ERS HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 509 of 1139

EPS Components

aGeneral Troubleshooting Information

EPS Indicator

Under normal conditions, the EPS indicator comes on when

the ignitlon switch is turned to the ON (ll) position, then goes

off after the engine is started. This indicates that the bulb and

its circuit are operating correctly.

lf there is any trouble in the system after the engine is started,

the EPS indicator will stay on, and the power assist is turned

off.

When EPS indicator light comes on, the control unit

memorizes the DTC. In this case, the control unit will not

activate the EPS system after the engine starts again, but it

keeps the EPS indicator on.

When DTC 12, 16, 17, 18 or 67 is stored in the control unit, the

EPS indicator will stay on until the DTC is erased. When a

problem is detected and the EPS indicator comes on, there are

cases when the indicator stays on untilthe ignition switch is

turned 0FF, and cases when the indicator goes off

automatically when the system returns to normal. Even though

the system is operating normally, the EPS indicator will come

on under the following conditions:

Condition '1:

. The vehicle was traveling at least 12.4 mph (20 km/h), then. A rapid change in vehicle speed was detected, then. The vehicle (or the vehicle speed sensor signal) stopped for

at least 5 seconds. The engine speed was still 'l,640rpmorhigherforatleastS

seconds

Condition 2:

After the vehicle (or the vehicle speed sensor signal) has

stopped for at least 10 seconds, yet the engine speed was still

1,640 rpm or higherfor at least 20 seconds.

Condition 3:

When the engine speed is 280 rpm or less, and the vehicle is traveling at

a speed of 6,2 mph (10 km/h) or more for 3 seconds.

To determine the actual cause ofthe problem, question the

customer about the conditions during which the problem

occured, taking the above conditions into consideration.

Diagnostic Trouble Code (DTCI

. lf the CPU cannot be activated, or itfails,the EPS indicator

comes on, but the DTC is not memorized.. The memory can hold any number of DTCS. However, when

the same DTC is detected more than once, the most recent

DTC is written over the prior DTC, therefore only one

occurrence is memorized.. The DTCS are indicated repeatedly untilthe ignition switch is

turned OFF.. lf the DTC is not memorized,the EPS indicator blinks.

. The DTCS are memorized in the EEPRO| (non-volatile

memory) therefore the memorized DTCS cannot be erased

by disconnecting the battery. Perform the specified

procedures to clear DTCS.

Self-diagnosis

Self-diagnosis can be classified into two categories:.Initial diagnosis: performed right after the engine

starts and until the EPS indicator goes off.. Regular diagnosis: performed right after the initial

diagnosis until the ignition switch is turned OFF.

The EPS control unit performs the following functions

when a problem is detected by self-diagnosis;

'1. Turns on the EPS indicator.

2. Memorizes the DTC.

3. Stops power assist and manual steering operation

begrns.

NOTE:. When DTC 23 (a problem with the circuit for

engine speed signal) is detected, the power

assist will return to normal when the vehicle

speed is 0.62 mph (1 km/h) or above.. Fot DfCs 22,23, 64, or 66 the EPS indicator goes

off automatically when the system relurns to

normal. For all other codes, the EPS indicator

goes off when the system is OK after the ignition

switch is turned from OFF to ON (ll).

Restriction on Power Assist Operation

Repeated extreme steering force. such as turning the

steering wheel continuously back-and-forth with the

vehicle stopped, causes an increase of power

consumption in the EPS motor. The increase of electric

current causes the motor to heat up. Because this heat

adversely affects the system, the control unit monitors

the electric current of the motor.

When the control unit detects heat build-up in the motor,

it reduces the electric current to the motor gradually to

protect the system, and it restricts the power assist

operation. The EPS indicator does not come on during

this function.

When steering torque is not applied to the steering

wheel, or when the ignition is turned off, and the motor

cools, the control unit will restore the power assist

gradually until it's fully restored (after approximately 15

minutes maximum).

17-18

Page 541 of 1139

EPS Components

(Motor RemovaUlnstallation (cont'dl

lnsiallation

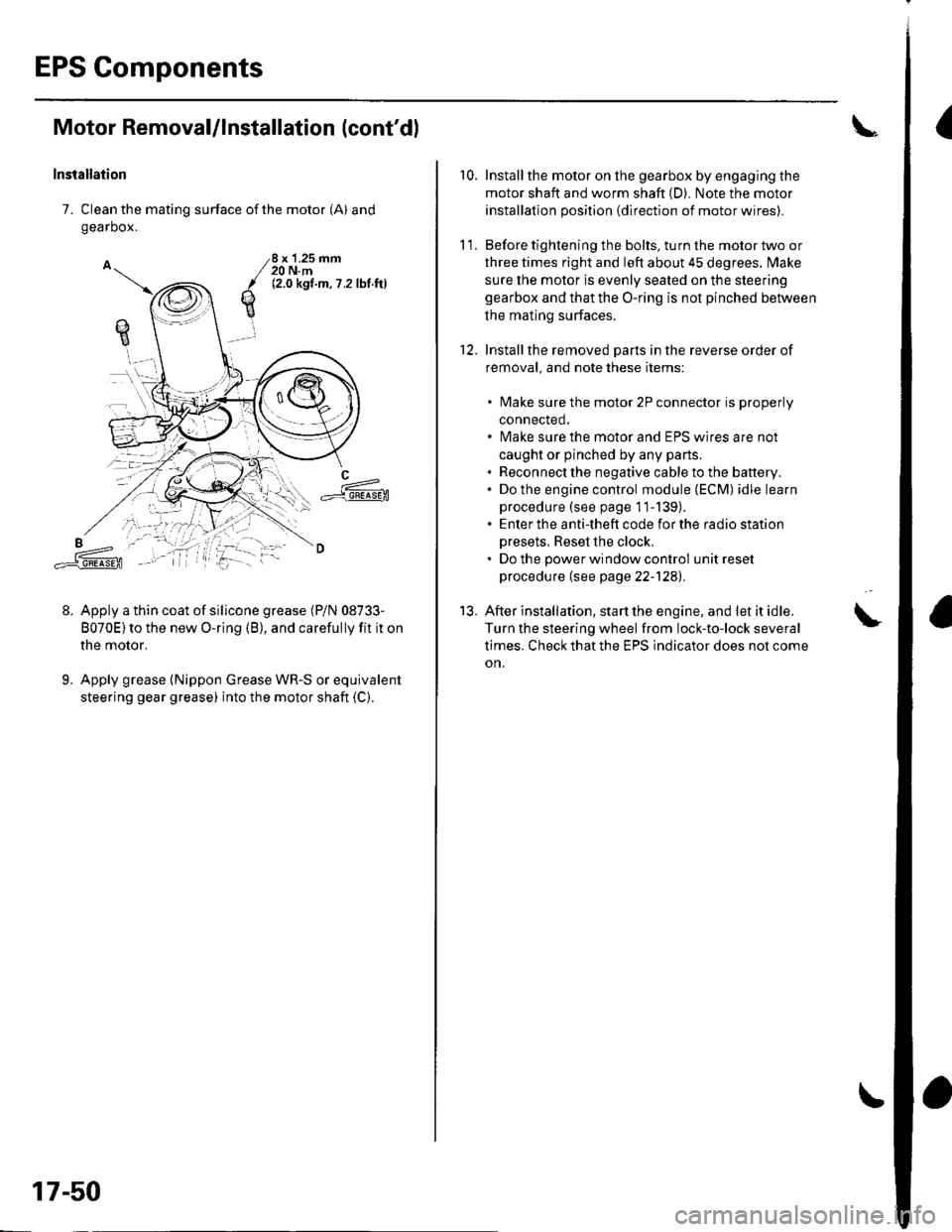

7. Clean the mating surface of the motor (A) and

gearbox.

Apply a thin coat of silicone grease (P/N 08733-

8070E)to the new O-ring (B), and carefully fit it on

the motor.

Apply grease {Nippon Grease WR-S or equivalent

steering gear grease) into the motor shaft (C).

qE

8 x '1.25 mm20 N.m12.0 kgt.m,7 .2lbl ftl

L==-c].E@

9.

17-50

r0.Install the motor on the gearbox by engaging the

motor shaft and worm shaft (D). Note the motor

installation position {direction of motor wires).

Before tightening the bolts, turn the motor two or

three times right and left about 45 degrees. lvlake

sure the motor is evenly seated on the steering

gearbox and that the O-ring is not pinched betlveen

the mating surfaces.

Installthe removed Darts in the reverse order of

removal. and note these items:

lvlake sure the motor 2P connector is properly

connected.

lvlake sure the motor and EPS wires are not

caught or pinched by any parts.

Reconnect the negative cable to the battery.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

Enter the anti-theft code for the radio station

Dresets. Reset the clock,

Do the oower window control unit reset

procedure (see page 22-1241.

After installation, start the engine, and let it idle.

Turn the steering wheel from lock-to-lock several

times. Check that the EPS indicator does not come

on.

11.

12.

13.

Page 547 of 1139

EPS Components

Steering Gearbox Overhaul (cont'dl

Special Tools Required. Locknut wrench 07ZAA-S5A0100. Pincers, Oetiker 1098 or equivalent, commercially

available.

NOTE:. Refer to the Exploded View as needed during thisprocedure.

. Do not allow dust, dirt, or other foreign materials toenter into the steering gearbox.

Eemoval

1, Remove the steering gearbox (see page 17-b1).

Disassembly

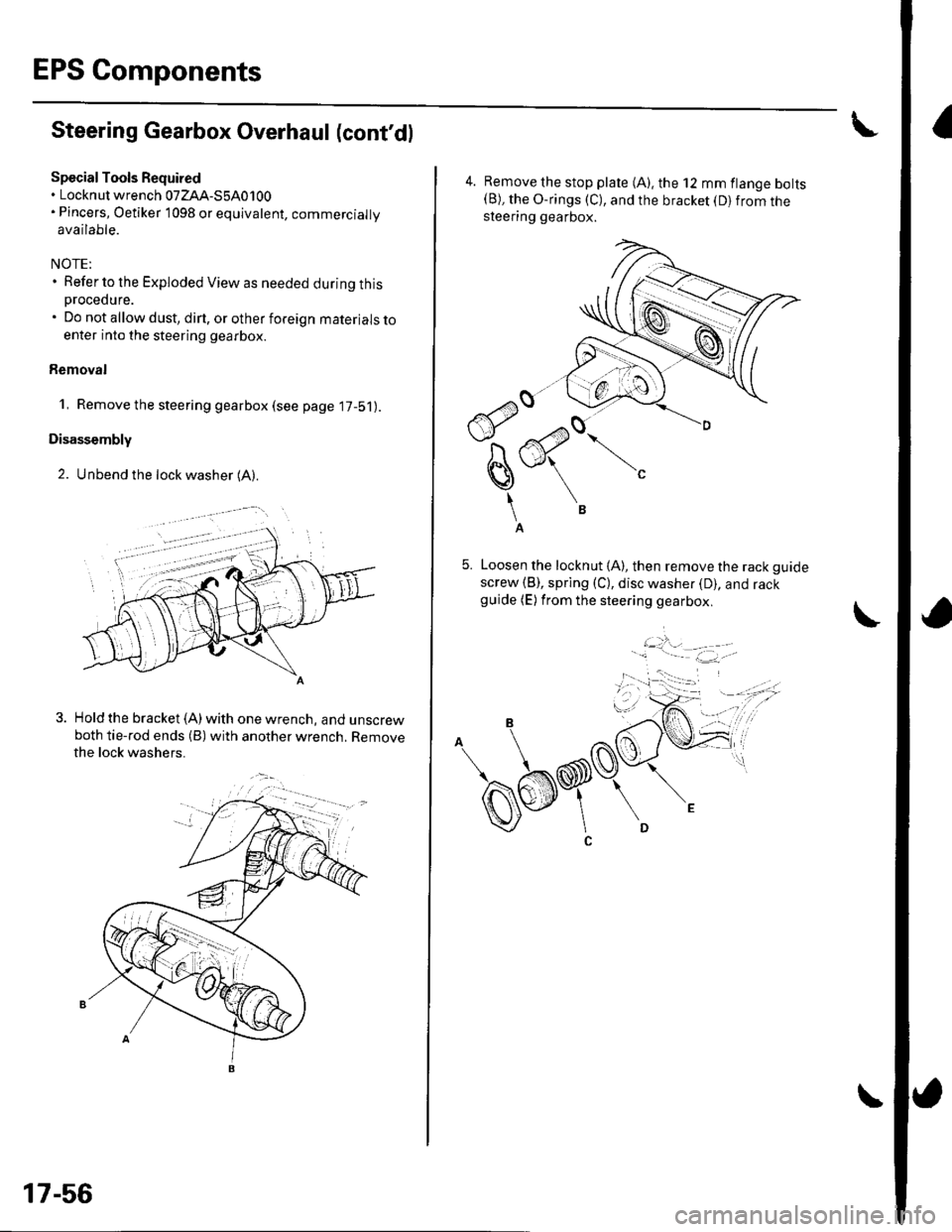

2. Unbend the lock washer (A).

. - -,'i.

Hold the bracket (A) with one wrencn, anq unscrewboth tie-rod ends (B) with another wrench. Removethe lock washers.

17-56

4. Remove the stop plate (A). the 12 mm flange bolts(B), the O-rings (C), and the bracket (D) from thesleering gearbox.

Loosen the locknut (A), then remove the rack guide

screw (B), sprlng (C), disc washer (D), and rackguide (E) from the steering gearbox.

i::..:4,. , -- -. - :.--. '

Page 548 of 1139

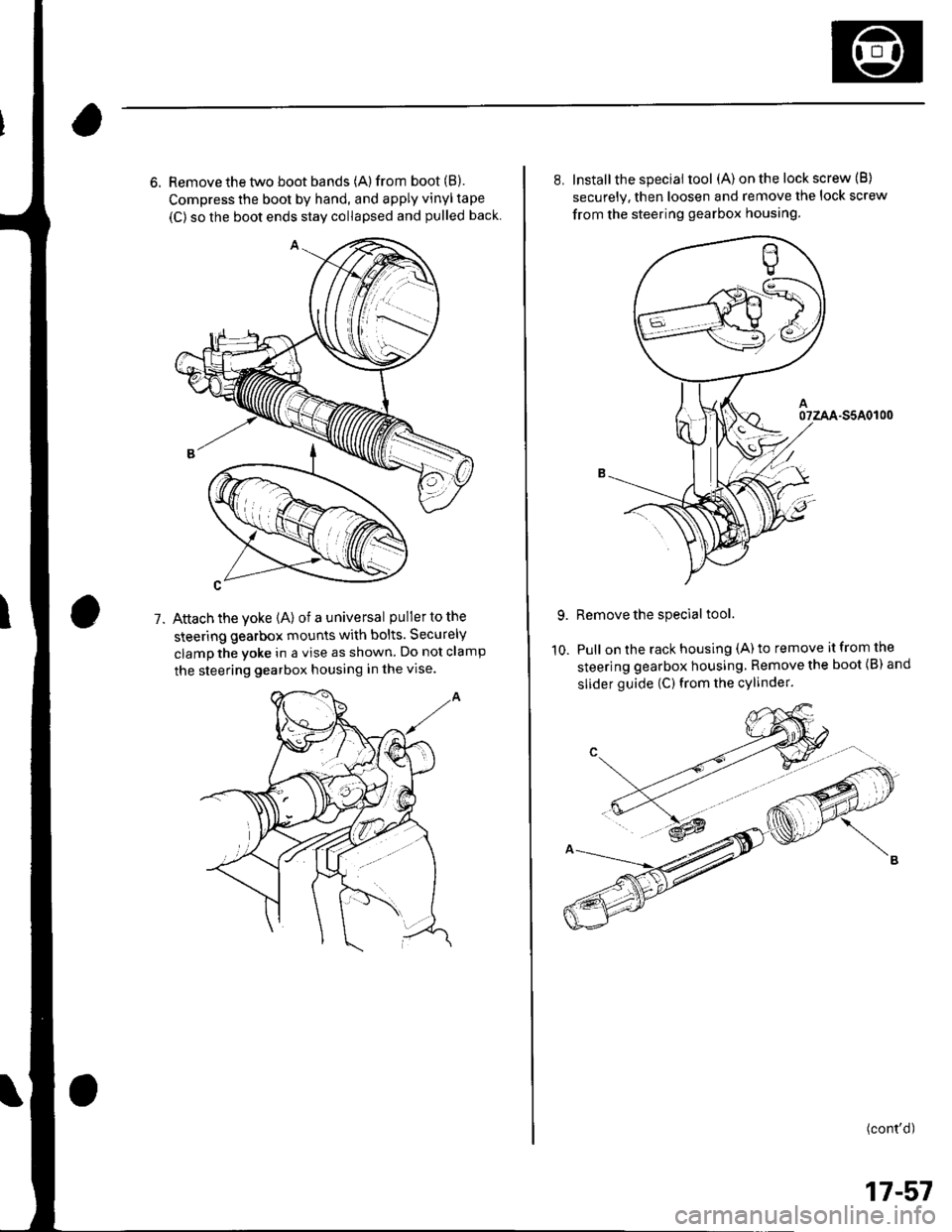

6. Remove the two boot bands (A) from boot (B).

Compress the boot by hand, and apply vinyl tape

(C) so the boot ends stay collapsed and pulled back

Attach the yoke (A) of a universal puller to the

steering gearbox mounts with bolts. Securely

clamp the yoke in a vise as shown. Do not clamp

the steering gearbox housing in the vise.

1.

10.

8. Installthe special tool (A) on the lock screw (B)

securely. then loosen and remove the lock screw

from the steering gearbox housing.

07zAA-S5A0r00

Remove the special tool.

Pull on the rack housing (A) to remove it from the

steering gearbox housing, Remove the boot {B) and

slider guide (C) from the cylinder.

(cont'd)

17-57

Page 549 of 1139

EPS Components

Steering Gearbox Overhaul (cont'd)

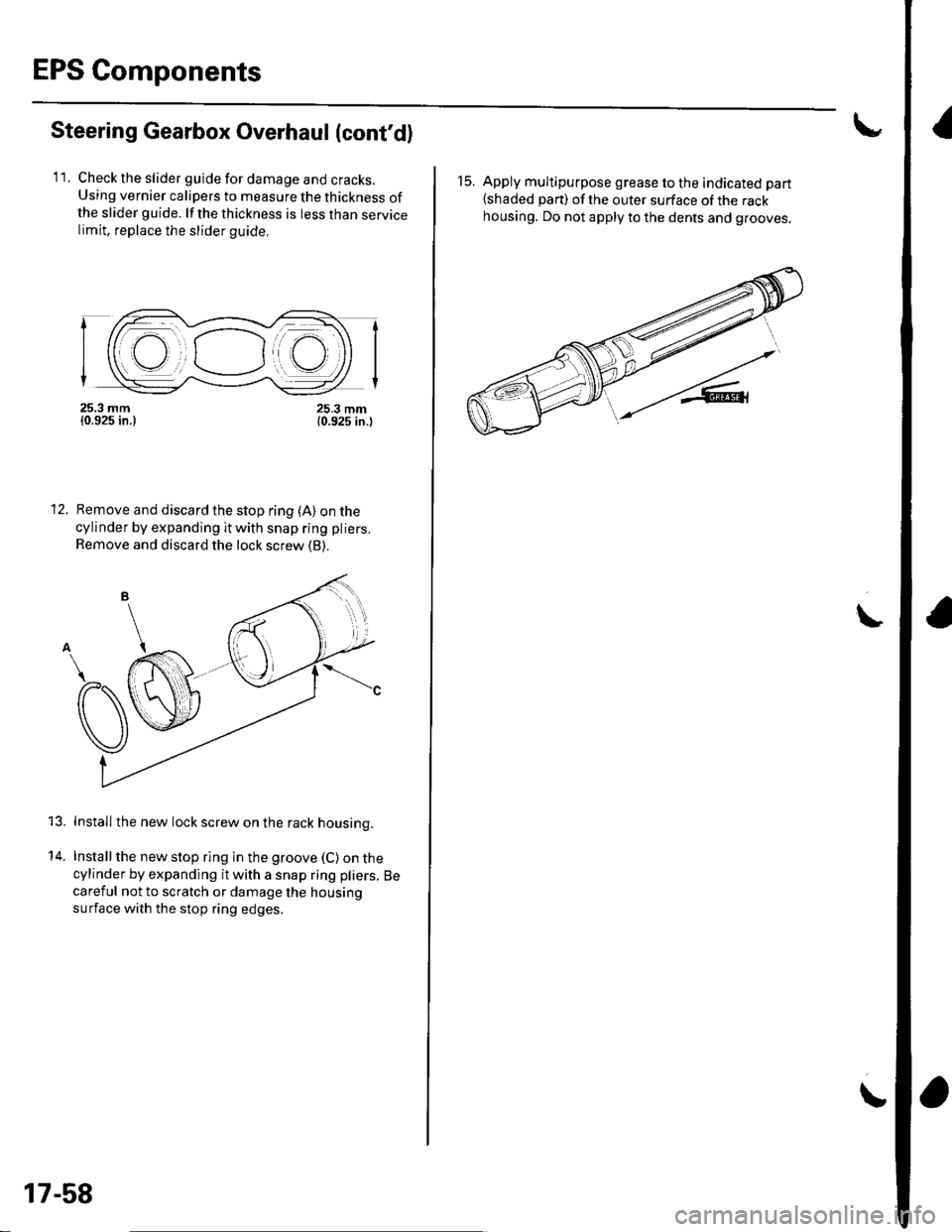

'll. Check the slider guide for damage and cracks.Using vernier calipers to measure the thickness ofthe slider guide. lf the thickness is less than servicelimit, replace the slider guide,

f Z,-----:-r-.--------.t.t'E-r

I (fr--', -.----

/i Il il ( t t , ,)))

|i@r

25.3 mm{0.925 in.}

Remove and discard the stop ring {A)on the

cylinder by expanding it with snap ring pliers.

Remove and discard the lock screw {B}.

13. Install the new lock screw on the rack housing.

14. Installthe new stop ring in the groove (C)on thecylinder by expanding it with a snap ring pliers. Becareful not to scratch or damage the housing

surface with the stop ring edges.

25.3 mm{0.925 in.l

12

17-58

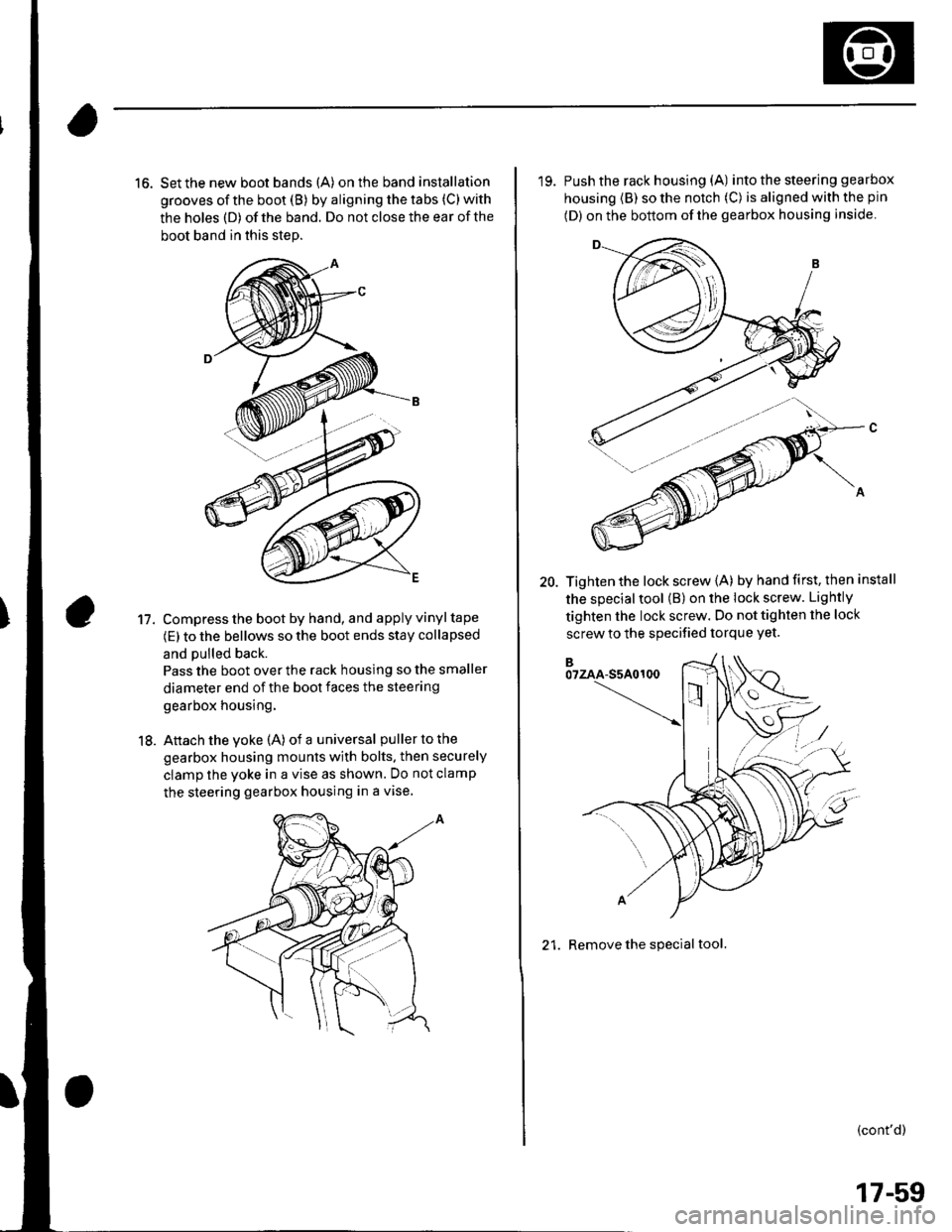

15. Apply multipurpose grease to the indicated part

{shaded part) of the outer surface of the rackhousing. Do not apply to the dents and grooves.

\

I

Page 550 of 1139

16. Set the new boot bands (A) on the band installation

grooves of the boot (B) by aligning the tabs (C) with

the holes (D) of the band. Do not close the ear of the

boot band in this step.

Compress the boot by hand, and apply vinyl tape

(E) to the bellows so the boot ends stay collapsed

and pulled back.

Pass the boot over the rack housing so the smaller

diameter end of the boot faces the steering

gearbox housing.

Attach the yoke (A) of a universal puller to the

gearbox housing mounts with bolts. then securely

clamp the yoke in a vise as shown. Do not clamp

the steering gearbox housing in a vise.

11.

18.

'19. Push the rack housing (A) into the steering gea rbox

housing (B) so the notch (C) is aligned with the pin

(D) on the bottom of the gearbox housing inside

20. Tighten the lock screw {A) by hand first, then install

the special tool (B) on the lock screw. Lightly

tighten the lock screw. Do not tighten the lock

screw to the specified torque Yet.

21. Remove the special tool.

(cont'd)

17-59

Page 552 of 1139

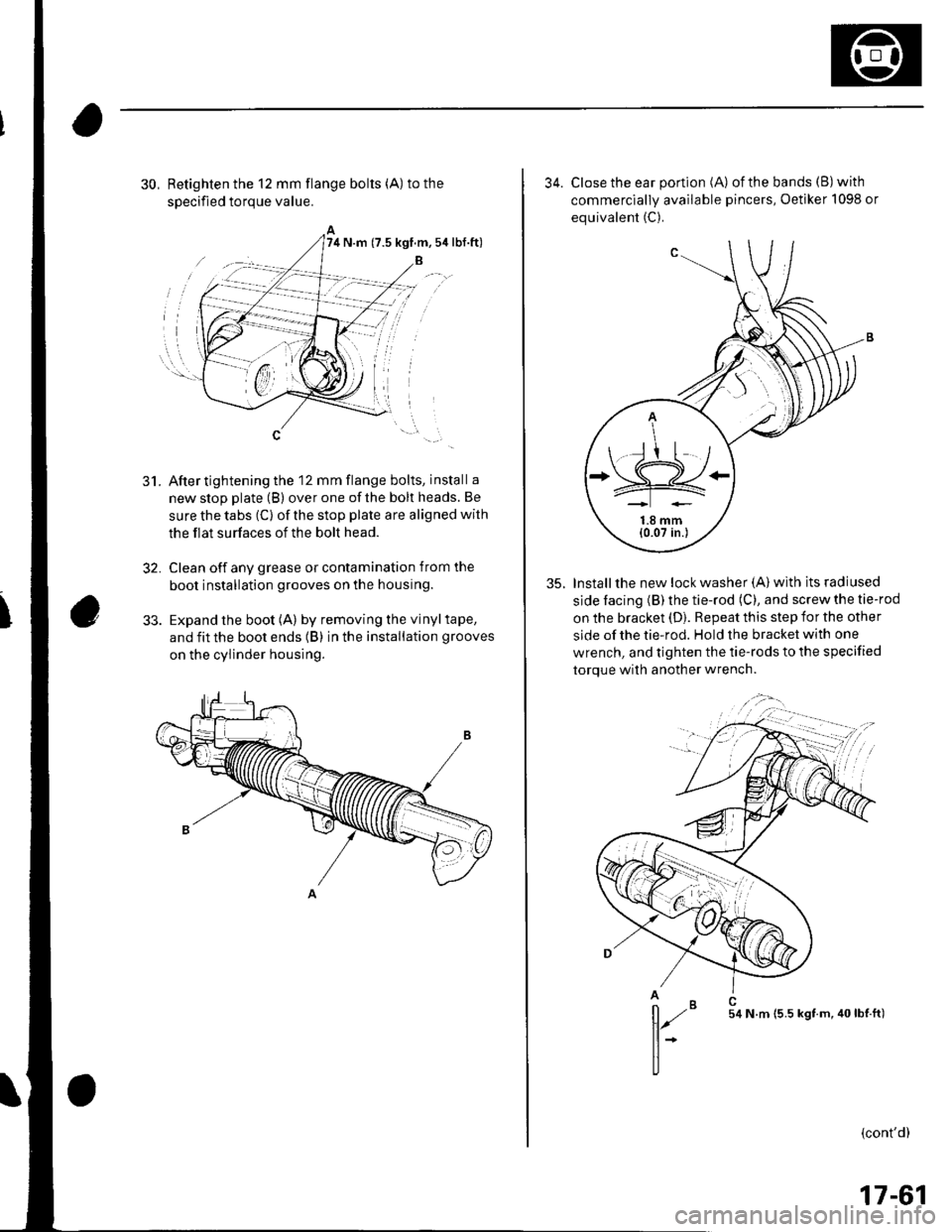

30, Retighten the 12 mm flange bolts (A) to the

soecified toroue value.

After tightening the 12 mm flange bolts, install a

new stop plate (B) over one of the bolt heads. Be

sure the tabs (C) of the stop plate are aligned with

the flat surfaces of the bolt head.

Clean off any grease or contamination from the

boot installation grooves on the housing.

Expand the boot (A) by removing the vinyltape,

and fit the boot ends (B) in the installation grooves

on the cylinder housing.

5t.

32,

74 N.m (7.5 kgf.m,5ir lbf.ft)

34. Close the ear portion (A) ofthe bands (B)with

commerciallv available pincers, Oetiker 1098 or

equivalent (C).

35. Installthe new lock washer (A) with its radiused

side facing (B) the tie-rod (C), and screw the tie-rod

on the bracket (D). Repeat this step for the other

side of the tie-rod. Hold the bracket with one

wrench, and tighten the tie-rods to the specified

torque with another wrench.

,,";=-...,.,

(cont'd)

*=,,',

17-61

Page 553 of 1139

EPS Components

Steering Gearbox Overhaul (cont'dl

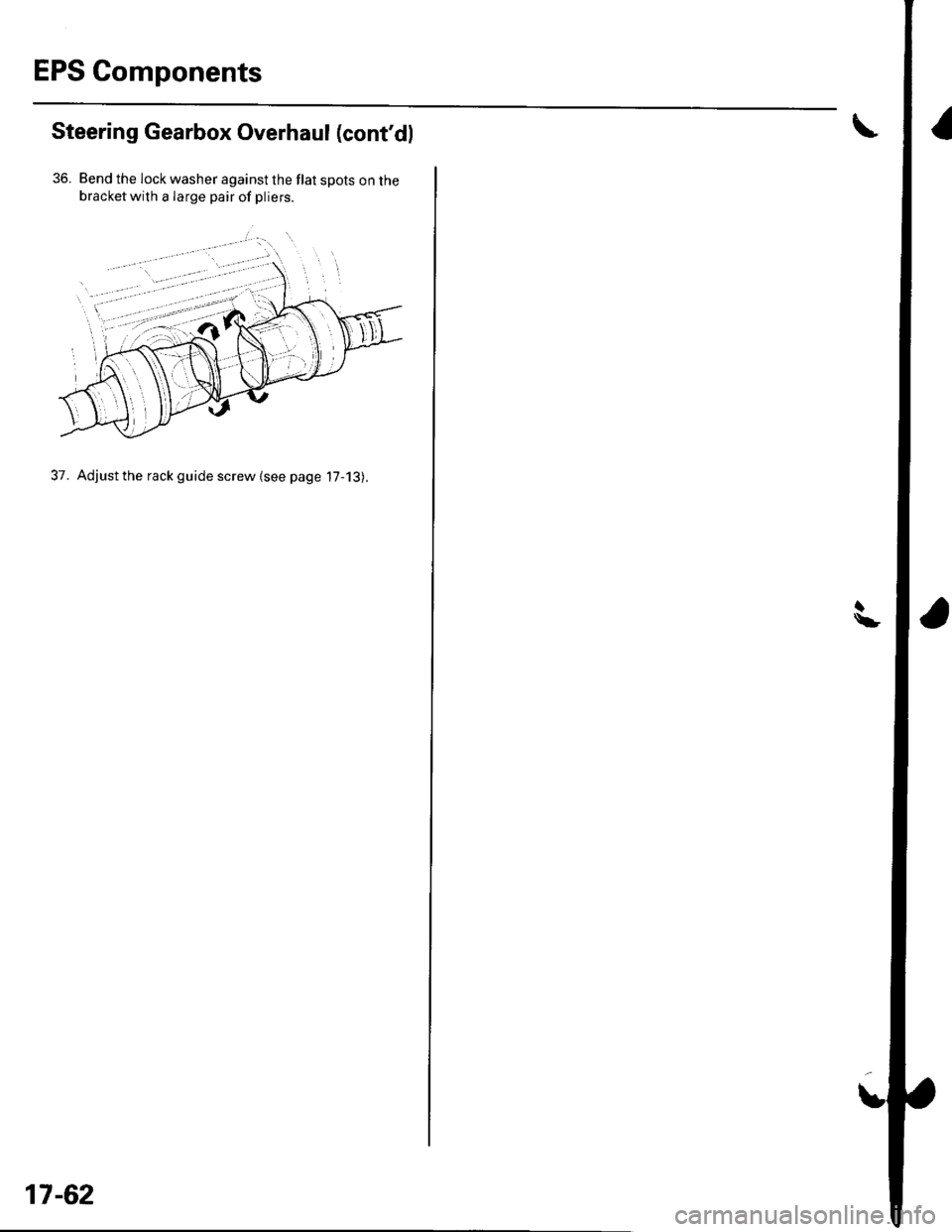

36. Bend the lock washer against the flat spots on thebracketwith a Iarge pair of pliers.

37. Adjust the rack guide screw {see page 17-13).

17-62

Page 558 of 1139

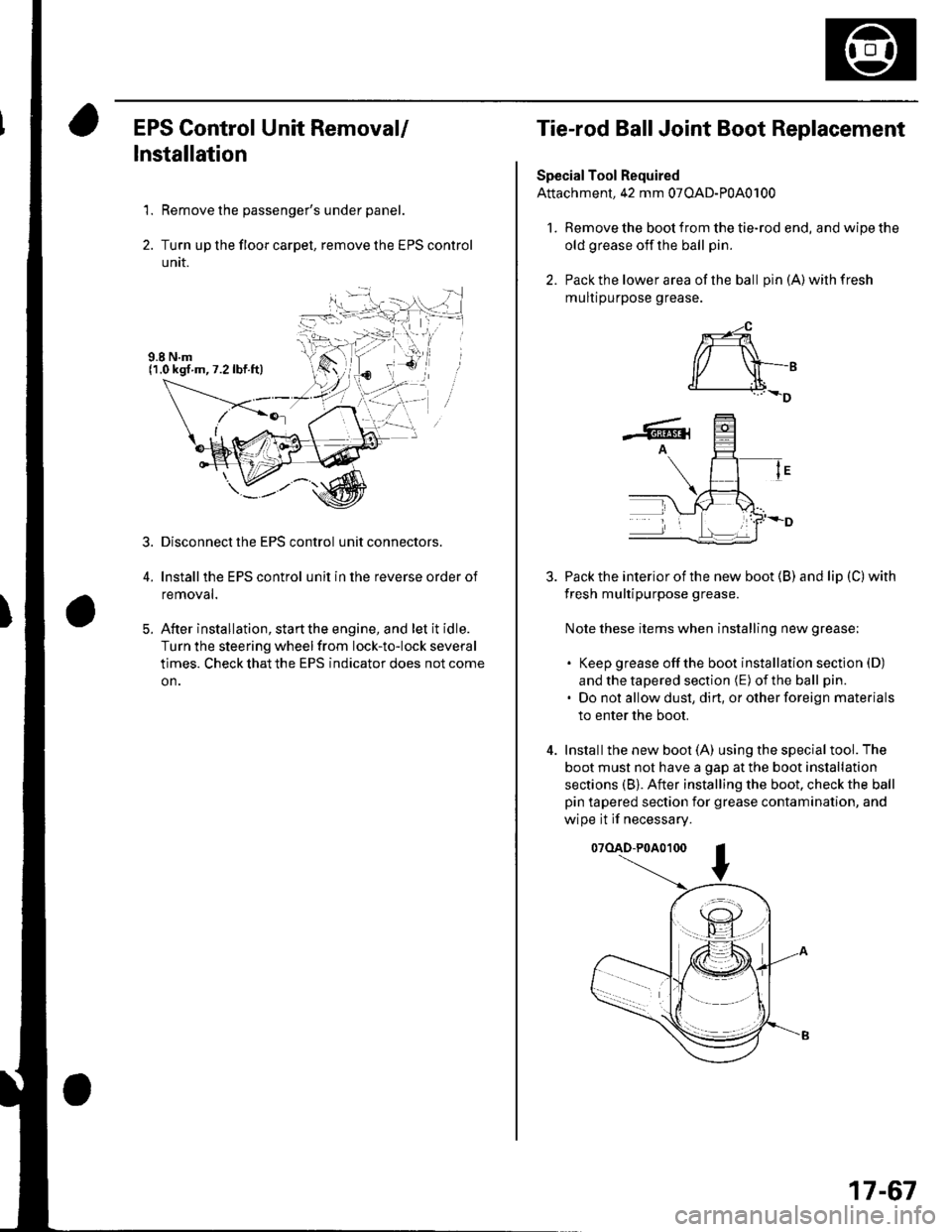

EPS Control Unit Removal/

Installation

1. Remove the passenger's under panel.

2. Turn up the floor carpel, remove lhe EPS control

untr.

Disconnect the EPS control unit connectors.

lnstallthe EPS control unit in the reverse order of

removal.

After installation, start the engine, and let it idle.

Turn the steering wheelfrom lock-to-lock several

times. Check that the EPS indicator does not come

on.

3.

E

Tie-rod Ball Joint Boot Replacement

Special Tool Required

Attachment, 42 mm 07OAD-P0A0100

l. Remove the boot from the tie-rod end, and wipe the

old grease off the ball pin.

2. Pack the lower area of the ball pin(A)wilhfresh

mulr purpose grease.

3. Pack the interior of the new boot (B) and lip (C) with

fresh multipurpose grease.

Note these items when installing new grease;

. Keep grease offthe boot installation section (D)

and the tapered section (E) of the ball pin.

. Do not allow dust, dirt, or other foreign materials

to enter the boot.

4. Installthe new boot (A) using the specialtool. The

boot must not have a gap at the boot installation

sections (B). After installing the boot. check the ball

pin tapered section for grease contamination, and

wipe it if necessary.

07(lAD-P0A0100

*-4

r/ \-,d______i.l+_D

-6rA

17-67

Page 573 of 1139

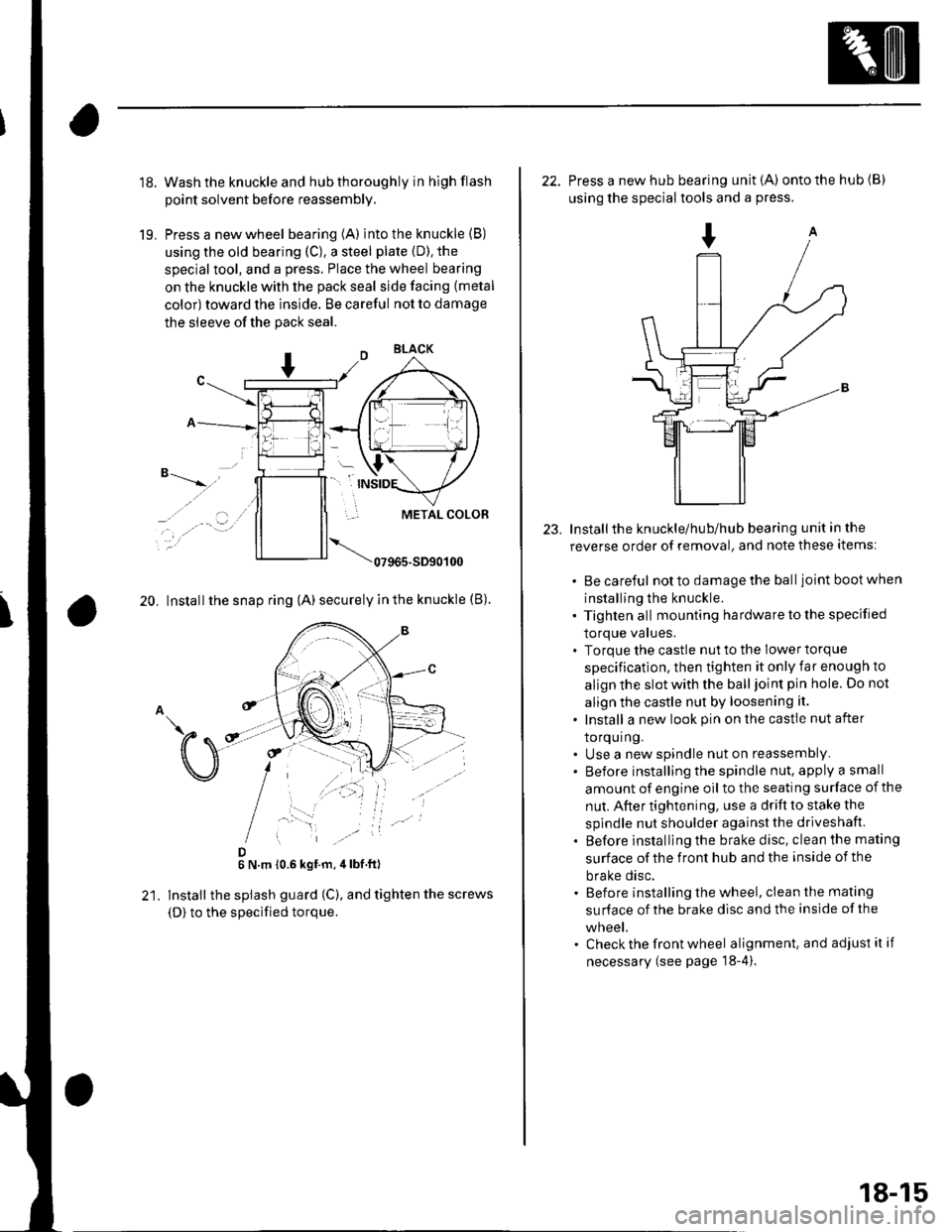

18.

19.

Wash the knuckle and hub thoroughly in hlgh flash

point solvent before reassembly.

Press a new wheel bearing (A) into the knuckle (B)

using the old bearing (C), a steel plate {D). the

special tool, and a press. Place the wheel bearing

on the knuckle with the pack seal side facing (metal

color) toward the inside. Be careful not to damage

the sleeve of the pack seal.

"-t-_"*,,''

_, .' . . a-�.) ../

..-.

20. Install the snap ring (A) securely in the knuckle (B).

D6 N.m 10.6 kgf.m,4lbf ft)

lnstall the splash guard (C), and tighten the screws

(D) to the specified torque.

23.

22. Press a new hub bearing unit {A) ontothehub(B)

using the special tools and a press.

Installthe knuckle/hub/hub bearing unit in the

reverse order of removal, and note these items:

. Be careful notto damagethe balljoint bootwhen

installing the knuckle.. Tighten all mounting hardware to the specified

lOrque values.. Torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the ball joint pin hole. Do not

align the castle nut by loosening it.

. Install a new look pin on the castle nut after

torquing.. Use a new spindle nut on reassembly.. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut. After tightening, use a drift to stake the

spindle nut shoulder against the driveshaft.

. Before installlng the brake disc, clean the mating

surface of the front hub and the inside of the

brake disc.. Before installing the wheel, clean the mating

su rface of the brake disc and the inside of the

wneet.. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

18-15