connector HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 337 of 1139

ldle Control System

DTC Troubleshooting

DTC P0505: ldle Control System Malfunction

NOTE: lf DTC P1519 is stored atthe same time as DTC

P0505, troubleshoot DTC P1519 first, then recheck for

DTC P0505.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle,

2. Checkthe engine speed at idle with no,load

conditions: headlights, blower fan, rear defogger,

radiator fan, and air conditioner off.

Is the engine running at 750t50 rpm?

YES - Intermittent failure, system is OK at this

trme.I

NO lf the idle speed is less than 700 rpm, go to

step 3; if it's 800 rpm or higher, go to step 4.

3. Disconnect the idle air control {lAC) valve3P

connector.

Does the engine speed increase or fluctuate?

YES- Check the idle speed {see page 1 1-138). lf the

idle will not adjust properly, clean the passage in

the throttle body, and then adjust the idle. I

NO- Replace the IAC valve.I

4. Turn the ignition switch OFF.

5. Remove the intake air duct from the throttle body.

6. Start the engine, and let it idle.

11-130

(

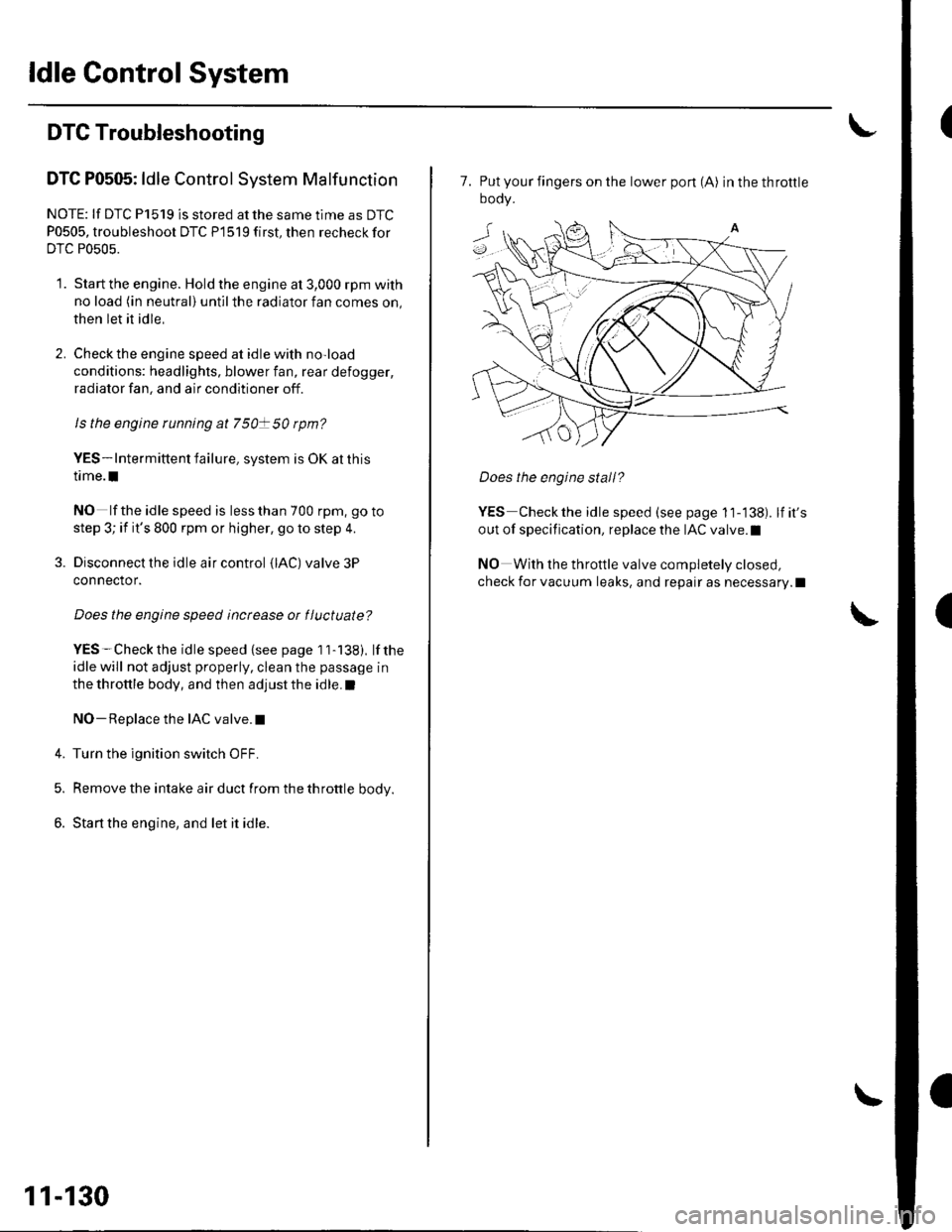

7. Put your fingers on the lower pon (A) inthethrottle

oooy.

Does the engine stall?

YES Checkthe idle speed (see page 11-138). lfit's

out of specification, replace the IAC valve.l

NO With the throttle valve completely closed,

check for vacuum leaks, and repair as necessary.l

Page 338 of 1139

DTC Pl519: IAC Valve Circuit Malf unction

1. Resetthe ECM (see page 11-4).

2. Turn the ignition switch ON (ll)

ls DTC P 1519 indicated?

YES Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the IAC valve and at the ECM.I

3. Turn the ignition switch OFF.

4. Disconnect the IAC valve 3P connector.

5. Turn the ignition switch ON (ll).

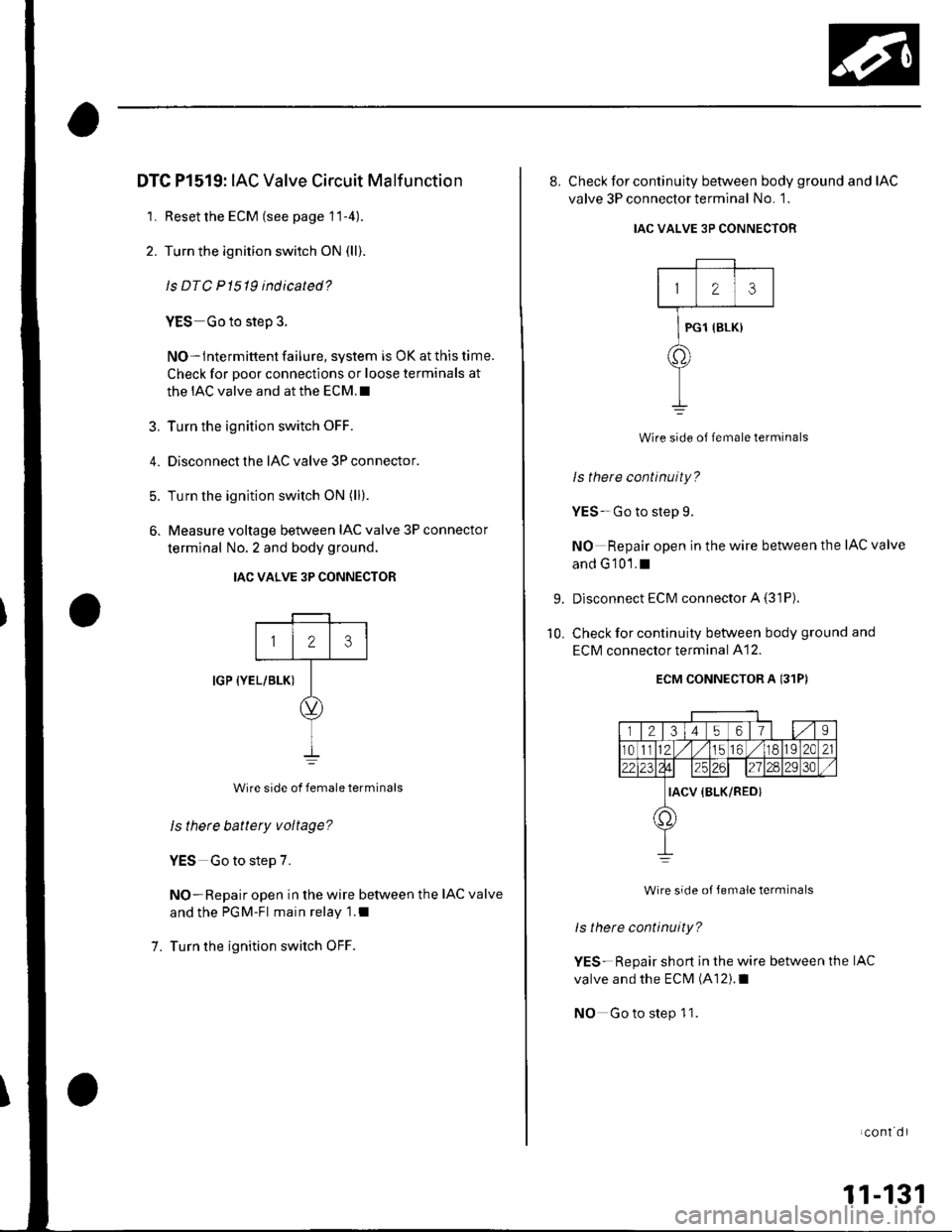

6. Measure voltage betlveen IAC valve 3P connector

terminal No. 2 and body ground.

IAC VALVE 3P CONNECTOR

IGP {YEL/BLK)

Wire side of female terminals

ls there battery voltage?

YES Go to step 7.

NO-Repair open in the wire between the IAC valve

and the PGM-Fl main relay 1.1

Turn the ignition switch OFF.

123

7.

8, Check for continuity between body ground and IAC

valve 3P connector terminal No. 1.

IAC VALVE 3P CONNECTOR

123

PG1 {BLK}

a.

Wire side of lemale terminals

Is there continuity?

YES-Go to step 9.

NO Repair open in the wire between the IAC valve

and G'101.1

Disconnect ECM connector A (31P)

Check for continuity between body ground and

ECM connector terminal A12.

ECM CONNECTOR A 131P)

r l2l3l4 5617s

r01l12 .// 1156 ./118192C21

da25126l27ln2930

IACV {BLK/RED}

1,)

Wire side oJ Jemale terminals

ls there continuity?

YES-Repair short in the wire between the IAC

valve and the ECM (A12).1

NO Go to step 1 1.

9.

10.

LCOnI Ol

11-131

Page 339 of 1139

ldle Control System

(DTC Troubleshooting (cont'd)

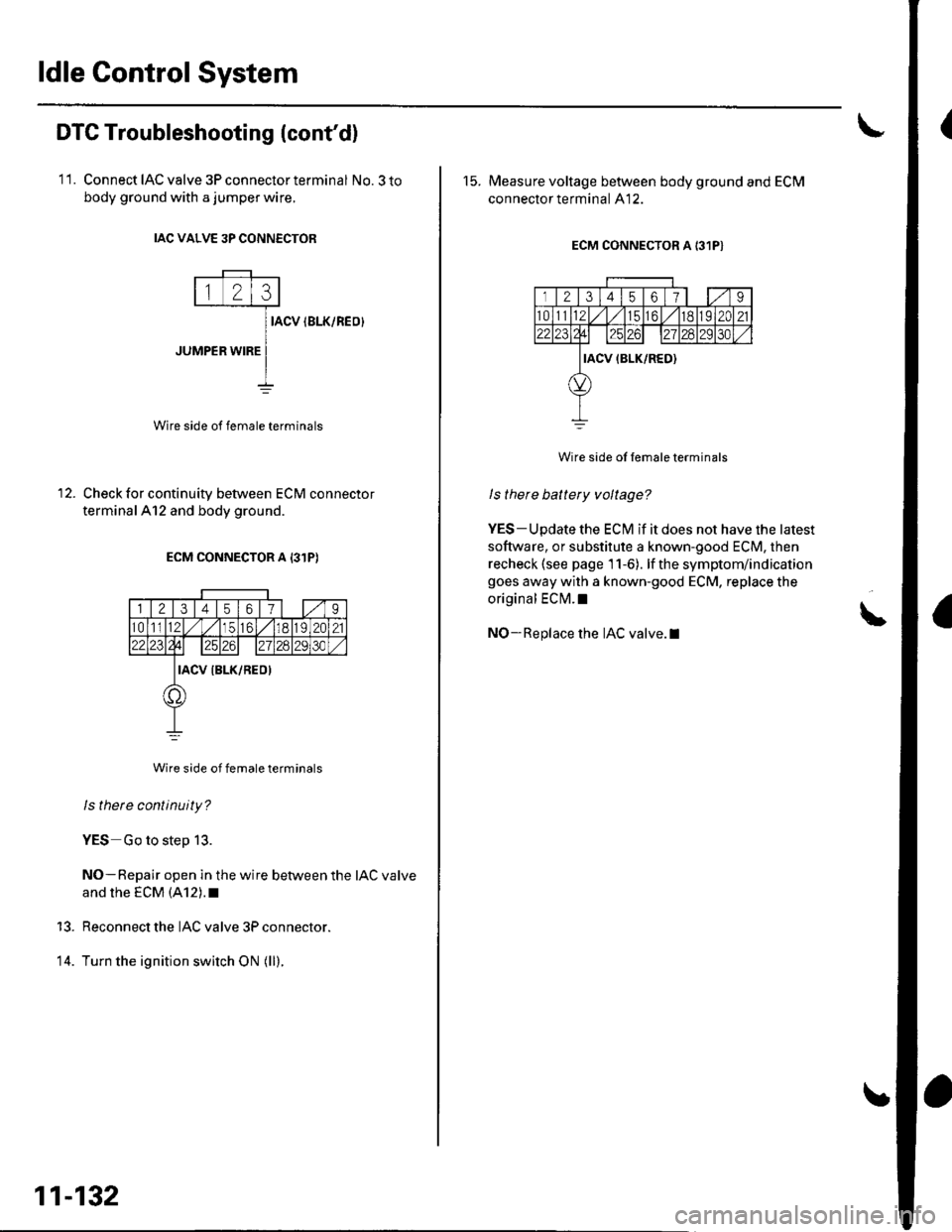

11. Connect IAC valve 3P connector terminal No.3 to

body ground with a jumper wire.

IAC VALVE 3P CONN€CTOR

IACV IBLK/REO}

JUMPER WIRE

Wire side of female terminals

Check for continuity between ECM connector

terminalAl2 and body ground.

ECM CONNECTOR A 131P)

Wire side of female terminals

ls there continuity?

YES Go to step 13.

NO-Repair open in the wire between the IAC valve

and rhe EcM (A12).r

Reconnect the IAC valve 3P connector.

Turn the ignition switch ON (ll).

13.

14.

11-132

15. Measure voltage between body ground and ECM

connector terminal A12.

ECM CONNECTOR A 131P}

rl2l31456179

t01tl12l,/l/tc6,/ 1182C2122231?4l| 12.zil2830

IACV IBLK/RED)

Wire side ol female terminals

I s there battery voltage?

YES-Update the ECI\4 if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECI\4.1

NO-Replace the IAC valve.I!

Page 340 of 1139

A/G Signal Circuit Troubleshooting

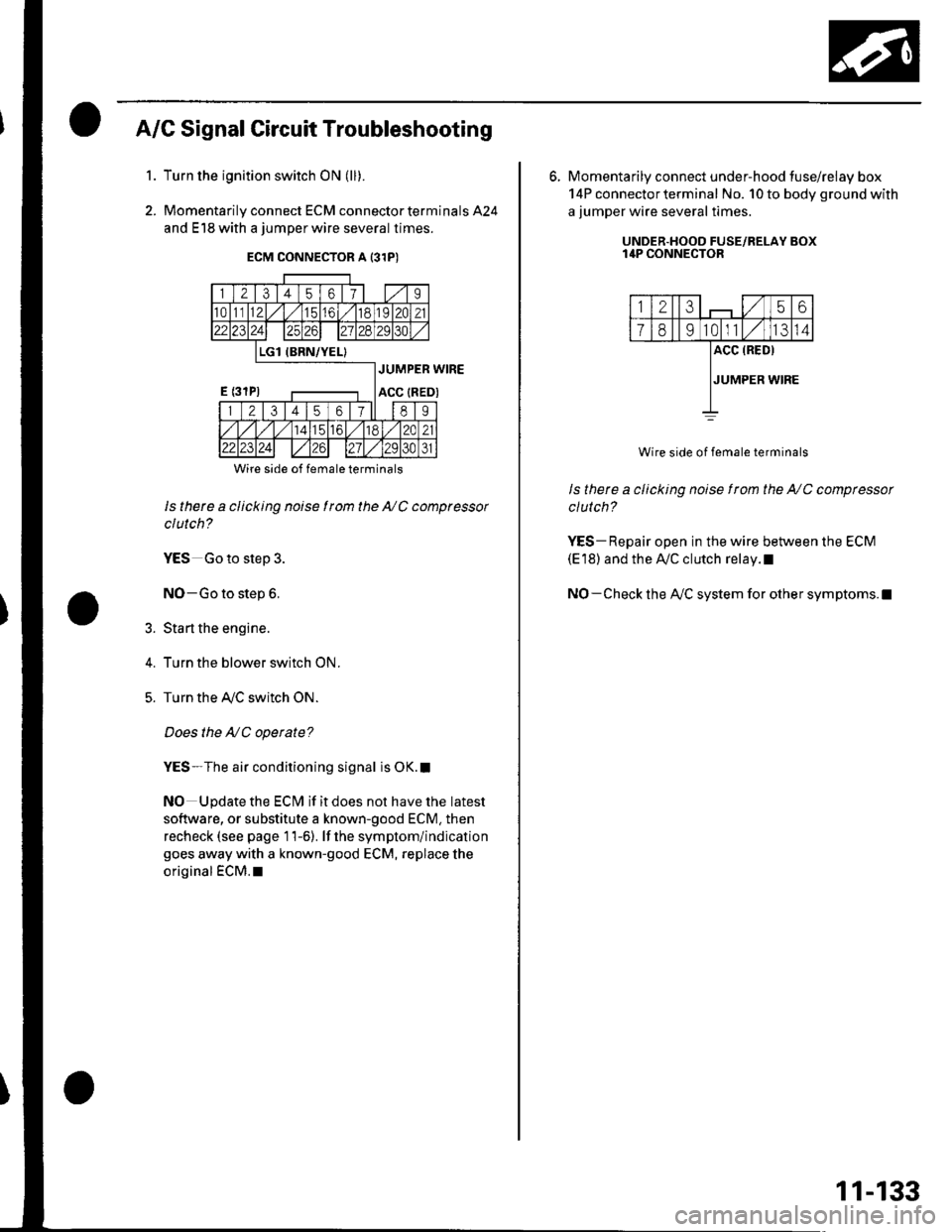

Turn the ignition switch ON (ll).

Momentarily connect ECM connector terminals 424

and E18 with a jumper wire several times.

1.

2.

5.

Wire side of female terminals

ls there a clicking noise I rom the NC compressor

clutch?

YES Go to step 3.

NO-Go to step 6.

Sta rt the engine.

Turn the blower switch ON.

Turn the Ay'C switch ON.

Does the NC operate?

YES-The air conditioning signal is OK.I

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM. then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original €CM.l

6. Momentarily connect under-hood tuse/relay box

14P connector terminal No. 10 to body ground with

a jumper wire several times.

UNDER.HOOD FUSE/RELAY BOXI4P CONNECTOR

12356

1891011IJ14

ACC (RED)

JUMPER WIRE

Wire side of female terminals

ls there a clicking noise f rom the NC compressor

clutch?

YES- Repair open in the wire between the ECM(E'18) and the Ay'C clutch relay.l

NO- Check the A/C system for other symptoms.l

11-133

Page 341 of 1139

ldle Gontrol System

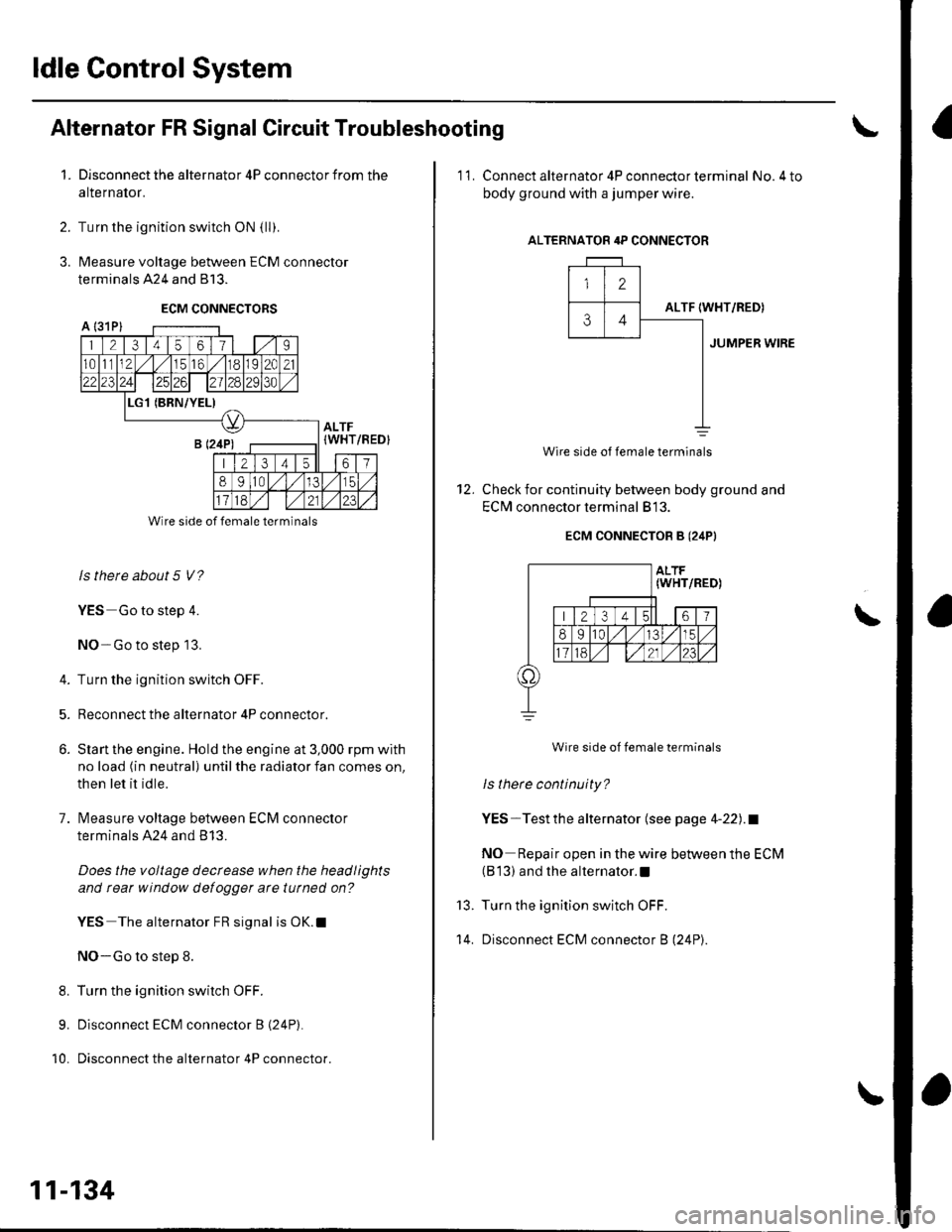

't.

Alternator FR Signal Circuit Troubleshooting

Disconnect the alternator 4P connector from the

alternalor.

Turn the ignition switch ON {ll).

Measure voltage between ECM connector

terminals 424 and 813.

ECM CONNECTORS

2.

3.

A l31Pl

1 21345611 | 1.,'I

1011112,/56,/r8119l2C21

2312428129130

L(BRN/YEL)

ALTF(WHT

213 4t561

89ltal,/l/15

Wire side of female terminals

ls there about 5 V?

YES Go to step 4.

NO-Go to step 13.

4. Turn the ignition switch OFF.

5. Reconnect the alternator 4P connector.

6. Slan the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

7. lvleasure voltage between ECM connector

terminals A24 and B 13.

Does the voltage decrease when the headlights

and rear window defogger arc tutned on?

YES The alternator FR signal is OK.l

NO-Go to step 8.

8. Turn the ignition switch OFF.

9. Disconnect ECM connector B (24P).

10. Disconnect the alternator 4P connector.

/REDI

11-134

'11. Connect alternator 4P con necto r term inal No.4 to

body ground with a jumper wire.

ALTERNATOR 4P CONNECTOR

12

ALTF34IWHT/RED)

JUMPER WIRE

12.

Wire side of female terminals

Check for continuity between body ground and

EClvl connector terminal 813.

ECM CONNECTOB B (24PI

Wire side of female terminals

ls there continuity?

YES-Testthe alternator (see page 4-22).1

NO Repair open in the wire between the ECM(B 13) and the alternator.l

Turn the ignition switch OFF.

Disconnect ECM connector B (24P).

\

13.

't 4.

Page 342 of 1139

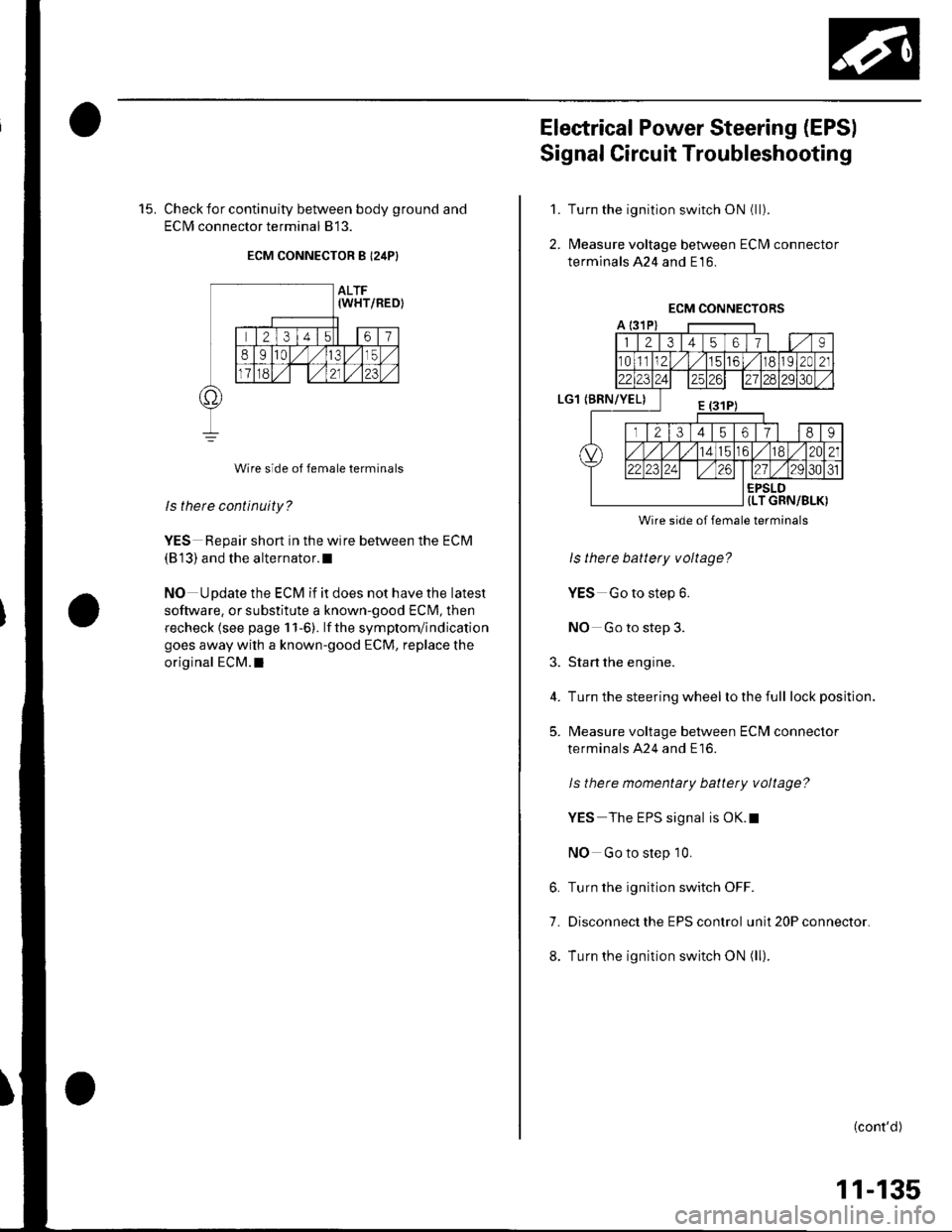

15. Check for continuity between body ground and

ECIM connector terminal 813.

ECM CONNECTOR B I24P}

Wire side of female terminals

ls there continuity?

YES Repair short in the wire between the ECM

(813) and the alternator.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck lsee page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

Electrical Power Steering (EPSI

Signal Circuit Troubleshooting

Turn the ignition switch ON (ll).

l\4easure voltage between ECM connector

terminals 424 and E16.

1.

2.

3.

4.

5.

Wire side of female terminals

ls there battery voltage?

YES Go to step 6.

NO Go to step 3.

Start the engine.

Turn the steering wheel lo the full lock position.

l\4easure voltage between ECM connector

terminals A24 and E16.

ls there momentaty battery voltage?

YES The EPS signal is OK.t

NO Go to step 10.

6. Turn the ignition switch OFF.

7. Disconnect the EPS control unit 20P connector.

8. Turn the ignition switch ON (ll).

(cont'd)

11-135

Page 343 of 1139

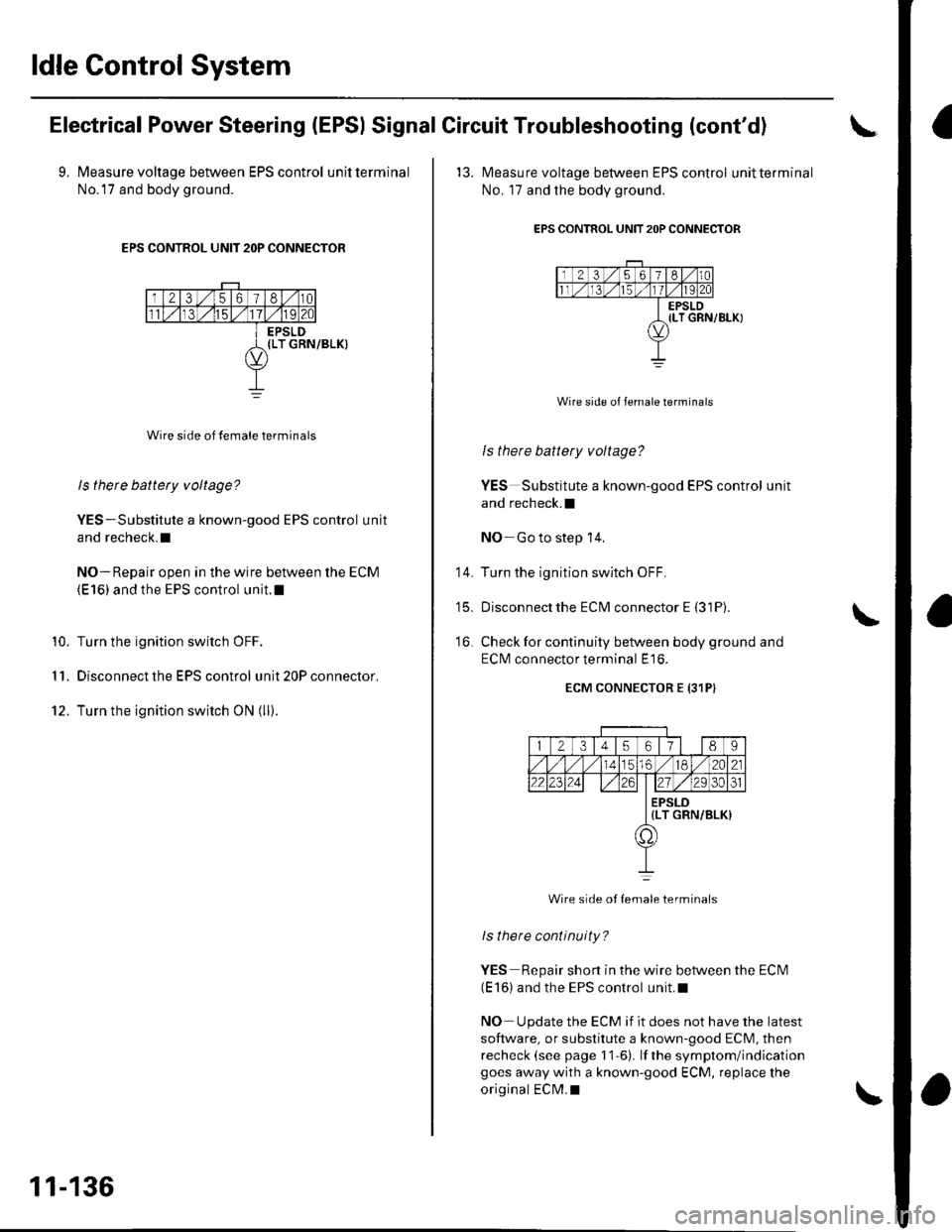

ldle Control System

Electrical Power Steering (EPSI Signal Circuit Troubleshooting (cont'd)

9. Measure voltage between EPS control unitterminal

No.l7 and body ground.

EPS CONTROL UNIT 2OP CONNECTOR

Wire side of female terminals

ls there battety voltage?

YES-Substitute a known-good EPS control unit

and recheck.I

NO- Repair open in the wire between the ECM(E 16) and the EPS control unit.l

Turn the ignition switch OFF.

Disconnect the EPS control unit 20P connector.

Turn the ignition switch ON (ll).

10.

I '�I.

12.

11-136

'13. l\4easure voltage between EPS control unitterminal

No. 17 and the body ground.

EPS CONTROL UNIT 2OP CONNECTOR

Wire side of female terminals

ls there battery voltage?

YES Substitute a known-good EPS control unit

and recheck.l

NO-Go to step 14,

Turn the ignition switch OFF.

Disconnectthe ECM connector E {31P).

Check for continuity between body ground and

ECI\4 connector terminal E16.

ECM CONNECTOR E {31PI

14.

t5_

16.

12345617l 189

56./182A21

2223zi ./29 30ol

EPSLD{LT GRN/BLK)

a,

Wire side ot Iemale terminals

lsthere continuity?

YES Repair short in the wire between the ECN4(E 16) and the EPS control unit.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indicationgoes away with a known-good ECM, replace the

original ECM.I

Page 344 of 1139

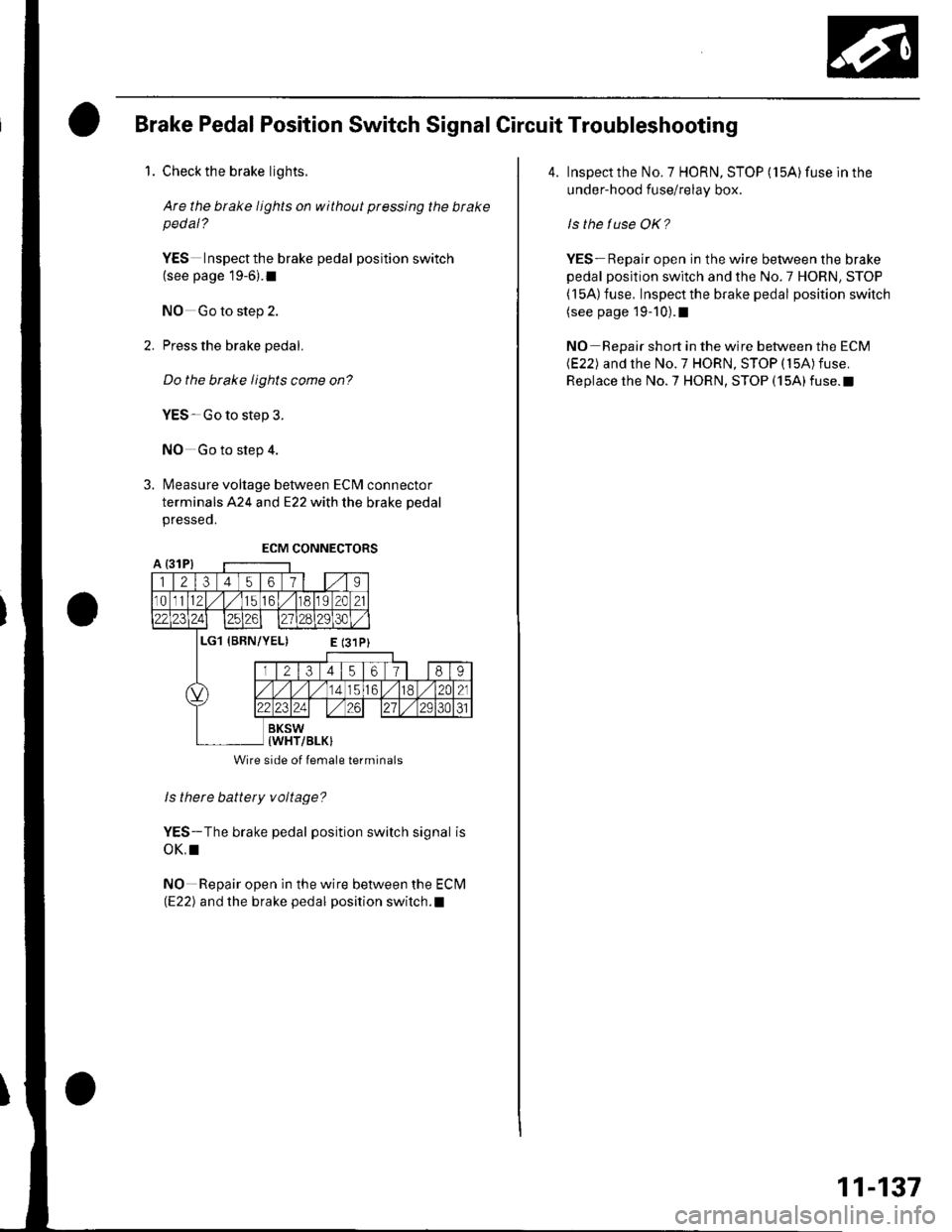

Brake Pedal Position Switch Signal Circuit Troubleshooting

1. Check the brake lights.

Are the brake lights on without pressing the brakepedal?

YES Inspectthe brake pedal position switch(see page 19-6).I

NO Go to step 2.

2. Press the brake pedal.

Do the brake lights come on?

YES-Go to step 3.

NO Go to step 4.

3. Measure voltage between ECM connector

terminals A24 and E22 with the brake pedal

presseo.

ls there battery voltage?

YES-The brake pedal position switch signal is

oK,I

NO Repair open in the wire between the Eclvl(E22) and the brake pedal position switch.l

Wire side of lemale terminals

4. Inspect the No. 7 HORN, STOP (15A) fuse ln the

under-hood fuse/relay box.

ls the tuse OK?

YES- Repair open in the wire between the brake

pedal position switch and the No.7 HORN, STOP( l5A) fuse, Inspect the brake pedal position switch(see page 19-10).1

NO Repair short in the wire between the ECM(E22) and the No.7 HORN, STOP (15A)fuse.

Replace the No.7 HORN, STOP (15A)fuse.t

11-137

Page 345 of 1139

ldle Control System

ldle Speed lnspection

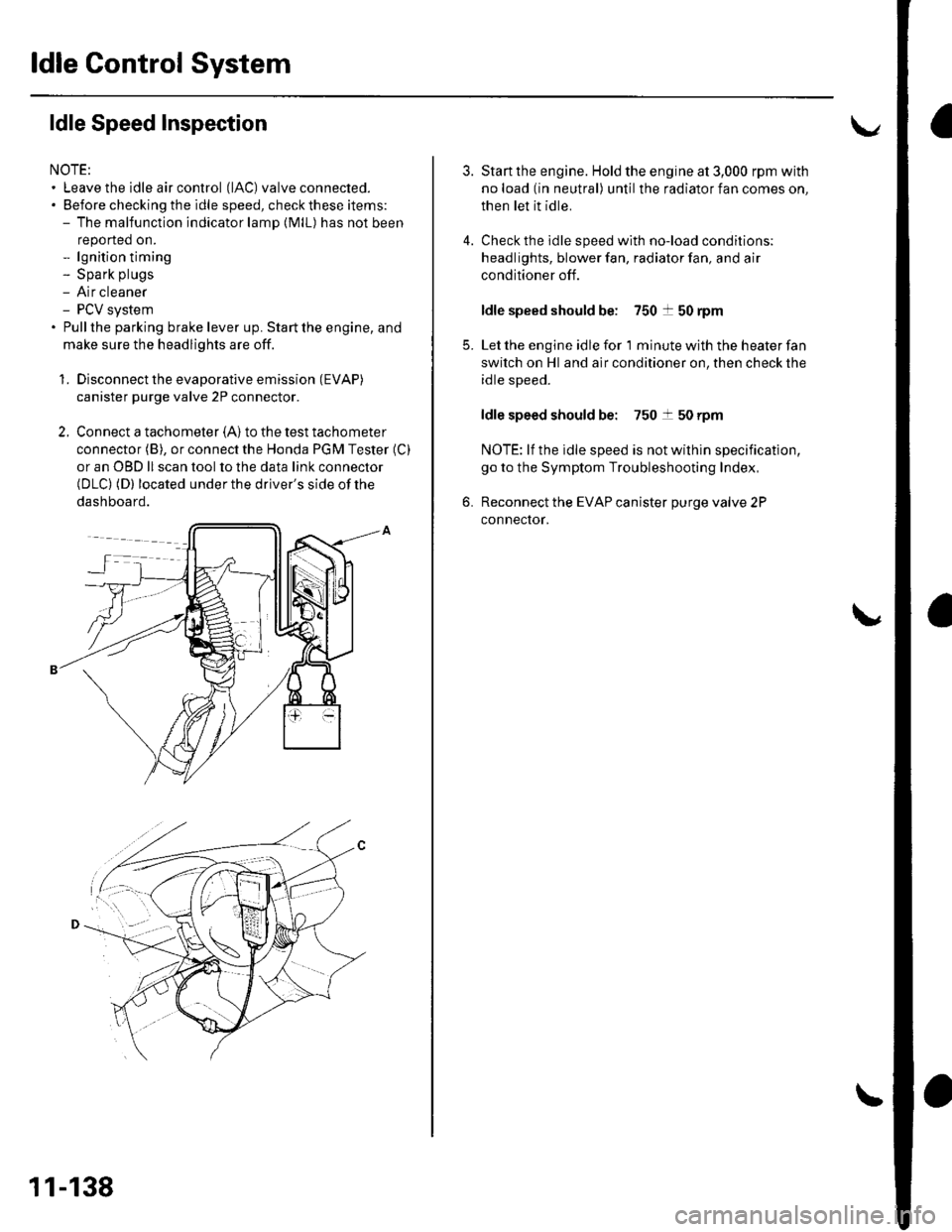

NOTE:' Leave the idle air control (lAC) valve connecled.. Before checking the idle speed, check these items:- The malfunction indicator lamp (MlL) has not been

reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system. Pullthe parking brake lever up. Start the engine, and

make sure the headlights are off.

1. Disconnect the evaporative emission (EVAP)

canister purge valve 2P connector.

2. Connect a tachometer (A)to the test tachometer

connector (B), or connect the Honda PGM Tester (C)

or an OBD ll scan tool to the data link connector(DLC) (D) located under the driver's side of the

dashboard.

11-138

4.

3.

5.

6.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

Check the idle speed with no-load conditions;

headlights, blower fan, radiator fan, and air

conditioner off.

ldle speed should be: 750 t 50 rpm

Let the engine idle for 1 minute with the heater fan

switch on Hl and air conditioner on, then check the

idle speed.

ldle speed should be: 750 t 50 rpm

NOTE: lf the idle speed is not wilhin specification,

go to the Symptom Troubleshooting Index,

Reconnect the EVAP canister purge valve 2P

connector.

Page 346 of 1139

ECM ldle Learn Procedure

The idle learn procedure must be done so the ECM can

learn the engine idle characteristics.

Do the idle learn procedure whenever you do any of

these actions:. Disconnect the battery.

Replace the ECM or disconnect its connector.

Reset the ECM.

NOTE: Erasing DTCS with the Honda PGM Tester

does not require you to do the idle learn procedure.

Remove the No.6 ECU {ECM) ( 15A) fuse from the

under-hood fuse/relay box.

Remove the No.19 baftery (80A) fuse from the under-

hood fuse/relay box.

Remove PGM-FI main relay 1.

Remove any of the wires from the under-hood fuse/

retay Dox.

Disconnect any of the connectors from the under

hood fuse/relay box.

Disconnect the connector between the engine

compartment wire harness and ECM wire harness.

Disconnect the G2 terminal from the transmission

ho u srng.

Disconnectthe G'l terminal from the body.

Disconnectthe G101 terminal from the cylinder head

cover.

Procedure:

To complete the idle learn procedure, do this:

1. Make sure all electrical items (Ay'C, audio, rear

defogger, l:ghts, etc.,) are off.

2. Start the engine, and hold it at 3,000 rpm with no

load {in neutral) until the radiator fan comes on, or

until the engine coolanttemperature reaches 194"F(90'c).

3. Let the engine idle for about 5 minutes with the

throttle fully closed.

NOTE: lf the radiator fan comes on, do not include its

running time in the 5 minutes.

11-139