battery HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 720 of 1139

Dashboard

Dashboard Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations (see page 23-13) and the

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

NOTE:. When prying with a flat-tip screwdriver, wrap it with

protective tape, and apply protective tape around the

related parts to prevent damage.. Have an assistant help you when removing and

installing the dashboa rd.. Take care not to scratch the dashboard, body, and

other related parts.

. Put on gloves to protect your hands.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

Disconnect the negative cable from the battery, and

wait at least three minutes before beginning work.

Remove these items:

. Driver's dashboard lower cover (see page 20-59). Driver's dashboard under cover (see page 20-60). Passenger's dashboard lower cover (see page

20-63). Glove box (see page 20-63). Consoles, front and rear (see page 20-57). Shift lever trim {see page 20-61). Center panel (see page 20-62). Kick panels, both sides (see page 20-50). A-pillar trim. both sides (see page 20-50). Steering column (see page 17-9)

20-66

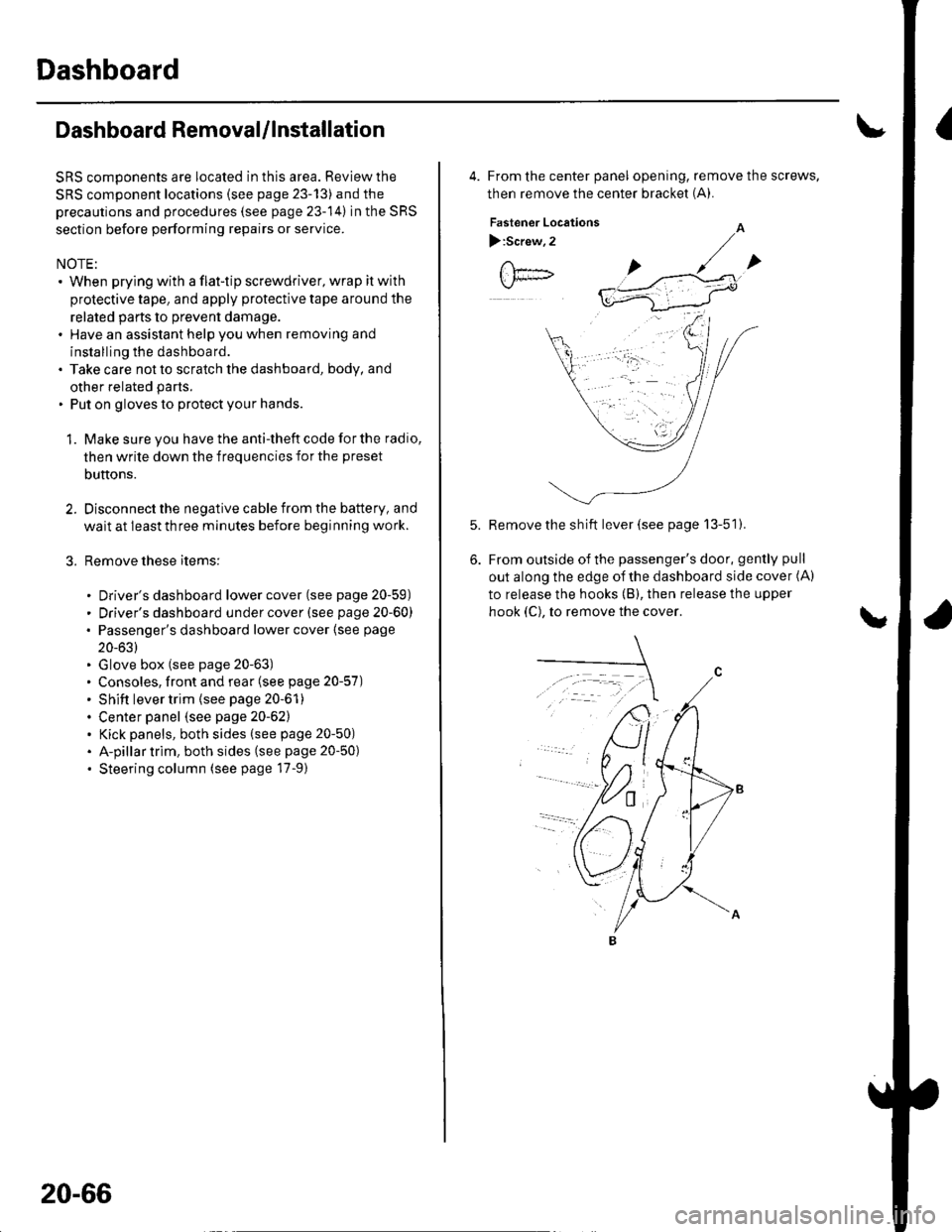

4. From the center panel opening, remove the screws,

then remove the center bracket (A).

Fastener Locations

):Screw,2

Remove the sh ift lever (see page 13-51).

From outside of the passenger's door, gently pull

out along the edge of the dashboard side cover (A)

to release the hooks (B), then release the upper

hook (C), to remove the cover.

Page 722 of 1139

Dashboard

Dashboard Removal/lnstallation

(cont'd)

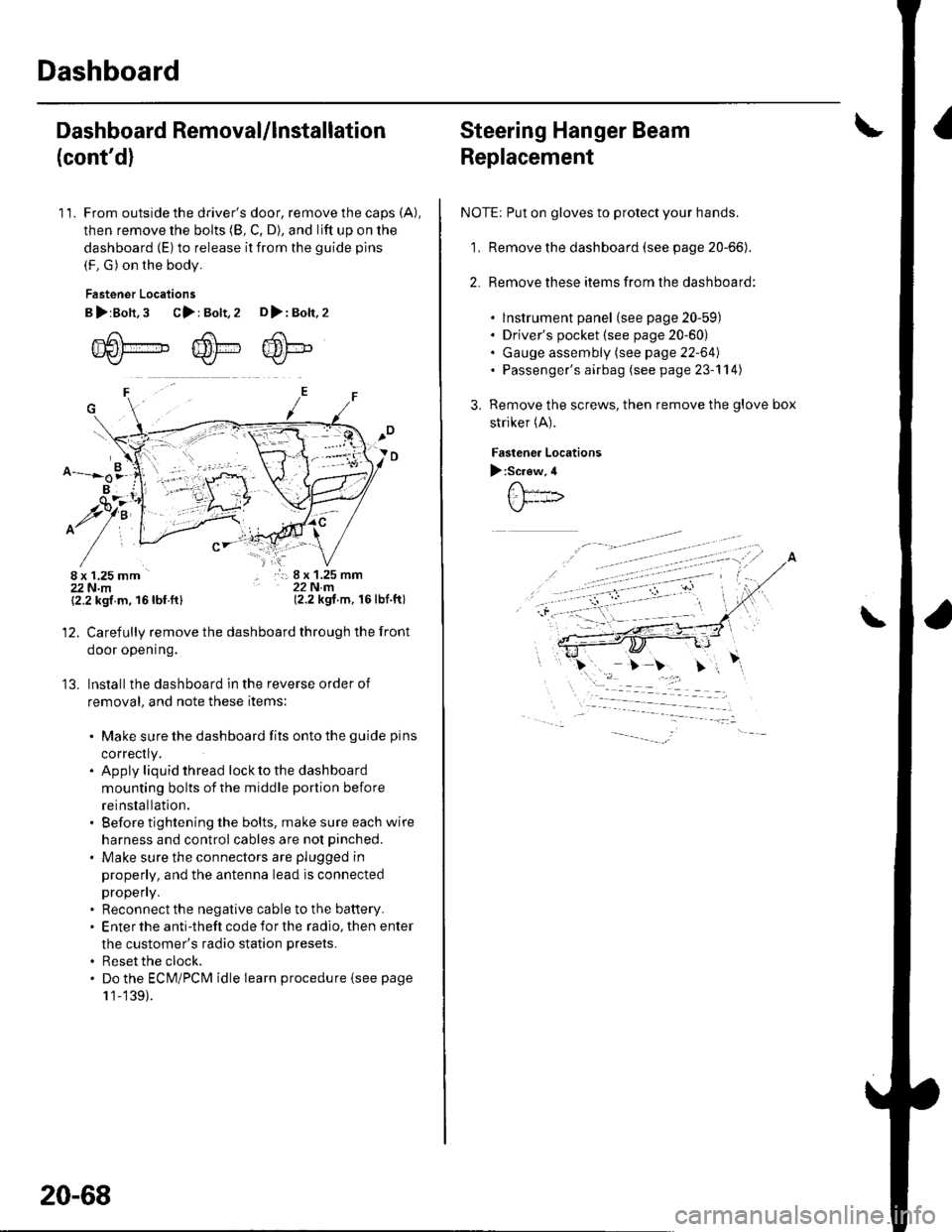

11. From outside the driver's door, remove the caps (A),

then remove the bolts (8, C, D), and lift up on the

dashboard (E) to release it from the guide pins

(F. G) on the body.

Fastener Locations

B>rBolt.3 C>: Bolt,2 D>: Bolt,2

m6[-,,,,",",,-,F6't---'' ffi'!--v{/- Kr* w-

B

$7:

^/761:

/,-,. r:; 8 x 1.25 mm22Nm(2.2 kgf.m, 16lbf.ft)

13.

{2.2 kgf m, 16lbf.ftl

Carefully remove the dashboard through the front

door opening.

lnstall the dashboard in the reverse order of

removal, and note these items:

. Make sure the dashboard fits onto the guide pins

correctly.. Apply liquid thread lock to the dashboard

mounting bolts of the middle portion before

reinstallation.. Before tightening the bolts, make sure each wire

harness and control cables are not pinched.

. Make sure the connectors are plugged in

properly, and the antenna lead is connected

propeny.. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure isee page

1 '1-139).

20-68

Steering Hanger Beam

Replacement

NOTE: Put on gloves to protect your hands.

1, Remove the dashboard (see page 20-66).

2. Remove these items from the dashboard:

. lnstrument panel (see page 20-59). Driver's pocket (see page 20-60). Gauge assembly (see page 22-64). Passenger's airbag (see page 23-'l 14)

Remove the screws, then remove the glove box

striker (A).

Fastenea Locations

):Screw,4

\

Page 725 of 1139

Front Seat Removal/lnstallation

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23-'13) and the precautions and procedures (see page

23-14) in the SRS section before performing repairs or

service.

NOTE. When prying with a flat-tip screwdriver, wrap it with

protective tape to prevent damage.. Take care not to scratch the body or tear the seat

covers.. Put on gloves to protect your hands.

1, Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

butlons.

Disconnect the negative cable from the battery, and

wait at least 3 minutes before beginning work.

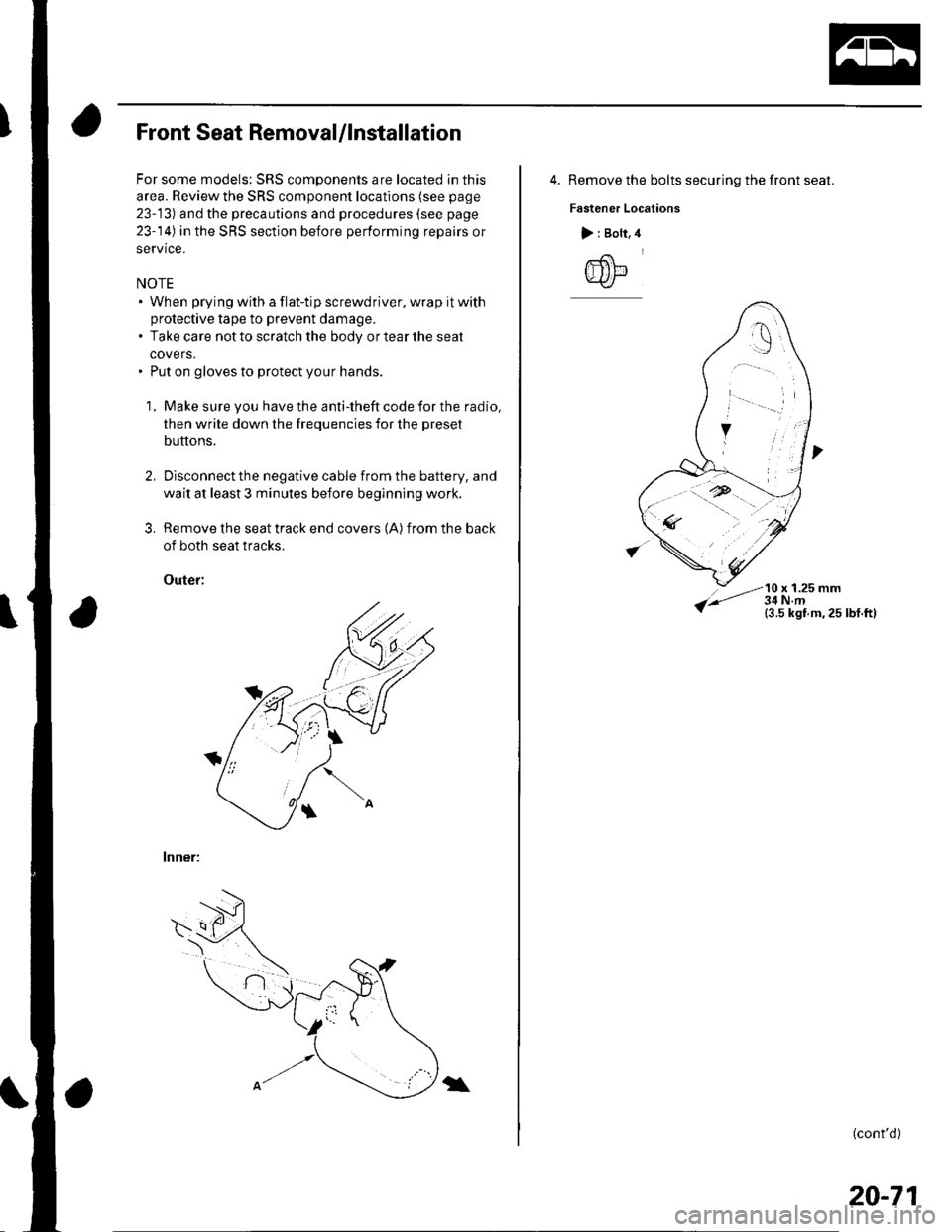

Remove the seat track end covers (A) from the back

of both seat tracks.

Outef:

lnner:

3.

\

4. Remove the bolts securing the front seat.

Fastener Locations

10 x 1.25 mm

> : Bolt,

@

(cont'd)

20-71

Page 726 of 1139

Seats

Front Seat Removal/lnstallation (cont'dl

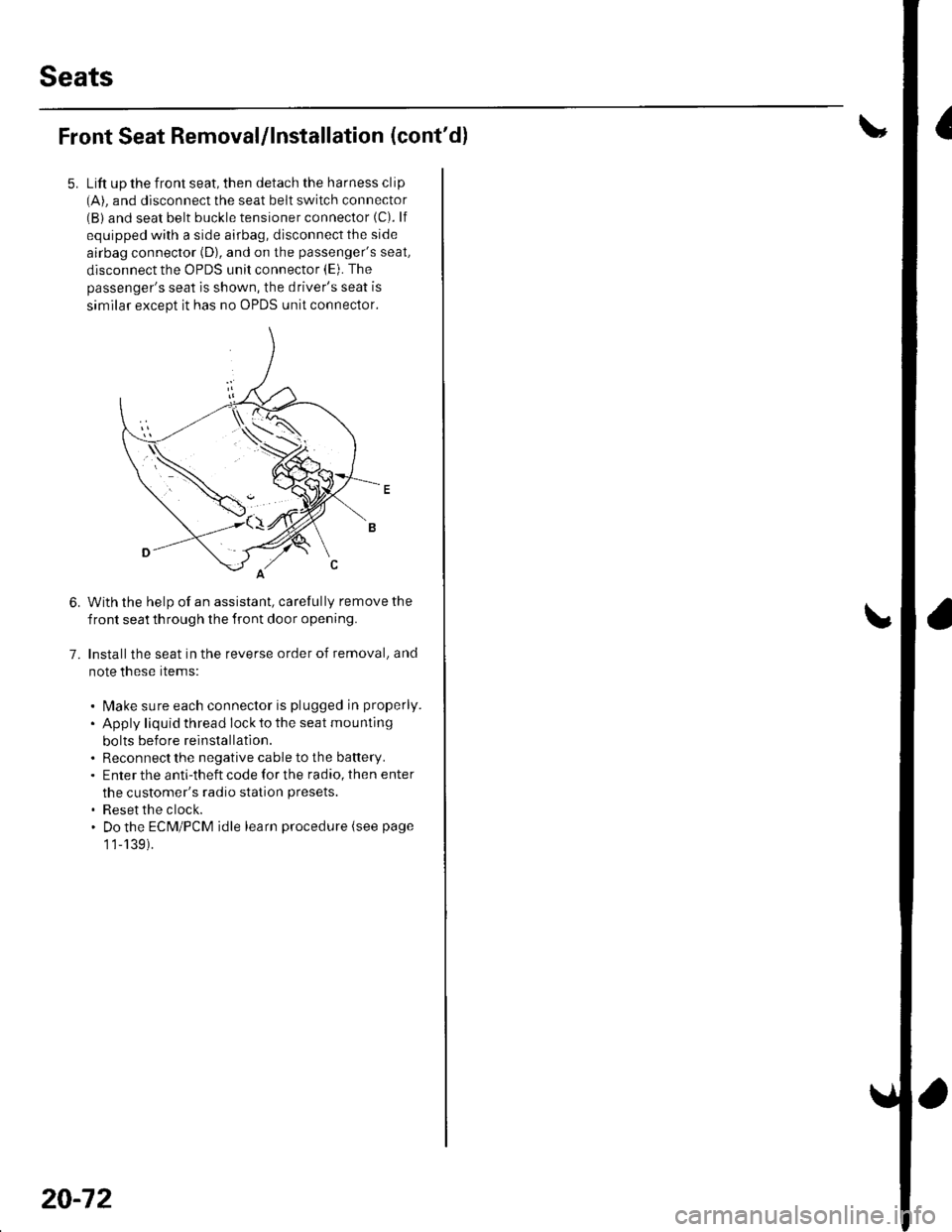

Lift up the front seat, then detach the harness clip(A). and disconnect the seat belt switch connector(B) and seat belt buckle tensioner connector (C). lf

equipped with a side airbag, disconnect the side

airbag connector (D), and on the passenger's seat,

disconnect the OPDS unit connector (E). The

passenger's seat is shown, the driver's seat is

similar except it has no OPDS unit connector.

With the help of an assistant, carefully remove the

front seat th rough the front door opening.

Installthe seat in the reverse order of removal, and

note these rtems:

. l\4ake sure each connector is plugged in properly.

. Apply liquid thread lock to the seat mounting

bolts before reinstallatlon.. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure (see page

1 1-139).

6.

7.

20-72

Page 778 of 1139

Heating and Air Conditioning

A/C Service Tips and Precautions

Compressed air mixed with R- 134a forms a

combustible vapor.

The vapor can burn or explode causing serious

injury.

Never use compressed air to pressure test

R-134a service equipment or vehicle air

conditioning systems.

Air conditioning refrigerant or lubricant vapor

can irritate your eyes, nose, or throat.

Be careful when connecting service equipment.

Do not breathe refrigerant or vapor.

The air conditioning system uses HFC-134a (R-134a)

ref rigerant and polyalkyleneglycol (PAG) ref rigerant oil,

which are not compatible with CFC'12 (R-12) refrigerant

and mineral oil. Do not use R-'12 refrigerant or mineral

oil in this system, and do not aftempt to use R 12

servicing equipment; damage to the air conditioning

system or your servicing equipment will result.

Use only service equipment that is U.L.-listed and is

certified to meet the requirements of SAE J2210 to

remove R-134a from the air conditioning system.

lf accidental system discharge occurs, ventilate the

work area before resuming service.

R-134a service equipment or vehicle air conditioning

systems should not be pressure tested or leak tested

with compressed air.

Additional health and safety information may be

obtained from the refrigerant and lubricant

manufacturers.

. Always disconnect the negative cable from the

battery whenever replacing air conditioning parts.

. Keep moisture and dirt out of the system. When

disconnecting any lines, plug or cap the fittings

immediately; don't remove the caps or plugs until

iust be{ore you reconnect each line.' Before connecting any hose or line, apply a few drops

of relrigerant oil to the O-ring.. When tightening or loosening a fitting, use a second

wrench to support the matching fitting.. When discharging the system, use a R-'134a

ref rigerant recovery/recycling/charging station; don't

release refrigerant into the atmosphere.

21-6

A: 130 m0 {4 l/3 tl.oz,4.6 lmp.oz)

],^

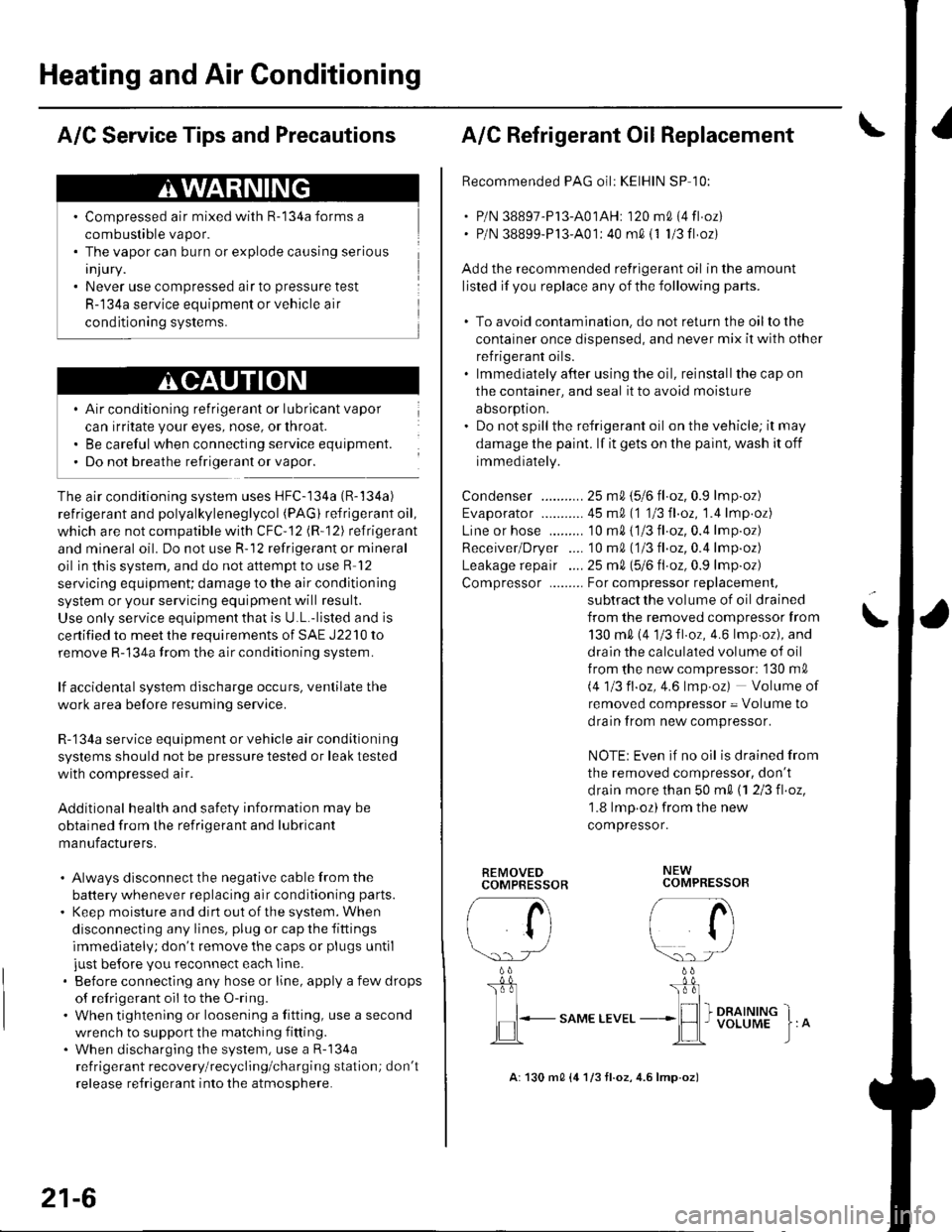

A/C Refrigerant Oll Replacement

Recommended PAG oil: KEIHIN SP 10:

. P/N 38897-P l3-A01AH: '120 m0 i4 fl oz). P/N 38899-P13'A01: 40 m0 i1 1/3 fl oz)

Add the recommended refrigerant oil in the amount

listed if you replace any of the following parts.

. To avoid contamination. do not return the oilto the

container once dispensed, and never mix it with other

refrigerant oils.. lmmediately af'ter using the oil, reinstallthe cap on

the container, and seal it to avoid moisture

aosorpron.. Donotspill the refrigerant oil on the vehicle; it may

damage the paint. lf it gets on the paint, wash it off

immediately.

Condenser ...........25 mA \516 tl.oz, 0.9 lmp.oz)

Evaporator ........... 45 m0 (1 113Il.oz, '1.4 lmp.oz)

Line or hose ......... '10 m0 {1/3 fl.oz,0.4 lmp.oz)

Receiver/Dryer .... '10 m0 ('113 fl.oz,0.4 lmp.oz)

Leakage repai r .... 25 m0, 1516 Il oz, 0.9 lmp.oz)

Compressor ......... For compressor replacemenl,

subtract the volume of oil drained

from the removed compressor from

130 m0 (4 1/3fl.oz, 4.6lmp.oz), and

drain the calculated volume of oil

f rom the new compressor: '130 m0

i.4113 fl.oz,4.6 lmp.oz) Volume of

removed compressor = Volume to

drain from new compressor.

NOTE: Even if no oil is drained from

the removed compressor, don't

d rain more than 50 m0 \1 2/3 fl.oz,'1.8 lmp oz)from the new

compressor.

\

REMOVEDCOMPBESSOR

rA

li

\.. rJ

b

I

,lEL.-

"o*t ttu"

NEWCOMPRESSOR

/- a\i tl

r/

\:)-) -/

_ 0L'r:l_

I I I DRAINING_*lH I voLUME

Page 792 of 1139

1a

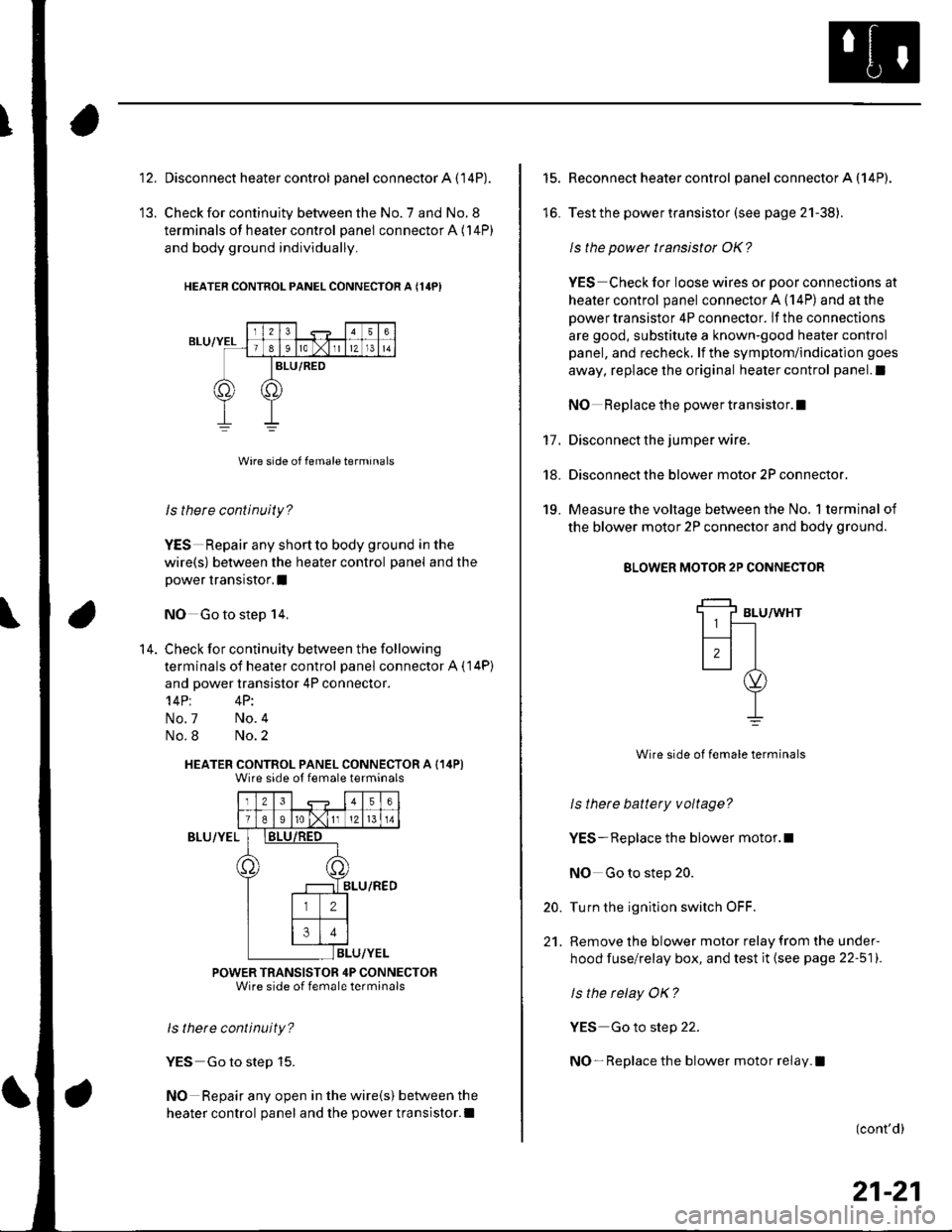

13.

Disconnect heater control panel connector A (14P).

Check for continuity between the No. 7 and No. 8

terminals of heater control panel connector A (14P)

and body ground individually.

HEATER CONTNOL PANEL CONNECTOR A {14PI

ls there continuity?

YES Repair any shortto body ground in the

wire(s) between the heater control panel and the

power transistor.I

NO Go to step 14,

Check for continuity between the following

terminals of heater control panel connector A ( 14P)

and power transistor 4P connector.'l4Pt 4P:

No.7 No.4

No.8 No.2

HEATER CONTROL PANEL CONNECTOR A (14P)Wire side ot female terminals

Iz341516

T89ro lxlI12l 13 l 14

)8LU/RED

ILU/YEL

POWER TRANSISTOR 4P CONNECTORWire side of female terminals

ls thete continuity?

YES Go to step 15.

NO Repair any open in the wire(s) between the

heater control panel and the power transistor.l

14.

BLU/YEL

15.

lo.

17.

18.

19.

Reconnect heater control panel connector A (14P).

Test the power transistor (see page 21-38).

ls the power transistor OK?

YES Check for loose wires or poor connections at

heater control panel connector A (14P) and at the

power transistor 4P connector. lf the connections

are good, substitute a known-good heater control

panel, and recheck. lf the symptom/indication goes

away, replace the original heater control panel.l

NO Replace the power transistor.I

Disconnect the jumper wire.

Disconnect the blower motor 2P connector.

Measure the voltage between the No, 1 terminal of

the blower motor 2P connector and body ground.

BLOWER MOTOR 2P CONNECTOR

BLU/WHT

Wire side of female terminals

ls thete battery voltage?

YES- Replace the blower motor.l

NO Go to step 20.

Turn the ignition switch OFF.

Remove the blower motor relay from the under-

hood fuse/relay box, and test it (see page 22-511.

ls the relay OK?

YES Go to step 22.

NO- Replace the blower motor relay.l

20.

21.

(cont'd)

21-21

Page 793 of 1139

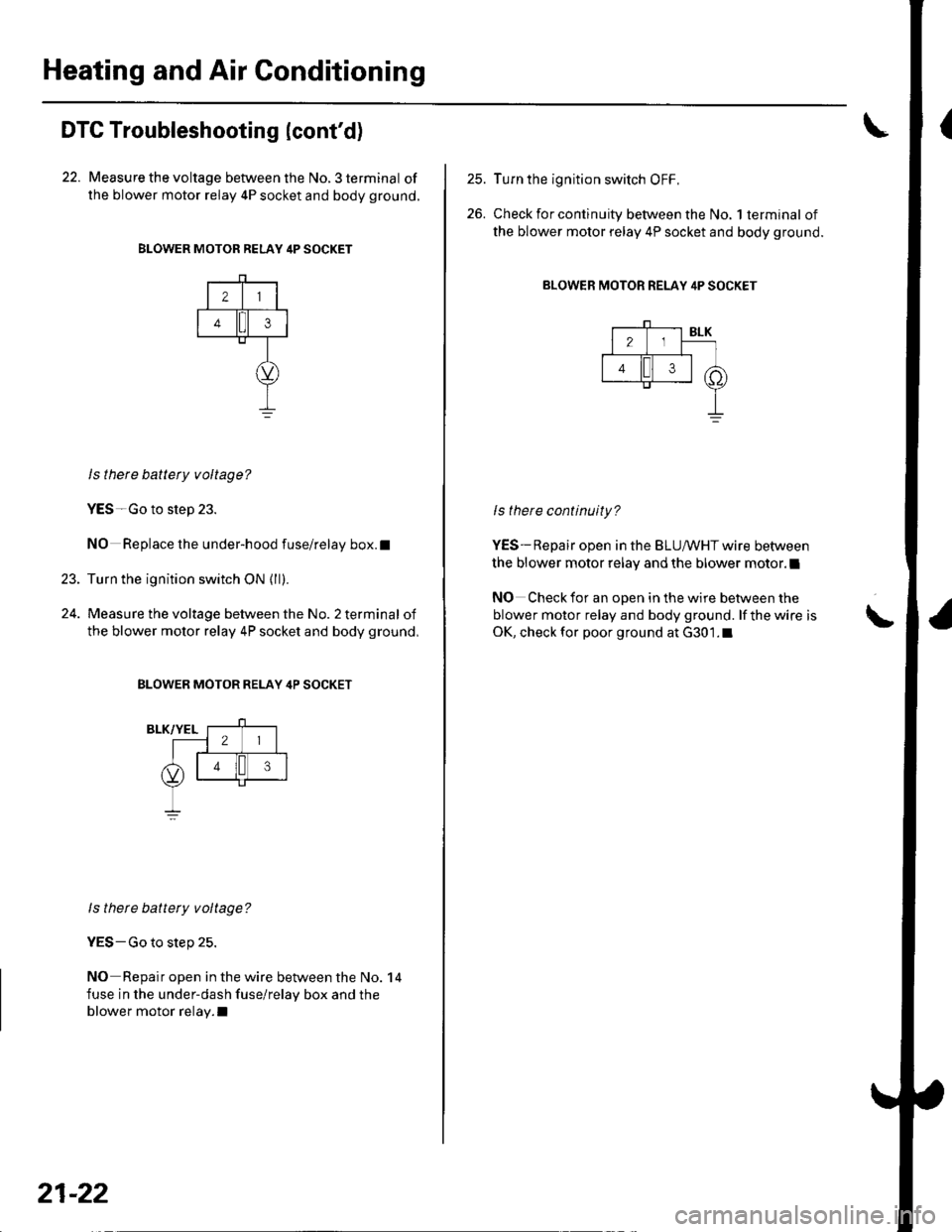

Heating and Air Conditioning

DTC Troubleshooting lcont'd)

22. Measure the voltage between the No. 3 terminal of

the blower motor relay 4P socket and body ground.

BLOWER MOTOR RELAY 4P SOCKET

21

43

23.

ls there battety voltage?

YES-Go to step 23.

NO Replace the under-hood fuse/relay box.t

Turn the ignition switch ON {ll).

Measure the voltage between the No. 2 terminal of

the blower motor relay 4P socket and body ground,

BLOWER MOTOR RELAY 4P SOCKET

ls there battery voltage?

YES-Go to step 25.

NO Repair open in the wire between the No. 14

fuse in the under-dash fuse/relay box and the

blower motor relay.I

21-22

25.

26.

Turn the ignition switch OFF,

Check for continuity between the No. 1 terminal of

the blower motor relay 4P socket and body ground.

BLOWER MOTOR RELAY 4P SOCKET

ls there continuity?

YES-Repair open in the BLUIr'/HT wire between

the blower motor relay and the blower motor.l

NO Check for an open in the wire between the

blower motor relay and body ground. lf the wire is

OK, check for poor ground at G301.1\

Page 796 of 1139

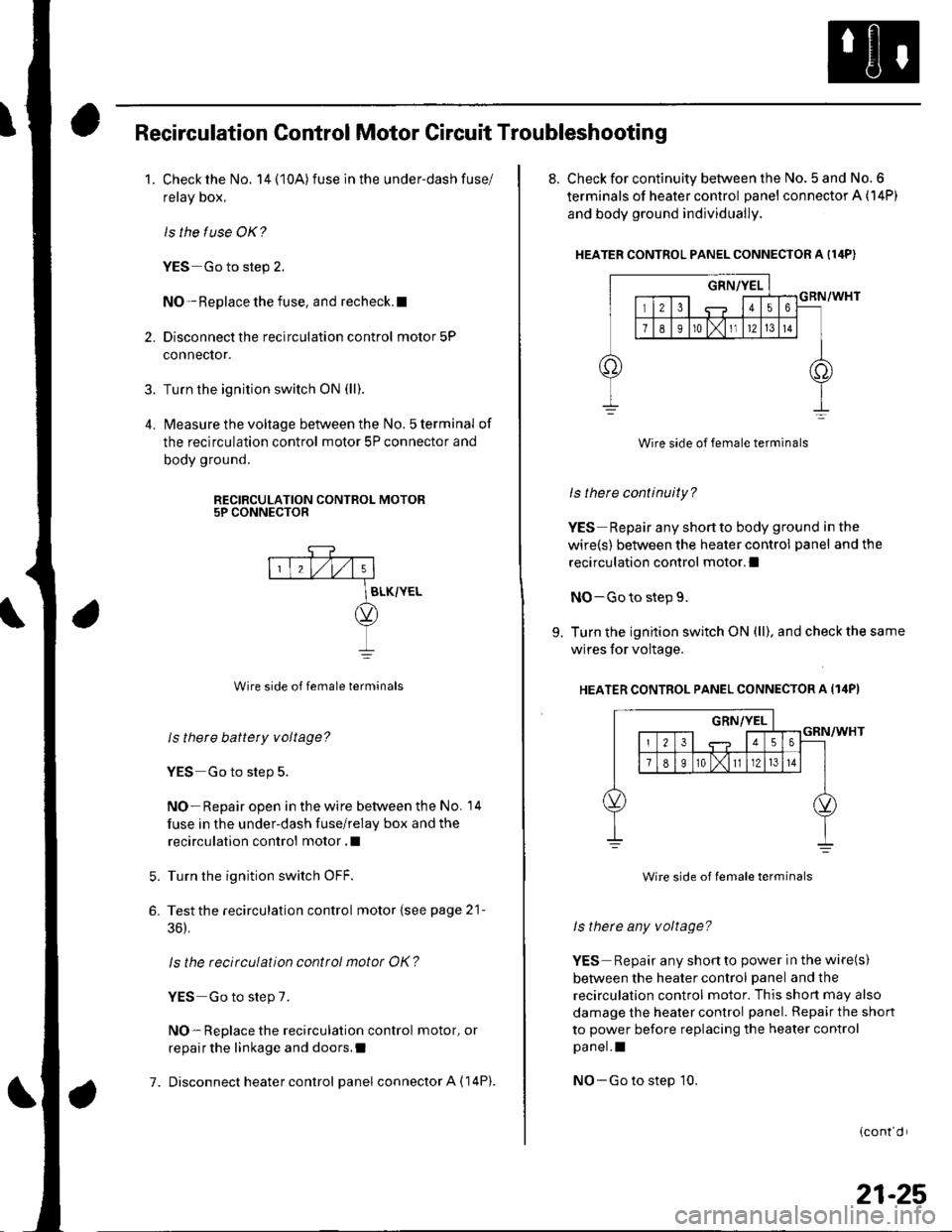

3.

Recirculation Control Motor Circuit Troubleshooting

1. Check the No. 14('10A)fuse inthe under-dashfuse/

relay box.

ls the f use OK?

YES Go to step 2.

NO- Replace the fuse, and recheck.l

2. Disconnect the recirculation control motor 5P

conneclor.

Turn the ignition switch ON (ll).

lvleasure the voltage between the No. 5 terminal of

the recirculation control motor 5P connector and

body ground.

RECIRCULATION CONTROL MOTOR5P CONNECTOR

7.

Wire side of female terminals

ls there battery voltage?

YES Go to step 5.

NO- Repair open in the wire between the No. 14

fuse in the under-dash fuse/relay box and the

recirculation control motor .l

Turn the ignition switch OFF.

Testthe recirculation control motor {see page 21-

36),

ls the recirculation control motor OK?

YES Go to step 7.

NO- Replace the recirculation control motor, or

repair the linkage and doors.I

Disconnect heater control panel connector A (14P).

5.

6.

8. Check for continuity between the No. 5 and No. 6

terminals of heater control panel connector A (14P)

and body ground individually.

HEATER CONTROL PANEL CONNECTOR A I14P)

Wire side of female terminals

ls there continuity?

YES Repair any shortto body ground in the

wire(s) between the heater control panel and the

recirculation control motor.l

NO-Go to step 9.

9. Turn the ignition switch ON (ll), and check the same

wires for voltage.

HEATER CONTROL PANEL CONNECTOR A Il4PI

Wire side of lemale terminals

ls therc any voltage?

YES Repair any shonto power in the wire(s)

between the heater control panel and the

recirculation control motor. This shon may also

damage the heater control panel. Repair the shon

to power before replacing the heater control

pa nel. I

NO-Go to step 10.

{cont d r

21-25

Page 798 of 1139

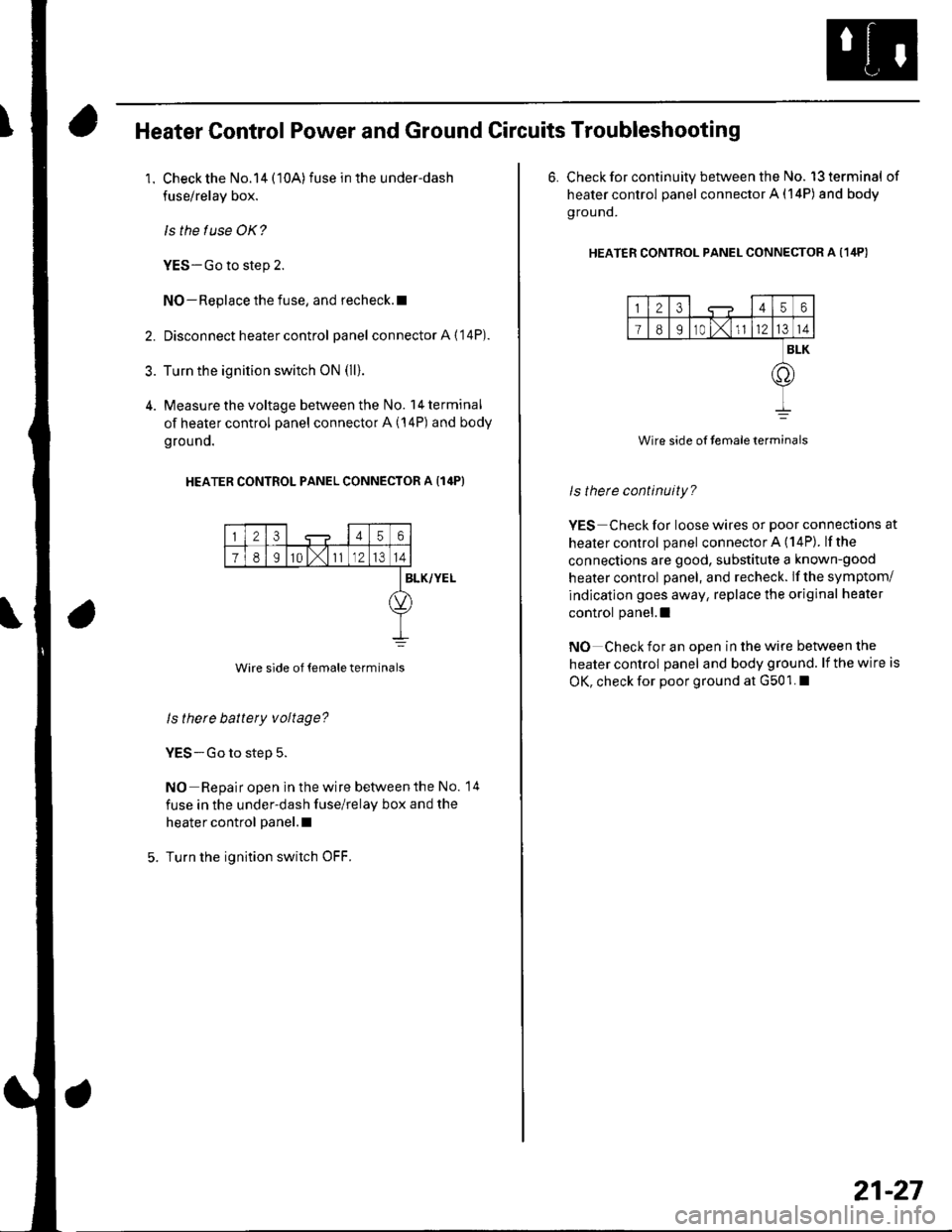

Heater Control Power and Ground Circuits Troubleshooting

1. Check the No.14 (10A)fuse in the under-dash

fuse/relay box.

ls the f use OK?

YES-Go to step 2.

NO-Replace the fuse, and recheck.l

2. Disconnect heater control panel connectorA{'14P).

3. Turn the ignition switch oN (ll).

4. Measure the voltage between the No. l4terminal

of heater control panel connector A (14P) and body

grouno.

HEATER CONTROL PANEL CONNECTOR A {14P}

23456

78I10 l,111214

Wire side of temale terminals

BLK/YEL

ls there battery voltage?

YES-Go to step 5.

NO Repair open in the wire betvveen the No. 14

fuse in the under-dash fuse/relay box and the

heater control panel.l

Turn the ignition switch OFF.

6. Check for continuity between the No. l3terminal of

heater control panel connector A (14P) and body

g rou nd.

HEATER CONTRoL PANEL CONNEcToR A (1ilP)

123456

I89r0 t,1l1214

BLK

.o

Wire side of temaleterminals

ls therc continuity?

YES Check for loose wires or poor connections at

healer control panel connector A (14P). lfthe

connections are good, substitute a known-good

heater control panel, and recheck. lf the symptom/

indication goes away, replace the original heater

control panel.l

NO Check for an open in the wire between the

heater control panel and body ground. lf the wire is

OK, check for poor ground at G501. I

21-27

Page 799 of 1139

Heating and Air Conditioning

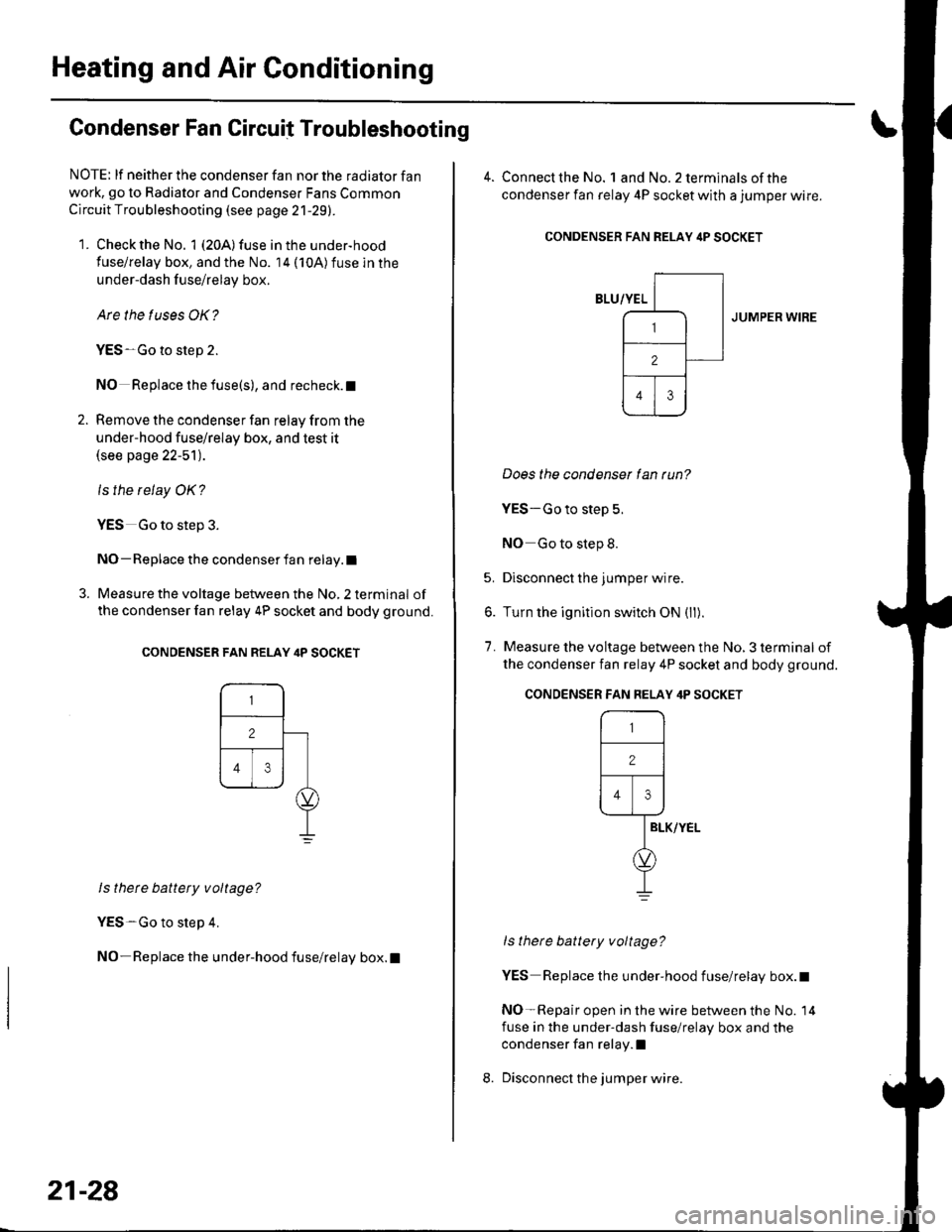

Condenser Fan Circuit Troubleshooting

NOTE: lf neither the condenser fan nor the radiator fan

work, go to Radiator and Condenser Fans Common

Circuit Troubleshooting (see page 21-29).

1. Check the No. 1 (20A) fuse in the under-hood

fuse/relay box, and the No. 14 (10A)fuse in the

under-dash f use/relay box.

Are the tuses OK?

YES-Go to step 2.

NO Replace the fuse(s), and recheck. t

2. Remove the condenser fan relay from the

under-hood fuse/relay box, and test it(see page 22-51).

ls the relay OK?

YES Go to step 3.

NO- Replace the condenser fan relay.l

3. Measure the voltage between the No, 2 terminal of

the condenser fan relay 4P socket and body ground.

CONDENSER FAN RELAY ilP SOCKET

ls thete battery voltage?

YES-Go to step 4.

NO-Replace the under-hood fuse/relay box.l

21-28

4. Connect the No. landNo.2terminalsof the

condenser fan relay 4P socket with a jumper wire.

CONDENSER FAN RELAY itP SOCKET

JUMPER WIRE

Does the condenser lan tun?

YES-Go to step 5.

NO Go to step 8.

5. Disconnect the jumper wire.

6. Turn the ignition switch ON (ll).

7. Measure the voltage between the No, 3 terminal of

the condenser fan relay 4P socket and body ground.

ls there battery voltage?

YES Replace the under-hood fuse/relay box.t

NO-Repair open in the wire between the No. 14

fuse in the under-dash fuse/relay box and the

condenser fan relay.l

Disconnect the jumper wire.

CONDENSER FAN FELAY 4P SOCKET

r-,_-l

12 |

Flr\----1--rl

IELK/YEL

d,

I