ESP HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 274 of 1139

8.Check the secondary H02S (Sensor 2) output

voltage with the scan tool,

ls there 1.0 V ot mote?

YES-Go to step 9.

NO Replace the secondary HO2S (Sensor 2).1

Turn the ignition switch OFF.

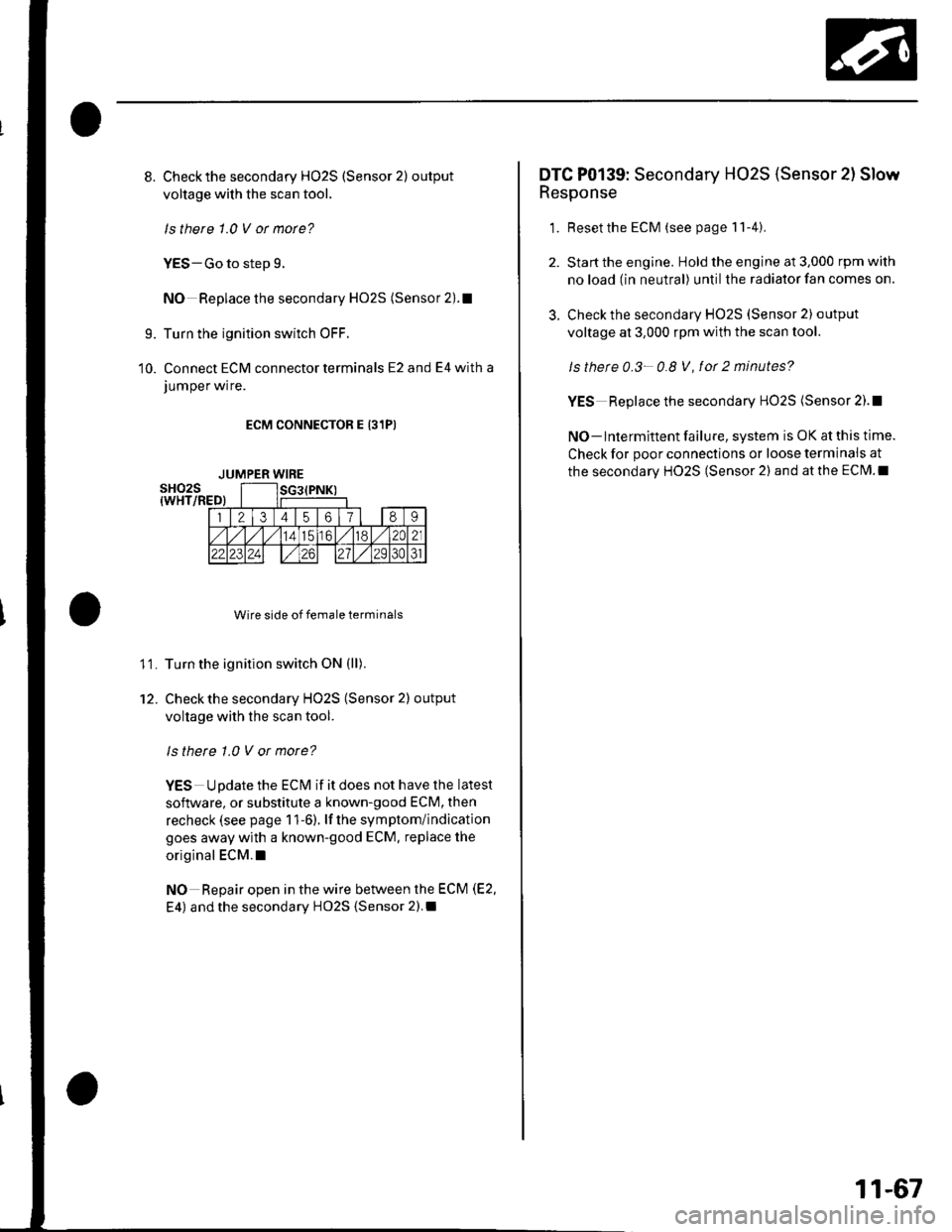

Connect ECM connector terminals E2 and E4 with a

JUmper wrre.

ECM CONNECTOR E 131PI

Wire side of female terminals

Turn the ignition switch ON (ll).

Check the secondary HO2S (Sensor 2) output

voltage with the scan tool.

ls there 1.0 V or more?

YES Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM. replace the

original ECM.I

NO Repair open in the wire between the ECM (E2,

E4) and the secondary HO2S {Sensor 2).I

9.

10.

11.

12.

JUMPER WIRE

3.

DTC P0139: Secondary HO2S (Sensor 2l Slow

Response

1. Resetthe ECM (see page 11-4).

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

Check the secondary HO2S (Sensor 2) output

voltage at 3,000 rpm with the scan tool.

ls thete 0.3- 0.8 V, fot 2 minutes?

YES Replace the secondary HO2S (Sensor 2).!

NO- lntermittent failure, system is OK at this time.

Check for poor connections or loose terminais at

the secondary HO2S (Sensor 2) and at the ECM.I

11-67

Page 295 of 1139

PGM-FI System

DTC Troubleshooting (cont'dl

DTC Pl163: Ay'F Sensor (Sensor 1 ) SlowResponse

NOTE: lf DTC P1162 is stored at the same time as DTC

P1163. troubleshoot DTC P1162 first, then recheckfor

DTC P1163.

1. Reset the ECM (see page 1 1-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

3. Test-drive under the following conditions:

. 55 mph (89 km/h) steady speed' Transmission in sth gear' Until the Ay'F sensor readiness code or

Temporary DTC Pl163 comes on

4. Check for a Temporary DTC with the scan tool.

ls Temporary DTC P 1163 indicated?

YES Replace the Ay'F sensor (Sensor 1).I

NO Intermittent failu re, system is OK at this time.

Check for poor connections or loose terminals at

the A'lF sensor (Sensor 1 ) and at the ECM. t

11-88

DTC Pl164: A,/F Sensor (Sensor 1) Circuit

Range/Performance Problem

1. Resetthe ECI\4 (see page 1t-4).

2. Start the engine. Holdtheengineat3,000 rpmwith

no load (in neutral) until the radiator fan comes on,

3. Test-drive in 3rd gear. Starting at 1,600 rpm,

accelerate using wide open throttle for at least

5 seconds. Then decelerate for at least 5 seconds

with the throttle completely closed until the A,/F

sensor readiness code is set to complete or

Temporary DTC P1 164 comes on.

4. Check for a Temporary DTC with the scan tool.

ls Temporary DTC P1164 indicated?

YES- Replace the A,,/F sensor (Sensor 1). I

NO Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the Ay'F sensor relay, at the Ay'F sensor (Sensor 1),

and at the EcM.l

Page 409 of 1139

Glutch

Clutch Replacement (cont'dl

Clutch Disc and Pressure Plate Installation

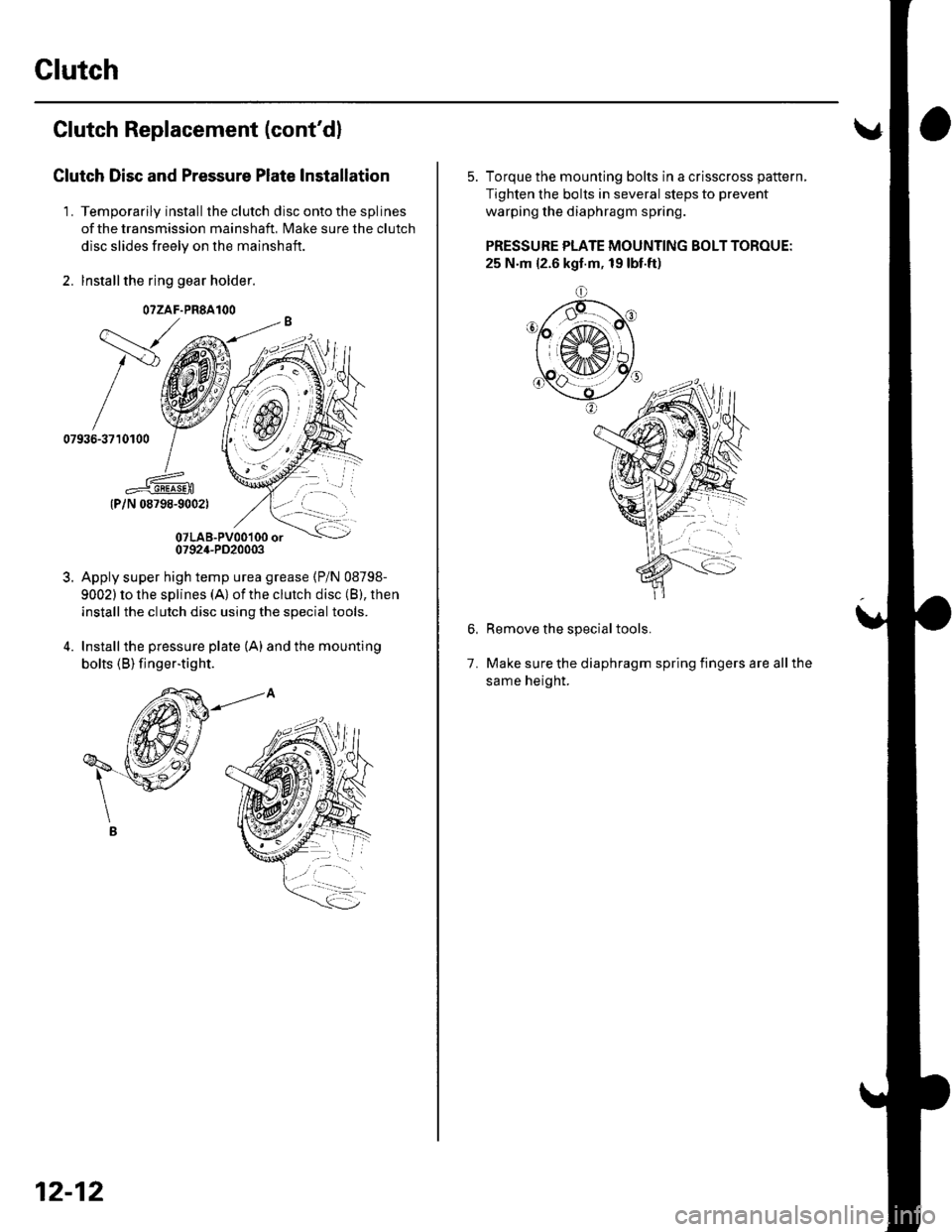

'L Temporarily install theclutch disc ontothesplines

of the transmission mainshaft, Make sure the clutch

disc slides freely on the mainshaft.

2. lnstallthe ring gear holder.

{P/N 08798-9002)

07LAB-PVo0'100 or0792,1-PD20003

Apply super high temp urea grease (P/N 08798-

9002) to lhe splines (A) of the clutch disc (B), then

install the clutch disc using the special tools.

Installthe pressure plate (A) and the mounting

bolts (B) finger-tig ht.

\---,

/v

07936-3710100

3.

O?ZAF.PRSAIOO

12-12

5. Torque the mounting bolts in a crisscross pattern,

Tighten the bolts in several steps to prevent

warping the diaphragm spring.

PRESSURE PLATE MOUNTING BOLT TOROUE:

25 N.m {2.6 kgt.m, 19 lbt.ft)

o

Remove the special tools.

Make sure the diaphragm spring fingers are all the

same height.

1.

Page 576 of 1139

Front Suspension

Stabilizer Link Removal/lnstallation

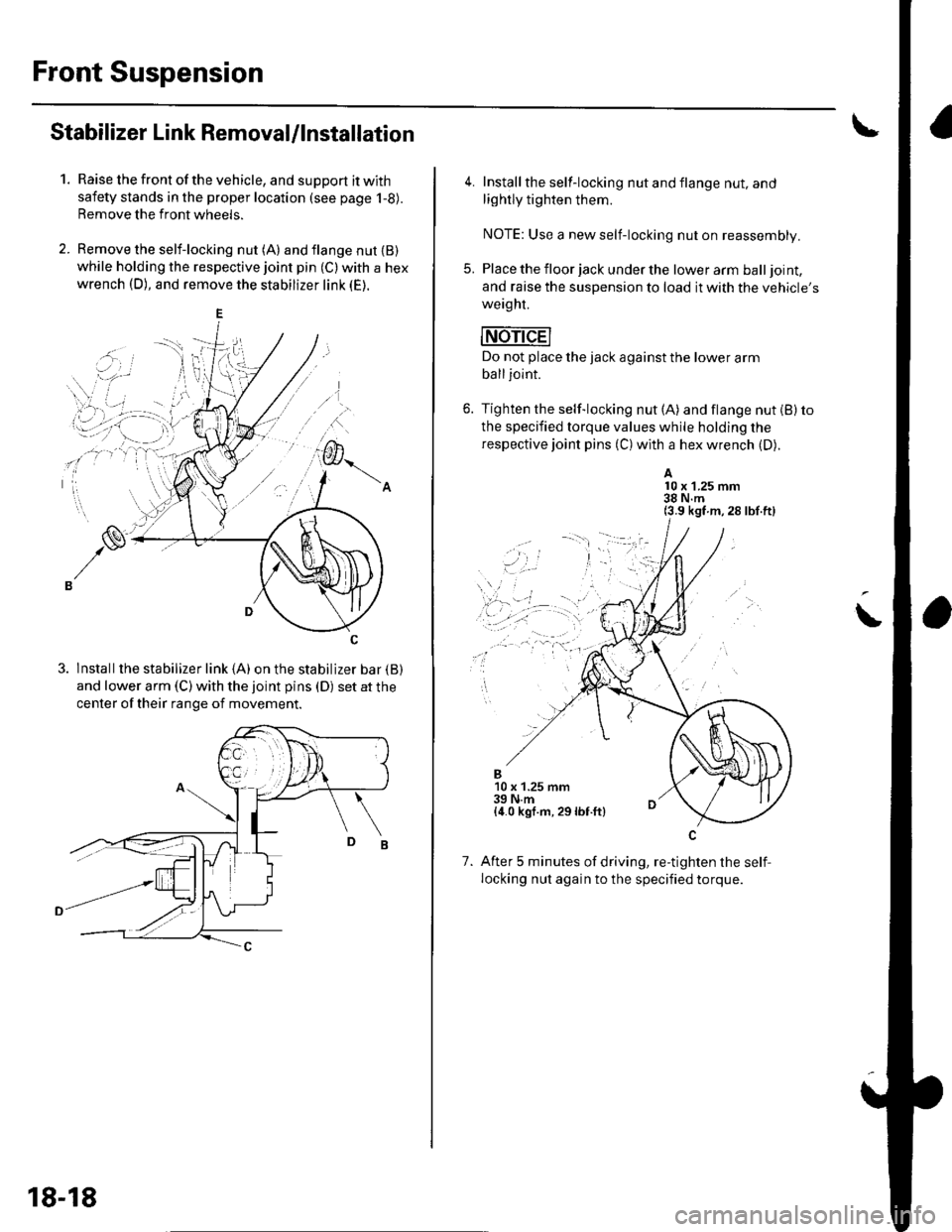

1.Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Remove the self-locking nut (A) and flange nut {B)while holding the respective joint pin (C) with a hex

wrench (D), and remove the stabilizer link (E).

3. lnstallthe stabilizer link (A) on the stabilizer bar {B)

and lower arm (C) with the joint pins (D) set at the

center of their range of movement.

18-18

4. Install the self-locking nut and flange nut, and

lightly tighten them.

NOTE: Use a new self-locking nut on reassembly.

5. Place the floor jack under the lower arm balljoint,

and raise the suspension to load it with the vehicle's

weaght.

mri-dEl

Do not place the jack against the lower arm

balljoint.

6. Tighten the self-locking nut (A) and flange nut (B) to

the specified torque values while holding the

respective joint pins (C) with a hex wrench (D).

A10 x 1.25 mm38 N.m(3.9 kgf m,28 lbf.ft)

\

..,

1.

B10 x 1.25 mm39 N.m{4.0 kgf.m, 29lbf.ft}

After 5 minutes of driving, re-tighten the self,

locking nut again to the specified torque.

Page 588 of 1139

Rear Suspension

1.

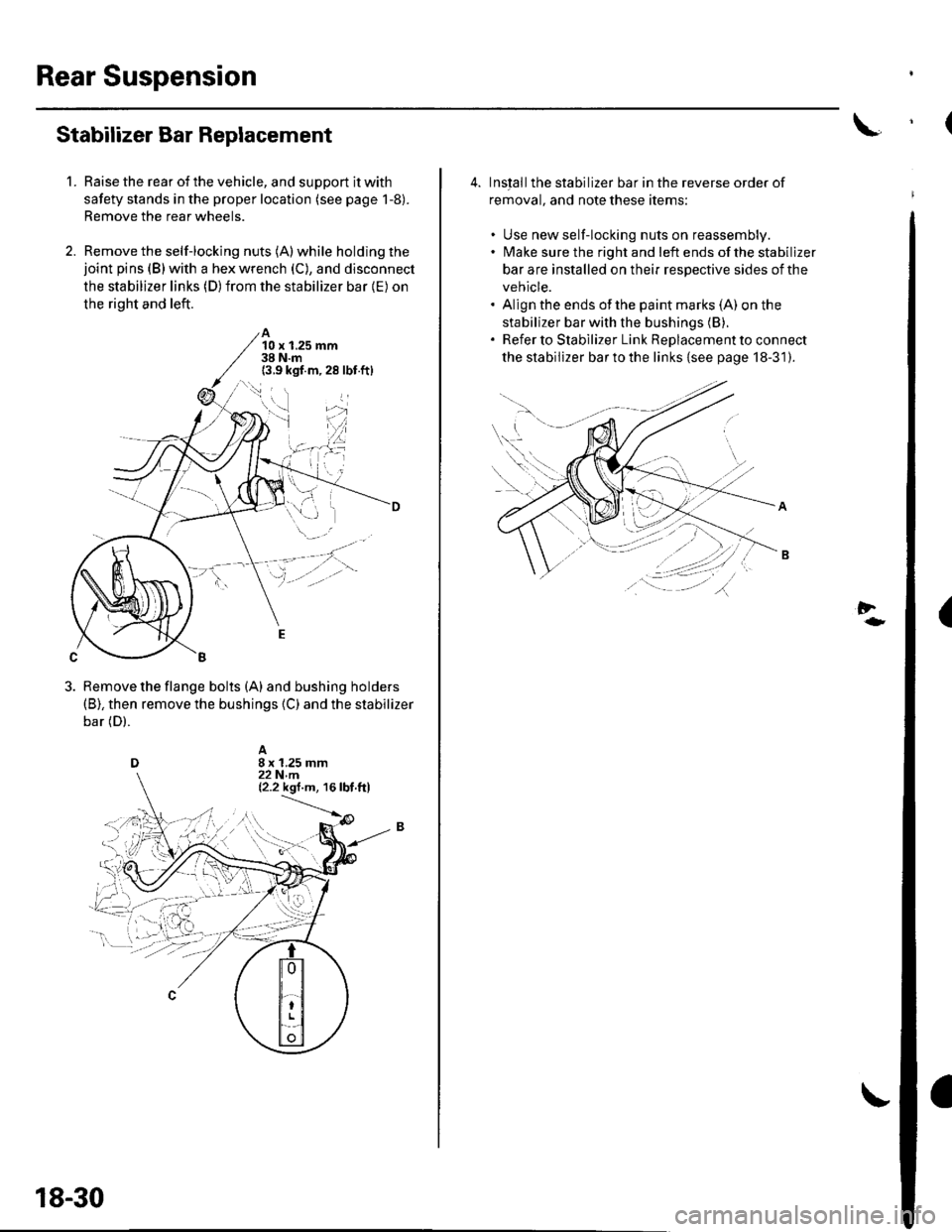

Stabilizer Bar Replacement

Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the rear wheels.

Remove the self-locking nuts (A) while holding thejoint pins (B) with a hex wrench (C), and disconnect

the stabilizer links (D) from the stabilizer bar {E) on

the right and left.

A10 x 1.25 mm38 N.m(3.9 kgf.m,28 lbf.ft)

Remove the flange bolts (A) and bushing holders(B), then remove the bushings {C) and the stabilizer

bar (D).

18-30

4. Inslallthe stabilizer bar in the reverse order of

removal, and note these items:

. Use new self-locking nuts on reassembly.. lMake sure the right and left ends of the stabilizer

bar are installed on their respective sides of the

vehicle.. Align the ends of the paint marks (A) on the

stabilizer bar with the bushings (B).

. Refer to Stabilizer Link ReDlacement to connect

the stabilizer bar to the links {see page 18-31).

Al\.... '..: .

.----'';-r'--\---r-

-tt'.,'t),

(

Page 589 of 1139

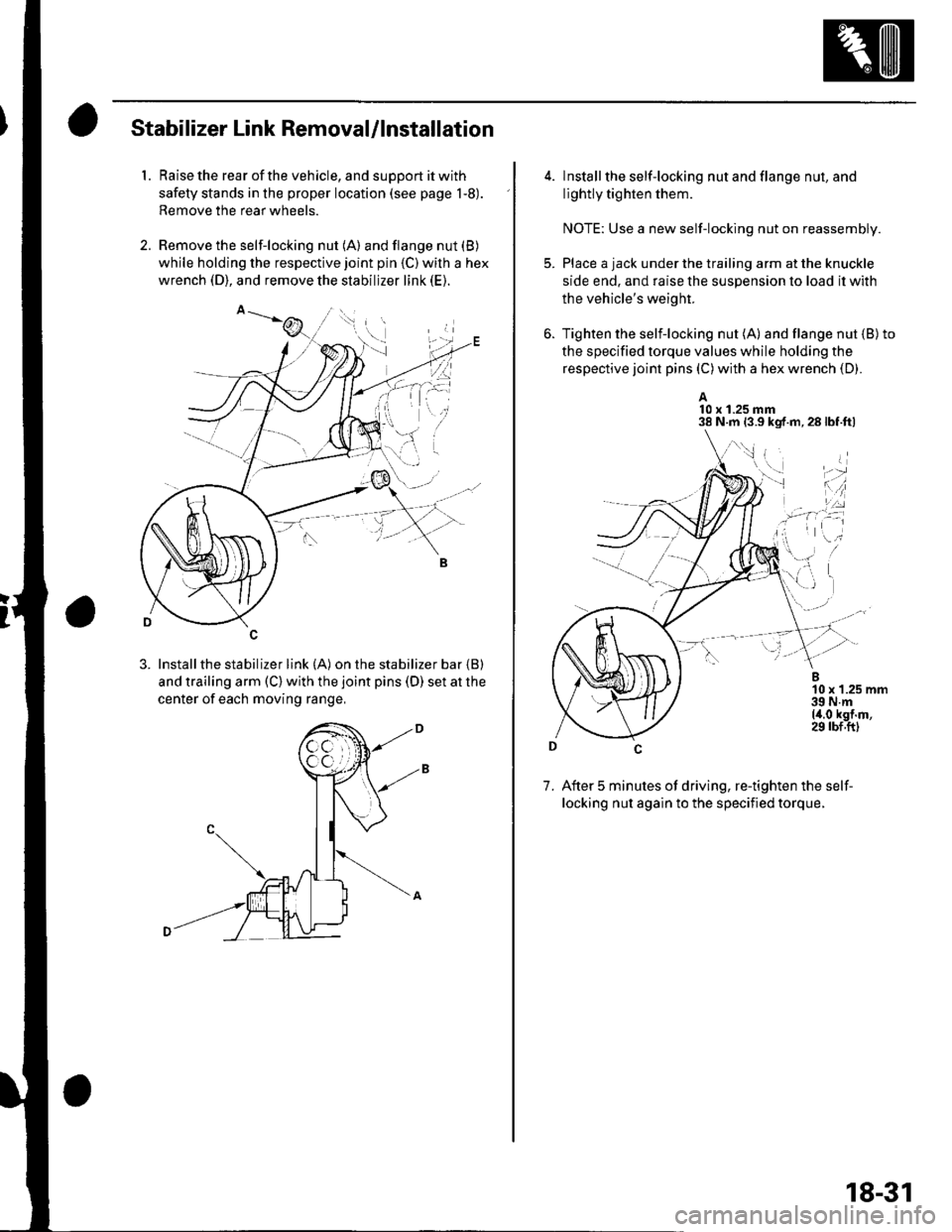

Stabilizer Link Removal/lnstallation

1. Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the rear wheels.

2. Remove the self-locking nut (A) and flange nut (B)

while holding the respective joint pin {C) wilh a hex

wrench (D), and remove the stabilizer link (E).

3. Installthe stabilizer link (A) on the stabilizer bar {B)

and trailing arm (C) with the joint pins (D) set at the

center of each moving range,

4. lnstall the self-locking nut and flange nut, and

lightly tighten them.

NOTE: Use a new self-locking nut on reassembly.

Place a jack under the trailing arm at the knuckle

side end. and raise the suspension lo load it with

the vehicle's weight.

Tighten the selflocking nut (A) and flange nut {B)to

the specified torque values while holding the

respective joint pins (C) with a hex wrench (D).

A10 x 1.25 mm38 N.m 13.9 kgf.m,28lbf.ftl

7. After 5 minutes of driving, re-tighten the self-

locking nut again to the specified torque.

\,1 i

i'-r d

*l'',:

18-31

Page 611 of 1139

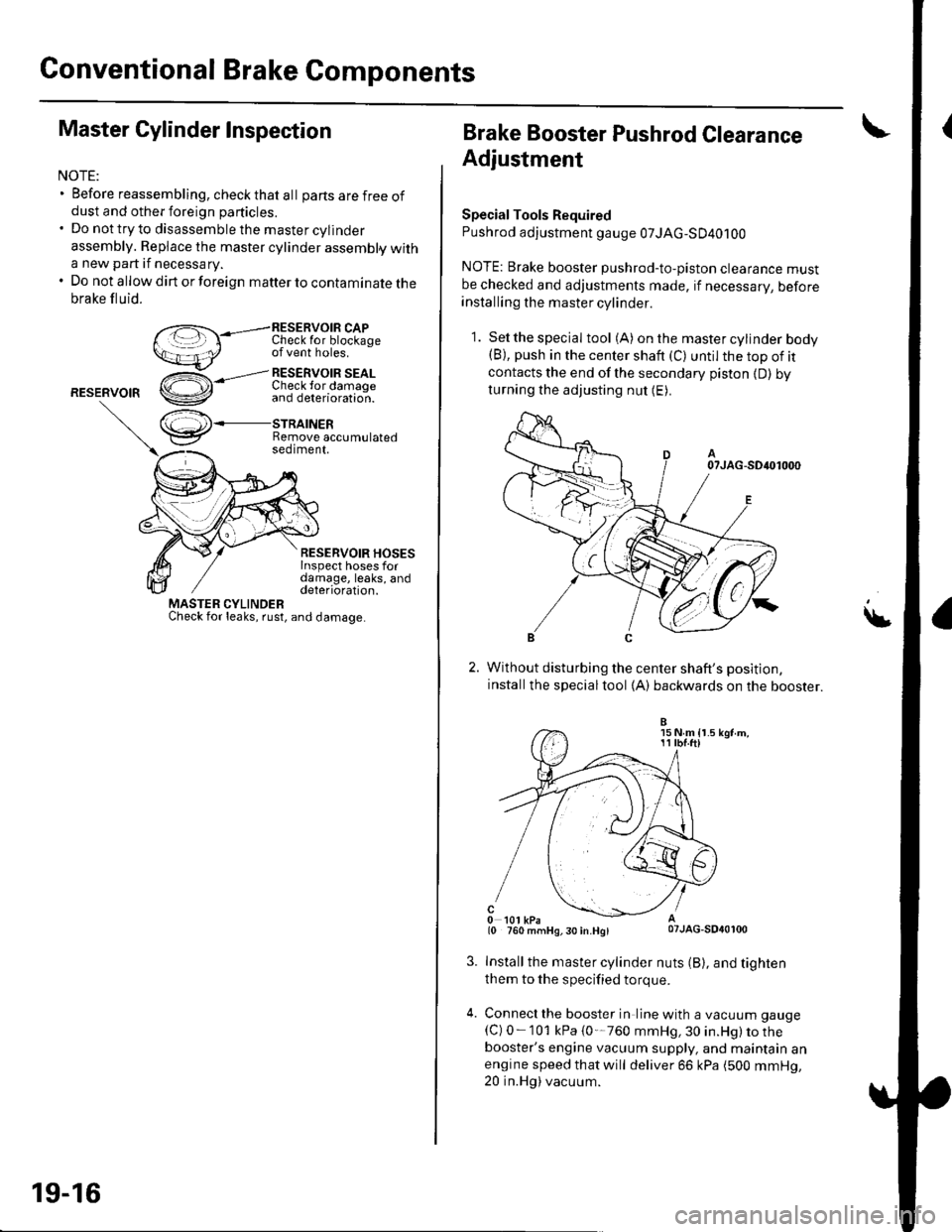

Conventional Brake Components

Master Cylinder Inspection

NOTE:. Before reassembling, check that al I parts are f ree ofdust and other foreign particles.. Do nottryto disassemblethe mastercylinder

assembly. Replace the master cylinder assembly witha new part if necessary.. Do not allow dirt or foreign matter to contaminate thebrake fluid.

RESERVOIB CAPI unecK Ior otocKageof vent holes.

RESERVOIR

,--l RESERvOIR SEALCheck lor damaoe

RESERVOIR HOSESInspect hoses fordamage, leaks, anddeterioration.

r',,.J\+

v

MASTER CYLINDERCheck for leaks, rust, and damage

and deterioration.

STRAINERRemove accumulatedseotment.

19-16

Brake Booster Pushrod Clearance

Adjustment

SpecialTools Required

Pushrod adjustment gauge 07JAG-SD40100

NOTE: Brake booster pushrod-to-piston clearance mustbe checked and adjustments made, if necessarV, beforeinstalling the master cylinder.

1. Setthespecial tool (A) onthe mastercylinder bodv(B), push in the center shaft (C) until the top of itcontacts the end of the secondary piston {D) byturning the adjusting nut (E).

Without disturbing the center shaft's position,

installthe specialtool (A) backwards on the booster.

Install the master cylinder nuts (B), and tighten

them to the specified torque.

Connecl the booster in line with a vacuum gauge

{C) 0-101 kPa {0'-760 mmHg, 30 in.Hg) to thebooster's engine vacuum supply, and maintain anengine speed that will deliver 66 kPa (500 mmHg,20 in.Hg) vacuum.

15 N m {r.511 tbf.ftl

Page 635 of 1139

t

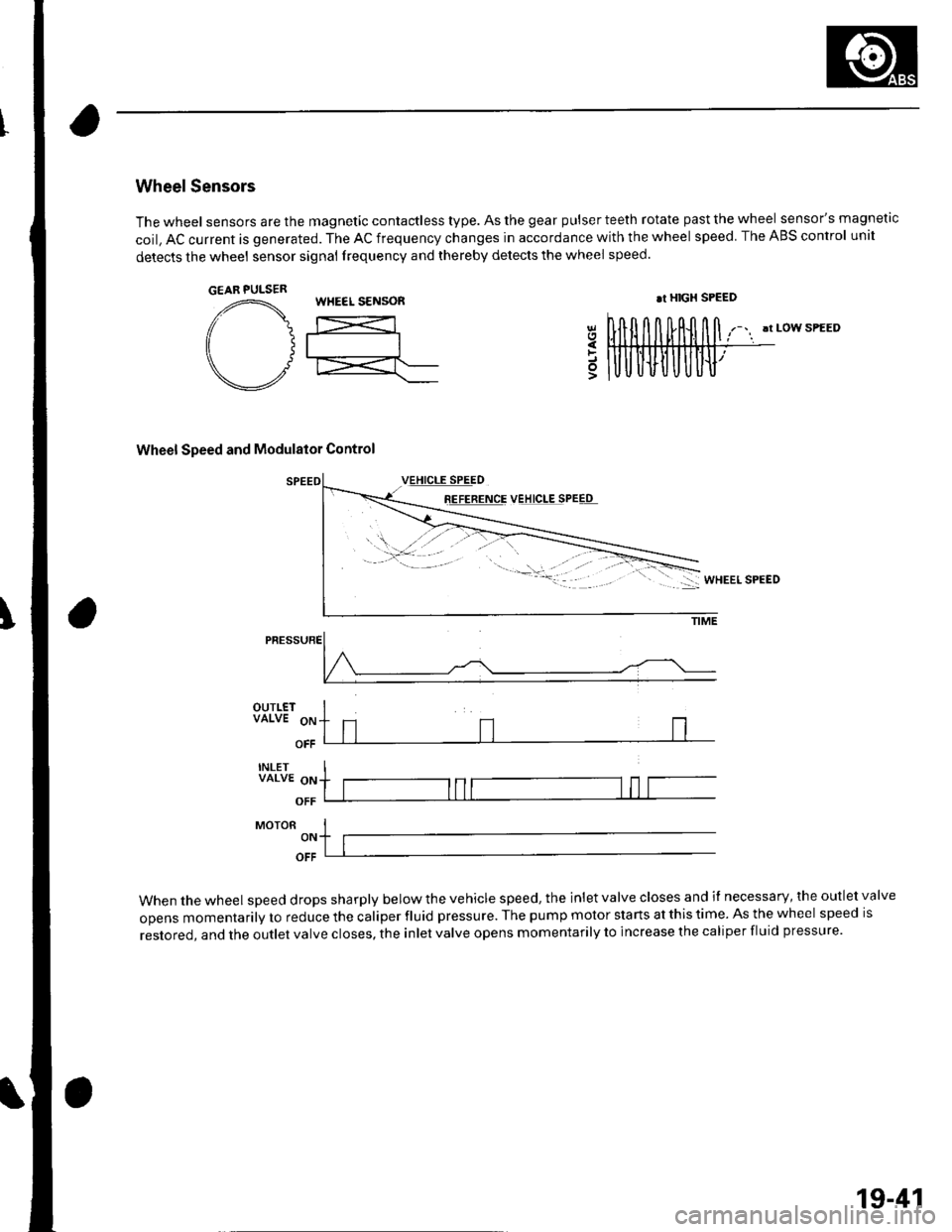

Wheel Sensors

The wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit

detects the wheel sensor signal frequency and thereby detects the wheel speed.

!t LOW SPEED

Wheel Speed and Modulator Control

8E!EEETqE VEJ!q!ESPEEq

5

PRESSURE

OUTLETVALVE 9p

OFF

INLETVALVE oN

OFF

MoroR I-,. ltlOFF

When the wheel speed drops sharply below the vehicle speed, the inlet valve closes and il necessary, the outlet valve

opens momentarily to reduce the caliper fluid pressure. The pump motor starts at this time. As the wheel speed is

restored, and the outlet valve closes, the inlet valve opens momentarily to increase the caliper fluid pressure.

GEAR PULSERWHEEL S€NSOR.r HIGX SPEED

19-41

Page 670 of 1139

Mirrors

Rearview Mirror Replacement

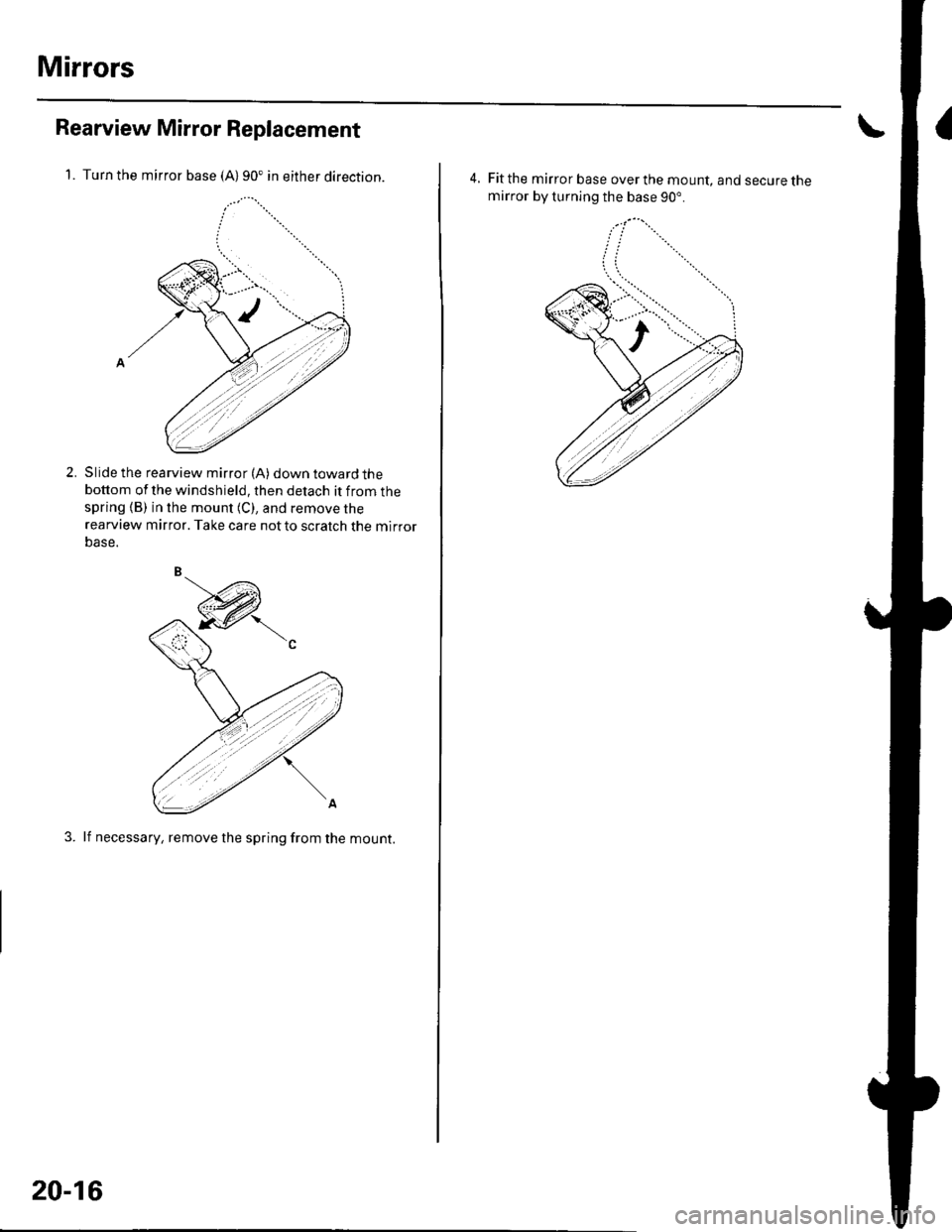

1. Turn the mirror base (A)90. in either direction.

Slide the rearview mirror (A) down toward thebottom of the windshield, then detach it from thespring (B) in the mount (C), and remove the

rearview mirror. Take care notto scratch the mirror

Dase.

3. lf necessary, remove the spring from the mount.

2.

20-16

4, Fit the mirror base over the mount, and secure themirror by turning the base 90".

Page 740 of 1139

Bumpers

Rear Bumper RemovaUlnstallation

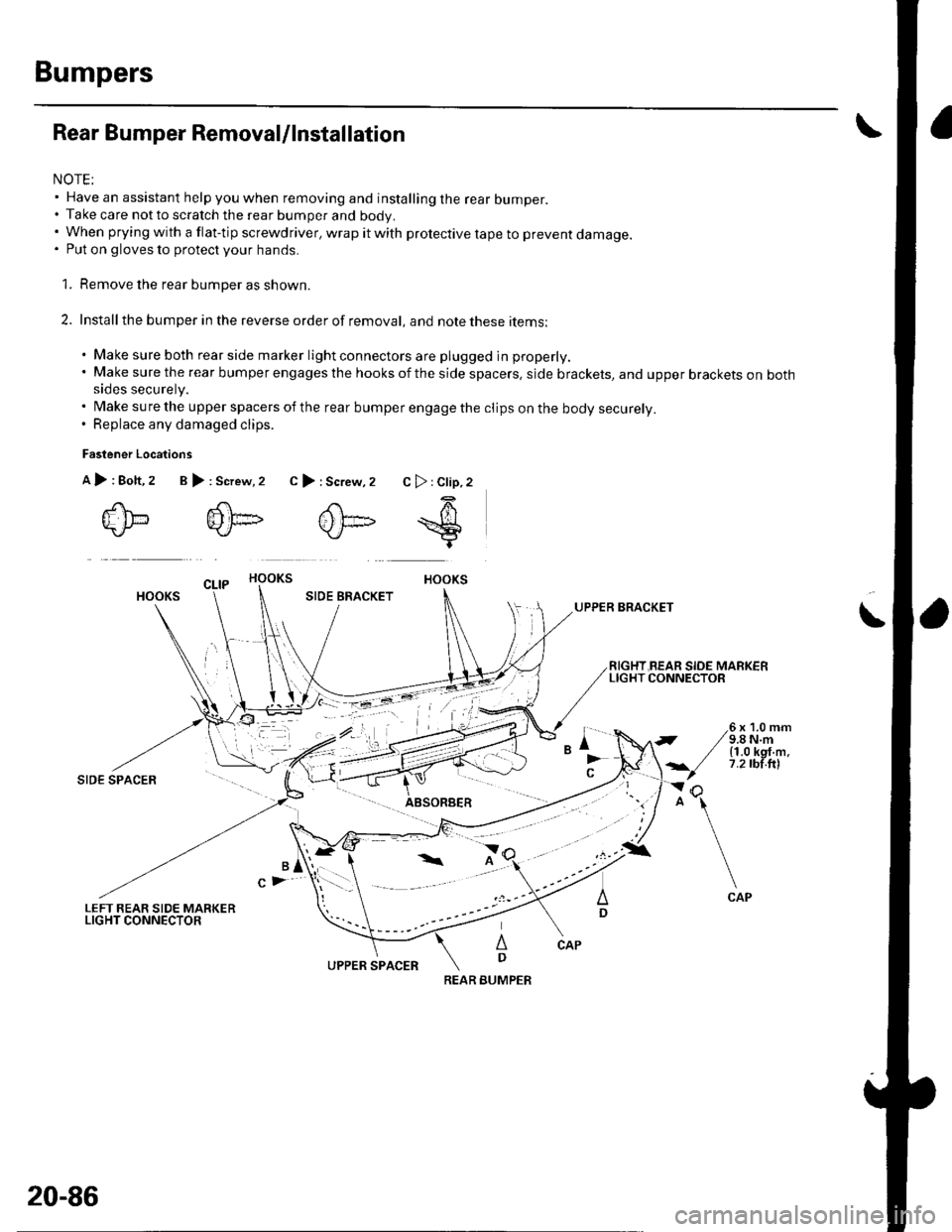

NOTE:' Have an assistant help you when removing and installing the rear bumper.. Take care not to scratch the rear bumper and body.. When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage.. Put on gloves to protect your hands.

L Remove the rear bumDer as shown.

2. Installthe bumper in the reverse order of removal, and note these items:

. Make sure both rear side marker light connectors are plugged in properly.'Makesuretherearbumperengagesthehooksofthesidespacers,sidebrackets,andupperbracketsonboth

sides securely.. Make sure the upper spacers of the rear bumper engage the clips on the body securely.. Replace any damaged clips.

: Screw, 2

XJ

) : Clip,

?ri)

\sI

Fastener Locations

A>:Bolt,2 B

/h-

\-P-

) : Screw, 2

ffiI"-ut ^*

c>

SIDE BRACKET

UPPER SPACER

UPPER BRACKET

\

SIDE SPACER

:r

'-

A

AD

LEFT REAR SIDE MARKERLIGHT CONNECTOR

,6 x 1.0 mm/ 9.eN.n,/ 11.0 kgl m,./ 1.2tbt.ttl

a

\

CAP

REAR BUMPER

20-86