valve HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 391 of 1139

EVAP System

DTC Troubleshooting (cont'dl

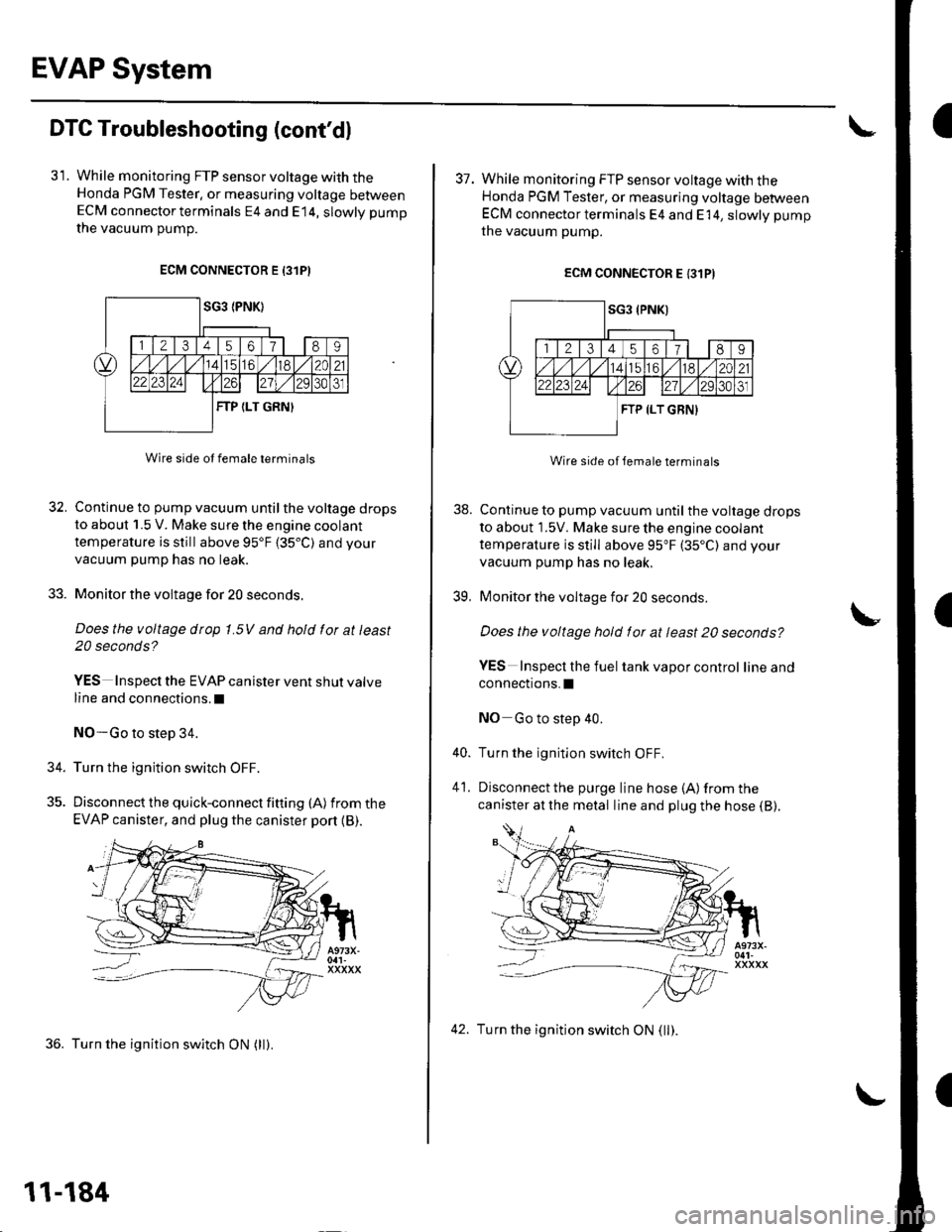

31. While monitoring FTP sensor voltage with theHonda PGM Tester, or measuring voltage betweenECM connector terminals E4 and E14, slowly pump

the vacuum oumD.

ECM CONNECTOR E 13lPI

Wire side ot female terminals

32. Continue to pump vacuum until the voltage drops

to about 1.5 V. Make sure the engine coolant

temperature is still above 95'F 135.C) and your

vacuum pump has no leak.

33. Monitor the voltage for 20 seconds.

Does the voltage drop 1.5V and hold for at least

20 seconds?

YES Inspect the EVAP canister vent shut valve

line and connections.l

NO-Go to step 34.

34. Turn the ignition switch OFF.

35. Discon nect the quick-con nect fitting (A) fromthe

EVAP canister, and plug the canister port {B).

36. Turn the ignition switch ON (ll).

11-184

42. Turn the ignition switch ON (ll).

I

38.

39.

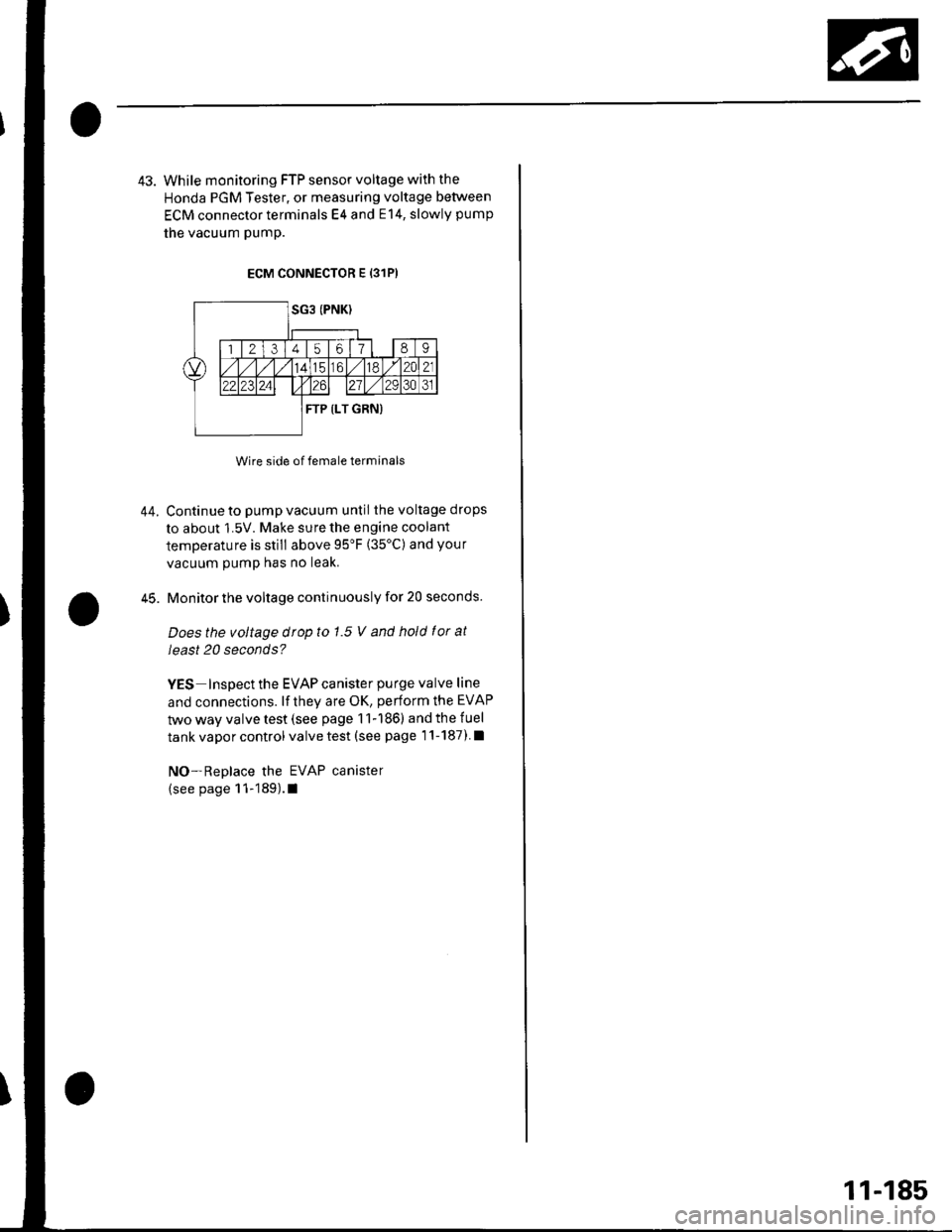

37. While monitoring FTP sensor voltage with theHonda PGM Tester, or measuring voltage betweenECM connector terminals E4 and E 14, slowly pump

the vacuum pump.

ECM CONNECTOR E {31PI

Wire side of lemale terminals

Continue to pump vacuum until the voltage drops

to about 1.5V. Make sure the engine coolant

temperature is still above 95"F (35"C) and your

vacuum pump has no leak.

Monitor the voltage for 20 seconds

Does the voltage hold for at least 20 seconds?

YES Inspecl the fuel tank vapor control lineand

connections.I

NO Go to step 40.

Turn the ignition switch OFF.

Disconnect the purge line hose {A) from the

canister at the metal line and plug the hose (B).

40.

41.

Page 392 of 1139

43. While monitoring FTP sensor voltage with the

Honda PGM Tester, or measuring voltage between

ECM connector terminals E4 and E14, slowly pump

the vacuum pump.

ECM CONNECTOR E {31P)

Wire side of female terminals

Continue to pump vacuum until the voltage drops

to about 1.5V. Make sure the engine coolant

temperature is still above 95'F (35'C) and your

vacuum pump has no leak.

Monitor the voltage continuously for 20 seconds.

Does the voltage drop to 1.5 V and hold f or at

least 20 seconds?

YES Inspect the EVAP canister purge valve line

and connections. lf they are OK, perform the EVAP

two way valve test (see page 11-186) and the fuel

tank vapor control valve test (see page 1'l-187) l

NO-Replace the EVAP canister

(see page 11-189).1

44.

45.

11-185

Page 393 of 1139

EVAP System

EVAP Two Way Valve Test

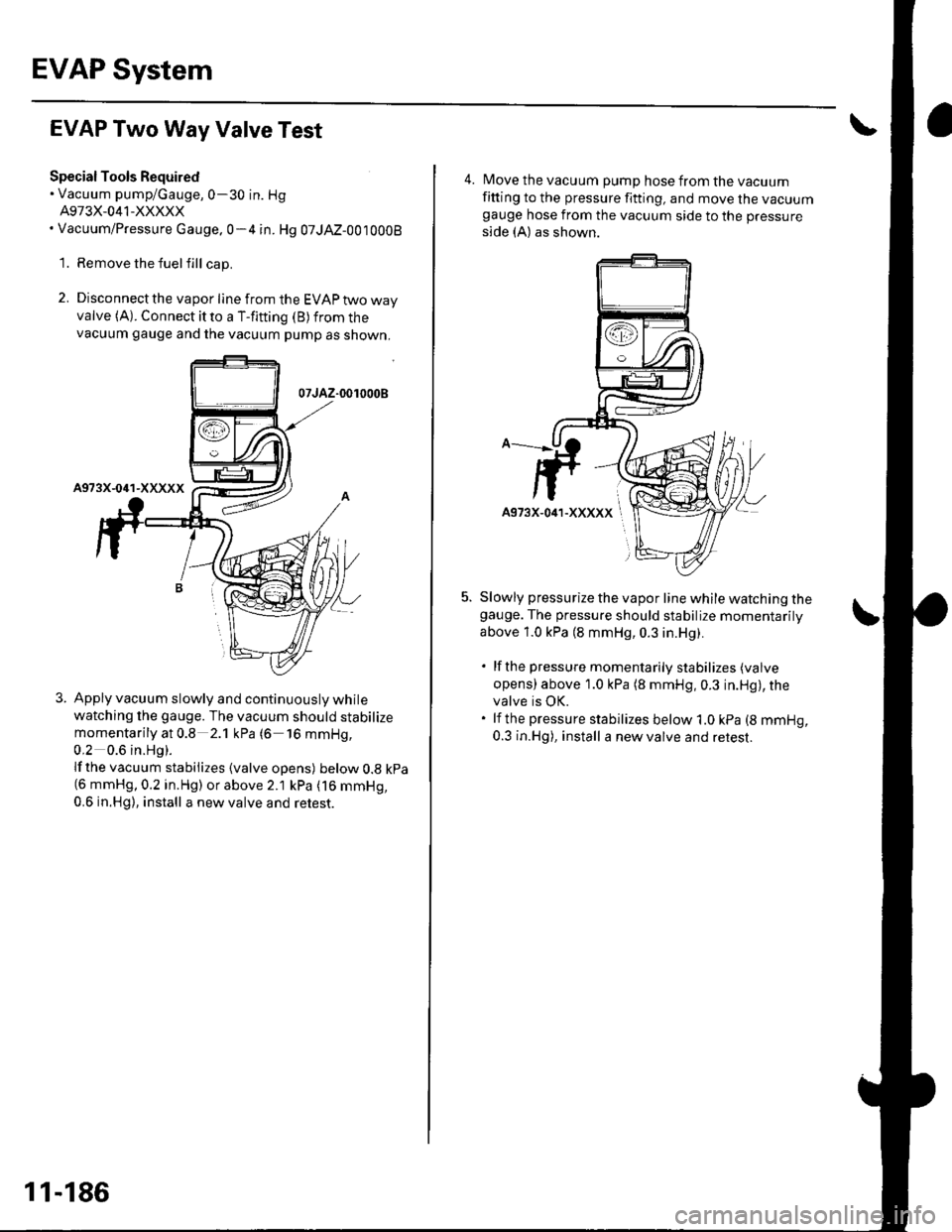

Special Tools Required. Vacuum pump/Gauge,0-30 in. Hg

A973X-041-XXXXX. Vacuum/Pressure cauge.0-4 in. Hg 07JAZ-0010008

1. Remove the fuelfill cap.

2. Disconnect the vapor line from the EVAP two wayvalve (A). Connect it to a T-fitting (B) from thevacuum gauge and the vacuum pump as shown,

07JAZ-0010008

Apply vacuum slowly and continuously while

watching the gauge. The vacuum should stabilize

momentarily at 0.8 2.1 kPa (6 16 mmHg,

0,2 0.6 in.Hg).

lf the vacuum stabilizes {valve opens) below 0.8 kpa(6 mmHg,0.2 in.Hg) or above 2.1 kPa (16 mmHg,

0.6 in.Hg), install a new valve and retest.

11-186

4. Move the vacuum pump hose from the vacuumfitting to the pressure fitting, and move the vacuumgauge hose from the vacuum side to the pressure

side (A) as shown.

Slowly pressurize the vapor line while watching thegauge. The pressure should stabilize momentarilV

above 1.0 kPa (8 mmHg, 0.3 in.Hg).

. lfthe pressure momentarily stabilizes (valve

opens) above 1.0 kPa (8 mmHg,0.3 in.Hg), thevalve is OK.. lf the pressure stabilizes below 1.0 kPa (8 mmHg,

0.3 in.Hg), install a new valve and retest.

Page 394 of 1139

FuelTank Vapor Control Valve Test

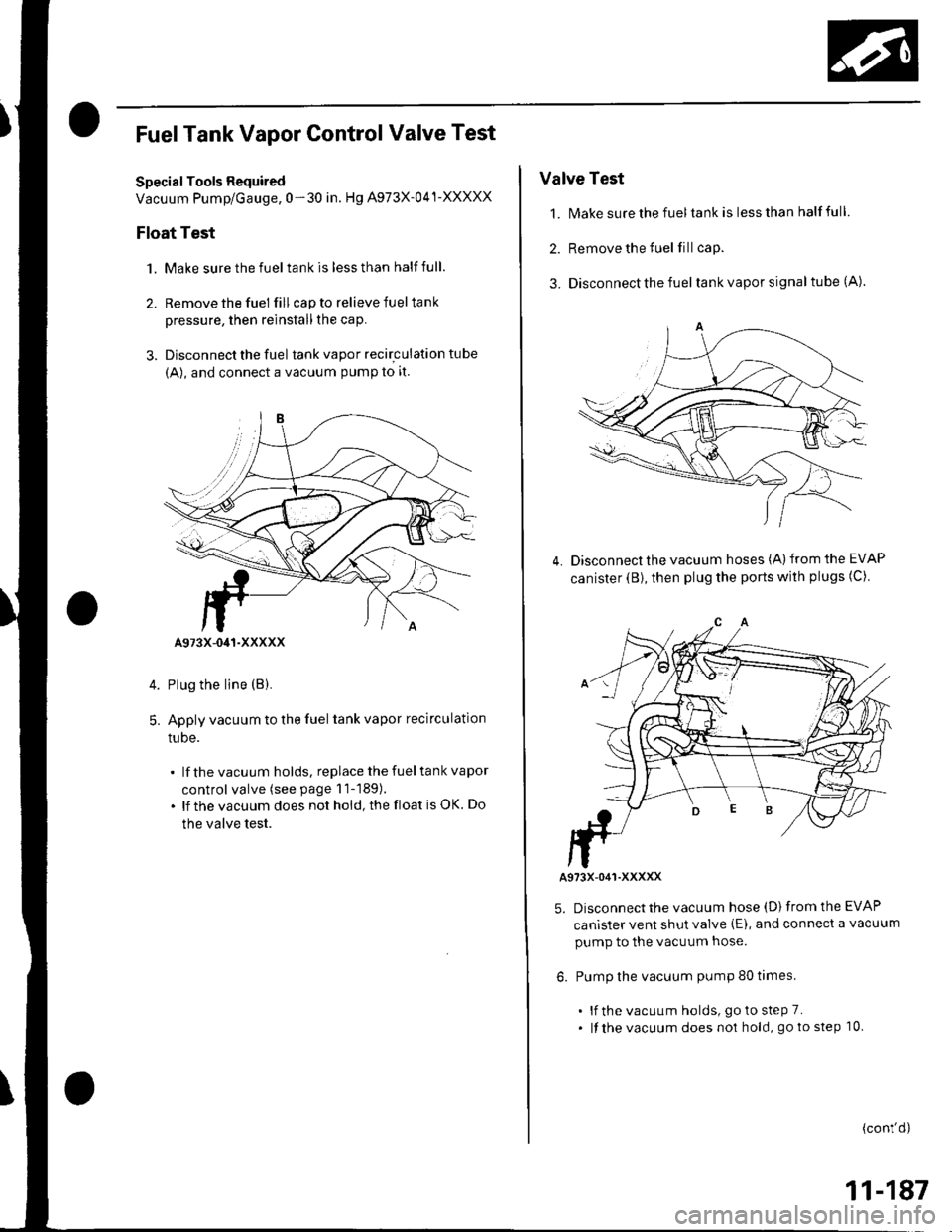

Special Tools Required

Vacuum Pump/Gauge, 0-30 in. Hg A973X-041-XXXXX

Float Test

1. Make sure the fuel tank is less than half full.

2. Remove the fuel fill cap to relieve fuel tank

pressure, then reinstall the cap.

3. Disconnect the fuel tank vapor recirculation tube

{A), and connect a vacuum PumP to it.

Plug the line (B).

Apply vacuum to the fuel tank vapor recirculation

tuDe.

lf the vacuum holds, replace the fuel tank vapor

control valve (see page 11-189).

lf the vacuum does not hold, the float is OK. Do

the valve test.

5.

A973X-041-XXXXX

Valve Test

1. N4ake sure the fuel tank is less than half full

2. Remove the fuel fill cap.

3. Disconnect the fuel tank vapor signal tube (A).

Disconnect the vacuum hoses (A) from the EVAP

canister (B), then plug the ports with plugs (C)4.

A973X-O41-XXXXX

5. Disconnect the vacuum hose (D) from the EVAP

canister vent shut valve (E), and connect a vacuum

pump to the vacuum hose.

6. Pump the vacuum pump 80 times.

. lf the vacuum holds, goto steP 7.. lf the vacuum does no1 hold, go to step 10.

(cont'd)

11-187

Page 395 of 1139

EVAP System

FuelTank Vapor ControlValve Test (cont'd)

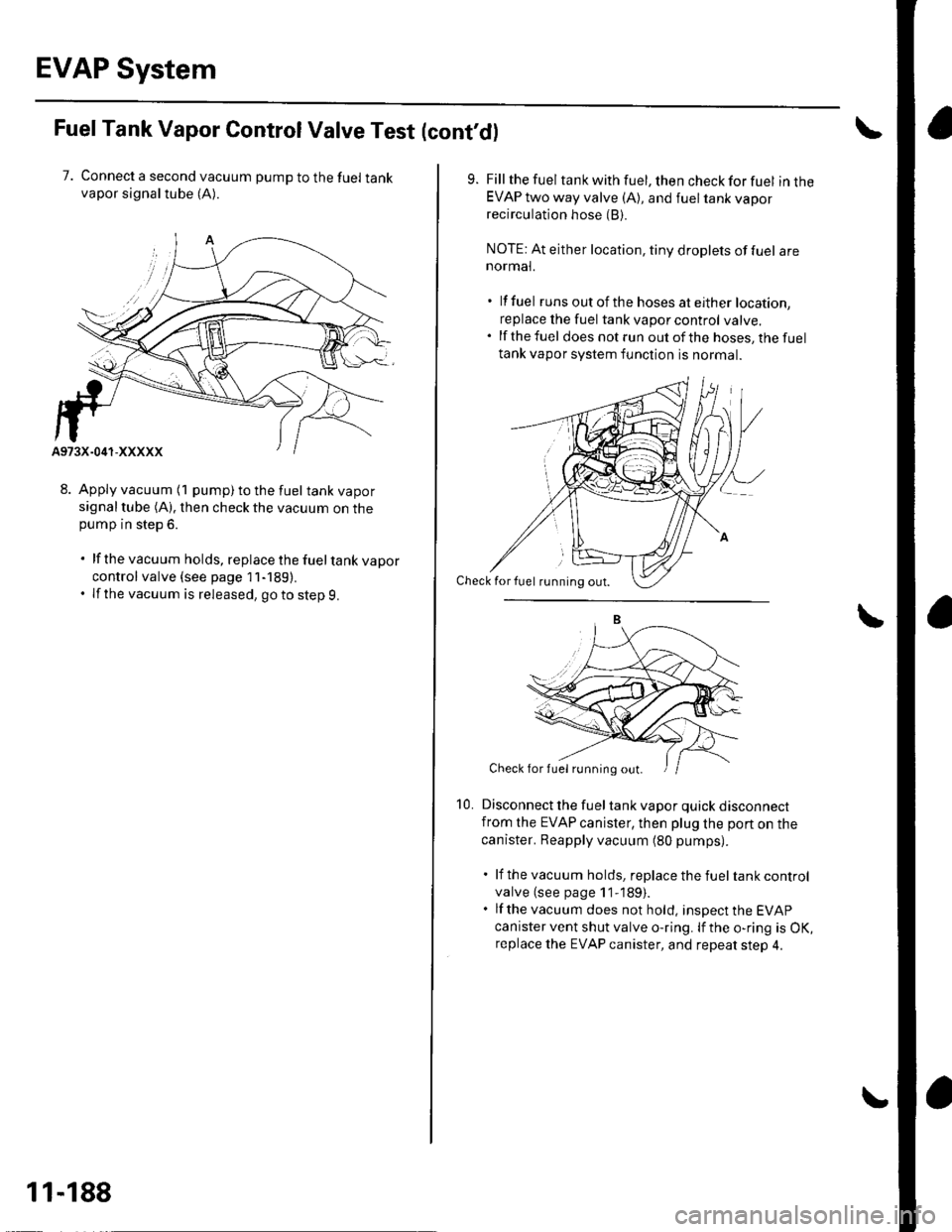

7. Connect a second vacuum pump to the fuel tankvapor signaltube (A).

8. Apply vacuum (1 pump) to the fuel tank vaporsignal tube (A). then check the vacuum on thepump in step 6.

. lf the vacuum holds, replace the fueltank vapor

control valve {see page 11-189).. If the vacuum is released, goto step 9.

11-188

10.

Fill the fuel tank with fuel, then check for fuel in theEVAP two way valve (A), and fuel tank vaporrecirculation hose (B).

NOTE: At either location, tiny droplets of fuel arenormal.

. lf fuel runs out of th e hoses at either location,

replace the fuel tank vapor control valve..lfthefuel does not run out of the hoses, the fuel

tank vapor system function is normal.

Disconnect the fuel tank vapor quick disconnectfrom the EVAP canister, then plug lhe port on the

canister. Reapply vacuum (80 pumps).

. lf the vacuum holds, replace the fuel tank control

valve (see page 1 1-189).. lf the vacuum does not hold, insDect the EVAP

canister vent shut valve o-ring. lf the o-ring is OK,replace the EVAP canister, and repeat step 4.

Check for fuel rirnning out.

Check for fuel running out.

Page 396 of 1139

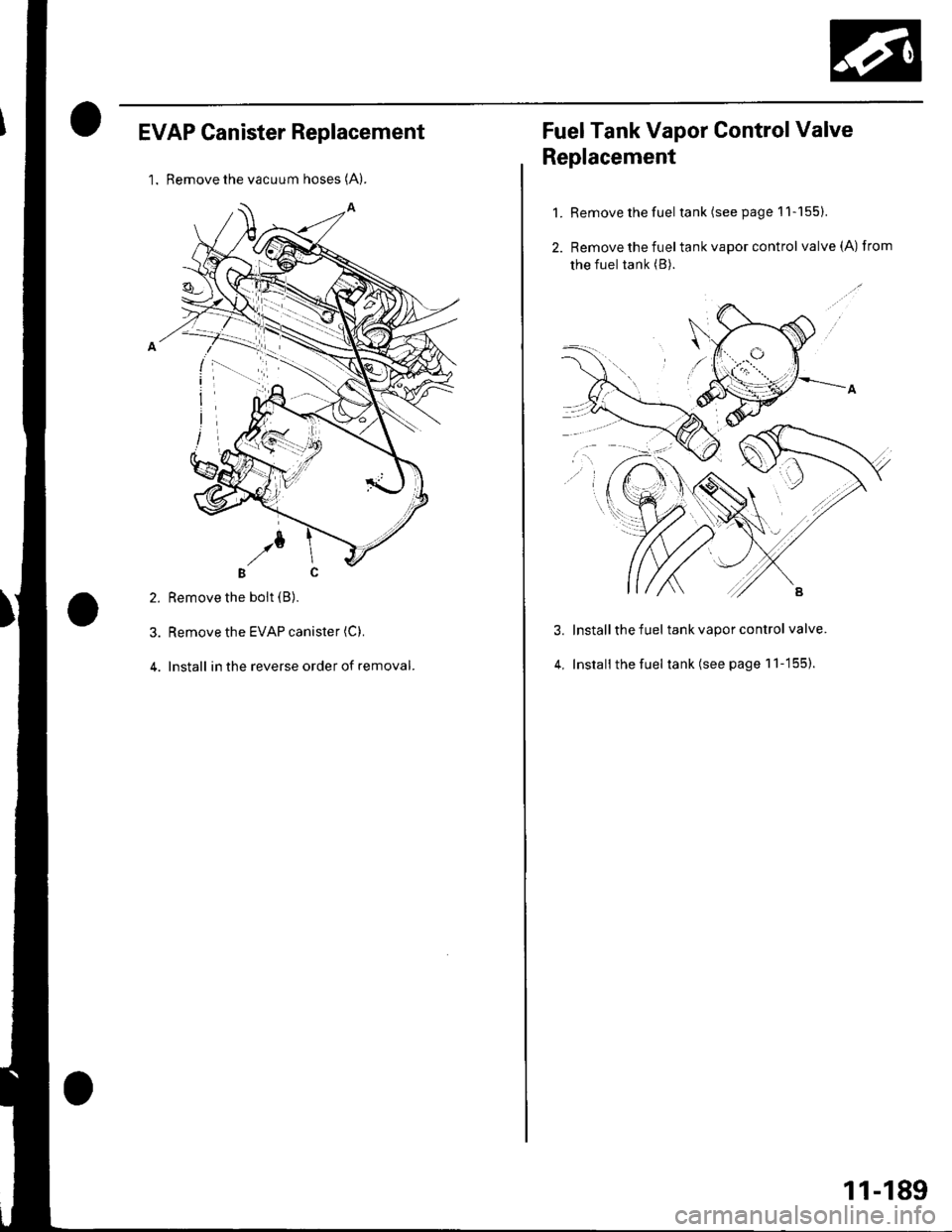

EVAP Canister Replacement

l. Remove the vacuum hoses (A).

2. Remove the boit (B).

3. Remove the EVAP canister (C).

4. Install in the reverse order of removal.

Fuel Tank Vapor Control Valve

Replacement

1. Remove the fuel tank(seepagell-155).

2. Remove the fueltank vapor control valve(A) from

the fuel tank (B).

Install the fuel tank vapor control valve.

Install the fuel tank (see page 1 'l -155).

3.

4,

11-189

Page 543 of 1139

EPS Components

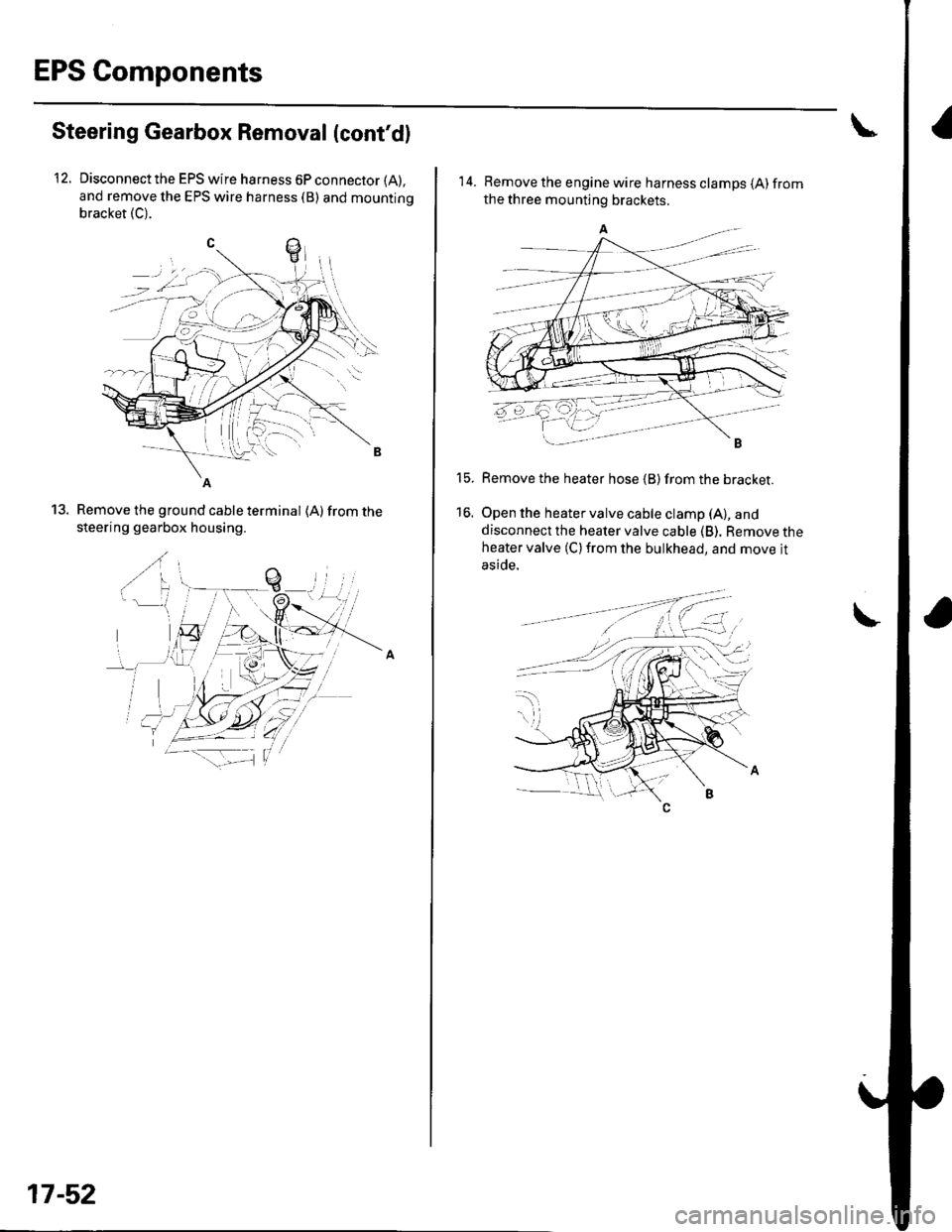

Steering Gearbox Removal (cont'd)

Disconnect the EPS wire harness 6P connector (A),

and remove the EPS wire harness (B) and mountino

bracket (C).

12.

Remove the ground cable terminal (A) from the

steering gearbox housing.

..(

.,/ a

b-H\

ry T,-.lt'^ \

'" \--

13.

_-1..1.-'

-a--zii F--_1

17-52

14. Remove the engine wire harness clamps {A)fromthe three mounting brackets.

Remove the heater hose {B) from the bracket.

Open the heater valve cable clamp (A), and

disconnect the heater valve cable (B). Remove theheater valve (C) from the bulkhead, and move jt

aside.

t5.

16.

I

Page 555 of 1139

EPS Components

Steering Gearbox Installation (cont'd)

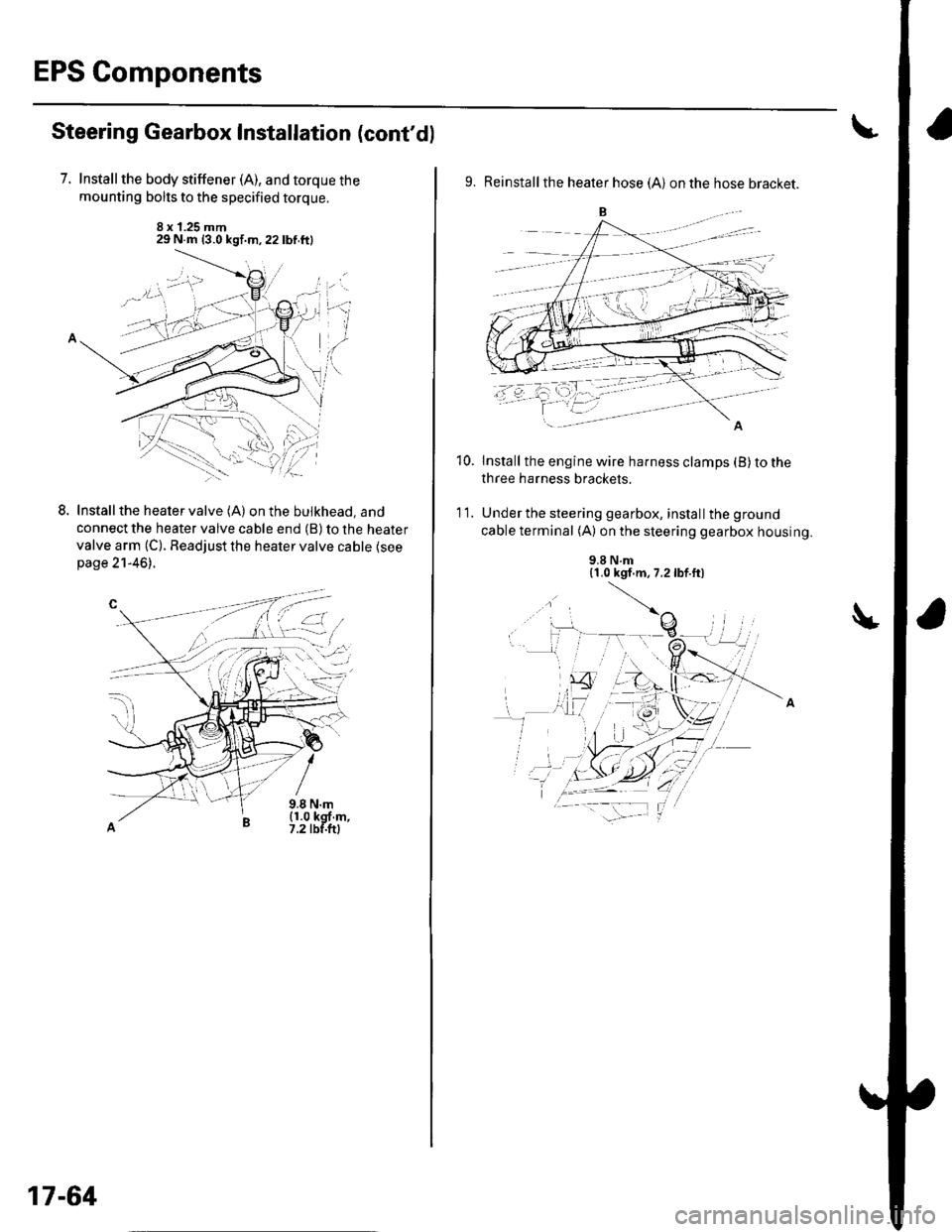

7. Installthe body stiffener (A), and torque the

mounting bolts to the specified torque.

8 x 1.25 mm29 N.m {3.0 kgf.m,22lbf.ftl

LInstall the heater valve (A) on the bulkhead, and

connect the heater valve cable end (B) to the heater

valve arm (C). Readjust the heater valve cable {seepage 21-46).

9.8 N.m(1.0 kgf m,7.2 tbf.ftl

L-t ,:.i.t'

17-64

9. Reinstall the heater hose (A) on the hose bracket.

Install the engine wire harness clamps (B) to the

three harness brackets.

Under the steering gearbox, install the ground

cable terminal (A) on the steering gearbox housing.

10.

'I t.

9.8 N.m{1.0 kgf.m, 7.2lbf.ft)

Page 613 of 1139

Gonventional Brake Components

IBrake Booster Test

Functional Test

1. With the engine stopped, press the brake pedal

several times to deplete the vacuum reservoir, thenpress the pedal hard, and hold itfor 15 seconds. lfthe pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines. modulator, or calipers) is leaking.

2. Start the engine with the brake pedal pressed. lf thepedal sinks slightly, the vacuum booster is workingproperly. lf the pedal height does not vary, thebooster or check valve is faulty.

3. With the engine running, press the brake pedal

lightly. lfthe brake pedal sinks more than 1O mm

{3/8 in, ) in 3 minutes, the master cylinder is faulty.A slight change in pedal height when the Ay'C

compressor cycles on and off is normal. (The A,/C

compressor load changes the vacuum available tothe booster.)

Leak Test

1. Press the brake pedal with the engine running, thenstop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum boosteris OK. lf the pedal rises, the booster is faulty.

2. With the engine stopped, press the brake pedal

several times using normal pressure. When thepedal is first pressed, it should oe row.

On consecutive applications, the pedal height

should gradually rise. lfthe pedal position does notvarv, check the booster check valve.

19-18

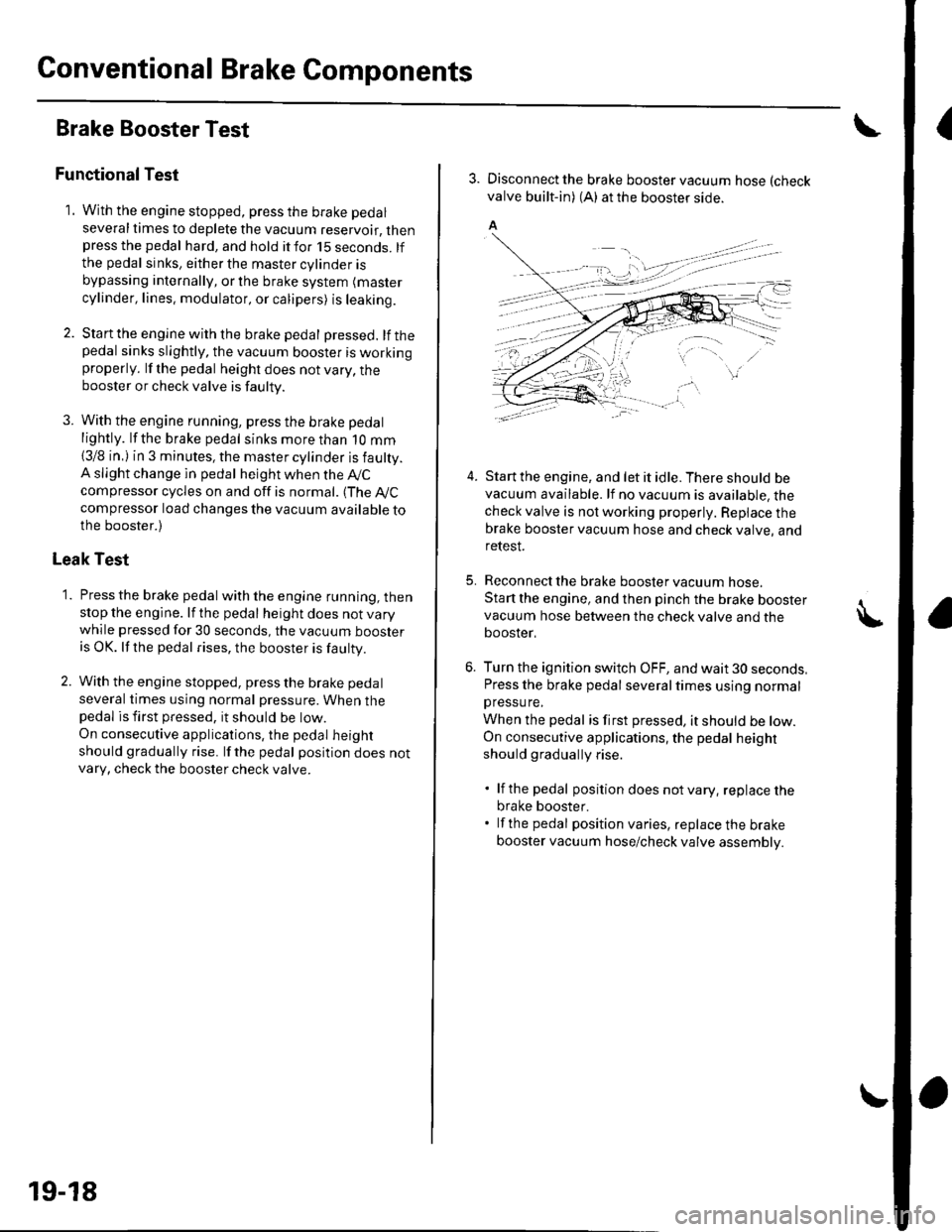

3. Disconnect the brake booster vacuum hose (check

valve built-in) (A) at the booster side.

5.

4.Start the engine, and let it idle. There should bevacuum available. lf no vacuum is available, thecheck valve is not working properly. Repiace thebrake booster vacuum hose and check valve, andrelesI.

Reconnect the brake booster vacuum nose.

Start the engine, and then pinch the brake boostervacuum hose between the check valve and thebooster,

Turn the ignition switch OFF, and wait 30 seconds,Press the brake pedal several times using normalpressu re,

When the pedal is first pressed, it should be low.On consecutive applications, the pedal height

should gradually rise.

. lf the pedal position does notvary, replacethe

brake booster.. lf the pedal position varies, replace the brake

booster vacuum hose/check valve assembly.

Page 619 of 1139

Conventional Brake Components

{Brake Hoses and Lines Inspection

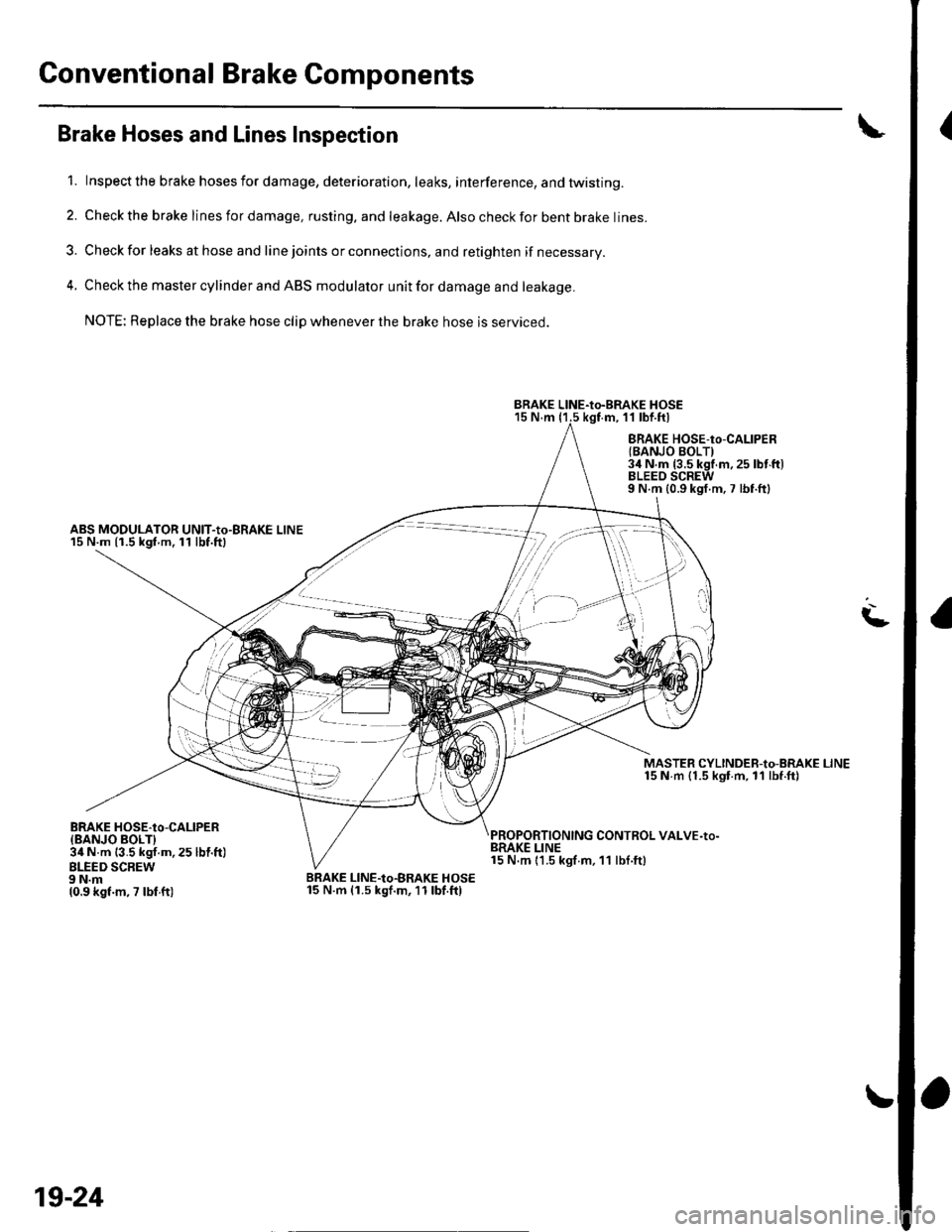

1. Inspect the brake hosesfordamage, deterioration, leaks, interference, andtwisting.

2. Check the brake lines for damage, rusting. and leakage. Also check for bent brake lines.

3. Check for leaks at hose and line joints or connections, and retighten if necessary.

4. Check the master cylinder and ABS modulator unit for damage and leakage.

NOTE: Replace the brake hose clip whenever the brake hose is serviced.

15 N.m (1.5 kgf.m, 11 lbf.ftl

ABS MODULATOR UNIT-Io-BRAKE LINE15 N.m {1.5 kgf m.11 lbf.ftl

BRAKE HOSE-to-CALIPERlBANJO BOLTI3il N.m {3.5 kgf.m.25 lbt'ft)BLEEO SCREW9 N.m {0.9 kgf.m,7 lbf.ftl

MASTER CYLINDEB-to-BRAKE LINE15 N m {1.5 kgt.m, ll lbf.ft)

CONTROL VALVE-to-

L

BRAKE HOSE.tO-CALIPER{BANJO BOLTI34 N.m {3.5 kgf.m, 25 lbl.ft)BLEED SCBEW9 N.m10.9 kgf.m, 7 lbf ft)

BRAKE LINE15 N.m 11.5 kgf m, 11 lbf.ft)

BRAKE LINE-Io-BRAKE HOSE15 N.m (1.5 kgf.m,11lbf.ftl

BRAKE LINE-to-BRAKE HOSE

t''/,i'i'

,/ ,l

t t,.. -)

19-24