valve HONDA CIVIC 2003 7.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 366 of 1139

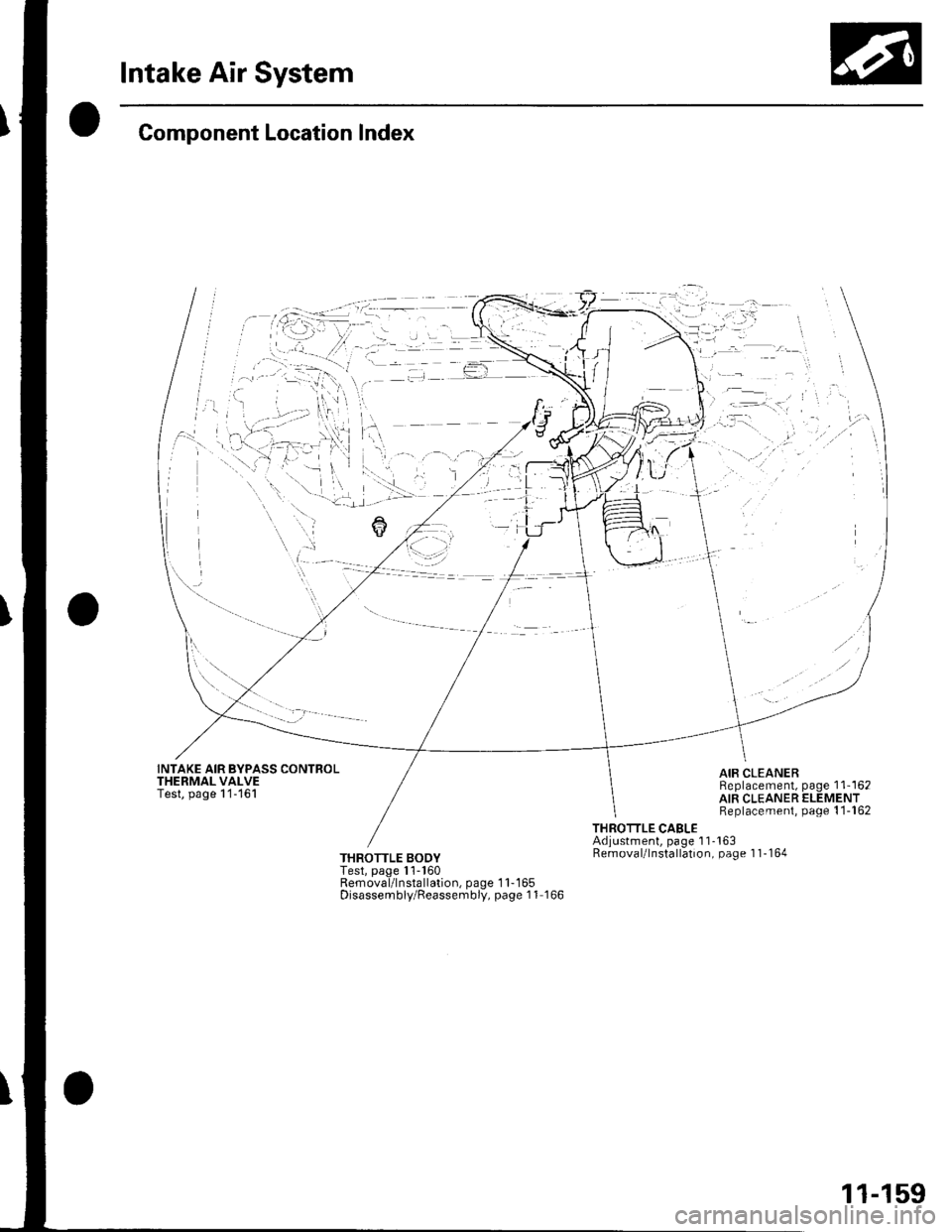

Intake Air System

Component Location Index

INTAKE AIR BYPASS CONTROLTHERMAL VALVETest, page 1'1-161

i l.

AIR CLEANERReplacement, page 1 1'162AIR CLEANER ELEMENTReplacement, page 1 1-162

THROTTLE CABLEAdjustment, page 1 1-163Removal/lnstallation, page 1 1-164THROTTLE BODYTest, page l'l-160Removal/lnstallation, page 1 1-165Disassembly/Reassembly, page 1 1 166

11-159

Page 367 of 1139

Intake Air System

Throttle Body Test

NOTE:. Do not adjust the throttle stop screw. lt is preset at the

factory.. lf the malfunction indicator lamp (MlL) has been

reported on, check for diagnostic trouble codes(DLCS) (see page 11 3).

1. With the engine off, check the throttle cable

movement. The cable should move without binding

or sticking.

. lf lhe cable moves OK, goto step 2.. lf the cable binds or sticks, check it and its routing.. lf the cable isfaulty, reroute itor replace itand

adjust it (see page 11-163), then go to step 2.

2. l\4ove the throttle lever by hand to see if the throftle

valve and/or shaft are too loose or too tight.

. lf there is excessive play in the throttle valve

shaft, or any binding in the throttle valve at the

fully closed position, replace the throttle body.. lf thethrottlevalve and shaft are OK, goto step3.

3. Connect the scan toolto the DLC.

Turn the ignition switch ON (ll).

Check the throttle position with the scan tool. The

reading should be about 10% when the throttle is

fully closed and about 90% when the throttle is fully

openeo.

. lf the throttle position is correct, the throttle body

is OK.. lf thethrottle position is notcorrect, replace the

throttle body.

5.

11-160

!

Page 368 of 1139

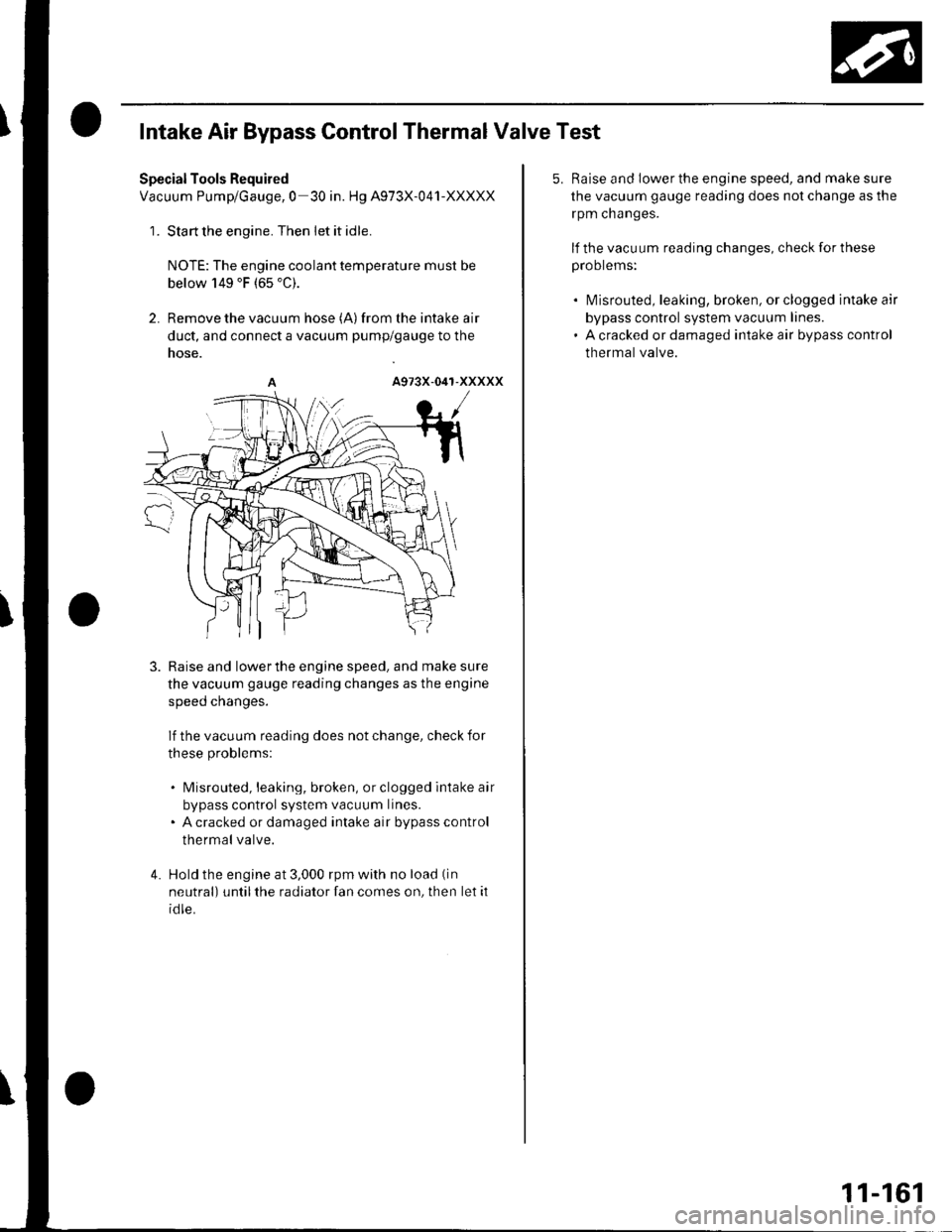

Intake Air Bypass GontrolThermalValve Test

Special Tools Required

Vacuum Pump/Gauge,0 30 in. Hg A973X-041-XXXXX

1. Stan the engine. Then let it idl€.

NOTE: The engine coolant temperature must be

below 149'F (65'C).

2. Remove the vacuum hose (A)from the intake air

duct, and connect a vacuum pump/gauge to the

nose.

3. Raise and lowerthe engine speed. and make sure

the vacuum gauge reading changes as the engine

speeo cnanges.

lf the vacuum reading does not change, check for

these problems:

. Misrouted, leaking, broken, or clogged intake air

bypass control system vacuum lines.. A cracked or damaged intake air bypass control

thermal valve.

4. Hold the engine at 3,000 rpm with no load (in

neutral) until the radiator fan comes on, then let it

id le.

5. Raise and lower the engine speed, and make sure

the vacuum gauge reading does not change as the

rpm cnanges.

lf the vacuum reading changes, check for these

proorems:

. l\4isrouted, leaking, broken, or clogged intake air

bypass control system vacuum lines.. A cracked or damaged intake air bypass control

thermal valve.

11-161

Page 370 of 1139

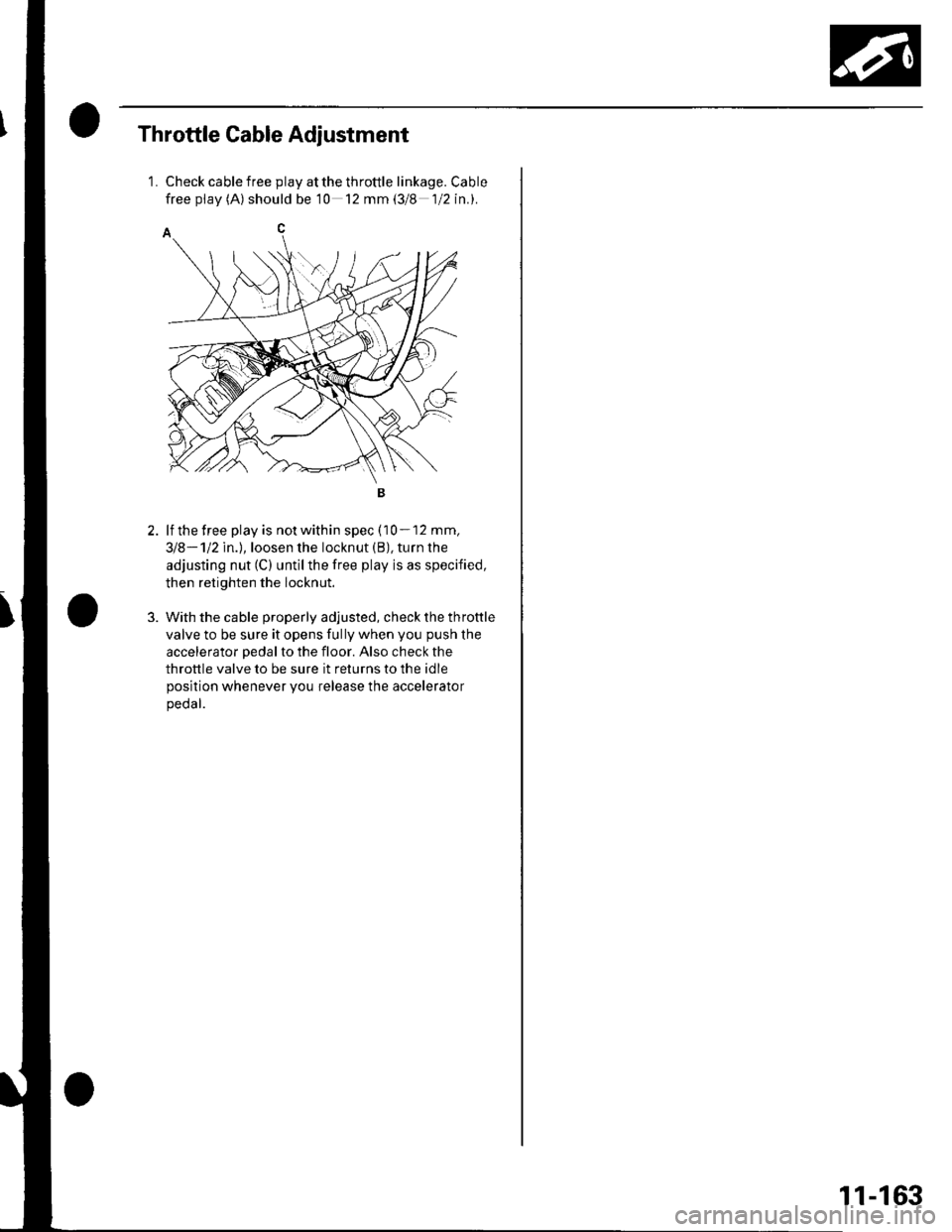

Throttle Cable Adjustment

1.Check cable free play at the throttle linkage. Cable

free pf av (A) should be 10 12 mm (3/8 1/2 in.).

lf the free play is not within spec (10 - 12 mm,

318-112ln.l,loosen the locknut (B), turn the

adjusting nut (C) untilthe free play is as specified,

then retighten the locknut.

With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the

throttle valve to be sure it returns to the idle

position whenever you release the accelerator

peoar.

11-163

Page 371 of 1139

Intake Air System

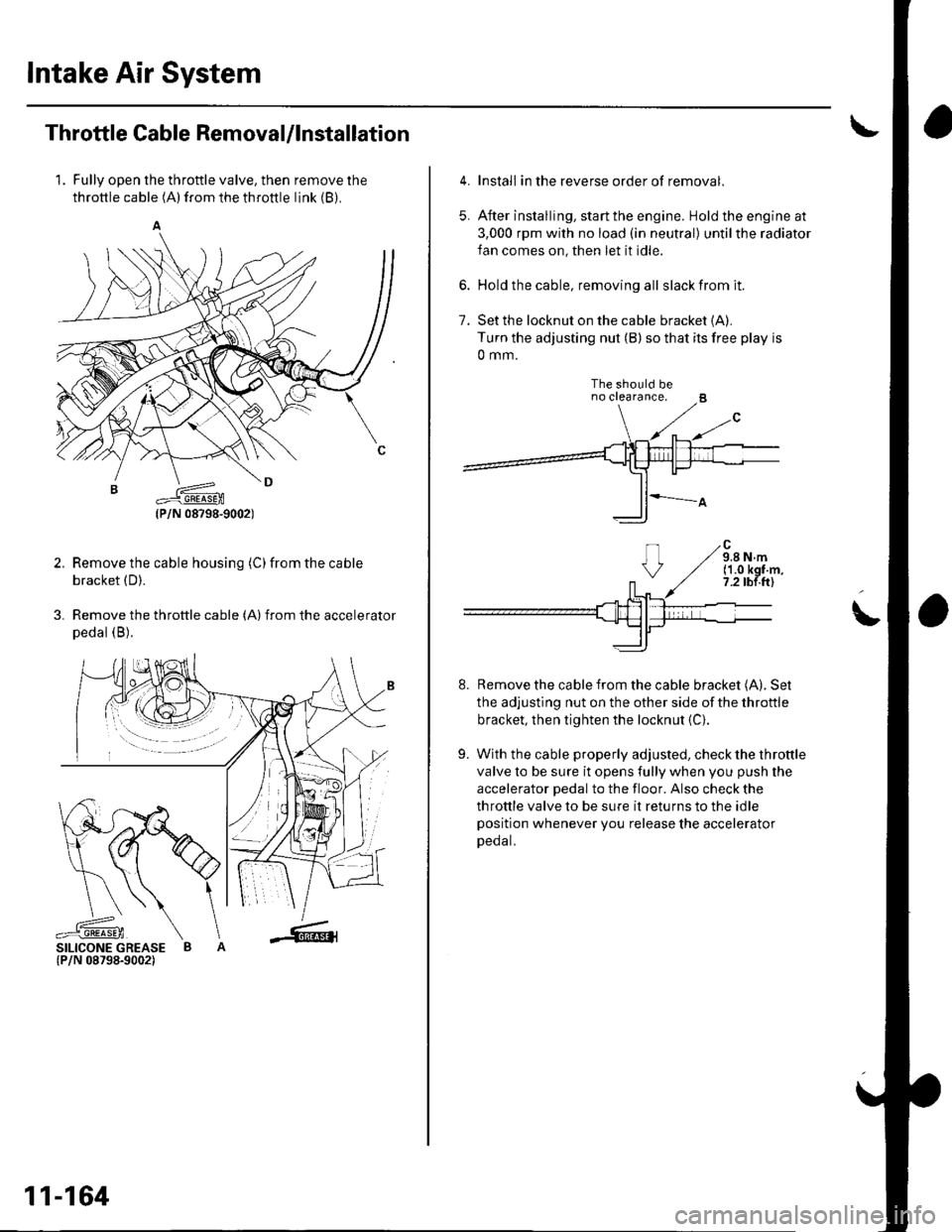

Throttle Cable Removal/lnstallation

1. Fully open the throttle valve, then remove the

throttle cable (A) from the throttle link (B).

Remove the cable housing (C)from the cable

bracket (D).

Remove the throttle cable (A)from the accelerator

pedal (B).

2.

3.

SILICONE GREASE B(P/N 08798-9002)

(P/N 08?98-9002)

11-164

5.

Install in the reverse order of removal.

After installing, start the engine. Hold the engine at

3,000 rpm with no load (in neutral) untilthe radiator

fan comes on, then let it idle.

Hold the cable, removing all slack from it.

Set the locknut on the cable bracket {A).Turn the adjusting nut (B) so that its free play is

0 mm.

The should beno crearance.

Remove the cable from the cable bracket (A). Set

the adjusting nut on the other side of the throttle

bracket, then tighten the locknut {C}.

With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the

throttle valve to be sure it returns to the idle

position whenever you release the accelerator

Deoat.

7.

!

8.

9.

('1.0 kgf.m,7.2 tbf.ftl

Page 372 of 1139

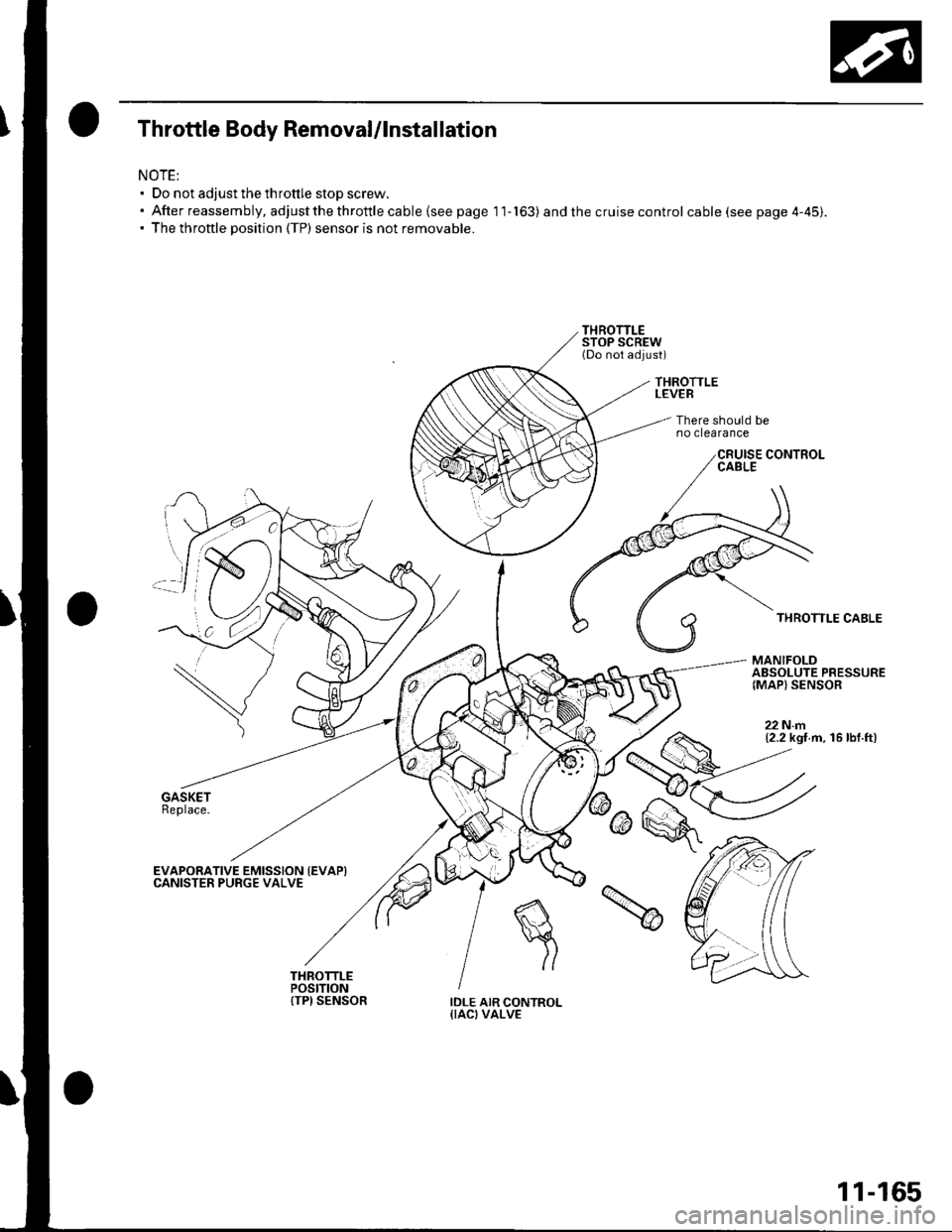

Throttle Body Removal/lnstallation

NOTE:' Do not adjust the throttle stop screw.. Afterreassembly,adjustthethrottlecable{seepagell-163) and the cruise control cable (see page 4-45).. The throttle position (TP) sensor is not removable.

THROTTLELEVER

There should beno clearance

THROTTLE CABLE

MANIFOLDABSOLUTE PRESSURE{MAP} SENSOR

22Nm(2.2 kgt.m, 16 lbf.ft)

EVAPORATIVE EMISSION {EVAPICANISTER PURGE VALVE

IDLE AIR CONTROL{IACI VALVE

11-165

Page 373 of 1139

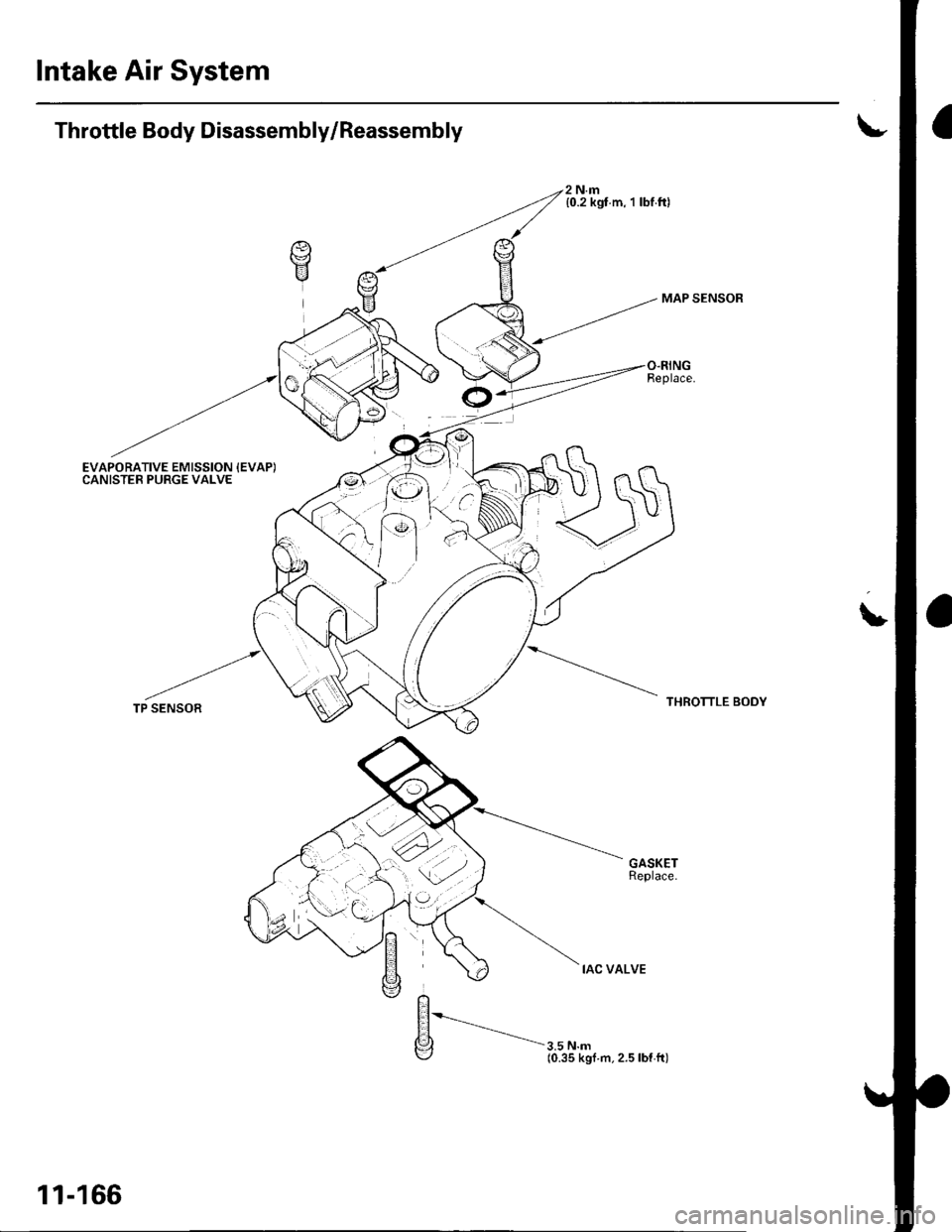

Intake Air System

Throttle Body Disassembly/Reassembly

EVAPORATIVE EMISSION {EVAP)CANISTER PURGE VALVE

A

V

2 N.m{0.2 kgt m, 1 lbf.ft)

3.5 N.m(0.35 kgf m.2.5lbf ft)

MAP SENSOR

THROTTLE BODY

L

TP SENSOR

11-166

Page 375 of 1139

PCV System

DTC Troubleshooting

DTC P1505: PCV Air Leakage

1. Reset the ECM (see page 11-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on

3. Let the engine idle tor al least 40 seconds with the

throttle fully closed.

4. Check for a DTC P1505 with the scan tool

ls DTC P1505 indicated?

YES-Check these parts for vacuum leaks l

. PCV valve. PCV hose. EVAP canister purge valve

. Throttle body. Brake booster hose

NO - Intermittent failure, system is OK at this

time.l

11-168

Page 376 of 1139

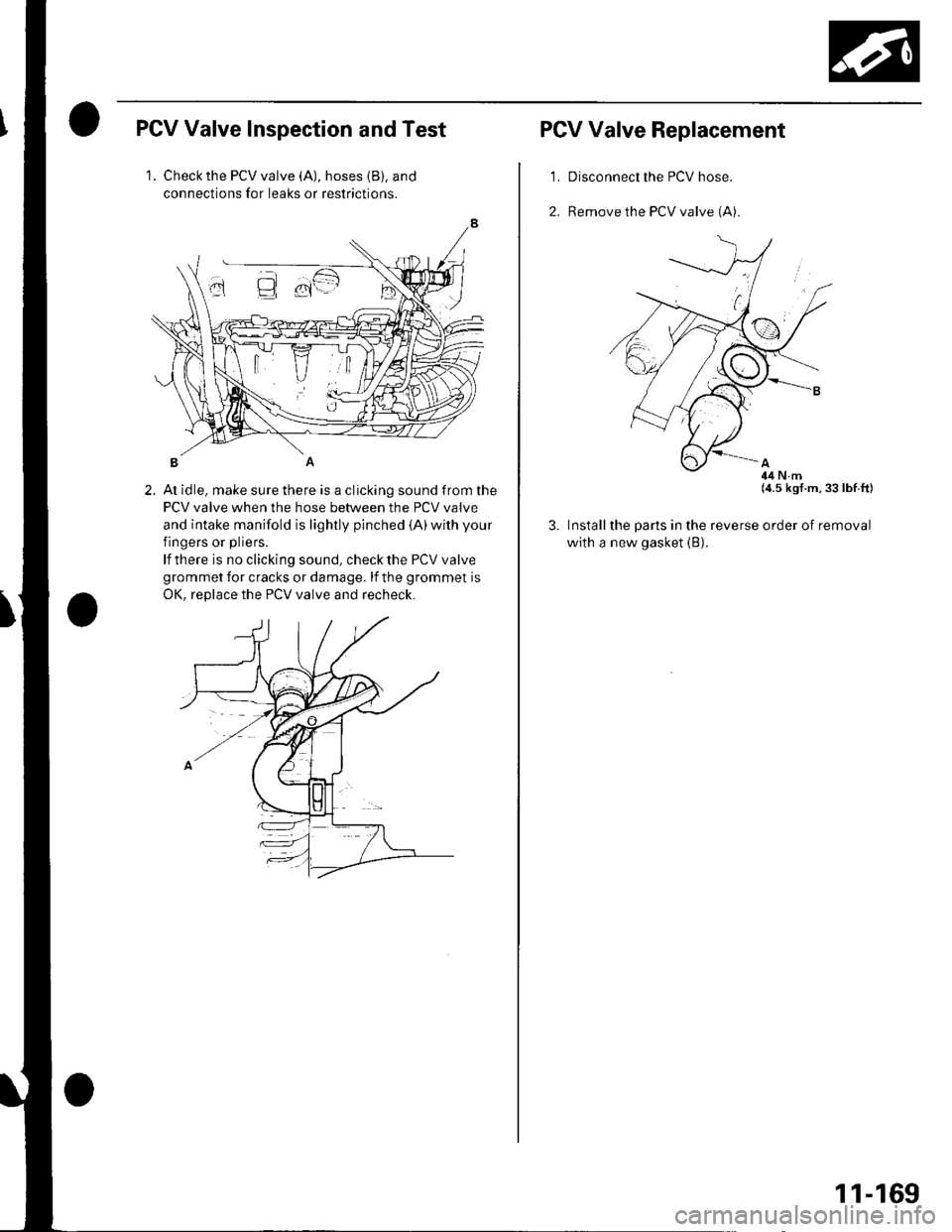

PCV Valve Inspection and Test

2.

1. Check the PCV valve (A), hoses {B), and

connections for leaks or restrictions.

At idle, make sure there is a clicking sound from the

PCV valve when the hose between the PCV valve

and intake manifold is lightly pinched {A)with your

fingers or pliers.

lf there is no clicking sound, check the PCV valve

grommet for cracks or damage. lf the grommet is

OK. reDlace the PCV valve and recheck.

PCV Valve Replacement

'LDisconnect the PCV hose.

Remove the PCV valve (A).

3. Install

with a

(4.5 kgf.m,33 lbf.ft)

the parts in the reverse order of removal

new gasket (B).

11-169

Page 377 of 1139

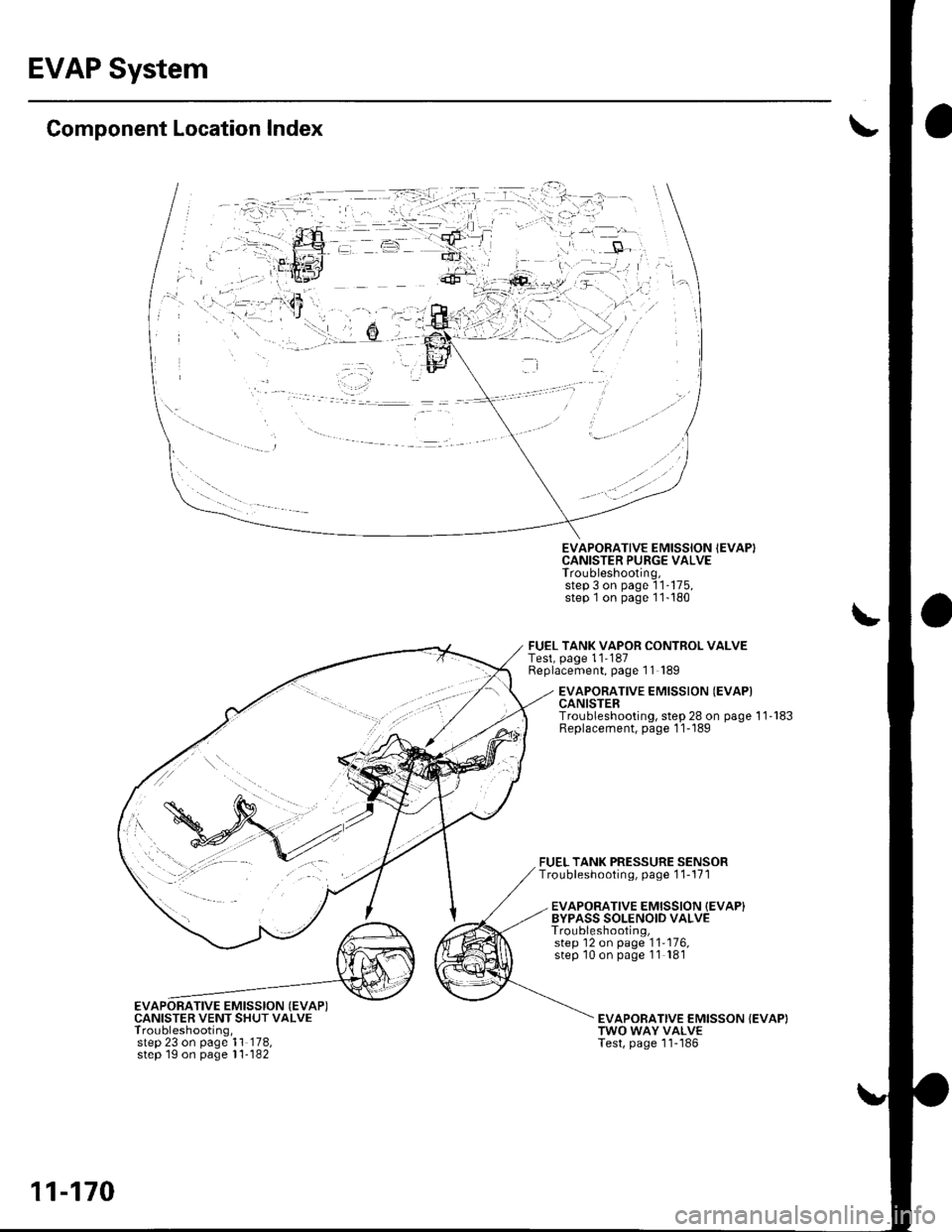

EVAP System

Component Location Index

EVAPORATIVE EMISSION {EVAP)CANISTER VENT SHUT VALVETroubleshooting,step 23 on page 1'l 178,step 1g on page l1- 182

EVAPORATIVE EMISSION IEVAPICANISTER PURGE VALVETroubleshooting,step 3 on page 'l1-175,

step 1on page 11-180

FUEL TANK VAPOR CONTROL VALVETest, page 11'187Replacement, page 11 189

FUEL TANK PRESSURE SENSORTroubleshooting, page 1 1-171

EVAPORATIVE EMISSION {EVAPICANISTERTroubleshooting, step 28 on page 11'183Replacement, page 1 1-189

EVAPORATIVE EMISSION {EVAP}BYPASS SOLENOID VALVETroubleshooting,step 12 on page '11'176,

step '10 on page 11 181

EVAPOBATIVE EMISSON {EVAP)TWO WAY VALVETest, page 'l1-'186

11-170