Body HONDA CIVIC 2003 7.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 387 of 1139

EVAP System

DTC Troubleshooting (cont'd)

DTC Pl457: EVAP Control System(EVAP Canister System)

Leakage

The fuel system is designed to allow specified

maximum vacuum and pressure conditions. Do not

deviate from the vacuum and pressure tests as

indicated in these procedures. Excessive pressure/

vacuum would damage the EVAP components or

cause eventual fuel tank system failure.

SpecialTools Required

Vacuum pump/gauge, 0-30 in.Hg A973X-041-XXXXX

This is a two-trip code. Once cleared, it cannot be

reproduced in one trip. Also, certain specific driving

and ambient conditions must occur before the ECfM will

complete the system checks, Additional test drives may

still not meet the specific conditions needed to16^r^.1' '^6 rh6 ^^.16

Follow these troubleshooting procedures carefully to

ensure the integrity of the system and to confirm the

cause of the problem or code.

NOTE: Fresh fuel has a higher volatility lhat creates

greater pressure/vacuum. The optimum condition for

testing is fresh fuel, and there must be less than a full

tank. lf possible, to assist in leak detection, add I gallon

of fresh fuel to the tank (as long as it will not fill the

tank), just before starting these procedures.

EVAP Canister Purge Valve Test

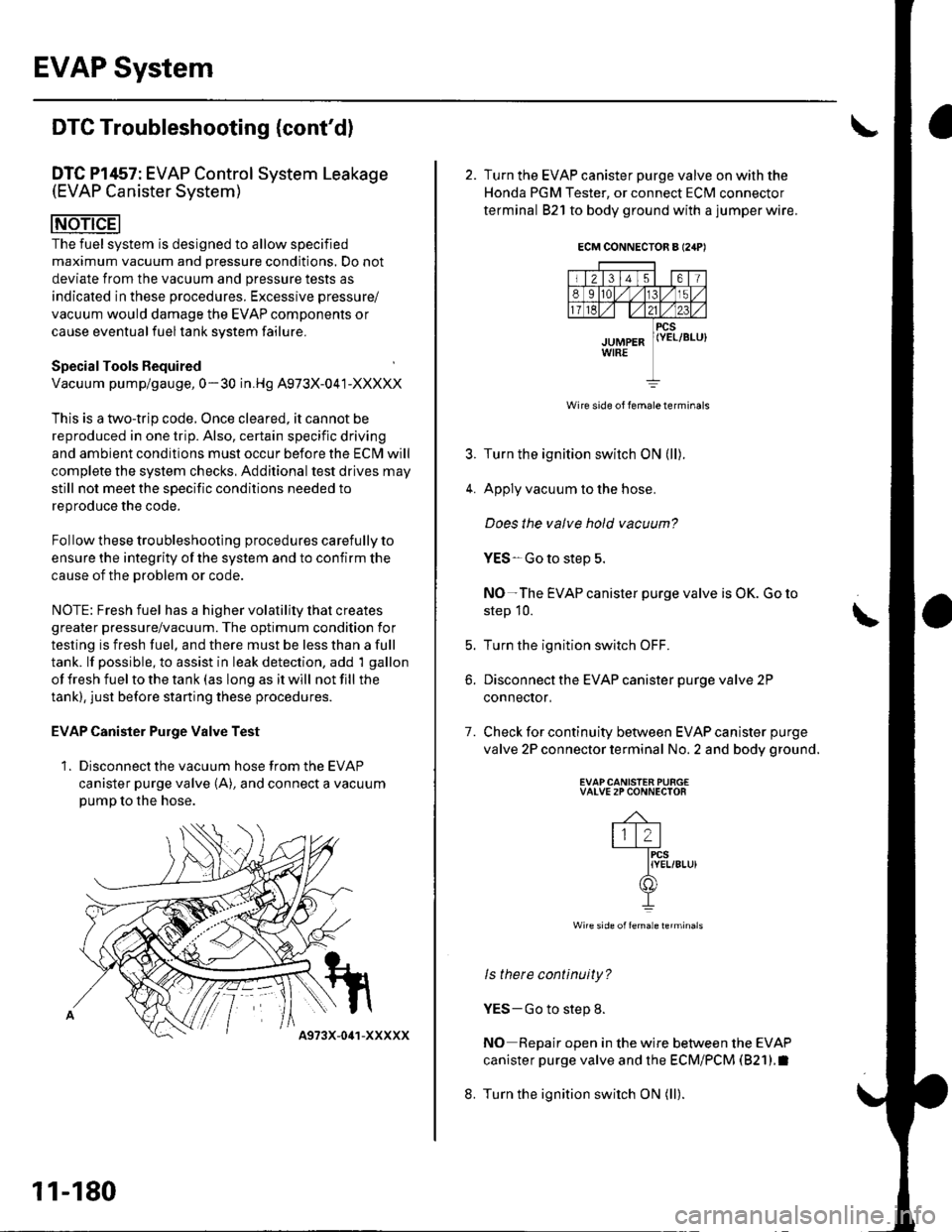

1. Disconnect the vacuum hose from the EVAP

canister purge valve (A), and connect a vacuumpump to the hose.

11-180

4973X-041-XXXXX

ECM CONNECTOR A I24P'

Wire side of lemale terminals

4.

7.

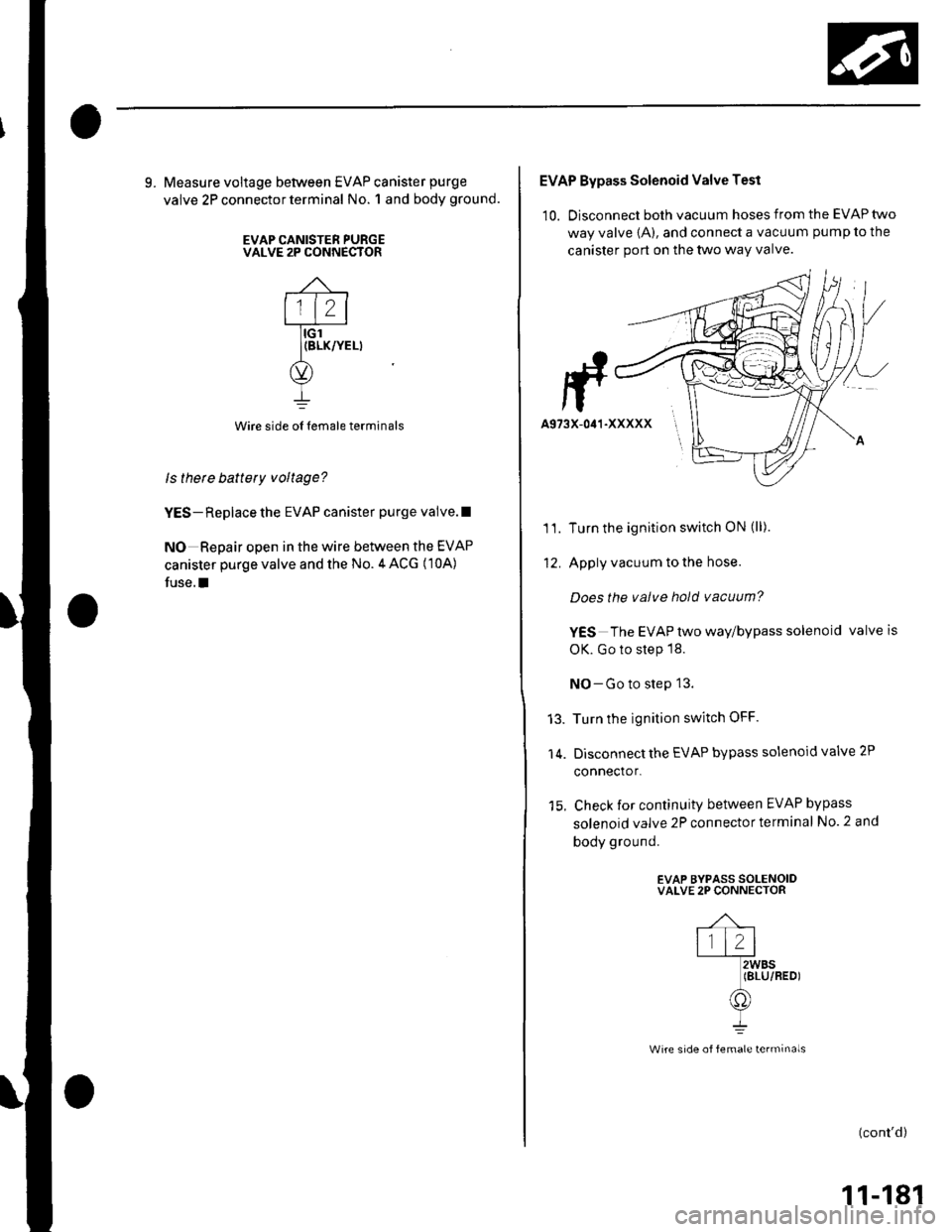

2. Turn the EVAP canister purge valve on with the

Honda PGM Tester, or connect ECM connector

terminal 821 to body ground with a jumper wire.

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-Go to step 5.

NO-The EVAP canister purge valve is OK. Go to

step 10.

Turn the ignition switch OFF.

Disconnect the EVAP canister purge valve 2P

conneclor,

Check for continuity between EVAP canister purge

valve 2P connector terminal No. 2 and body ground.

EVAPCANISTEN PURG€VALVE 2P CONNECTOR

-4-

lll2l-fircs

IYEL/8Lu)(f])

I

Wire side offemale lerminals

ls there continuity?

YES-Go to step 8.

NO Repair open in the wire between the EVAP

canister purge valve and the ECM/PCM (821).I

Turn the ignition switch ON (ll).

t

b.

8.

Page 388 of 1139

9. Measure voltage between EVAP canister purge

valve 2P connector terminal No. 1 and body ground.

EVAP CANISTER PURGEVALVE 2P CONNECTOR

Wire side oI lemale terminals

ls thete battery voltage?

YES- Replace the EVAP canister purge valve.l

NO Repair open in the wire between the EVAP

canister purge valve and the No.4 ACG (10A)

fuse.I

EVAP Bypass Solenoid Valve Test

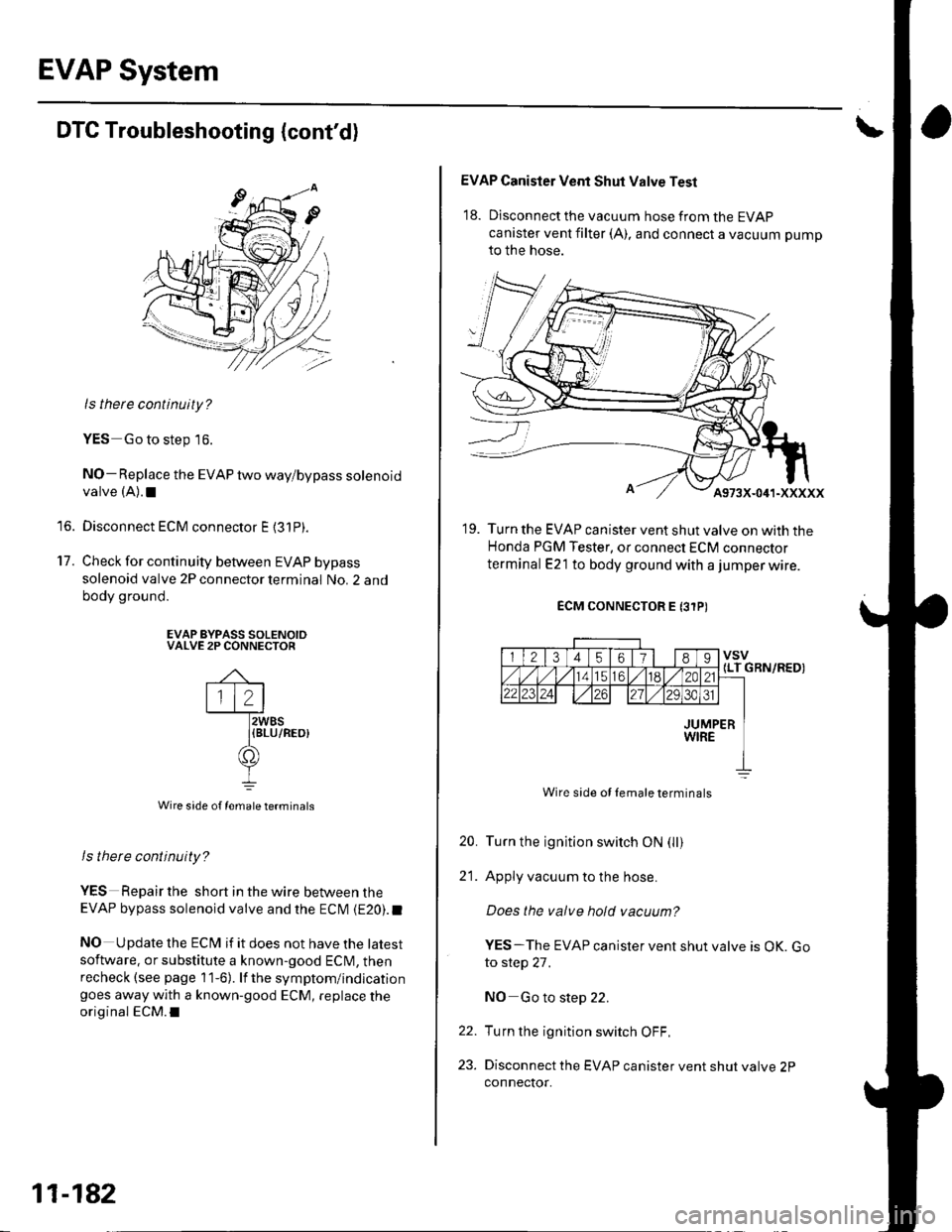

10. Disconnect both vacuum hoses from the EVAP two

way valve {A), and connect a vacuum pump to the

canister port on the two way valve.

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES The EVAP two way/bypass solenoid valveis

OK. Go to step 18.

NO-Go to step 13.

Turn the ignition switch OFF.

Disconnect the EVAP bypass solenoid valve 2P

connector.

Check for continuity between EVAP bypass

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

11.

'It

14.

(cont'd)

11-181

Wire side of female terminals

Page 389 of 1139

EVAP System

to.

't7.

DTC Troubleshooting (cont'd)

ls there continuity?

YES Go to step 16.

NO- Replace the EVAP two waylbypass solenoidvalve (A).1

Disconnect ECM connector E {31P).

Check for continuity between EVAP bypass

solenoid valve 2P connector terminal No. 2 and

body ground.

ls there continuity?

YES Repair the short in the wire between theEVAP bypass solenoid valve and the ECM {E20). f

NO Update the ECI\4 if it does not have the latest

software. or substitute a known-good EClvl, thenrecheck (see page 11-6). lf the symptom/indlcationgoes away with a known-good ECM, replace theoriginal ECM.I

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR

\,

lll2lI t-l2WBS

-[BLU/REo)())

I

Wire side of female terminals

11-182

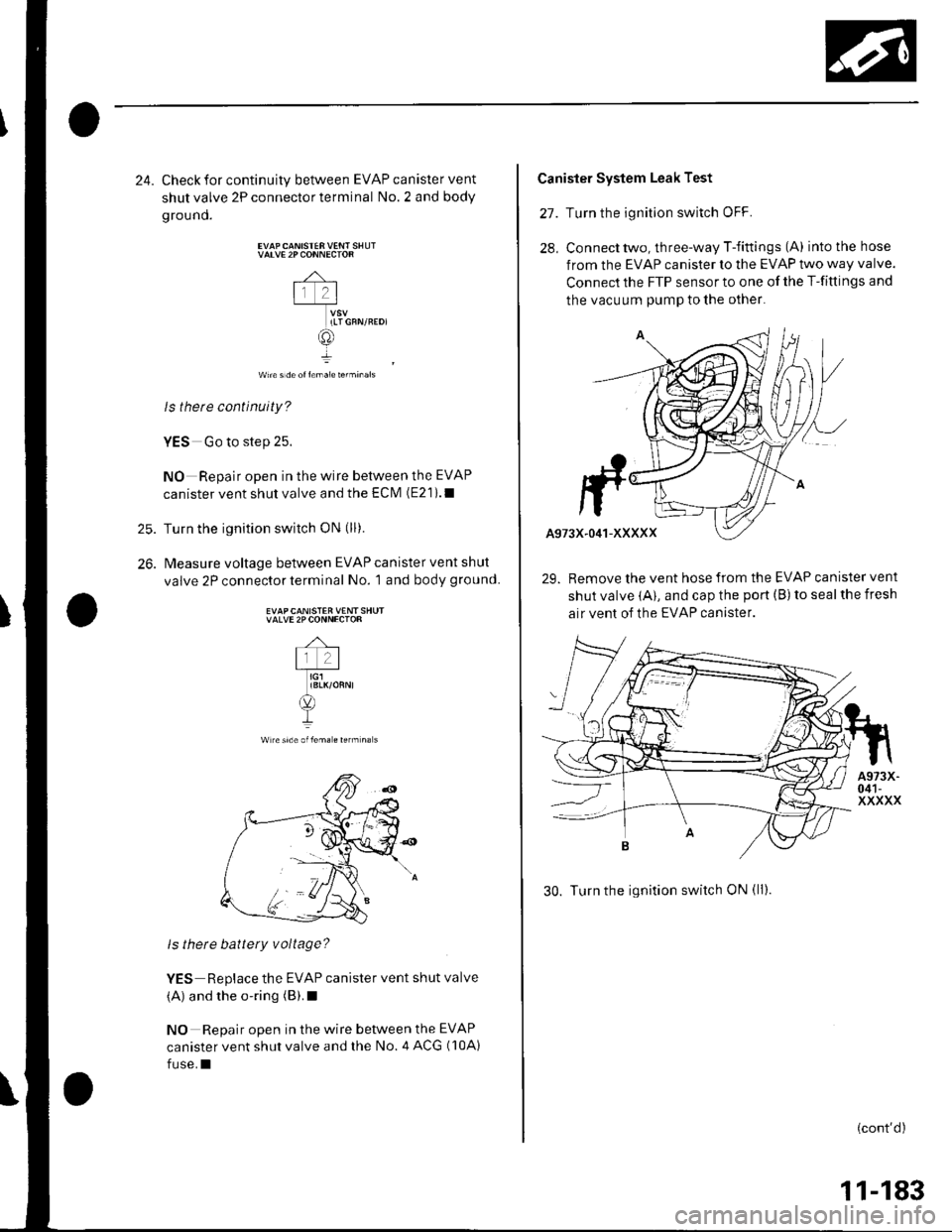

EVAP Canisler Vent Shut Valve Test

18. Disconnect the vacuum hose from the EVAP

canister vent filter (A), and connect a vacuum pump

to the hose.

19. Turn the EVAP canister vent shut valve on with theHonda PGM Tester, or connect ECM connector

terminal E21 to body ground with a jumper wire.

ECM CONNECTOR E (3TP)

112134589vsv{LT (1/15tal/la2A21

z3lz4zil./m31

JUMPERWIRE

Wire side ol lemale terminals

Turn the ignition switch ON (ll)

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-The EVAP canister vent shut valve is OK. Goto step 27.

NO Go to step 22.

Turn the ignition switch OFF.

Disconnect the EVAP canister vent shut valve 2Pconnector.

GBN/RED)

20.

21.

22.

23.

Page 390 of 1139

25.

26.

24. Check for continuity between EVAP canister vent

shutvalve 2Pconnectorterminal No.2 and body

ground.

VATVE 2P CONNECTOR

-4-

lr 2l-T_*u

ILTGFN/REDI

@

wn€ s de ol l€ma1e terminals

ls therc continuity?

YES Go to step 25.

NO Repair open in the wire between the EVAP

canister vent shut valve and the ECIVI (E21).1

Turn the ignition switch oN (ll).

Measure voltage between EVAP canister vent shut

valve 2P connector terminal No. 1 and body ground.

EVAPCANISTER VENT SHUTVALVE 2PCONNECTOR

Wlreside oflem. € rerm na s

ls there battery voltage?

YES Replace the EVAP canister vent shut valve

(A) and the o-ring (B).I

NO Repair open in the wire between the EVAP

canister vent shut valve and the No. 4 ACG (10A)

fuse.I

Canister System Leak Test

27. Turn the ignition switch oFF.

28, Connecttwo, three-way T-fittings (A) intothehose

from the EVAP canister to the EVAP two way valve.

Connect the FTP sensor to one of the T-fittings and

the vacuum pump to the othel

29. Remove the vent hose from the EVAP canister vent

shut valve (A), and cap the port (B) to seal the fresh

air vent of the EVAP canister.

30. Turn the ignition switch ON (ll).

(cont'd)

11-183

Page 504 of 1139

Steering

Steering Lock Replacement

NOTE: Do not try to re-key a replacement steering lock.

lf necessary, re-key the other locks.

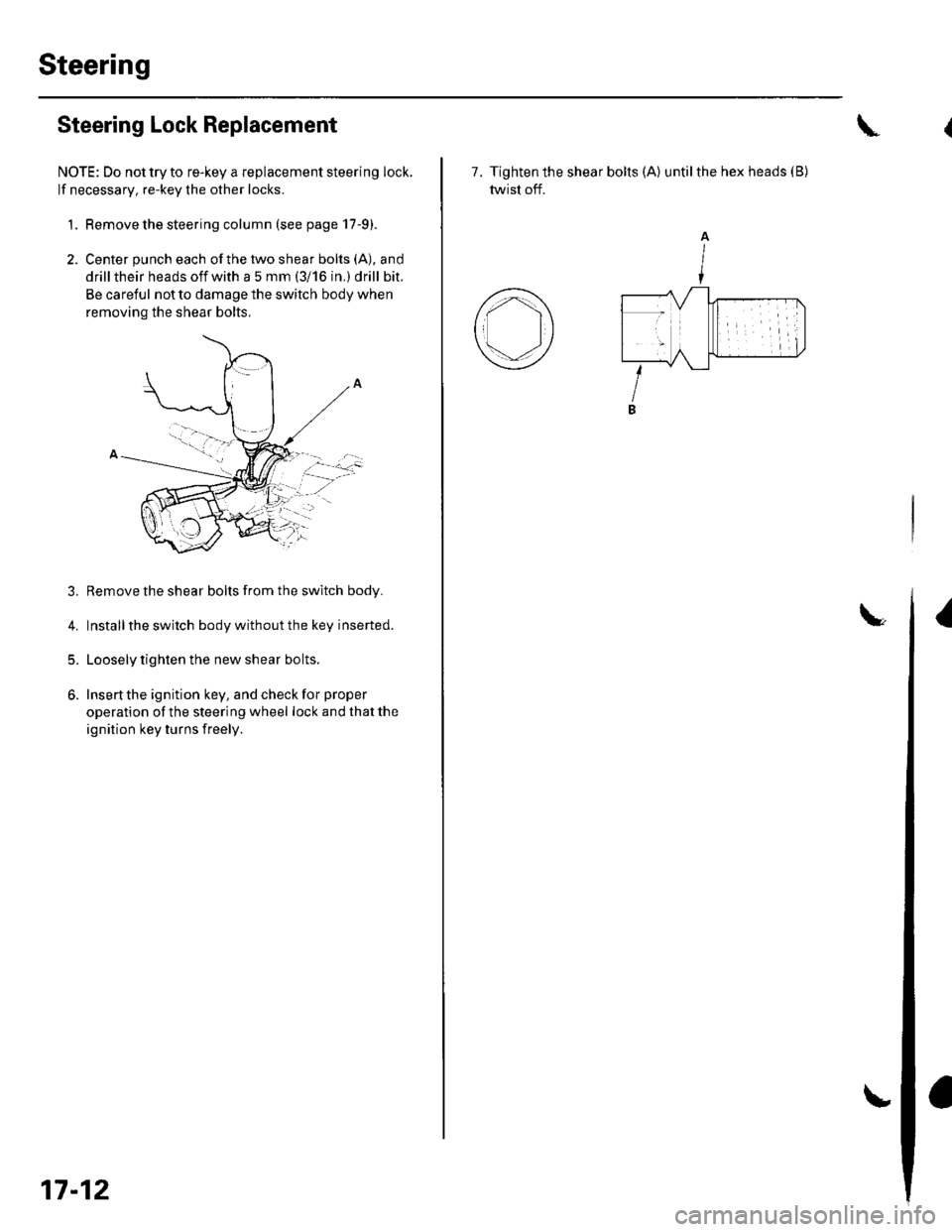

1. Remove the steering column (see page 17-9).

2. Center punch each ofthe two shear bolts (A), and

drill their heads off with a 5 mm (3i 16 in.) drill bit.

Be careful not to damage the switch body when

removing the shear bolts,

3. Remove the shear bolts from the switch body.

4. Installthe switch body without the key inserted.

5. Loosely tighten the new shear bolts.

6. Insert the ignition key, and check for proper

operation of the steering wheel lock and that the

ignition key turns freely.

:..'-":'

17-12

7. Tighten the shear bolts (A) untilthe hex heads (B)

twist off.

I

A

I

Page 510 of 1139

How to Troubleshoot EPS DTCs

The troubleshooting flowchart procedures assume that

the cause of the problem is still present and the EPS

indicator is still on, Following the flowchart when the

EPS indicator does not come on can result in incorrect

diagnosis.

The connector iliustrations show the female terminal

connectors with a single outline and the male terminal

connectors with a double outline.

1. Ouestion the customer about the conditions when

the problem occured, and try to reproduce the

same conditions for troubleshooting. Find out

when the EPS indicator came on, such as while

turning. afterturning, when the vehicle was at a

ce rta in speed, etc.

2. When the EPS indicator does not come on during

the test drive, but troubleshooting is done based on

the DTC, check for loose connectors, poor terminal

contact. etc in the affected circuit, before you start

troubleshooting.

3. After trou bleshooting, clear the DTC and test-drive

the vehicle. Be sure the EPS indicator does not

come on.

How to Retrieve EPS DTCs

Honda PGM Tester Method:

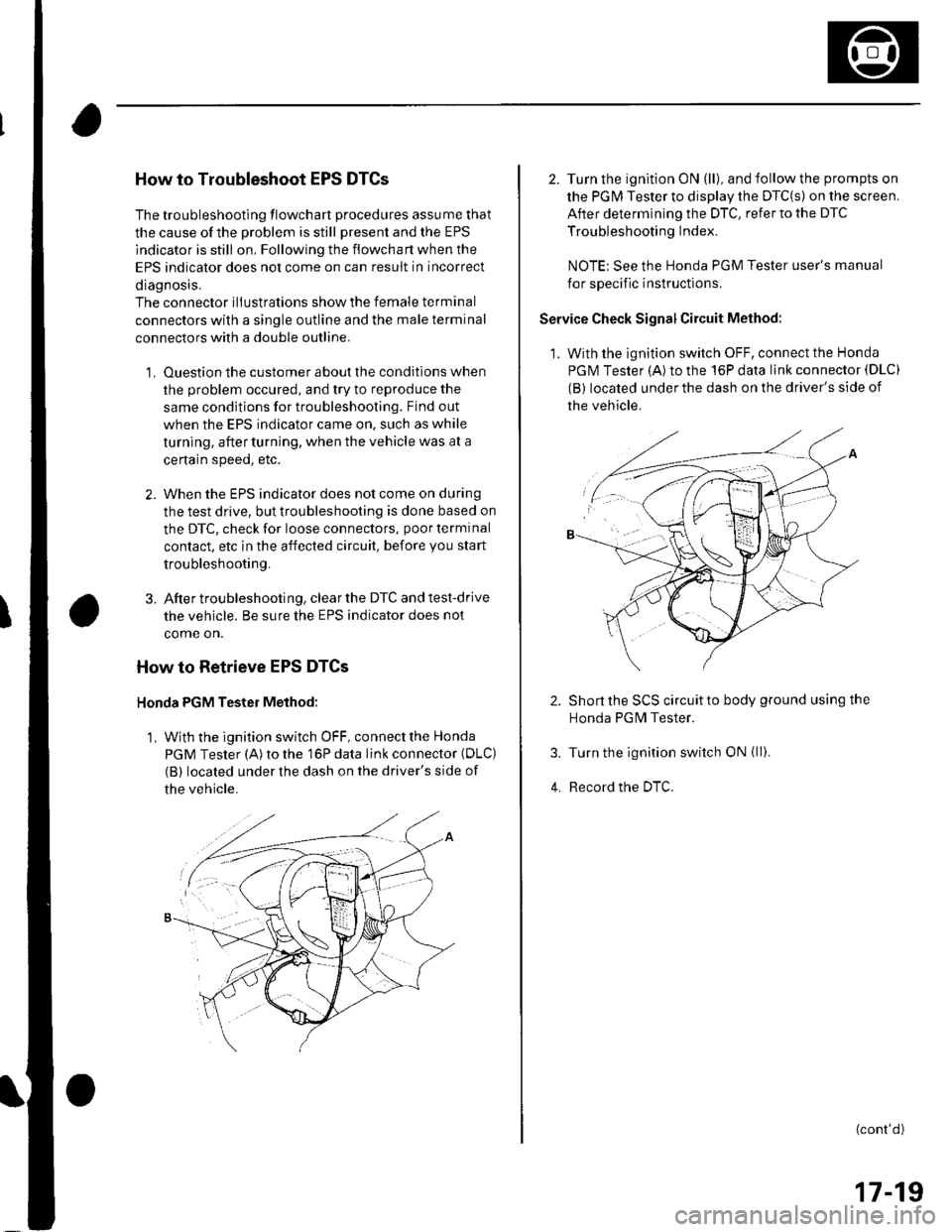

1, With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

2. Turn the ignition ON (ll), and follow the prompts on

the PGM Tester to display the DTC(s) on the screen.

After determining the DTC, refer to the DTC

Troubleshooting Index.

NOTE: See the Honda PGM Tester user's manual

for specific instructions.

Service Check Signal Circuit Method:

1. With the ignition switch OFF, connect the Honda

PGM Tester (A)to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

Short the SCS circuit to body ground using the

Honda PGN4 Tester.

Turn the ignition switch ON {ll).

Record the DTC.

(cont'd)

17-19

Page 511 of 1139

EPS Components

General Troubleshooting Information (cont'dl

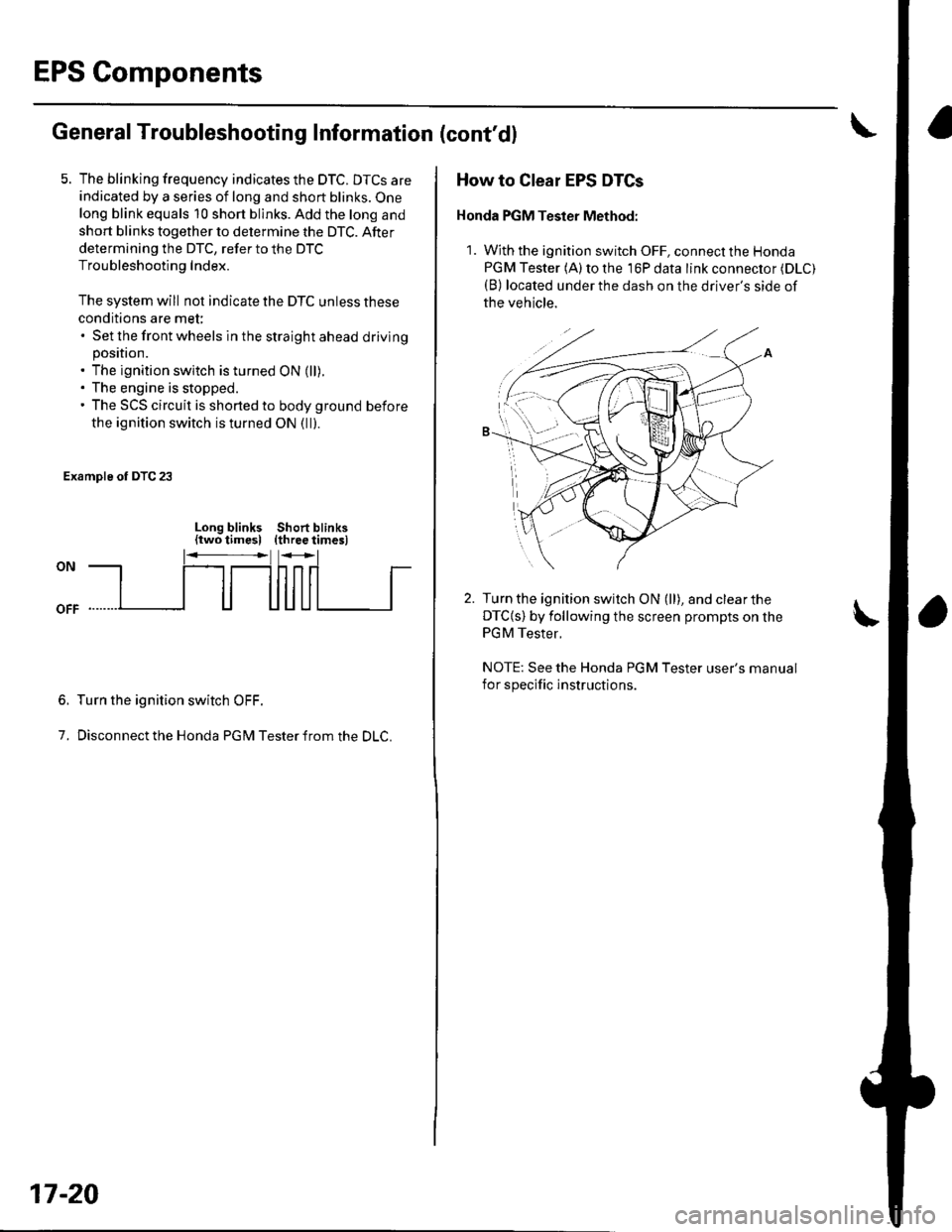

5. The blinking frequency indicates the DTC. DTCS are

indicated by a series of long and short blinks. One

long blink equals 10 short blinks. Add the long and

short blinks together to determine the DTC. After

determining the DTC, refer to the DTC

Troubleshooting Index.

The system will not indicate the DTC unless these

conditions are met:. Set the front wheels in the straight ahead drivingposition.. The ignition switch is turned ON (ll).. The engine is stopped.. The SCS circuit is shorted to body ground before

the ignition switch is turned ON (ll).

Example of DTC 23

Long blinks Short blinks(two times) (three timesl

6.

7.

Turn the ignition switch OFF.

Disconnect the Honda PGM Tester from the DLC.

17-20

How to Clear EPS DTCs

Honda PGM Tesler Method:

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

Turn the ignition switch ON (ll), and clear the

DTC{s) by following the screen prompts on the

PGM Tester.

NOTE: See the Honda PGM Tester user's manual

for specific instructions.

Page 512 of 1139

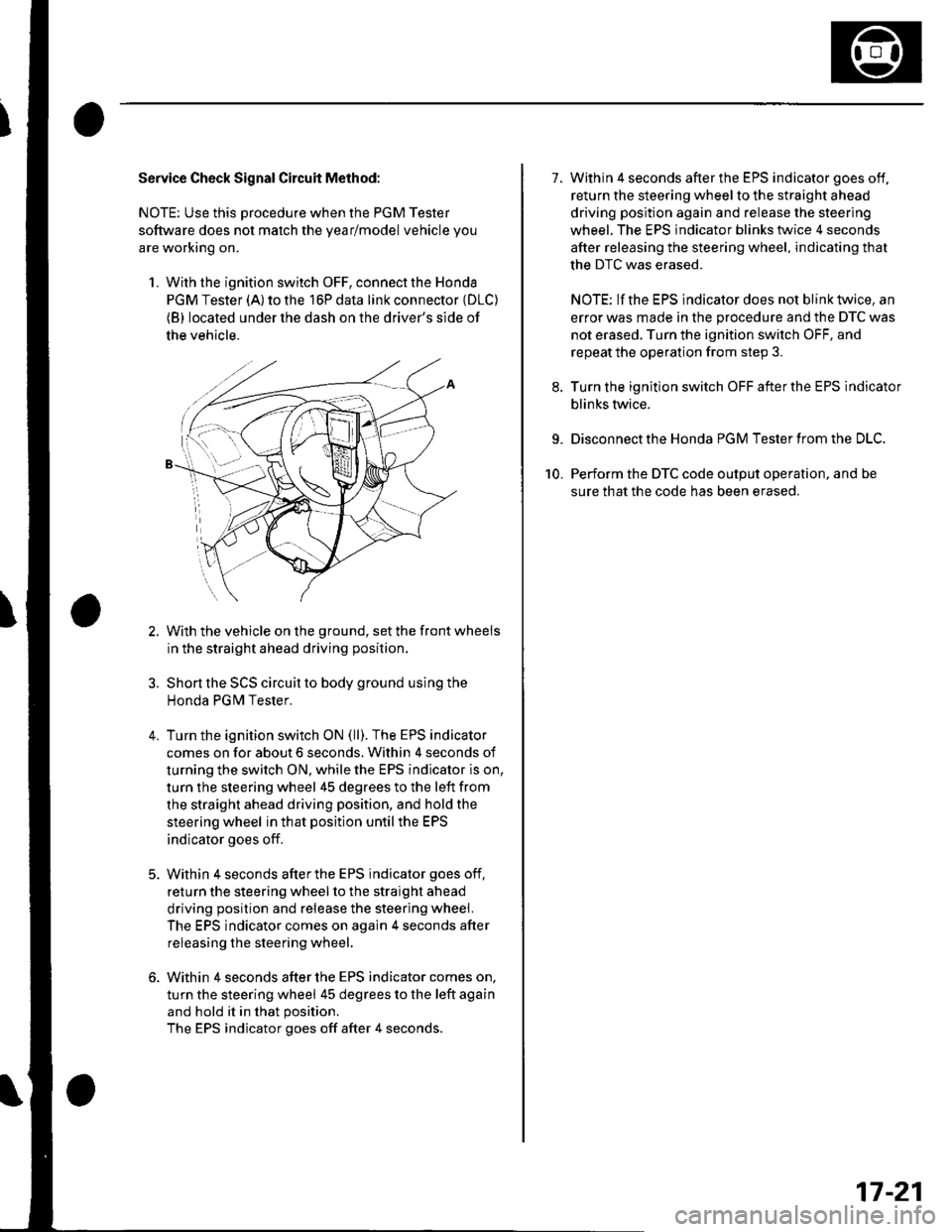

Service Check Signal Circuit Method:

NOTE: Use this procedure when the PGM Tester

software does not match the yearlmodel vehicle you

are working on.

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector {DLC)(B) located under the dash on the driver's side of

the vehicle.

With the vehicle on the ground, set the front wheels

in the straight ahead driving position.

Short the SCS circuit to body ground using the

Honda PGM Tester.

Turn the ignition switch ON (ll). The EPS indicator

comes on for about 6 seconds. Within 4 seconds of

turning the switch ON, while the EPS indicator is on,

turn the steering wheel 45 degrees to the left from

the straight ahead driving position, and hold the

steering wheel in that position until the EPS

indicator goes off.

Within 4 seconds afterthe EPS indicator goes off,

return the steering wheel to the straight ahead

driving position and release the steering wheel.

The EPS indicator comes on again 4 seconds after

releasing the steering wheel,

Within 4 seconds after the EPS indicator comes on,

turn the steering wheel 45 degrees to the left again

and hold it in that position.

The EPS indicator goes off after 4 seconds.

4.

1.Within 4 seconds after the EPS indicator goes off,

return the steering wheel to the straight ahead

driving position again and release the steering

wheel. The EPS indicator blinks twice 4 seconds

after releasing the steering wheel, indicating that

the DTC was erased.

NOTE: If the EPS indicator does not blink twice, an

error was made in the procedure and the DTC was

not erased. Turn the ignition switch OFF, and

repeat the operation from step 3.

Turn the ignition switch OFF afterthe EPS indicator

blinks twice.

9. Disconnect the Honda PGM Tester from the DLC.

10. Perform the DTC code output operation, and be

sure that the code has been erased.

17-21

Page 519 of 1139

EPS Components

DTC Troubleshooting

DTC 12: Torque Sensor T/SIG

1. Clear the DTC.

2. Stan the engine.

3. Wait at least 10 seconds.

Does the EPS indicatot come on?

YES Go to step 4.

NO Check for loose wires or poor connections. lf

the connections are good, the system is OK at this

time.l

4.Stop the engine, and verify the DTC.

ls DTC12 indicated?

YES Go to slep 5.

NO-Perform the appropriate troubleshooting for

the code indicated. t

Make sure the ignition switch is OFF, then

disconnect EPS control unit connector C (20P) and

the torque sensor 6P connector.

Check for continuity between EPS control unit

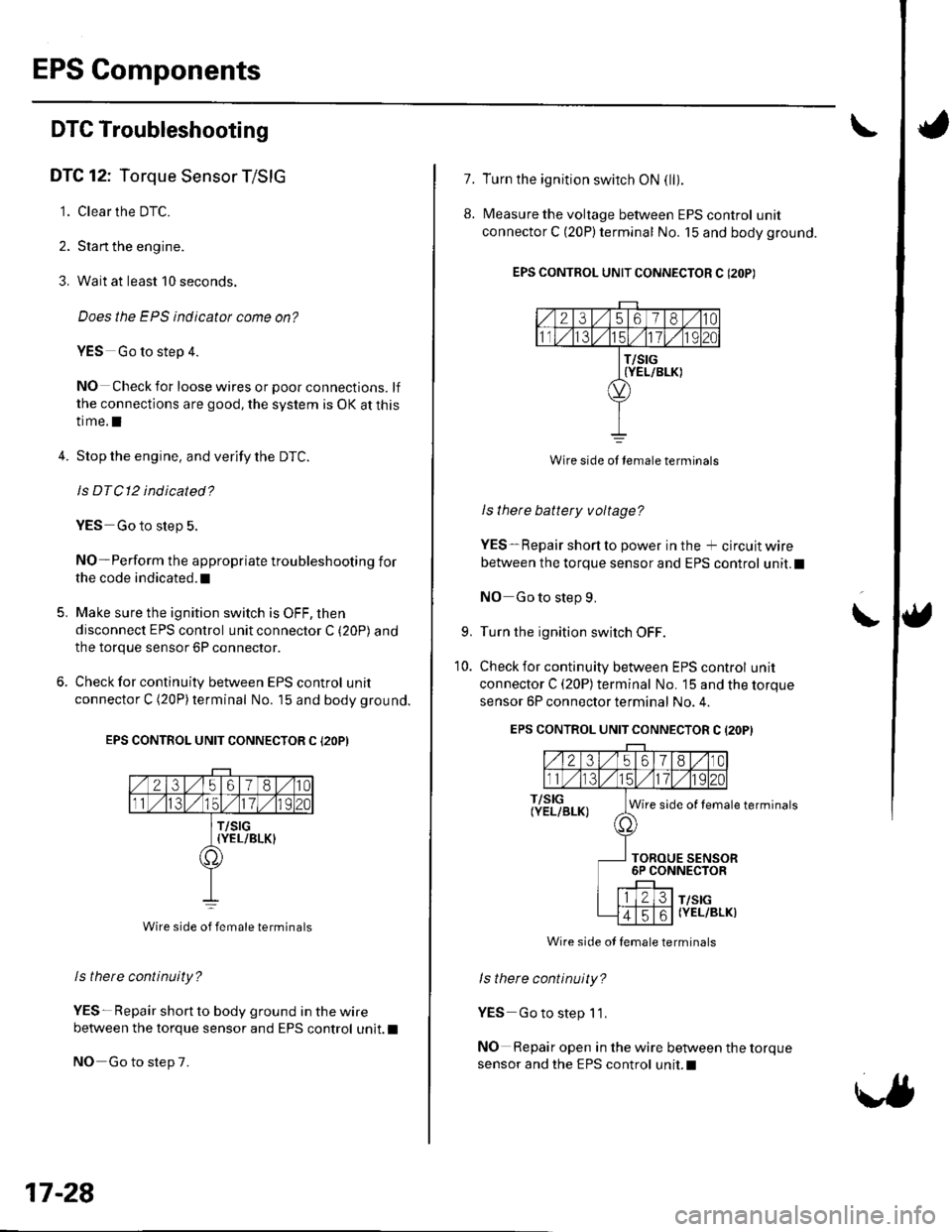

connector C (20P)terminal No. 15 and body ground.

EPS CONTROL UNIT CONNECTOR C {2OP)

Wire side of female terminals

ls there continuity?

YES- Repair short to body ground in the wire

between the torque sensor and EPS control unit.l

NO Go to step 7.

5.

17-28

1.

8.

Turn the ignition switch ON (ll).

Measure the voltage between EPS control unit

connector C (20P)terminal No. 15 and body ground.

EPS CONTROL UNIT CONNECTOR C (2OP)

2356180

T/SIG{YEL/BLK)

Wire side ot lemale terminals

I s there battery v oltage?

YES-Repair short to power in the + circuit wire

between the torque sensor and EPS control unit.l

NO Go to step 9.

Turn the ignition switch OFF.

Check for continuity between EPS control unit

connector C (20P) terminal No. 15 and the torque

sensor 6P connector terminal No. 4.

EPS CONTROL UNIT CONNECTOR C (2OPI

\9.

10.

T/SIG(YEL/BLK)Wire side of female terminals

TOROUE SENSOR6P CONNECTOR

T/SIG(YEL/BLK)

ls there continuity?

YES Go to step 1'1,

NO Repair open in the wire between the torque

sensor and the EPS control unit.I

Wire side ot female terminals

Page 520 of 1139

'I 1.Substitute a known-good EPS control unit, and

connect the all disconnected connectors.

Sta rt the engine.

Does the EPS indicator come on?

YES Go to step 13.

NO Check for loose EPS control unitconnectors. lf

necessary, replace the EPS control unit and

retest.l

Stop the engine, and verify the DTC.

ls DTCl2 indicated?

YES Check for loose torque sensor connectors.

lf necessary, substitute a known-good steering

gearbox and recheck.l

NO-Perform the appropriate troubleshooting for

the code indicated. !

12.

13.

DTC 16: Torque Sensor VT3 and W6

1. Clear the DTC.

2. Start the engine.

3. Wait at least 10 seconds.

Does the EPS indicator come on?

YES Go to step 4.

NO Check for loose wires or poor connnections. lf

the connections are good, the system is OK at this

time.l

4. Stop the engine, and verify the DTC.

ls DTC16 indicated?

YES-Go to step 5.

NO Perform the appropriate troubleshooting for

the code indicated. t

5. Make sure the ignition switch is OFF, then

disconnect EPS control unit connector C (20P) and

the torque sensor 6P connector.

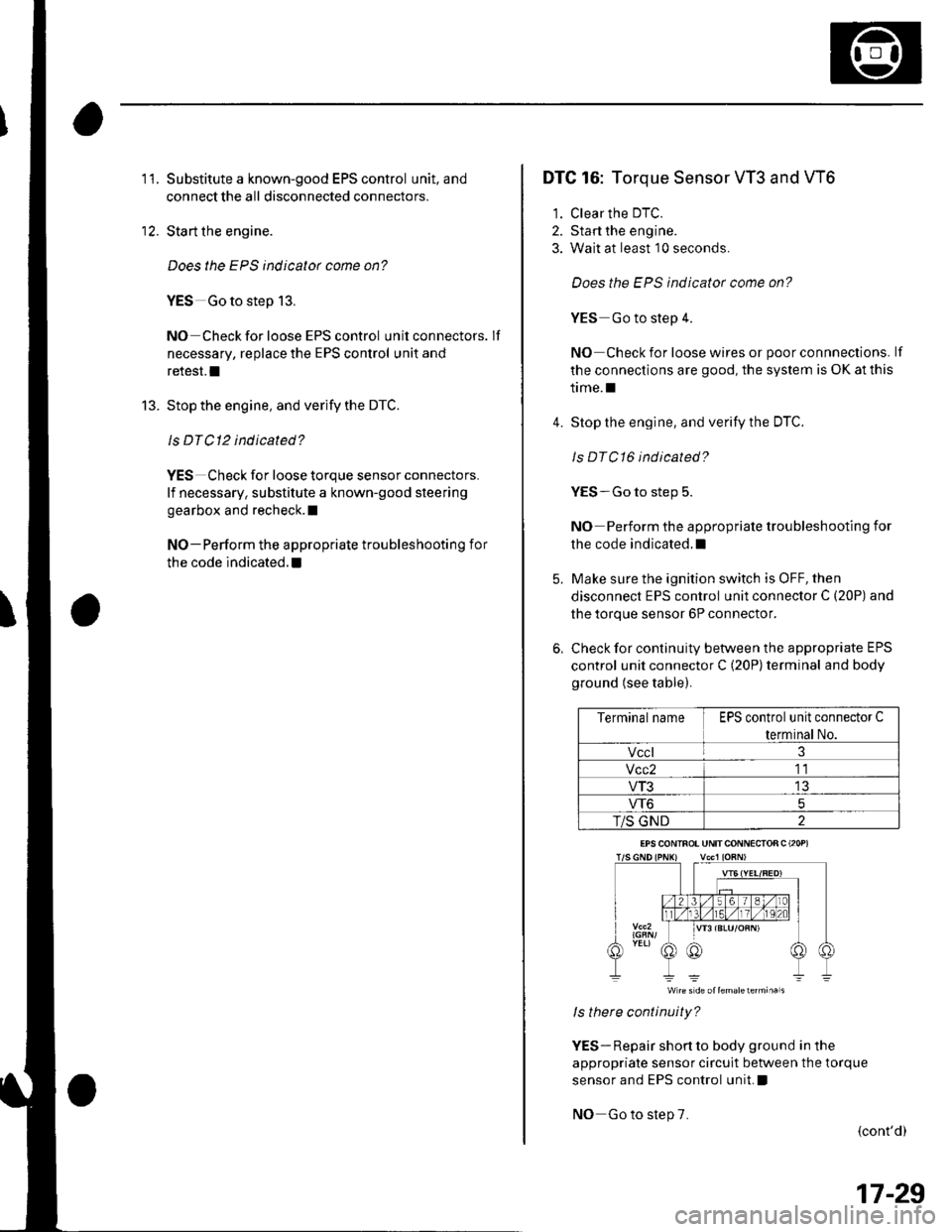

6, Check for continuity between the appropriate EPS

control unit connector C (20P) terminal and body

ground (see table).

Terminal nameEPS control unit connector C

terminal No.

Vccl3

Vcc211

VT313

VT65

T/S GND2

W re s d€ oltemalelermi.als

ls there continuity?

YES- Repair short to body ground in the

appropriate sensor circuit between the torque

sensor and EPS control unit, !

NO Go to step 7.

{cont'd)

EPS CONINOT UNITCONNECIOR C (2OP)

17-29