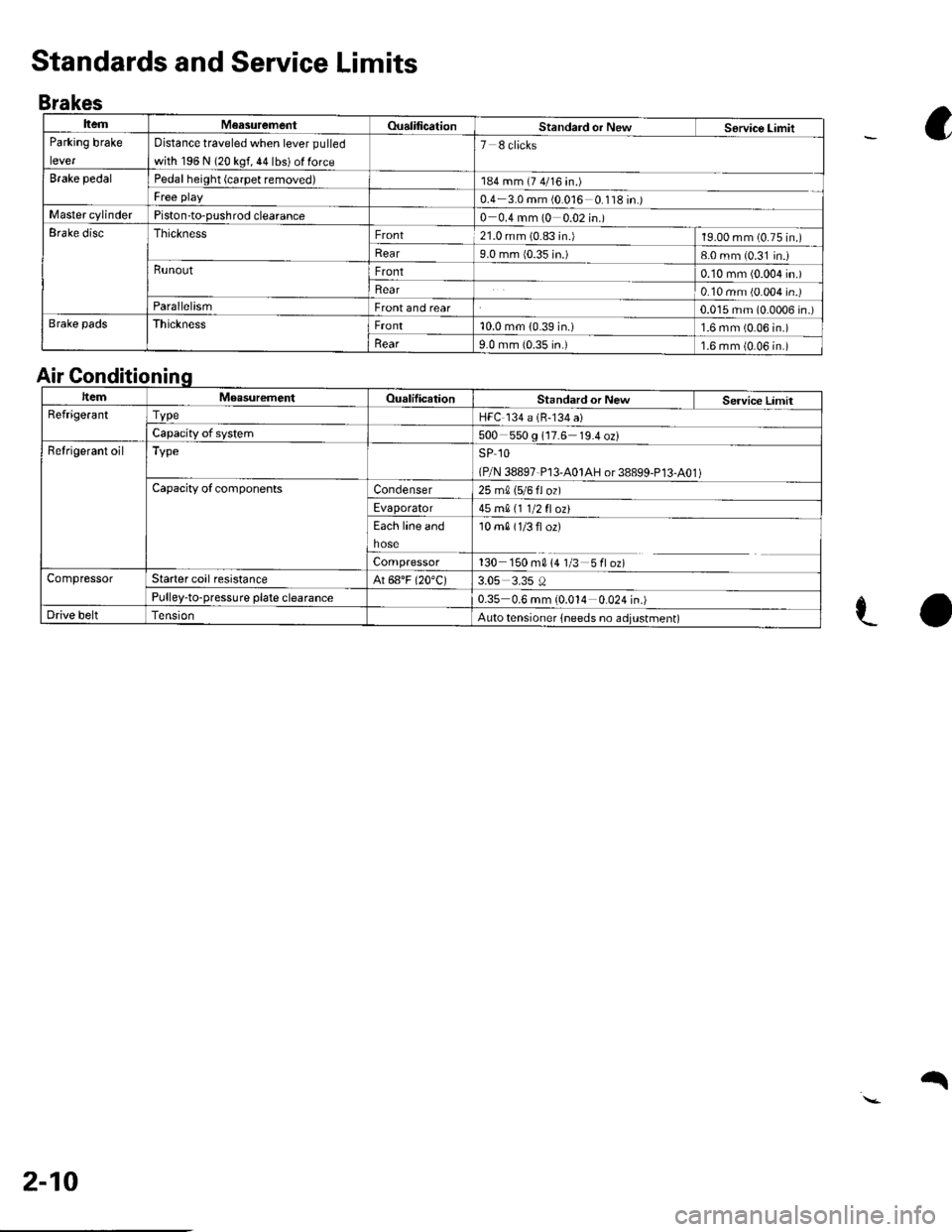

ItemM€asurementOualificationStandard or NewService LimitParking brake

lever

Distance traveled when lever pulled

with 196 N (20 kgf, 44 lbs) ol force

7 8 clicks

Brake pedalPedal height (carpet removed)184 mm (7 4/16 in.)

Free play0.4 3.0 mm (0 016 0 '118 in.)Master cylinderPiston-to-pushrod clearance0 0.4 mm (0 0.02 in.)Erake discThicknessFront21.0 mm (0.83 in.)19.00 mm (0.75 in.)

Rear9.0 mm {0.35 in.)8-0 mm (0.31 in.iRunoutFront0.10 mm (0.004 in.)

Rear0.10 mm (0.004 in.)ParallelismFront and rear0.015 mm (0.0006 in.)Brake padsThicknessFront10.0 mm (0.39 in.)1.6 mm (0.06 in.)

llear9.0 mm {0.35 in.)1.6 mm (0.06 in.)

Standards and Service Limits

Brakes

a

e-o

Air Gonditionin

ItemMoasurementOualilicationStandard or New Service LimitRefrige.antTvpeHFC 134 a (B-134 a)

Capacity of system500 550 g 117.6 19.4 oz)Refrigerant oilTypeSP 1O

(P/N 38897-P13-A01AH or 38899-P13-A01 )Capacity ofcomponentsCondenser25 m0, 15/6 fl ozl

Evaporator45 mA 11 1/2 fl ozt

Each line and

hose

10 m0 (1/3 fl or)

Compressor130 150 m014 1/3 5floz)CompressorStarter coil resistanceAt 68"F (20"C)3.05 3.35 0Pulley-to-pressure plate clearance0.35 0.6 mm (0.014 0.024 in.)Drive beltAuto tensioner lneeds no adjustment)

2-10

q

Page 24 of 1139

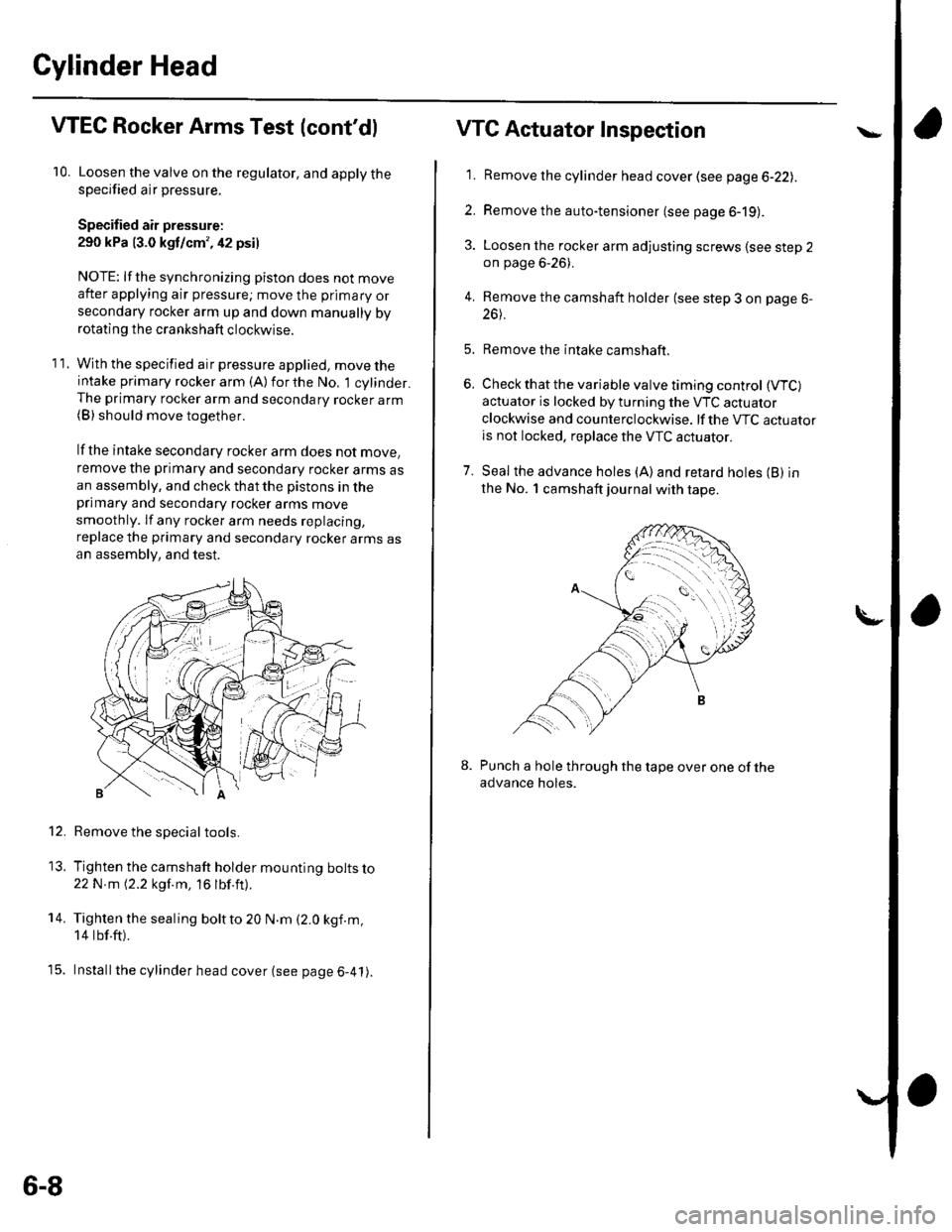

cont'

ItemMeasuremeniOualificationSpecilicationSTEERINGTypeElectric, Power assisted rack and pinion

Overall ratio15.1Turns,lock to-lock

Steering wheel diameter360 mm (14.2 in)SUSPENSIONTypeIndependent srrul with stabiliTer. coil springRearDouble wishboneShock absorberFrontTelescopic, hydraulic. nitrogen gas-frlled

RearTelescopic, hydraulic, nitrogen gas,filledWHEEL

ALIGNMENT

CamberFront0"00'

Bear0.45'�

CasterFront1'33'�TotaltoeFront0 mm (0 in.)

RearIn 2 mm (1/16 in.)BRAKESType of service brakeFrontPowerassisted self-adjusling ventilated disc

BearPower-assisted self-adjusting solid discType of parking brakeMechanical actuating, rear wheelsPad friction surface areaFront45 cm'(7.0 sq in.)x2

Rear28 cm'(4.3 sq in.) x 2TIRESSize offront and reartiresPl95/60 815 88VSize o{ spare tireT125r0 D15 95MAIR

CONDITIONING

CompressorTypeScroll

Number of

cylinders

Capacity85.7 m015.23 cu in.)/rev.

Maximum speed12,000 rpm

Lubricant capacity130 m0 {4 1/3 floz)

LubricanttypeSP-10 (P/N 38897'P13-A01AH or38899-P13 A01)CondenserTypeCorrugated finEvaporatorTvpeCorrugated fin

BlowerTypeSirocco fan

Motor type220 Wl12 V

Speed control4 Speeo

Maximum capacity480 m" 116.900 cu ft)/hTemperature controlAirmixtype

Compressor clutchTvpeDry, single plate, poly-V belt drive

Electricalpower

cons!mptron at

68"F (20.C)

42 W maximum at 12 V

RefrigerantTypeHFC 134a (R-134a)

Capacity500 550 g (17.6 19.4 oz)

Design Specifications

C

aL

2-12

../ a

Page 103 of 1139

Cylinder Head

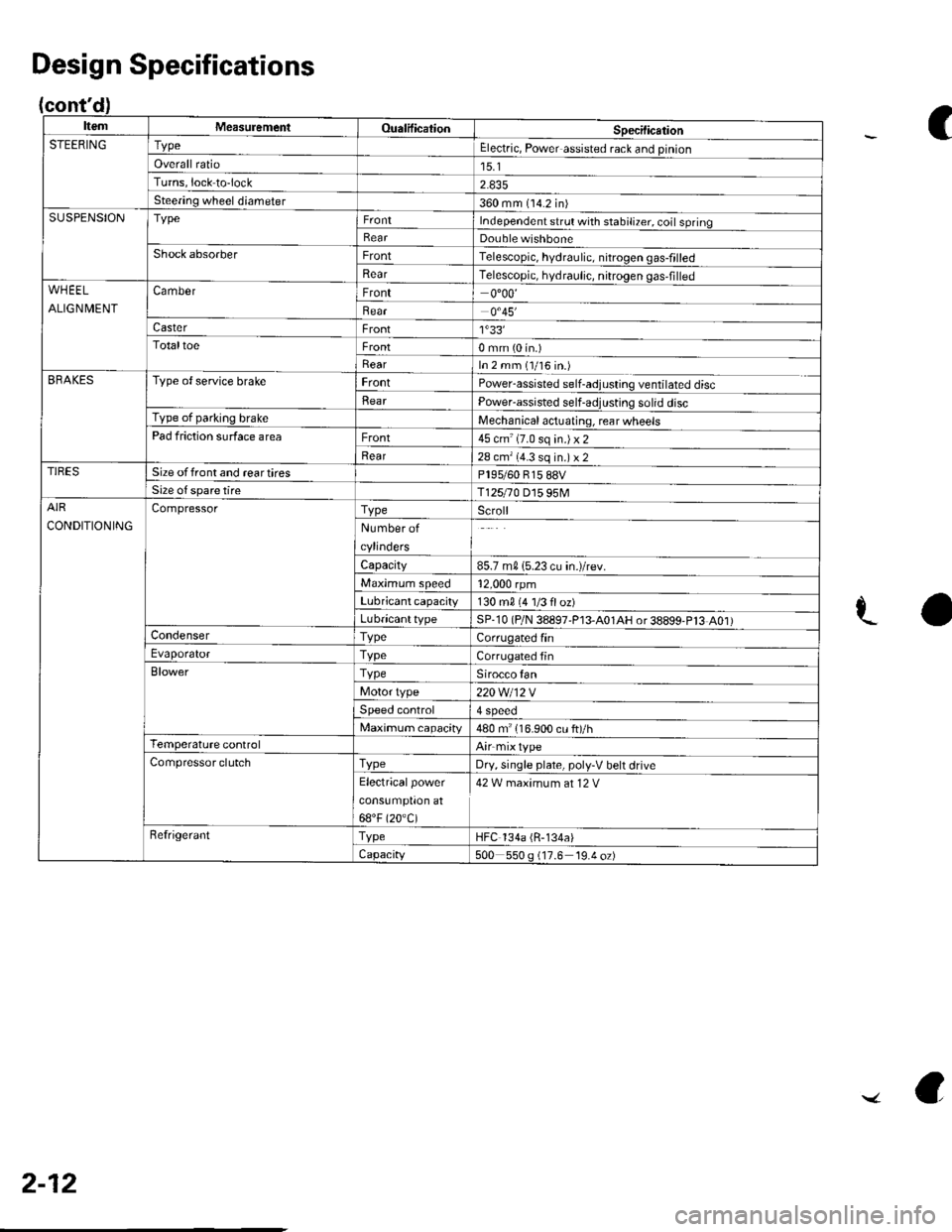

WEC Rocker Arms Test (cont'dl

'10. Loosen the valve on the regulator, and apply thespecified air pressure.

Specified air pressure:

290 kPa 13.0 kgt/cm', 42 psi)

NOTE: lf the synchronizing piston does not moveafter applying air pressure; move the primary orsecondary rocker arm up and down manually byrotating the crankshaft clockwise.

11. With the specified air pressure applied, move theintake primary rocker arm (A)forthe No, 1 cylinder.The primary rocker arm and secondary rocker arm(B) should move together.

lf the intake secondary rocker arm does not move,

remove the primary and secondary rocker arms asan assembly, and check that the pistons in theprimary and secondary rocker arms move

smoothly. lf any rocker arm needs replacing,

replace the primary and secondary rocker arms asan assembly, and test.

Remove the special tools.

Tighten the camshaft holder mounting bolts lo22N m 12.2 kgf.m, 16 lbf.ft).

Tighten the sealing boltto 20 N.m (2.0 kgf.m,

14 tbf.ft).

Installthe cylinder head cover (see page 6-41).

12.

13.

14.

t5.

6-8

VTG Actuator Inspection

'11. Remove the cylinder head cover (see page 6-22lr.

2. Remove the auto-tensioner (see page 6-19).

3. Loosen the rocker arm adjusting screws lsee step 2on page 6-26).

4. Remove the camshaft holder (see step 3 on page 6-

26t.

5. Remove the intake camshaft.

6, Check that the variable valve timing control (VTC)

actuator is locked by turning the VTC actuator

clockwise and counterclockwise. lf the VTC actuatoris not locked, replace the VTC actuator.

7. Seal the advance holes (A)and retard holes (B) in

the No. 1 camshaft journal with tape.

Punch a hole through the tape over one of theadvance holes.

Page 151 of 1139

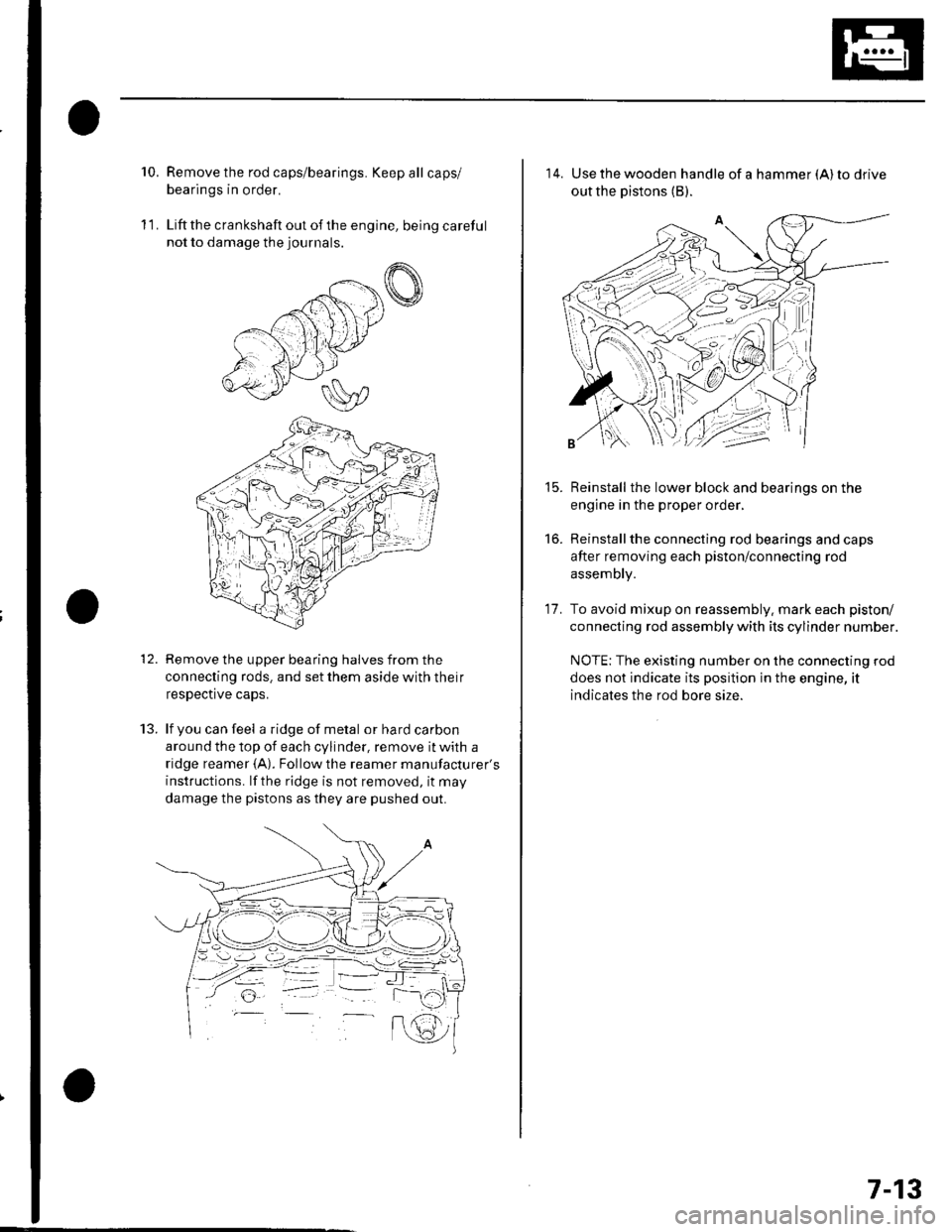

10.Remove the rod caps/bearings. Keep all caps/

bearings in order.

Liftthe crankshaft out ofthe engine, being careful

not to damage the journals.

Remove the upper bearing halves from the

connecting rods. and set them aside with their

respective caps.

lf you can feel a ridge of metal or hard carbon

around the top of each cylinder, remove it with a

ridge reamer {A). Followthe reamer manufacturer's

instructions. lf the ridge is not removed, it may

damage the pistons as they are pushed out.

11.

t.J.

14. Use the wooden handle of a hammer (A) to drive

out the pistons (B).

Reinstall the lower block and bearings on the

engine in the proper order,

Reinstallthe connecting rod bearings and caps

after removing each piston/connecting rod

assembly.

To avoid mixup on reassembly. mark each piston/

connecting rod assembly with its cylinder number.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it

indicates the rod bore size.

15.

to.

17.

7-13

Page 215 of 1139

Fuel and Emissions Systems

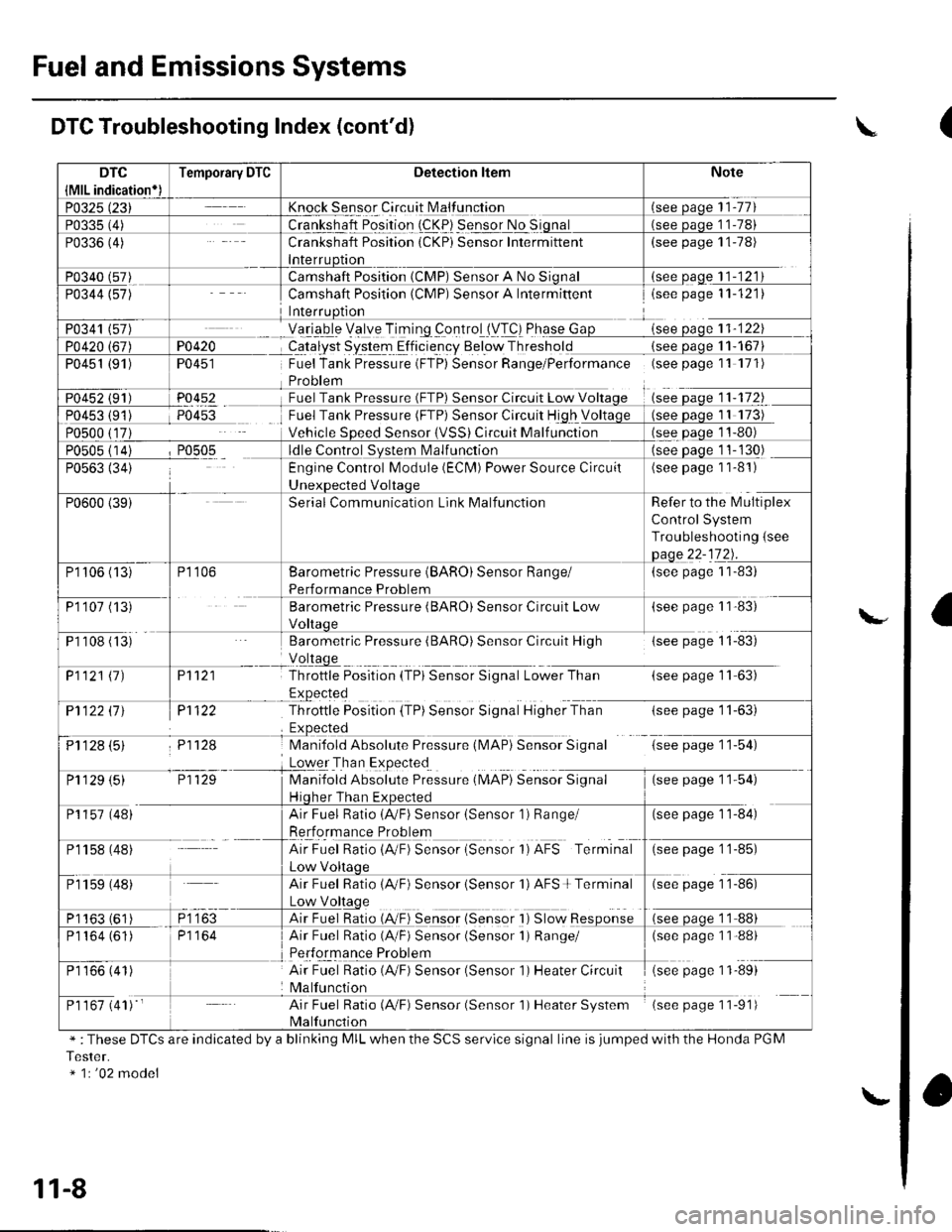

Knock Sensor Circuit N4alfunction

Crankshaft Position (CKP) Sensor Intermittent(see page 11-78)

(see oaqe 11-121

PO4i{�

TU45I

P0452

Camshaft Position (CMP) Sensor A Intermiftentisee page 11-121)

Yetrgb-le Velye TiTing _controlll/T!) Phqse Gsee oaoe 11-122

CqJalyst System Elficie-ncy Below Thresholdsee oaqe 1 1- 167

Fuel Tank Pressure (FTP) Sensor Range/Performance (seepagell 171)

Sensor Circuit Low V11-172

Fuel Tank Pressure (FTP) Sensor Circuit High V

Vehicle SDeed SensorCircuit Malf unction

Camshaft Position (CMP) Sensor A No

P0451 (91)

see Daqe 11-130)

(see page 1 1-81)

Refer to the l\4ultiplex

Control System

Troubleshooting {see

(see page 1 1-83)

(see paSe 1 1'83)

Barometric Pressure (BARO) Sensor Circuit High{see page 11-83)

P't 121

Pl122

P11f,.8

Throttle Position {TPi Sensor Signal Lower Than(see page 11-63)

-tsee page I r-oJ,

G;tp"s" 1 154)

(*" paSe 1 154)

P1122 ll J

ij1128 (5)

Throttle Position (TP) Sensor Signal Higher Than

Mani{old Absolute Pressure (l\,4AP} Sensor Signal

Loqer Tha n Expected

Manifold Absolute Preisure (MAP) SeiiioiSgnul

Hiqher Than Ex(see page 11-84)

Engine Control Module (ECN4) Power Source Circuil

Serial Communication Link Malfunction

P1106 (13)

P110? (13

P1 108 (ts'

Barometric Pressure (BARO) Sensor Range/

Performance Problem

Barometric Pressure (BARO) Sensor Circuit Low

P1121 11)

P1 129 (5)

P1157 (48)

Pr 158 (48)

Air Fuel Ratio (AVF) Sensor (Sensor 1) Range/

Rerformance Problem

AirFuel Ratio{A"F) Sensor {Sensor 1)AFS Terminal(see page 1 1-85)

Air Fuel Ratio 1AVF) Sensor isensor 'l) AFS + Terminal(see page 1 1-86)

Air Fuel Ratio {A,/F) Sensor {Sensor I ) Slow Response

Air Fuel Ratio (A/F) Sensor (Sensor 1) Range/(see page 1 1-88)

Air Fuel Ratio (4,/F) Sensor (Sensor 1) Heater Circuit

Malfunction

(see page 11-89)

Air Fuel Ratio (A,/F) Sensor (Sensor 1) Heater System

Malfunction

(see page 11-91)

P1 159 (48)

P1163 (61

P1164 (61)

P1 166 (41)

P1 167 (41) '

DTC Troubleshooting Index (cont'd)

" :These DTCS are indicated by a blinking MIL when the SCS servlce signal line is jumped with the Honda PGM

Tester.* 1r '02 model

\

l\."

11-8

\.

(

a

Page 227 of 1139

![HONDA CIVIC 2002 7.G Workshop Manual Fuel and Emissions Systems

System Descriptions {contd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV

HONDA CIVIC 2002 7.G Workshop Manual Fuel and Emissions Systems

System Descriptions {contd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV](/img/13/5744/w960_5744-226.png)

Fuel and Emissions Systems

System Descriptions {cont'd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV

'15

TPS16AFS_18

VSS

19IVAP20vcc221vccl

22AFSHTC+

23LG225

Ct\.4PA

26CMPB(rDc)

27IGPLS428IGPLS329IGPLS230IGPLS,I

NOTE: Standard battery voltage is 12 V.

JorminalnumberWirecolor[€rminal namoDescriptionSignal

19GRN/REDMAP (MANIFOLDABSOLUTE PRESSURESENSOR)

Detects MAP sensor signalWith ignition switch ON (ll):about3 VAt idle: about 1.0 V (depending on enginespeed)

20YEUBLUVCC2 (SENSOR VOLTAGE)Provides sensor voltageWith ignition switch ON {ll): about 5 VWith ionition switch OFF: about0V21YEUREDVCC] (SENSOB VOLTAGE)Provides sensor voltageWith ignition switch ON {ll): about 5 VWith ionition switch OFF: about0V22AFSHTC - (AIR FUELRATIO (A"iFiSENSORHEATER CONTROL + SIDE)

Detects a,/F sensor heatervoltageWith ign;tion switch ON lll): banery voltage

23BRN?ryE LLG2 (LOGIC GROUNDround for the ECM circuLessthan 1.0 V at alltimes24BRN?ryE L1(Lround for the ECM circuLess than '1.0 V at alltimes25B LU,^/VHTCMP A (CAMSHAFT

POSITION SENSOR A)Detects CMP sensor AstonalWith engine running: pulses

26GRNCMP B CAMSHAFTPOSITION (CMP)SENSOBB (TDC (TOP DEAD CENTERSENSORi)

Detects CMP sensor 8 (TDc

sensor)With engine running: pulses

27BRNIGPLS4 {No. 4IGNITIONCOIL PULSE)Drives No, 4 ignition coiWith ignition switch ON (ll)r about 0 vWith engine running: pulses28WHT/BLUIGPLS3 {No.3IGNITIONCOIL PULSE)Orives No.3 rgnition coi

29BLU/REDlGPLS2lNo.2 IGNITIONCOIL PTJLSE)Drives No.2 ignition coil

30YEUGRNIGPLSI (No. 1 IGNITIONco

PlltsF)Drives No. I ignition coil

11-20

\.

a

a

Page 237 of 1139

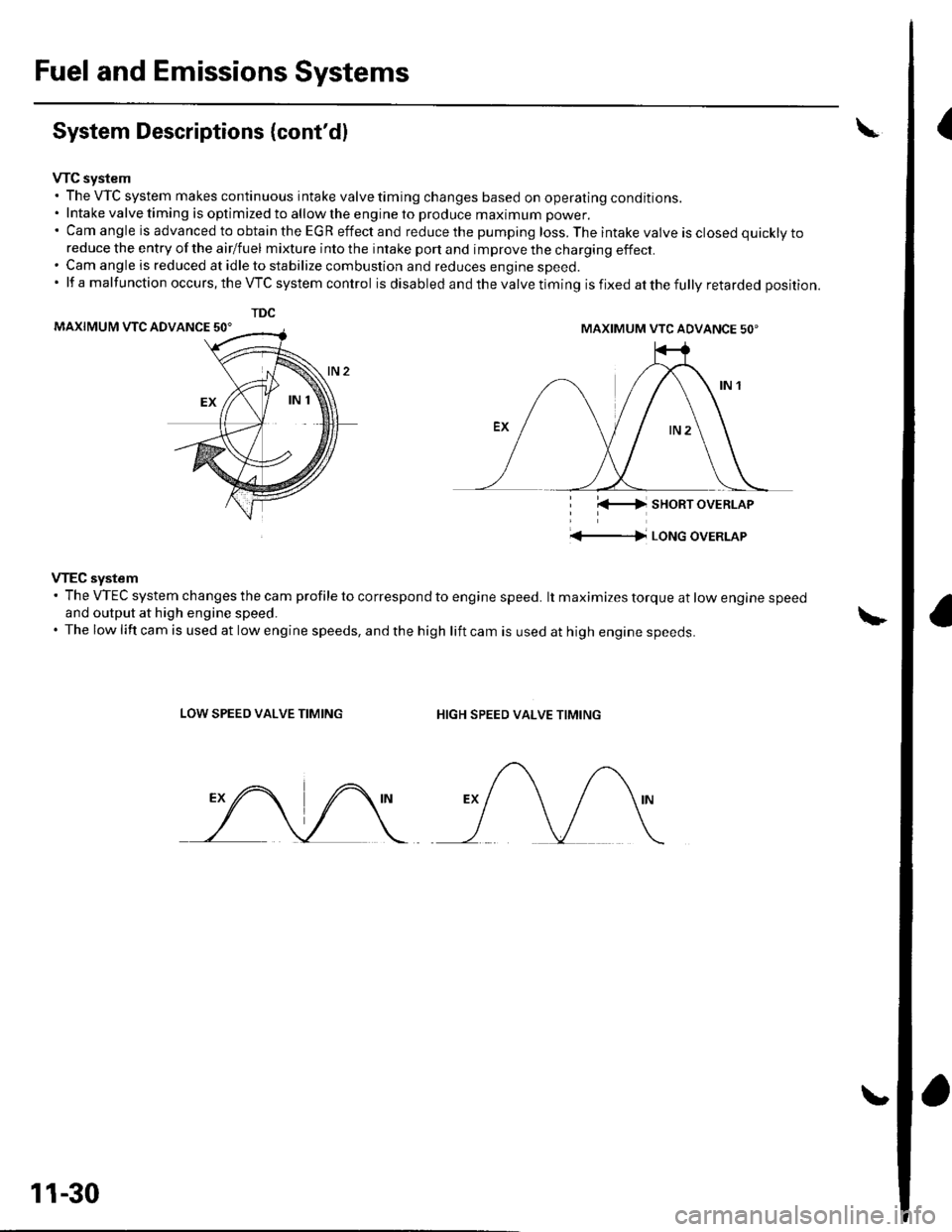

Fuel and Emissions Systems

(System Descriptions (cont'dl

VTC system. The VTC system makes continuous intake valve timing changes based on operating conditions.. Intake valve timing is optimized to allow the engine to produce maximum power.'CamangleisadvancedtoobtaintheEGReffectandreducethepumpingloss.Theintakevalveisclosedquicklyto

reduce the entry of the airlfuel mixture into the intake port and improve the charging effect.. Cam angle is reduced at idle to stabilize combustion and reduces engine speed.'lfamalfunctionoccurs,theVTCsystemcontrol is disabled and the valve timing is fixed at the fully retarded position.

MAXIMUM VTC ADVANCE 50'

i l(-4 sHoRT oVERLAP

'+-|l LoNG oVERLAP

VTEC system' The VTEC system changes the cam profile to correspond to engine speed. lt maximizes torque at low engine speedand output at high engine speed.. The low lift cam is used at low engine speeds, and the high lift cam is used at high engine speeds.

LOW SPEED VALVE TIMINGHIGH SPEED VALVE TIMING

TDC

MAXIMUM VTC ADVANCE 50'

11-30

Page 239 of 1139

Fuel and Emissions Systems

(

{

System Descriptions (cont'd)

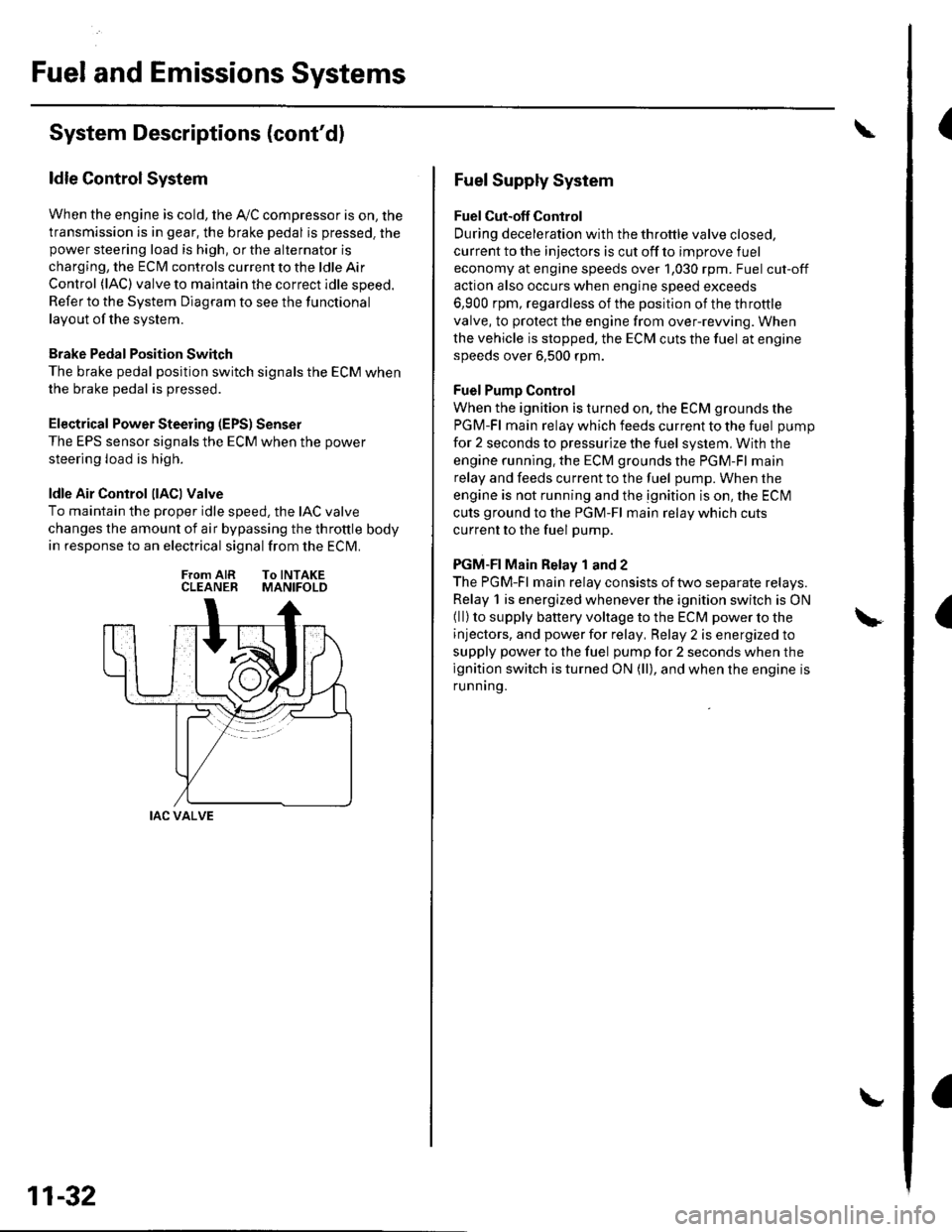

ldle Control System

When the engine is cold, the Ay'C compressor is on, the

transmission is in gear, the brake pedal is pressed. thepower steering load is high, or the alternator is

charging, the ECIM controls current to the ldle Air

Control (lAC) valve to maintain the correct idle speed.

Refer to the System Diagram to see the functional

layout of the system.

Brake Pedal Position Switch

The brake pedal position switch signals the ECM when

the brake pedal is oressed.

Electrical Power Steering (EPS) Senser

The EPS sensor signals the ECM when the power

steering load is high.

ldle Air Control llACl Valve

To maintain the proper idle speed, the IAC valve

changes the amount of air bypassing the throttle body

in response to an electrical signal from the ECM.

From AIR To INTAKECLEANER MANIFOLD

IAC VALVE

11-32

Fuel Supply System

Fuel Cut-off Control

During deceleration with the throttle valve closed,

current to the injectors is cut off to improve fuel

economy at engine speeds over 1,030 rpm. Fuel cut-off

action also occurs when engine speed exceeds

6,900 rpm, regardless of the position of the throttle

valve, to protect the engine from over-rewing. When

the vehicle is stopped. the ECM cuts the fuel at engine

speeds over 6,500 rpm.

Fuel Pump Control

When the ignition is turned on, the ECM grounds the

PGM-Fl main relay which feeds current to the fuel pump

for 2 seconds to pressurize the fuel system, With the

engine running. the ECM grounds the PGM-Fl main

relay and feeds current to the fuel pump. When the

engine is not running and the ignition is on, the ECI\4

cuts ground to the PGM-Fl main relay which cuts

current to the fuel pump.

PGM-FI Main Relay 1 and 2

The PGM-Fl main relay consists of two separate relays.

Relay 1 is energized whenever the ignition switch is ON(ll) to supply battery voltage to the ECM power to the

injectors, and power for relay, Relay 2 is energized to

supply power to the fuel pump for 2 seconds when the

ignition switch is turned ON (ll), and when the engine is

runnrng.

Page 242 of 1139

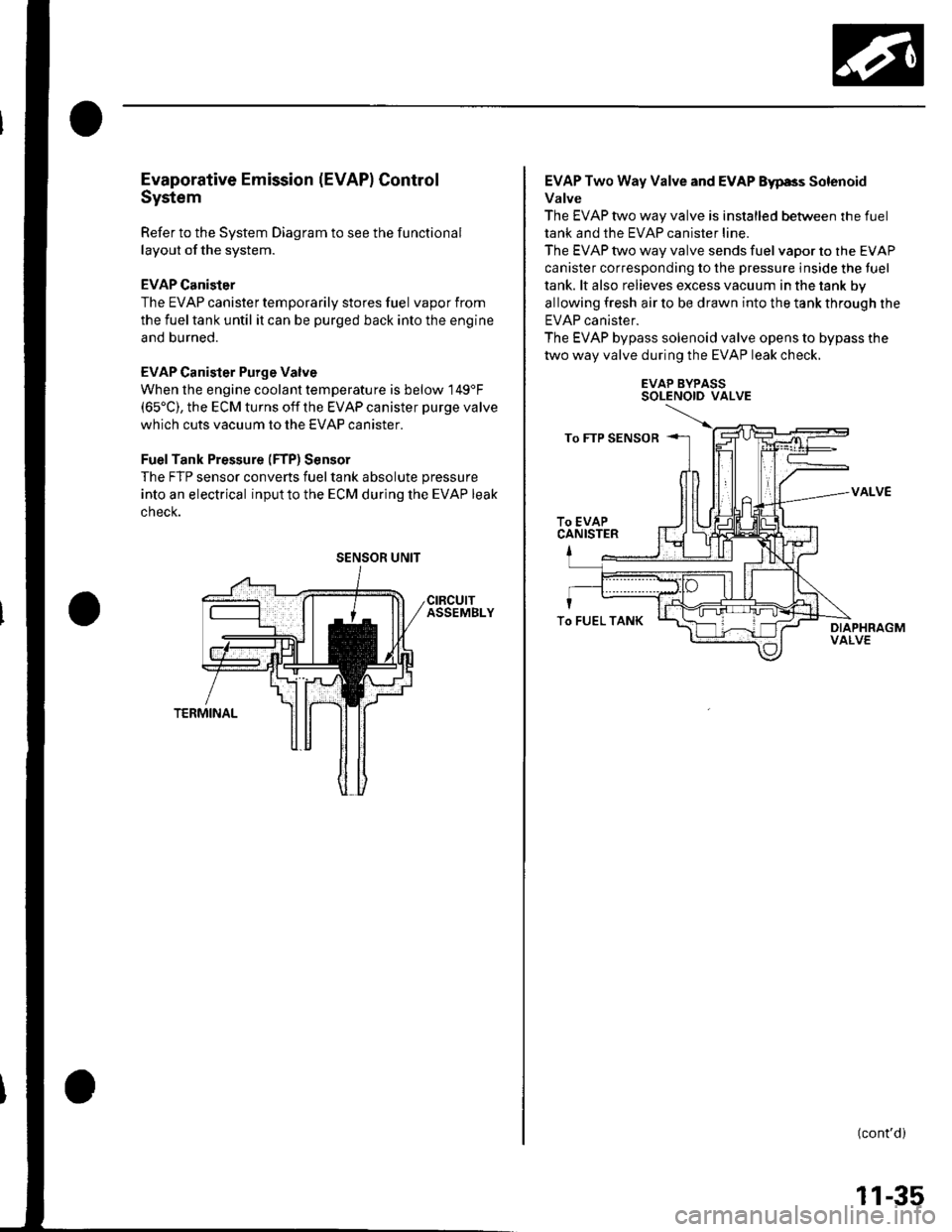

Evaporative Emission (EVAPI Control

System

Refer to the System Diagram to see the functional

layout of the system.

EVAP Canister

The EVAP canister temporarily stores fuel vapor from

the fuel tank until it can be purged back into the engine

and burned.

EVAP Canister Purge Valve

When the engine coolant temperatu re is below 149'F(65'C), the ECM turns off the EVAP canister purge valve

which cuts vacuum to the EVAP canister.

FuelTank Pressure (FTP) Sensor

The FTP sensor converts fueltank absolute pressure

into an electrical inputto the ECM during the EVAP leak

cnecK.

SENSOR UNIT

EVAP Two Way Valve and EVAP Eyp8s Solenoid

Valve

The EVAP two way valve is installed between the fuel

tank and the EVAP canister line.

The EVAP two way valve sends fuel vapor to the EVAP

canister corresponding to the pressure inside the tuel

tank. lt also relieves excess vacuum in the tank by

allowing fresh air to be drawn into the tank through the

EVAP canister.

The EVAP bypass solenoid valve opens to bypass the

two way valve during the EVAP leak check.

EVAP BYPASSSOLENOID VALVE

VALVE

(cont'd)

To FUEL TANK

11-35